Wet urea additive process for simultanously desulfurizing and denitrification

A urea additive and additive technology, applied in separation methods, chemical instruments and methods, air quality improvement and other directions, can solve the problems of complex catalyst preparation and regeneration process, secondary waste water pollution, difficult to repeat implementation, etc., to control environmental pollution and The effect of land acidification, investment and operation cost saving, and easy transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

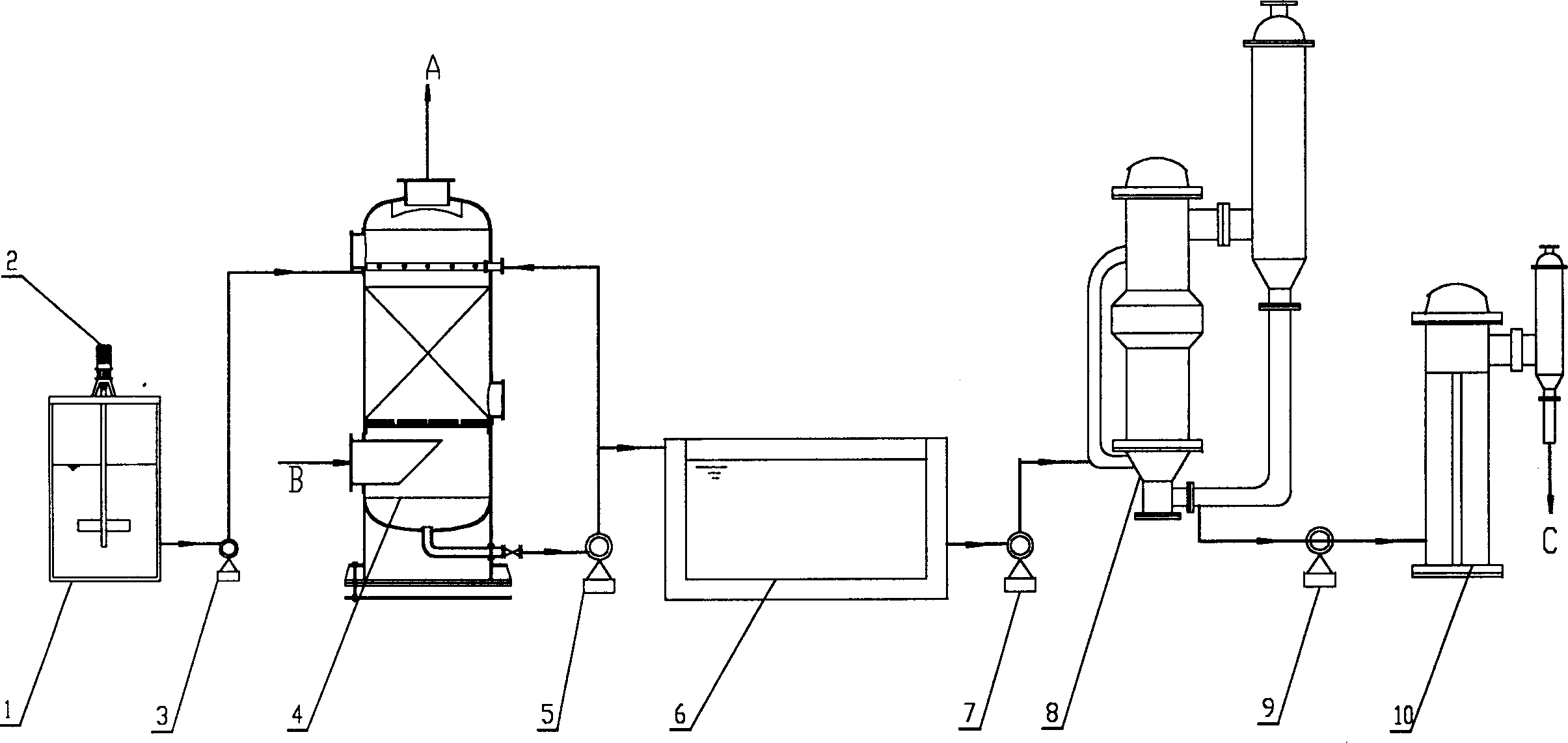

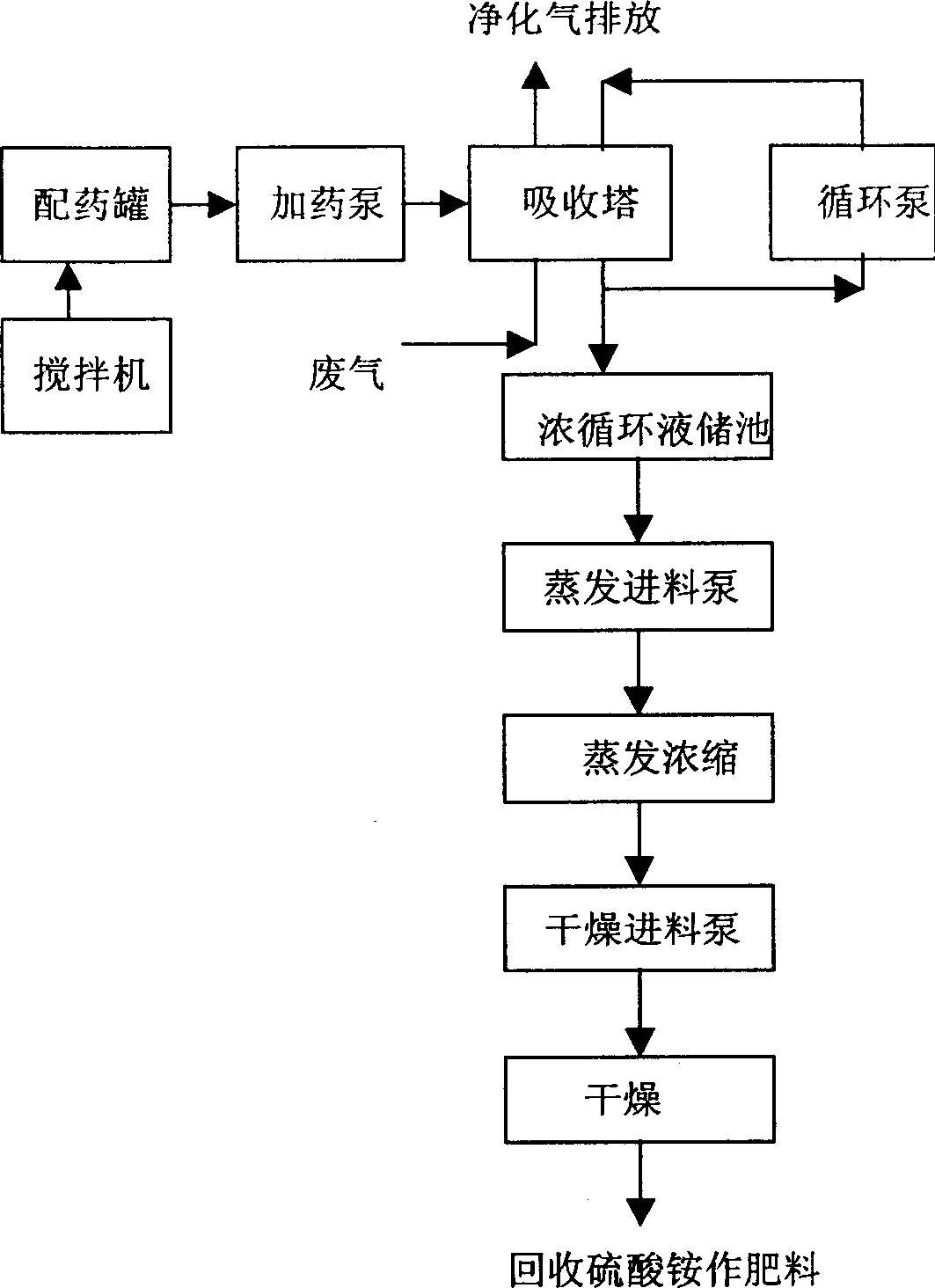

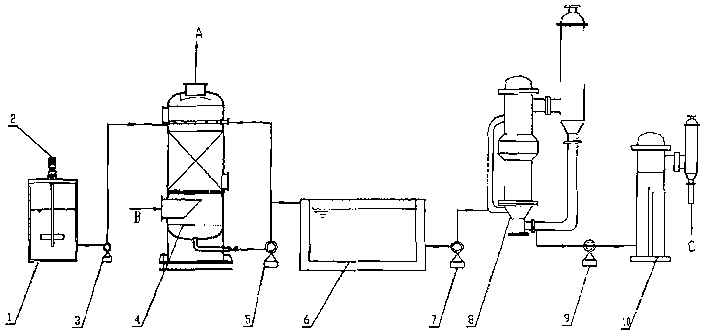

[0008] The inventor thinks that the preferred way to realize the present invention can be as follows: (1) according to figure 1 As shown, design, process and manufacture or purchase various components, for example: the dispensing tank 1 can be processed by steel plate by machining; the mixer 2 can be BLD1.5-2-112 type; the dosing pump 3 can be selected from Shanghai Shenyang Pump Factory Produced WBR-5 / 7 dosing pump; absorption tower 4 can be optional nozzleless atomization absorption tower TLD type, the effective height can be 1.0-3.0 meters, and the diameter can be 0.6 meters; circulation pump 5 can be selected from Guangzhou No. 1 Water Pump Factory The KF50-23 circulating pump is produced; the evaporator 8 can be the HN-01 forced external circulation four-effect evaporator improved and developed by the South China Environmental Science Research Institute; the dryer 10 can be the HN type double-pipe improved and developed by the South China Environmental Science Research Ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com