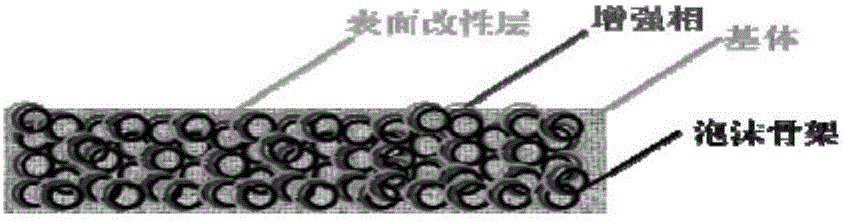

Foam skeleton structure reinforced metal-matrix composite material and preparation method

A technology of foam skeleton and composite materials, which is applied in metal material coating process, gaseous chemical plating, coating, etc., can solve the problems of low thermal conductivity of diamond, high thermal conductivity islands, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Embodiment one: foam diamond skeleton strengthens silver-based composite material

[0052] Foamed diamond skeleton reinforced silver-based composite material. In this example, foamed copper with a pore size of 0.2mm is used as the substrate. The foamed diamond reinforcement accounts for 20% of the volume fraction of the composite material. First, clean the foamed copper three-dimensional network substrate according to step (1) , then adopt magnetron sputtering technology in step (2) to deposit a molybdenum film with a thickness of 50nm on the surface of the copper foam three-dimensional network skeleton as an intermediate transition layer; Particle foam skeleton substrate; step (4) adopts hot wire CVD to deposit diamond film, deposition process parameters: hot wire distance 6mm, substrate temperature 800°C, hot wire temperature 2200°C, deposition pressure 3KPa, CH 4 / H 2 The volume flow ratio is 1:99, and the thickness of the diamond film is 60 μm by controlling the de...

Embodiment 2

[0053] Embodiment two: foamed graphene skeleton strengthens copper-based composite material

[0054] Foamed graphene skeleton reinforced copper-based composite material, in this example, the porous ceramic alumina with a pore size of 2 mm is used as the substrate, and the foamed graphene reinforcement accounts for 10% of the volume fraction of the composite material. The substrate is cleaned, and then a tungsten film with a thickness of 200nm is deposited on the surface of the foamed alumina three-dimensional network skeleton by magnetron sputtering according to step (2) as an intermediate transition layer; then a large amount of mosaic in the middle of the mesh is obtained according to step (3). The foam skeleton substrate of nanocrystalline and microcrystalline diamond particles; (4) use plasma-assisted chemical vapor deposition to grow graphene in situ on the substrate surface, apply plasma-assisted growth on the foam skeleton substrate during the deposition process, and Ad...

Embodiment 3

[0055] Embodiment three: graphene / diamond foam skeleton strengthens copper-based composite material

[0056]Foamed diamond skeleton reinforced copper matrix composite material. In this example, nickel foam with a pore size of 0.3 mm is used as the substrate. The foamed diamond reinforcement accounts for 30% of the volume fraction of the composite material. Cleaning, at first according to step (1) the surface of foamed nickel three-dimensional network substrate (aperture is 0.05mm) is pretreated, then according to step (2) adopts the method for vapor deposition to deposit the chromium that thickness is 300nm on the surface of foamed nickel three-dimensional network skeleton Membrane is used as intermediate transition layer; Then according to step (3) obtain the foam skeleton substrate inlaid with a large amount of nanocrystalline and microcrystalline diamond particles in the middle of the mesh; (4) adopt hot wire CVD to deposit diamond film, deposition process parameters: hot wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com