Halogen-free resin composition and copper clad laminate and printed circuit board applying the same

A halogen resin and composition technology, applied in printed circuit parts, circuit substrate materials, etc., can solve problems such as environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

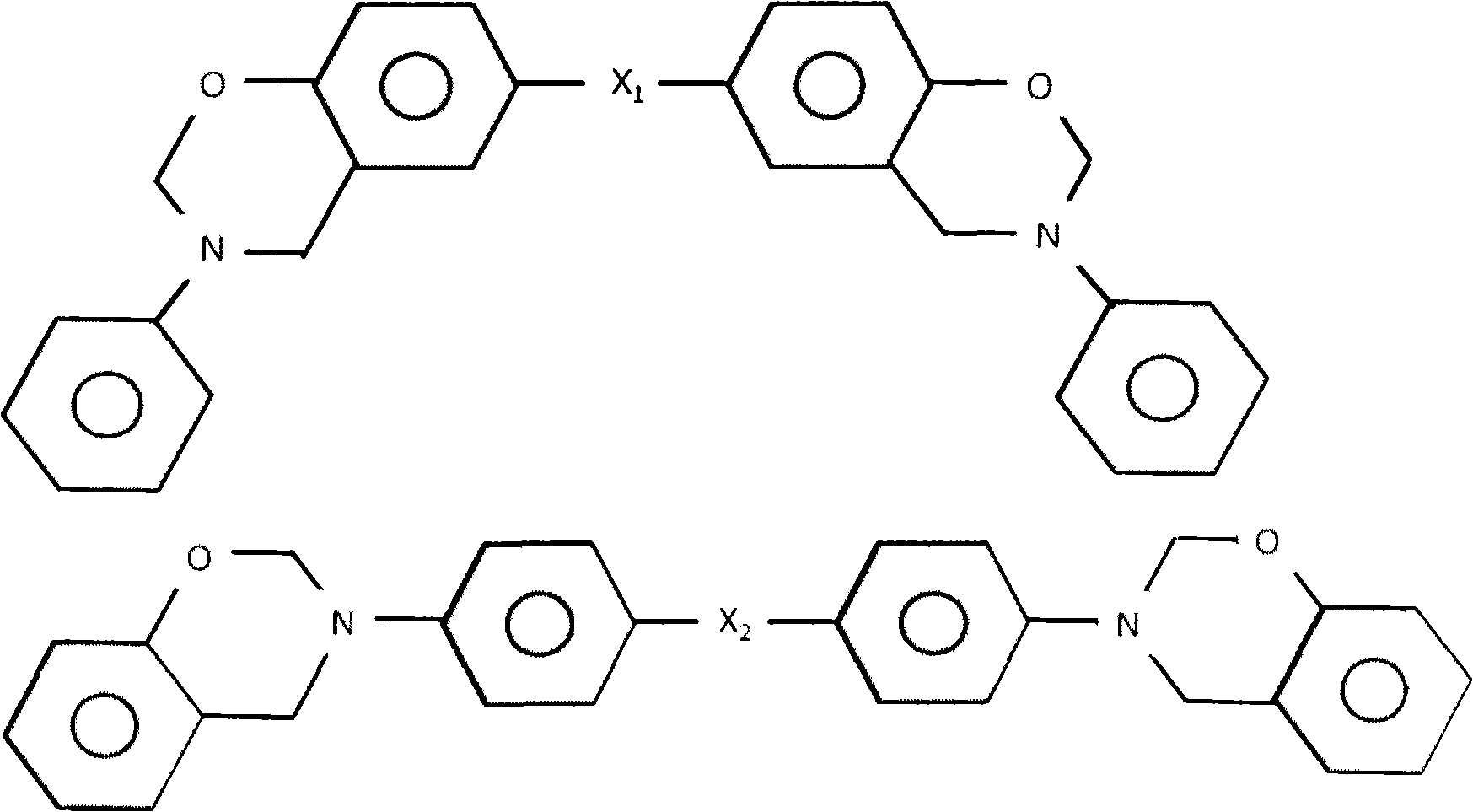

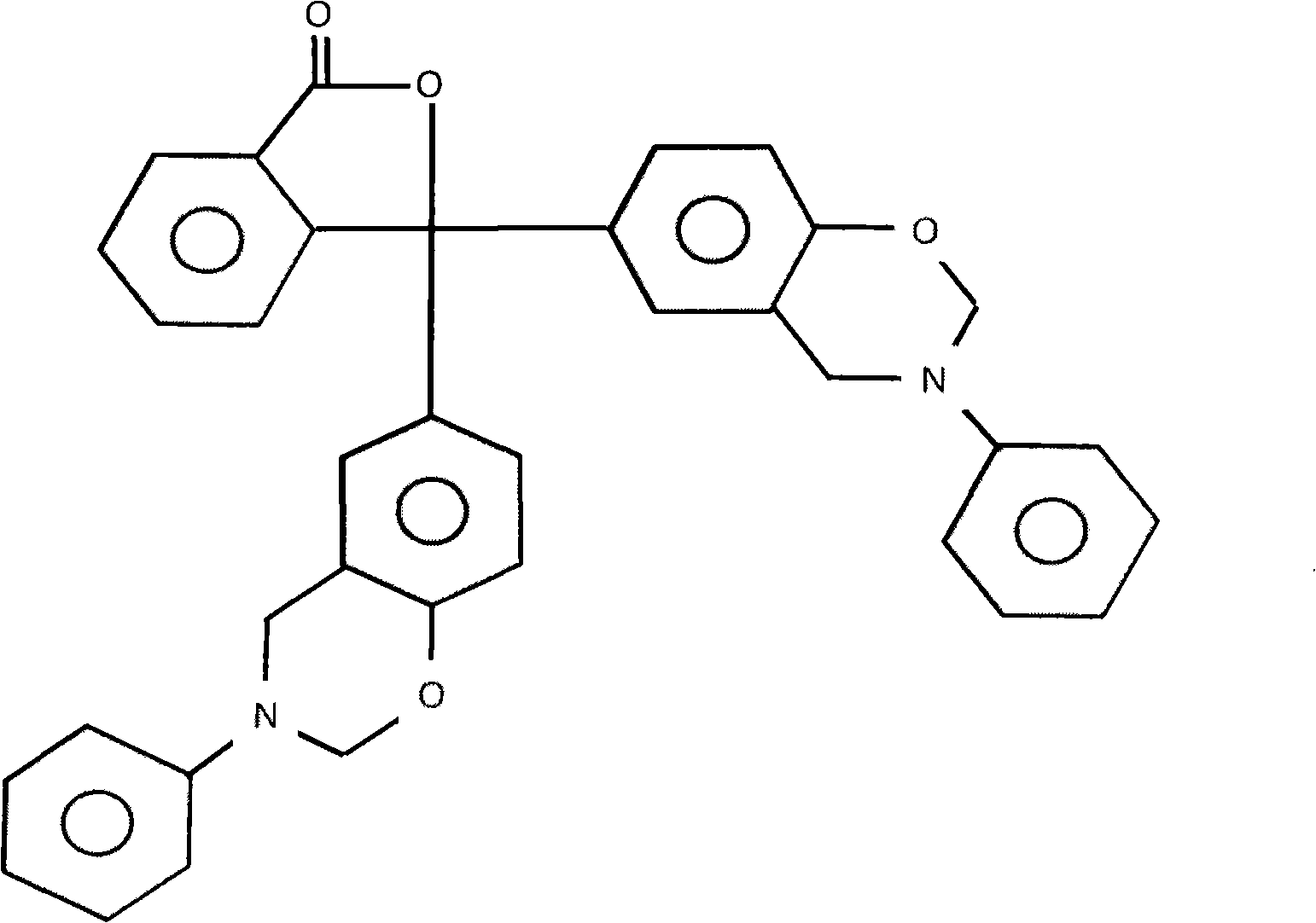

Method used

Image

Examples

Embodiment 1

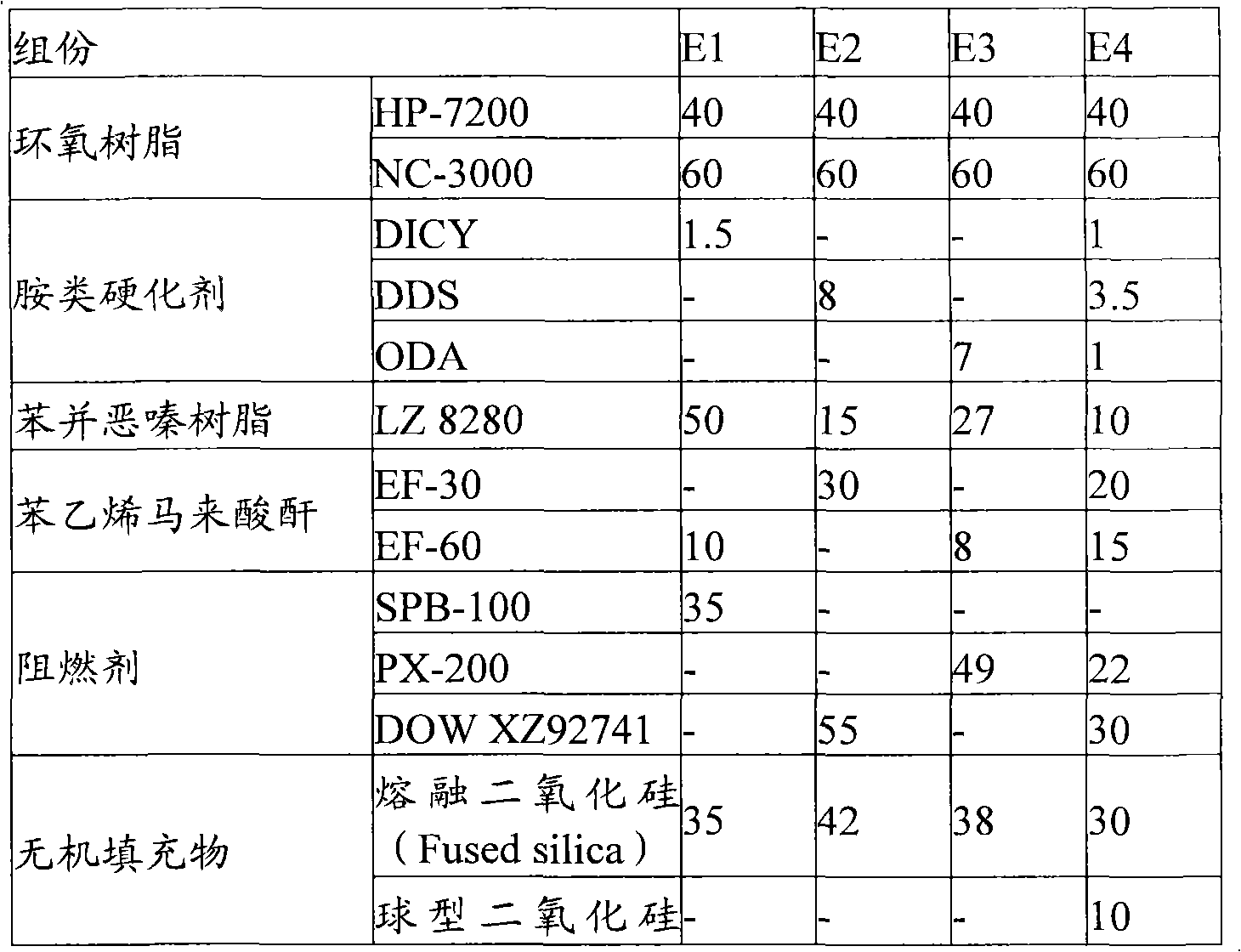

[0042] Example 1 (E1)

[0043] A resin composition comprising the following components:

[0044] (A) the dicyclopentadiene epoxy resin (HP-7200) of 40 weight parts;

[0045] (B) the biphenyl epoxy resin (NC-3000) of 60 weight parts;

[0046] (C) 1.5 parts by weight of dicyandiamide (DICY);

[0047] (D) benzoxazine resin (LZ 8280) of 50 parts by weight;

[0048] (E) 10 parts by weight of styrene maleic anhydride (EF-60);

[0049] (F) 35 parts by weight of the phosphazene compound (SPB-100);

[0050] (G) fused silica of 35 parts by weight;

[0051] (H) 0.3 parts by weight of catalyst (2E4MI);

[0052] (1) the methyl ethyl ketone solvent (MEK) of 45 weight parts;

[0053] (J) 20 parts by weight of dimethylformamide (DMAC).

Embodiment 2

[0054] Example 2 (E2)

[0055] A resin composition comprising the following components:

[0056] (A) the dicyclopentadiene epoxy resin (HP-7200) of 40 weight parts;

[0057] (B) the biphenyl epoxy resin (NC-3000) of 60 weight parts;

[0058] (C) the diaminodiphenyl sulfone (DDS) of 8 weight parts;

[0059] (D) benzoxazine resin (LZ 8280) of 15 parts by weight;

[0060] (E) 30 parts by weight of styrene maleic anhydride (EF-30);

[0061] (F) the flame retardant (Dow XZ92741) of 55 parts by weight;

[0062] (G) fused silica of 42 parts by weight;

[0063] (H) 0.3 parts by weight of catalyst (2E4MI);

[0064] (1) 35 parts by weight of methyl ethyl ketone solvent (MEK).

Embodiment 3

[0065] Example 3 (E3)

[0066] A resin composition comprising the following components:

[0067] (A) the dicyclopentadiene epoxy resin (HP-7200) of 40 weight parts;

[0068] (B) the biphenyl epoxy resin (NC-3000) of 60 weight parts;

[0069] (C) the diaminodiphenyl ether (ODA) of 7 weight parts;

[0070] (D) benzoxazine resin (LZ 8280) of 27 parts by weight;

[0071] (E) styrene maleic anhydride (EF-60) of 8 weight parts;

[0072] (F) the flame retardant (PX-200) of 49 weight parts;

[0073] (G) 38 parts by weight of fused silica;

[0074] (H) 0.3 parts by weight of catalyst (2E4MI);

[0075] (1) 77 parts by weight of methyl ethyl ketone solvent (MEK).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com