Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

125results about How to "Improve interlayer strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

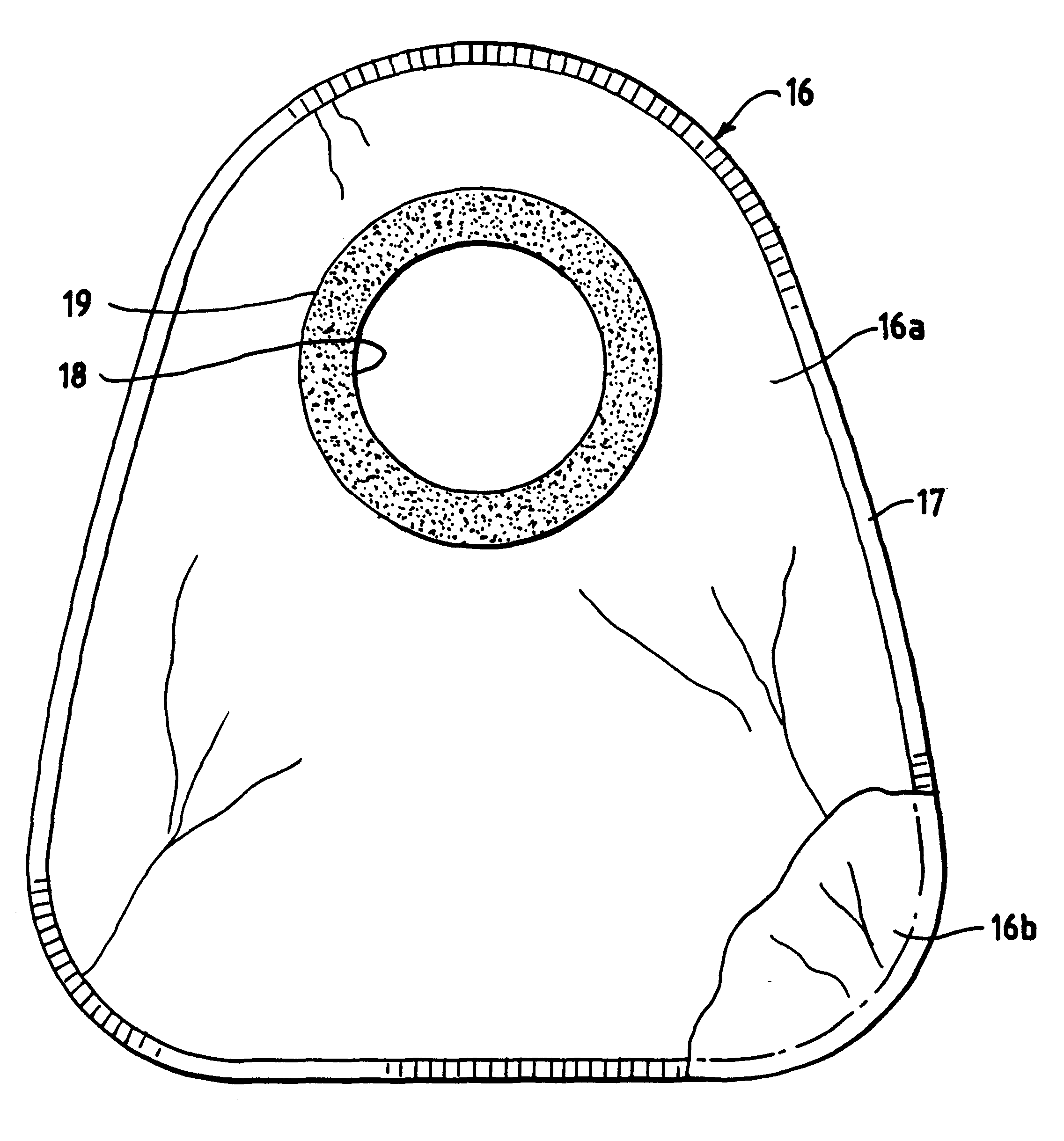

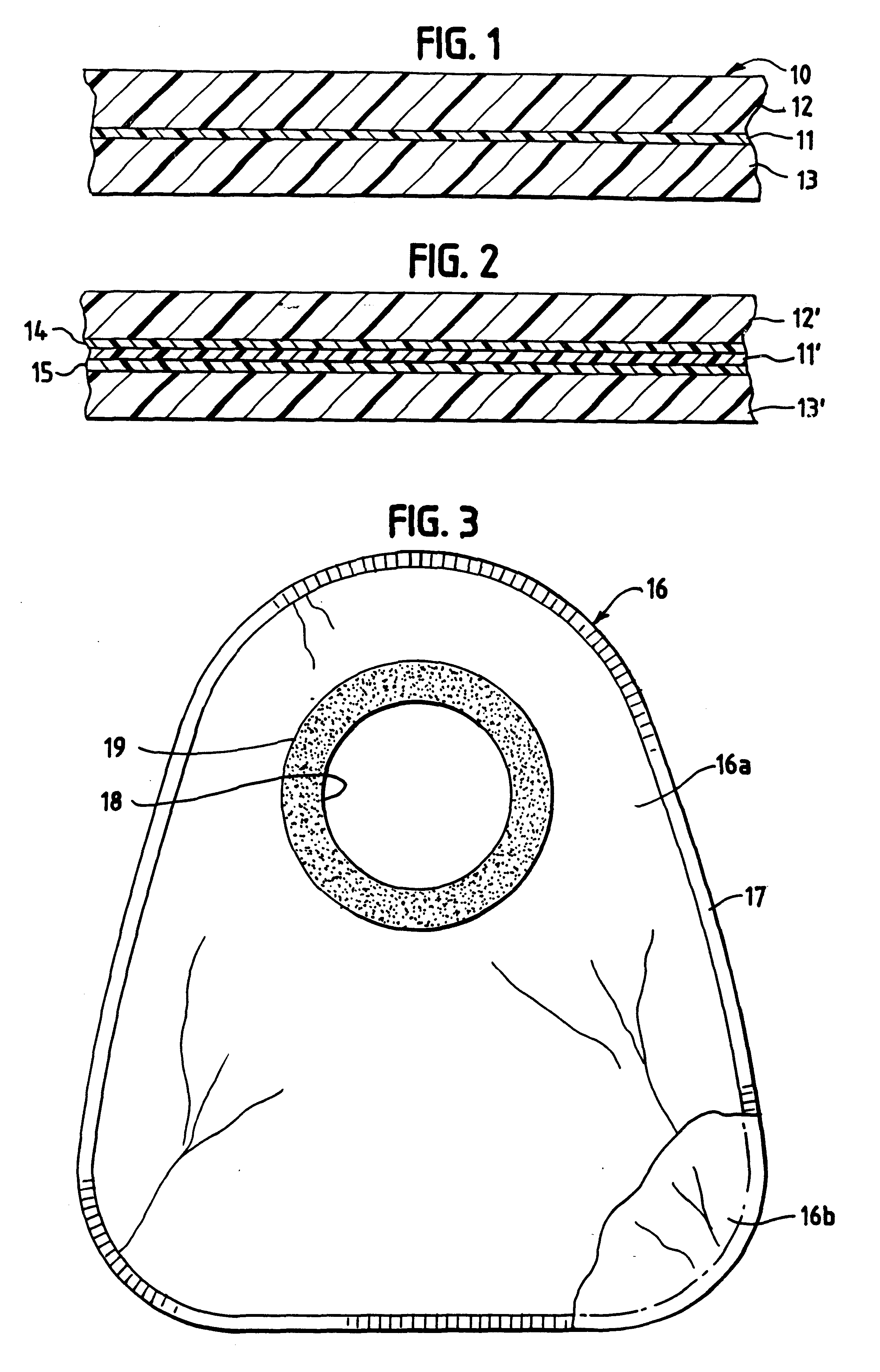

Multilayer chlorine-free film with polyester barrier layer and ostomy pouches formed therefrom

InactiveUS6258423B1Good odor barrier propertyMinimal noiseSynthetic resin layered productsColostomyLow noisePolyethylene terephthalate glycol

A multilayer heat-sealable chlorine-free film of relatively low modulus, high interlaminar strength, and low noise upon flexing is provided. The film comprises an odor barrier layer of polyester resin and at least one heat-sealable skin layer, preferably two such skin layers on opposite sides of said odor barrier layer, composed of a homopolymer of ethylene or a copolymer of ethylene and an alpha-olefin or an ester-containing monomer. In a preferred embodiment, the odor barrier layer is formed of polyethylene terephthalate and adhesive tie layers are interposed between the odor barrier layer and the skin layers, resulting in a multilayer film of five layers. Pouches formed of such multilayer films are also disclosed.

Owner:HOLLISTER INCORPORAED

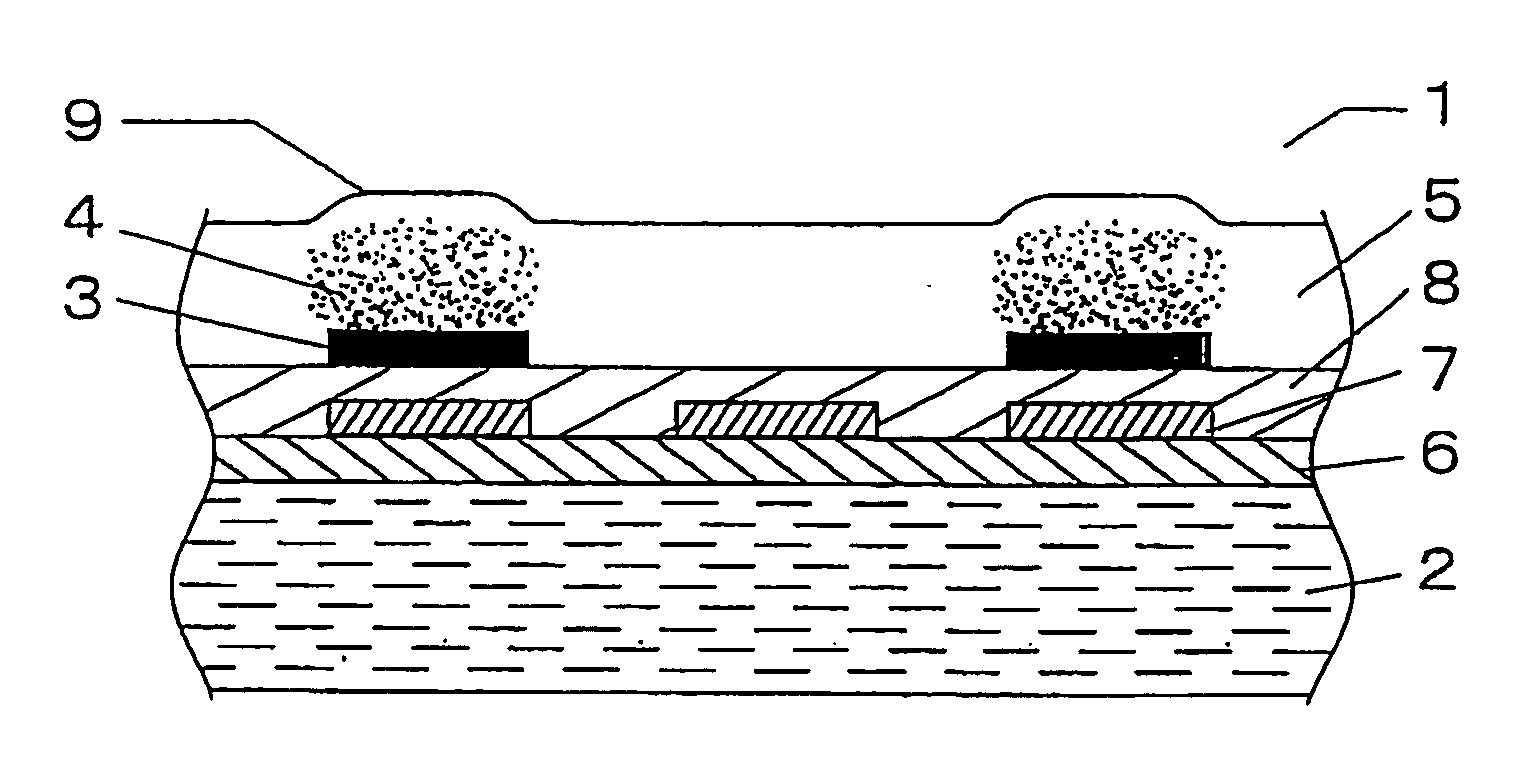

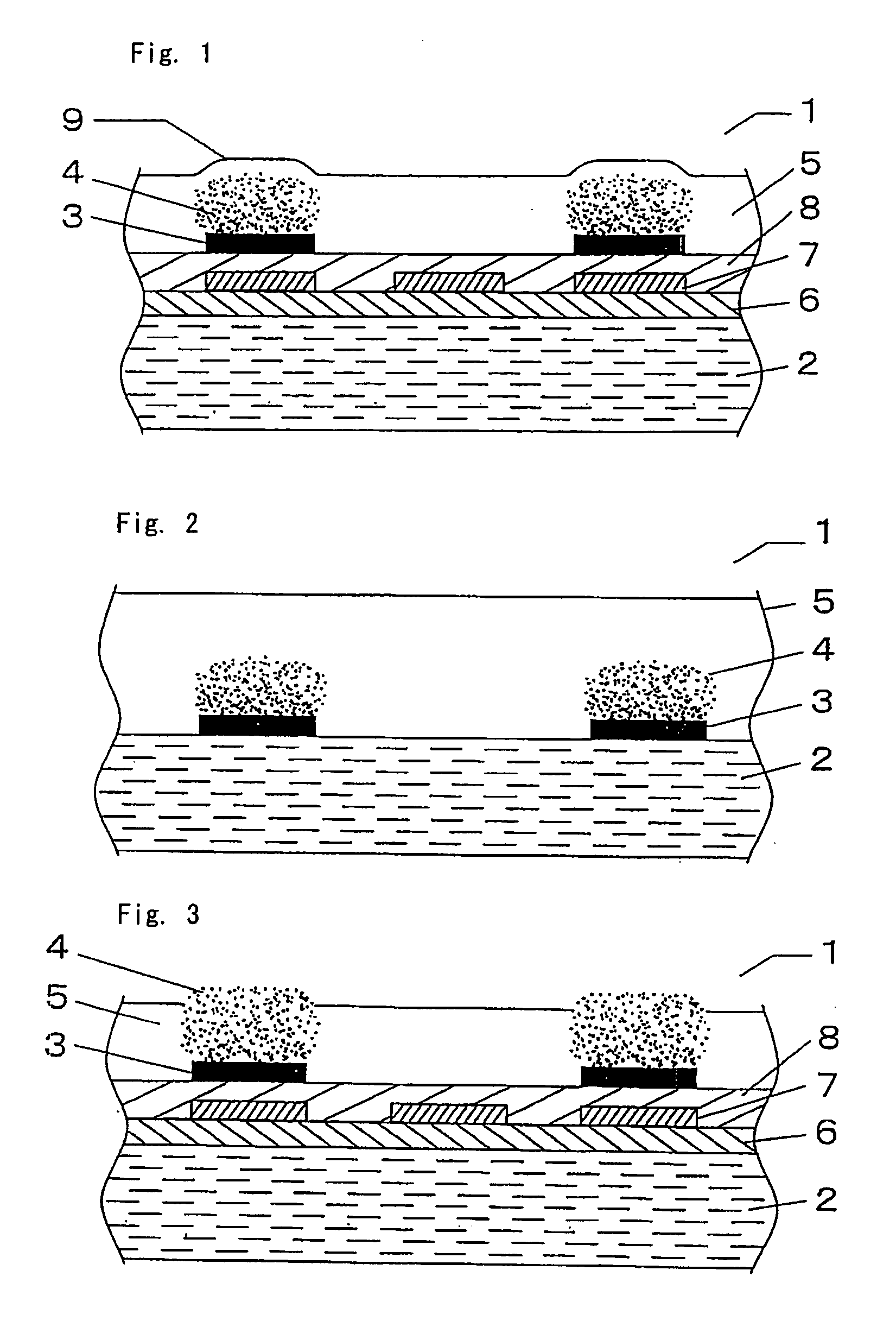

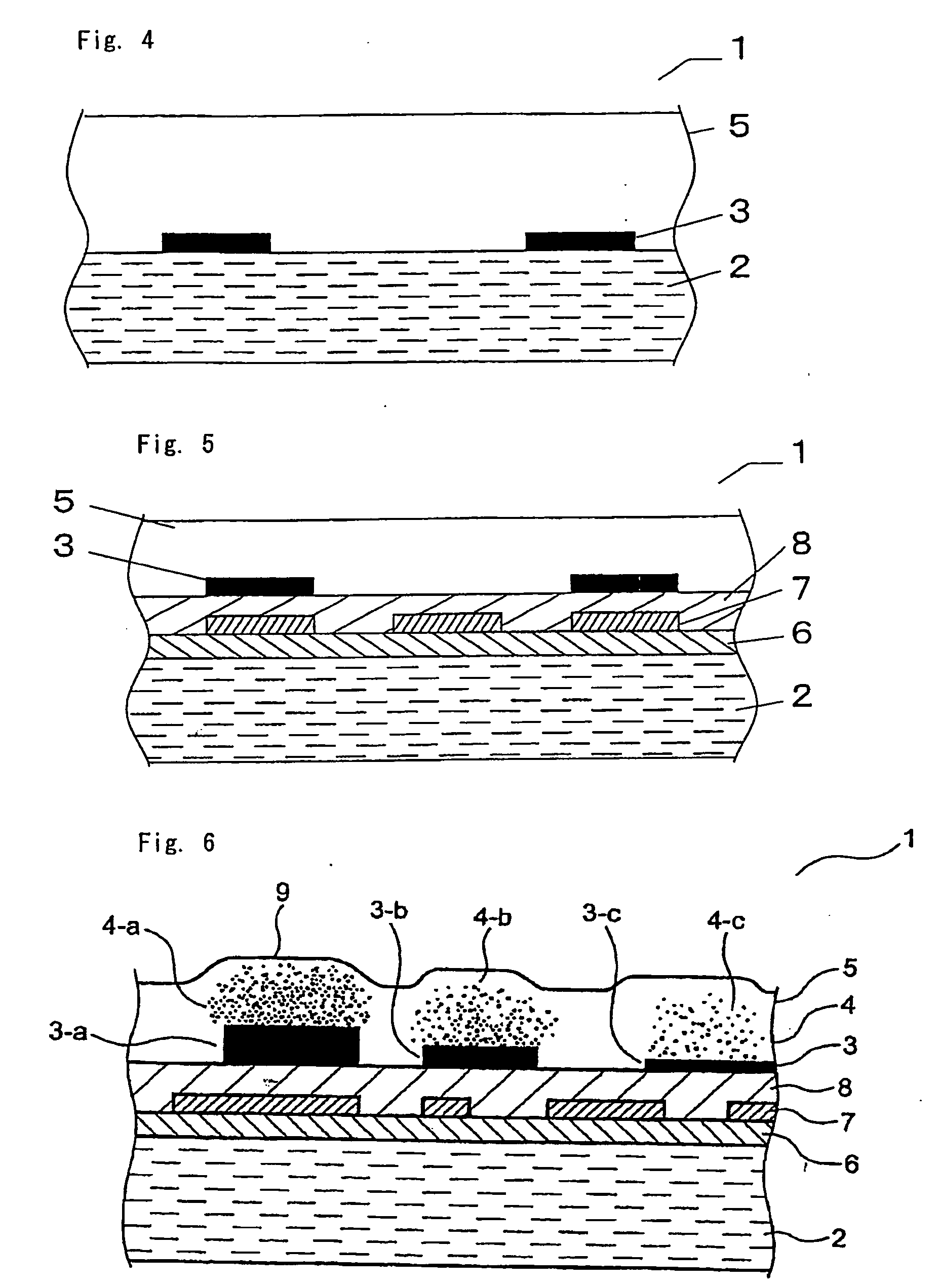

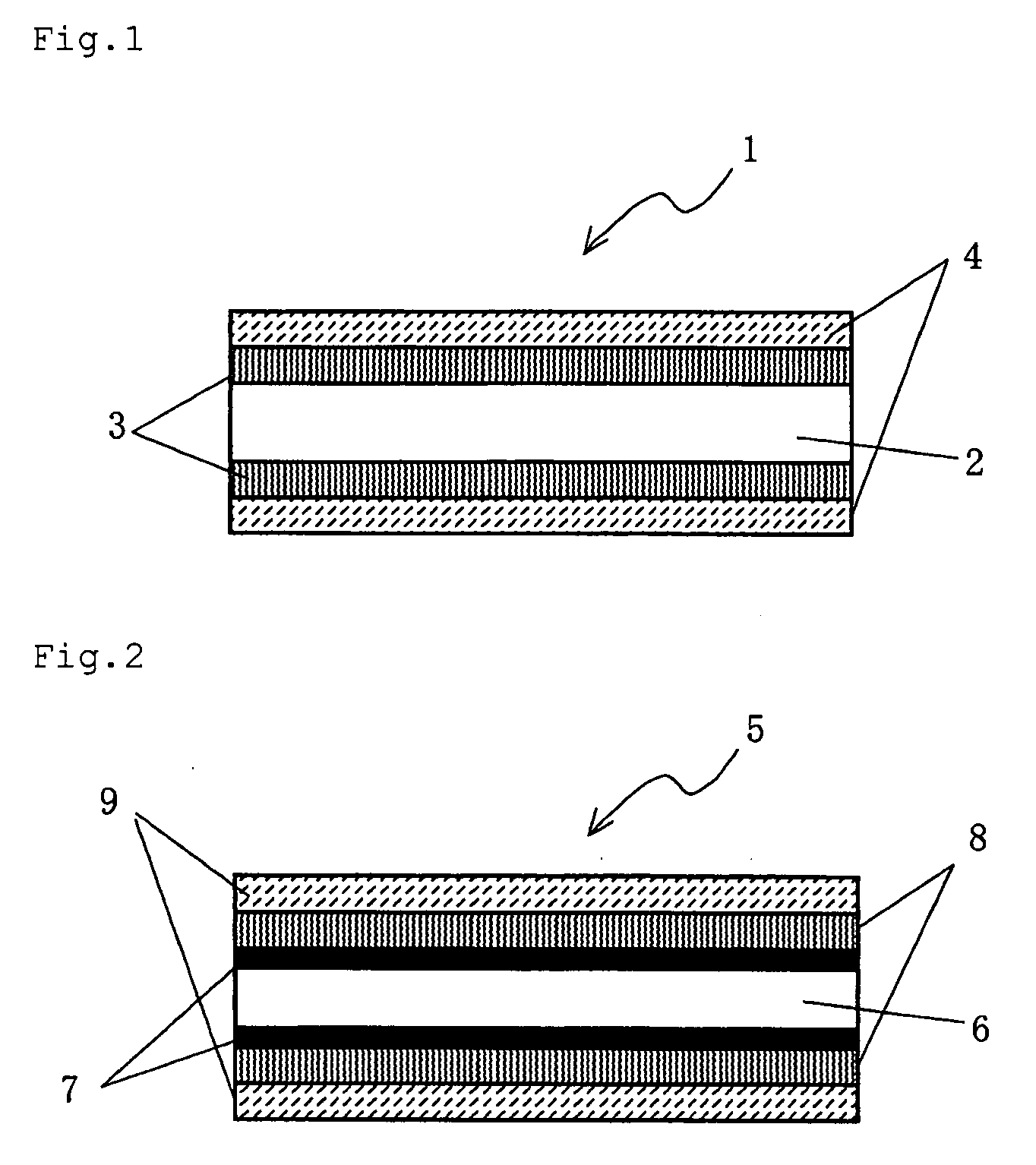

Decorating material

ActiveUS20070116933A1Good solvent resistance and abrasion resistanceHigh interlaminar strengthDecorative surface effectsSpecial ornamental structuresEngineering

There is provided a decorative material comprising at least a substrate, a low-luster pattern ink layer partially formed on the substrate, and a surface protective layer which is present on and contacted with the low-luster pattern ink layer so as to cover a whole surface including both a region where the low-luster pattern ink layer is formed and a region where no low-luster pattern ink layer is formed, wherein the surface protective layer is formed by crosslinking and curing an ionizing radiation-curable resin composition, and provided therein with a low-gloss region which is located in a portion just above the low-luster pattern ink layer and in the vicinity of the portion and visually recognized as a concave portion. The decorative material is provided on a surface thereof with a pattern, and exhibits a difference in gloss according to the pattern which is visually recognized as a concave portion, thereby imparting a good convexo-concave feeling to a surface thereof.

Owner:DAI NIPPON PRINTING CO LTD

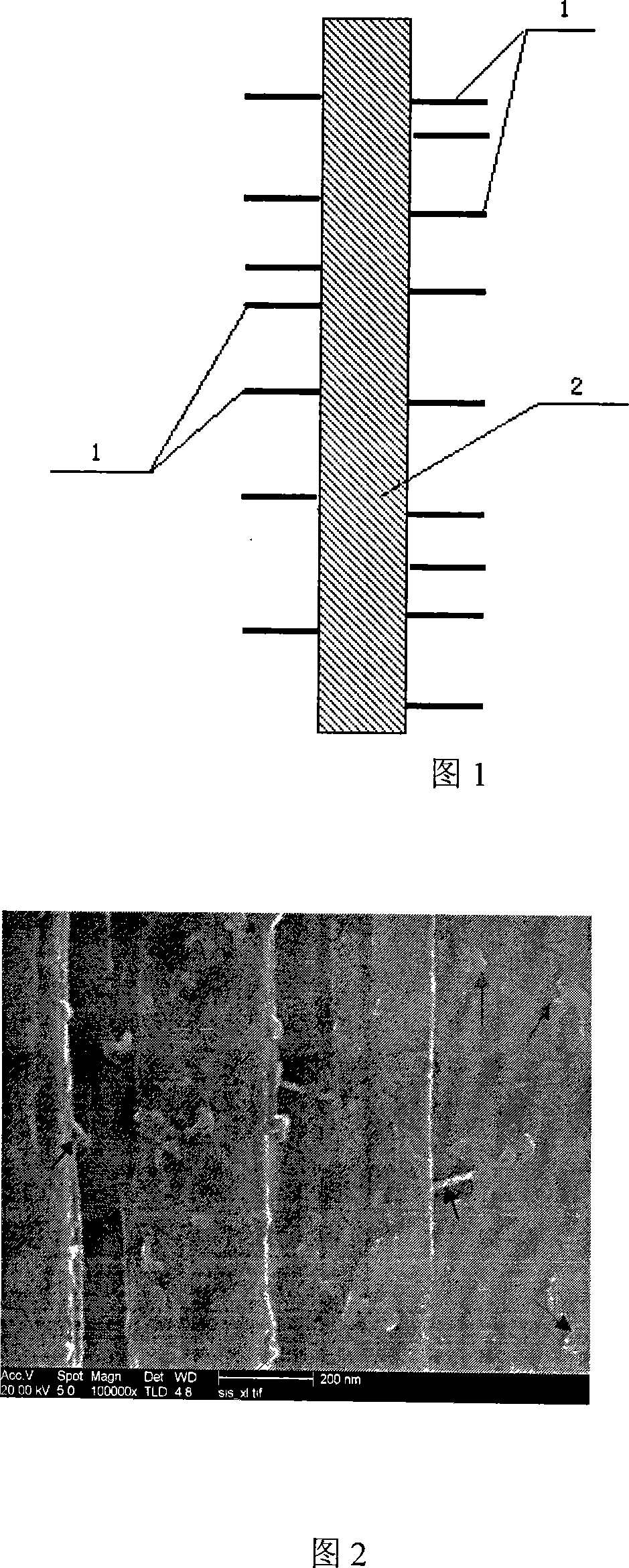

Carbon nano-tube connecting carbon fiber multi-scale reinforcing body and method for producing the same

InactiveCN101173386ATake full advantage of mechanical propertiesRealize chemical bond connectionFibre treatmentArtificial filament chemical after-treatmentFiberCarbon fibers

The invention discloses a multi-scale reinforcement body that carbon nano-tube is connected with carbon fiber and a preparation method aiming at solving the drawbacks of increasing rigidity at the interface, lowering toughness of material and not improving performance of resin base between the fibers and between carbon fiber plywoods after prior carbon fiber treatment is made. The multi-scale reinforcement body of carbon nano-tube connecting carbon fiber is made through combining between a carbon nano-tube decorated by 1, 6 hexamethylenediamine and carbon fiber with acyl chloride functional group on the surface. The preparation method comprises: the carbon nano-tube decorated by 1, 6 hexamethylenediamine and the carbon fiber with acyl chloride functional group on the surface are prepared before put into N,N-dimethylformamide for reaction, thereby getting the multi-scale reinforcement body of carbon nano-tube connecting carbon fiber. The invention has the advantages of big activity on the surface, a plurality of chemical activated functional groups, strong reactive activity, good cohesiveness with the base, improving shearing intensity at the interface for composite material by 127.5% to 144.7% and improving toughness for the base by 34.43% to 48.67%.

Owner:HARBIN INST OF TECH

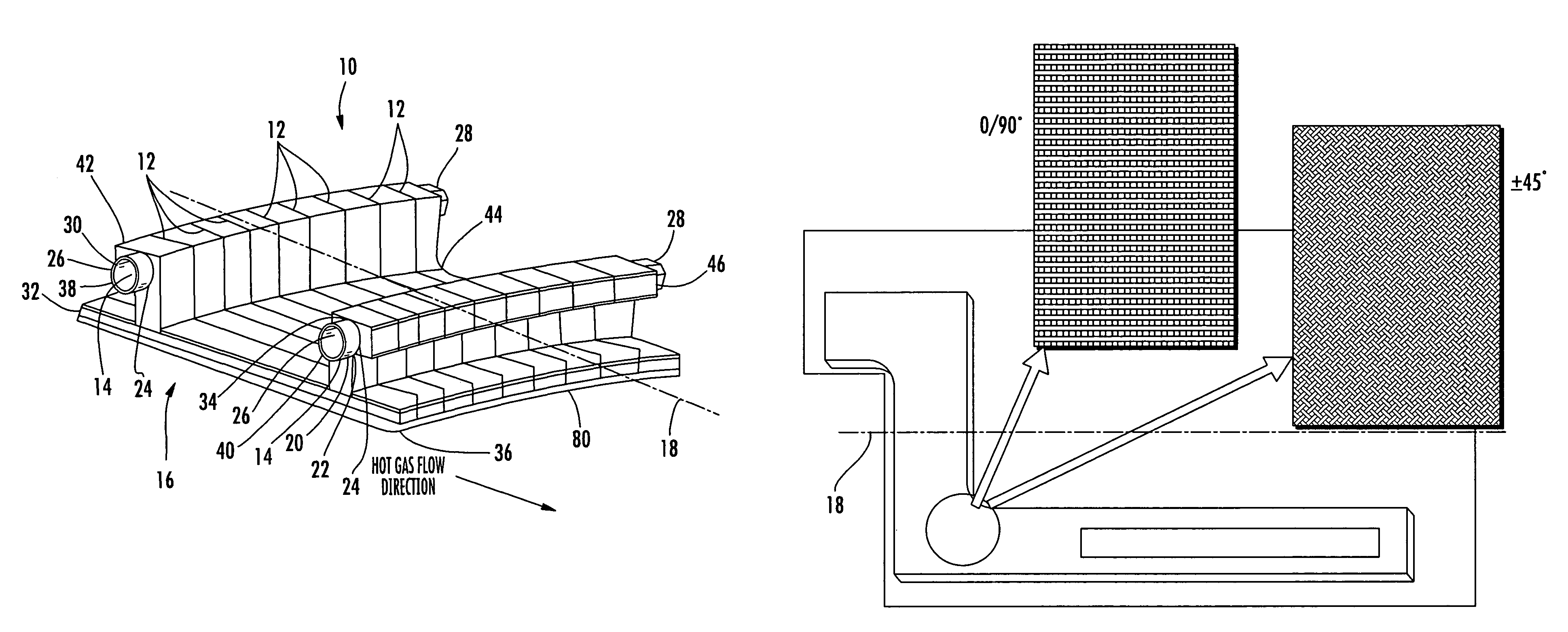

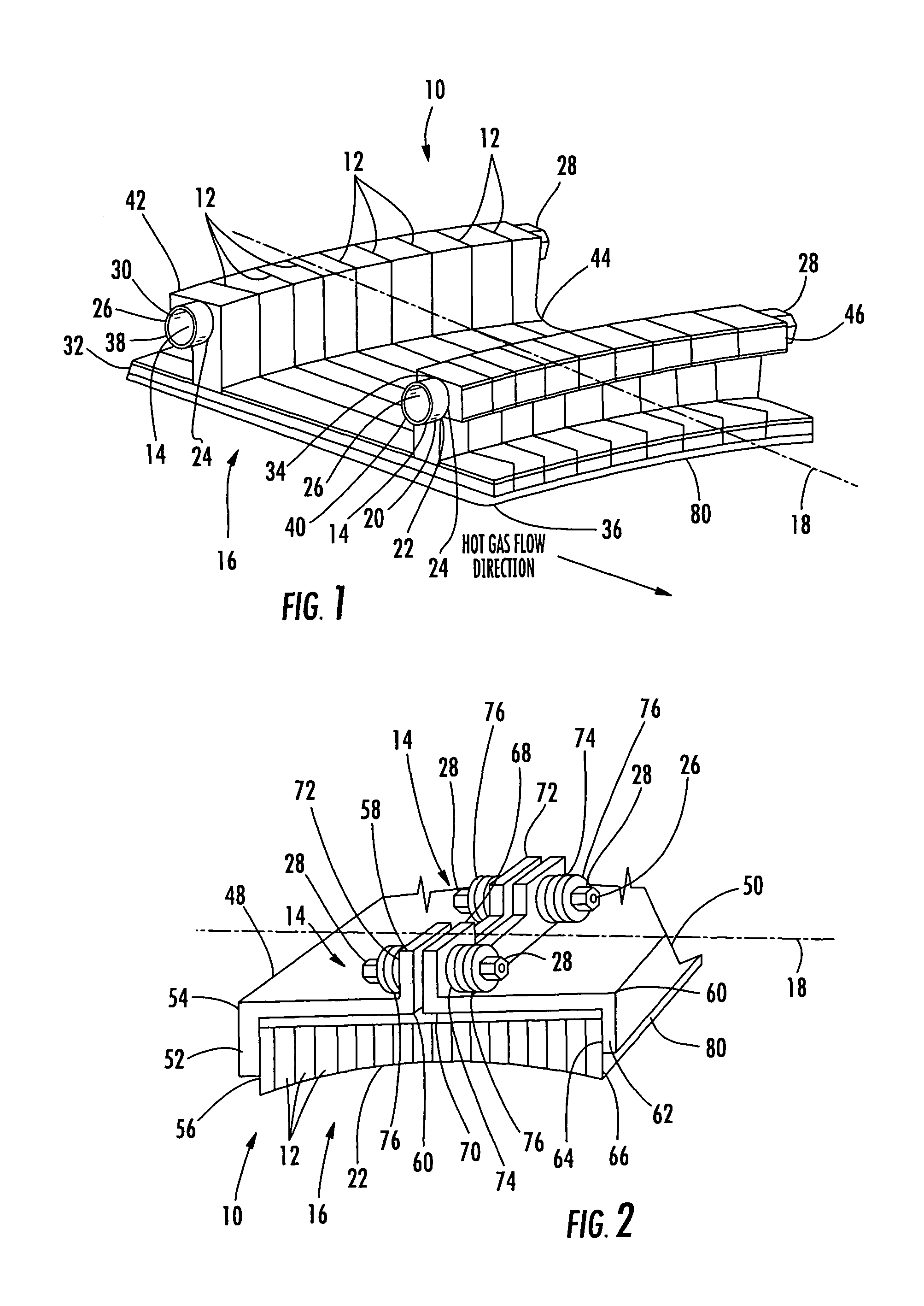

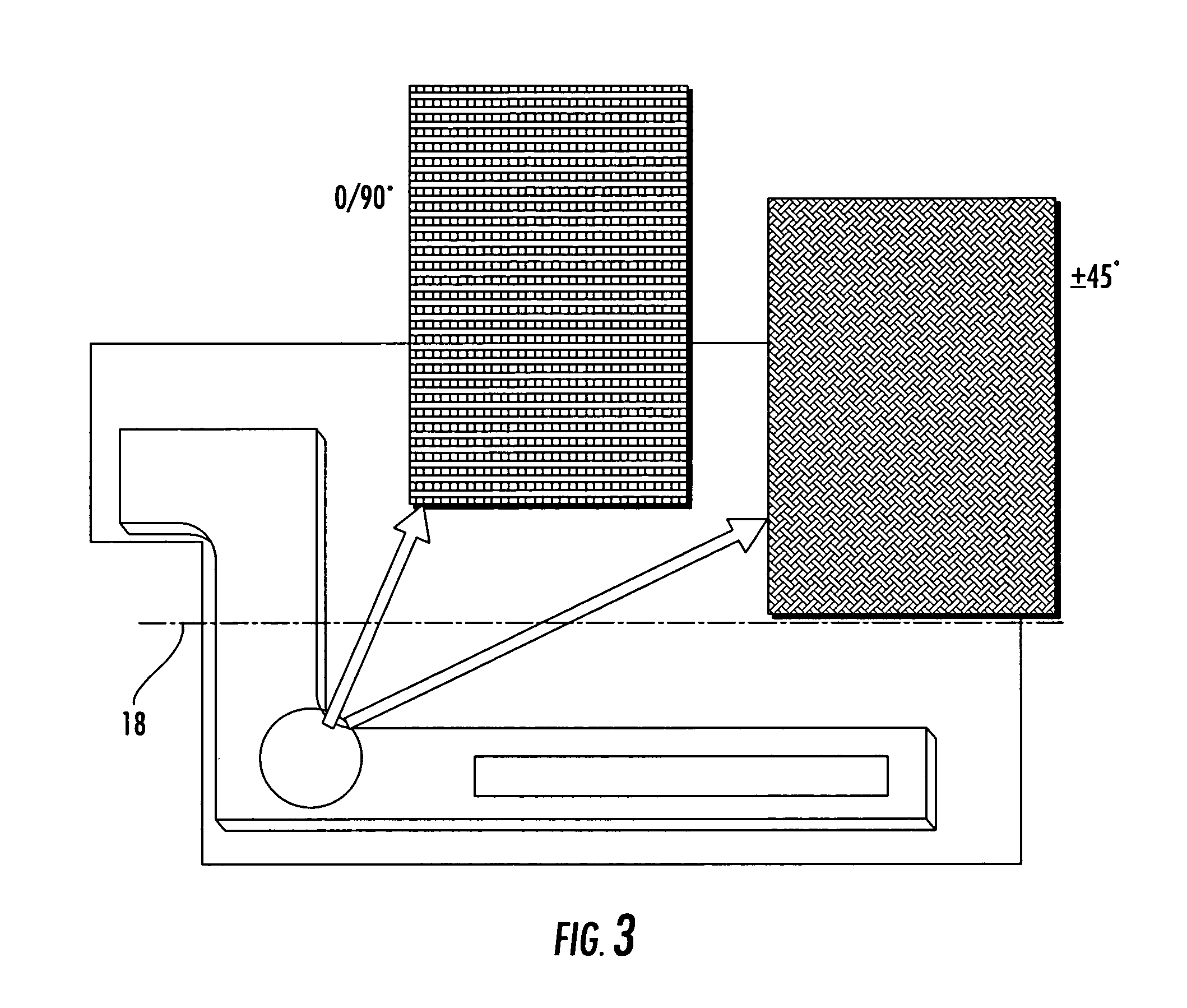

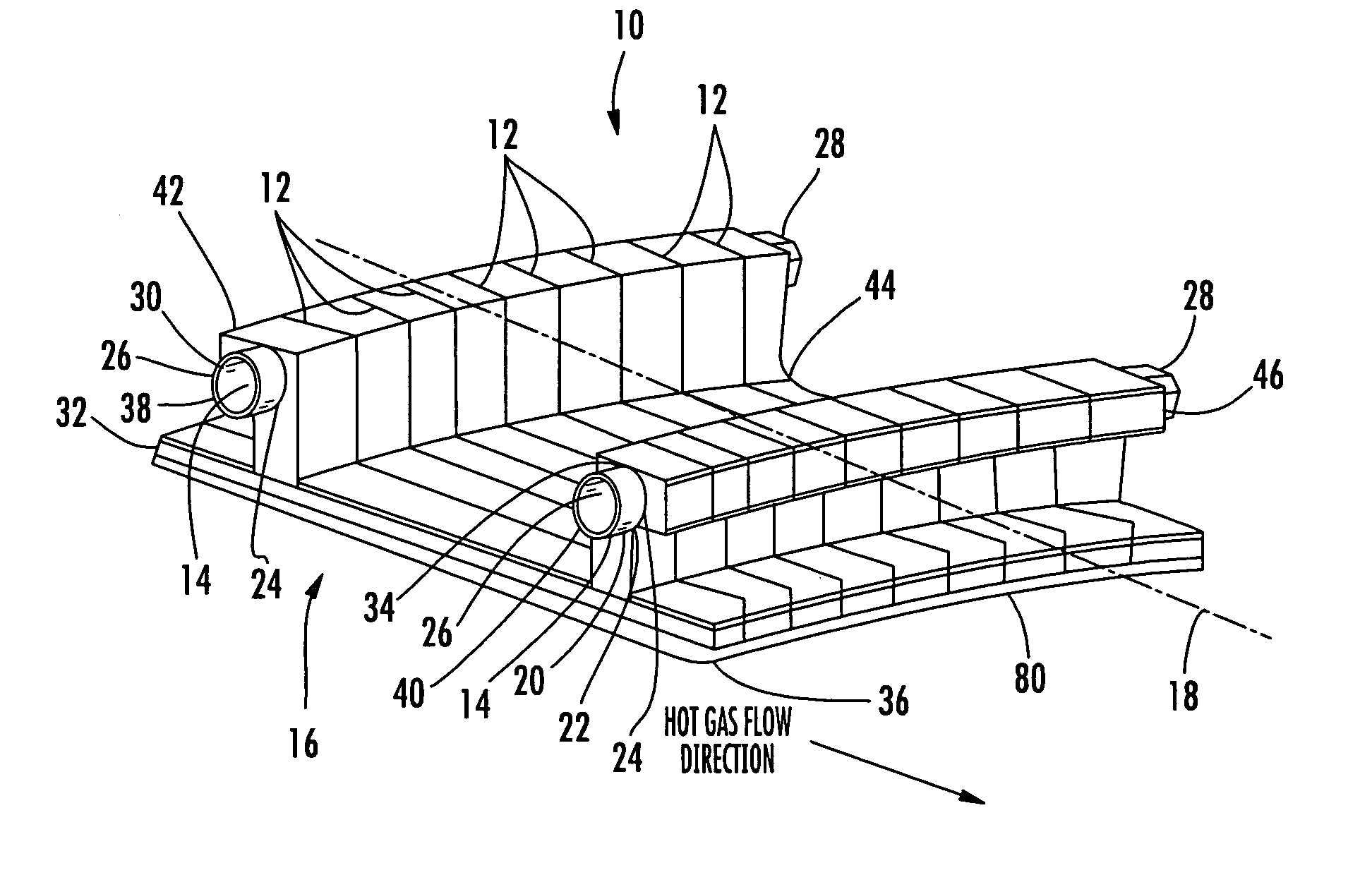

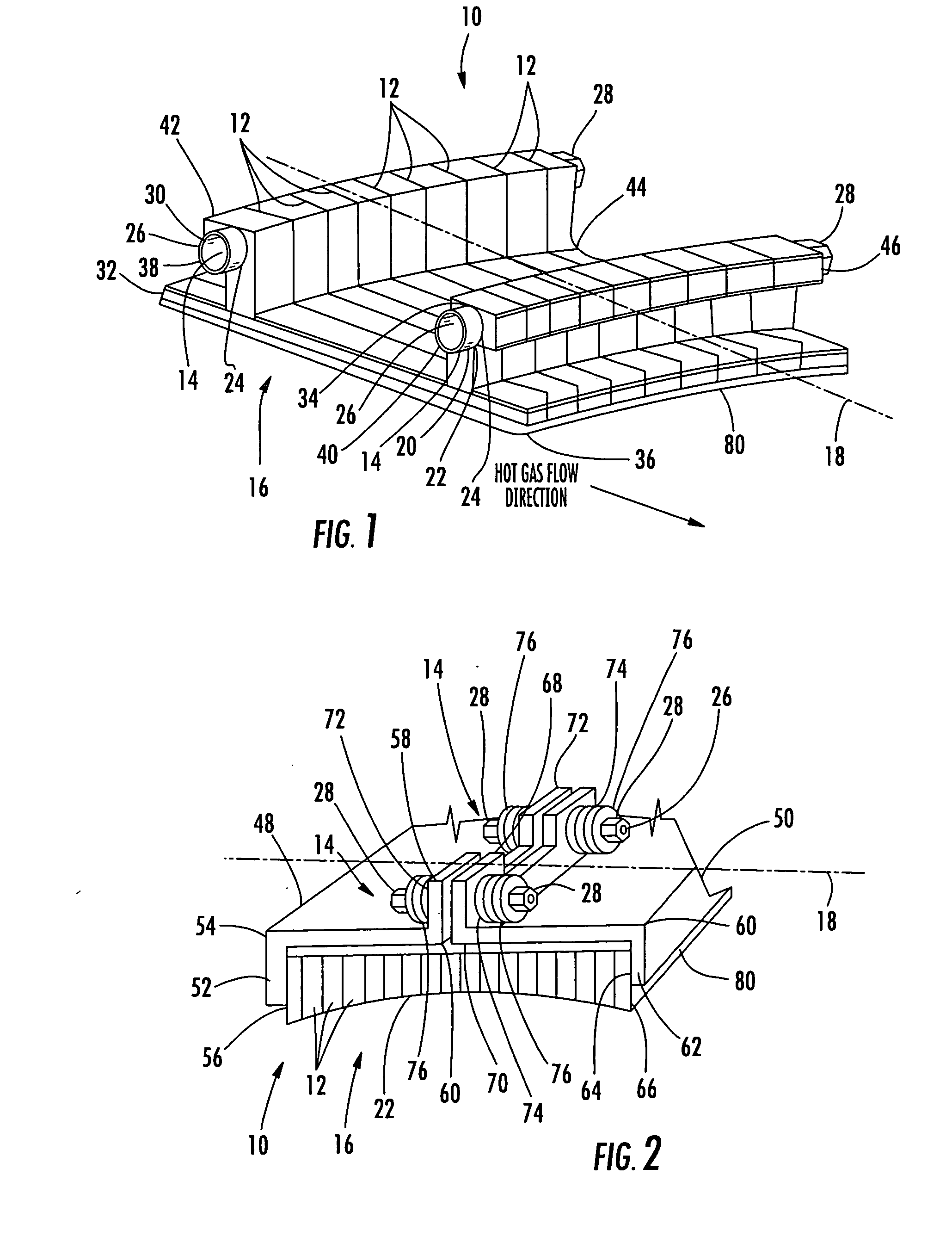

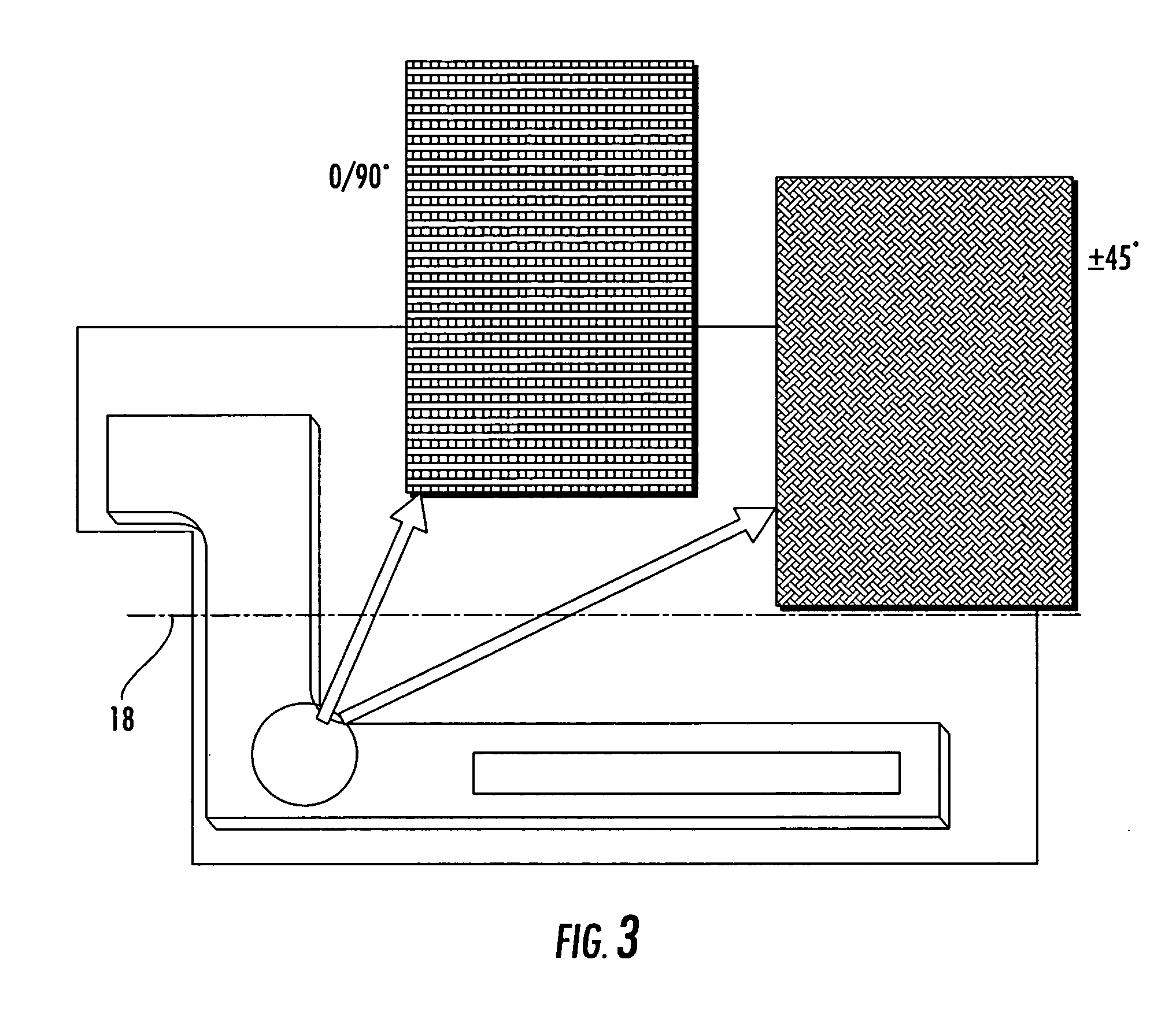

Stacked laminate bolted ring segment

InactiveUS7753643B2High strengthImprove interlayer strengthPump componentsMetal-working apparatusTurbineMetal

A ceramic ring segment for a turbine engine that may be used as a replacement for one or more metal components. The ceramic ring segment may be formed from a plurality of ceramic plates, such as ceramic matrix composite plates, that are joined together using a strengthening mechanism to reinforce the ceramic plates while permitting the resulting ceramic article to be used as a replacement for components for turbine systems that are typically metal, thereby taking advantage of the properties provided by ceramic materials. The strengthening mechanism may include a bolt or a plurality of bolts designed to prevent delamination of the ceramic plates when in use by keeping the ceramic plates in compression.

Owner:SIEMENS ENERGY INC

Stacked laminate bolted ring segment

InactiveUS20100150703A1High strengthImprove interlayer strengthPump componentsMetal-working apparatusTurbineMetal

A ceramic ring segment for a turbine engine that may be used as a replacement for one or more metal components. The ceramic ring segment may be formed from a plurality of ceramic plates, such as ceramic matrix composite plates, that are joined together using a strengthening mechanism to reinforce the ceramic plates while permitting the resulting ceramic article to be used as a replacement for components for turbine systems that are typically metal, thereby taking advantage of the properties provided by ceramic materials. The strengthening mechanism may include a bolt or a plurality of bolts designed to prevent delamination of the ceramic plates when in use by keeping the ceramic plates in compression.

Owner:SIEMENS ENERGY INC

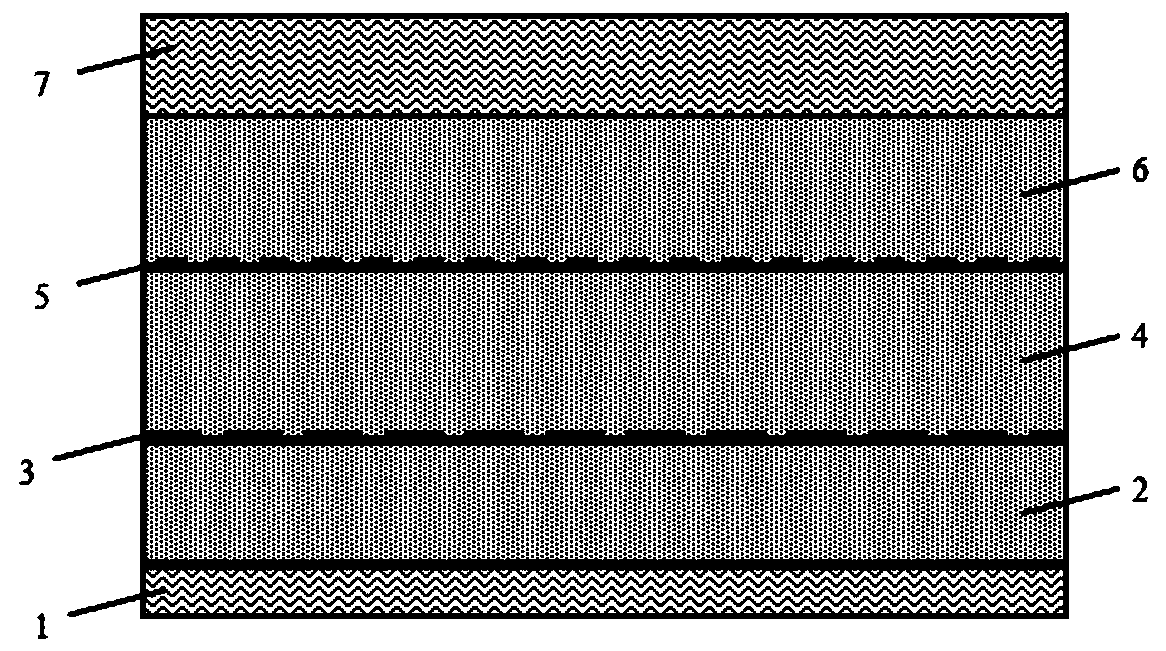

Heat preventing and insulating stealth compound material with broad-band wave absorption and preparation method thereof

ActiveCN107555940AMeet the needs of impedance matchingRealize broadband absorbing functionLamination ancillary operationsLaminationWeight gainingControllability

The invention discloses a heat preventing and insulating stealth compound material with broad-band wave absorption and a preparation method thereof. The compound material comprises a cold-faced panel,a first aerogel compound material heat-insulating layer, a first resistance high-temperature super-material layer, a second aerogel compound material heat-insulating layer, a second resistance high-temperature super-material layer, a third aerogel compound material heat-insulating layer and a hot-faced panel from inside to outside sequentially. In the aspect of heat preventing and insulating performance, compared with existing heat insulating tiles and cover plate type heat prevention systems, the integrated heat preventing and insulating stealth compound material has the advantages of good heat insulating performance, excellent mechanical performance, large component preparation availability, high reliability, easiness in maintenance and the like; and in the aspect of stealth performance, the technical scheme adopting the high temperature super-material has the advantages of strong designability and easiness in broad-band wave absorption implementation, weight gain is hardly generated in comparison with the technical scheme of a cold-faced by adopting a wave absorbing material, absorbent is not required to be added into a heat preventing and insulating material, the heat preventing and insulating performance is not influenced, and the material has good uniformity and strong controllability.

Owner:NAT UNIV OF DEFENSE TECH

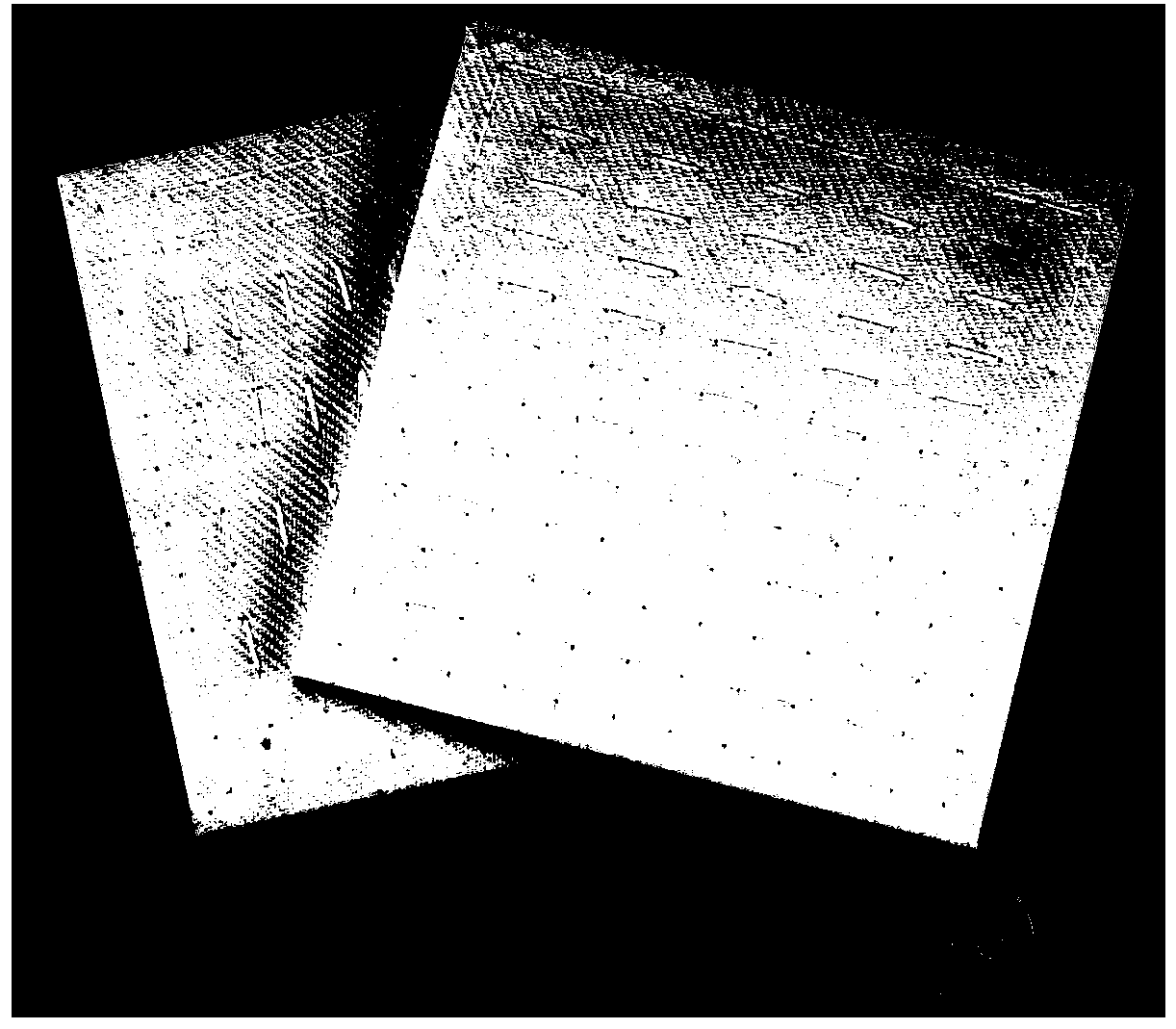

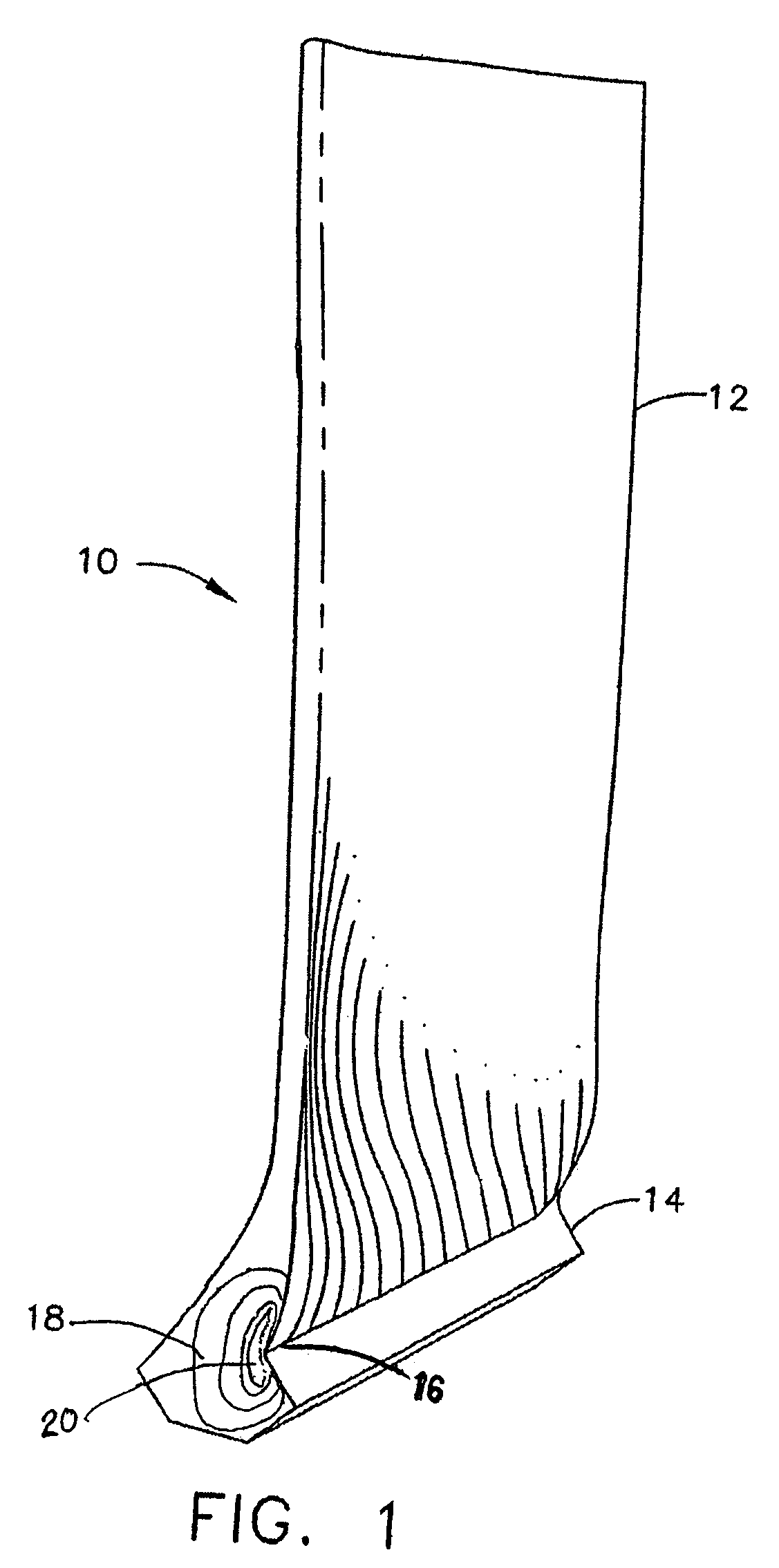

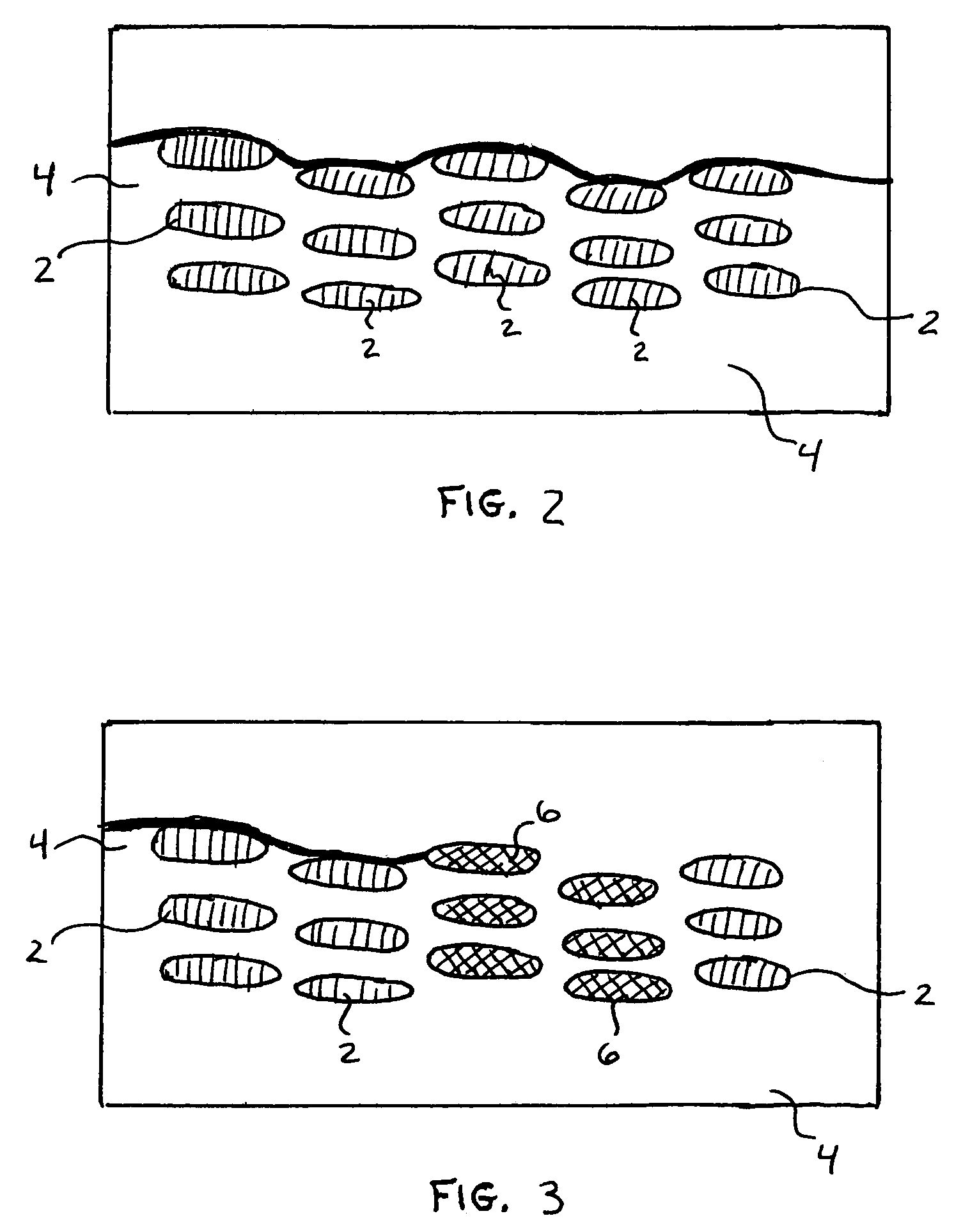

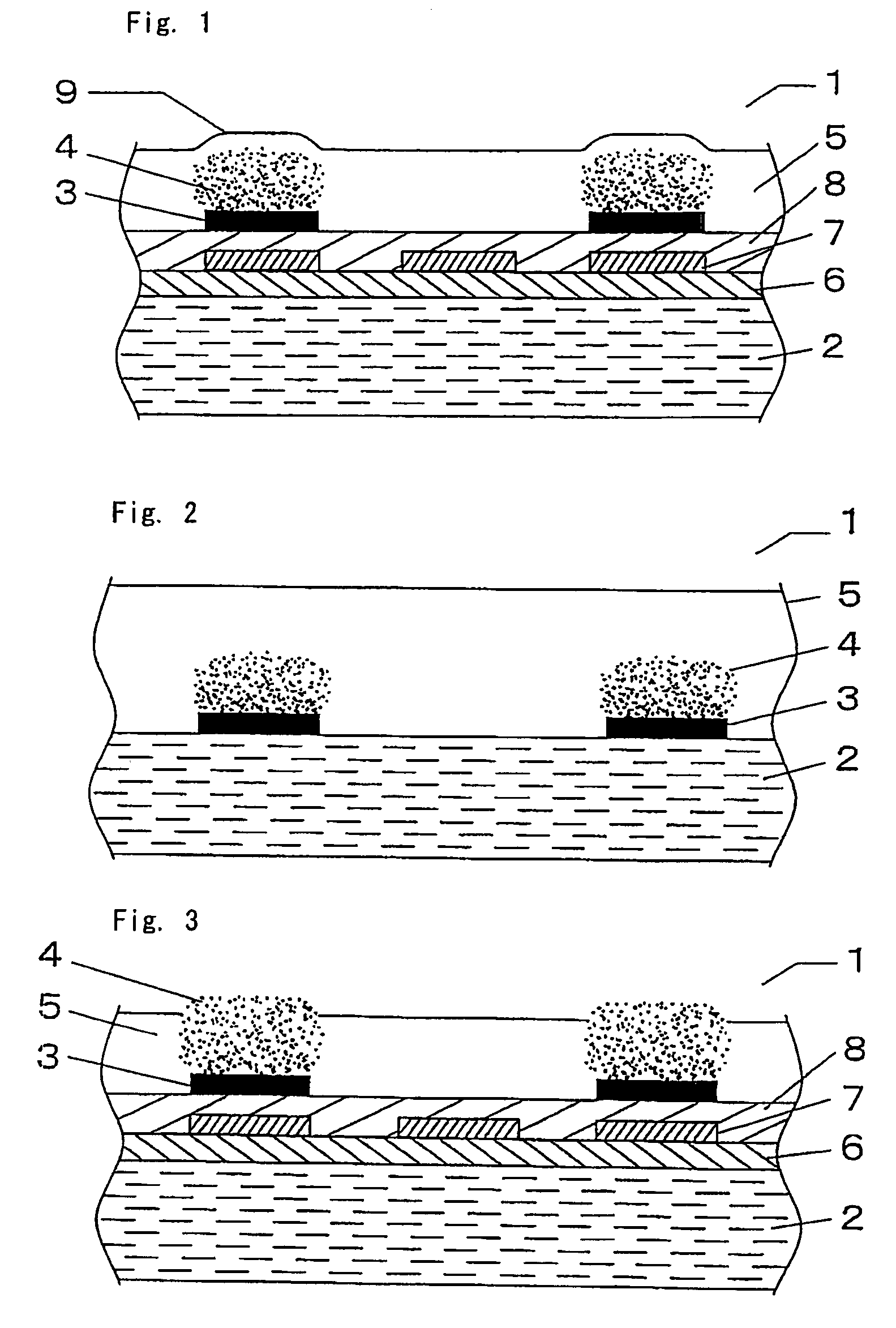

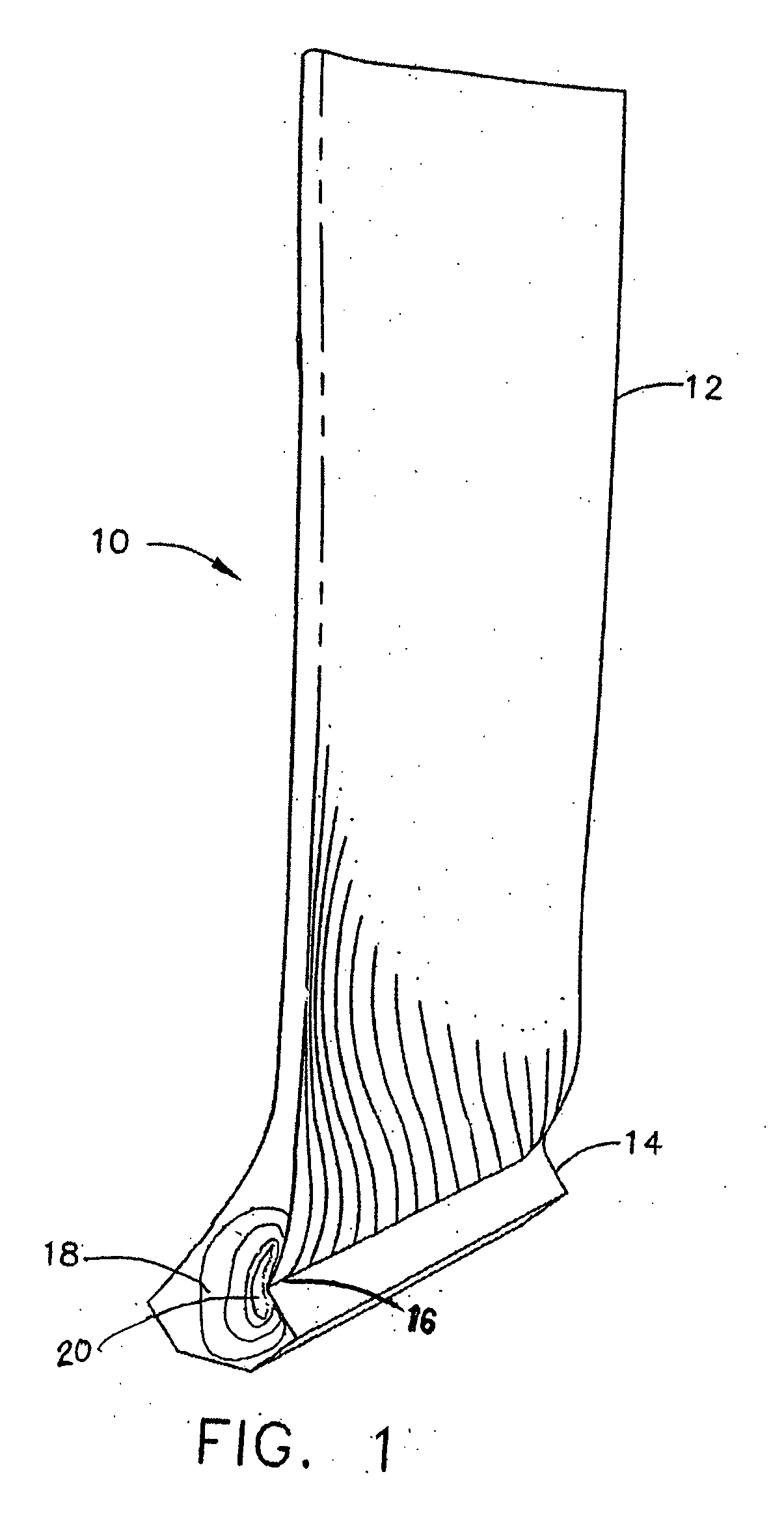

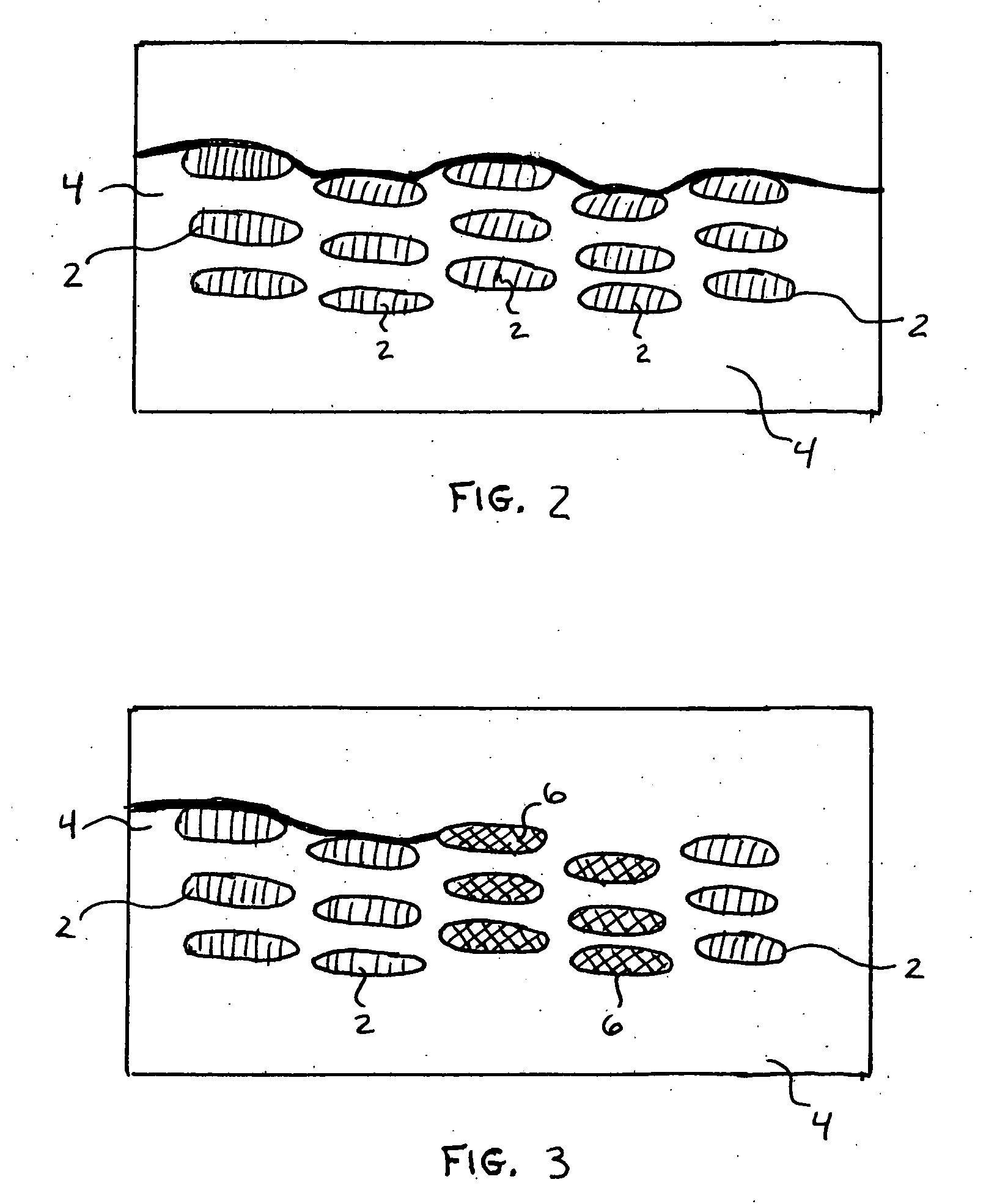

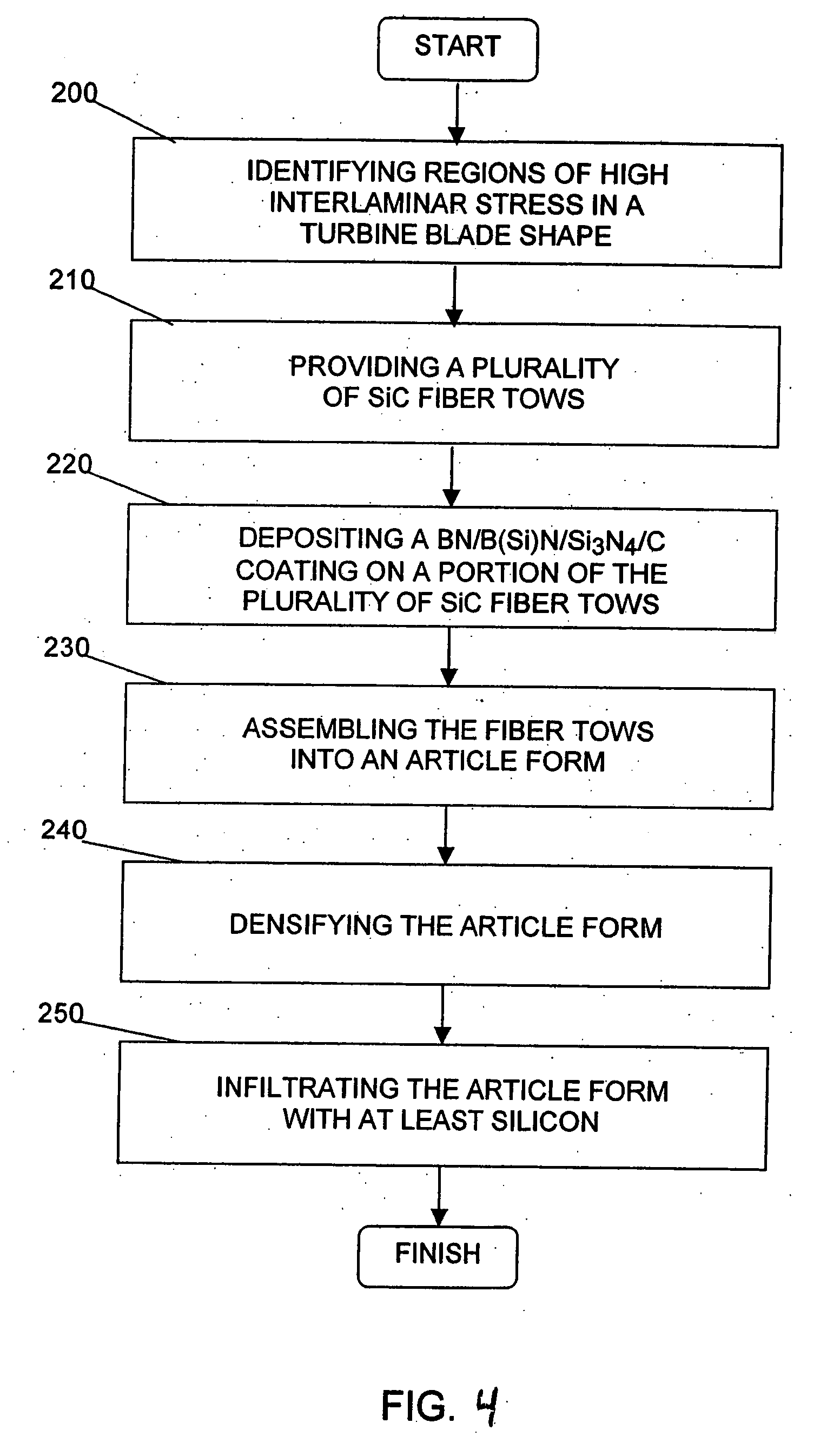

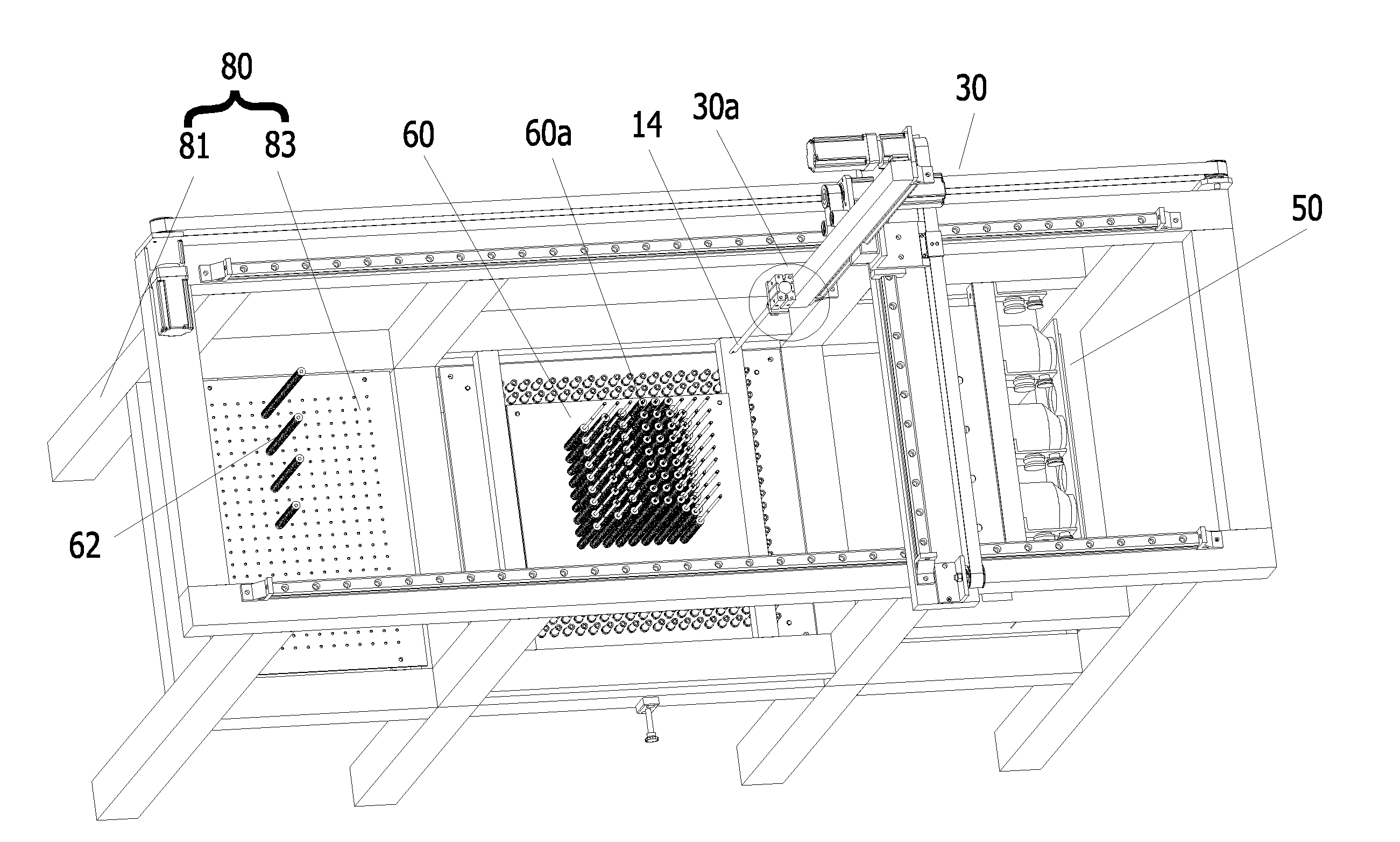

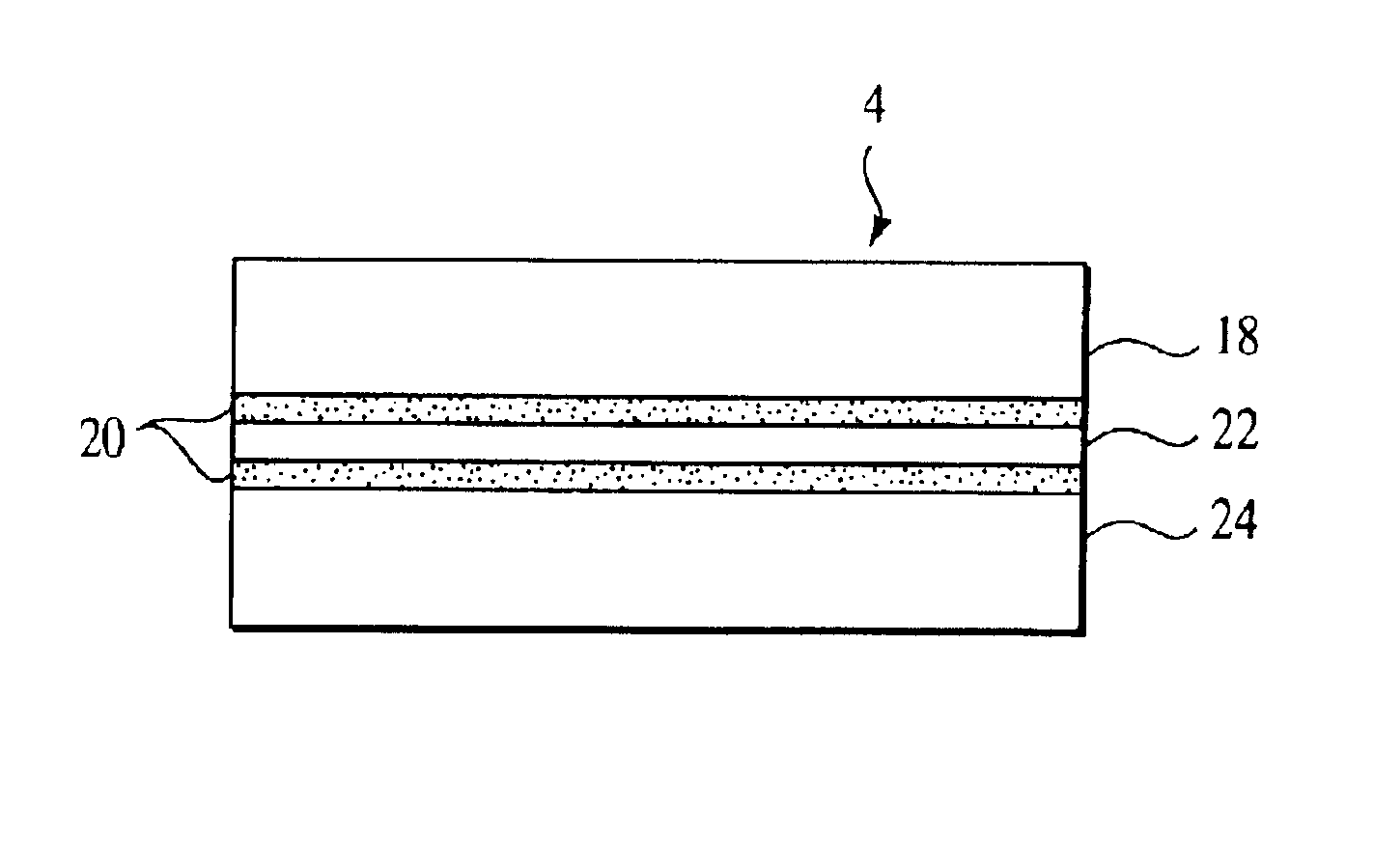

SiC/SiC composites incorporating uncoated fibers to improve interlaminar strength

ActiveUS7223465B2Low costImprove performanceBlade accessoriesEfficient propulsion technologiesFiber bundleTurbine

The present invention is a ceramic matrix composite turbine engine component, wherein the component has a region of expected higher interlaminate stress during normal engine operation. The component includes both coated fiber tows and uncoated fiber tows arranged together into a preselected form, wherein the uncoated fiber tows are located at predetermined regions of expected high interlaminate stress. The invention further includes method of manufacturing a CMC such as a composite turbine engine component, wherein the component has a region of expected higher interlaminate stress during engine operation.

Owner:GENERAL ELECTRIC CO

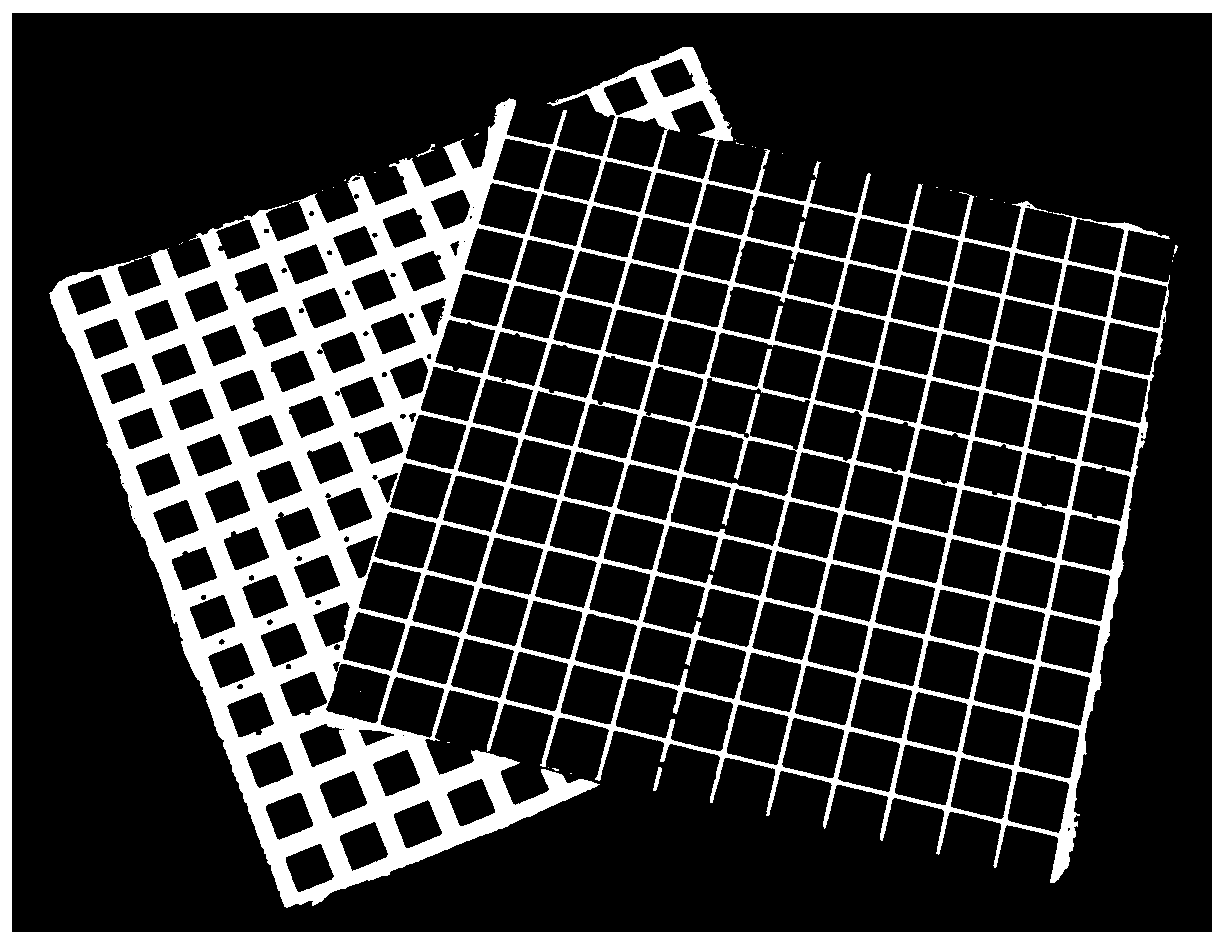

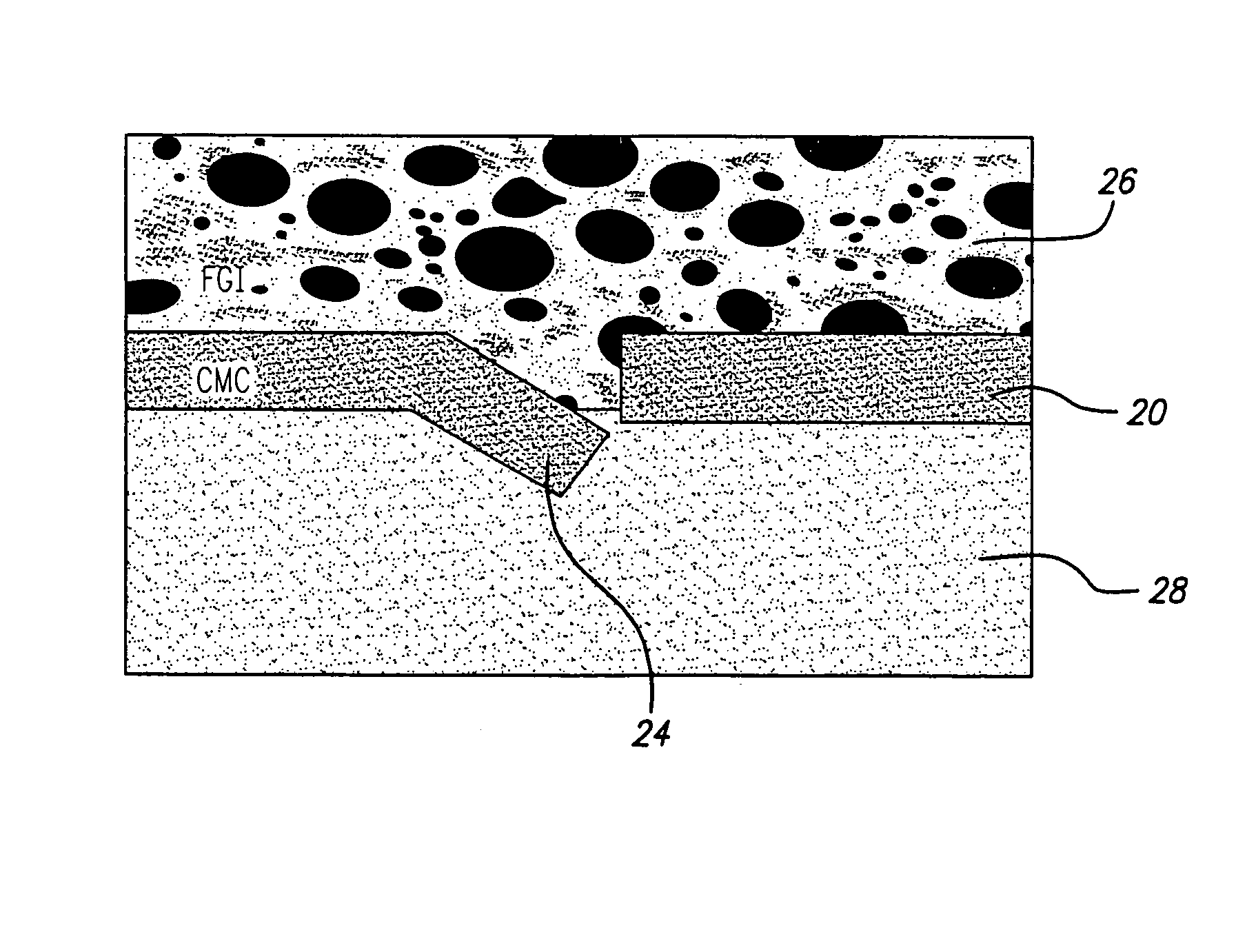

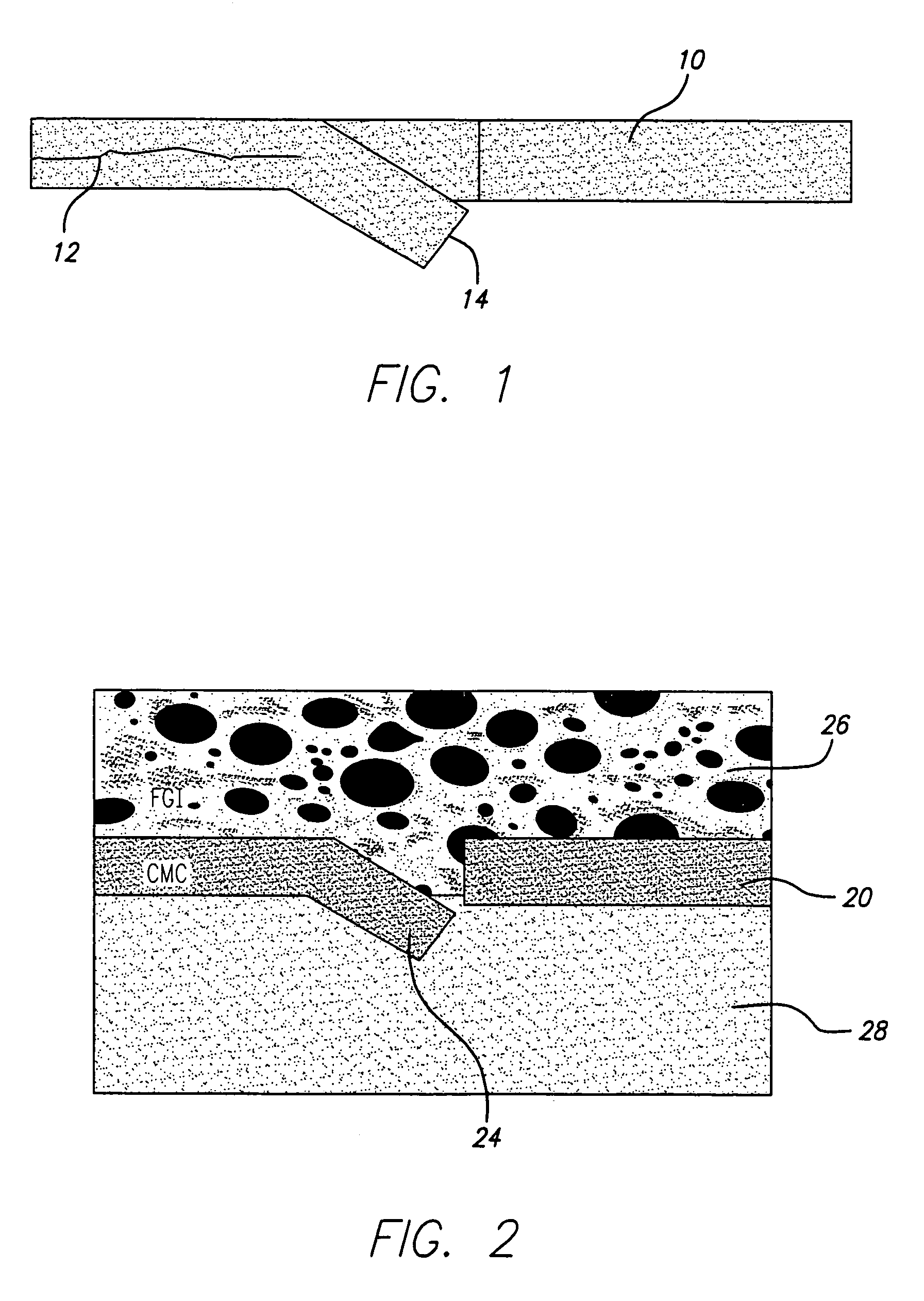

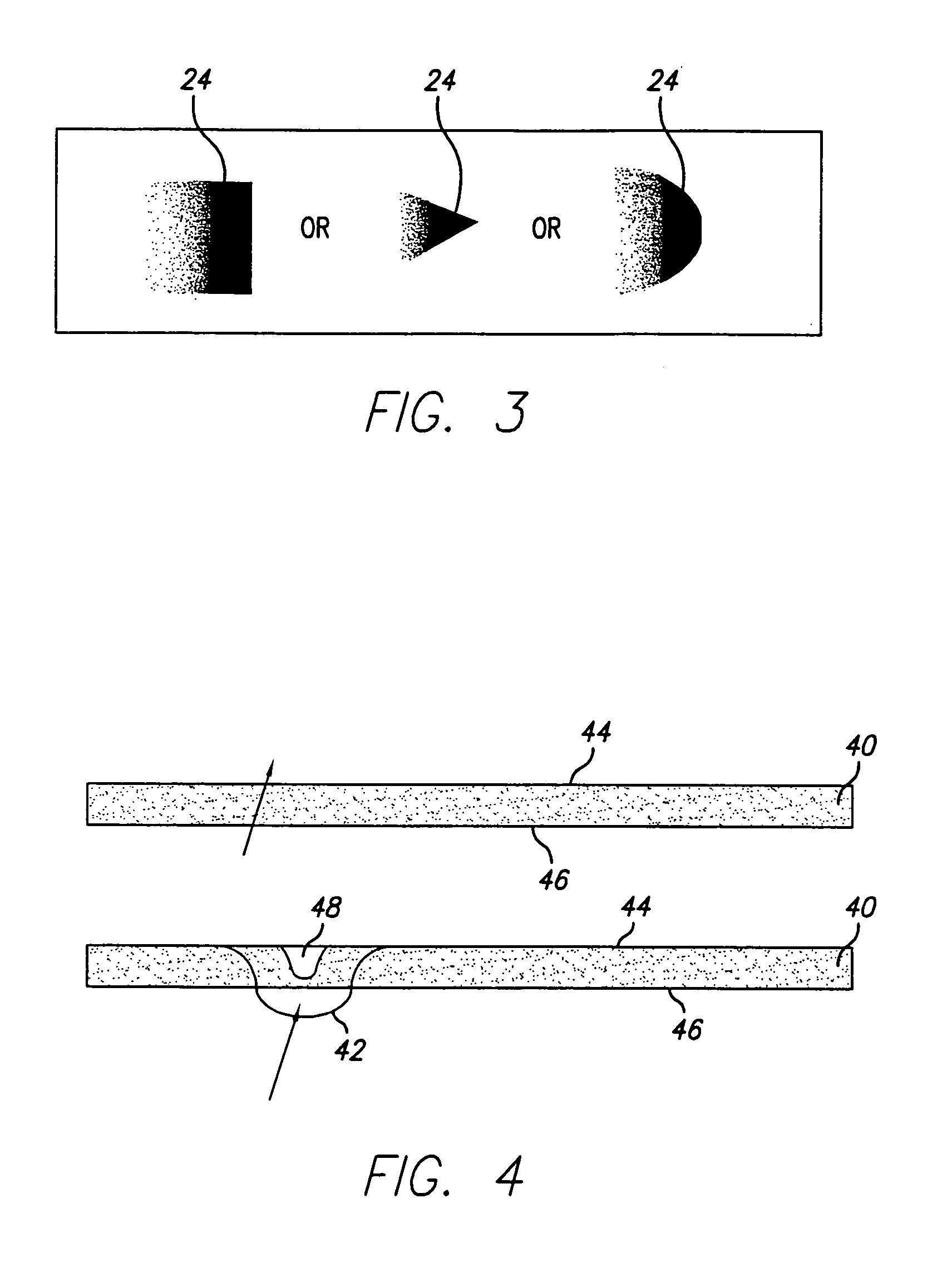

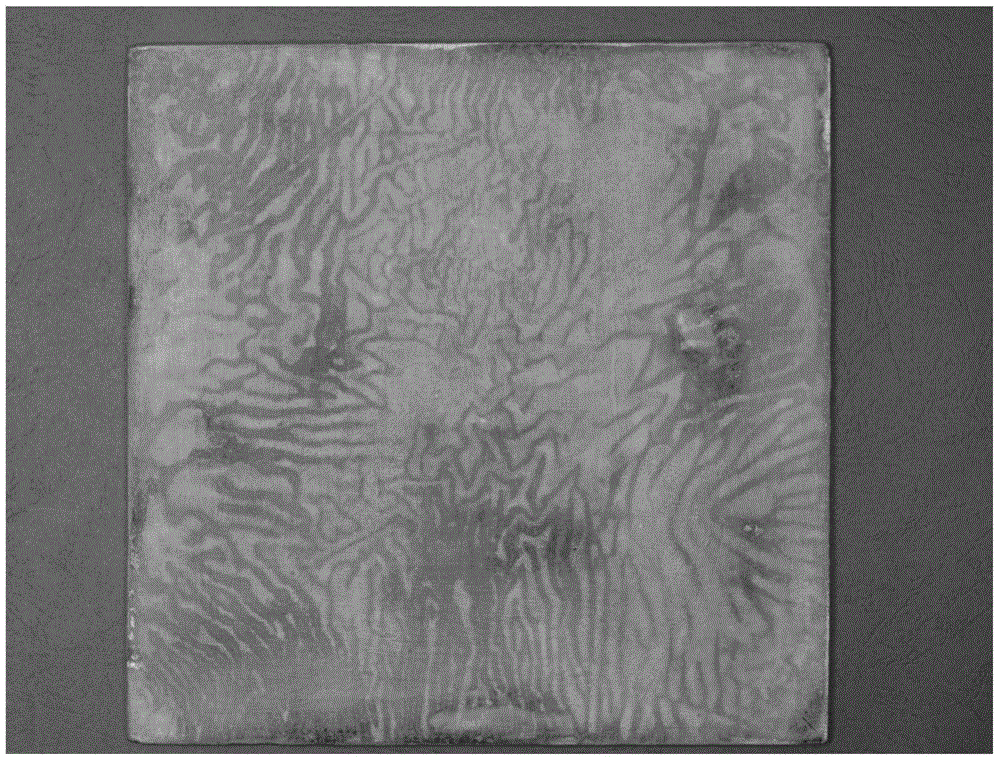

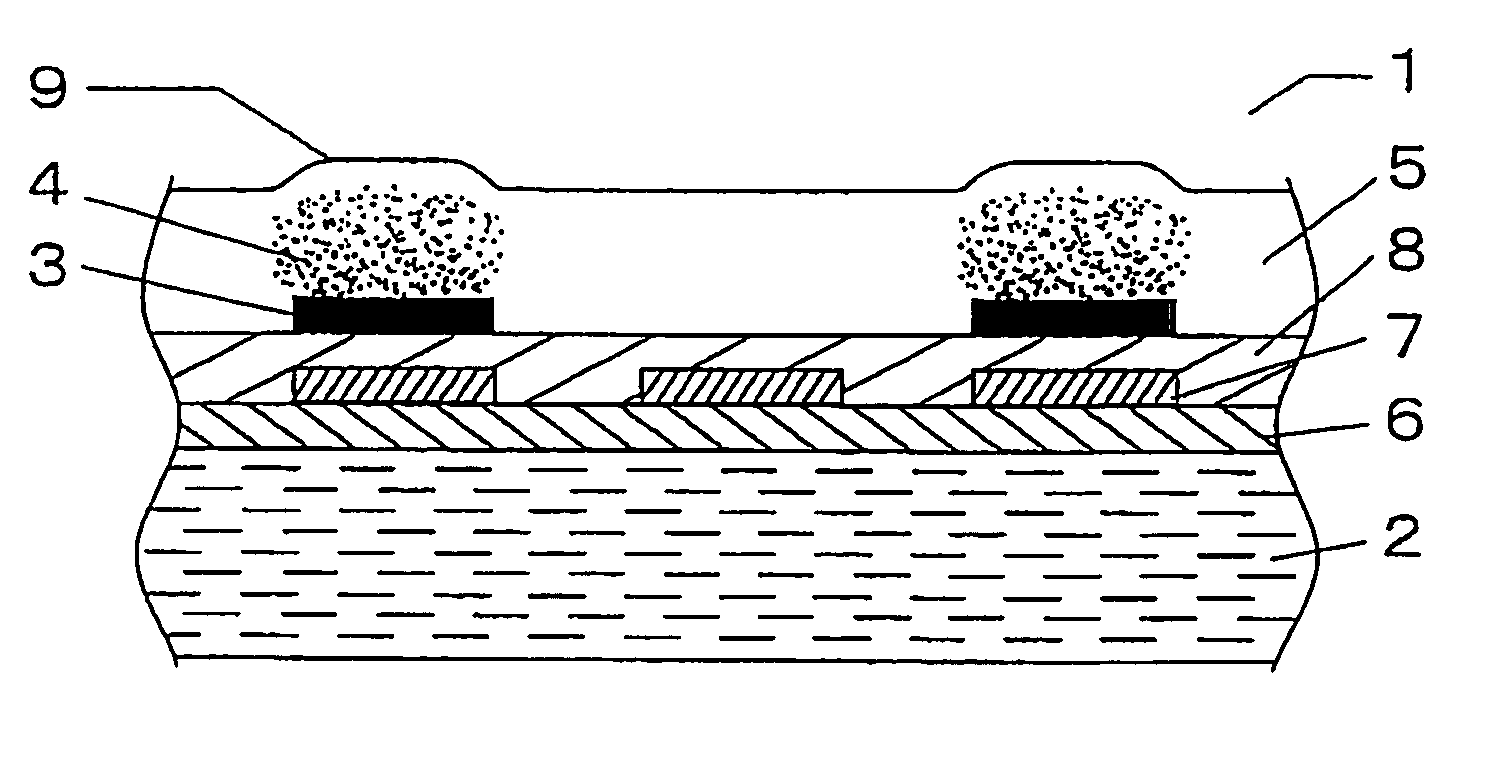

Tabbed ceramic article for improved interlaminar strength

InactiveUS7387758B2Improve interlayer strengthHigh bonding strengthPretreated surfacesWood working apparatusMachining processUltimate tensile strength

A ceramic article having improved interlaminar strength and a method of forming the article. The article may be a ceramic matrix composite article. The methods of forming the articles increase the interlaminar strength of the article by forming indentations in the article during processing. The indentations may be tabs that are formed such that they provide one or more beneficial features for ceramic articles, such as CMC articles and hybrid structures. The tabs may be any of a variety of shapes, orientations, spacings, and combinations. In an alternative embodiment, the indentations are formed by pulling one or more fibers from one side of the ceramic layer to the other side. The articles have increased surface area, which helps to increase the bonding strength between the ceramic layer and any thermal barrier coating layer and / or ceramic core in the ceramic article.

Owner:SIEMENS ENERGY INC

Carbon fiber composite material laminated plate with piezoelectric damping and preparation method thereof

InactiveCN102700203AExcellent piezoelectric damping performanceIncrease dampingSynthetic resin layered productsLaminationCarbon nanotubeGreek letter sigma

The invention provides a carbon fiber composite material laminated plate with piezoelectric damping and a preparation method thereof, and relates to a carbon fiber composite material laminated plate and a preparation method thereof. The invention aims to solve the problems that a polarization process is complex and a practical application is bad in the prior art. The carbon fiber composite material laminated plate comprises piezoelectric ceramic powder, carbon nano-tube and bismaleimide carbon fiber prepreg. The preparation method comprises the following steps of: preparing bismaleimide resin solution into the carbon fiber prepreg; grinding the polarized piezoelectric ceramic into the piezoelectric ceramic powder, and mixing the piezoelectric ceramic powder with the bismaleimide resin solution and the acidized carbon nano-tube so as to obtain pre-mixing sizing material after ultrasound; and laying the carbon fiber prepreg in a mold, painting the pre-mixing sizing material on the carbon fiber prepreg, and placing the carbon fiber prepreg into a hot press for processing so as to obtain the product. The damping los factor Delta tan sigma of the carbon fiber composite material laminated plate is more than or equal to 0.016 under a normal temperature, and the interlayer strength is improved by 3%-7%. The carbon fiber composite material laminated plate is applied to fields of aerospace crafts, naval vessels which have special usage requirements on material mechanical property and vibration and noise reduction.

Owner:HARBIN INST OF TECH

Heat-resistant wave-absorbing material and preparation method thereof

The invention discloses a heat-resistant wave-absorbing material, which is a composite material with quartz as matrix and a quartz fiber needled part as a reinforced phase. The composite material contains a short carbon fiber; the length of the short carbon fiber is 5-6mm; the volume content of the short carbon fiber in the composite material is 0.002-0.005g / cm<3>; the volume density of the quartz fiber needled part is 0.43-0.45g / cm<3>; and the preparation method disclosed by the invention comprises the following steps: selecting raw materials; preparing a fiber preformed part; dipping the fiber preformed part for a plurality of times; and carrying out gel and heat treatment until densification is finished. When the heat-resistant wave-absorbing material disclosed by the invention is 3.5mm in thickness, the reflectivity within a frequency range of 8-18GHz can be lower than -8dB; the heat-resistant wave-absorbing material has relatively good wave-absorbing property when the thickness is relatively small; and the preparation method disclosed by the invention is simple in processing step, free of a harmful and toxic pollutant in the technological process, and good in compatibility with the environment.

Owner:NAT UNIV OF DEFENSE TECH

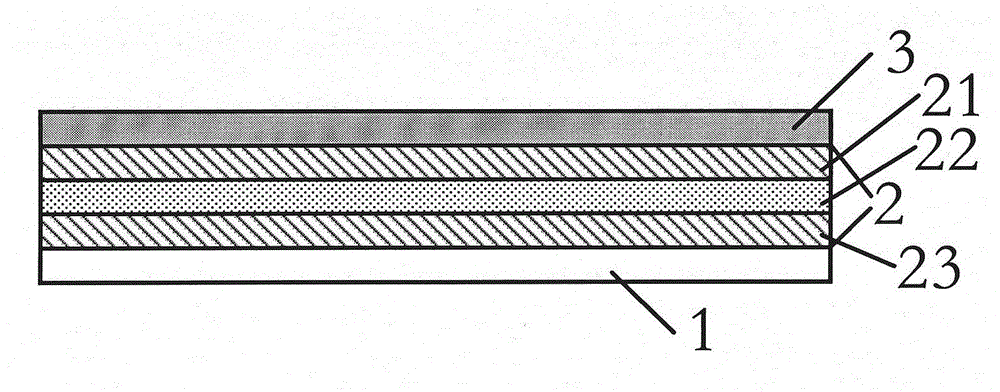

Decorating material

InactiveUS7931954B2Increase resistanceImprove interlayer strengthDecorative surface effectsSpecial ornamental structuresEngineering

There is provided a decorative material comprising at least a substrate, a low-luster pattern ink layer partially formed on the substrate, and a surface protective layer which is present on and contacted with the low-luster pattern ink layer so as to cover a whole surface including both a region where the low-luster pattern ink layer is formed and a region where no low-luster pattern ink layer is formed, wherein the surface protective layer is formed by crosslinking and curing an ionizing radiation-curable resin composition, and provided therein with a low-gloss region which is located in a portion just above the low-luster pattern ink layer and in the vicinity of the portion and visually recognized as a concave portion. The decorative material is provided on a surface thereof with a pattern, and exhibits a difference in gloss according to the pattern which is visually recognized as a concave portion, thereby imparting a good convexo-concave feeling to a surface thereof.

Owner:DAI NIPPON PRINTING CO LTD

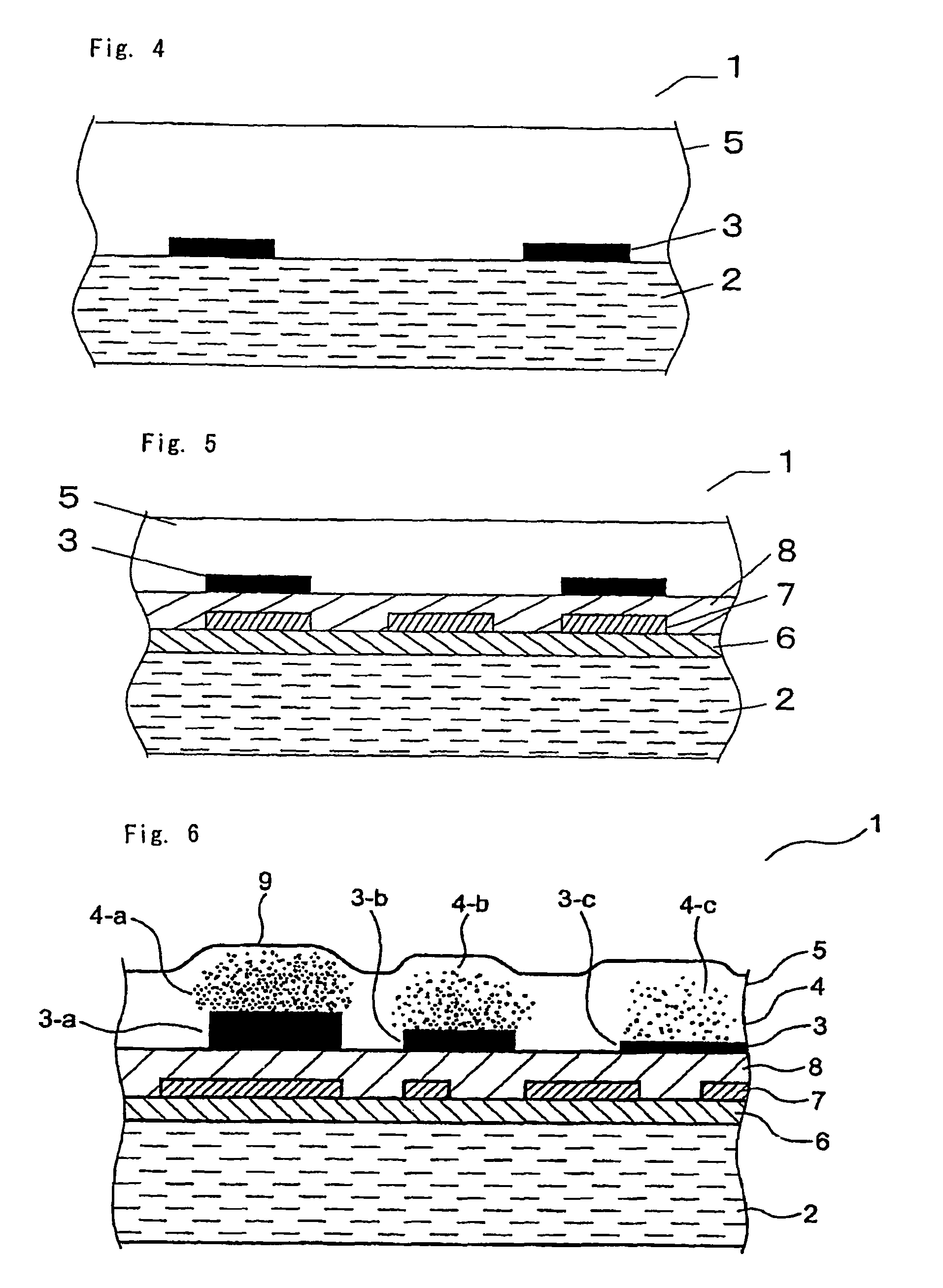

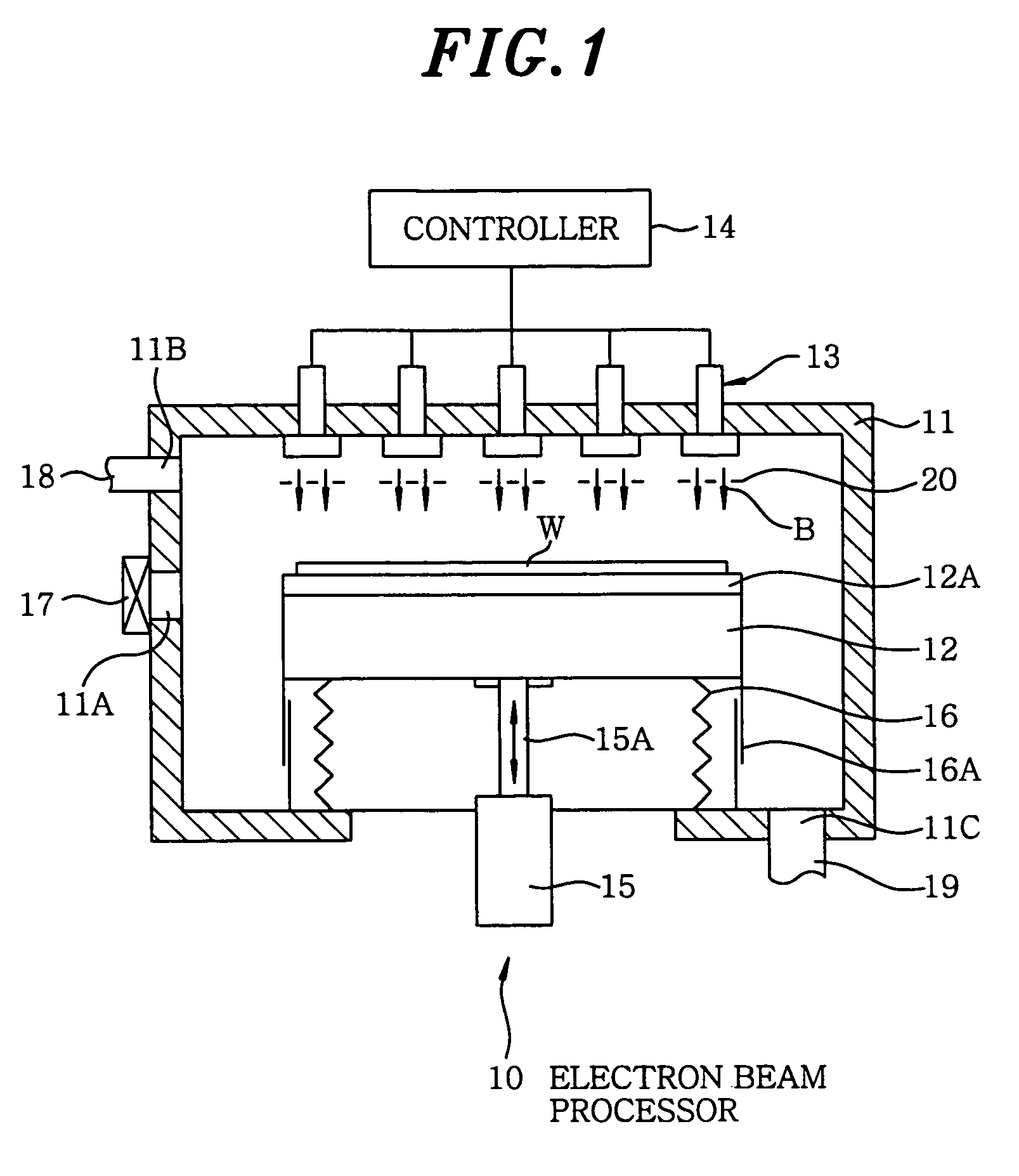

Method and apparatus for reforming laminated films and laminated films manufactured thereby

InactiveUS20050212179A1Improve throughputImprove interlayer strengthElectric discharge tubesSemiconductor/solid-state device manufacturingBeam tubeEngineering

There is provided a method for reforming laminated films, which simultaneously reforms a plurality of laminated films by irradiating electron beams on the laminated films. The method for reforming laminated films includes the steps of forming a lower film by coating a first low dielectric material in liquid form on a surface of a substrate; forming an upper film by coating a second low dielectric material in liquid form on the lower film; and irradiating electron beams on the lower and upper film. A laminated film manufacturing system includes a mounting table for mounting thereon a substrate on which the laminated films are formed; and an electron beam unit having a plurality of electron beam tubes for irradiating electron beams on the laminated films to thereby simultaneously reform the films.

Owner:TOKYO ELECTRON LTD

High-thermal-conductivity laminated graphene composite material and preparation method thereof

The invention discloses a high-thermal-conductivity laminated graphene composite material, and a preparation method thereof. The high-thermal-conductivity laminated graphene composite material comprises reduced graphene oxide, oxidized cellulose nanocrystalline, and epoxy resin; possesses a laminated structure which is mainly alternatively composed of reduced graphene oxide layers and oxidized cellulose nanocrystalline / epoxy resin layers; the oxidized cellulose nanocrystalline / epoxy resin layer is a mixture of oxidized cellulose nanocrystalline and the epoxy resin; the mass ratio of reduced graphene oxide to oxidized cellulose nanocrystalline is controlled to be 2:1-1:9; the mass ratio of reduced graphene oxide to epoxy resin is controlled to be 6:1-1:15. According to the preparation method, modification on the internal composition and the structure of the high-thermal-conductivity laminated graphene composite material, the whole process technology design and the steps of the preparation method is carried out, solvent volatilization self assembling is adopted to prepare the high-thermal-conductivity laminated graphene composite material, so that problems in the prior art such as small graphene composite size and poor thermal conductivity are solved, and the thermal conductivity of the high-thermal-conductivity laminated graphene composite material is capable of reaching 9 to 30W*m<-1>*K<-1>.

Owner:HUAZHONG UNIV OF SCI & TECH

Production method for high-bulk packing board

The invention discloses a production method for high-bulk packing board, which is characterized in that during preparing the pulp required by linings and cores, mechanical pulp is added into the waste paper pulp for preparing the linings and the cores during pulp mixing, and the binder formed by mixing starch and reinforcing agent is added to the mesh part of a paper machine during compounding the paper pulp layers, so as to compound the paperboard. The invention has the advantages that compared with the white cardboard processed through traditional method, the high-bulk packing board, (mainly the white cardboard) processed through the method has high bulk, (namely less quantitative property under the same thickness or high thickness under the same quantitative property), high interlayer strength, high printing applicability and excellent deflection, reduces the fiber consumption, reduces the consumption of the wood, and facilitates the protection of the environment and resources.

Owner:江苏博汇纸业有限公司

Decorating material

ActiveCN1860028AGood solvent resistanceExcellent abrasion resistanceLayered productsIonizationEngineering

A decorating material which comprises a substrate, a low glossy designated layer provided on at least a part thereof, and a surface-protecting layer which is present on and contacts with the designated layer and covers over the whole surface including the region having the designated layer and that having no designated layer, wherein said surface-protecting layer is formed by crosslinking and curing an ionization-curable resin composition, and wherein, in said surface-protecting layer, a low lustrous region being visually recognized as a concave portion is formed in the portion directly on said low glossy designated layer and in the vicinity of the portion. The decorating material has a design being formed on the surface thereof and exhibiting a difference in gloss according to the design, which difference is visually recognized as a concave portion, to provide a concave-convex feeling to the surface.

Owner:DAI NIPPON PRINTING CO LTD

SiC/SiC composites incorporating uncoated fibers to improve interlaminar strength

ActiveUS20060141257A1Low costImprove performanceBlade accessoriesEfficient propulsion technologiesFiber bundleUltimate tensile strength

The present invention is a ceramic matrix composite turbine engine component, wherein the component has a region of expected higher interlaminate stress during normal engine operation. The component includes both coated fiber tows and uncoated fiber tows arranged together into a preselected form, wherein the uncoated fiber tows are located at predetermined regions of expected high interlaminate stress. The invention further includes method of manufacturing a CMC such as a composite turbine engine component, wherein the component has a region of expected higher interlaminate stress during engine operation.

Owner:GENERAL ELECTRIC CO

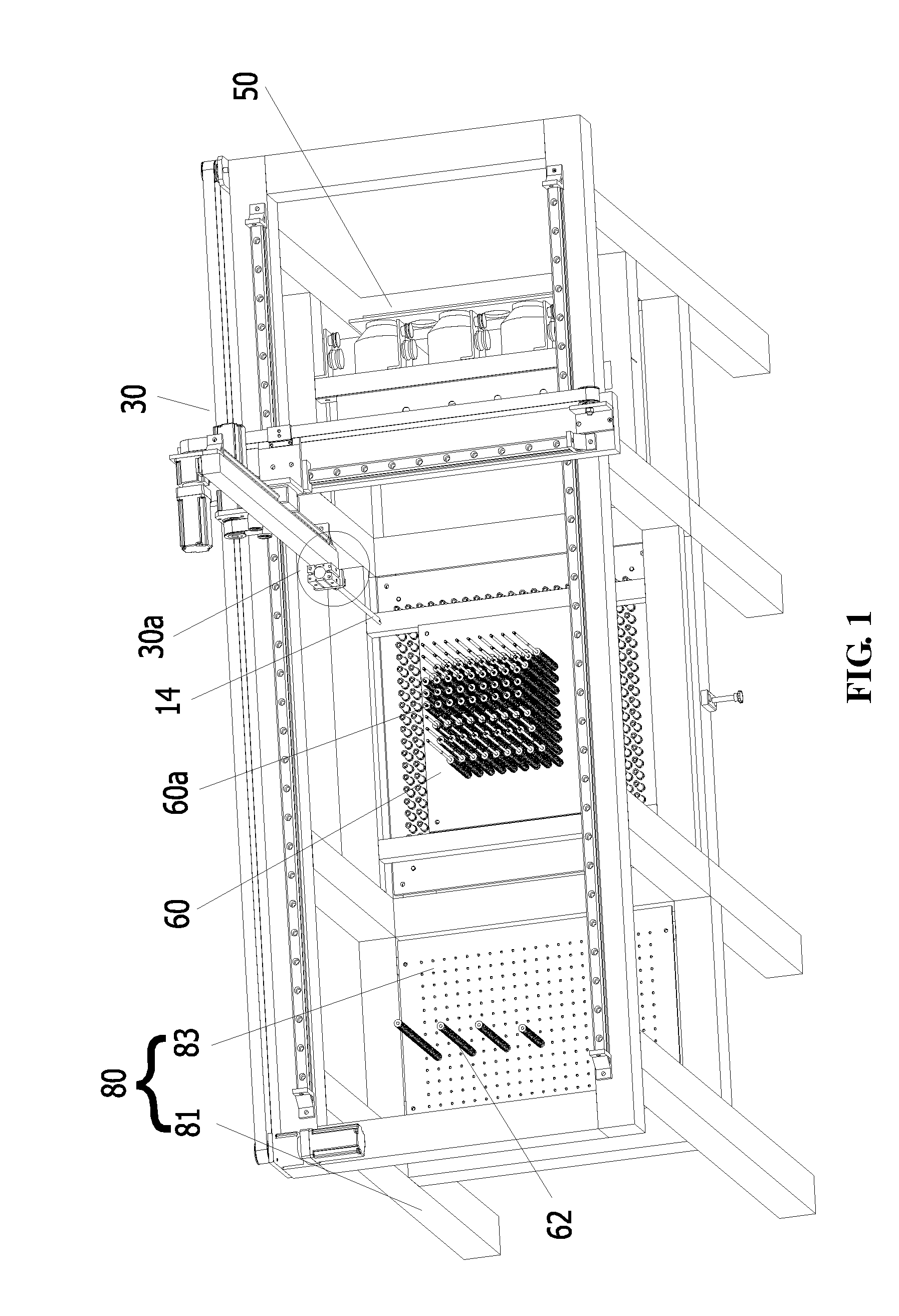

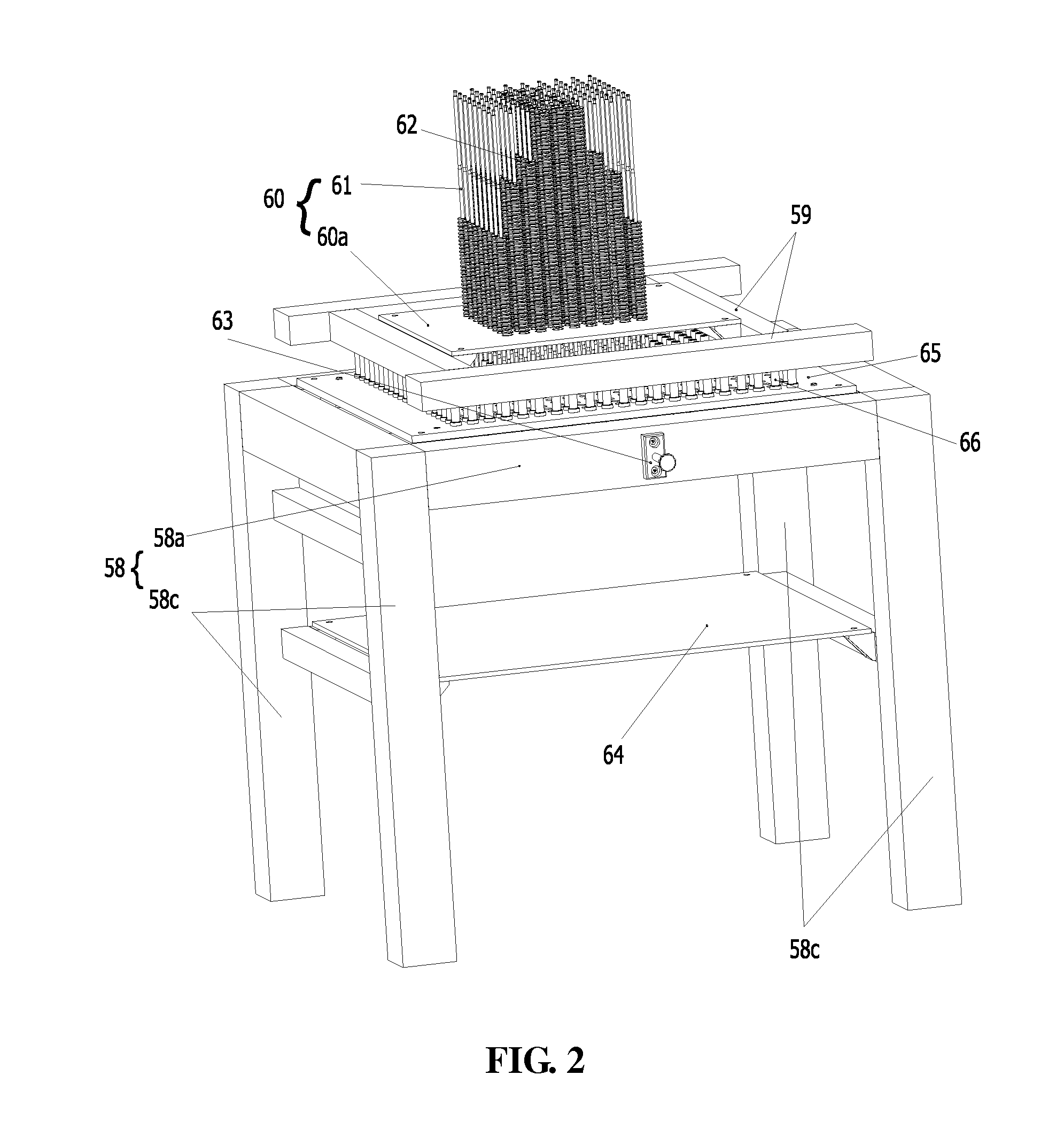

Multi-dimensional Weaving Shaping Machine of Composite Materials

ActiveUS20140360618A1Improve interlayer strengthFast technologyLoomsGeotextilesThree dimensional motionElectrical control

The disclosure provides a multi-dimensional weaving shaping machine of composite materials, including: a guide template including a plurality of cylindrical guiders arranged according to the geometrical shape of a prefabricated member; an electrical control three-dimensional motion mechanism including: a control signal receiving terminal configured to receive motion control signals corresponding to the geometrical shape of the prefabricated member; and a three-dimensional motion output terminal configured to form a motion track according to the motion control signals; a weaving needle being connected with the three-dimensional motion output terminal and making weave fibers distribute among the cylindrical guiders according to the geometrical shape of the prefabricated member. The multi-dimensional weaving shaping machine of composite materials of the disclosure utilizes the cylindrical guiders and the electrical control three-dimensional motion mechanism to make the weaving needle to drive braided cords to distribute among the cylindrical guiders along the motion track to form the guide template. The disclosure is applicable to multi-dimensional weaving shaping of large-scale and complicated materials and capable of improving the interlaminar strength of composite materials. The shaping machine applies a rapid shaping technology to multi-dimensional weaving shaping of composite materials and the technical processes are automatic.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH

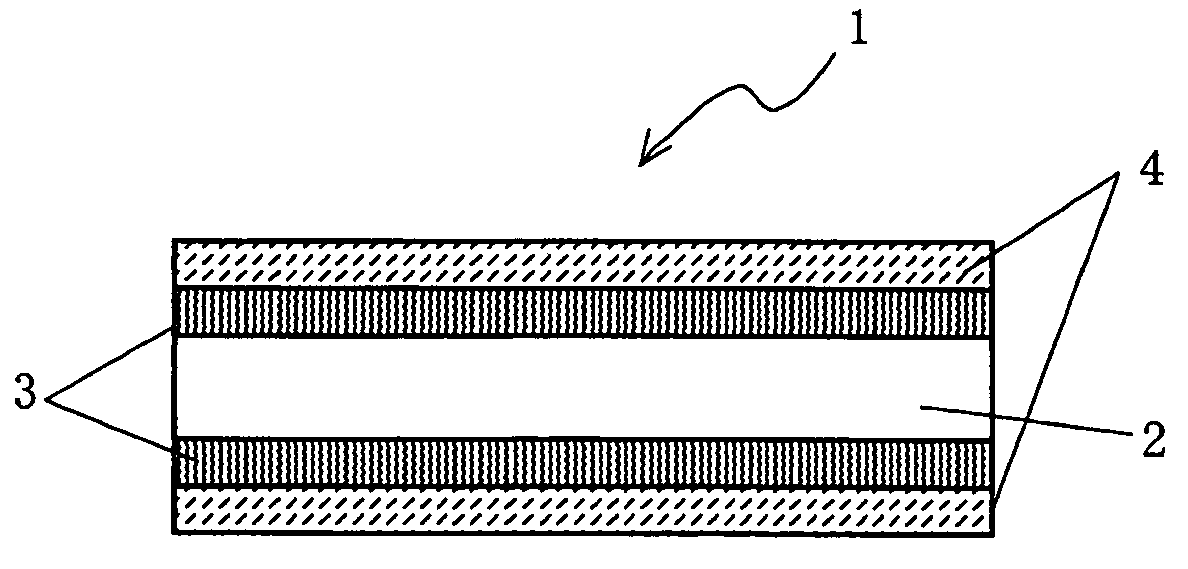

Shrink Film

InactiveUS20090061245A1Improve shrinkageAdequate shrinking speedSynthetic resin layered productsThin material handlingPolymer scienceGlycidyl methacrylate

Disclosed is a shrink film which includes a core layer; two plies of intermediate layer respectively arranged on both sides of the core layer; and two plies of surface layer respectively arranged on both outer sides of the intermediate layers, and which has a five-layered multilayer structure composed of three types of layers [(surface layer) / (intermediate layer) / (core layer) / (intermediate layer) / (surface layer)]. The core layer is a resinous layer mainly containing a polyolefin resin, the surface layer is a resinous layer mainly containing a polyester resin, and the intermediate layer is a resinous layer mainly containing a polyethylene resin containing a glycidyl methacrylate (GMA) component. The shrink film has a low specific gravity, shows excellent shrink properties, has a high interlayer strength between film layers, and is tough, excellent shrink film. It is particularly useful as a shrink label for PET bottles.

Owner:FUJI SEAL INTERNATIONAL INC

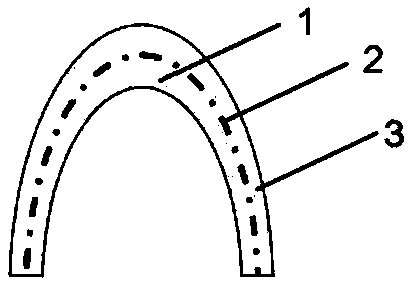

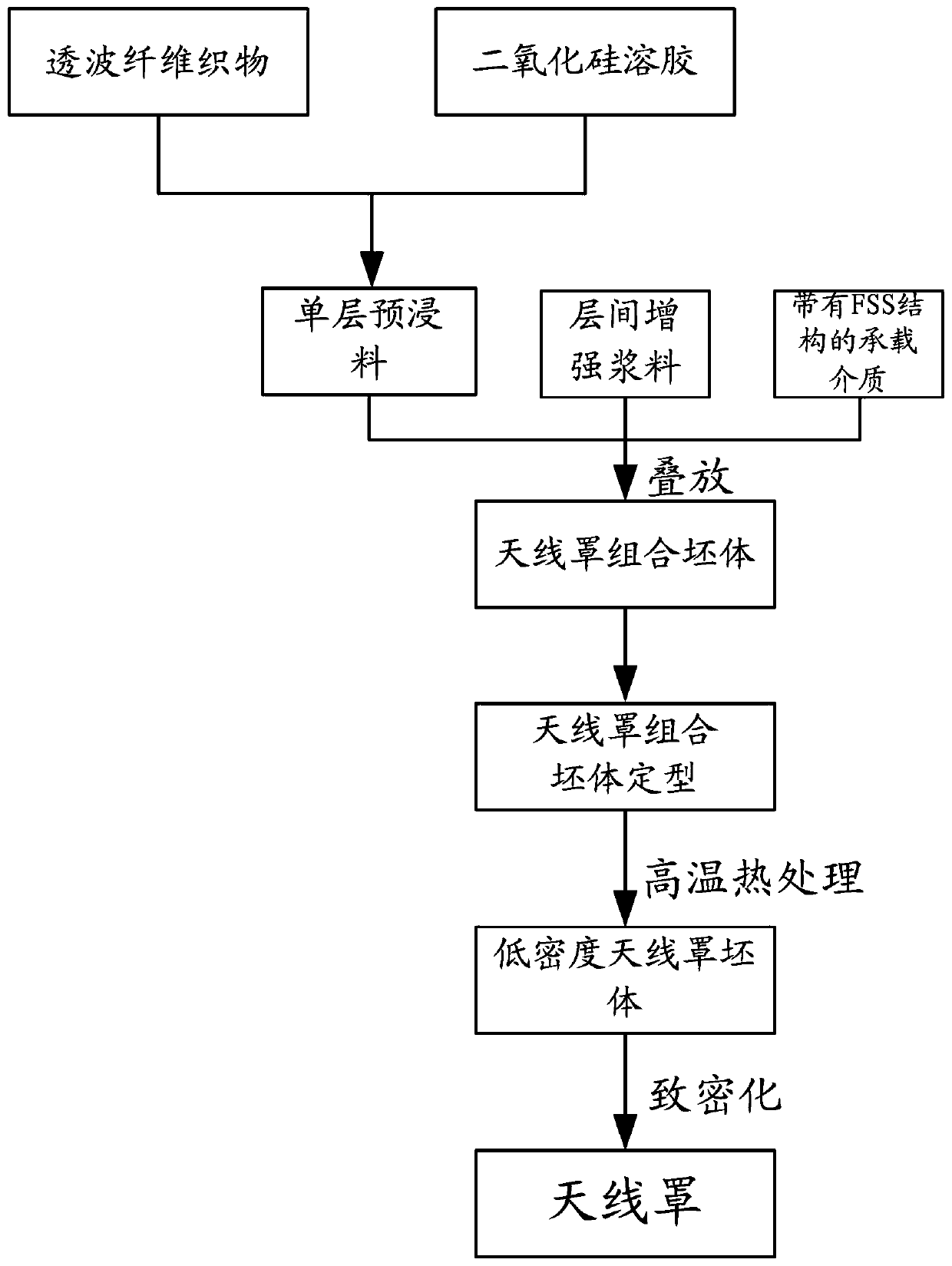

High-temperature-resistant frequency selective surface antenna cover and preparation method thereof

ActiveCN109786961AStable structureImprove adaptabilityRadiating element housingsEngineeringSilicon dioxide

The invention provides a high-temperature-resistant frequency selective surface antenna cover and a preparation method thereof, a layered structure is adopted, the antenna cover is composed of a bearing layer, at least one layer of FSS (frequency selective surface) structural layer and an anti-ablation / washing layer, the bearing layer and the anti-ablation / washing layer are a plurality of layers of 2D and / or 2.5D fabric reinforced silicon dioxide-based ceramic materials, and the FSS structural layer, the bearing layer and the anti-ablation / washing layer are integrally formed by adopting a gluedipping-gel technology. According to the antenna cover and the preparation method in the invention, a single-layer or multi-layer FSS structure is prepared inside the fiber-reinforced silicon dioxide-based ceramic material, the FSS structure is stable, the FSS structure is good in environmental adaptability under the protection of the fiber-reinforced silicon dioxide-based ceramic material, the application field is wider, and engineering application of the technology is facilitated.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

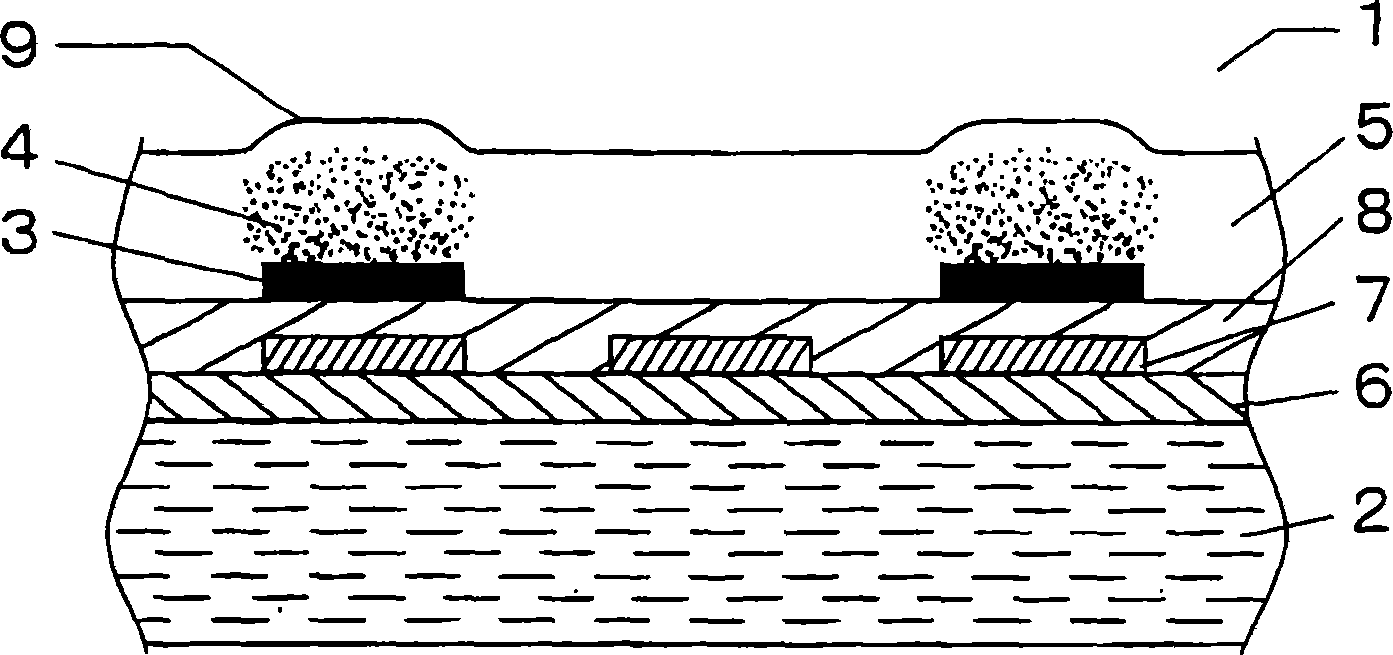

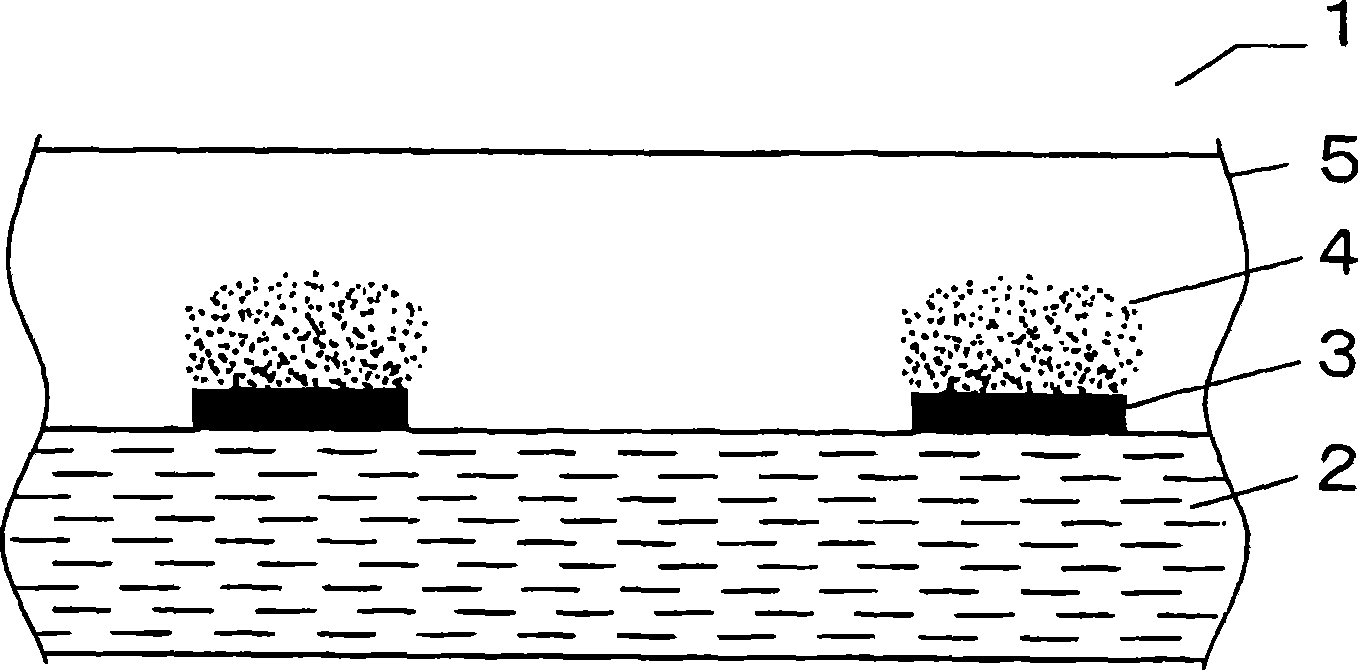

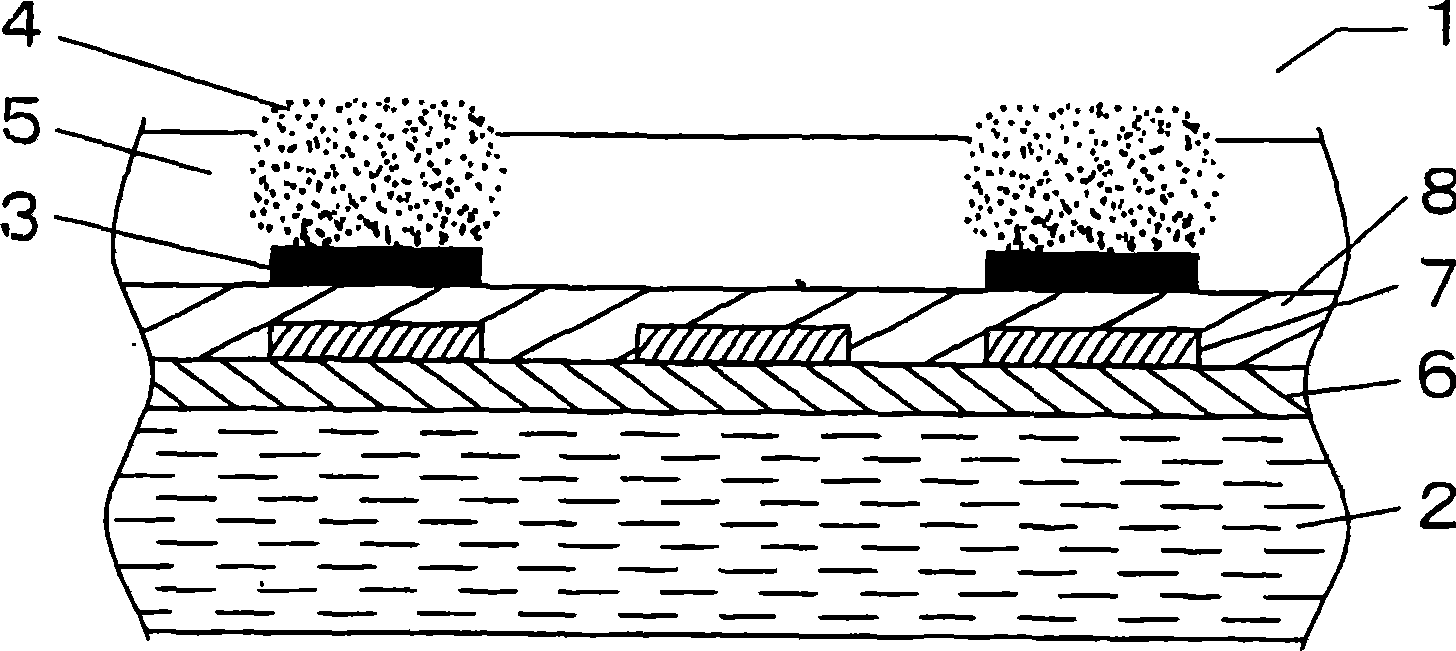

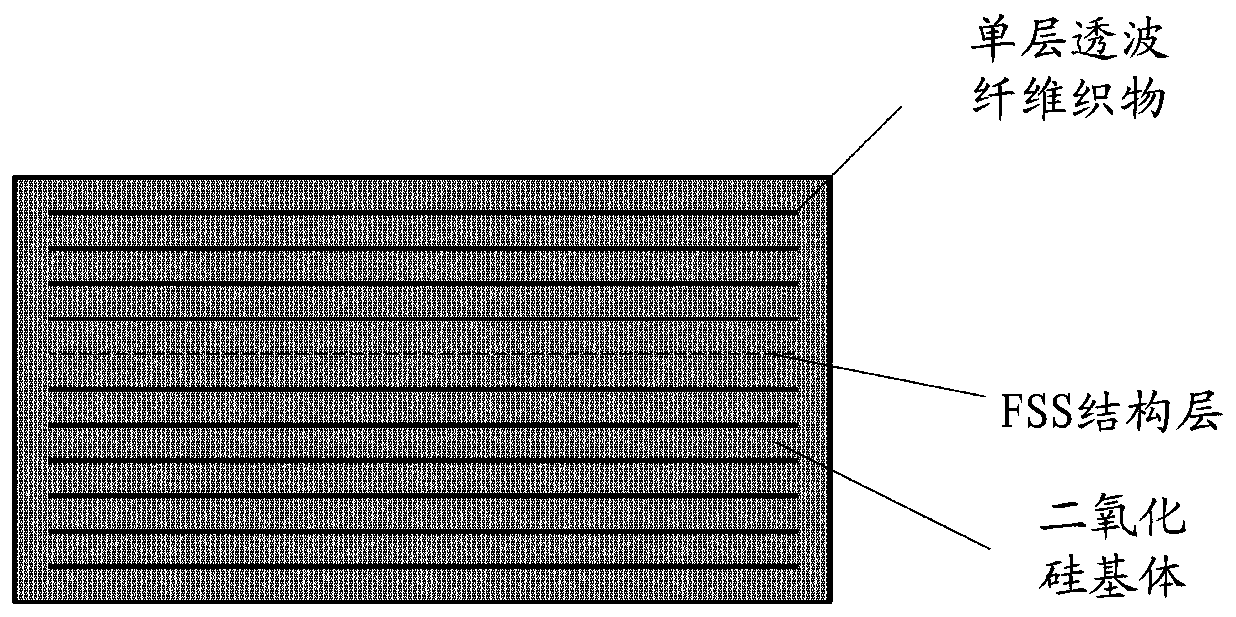

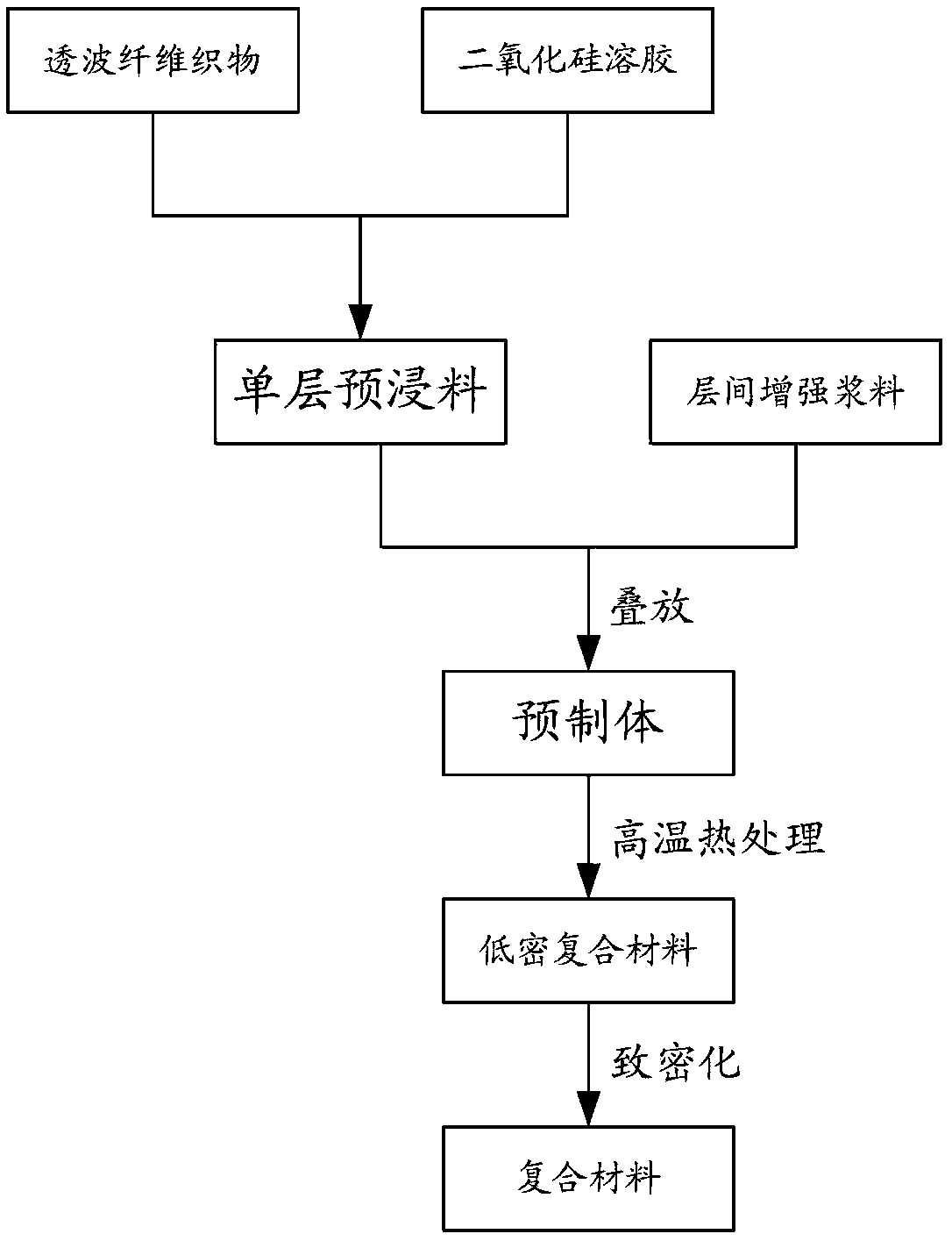

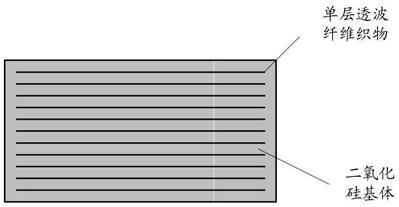

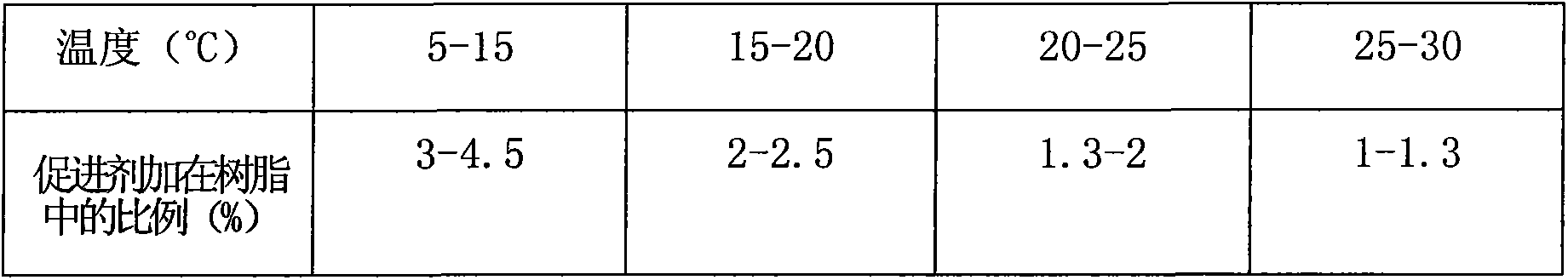

Fiber-strengthened ceramic-based wave-transmitting material and preparation method thereof

ActiveCN109456074AImprove interlayer strengthPrepreg hand lay-up process is practicalSilicon oxideCeramic

The invention provides a fiber-strengthened ceramic-based wave-transmitting material and a preparation method thereof. A plurality of fiber layers strengthen a silicon dioxide matrix and are distributed in the silicon dioxide matrix in parallel. Through adhesion of interlayer strengthened slurry, the interlayer strength of a 2D fiber strengthened silicon dioxide-based composite is greatly improved, so that the prepreg hand laying technology of a fiber-strengthened ceramic-based wave-transmitting composite is more practical, and the application range of the material is expanded.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

Three part high moisture barrier for packages

InactiveUS6902645B2Low production costImprove sealingLamination ancillary operationsLayered product treatmentPolyvinyl chloridePolymer thin films

A three part laminated material for use in making blister packages and a method of making such a material. The material is comprised of a central core layer of poly chloro-tri-fluoro ethylene to each side of which a separate polymer film is adhesively attached. The method of making the material involves use of a corona treater, a vertical forced air convection dryer, a horizontal convection dryer, a motor driven rewind, a chilled cylinder, a primary unwind and at least one laminating unwind. In the preferred embodiment, each of the polymer films is polyvinyl chloride, although a variety of different films may be used. The disclosed material provides a high moisture barrier, a stable inter-laminar structure and outer surfaces which lend themselves well to bonding with other materials.

Owner:KLOCKNER PENTAPLAST OF AMERICA INC

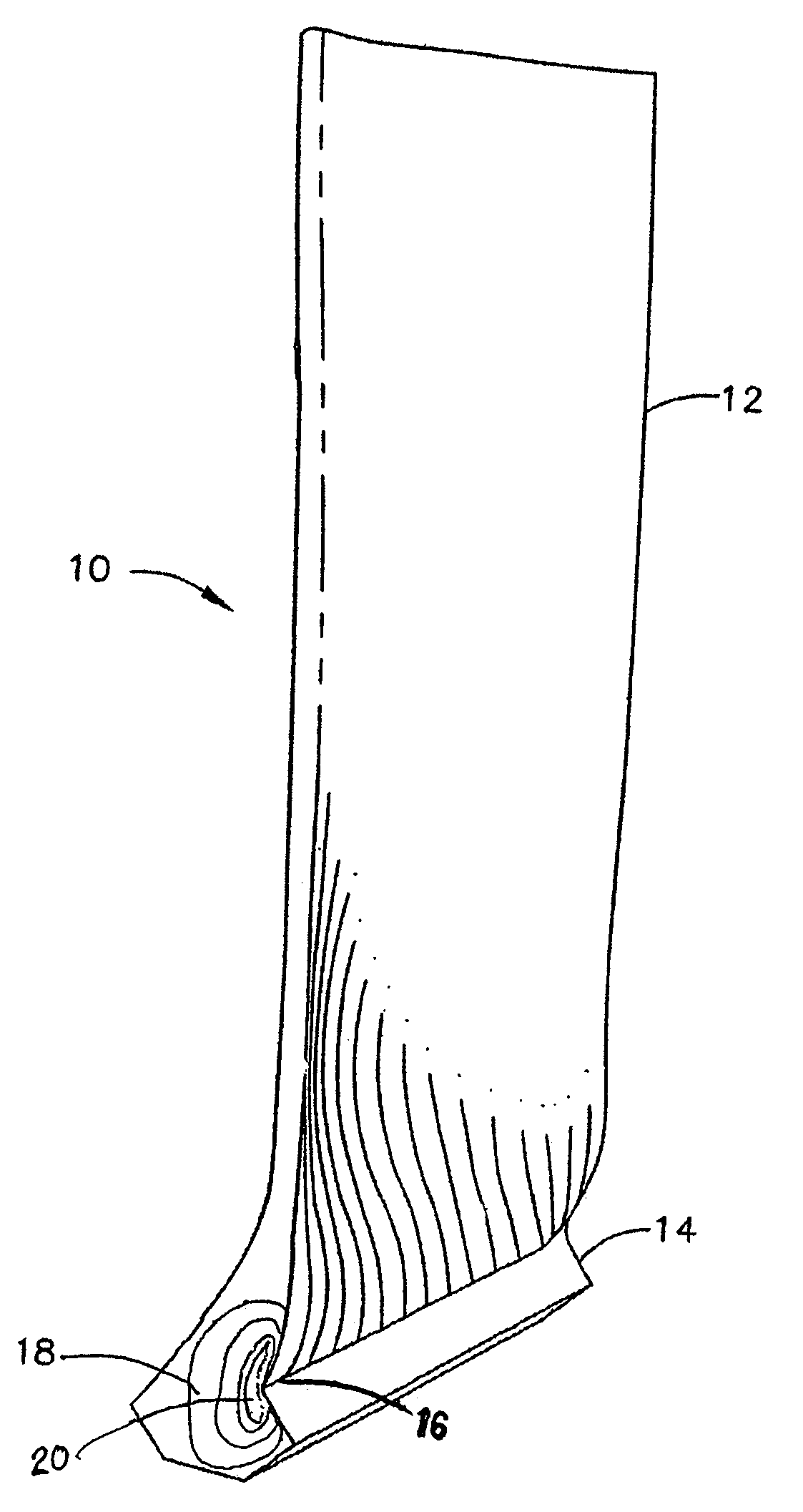

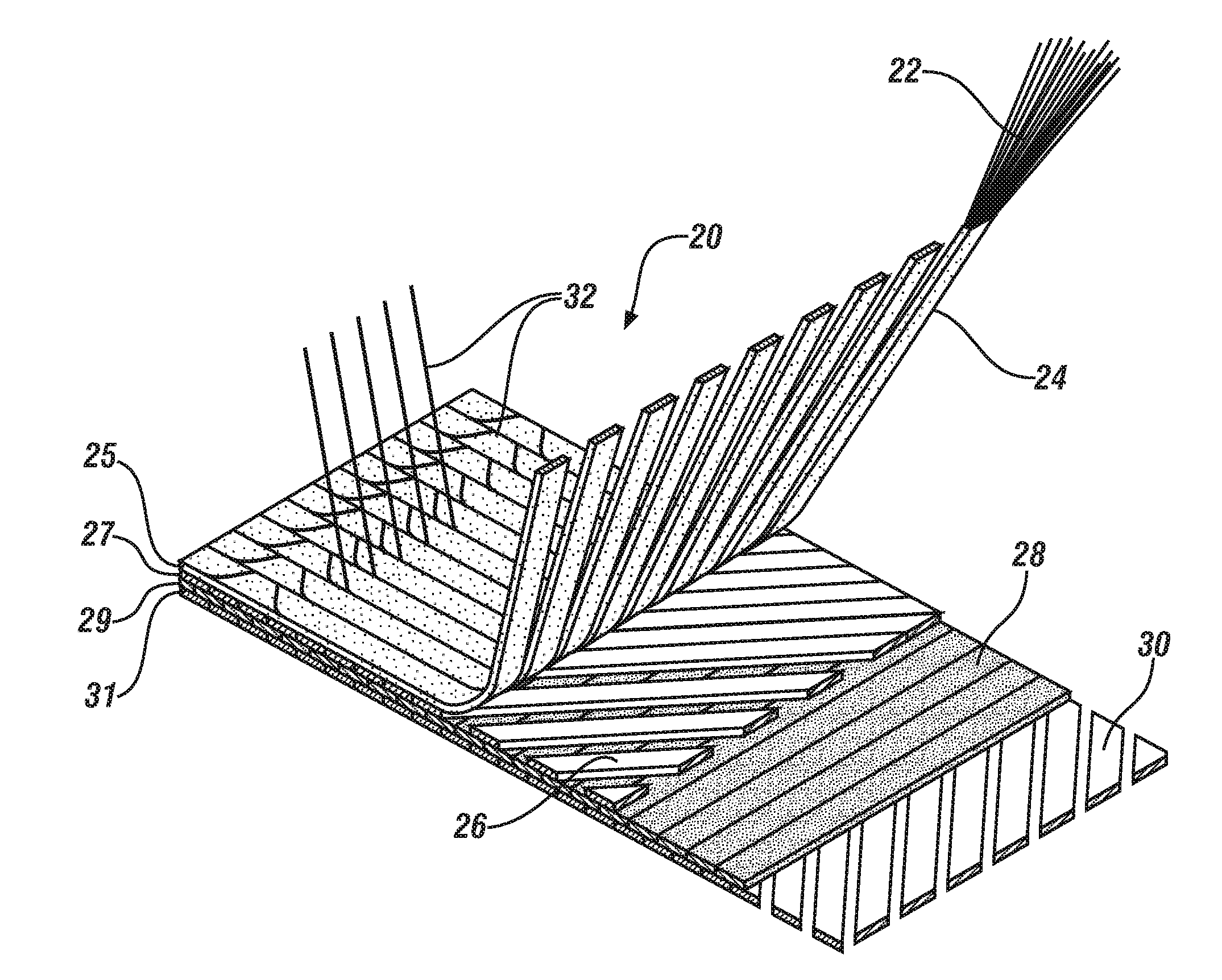

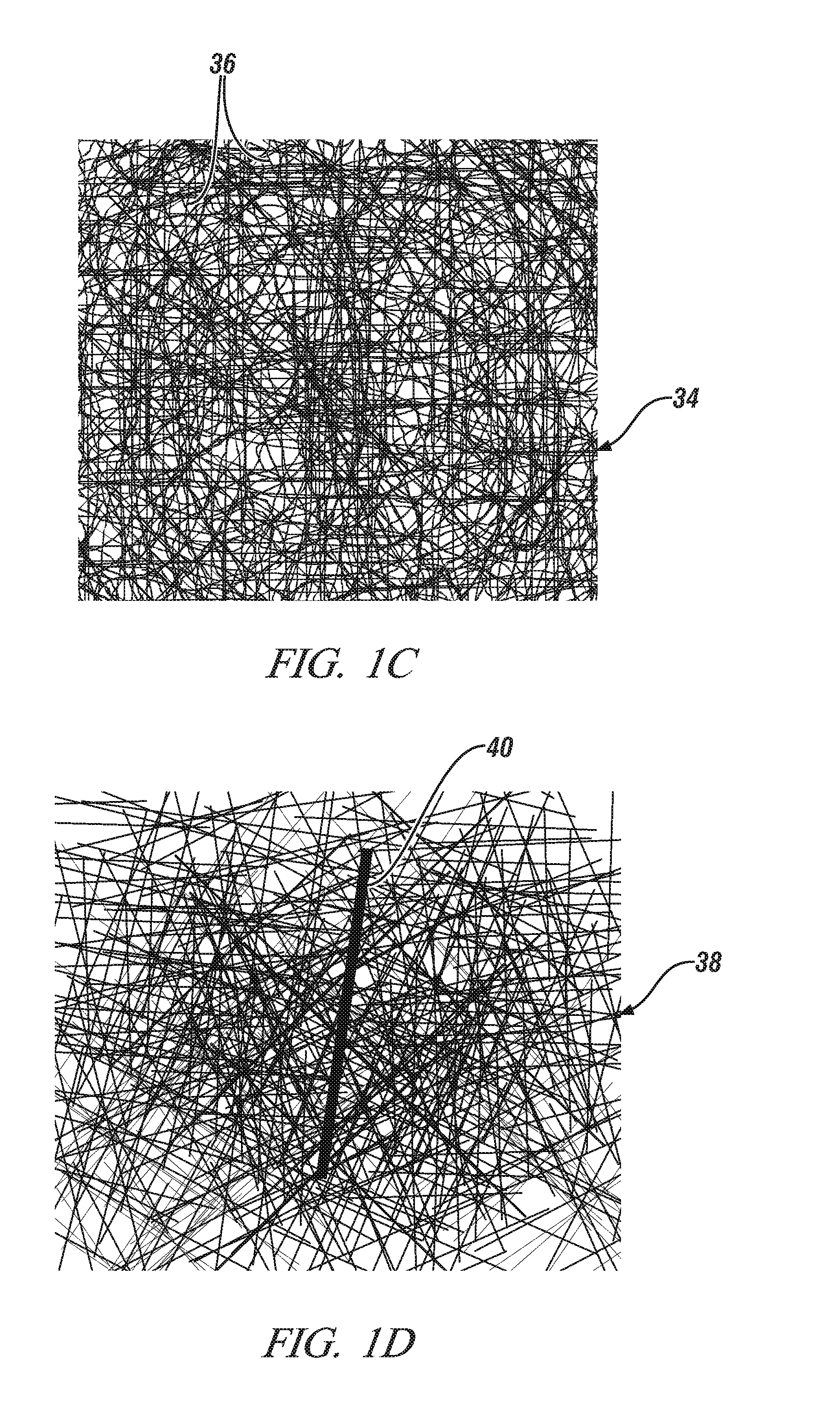

One-piece fiber reinforcement for a reinforced polymer combining aligned and random fiber layers

ActiveUS20130108824A1Enhance interlayer strengthSimplifies manufactureLayered productsWoven fabricsFiber layerPolymer

A one-piece fiber reinforcement for a reinforced polymer is described. In an embodiment, a one-piece reinforcement is fabricated by first assembling an interior randomly oriented fiber layer between two exterior aligned fiber layers. With all layers in face to face contact, a preselected number of fibers from the aligned layer is conveyed out of its aligned layer and threaded into at least the random fiber layer so that the conveyed fibers engage and mechanically and frictionally interfere with the random fibers. The fibers may be conveyed from one aligned layer to the other for yet greater interference. The interfering fibers serve to secure and interlock the layers together, producing a one-piece reinforcement which, when impregnated with a polymer precursor, shaped and cured may be incorporated in a polymer reinforced composite article.

Owner:GM GLOBAL TECH OPERATIONS LLC

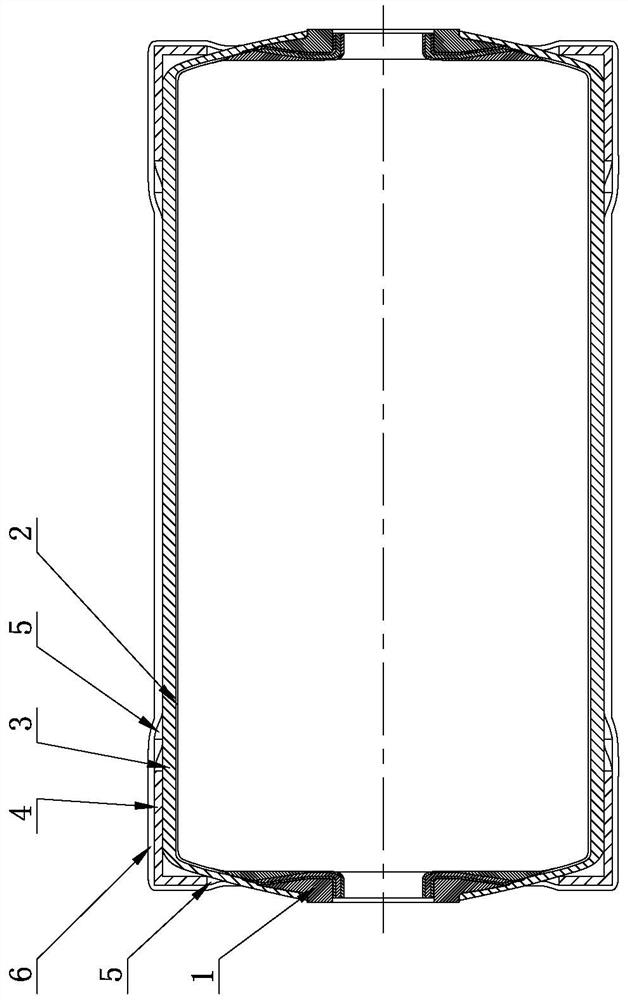

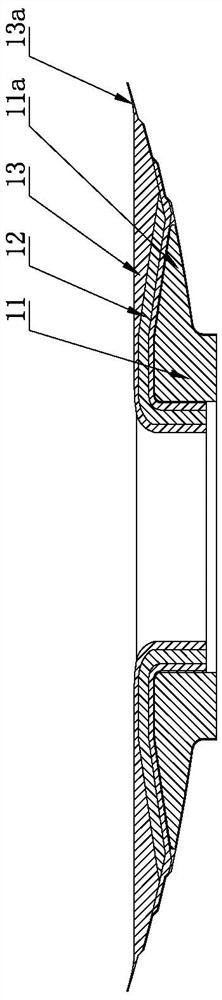

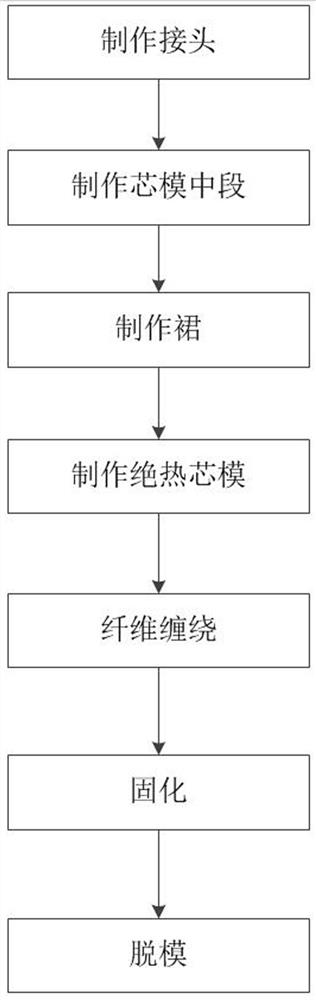

Manufacturing method of all-composite case of rocket engine

InactiveCN112297462AGood insulation performanceGuaranteed reliabilityDomestic articlesYarnCarbon fibers

The invention discloses a manufacturing method of an all-composite case of a rocket engine. The manufacturing method comprises the following steps: 1) manufacturing joints; 2) manufacturing a core mold middle section; 3) manufacturing a skirt; 4) manufacturing a heat insulation core mold: manufacturing a rubber layer on the end face, close to the core mold, of each joint manufactured in the step 1), then installing the joints and seal head rubber layers at the two ends of the core mold, and finally, laying a heat insulation layer on the surface of the core mold middle section, manufactured inthe step 2), by employing a laying process, and performing vacuumizing and pre-compacting after heat insulation layer laying to obtain the heat insulation core mold; (5) performing fiber winding: winding carbon fiber yarns impregnated with resin around the heat insulation core mold by cooperating spiral inclined winding with hoop winding, wherein a glue solution on the surface of a winding layer needs to be scraped off in the winding process; after fiber winding is finished, making the skirt manufactured in the step 3) sleeve the two ends of the core mold wound with the fibers, and performinghoop winding after fixation is completed; 6) curing; and 7) demolding. The manufacturing method has the characteristics of that the weight reduction effect is obvious, the reliability is high, the cost is low and the bursting pressure is high.

Owner:JIANGSU XINYANG NEW MATERIALS CO LTD

Pressing-on device for pressing on fiber-reinforced thermoplastic materials, fiber arranging device, and method for arranging a fiber-reinforced thermoplastic material

InactiveUS20120073749A1Maintain propertiesImprove insulation effectAdhesive processesPaperhangingHeat resistanceInorganic materials

A pressing-on device for pressing fiber-reinforced thermoplastic materials onto a mold is described. The pressing-on device has a main body and a pressing-on layer provided on a surface of the main body. The pressing-on layer is implemented in this case using an inorganic material, preferably a ceramic material, and has a flexibility because of its structure which allows it to adapt itself to the contour of a mold. Increased heat resistance of the pressing-on device and improved properties of the processed fiber-reinforced thermoplastic material can be achieved.

Owner:AIRBUS OPERATIONS GMBH

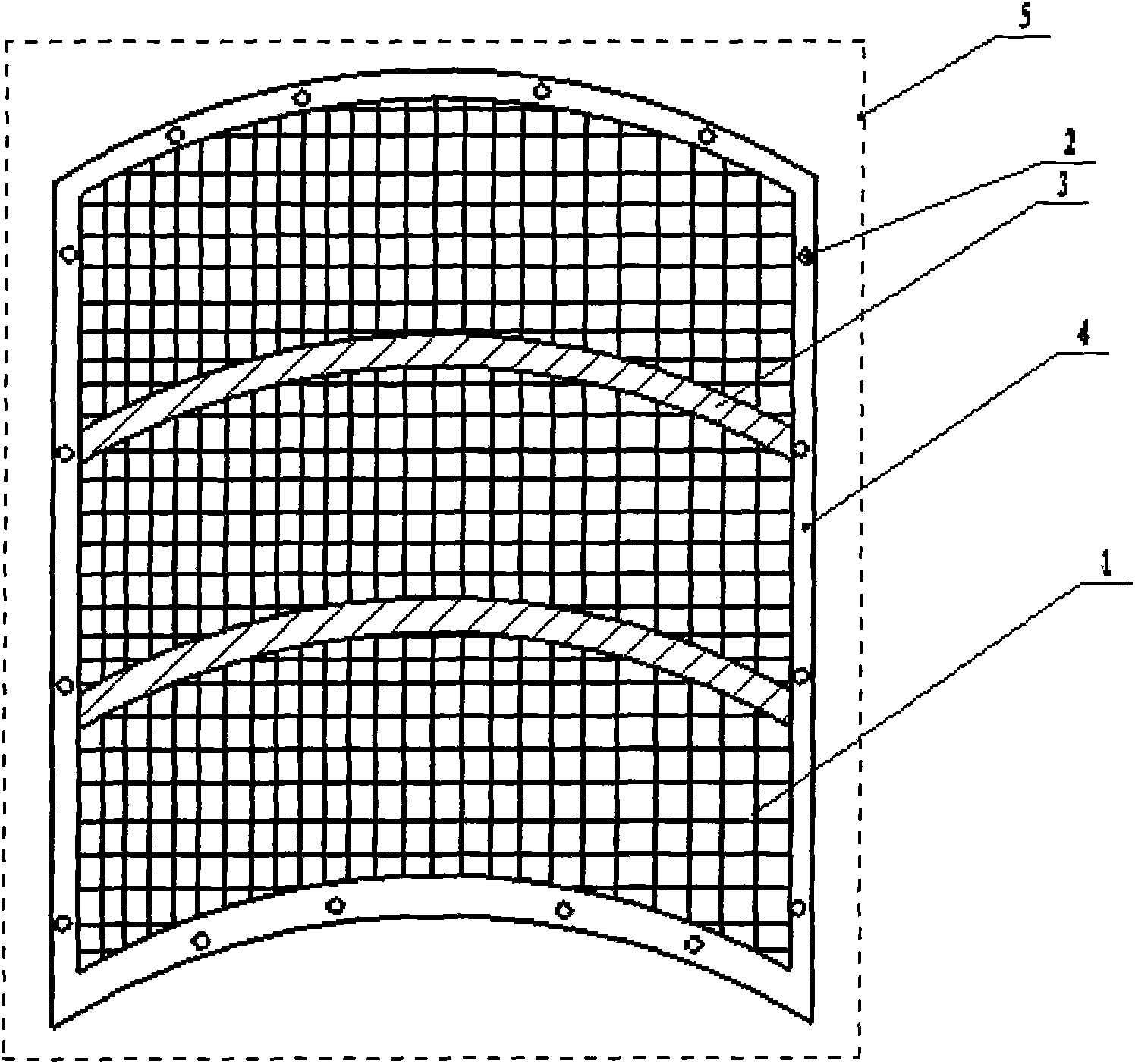

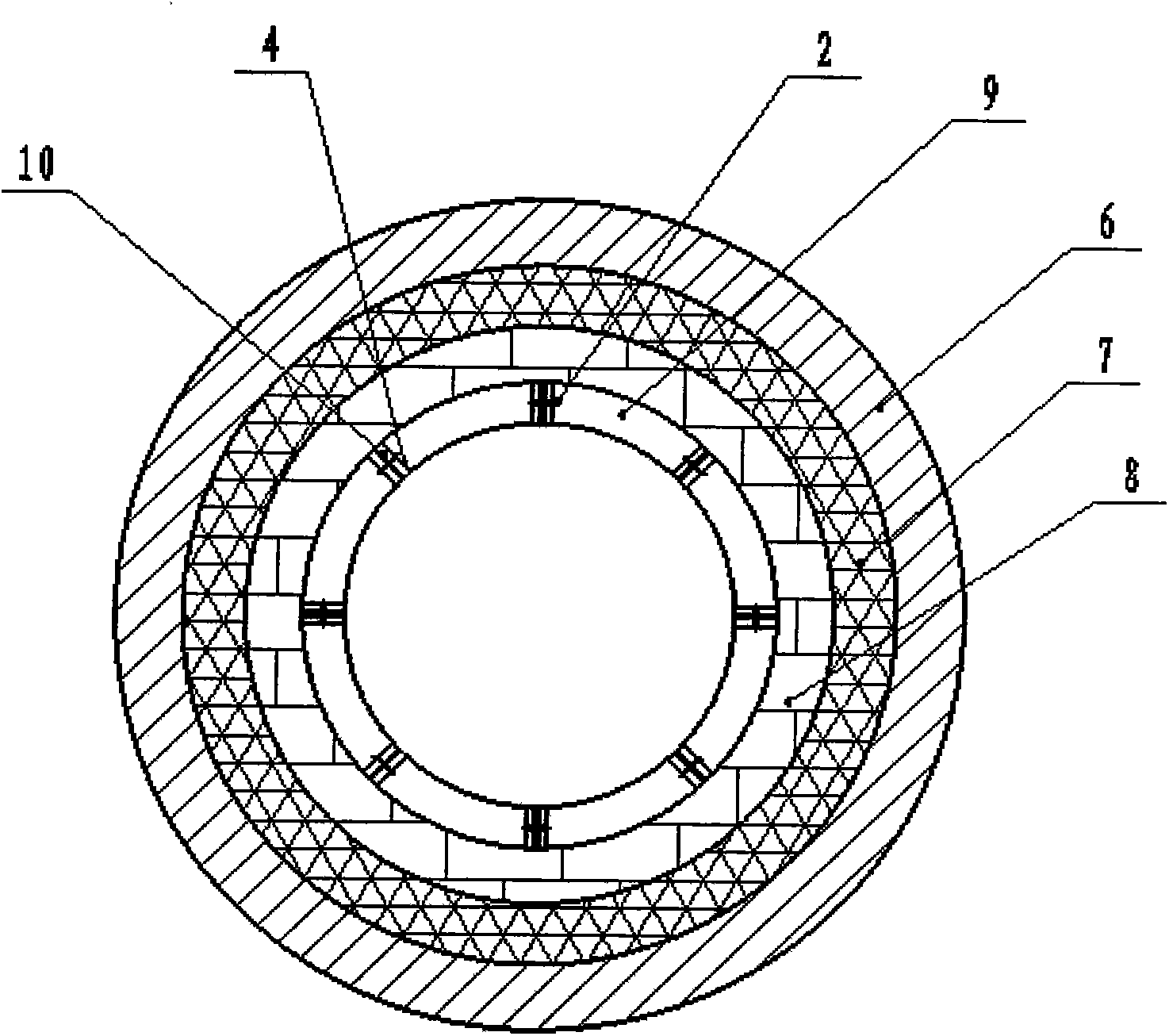

Construction method using glass fiber reinforced plastics as inner cavity protective materials for steel and concrete chimney

The invention discloses a construction method using glass fiber reinforced plastics as inner cavity protective materials for a steel and concrete chimney, and belongs to the field of flue gas emission. A novel structure is proposed to enable the chimney to be higher in strength and longer in service life. Firstly, a mold having an identical shape and a slightly smaller diameter with the steel and concrete chimney is made, the mold is formed by at least one single mold body, a gel coat with the thickness of 0.3mm to 0.4mm coats or is sprayed on the outer surface of the single mold body, then a glass fiber reinforced plastics composite reinforcement layer is made in a pasting mode, then the single mold body is assembled in the chimney, then resin slurry is injected between the glass fiber reinforced plastics composite reinforcement layer and the inner surface of the chimney, and finally the mold is demounted. The construction method using the glass fiber reinforced plastics as the inner cavity protective materials for the steel and concrete chimney is widely applied to the field of flue gas emission, and prevents sulfur dioxide, smog and other harmful gases which are not eliminated completely from bringing adverse effects on the steel and concrete chimney.

Owner:QINGSHAN ENVIRONMENTAL PROTECTION PROJECT

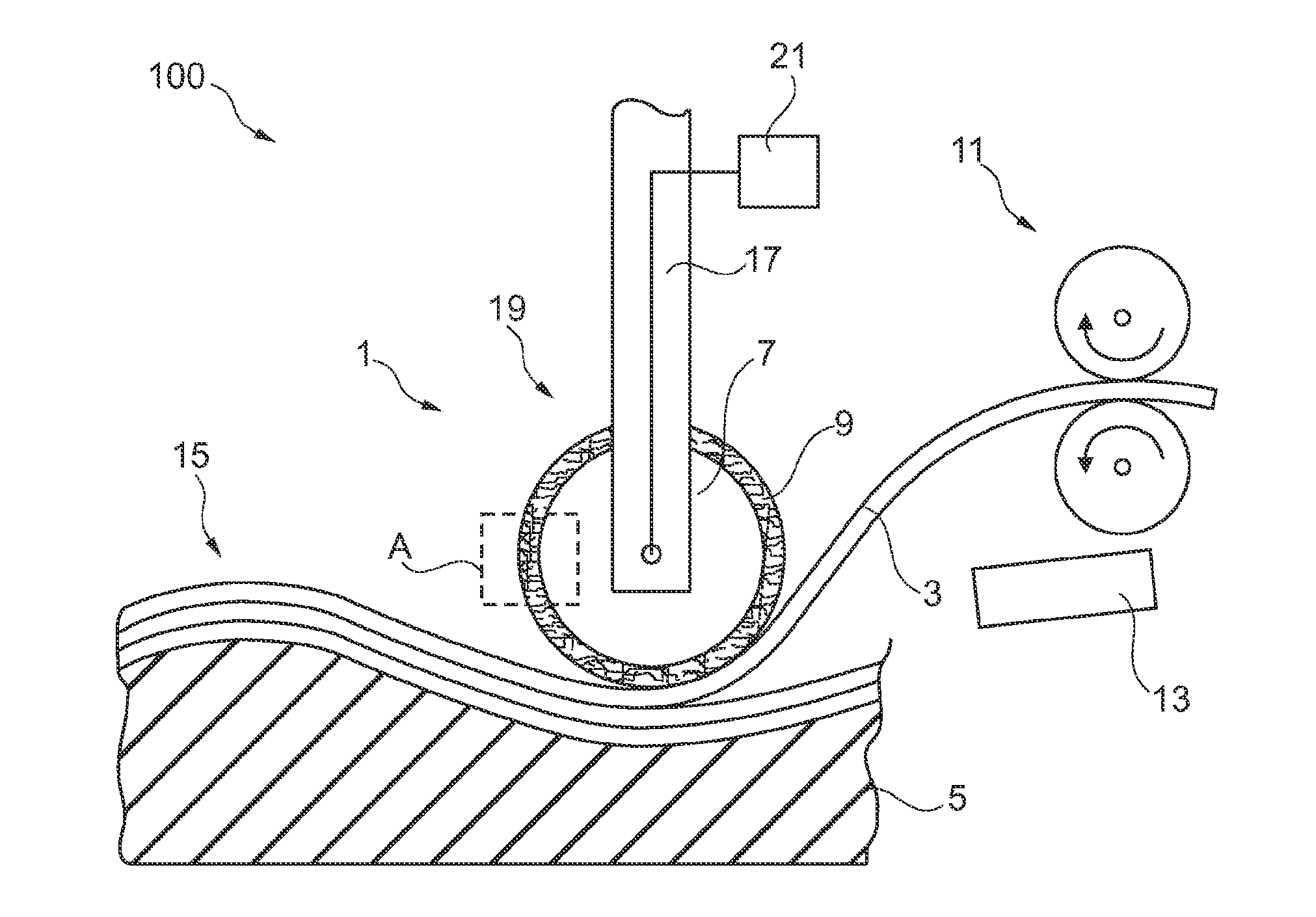

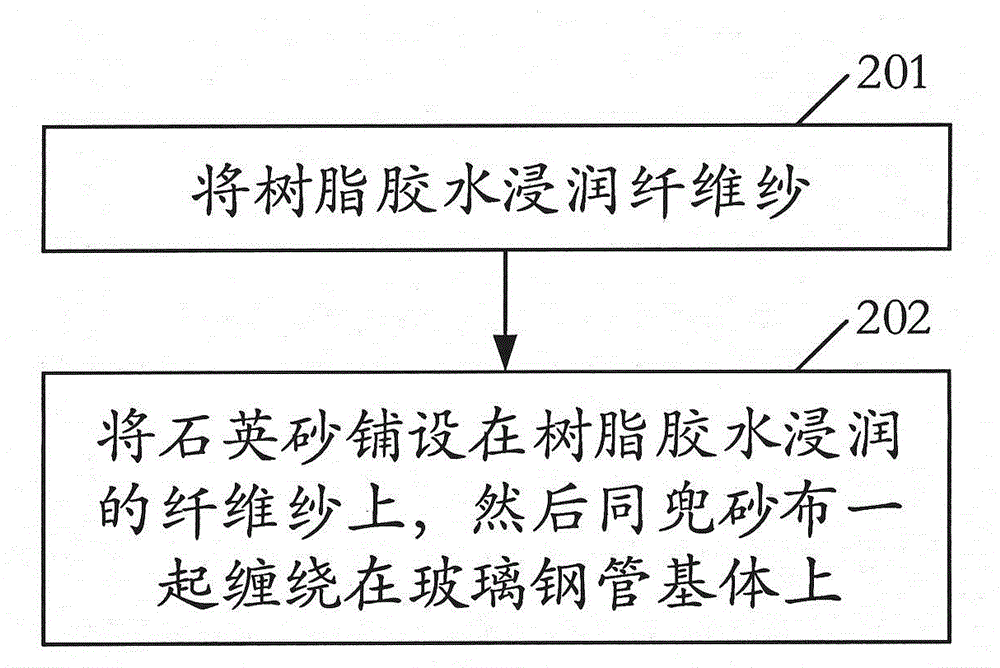

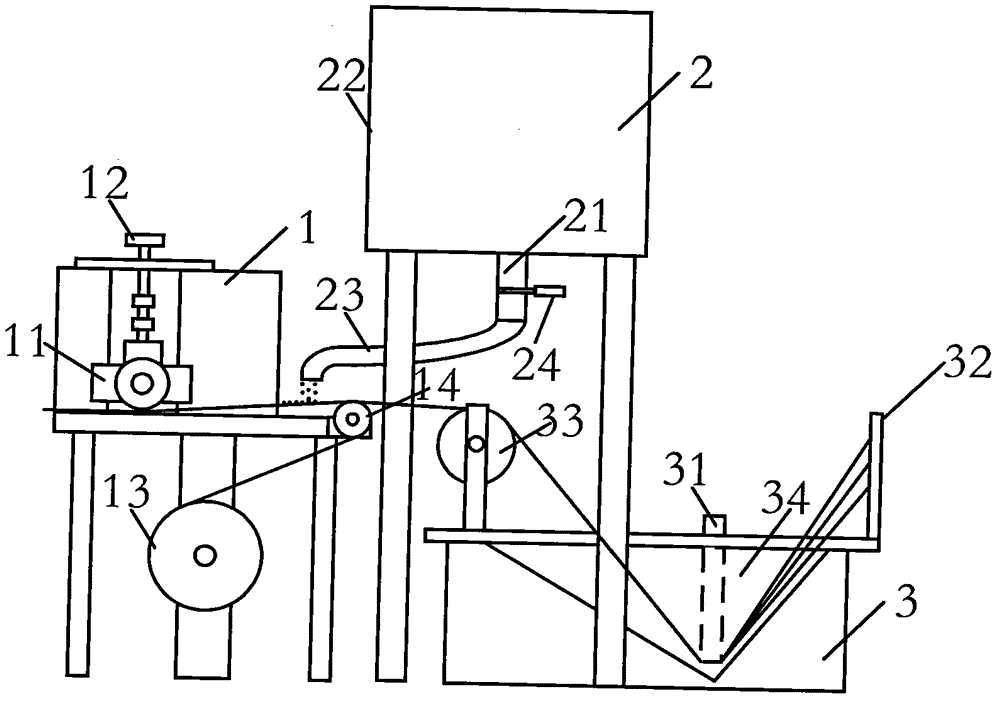

Fiber winding fiber reinforced plastic pipeline structure and sand inclusion layer manufacturing method and device

The invention relates to the technology field of fiber winding and discloses a fiber winding fiber reinforced plastic pipeline structure and a sand inclusion layer manufacturing method and device. The fiber winding fiber reinforced plastic pipeline structure comprises an inside liner, a structural layer and an outer protection layer. The structural layer comprises an outer winding layer, a sand inclusion layer and an inner winding layer. The inner winding layer and the outer winding layer are formed by dipping glass fibers through resin glue in a composite mode. The sand inclusion layer is formed by winding pocket abrasive cloth and fiber yarn on quartz sand dipped with the resin glue. By means of a fiber winding fiber reinforced plastic pipeline provided by the invention, the adsorption force of the sand inclusion layer and the interlayer binding force and the interlayer strength of the wall of the pipe are improved, and the flexibility, the tensile strength and the rigidity are improved.

Owner:GUIZHOU LONGCHEN IND CO LTD

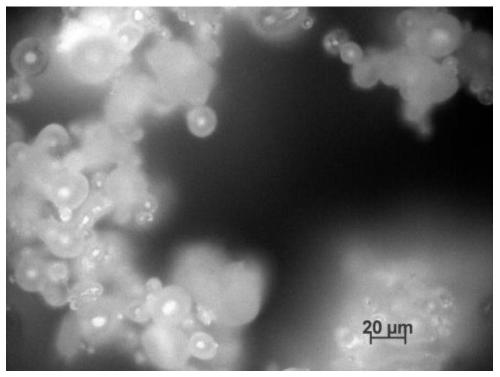

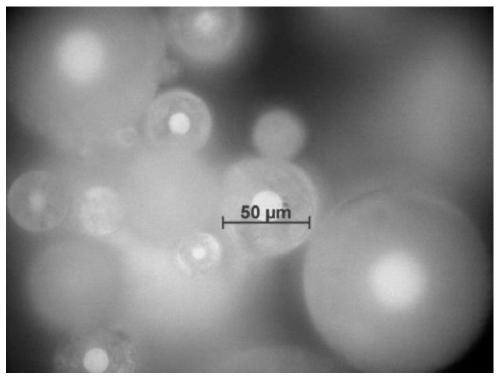

Amorphous polyaryletherketone/sulfone powder for laser sintering 3D printing and preparation method of amorphous polyaryletherketone/sulfone powder

The invention provides amorphous polyaryletherketone / sulfone powder for laser sintering and a preparation method of the amorphous polyaryletherketone / sulfone powder, and belongs to the technical fieldof additive manufacturing. The method comprises the following steps: dissolving amorphous PEKN / sulfone resin coarse powder in a solvent, blending with water, a stabilizer and an emulsifier in a reaction container, and stirring at a high speed at 40-50 DEG C to form an emulsion; heating to 90-95 DEG C in a gradient manner, and evaporating to remove the solvent; and cooling to room temperature, filtering, washing with water and drying to obtain the amorphous polyaryletherketone / sulfone powder for laser sintering. The amorphous polyaryletherketone / sulfone laser sintering powder material which ishigh in sphericity degree, uniform and controllable in particle size and good in fluidity is prepared through a solvent emulsification method.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

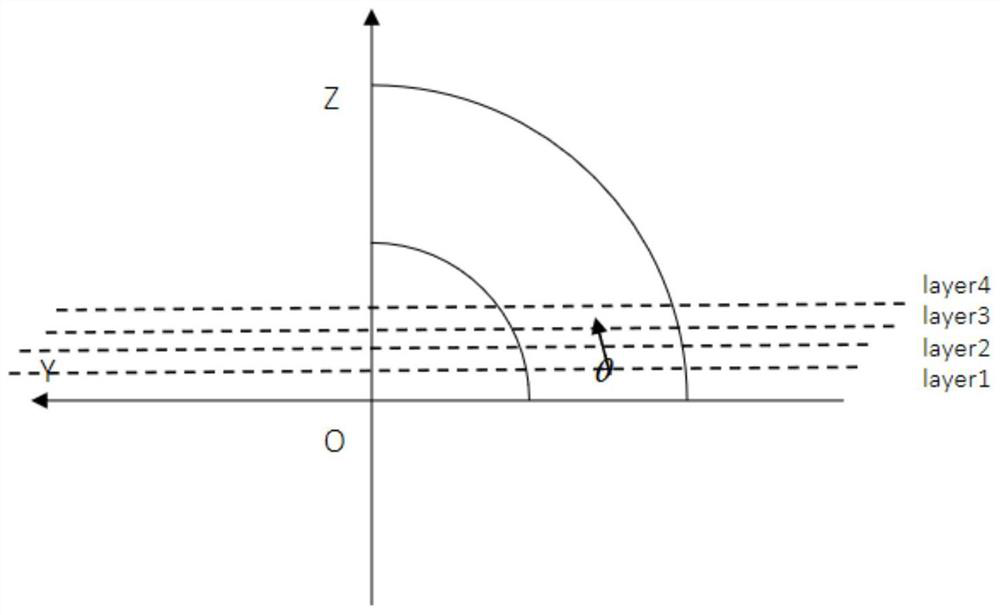

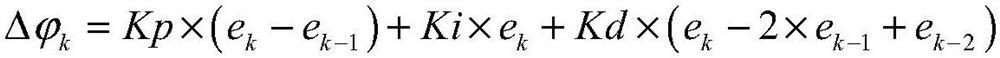

Thin-walled tubular model slicing method and system of five-axis 3D printer and printing method

ActiveCN112659544AImprove surface accuracyImprove interlayer strengthAdditive manufacturing apparatusIncreasing energy efficiencyComputer printingGravity center

The invention provides a thin-walled tubular model slicing method and system of a five-axis 3D printer and a printing method. The thin-walled tubular model slicing method comprises the steps that a coordinate system is established, and a three-dimensional model of a to-be-printed workpiece is read; the gravity center of each height cross section of the three-dimensional model is extracted, and all gravity centers are sequentially connecting to obtain a gravity center curve; rotation transformation is performed on a working turntable to enable the projection of a curvature vector of the gravity center curve of the current height layer of the three-dimensional model on the horizontal plane to be zero, the rotating posture information of the working turntable corresponding to the current height layer of the three-dimensional model is obtained, and the slicing information of the current height layer of the three-dimensional model is obtained through calculation; and the current height layer of the three-dimensional model is updated, and the steps are repeated until hierarchical slicing is completed, and the hierarchical slicing information of the to-be-printed workpiece is obtained; According to the thin-walled tubular model slicing method, the projection of the curvature vector of the gravity center curve of the current height layer of the three-dimensional model on the horizontal plane is enabled to be zero through rotation transformation of the table top of the turntable, the posture of the three-dimensional model is adjusted to be vertically upward, support-free printing is realized, the printing effect is good, and the surface precision of a formed part is high.

Owner:XI AN JIAOTONG UNIV

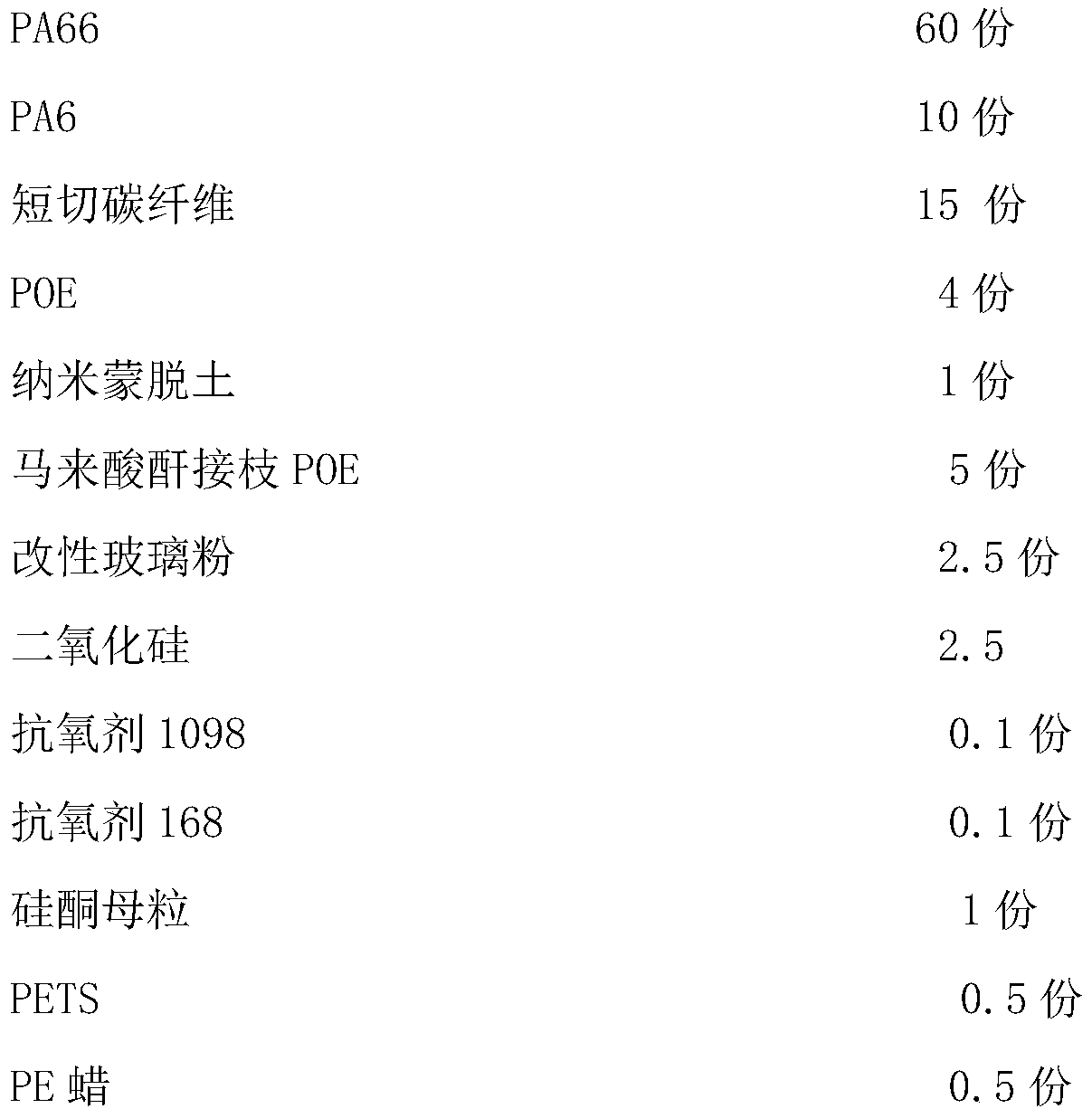

Carbon fiber reinforced polyamide composite material pre-infiltrated basalt fiber cloth and preparation method thereof

The invention discloses carbon fiber reinforced polyamide composite material pre-infiltrated basalt fiber cloth and a preparation method thereof. The preparation method includes the steps that basaltfiber cloth base cloth is subjected to carbon fiber reinforced polyamide composite material pre-infiltration and then subjected to rolling traction, and the basalt fiber cloth is obtained; the carbonfiber reinforced polyamide composite material is prepared from the following raw materials: PA66, PA6, chopped carbon fibers, a toughening agent, a compatilizer, a filling modifier, an antioxidant, alubricating agent and a dispersing agent. The carbon fiber reinforced polyamide composite material is used for replacing traditional thermosetting resin pre-infiltrated basalt fiber cloth, the production cost is reduced, the forming period is shortened, and the carbon fiber reinforced polyamide composite material can be recycled; the chopped carbon fibers play a riveting role between the fiber cloth and the polyamide resin, so that the interlayer strength is improved. The basalt fiber cloth is higher than glass fiber cloth in strength and far lower than carbon fiber cloth in price, and is a novel inorganic material with high cost performance.

Owner:ORINKO NEW MATERIAL CO LTD

Coating type multi-layer composite high-barrier film as well as preparation method and application thereof

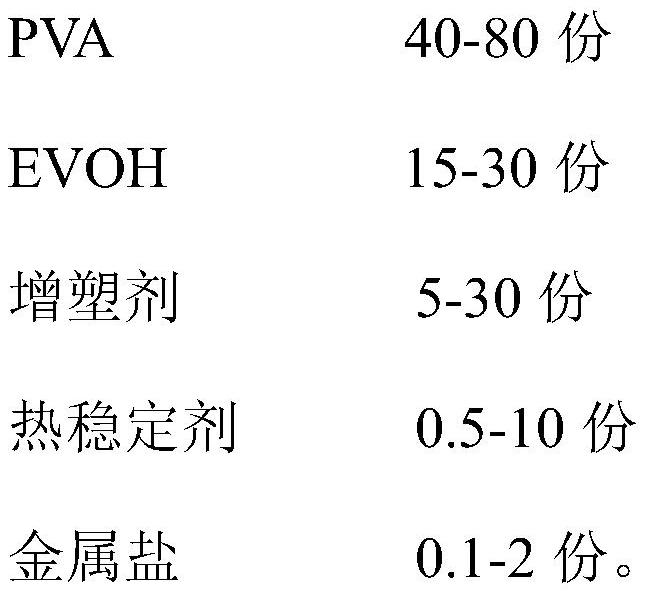

InactiveCN111703165AImprove barrier propertiesHigh gas barrierFlexible coversWrappersPolymer chemistryPlasticizer

The invention relates to a coating type multilayer composite high-barrier film, a preparation method and application thereof, wherein the coating type multilayer composite high-barrier film is formedby compounding multilayer polymers through a coating composite molding method; the structural expression is A / (adh / C)n / B / (adh / C)n / adh / A; in the formula, n is an integer greater than 0, the A represents a surface layer, the B represents a barrier layer, the adh represents an adhesive layer, and the C represents an additional layer. The barrier layer B is a PVA-EVOH composition which is prepared from the following raw materials in parts by weight: 40 to 80 parts of PVA, 15 to 30 parts of EVOH, 5 to 30 parts of plasticizer, 0.5 to 10 parts of heat stabilizer and 0.1 to 2 parts of metal salt; andthe surface layers A and C are thermoplastic high-molecular polymers. The film disclosed by the invention has excellent strength and oxygen-blocking and water-blocking properties, and can be applied to the field of packaging of various foods, medicines and the like.

Owner:JIANGNAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com