Fiber-strengthened ceramic-based wave-transmitting material and preparation method thereof

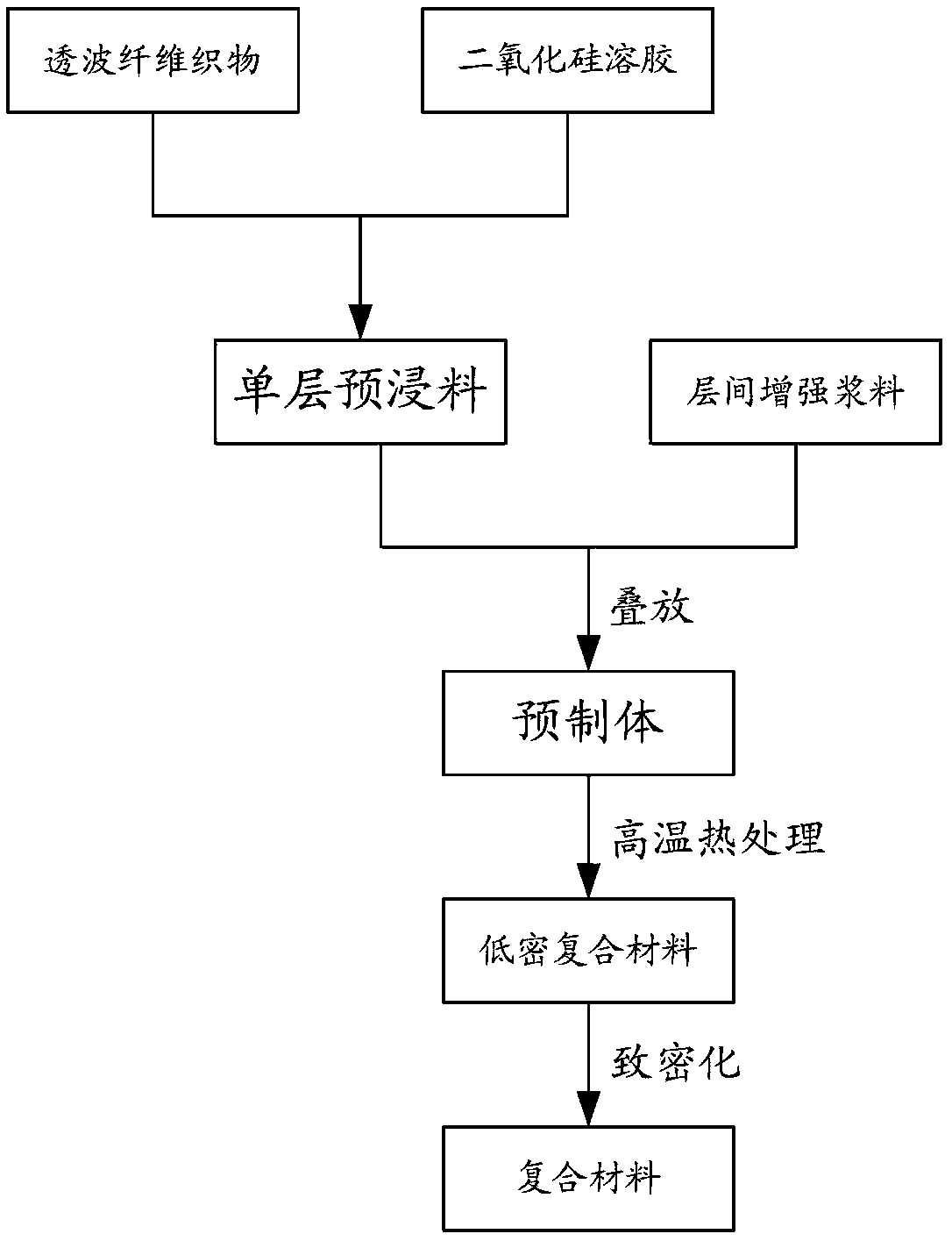

A fiber-reinforced, ceramic-based technology, which is applied in the field of wave-transparent composite material preparation, can solve the problems that the product strength is difficult to meet the radome, the high and low temperature dielectric properties are unstable, and the interlayer strength is not strong, and the bonding effect can meet the equipment requirements. Low, improve the interlayer strength, the effect of low sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] 1. Raw material preparation

[0069] Mix commercially available low-temperature sintered alkali-free lead-free glass powder and fumed silica at a mass ratio of 10:90 to obtain reinforced powder. The glass powder includes the following components in mass percentage: B 2 o 3 : 30wt%; BiO 2 :35wt%; Al 2 o 3 : 10wt%; SiO 2 : 25wt%. Mix terpineol, ethyl cellulose, and the above-mentioned reinforcing powder at a mass ratio of 29:1:70, and grind to obtain an interlayer reinforcing slurry with a viscosity of 400-500 Pa.S.

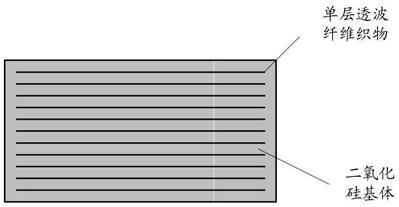

[0070] 2. Preparation of single-layer prepreg

[0071] The reinforced 2D wave-transparent fiber fabric is quartz fiber satin cloth with a thickness of 0.28mm. Boil the quartz cloth in acetone three times to remove the wetting agent on the surface of the fabric. After the last boiling, wait for the acetone to drop to room temperature, soak and rinse the fabric in new acetone, and ventilate and dry it in a fume hood for later use.

[0072] Single-ply...

Embodiment 2

[0088] 1. Mix commercially available low-temperature sintered alkali-free lead-free glass powder and fumed silica at a mass ratio of 30:70 to obtain a reinforced powder. The glass powder includes the following components in mass percentage: B 2 o 3 : 35wt%; BiO 2 :30wt%; Al 2 o3 :15wt%; SiO 2 : 20wt%. Mix tributyl citrate, ethyl cellulose and the above-mentioned reinforcing powder at a mass ratio of 9.4:0.6:90, and grind to obtain an interlayer reinforcing slurry with a viscosity of 250-300 Pa.S.

[0089] The reinforced 2D wave-transparent fiber fabric is alumina fiber plain weave with a thickness of 0.14mm. Put the alumina cloth into a muffle furnace for high-temperature heat treatment to remove the wetting agent on the surface of the fabric for later use.

[0090] 2. Preparation of single-layer prepreg.

[0091] Cut the 2D fabric according to the size of the required material, with a density of 1.16g / cm 3 The prepreg is prepared by repeatedly brushing on the fiber cl...

Embodiment 3

[0104] 1. Mix self-synthesized low-temperature sintered alkali-free lead-free glass powder with fumed silica at a mass ratio of 20:80 to obtain a reinforced powder. The glass powder includes the following components in mass percentage: B 2 o 3 : 30wt%; BiO 2 :35wt%; Al 2 o 3 : 10wt%; SiO 2 : 25wt%. Mix terpineol, ethyl cellulose and the above-mentioned reinforcing powder at a mass ratio of 29:1:70, and grind to obtain an interlayer reinforcing slurry with a viscosity of 350-450 Pa.S.

[0105] The reinforced 2D wave-transparent fiber fabric is a woven plain weave of silicon boron nitrogen fiber. Put the woven cloth into acetone and boil three times, 12 hours each time, to remove the wetting agent on the surface of the fabric. After the last boiling, wait for the acetone to drop to room temperature, soak and rinse the fabric in new acetone, and ventilate and dry it in a fume hood for later use.

[0106] 2. The prepreg is prepared by cutting the 2D fabric on the curved su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com