Carbon fiber reinforced polyamide composite material pre-infiltrated basalt fiber cloth and preparation method thereof

A technology of basalt fiber cloth and basalt fiber, which is applied in the field of carbon fiber reinforced polyamide composite material pre-soaked basalt fiber cloth and its preparation, which can solve the problem of insufficient infiltration of thermoplastic pre-soaked carbon fiber cloth, high market price of carbon fiber, and easy damage to the surface of fiber cloth and other problems, to achieve super dispersion ability and anti-sedimentation performance, low production cost, and the effect of repairing surface defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

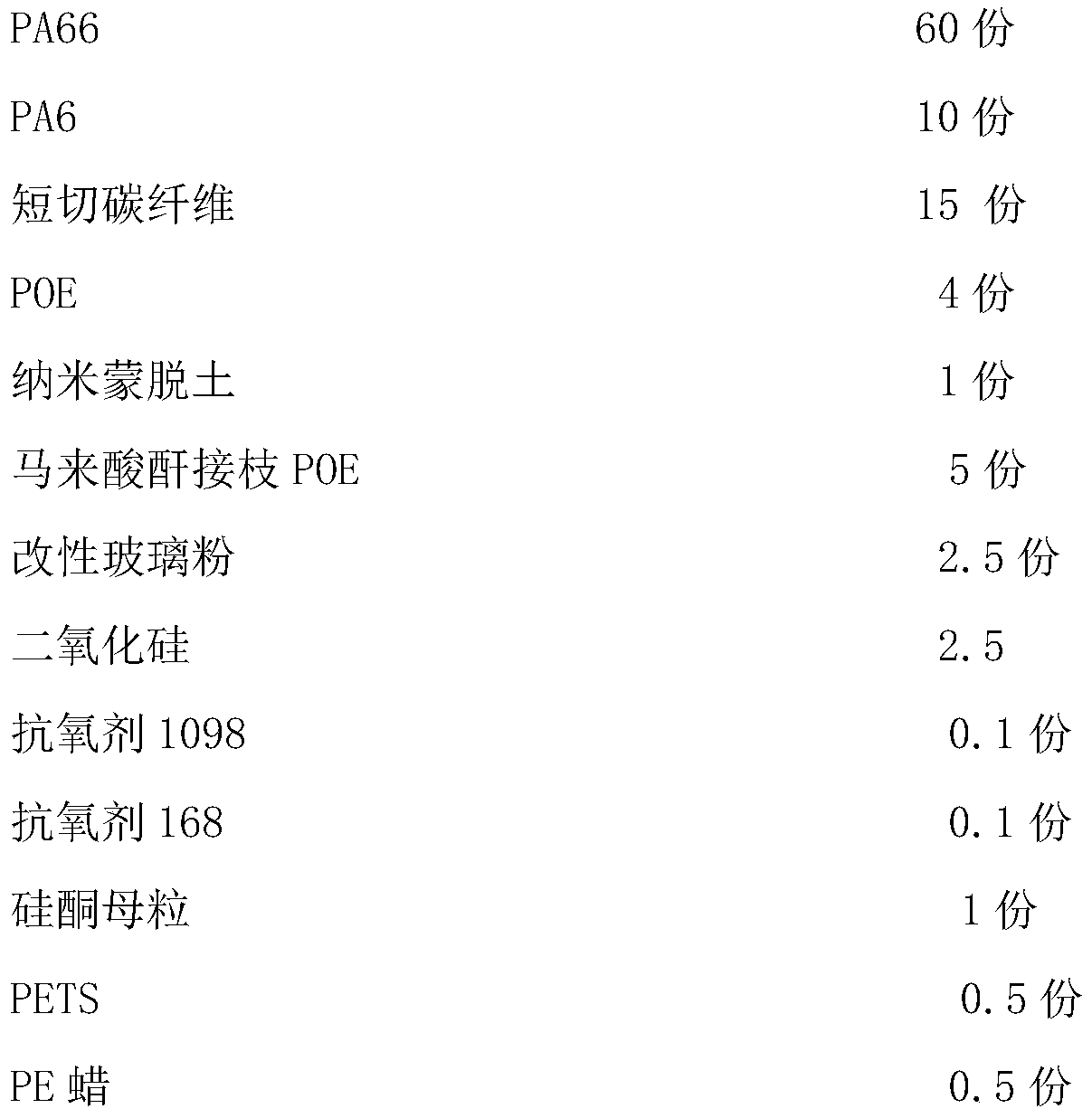

[0028] Carbon fiber reinforced polyamide composites are composed of the following raw materials by weight:

[0029]

[0030] The base cloth of basalt fiber cloth is 600g / m 2 , large tow gingham.

Embodiment 2

[0032] Carbon fiber reinforced polyamide composites are composed of the following raw materials by weight:

[0033]

[0034]

[0035] The base cloth of basalt fiber cloth is 600g / m 2 , large tow gingham.

Embodiment 3

[0037] Carbon fiber reinforced polyamide composites are composed of the following raw materials by weight:

[0038]

[0039] The base cloth of basalt fiber cloth is 600g / m 2 , large tow gingham.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com