Bead-chain-like graphitized carbon nitride nano material and preparation method thereof

A technology of nanomaterials and carbon nitride, which is applied in chemical instruments and methods, nanotechnology, nanotechnology, etc., can solve the problems of poor shape controllability, difficulty in obtaining samples, and high difficulty in synthesis, so as to achieve less surface defects and better Application prospect, good effect of crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] 1.1 Weigh 1.0g (0.0079mol) melamine into 50mL ethylene glycol, stir for 30min until a uniform initial solution is obtained;

[0036] 1.2 Take 20 mL of the initial solution, add 24 mL of the prepared nitric acid aqueous solution with a concentration of 0.3 mol / L dropwise into the initial solution, and keep stirring for 30 minutes until the precipitate is completely precipitated;

[0037] 1.3 Centrifuge the above precipitate, wash it with water twice, then wash it twice with ethanol, and dry it to obtain a white solid powder of the precursor;

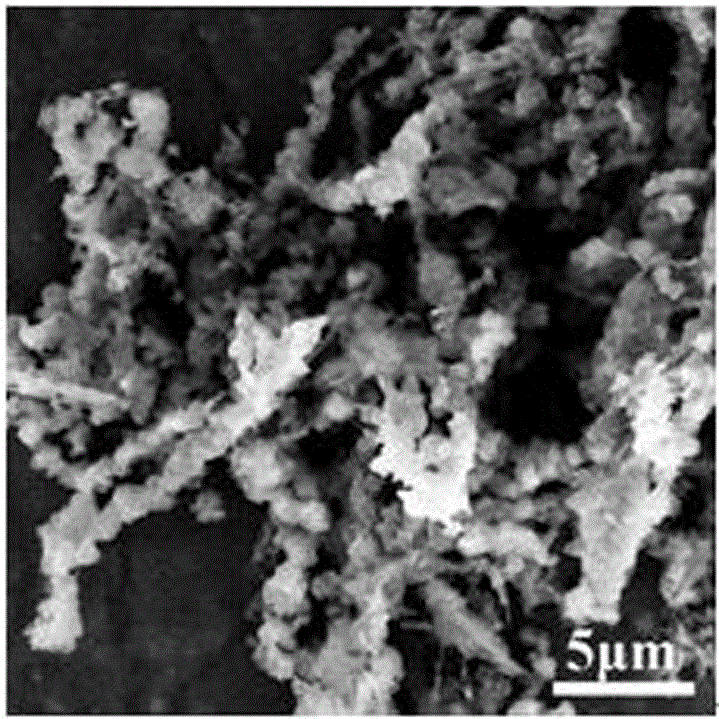

[0038] 1.4 Put the precursor solid powder obtained above in a tube furnace, under the protection of nitrogen atmosphere, heat up to 380°C at a heating rate of 10°C / min, keep it warm for 2 hours for calcination, and cool naturally to room temperature to obtain bead-like graphite Carbon nitride samples (such as figure 2 shown).

[0039] The structural feature of the obtained bead-like chain is: the diameter of the bead-like sub...

Embodiment 2

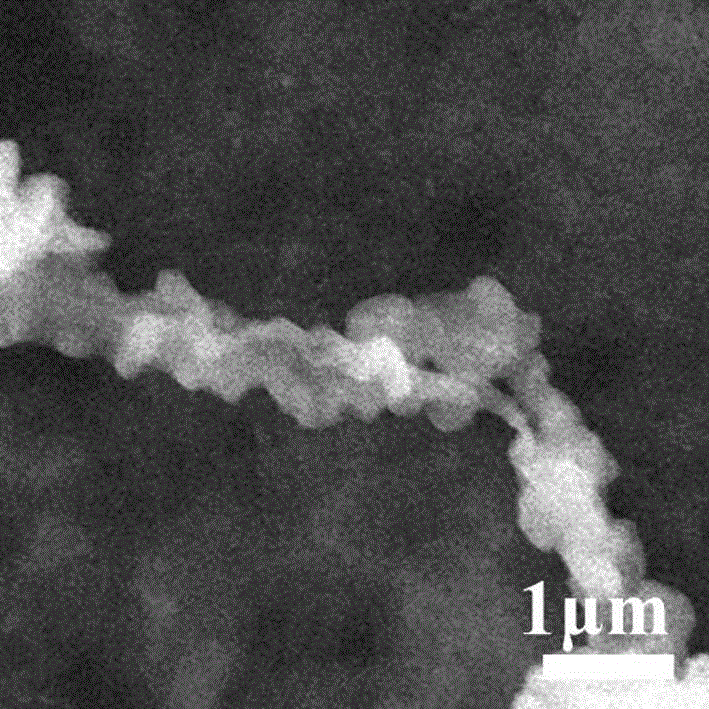

[0042] The preparation method is the same as that in Example 1, except that: after dripping 14.4 mL of nitric acid aqueous solution with a concentration of 0.5 mol / L, the stirring time is 10 min; calcination at 400 ° C for 1 h. The morphology of the obtained bead-like graphitized carbon nitride is as follows: image 3 As shown, the structural characteristics of the obtained bead-like chain are: the diameter of the bead-like objects is 300-500nm, and the distance between the bead-like objects is 200-500nm; the diameter of the nanorods connecting the bead-like objects is 80-250nm; the chain length 5-12.5nm.

Embodiment 3

[0044] The preparation method is the same as in Example 1, except that 14.4 mL of nitric acid aqueous solution with a concentration of 0.5 mol / L is added dropwise, the stirring time is 30 min, and the mixture is calcined at 450° C. for 1 h. The morphology of the obtained bead-like graphitized carbon nitride is as follows: Figure 4 As shown, the structural characteristics of the obtained bead-like chain are: the diameter of the bead-like objects is 300-500nm, and the distance between the bead-like objects is 200-500nm; the diameter of the nanorods connecting the bead-like objects is 80-250nm; the chain length 5-12.5nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Chain length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com