Manufacturing method of all-composite case of rocket engine

A rocket engine and composite material technology, applied to other household appliances, household appliances, household components, etc., to achieve the effect of improving interlayer strength, improving container efficiency, and improving thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below with a collection of specific examples.

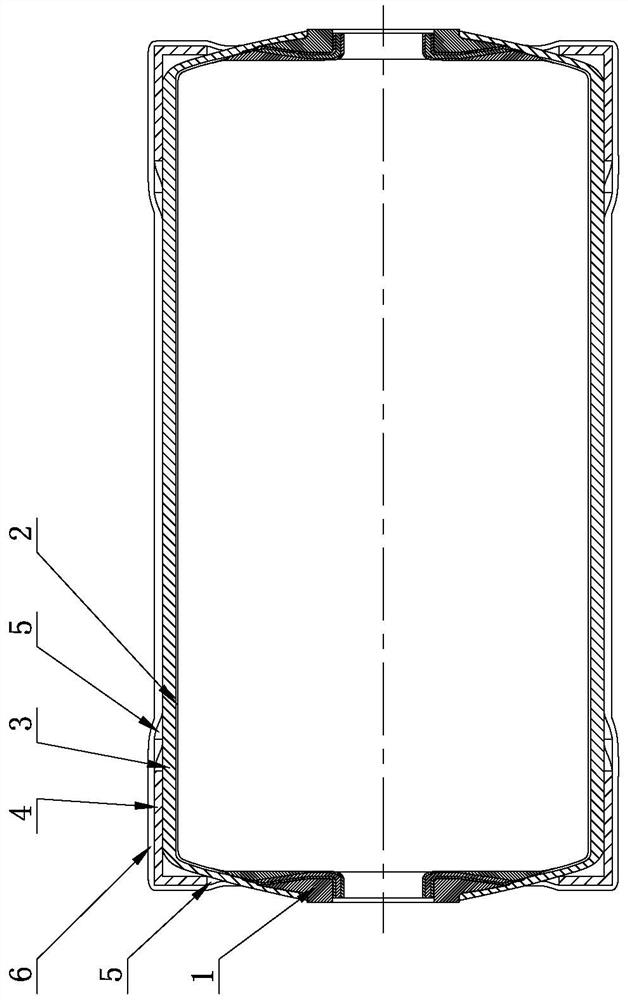

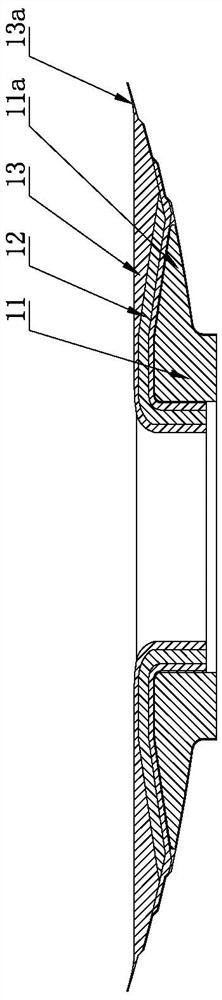

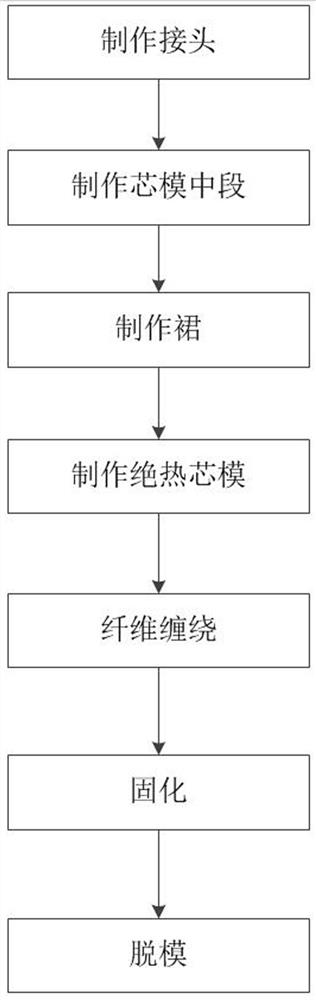

[0028] Such as Figure 1-2 Shown is an all-composite engine casing made by the method of the present invention, including composite material heat-insulating joints 1 arranged at both ends of the composite material casing 3, the inner periphery of the composite material casing 3 is provided with a heat-insulating layer 2, composite The outer two ends of the material shell 3 are provided with a composite material skirt 4, and the joint between the composite material skirt 4 and the composite material shell 3 is provided with a carbon cloth 5, the carbon cloth 5 is T800 plain carbon cloth 5 with a width of 200mm, and the composite The outer periphery of the material skirt 4 and the carbon cloth 5 is covered with a carbon fiber layer 6. The composite material thermal insulation joint 1 includes a composite material joint 11. An ablation-resistant braided layer 12 is embedded in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com