Method for preparing powder super-alloy by near net shape

A technology of superalloys and powders, which is applied in the field of near-net shape preparation of powdered superalloys, which can solve the problems of reducing the cost of raw material powders and process energy consumption, and achieve the effects of reducing oxygen content, avoiding oxidation, and reducing sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

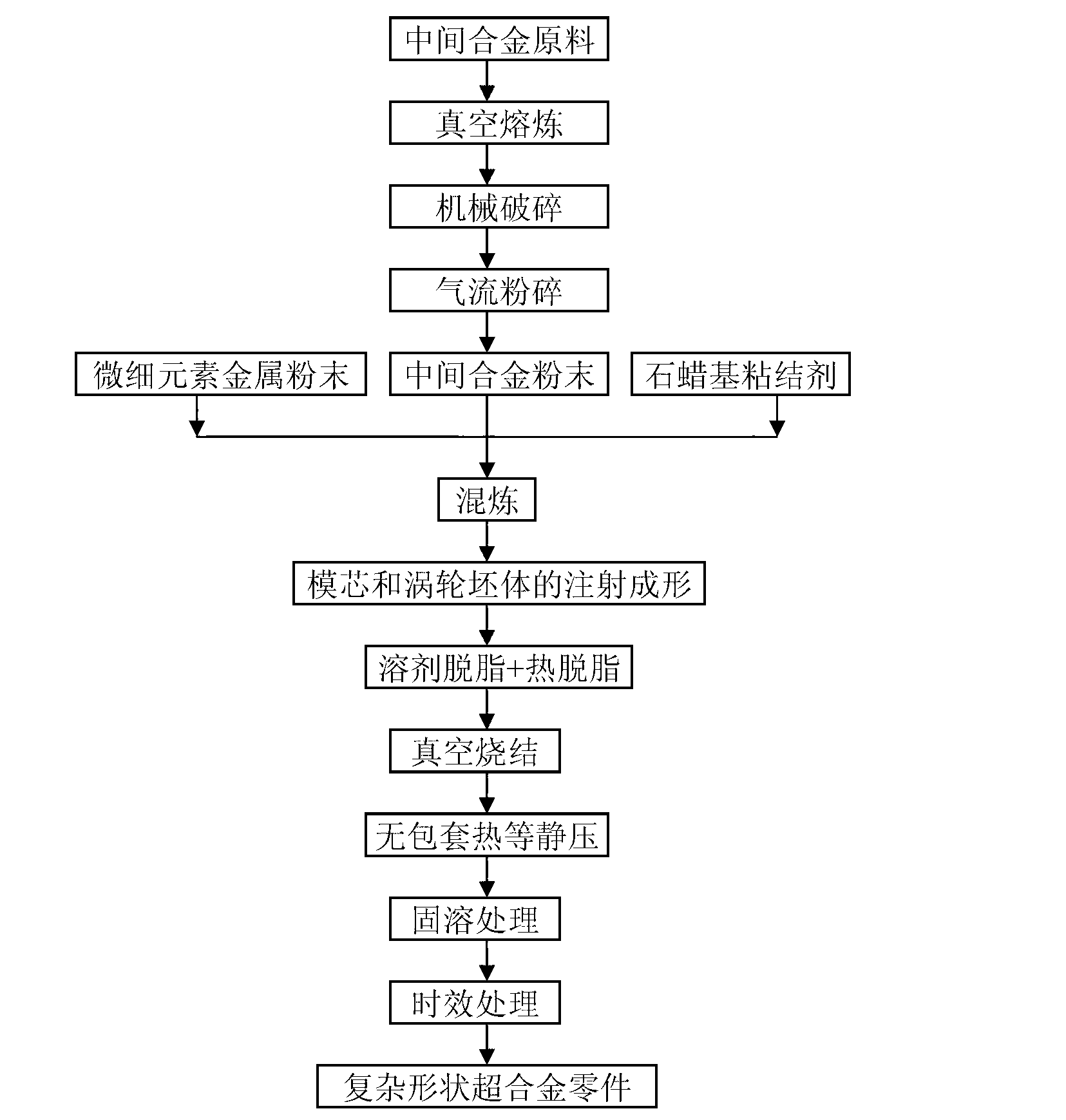

Method used

Image

Examples

Embodiment 1

[0016] Example 1: Preparation of iron-based superalloy K213 in near-net shape

[0017] According to the composition of the iron-based superalloy K213 (35wt.%Ni, 15wt.%Cr, 1.8wt.%Al, 3.5wt.%Ti, 5wt.%W, 0.08wt.%B, 0.08wt.%C and the balance Fe) design master alloy, the content of matrix element Fe in the master alloy is 25wt.%, and the rest are active elements, where W Cr :W Al :W Ti :W B :W C =15:1.8:3.5:0.08:0.08). The master alloy is smelted in a vacuum induction melting furnace to obtain master alloy ingots. Next, the master alloy ingot is turned into chips, and the chips are broken into fine particles on a high-speed pulverizer. The fine particles were further refined by jet crushing, the gas pressure was 8 MPa, and the frequency of the sorting wheel was 60 Hz to obtain master alloy powder with an average particle size of 6.6 μm. In a high-purity Ar atmosphere (99.999%), fine-grained (2-10 μm) metal powders (such as carbonyl nickel powder, carbonyl iron powder, reduce...

Embodiment 2

[0018] Example 2: Preparation of Nickel-based superalloy K418 in near-net shape

[0019] The master alloy is designed according to the composition of the nickel-based superalloy K418 (13%Cr, 6.0%Al, 0.8%Ti, 4.2%Mo, 2.3%Nb, 0.04%B, 0.09%Zr, 0.08%C and the balance of Ni). The content of the matrix element Ni in the alloy is 30wt.%, and the rest are active elements. The mass ratio of each active element is: W Cr :W Al :W Ti :W Nb : W B :W Zr :W C=13:6:0.8:2.3:0.04:0.09:0.08). The master alloy is smelted in a vacuum induction melting furnace to obtain master alloy ingots. The master alloy is smelted in a vacuum induction melting furnace to obtain master alloy ingots. Next, the master alloy ingot is turned into chips, and the chips are broken into fine particles on a high-speed pulverizer. The fine particles are further refined by jet crushing, the gas pressure is 6MPa, the frequency of the sorting wheel is 50Hz, and the master alloy powder with an average particle size of...

Embodiment 3

[0020] Example 3: Preparation of nickel-based superalloy René104 in near-net shape

[0021] According to the composition of nickel-based superalloy René104 (20%Co, 13%Cr, 3.8%Mo, 3.4%Al, 3.7%Ti, 2.1%W, 0.9Nb, 0.05%C, 0.025%B, 0.05%Zr, 2.4% Ta and the balance Ni) to design a master alloy, the content of the matrix element Ni in the master alloy is 35wt.%, and the rest are active elements, and the mass ratio of each active element is: W Cr :W Al :W Ti :W Nb :W C :W B :W Zr :W Ta =13:3.4:3.7:0.9:0.05:0.025:0.05:2.4). The master alloy is smelted in a vacuum induction melting furnace to obtain master alloy ingots. The master alloy is smelted in a vacuum induction melting furnace to obtain master alloy ingots. Next, the master alloy ingot is turned into chips, and the chips are broken into fine particles on a high-speed pulverizer. The fine particles were further refined by jet crushing, the gas pressure was 5 MPa, and the frequency of the sorting wheel was 40 Hz to obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com