Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

46 results about "Solvent debinding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing powder super-alloy by near net shape

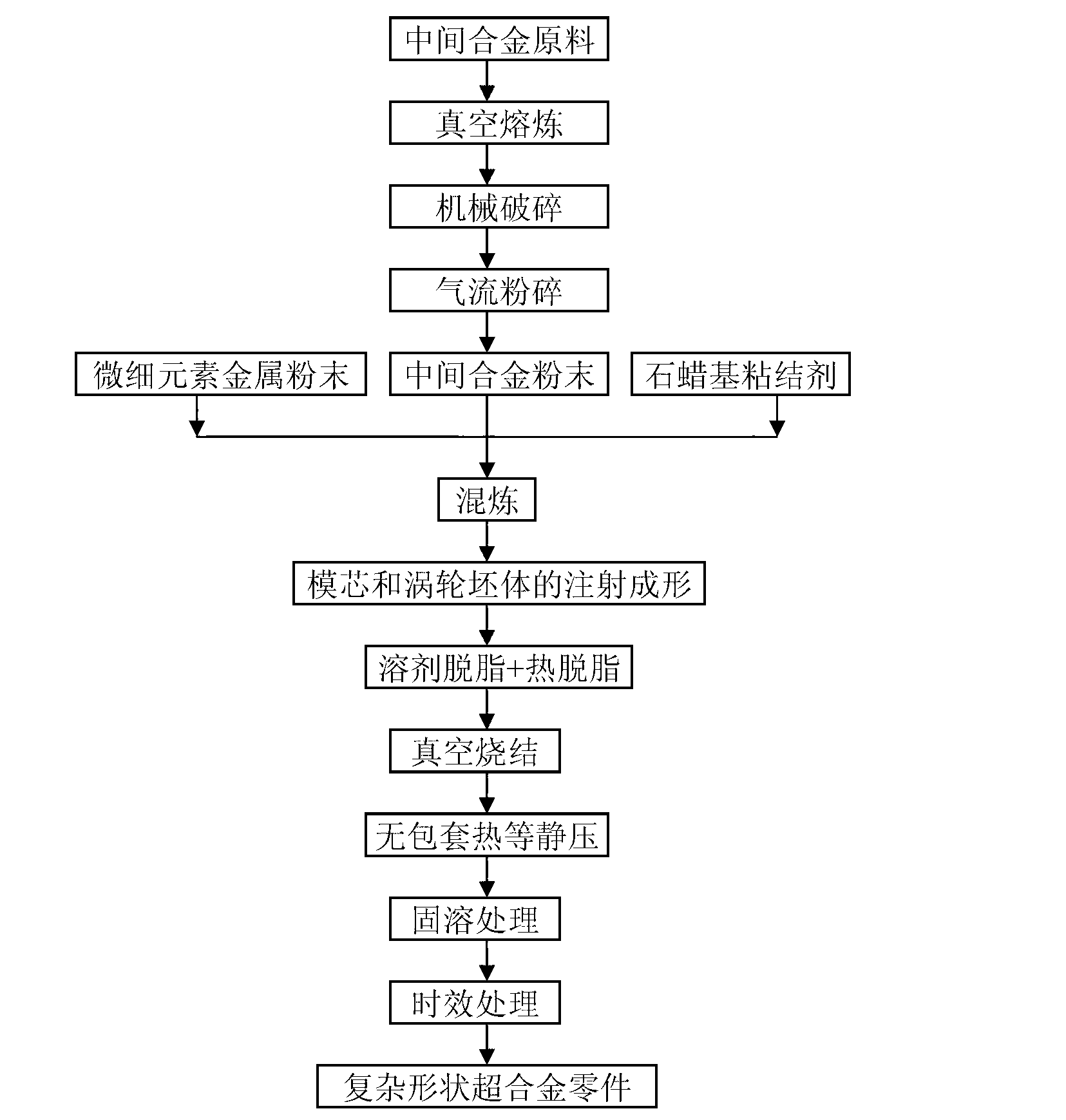

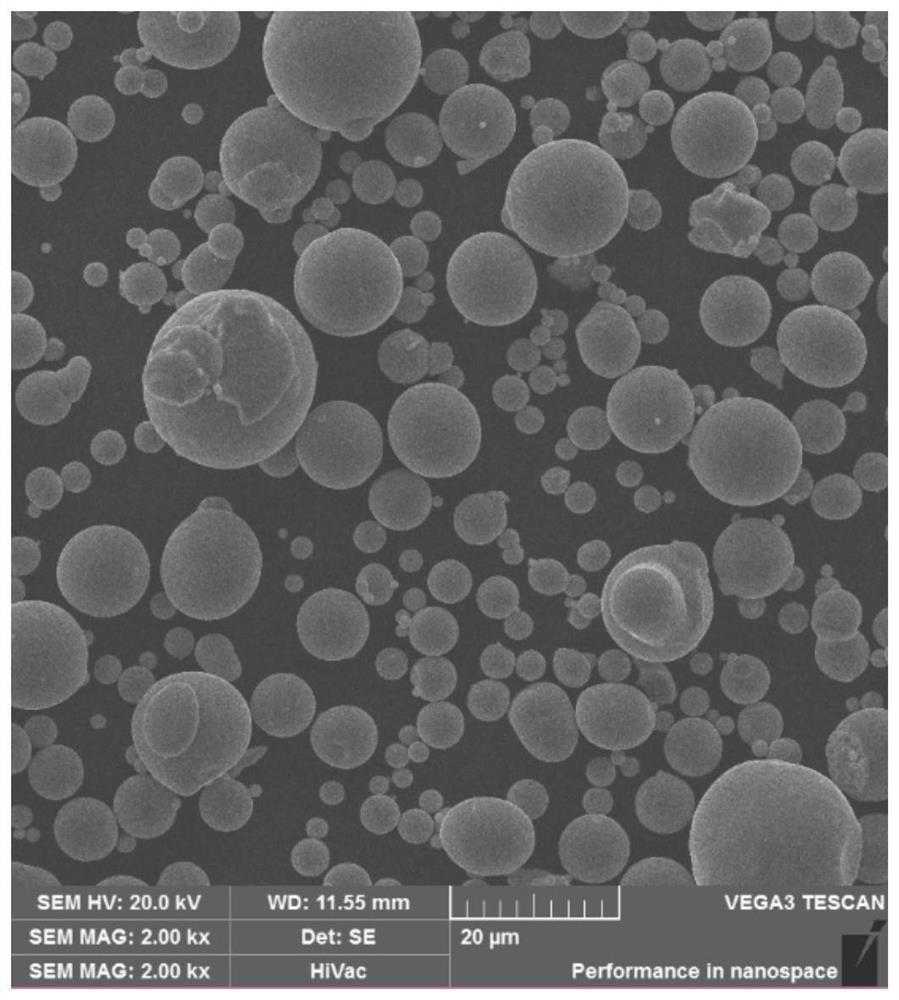

Disclosed is a method for preparing powder super-alloy by a near net shape. Firstly, high-purity intermediate alloy powder is prepared by the aid of vacuum melting and air jet pulverization technology. Secondly, the intermediate alloy powder and fine particle diameter metal powder (such as carbonyl nickel powder, carbonyl iron powder, reduction tungsten powder and reduction molybdenum powder) are mixed in a high-energy ball mill with protective atmosphere to obtain mixed powder. The mixed powder and paraffin base binders are uniformly premixed, feedstock with a uniform rheological performance is obtained by mixing and is formed on an injection forming machine to obtain a blank in a complicated shape. The binders are removed from the blank in the complicated shape by the aid of solvent degreasing and hot degreasing technologies, the degreased blank is sintered in the vacuum atmosphere, the sintered blank is further compacted by the aid of unjacketed hot isostatic pressure, and finally, a super-alloy part in the complicated shape is obtained by the aid of solid solution and aging treatment. Raw material powder cost and technological energy consumption are remarkably reduced, and prepared super-alloy is almost fully compact, uniform in structure and excellent in comprehensive mechanical property.

Owner:UNIV OF SCI & TECH BEIJING

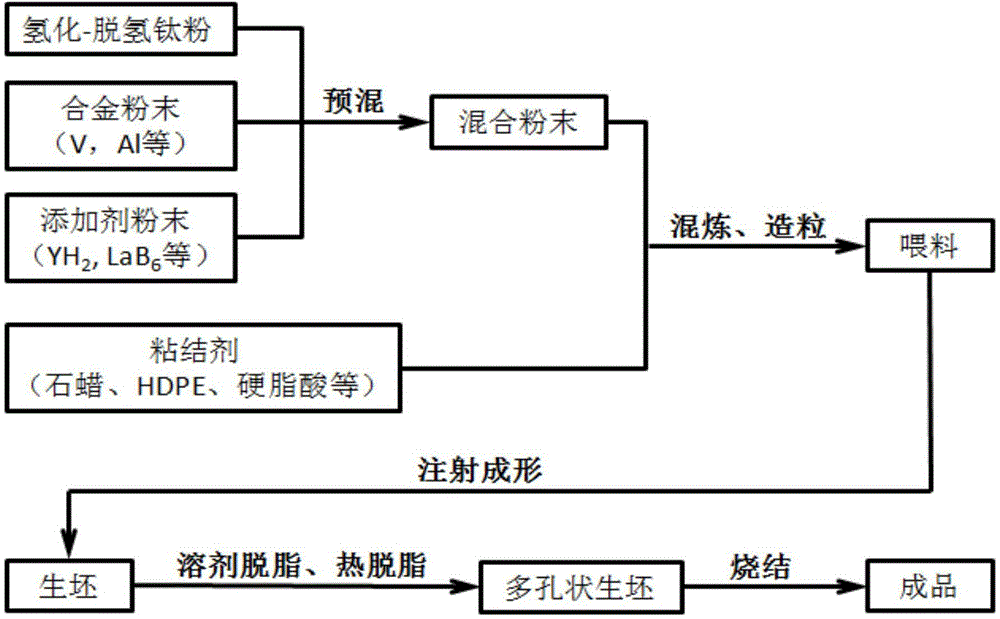

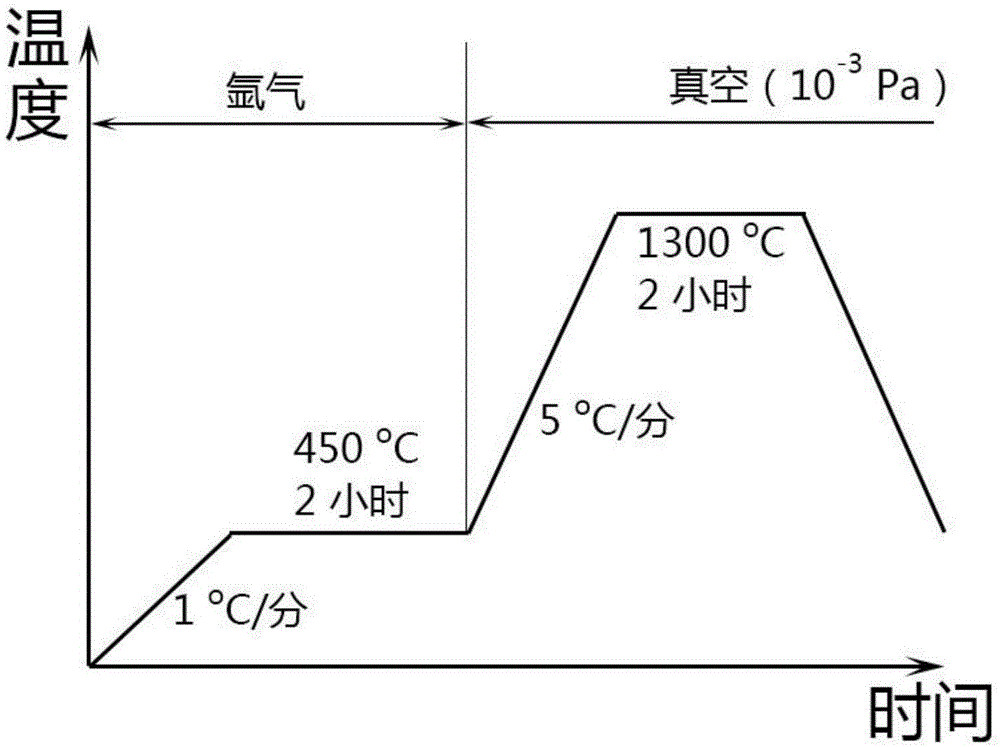

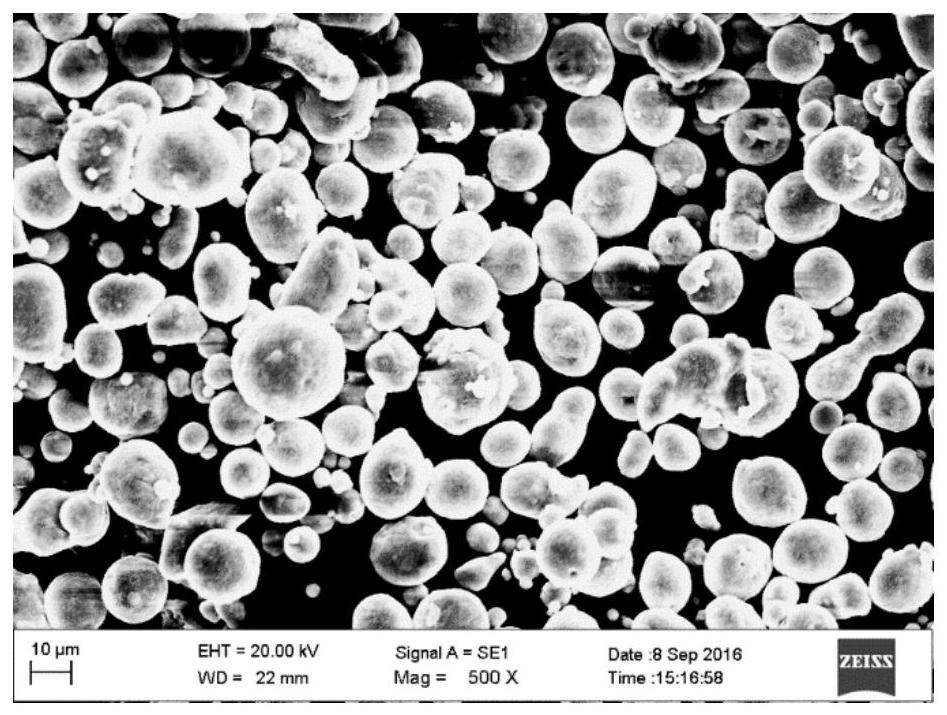

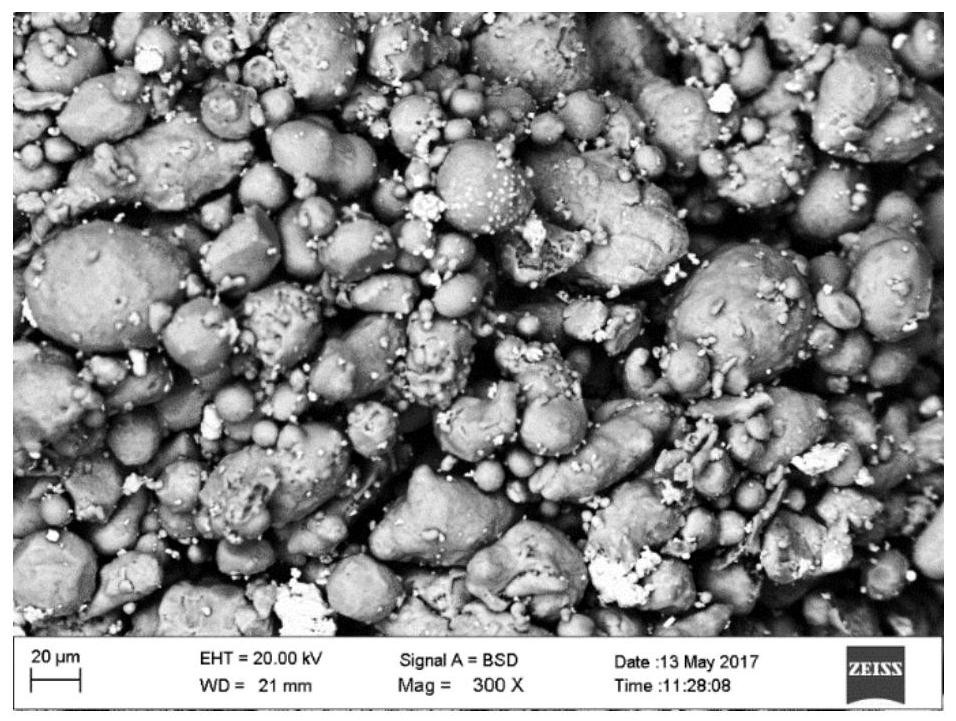

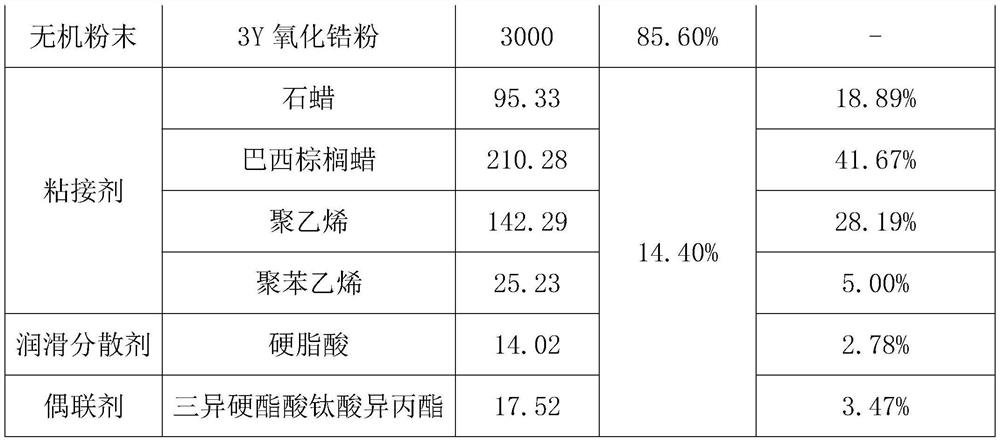

Powder injection molding process by utilizing low-cost hydrogenated-dehydrogenated titanium powder

The invention relates to titanium alloy molding process, and particularly discloses a powder injection molding process by utilizing low-cost hydrogenated-dehydrogenated titanium powder. The process comprises the following steps: mixing hydrogenated-dehydrogenated titanium powder with alloy element powder, additive powder and an adhesive, mixing and pelletizing to obtain feeds; manufacturing blanks by utilizing an ultrasonic-assisted injection molding method; removing the adhesive in the blanks by utilizing solvent debinding and thermal debinding; finally sintering at high temperature to manufacture finished products. According to the powder injection molding process by utilizing the low-cost hydrogenated-dehydrogenated titanium powder as a raw material, the preparation cost of titanium alloy products is low, and the process is suitable for large-scale industrial production.

Owner:SHENZHEN ELEMENTPLUS MATERIAL TECH CO LTD

Preparation method of Wolfram-Nickel-Ferrum (W-Ni-Fe) alloy parts

The invention discloses a preparation method of W-Ni-Fe alloy parts. The preparation method includes the steps of (1) material preparing by using reducted tungsten powder, hydroxy nickel powder and hydroxy iron powder as metal powder; (2) powder blending by weighing W powder, Fe powder and Ni powder in the proportion of 95:3.5:1.5; (3) binder preparation; (4) W-Ni-Fe materials mixing and feeding; (5) pelletizing; (6) injection molding; (7) solvent degreasing; (8) thermal debinding; (9) sintering; (10) thermal treating after sintering. By the preparation method, problem caused by using the present manufacturing process of W-Ni-Fe alloy is solved, so that product shapes are diversified, product design is liberated, mass production is implemented, manufacturing cost is reduced and the like.

Owner:LUOYANG SIFON ELECTRONICS

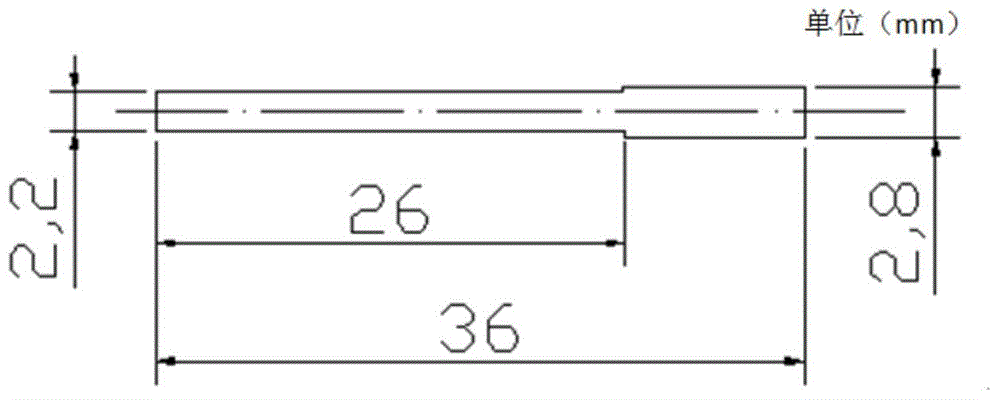

Large-length-diameter-ratio ultrafine grain hard alloy step-shaped bar and preparation method

The invention belongs to the technical field of powder metallurgy, and in particular, relates to a large-length-diameter-ratio ultrafine grain hard alloy step-shaped bar and a preparation method. The preparation method comprises the following steps: (1) ultrafine tungsten carbide powder and cobalt powder are mixed and grinded to obtain mixed powder; (2) the mixed powder and a multi-component binding agent consisting of paraffin-low molecular coupling agent-high molecular polymer are uniformly mixed to prepare a feedstock; (3) the feedstock is injected on an injection molding machine to form a molded blank; (4) the solvent degreasing and the thermal debinding are performed for the injection-molded blank in sequence; and (5) the ultrafine grain hard alloy step-shaped bar is obtained through sintering. The prepared ultrafine grain hard alloy step-shaped bar is small in alloy porosity and high in hardness and strength; and the diameter and size deviations are +-0.03 mm.

Owner:GRIMAT ENG INST CO LTD

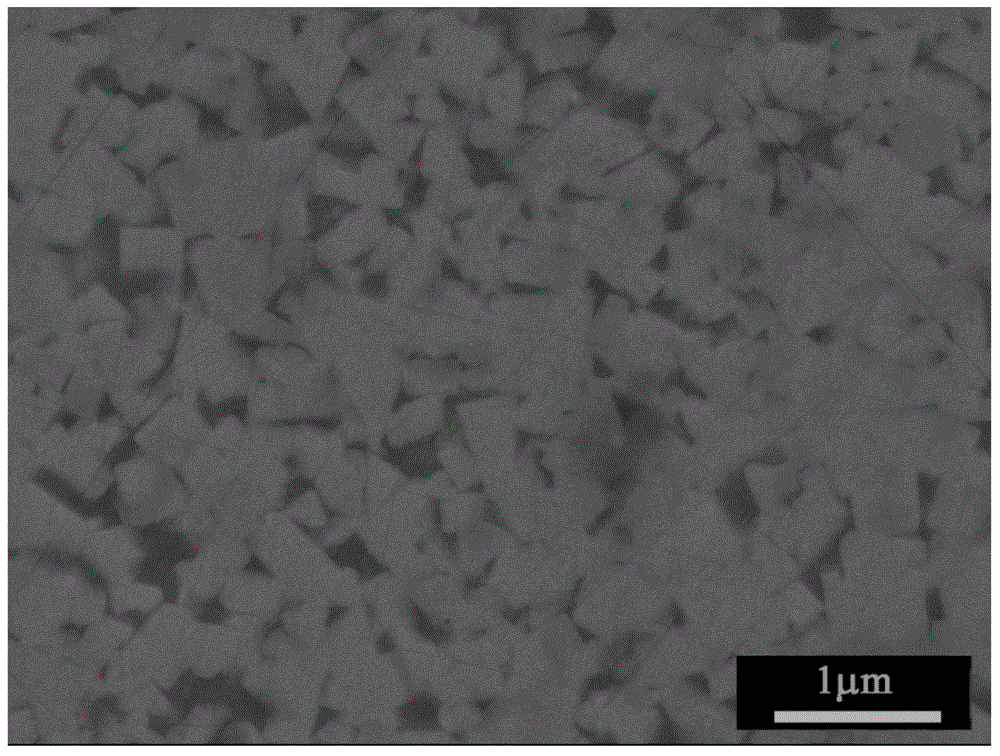

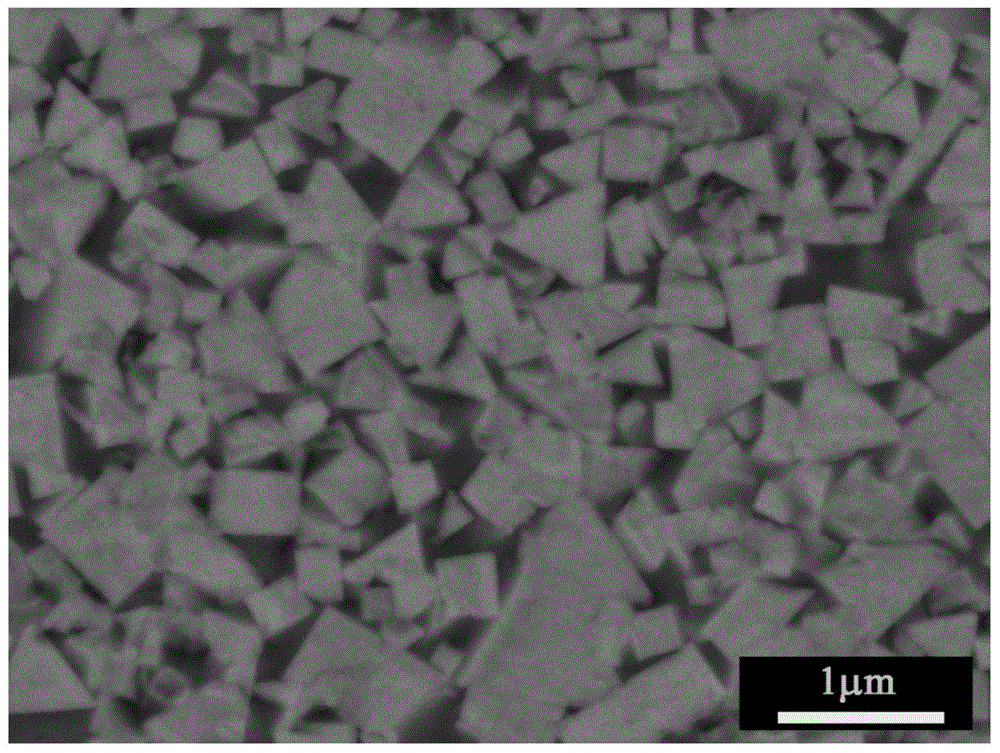

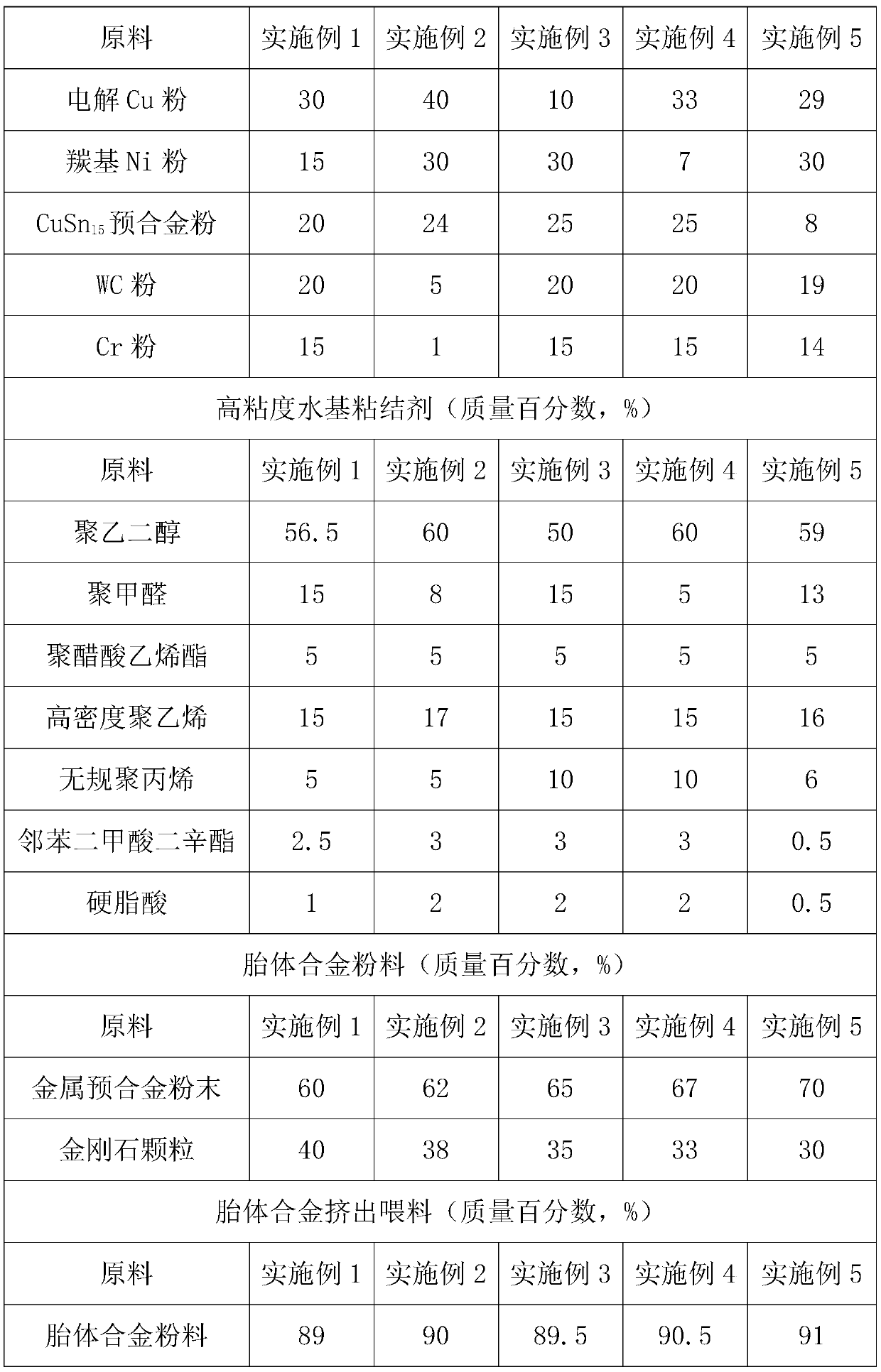

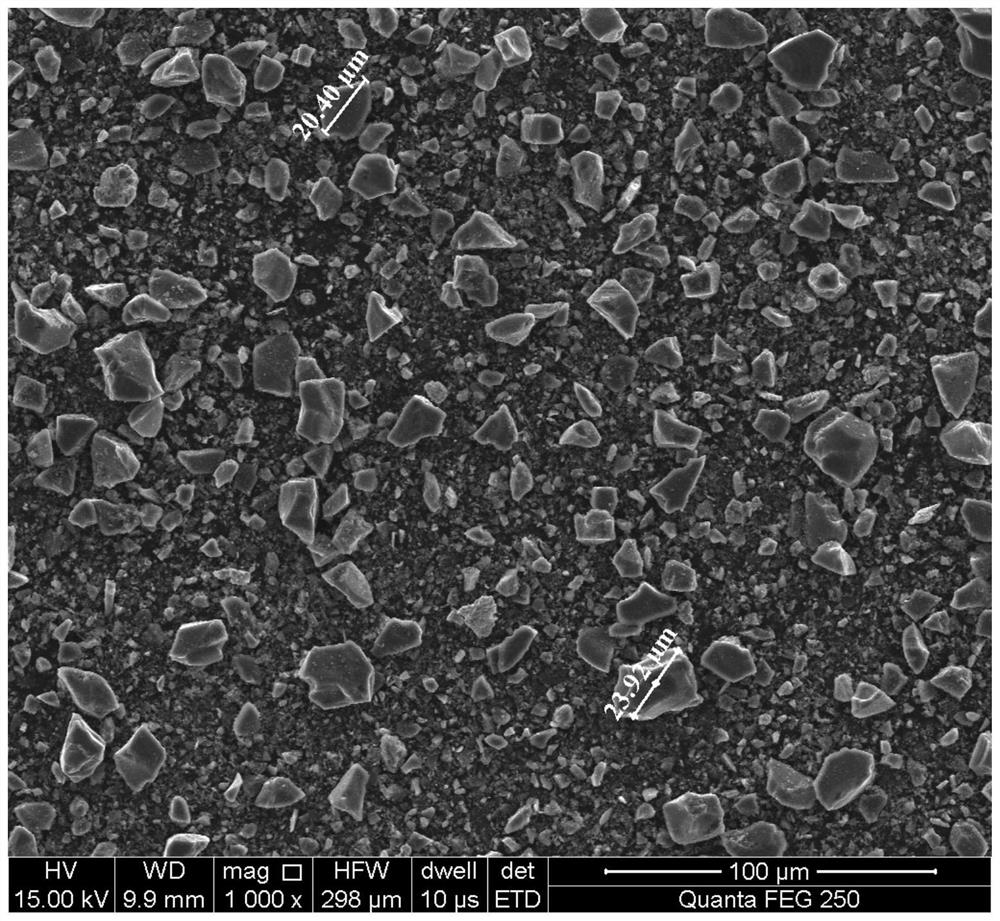

Preparation method of diamond rope saw bead string based on metal powder extrusion molding

ActiveCN110976878AFast cutting speedExtended service lifeTransportation and packagingMetal-working apparatusDry mixingAlloy

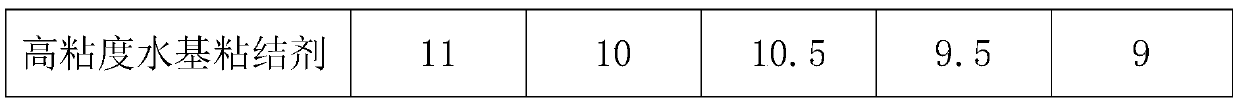

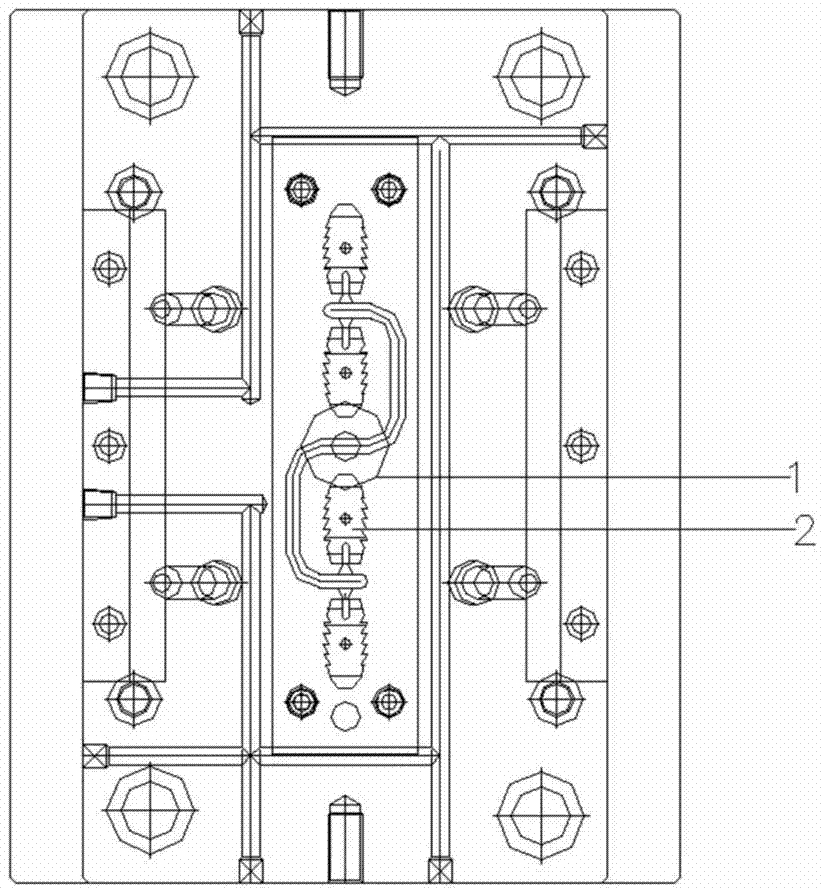

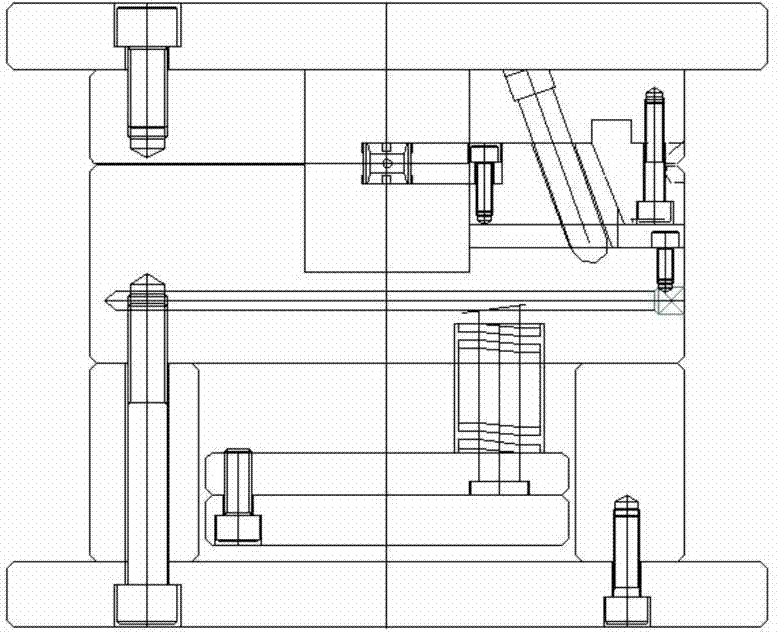

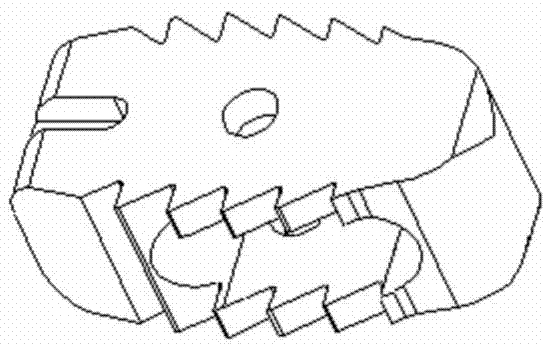

The invention relates to the field of diamond rope saw bead strings, in particular to a preparation method of a diamond rope saw bead string based on metal powder extrusion molding. The preparation method of the diamond rope saw bead string based on metal powder extrusion molding comprises the following steps of A, performing dry mixing on metal pre-alloy powder and diamond particles, and heatingand kneading matrix alloy powder and a high-viscosity water-based binder; B, extruding and molding the matrix alloy extrusion feed into a matrix alloy round tube; C, cutting the matrix alloy round tube into a circular ring blank; and D, carrying out dip soaking water solvent degreasing and drying treatment on the diamond bead string ring blank. By means of the preparation method of the diamond rope saw bead string based on metal powder extrusion molding, a diamond rope saw bead string with uniformly-distributed diamond particles in an alloy matrix is prepared, the cutting speed of a diamond rope saw is improved, and the service life is prolonged.

Owner:荣成中磊科技发展有限公司

Method for preparing miniature mold by powder micro injection forming method

The invention relates to a method for preparing a miniature mold by a powder micro injection forming method. According to the method, high-hardness material powder and ceryl multi-ingredient bonding agents are adopted and mixed to be prepared into uniform feed, the feed is injected on an injection forming machine to obtain an injection blank of the miniature mold with the shape of a miniature part, the injection blank is subjected to hot degreasing and pre-sintering in a degreasing furnace after the solvent degreasing, finally, a test specimen subjected to the pre-sintering is subjected to high-temperature sintering, and the miniature mold with the good shape maintenance effect is obtained. The method provided by the invention can be used for making the miniature mold with complicated shapes in the micrometer dimension, the mold has the characteristics of high hardness, high wear resistance, low thermal conductivity coefficient and the like, an the mass production requirement of the miniature parts can be perfectly met.

Owner:UNIV OF SCI & TECH BEIJING

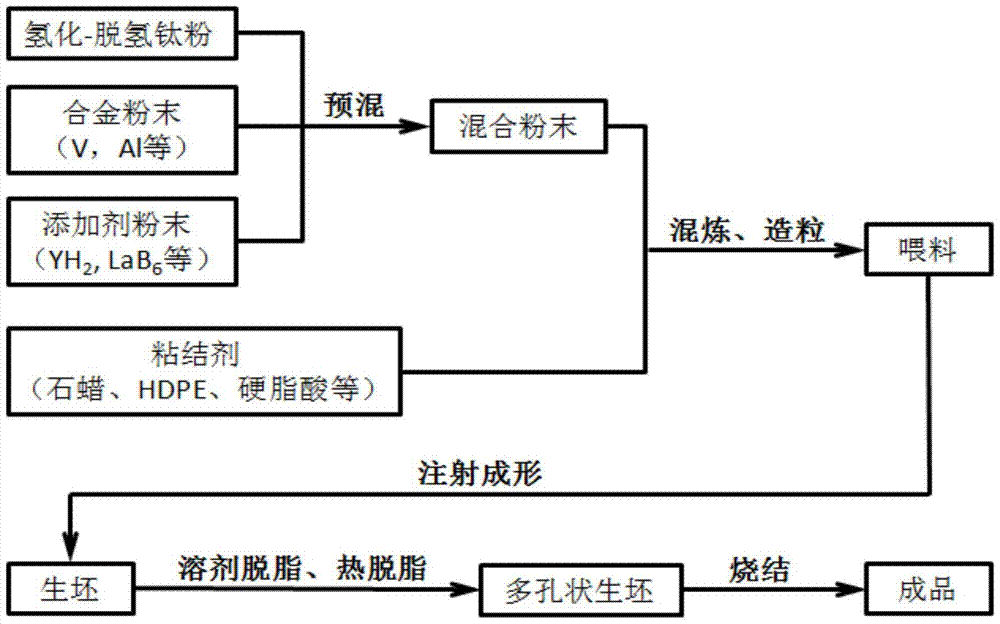

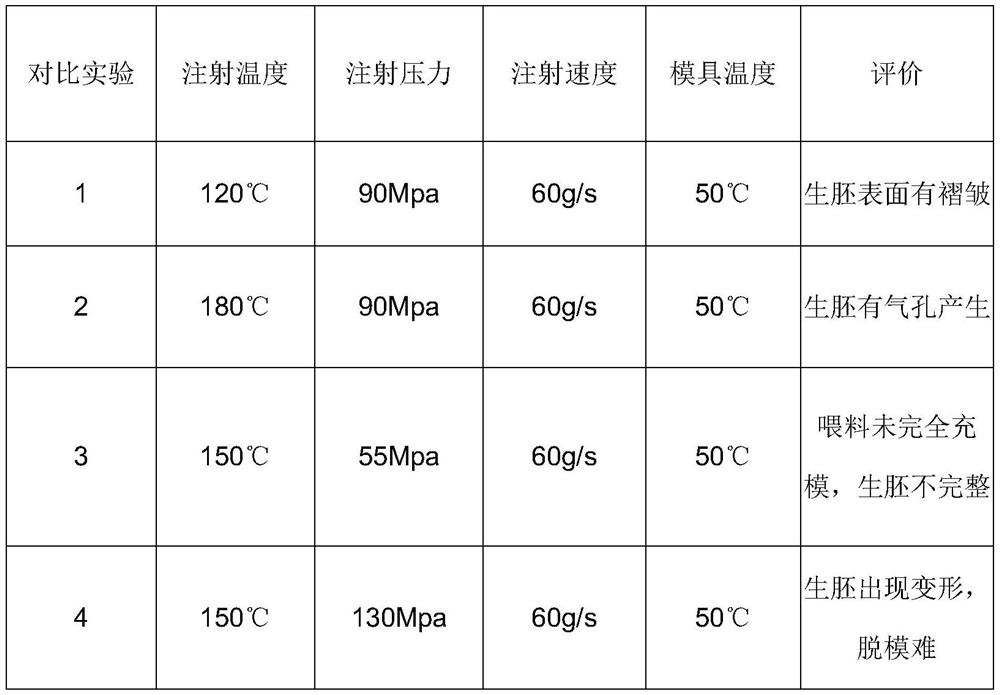

Method for preparing orthopaedic implants

The invention discloses a method for preparing orthopaedic implants. The method comprises the steps that metal powder or ceramic powder is mixed with a binding agent and then is heated, mixed, cooled and granulated to obtain a feed; the feed is injected into a mold under the proper injection temperature, injection pressure and injection rate, the mold temperature ranges from 30 DEG C to 45 DEG C, the pressure of the mold ranges from 2 MPa to 10 MPa, and after pressure maintaining and cooling, a green body is obtained; solvent degreasing and heat degreasing are carried out on the green body successively to obtain a degreasing green body; the degreasing green body is placed in a sintering furnace and is heated to 800 DEG C to 1100 DEG C under the vacuum, and then heated to 1300 DEG C to 1600 DEG C under the argon atmosphere to be sintered for 90 min to 300 min, and the orthopaedic implants are obtained. According to the preparation method, one-time forming and mass production of the orthopaedic implants can be achieved, and the orthopaedic implants are high in raw material utilization rate and low in cost.

Owner:THE THIRD XIANGYA HOSPITAL OF CENT SOUTH UNIV

Tungsten alloy powder casting machining method

PendingCN112570710AEvenly heatedControl shapeTransportation and packagingMetal-working apparatusAdhesiveManufactured material

The invention discloses a tungsten alloy powder casting machining method. The method comprises the steps that S1, spherical tungsten powder is prepared; S2, mixed tungsten alloy powder is prepared; S3, injection molding is conducted, specifically, the mixed tungsten alloy powder and an adhesive are mixed and then made into granules, and then the granules are fed into an injection molding machine to be subjected to injection molding in a mold to obtain a tungsten alloy blank; S4, solvent degreasing is conducted, specifically, the tungsten alloy blank is put into a normal-temperature n-heptane solvent to be soaked for 6-10 hours and then dried for standby application; and S5, thermal degreasing is conducted, specifically, the tungsten alloy blank obtained after solvent degreasing is buried in Al2O3 powder to be subjected to segmented thermal degreasing, and is slowly cooled to the normal temperature to obtain an ultrahigh-density tungsten alloy powder casting. According to the method, tungsten alloy parts with ultrahigh density and ultrahigh shape complexity can be directly prepared, and the problems that in the prior art, machining is complex, energy consumption is large, the manufacturing cost is high, raw material waste is large, and the rate of finished products is extremely low are solved.

Owner:SUZHOU MIMO METAL SCI & TECH

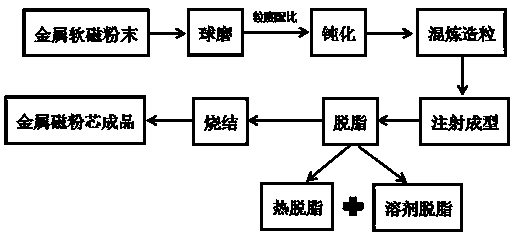

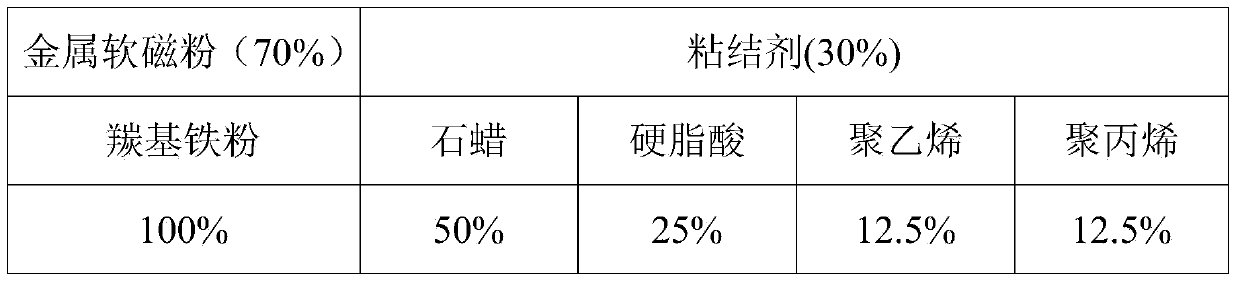

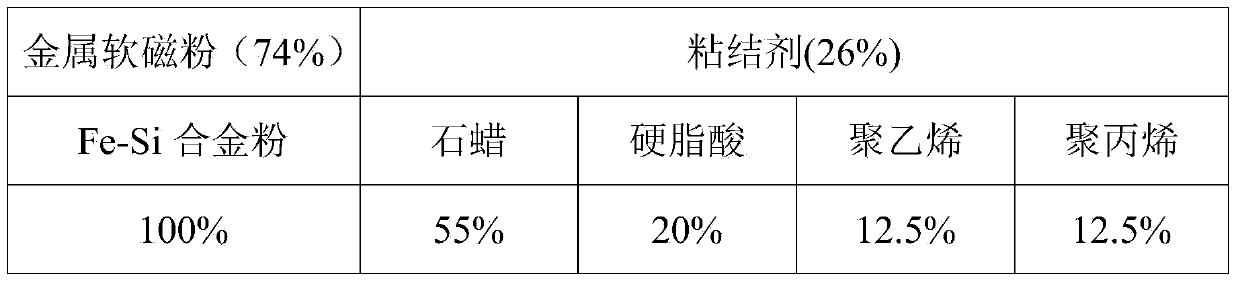

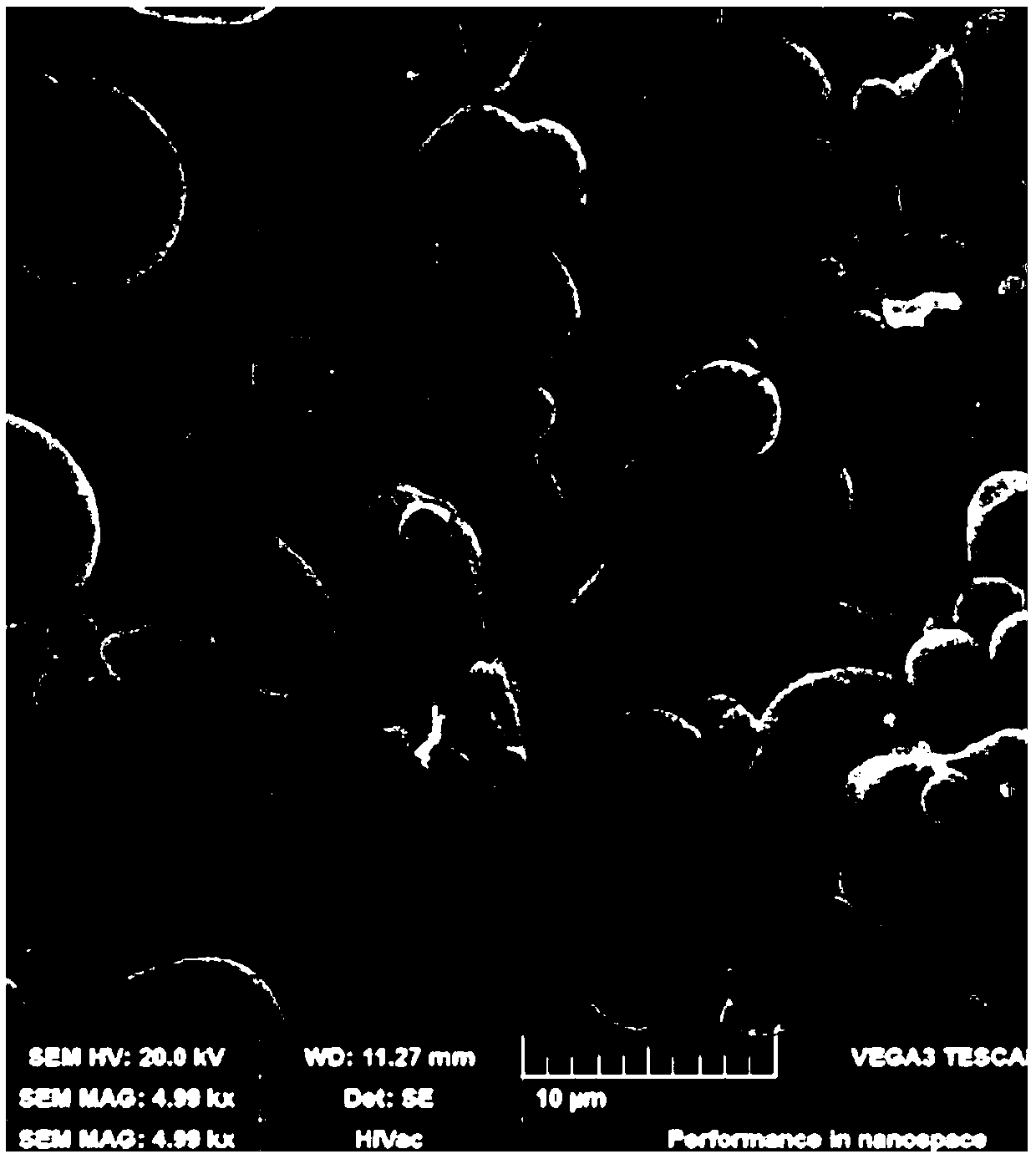

Injection molding preparation method for metal magnetic powder cores

ActiveCN104091667ASolve production and processing difficultiesHigh mechanical strengthInorganic material magnetismUltimate tensile strengthBall mill

The invention discloses an injection molding preparation method for metal magnetic powder cores. The preparation method comprises the following steps: 1) carrying out ball milling on metal soft magnetic alloy powder into powder of different particle sizes; 2) adding a passivator to carry out insulation coating after the powder is prepared according to a certain particle size; 3) after a binder is added and mixing granulation is carried out, carrying out injection molding on the powder to obtain magnetic powder core molding blank bodies; 4) after the magnetic powder core molding blank bodies are degreased and thermally degreased by a solvent, sintering to reach densification; 5) under the protection of inert gases, annealing magnetic powder cores and removing sintering stresses. The method disclosed by the invention is suitable for preparing small and medium-sized metal magnetic powder core components with complex shapes and high precision. The magnetic powder cores prepared by the method disclosed by the invention has the characteristics of uniform density, uniform internal organization, high mechanical strength, good direct current bias magnetic properties and relatively low power consumption.

Owner:ZHEJIANG UNIV +1

High-strength turbocharger spray nozzle ring blade and preparation method thereof

ActiveCN109513930AHigh temperature strengthImprove performanceTransportation and packagingMetal-working apparatusInjection pressureThermal fatigue

The invention discloses a high-strength turbocharger spray nozzle ring blade and a preparation method thereof and belongs to the technical field of production of vehicle-purpose turbocharger spray nozzle ring blades. According to the high-strength turbocharger spray nozzle ring blade and the preparation method thereof, the method comprises the steps that HK30 stainless steel gas atomized powder and adhesive are adopted, wherein an enhancer accounting for 0.8-1.5 % of the weight of the stainless steel gas atomized powder is added into the HK30 stainless steel gas atomized powder; the HK30 and enhancer powder and the adhesive are weighed according to the mass ratio of (80-95)%:(20-5)% and are subjected to mixing, cooling and crushing, and then feed is prepared; the prepared feed is injectedinto an injection moulding machine, and a blank is injection moulded, wherein the injection temperature is 140-175 DEG C, the injection pressure is 60-120 MPa, and the mould temperature is 30-60 DEG C; and after the blank is subjected to solvent degreasing and heating degreasing combined treatment, treatment of presintering and sintering procedures is performed to obtain a finished product. The high-strength turbocharger spray nozzle ring blade provided by the invention is high in product size precision and surface precision, high in product thermal fatigue resistance, and long in product service life under high-temperature strength conditions.

Owner:湖南英捷高科技有限责任公司

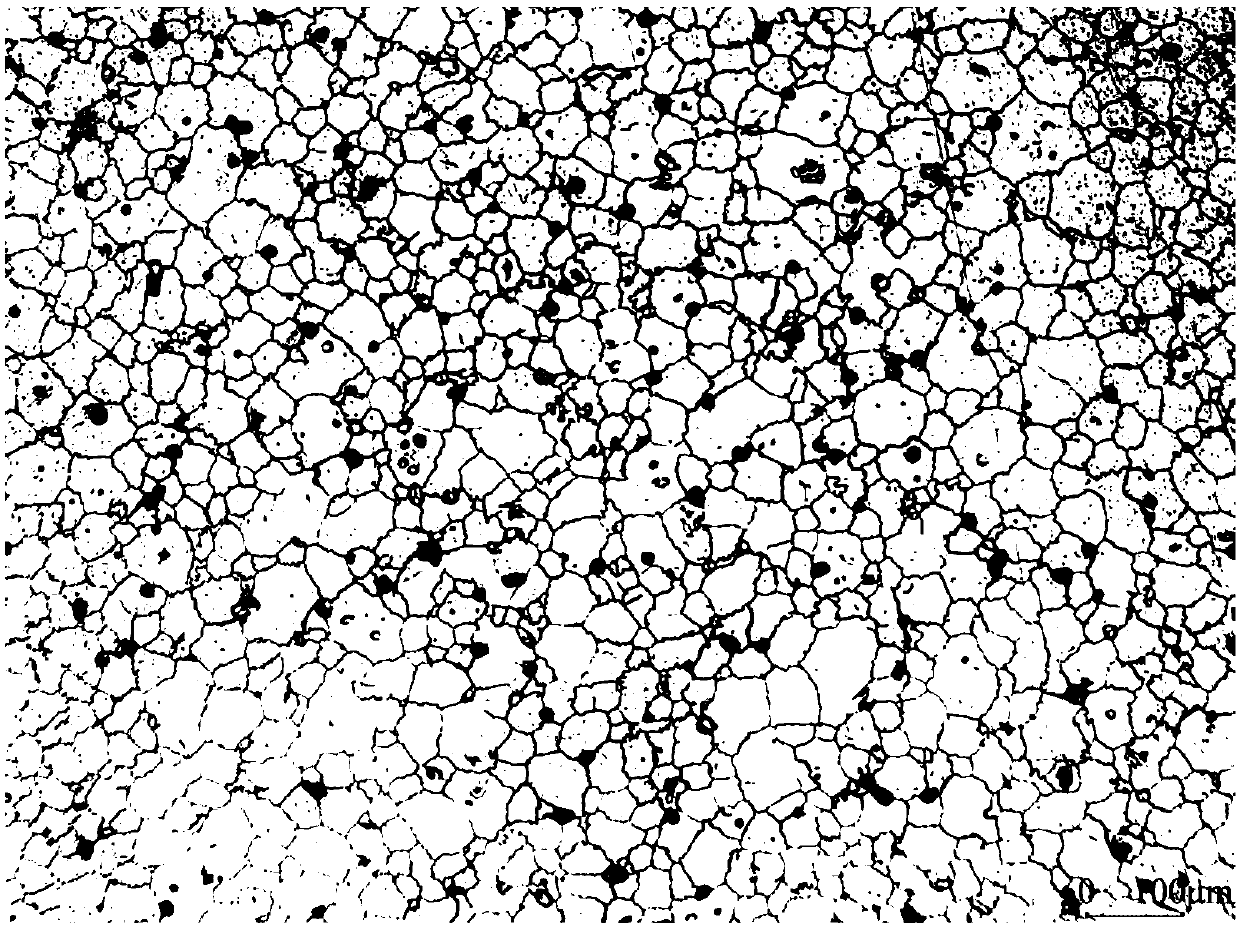

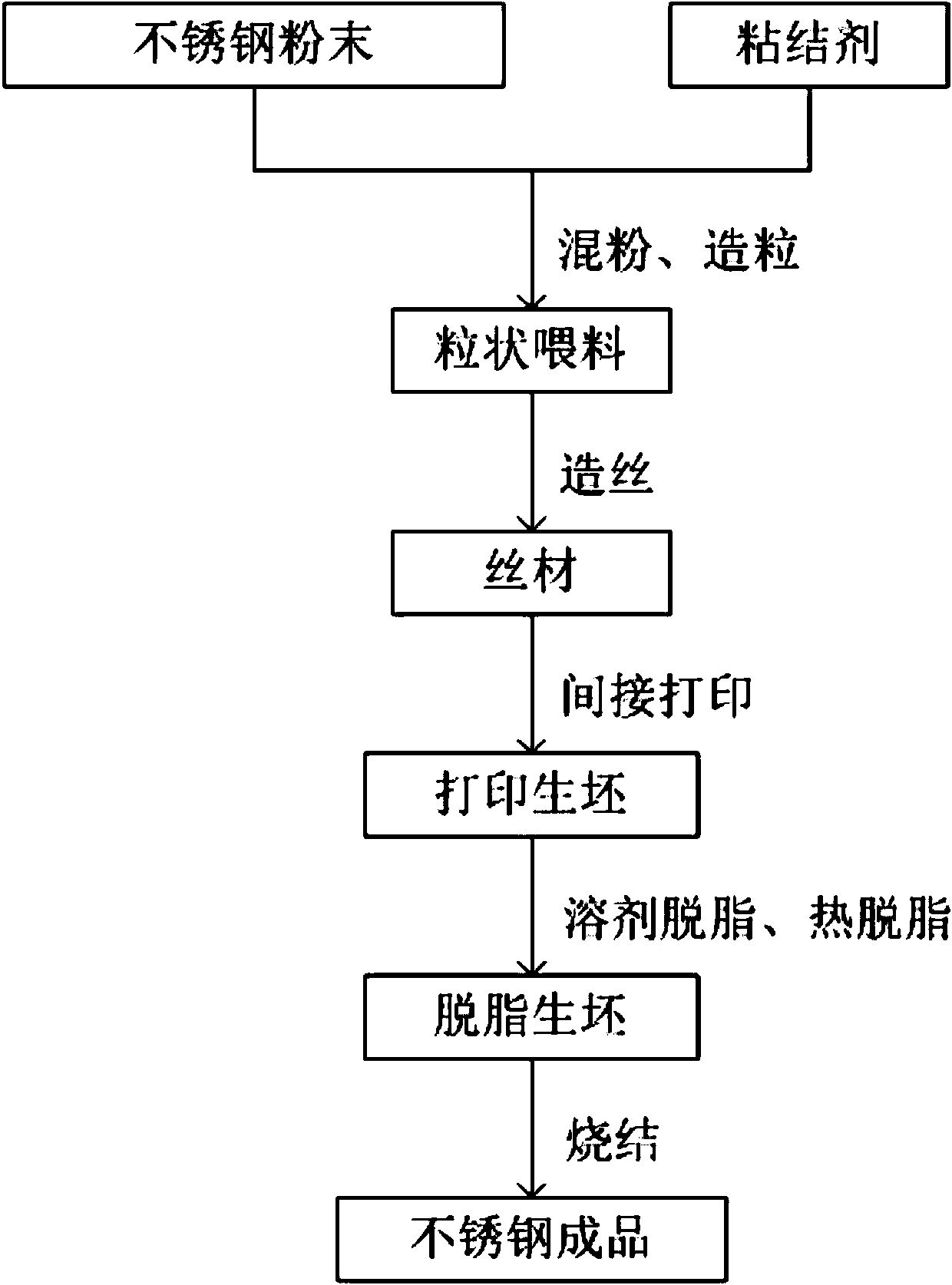

Low-cost stainless steel indirect additive manufacturing method

PendingCN111283185ALow costWide range of engineering applicationsAdditive manufacturing apparatusTransportation and packagingParaffin waxPolyoxymethylene

The invention discloses a low-cost stainless steel indirect additive manufacturing method. The low-cost stainless steel indirect additive manufacturing method includes the following steps that stainless steel powder and binders are fully mixed, stirred and heated, the particle specification of the stainless steel powder is 8-12 microns, and the weight ratio of the stainless steel powder to the binders is 92:8-90:10; the binders are made of the following raw materials, by weight, 20-25 parts of microcrystalline wax, 60-70 parts of polyformaldehyde, 6-9 parts of polyethylene, 3.5-4.5 parts of paraffin and 0.2-1 part of stearic acid; after being cooled, the mixed powder is prepared into granular feed through a granulator, and then an injection molding machine is utilized to process the granular feed into wires containing binders; the wires are loaded on a conventional plastic 3D printer and printed into stainless steel greens; solvent degreasing is first conducted on the stainless steel greens, and then thermal degreasing is carried out on the stainless steel greens; and finally, the stainless steel greens are consolidated through vacuum sintering, and highly compact stainless steel indirect printing finished products are obtained after cooling to the room temperature. The low-cost stainless steel indirect additive manufacturing method has the beneficial effects that the materialcost is low, processing equipment is simple, the rate of finished products is high, and the product quality is good.

Owner:LISHUI UNIV

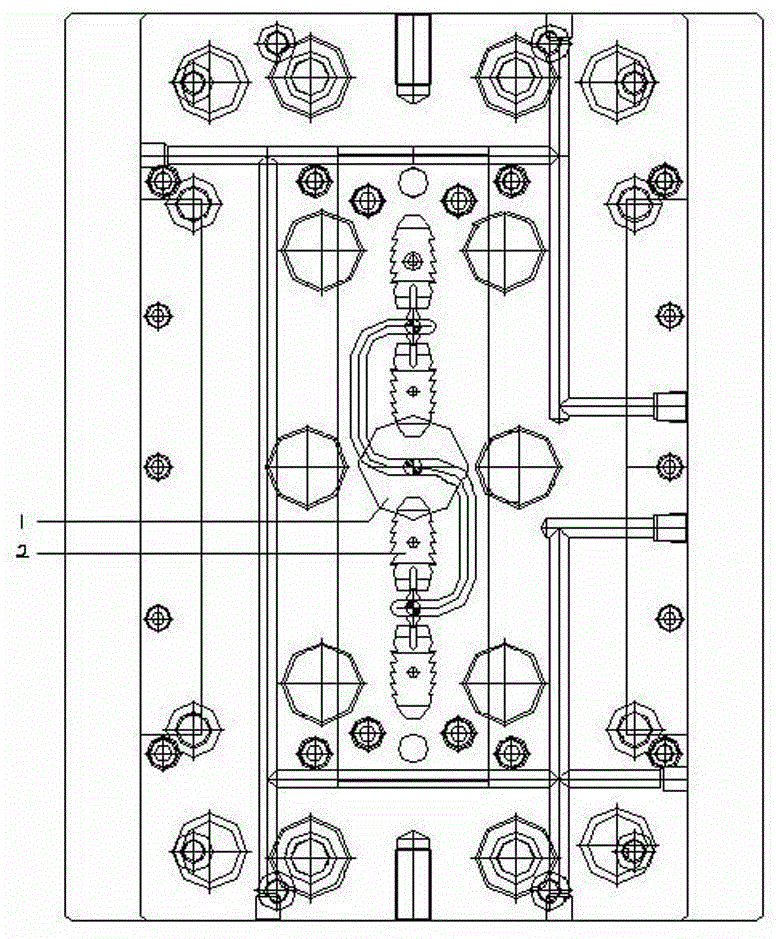

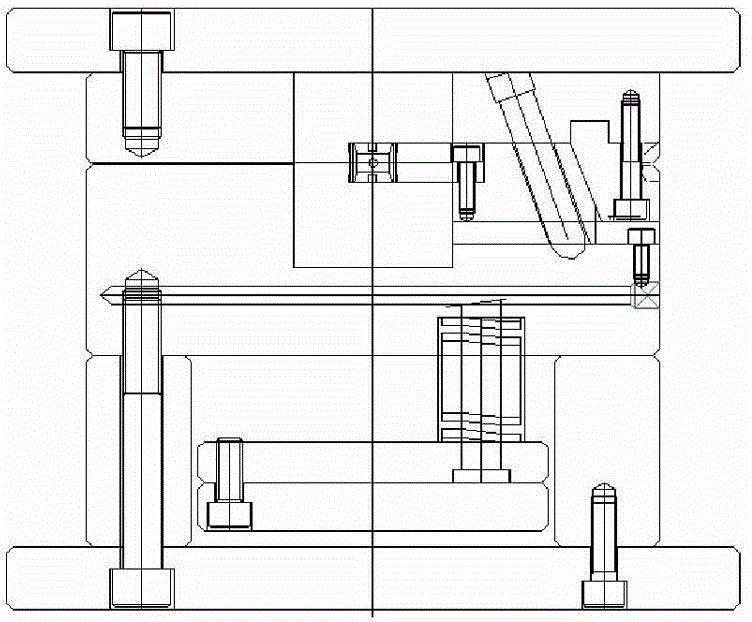

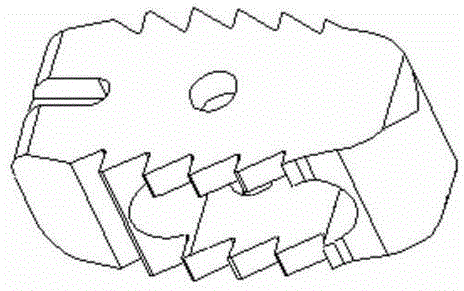

MIM manufacturing process of 17-4 PH linear multiple-cavity reactive fragment shell

ActiveCN110976881ASimple processHigh densityTransportation and packagingMetal-working apparatusPhysical chemistrySS - Stainless steel

The invention provides a MIM manufacturing process of a 17-4 PH linear multiple-cavity reactive fragment shell. The manufacturing process comprises the following steps that (1) gas atomization and water atomization 17-4 PH stainless steel powder are uniformly mixed to form 17-4 PH stainless steel powder; (2), 17-4 PH stainless steel powder and a binding agent are mixed according to the mass ratioof 11-13 : 1 and are mixed and granulated to obtain an injection feeding material; (3), the injection feeding material is heated, the flow state injection feeding material is injected into a mold forcooling and molding to obtain a blank body; (4), the blank body is placed in a degreasing tank to carry out solvent degreasing; and (5), the blank body after degreasing is carried into a vacuum furnace to carry out thermal degreasing and sintering in a protective atmosphere, and the 17-4 PH linear multiple-cavity reactive fragment shell prepared. The MIM manufacturing process of the 17-4 PH linearmultiple-cavity reactive fragment shell is reasonable in process, easy to control, low in cost and high in product density.

Owner:广州赛隆增材制造有限责任公司

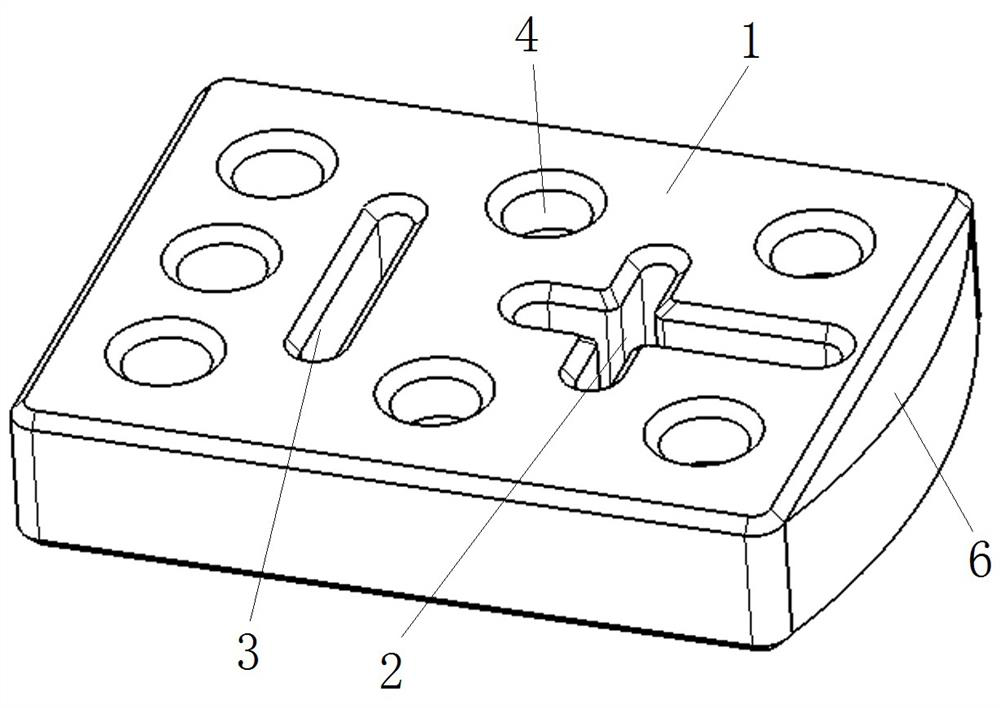

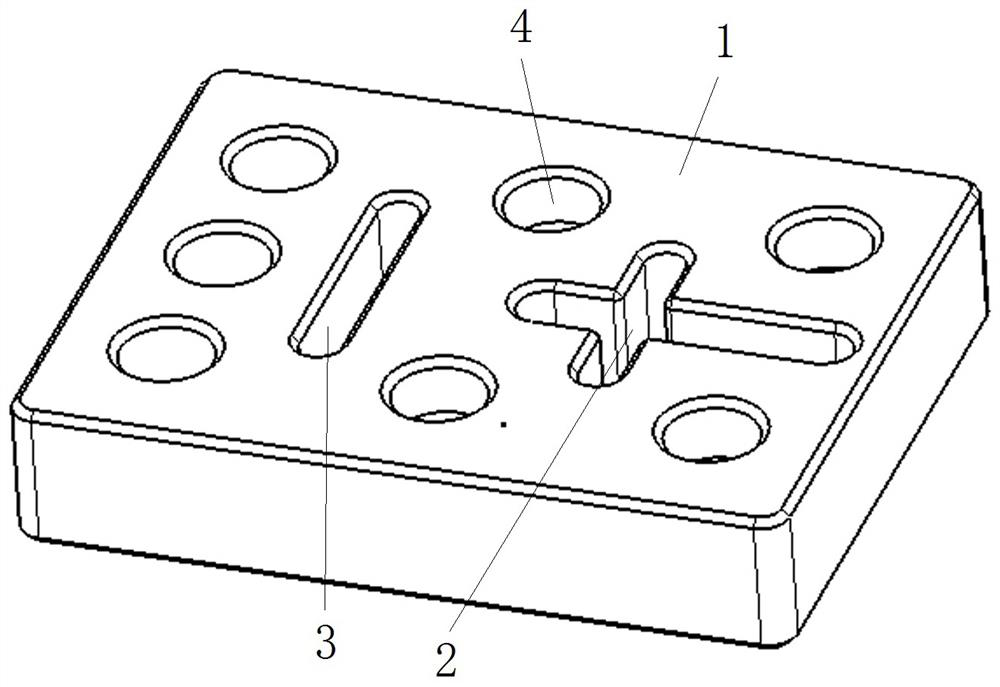

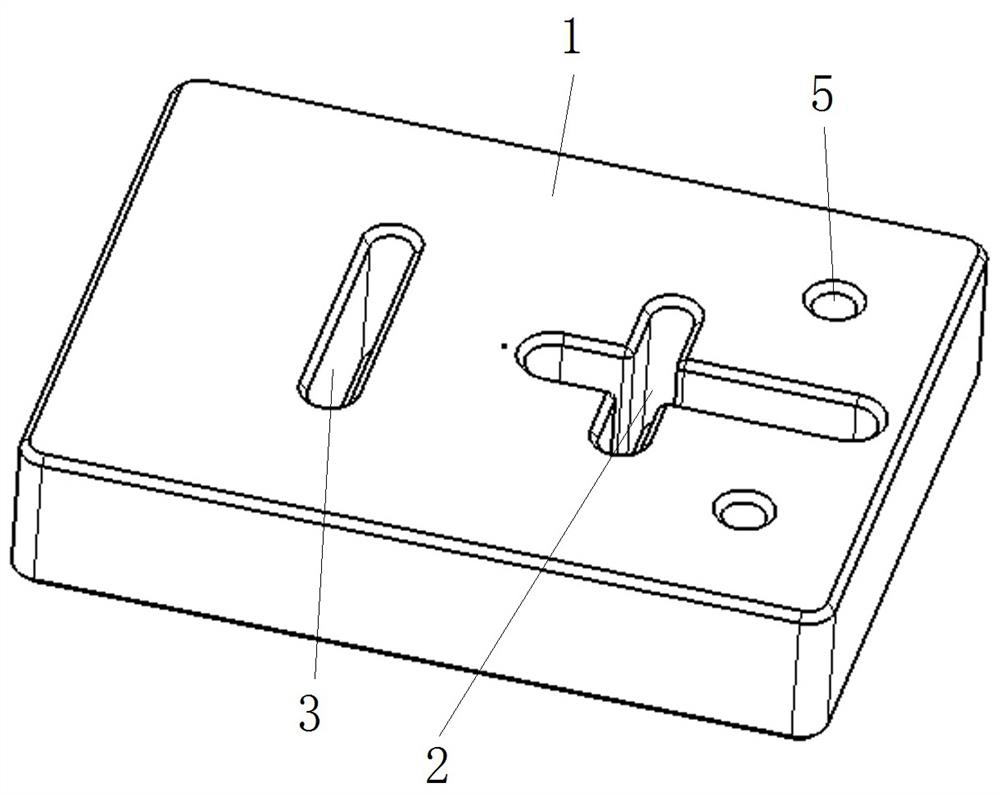

5G communication filter dielectric ceramic piece semi-finished product and forming method thereof

ActiveCN111668579AImprove injection molding defectsImprove defectsAuxillary shaping apparatusWaveguide type devicesDielectricMachining process

The invention relates to a 5G communication filter dielectric ceramic piece semi-finished product and a forming method thereof. The 5G communication filter dielectric ceramic piece semi-finished product comprises a main body, wherein the main body is provided with a cross-shaped through hole and a linear through hole, the cross-shaped through hole is located in the edge of the main body, a first blind hole is formed in the front face of the main body, a second blind hole is formed in the back face of the main body, the main body is provided with an extension part, the extension part is locatedon the side, which is close to the cross-shaped through hole, of the main body, and the extension part is of an arc-shaped structure. The forming method comprises the steps of designing a mold, manufacturing a feed, carrying out injection molding, degreasing with a solvent, carrying out thermal degreasing and sintering. The extension part is added to the thin wall of the main body, one-time injection molding can be achieved, the injection molding defect of the 5G communication filter dielectric ceramic piece is effectively overcome, the product quality is guaranteed, and the yield is increased. In addition, 5G communication filter dielectric ceramic piece semi-finished product is simple in machining process, and suitable for batch production.

Owner:HUIZHOU WEIBO HARDWARE PROD

Method for preparing metal and ceramic composite workpiece

InactiveCN110732673ALower requirementImprove bindingTransportation and packagingMetal-working apparatusCeramic compositeMetal powder

The invention relates to a method for preparing a metal and ceramic composite workpiece. The method comprises the following steps that S1, metal or ceramic is machined into a specific shape to serve as an insert; S2, the insert is pretreated; S3, ceramic powder or metal powder and a binder are mixed to form ceramic feed or metal feed; S4, the metal serves as the insert, the ceramic feed is injected into a mold cavity, and a composite material green body is obtained; or the ceramic serves as the insert, the metal feed is injected into the mold cavity, and a composite material green body is obtained; S5, the composite material green body is subjected to solvent degreasing in a solvent, and a degreased blank is obtained; and S6, the degreased blank is sintered in a reducing atmosphere under the temperature of 1250-1400 DEG C for 2-5h, and finally the metal and ceramic composite workpiece is obtained. According to the method, pressure does not need to be applied from the outside, the composite material green body is prepared through metal injection molding, the wettability between the metal and the ceramic is utilized, the combination of the metal and the ceramic is achieved, the requirement for sintering equipment is not high, and batch production can be achieved.

Owner:CHANGZHOU GIAN TECH +1

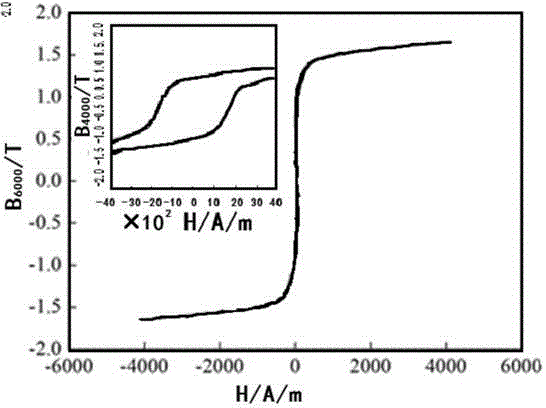

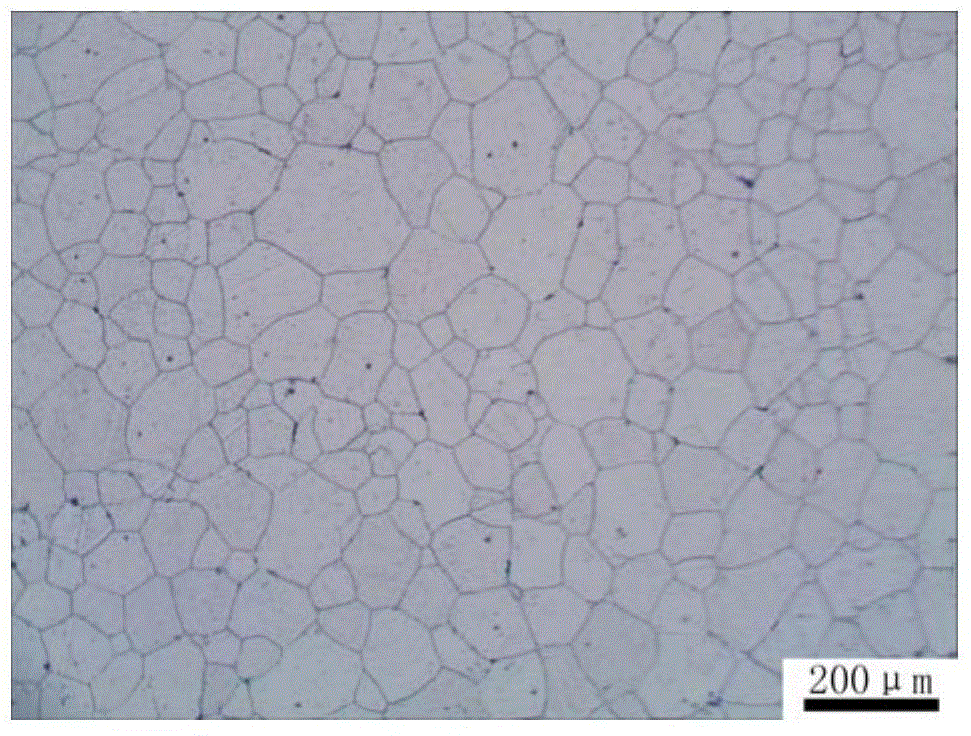

Wire printer yoke iron seat material and yoke iron seat part processing method

ActiveCN104962821ALow costIncrease magnetic inductionInductances/transformers/magnets manufactureMagnetic materialsIron powderDecomposition

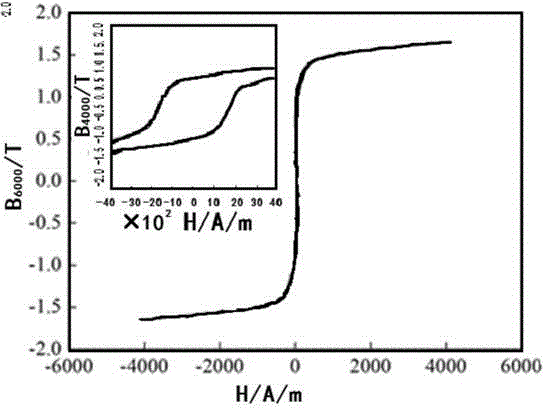

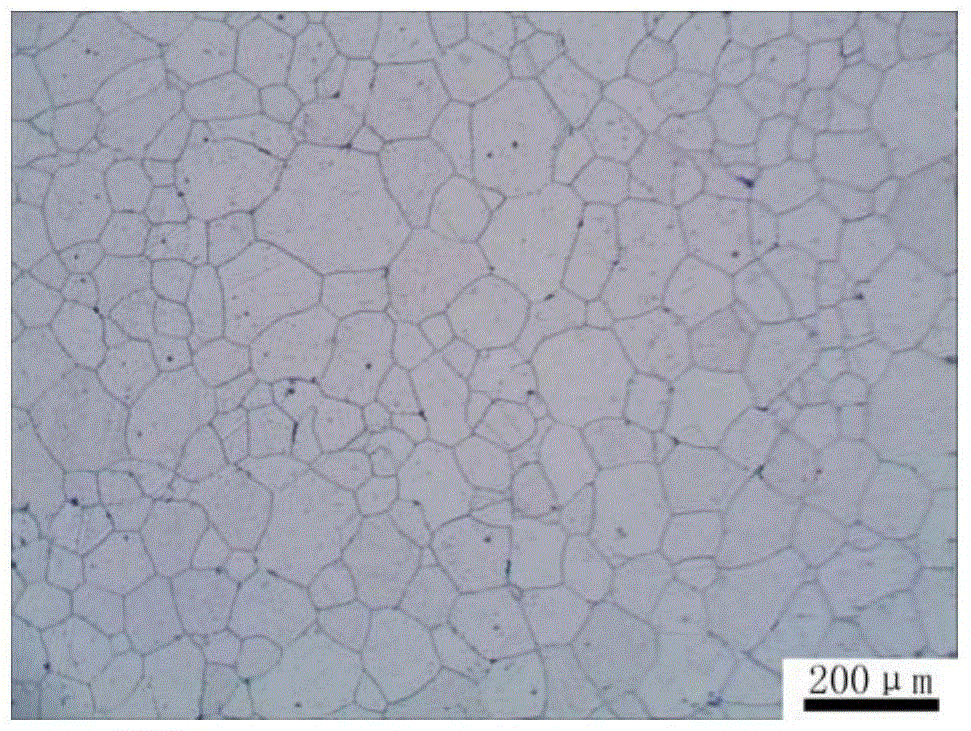

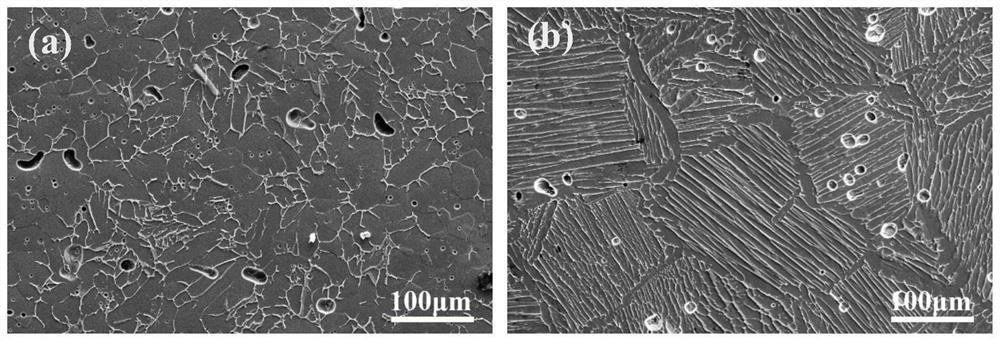

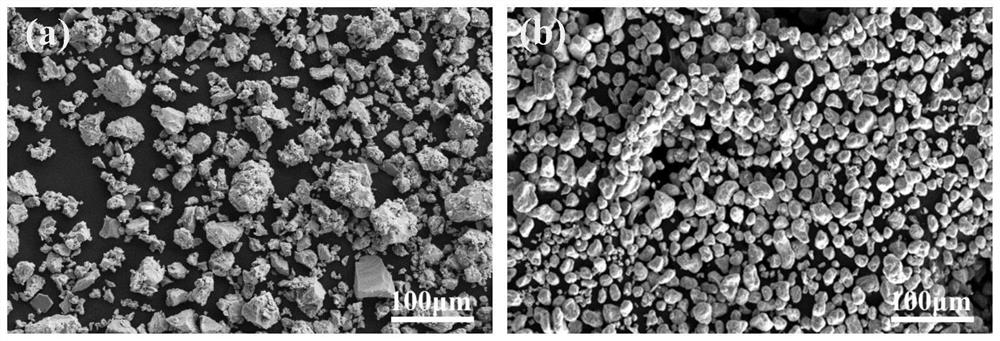

The invention relates to a wire printer yoke iron seat and a processing production method thereof, and belongs to the technical field of production of wire printer iron cores. The method comprises the following steps: mixing carbonyl iron powder, powder obtained by uniformly mixing alloy powders and an appropriate binder at a certain temperature to prepare a uniformly mixed charge with good rheological performances, and carrying out an injection molding technology to prepare a body of a yoke iron seat with a required shape; and removing parts of the binder from injection molded body through a solvent degreasing technology, completely removing the binder from the body through a heating decomposition technology, and sintering the binder removed body at 1200-1500DEG C for 1-10h to obtain the yoke iron seat product. The density of a yoke seat soft-magnetic material prepared in the invention is greater than 98%, the magnetic induction intensity B6000 is 1.6-2.0T, the maximum magnetic conductivity is 8-25mH / m, the coercive force is smaller than 120A / m, the resistivity is greater than 20[mu]omega.cm, and the dimension precision of the product is smaller than + / -0.3%.

Owner:UNIV OF SCI & TECH BEIJING

Manufacturing method for orthopaedics implant odd-shaped part

ActiveCN104959615ARealize mass productionIncrease profitTurbinesOther manufacturing equipments/toolsMetallurgyManufactured material

The invention discloses a manufacturing method for orthopaedics implant odd-shaped parts. The manufacturing method comprises: (1) mixing titanium alloy powders with a binder, heating and mixing, cooling, and pelleting, to obtain a feed material; (2) injecting the feed material to a mould, processing to obtain a green body; (3) performing solvent degreasing and thermal debinding on the green body to obtain a degreased green body; (4) sintering the degreased green body to obtain an orthopaedics implant odd-shaped part. The manufacturing method can realize to form orthopaedics implant odd-shaped parts in complex three-dimensional structure in one time and produce the orthopaedics implant odd-shaped parts in large volume, the odd-shaped parts being high in raw material utilization rate, low in cost, excellent in mechanical property.

Owner:长沙瑞泰医学科技有限公司

Feeding product for injection molding of titanium and titanium alloy and preparation method thereof

The invention relates to a feeding product for injection molding of titanium and titanium alloy. The raw materials of the product are composed of titanium-containing powder and a binder, wherein the titanium-containing powder accounts for 55%-60% of the total volume of the feeding product; the binder accounts for 40%-45% of the total volume of the feeding product; the binder is composed of PEG, PMMA, PVB, EVA, PW and SA; and the binder comprises the following components of, in percentage by mass, 50%-70% of PEG, 5%-10% of PMMA, 15%-25% of PVB, 1%-5% of EVA, 1%-5% of PW and 1%-5% of SA. In the injection molding process of the feeding product, the feed fluidity is good, the strength is high, the solvent degreasing rate is high, an obtained sintered blank is few in defect, good in shape preservation, low in porosity and high in strength, and it is guaranteed that the final product has excellent tissue and mechanical properties.

Owner:湖南省民鑫新材料股份有限公司

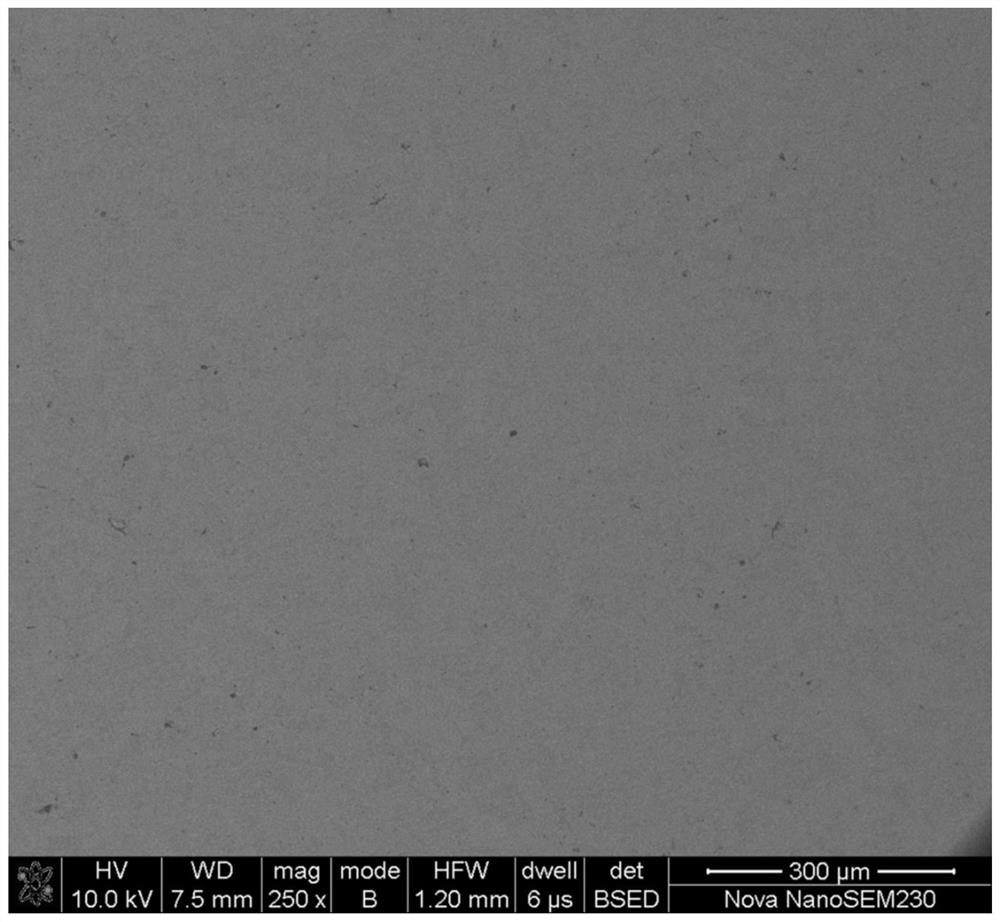

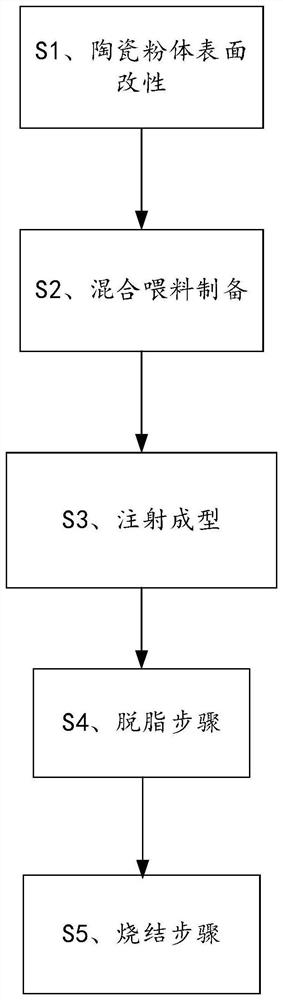

Preparation method of ceramic atomizing core

The invention provides a preparation method of a ceramic atomizing core, which comprises the following steps: S1, surface modification of ceramic powder: mixing the ceramic powder and a surface modifier, performing ball milling pretreatment, and drying to obtain surface modified ceramic powder; S2, mixed feed preparation: mixing an organic adhesive system with the surface modified ceramic powder to obtain the mixed feed; S3, injection molding: specifically, putting the mixed feed into a screw type injection machine, and after injection molding is conducted, obtaining a ceramic atomization core green body; S4, degreasing: performing degreasing treatment on the ceramic atomization core green body by using a solvent to obtain a solvent-degreased green body; and S5, sintering: sintering the solvent-degreased green body by adopting a hot-pressing method to obtain the ceramic atomizing core. According to the preparation method of the ceramic atomizing core, the strength of the ceramic atomizing core can be effectively improved, meanwhile, the ceramic atomizing core has the good oil absorption rate, and the preparation method is simple and efficient.

Owner:SHENZHEN TAOTAO TECH CO LTD

A method for preparing high-performance aluminum alloys using powder injection molding technology

ActiveCN107790729BIncrease profitIncrease productivityTransportation and packagingMetal-working apparatusBinary alloyAl powder

The invention discloses a method for preparing high-performance aluminum alloy by using powder injection molding technology, which belongs to the technical field of powder injection molding. The technological process of the invention is as follows: based on the Al-Cu-Mg-Si alloy system, it contains a small amount of alloy element Sn. Pure aluminum powder is used as the main raw material, and other alloying elements are added in the form of elemental powder or binary alloy powder. The aluminum alloy powder with specific components is mixed and mixed with wax-based binder on a roller mixer, and then prepared into an aluminum alloy green body by injection molding, after solvent degreasing and thermal degreasing, and then in high-purity N 2 Aluminum alloy products are obtained after sintering under atmosphere. By controlling the particle size of the raw material powder, optimizing the binder, adding trace alloy elements, and optimizing the sintering system, the densification and sintering of injection molded aluminum alloys has been realized. The invention provides a low-cost and mass-preparation technology for high-performance and complex-shaped aluminum alloy parts. The density of the prepared aluminum alloy is greater than 98%, and the tensile strength is greater than or equal to 300MPa.

Owner:UNIV OF SCI & TECH BEIJING

Turbine blade for high-performance gasoline engine, and preparation method thereof

ActiveCN112756610AImprove performanceMeeting the Needs of Turbine Blades for High-Performance Gasoline EnginesTurbinesInternal combustion piston enginesAl powderTurbine blade

The invention discloses a turbine blade for a high-performance gasoline engine, and a preparation method thereof. The preparation method comprises the following steps of uniformly mixing HK30 stainless steel powder and Al powder to obtain base materials, mixing and granulating the base materials and binders to obtain a uniform feed; then, injecting the feed into a mold cavity by using an injection molding technology to obtain a product green body; and removing the binders in the green body through solvent degreasing and thermal degreasing processes, and finally sintering and densifying the green body in a plasma sintering furnace to obtain the turbine blade product for the gasoline engine. Compared with the prior art, the preparation method has the advantages of being excellent in comprehensive performance, high in production efficiency, easy achievement of batch production and the like through combination of a Ni3Al dispersion strengthening technology and a spark plasma sintering technology, and the requirements of the turbine blade for the high-performance gasoline engine can be met; and the preparation method is suitable for preparing HK30-based turbine blade products.

Owner:湖南英捷高科技有限责任公司

Injection molding method of high-strength aluminum alloy turbine impeller

ActiveCN107775005AImprove mechanical propertiesImprove liquidityTurbinesTransportation and packagingImpellerHigh intensity

The invention discloses an injection molding method of a high-strength aluminum alloy turbine impeller and belongs to the technical field of preparation of aero-engine turbines. The method comprises raw material preparation, adhesive matching, primary smelting, secondary smelting, injection molding, solvent debinding, thermal debinding, sintering, solid solution treatment and aging treatment. Withthe adoption of the method, the mechanical performance of the turbine impeller alloy is improved substantially through component homogeneity improvement, grain refinement and the like, and the strength can meet the use requirement of the turbine impeller of an aero-engine.

Owner:安徽恒利增材制造科技有限公司

Method for preparing Kovar alloy electronic package box

InactiveCN1180908CHigh densityHigh dimensional accuracySemiconductor/solid-state device detailsSolid-state devicesHigh energyAdditive ingredient

The invention provides a method for preparing a Kovar alloy electronic packaging box body. Mixing iron, nickel and cobalt powder according to weight percentage Fe:Ni:Co=53~55:29~31:16~18, milling with high-energy ball mill for 2-8 hours to obtain alloy composite powder; adding binder to alloy composite powder , mixed into a uniform feed, the powder loading is 55-64%; the feed is injection-molded on the injection machine, the temperature is 150-170°C, and the pressure is 90-110MPa; the injection-molded blank is degreased by solvent degreasing + subsequent thermal degreasing Process, solvent degreasing the injection molding blank in trichlorethylene for 2 to 6 hours, and drying at a temperature of 40 to 60°C for 30 to 60 minutes; thermal degreasing is performed at room temperature to 600°C, and the time is 6 to 8 hours; injection After degreasing the formed body, it is sintered in a sintering furnace at 1250-1280° C. and kept for 1-3 hours. The sintered product is subjected to subsequent treatment to obtain a packaging box. The advantage lies in the high material utilization rate and the high dimensional accuracy of the product.

Owner:苏州创基精密制造有限公司

A processing method for yoke iron seat parts of dot matrix printer

ActiveCN104962821BLow costIncrease magnetic inductionInductances/transformers/magnets manufactureMagnetic materialsDot matrixIron powder

The invention relates to a wire printer yoke iron seat and a processing production method thereof, and belongs to the technical field of production of wire printer iron cores. The method comprises the following steps: mixing carbonyl iron powder, powder obtained by uniformly mixing alloy powders and an appropriate binder at a certain temperature to prepare a uniformly mixed charge with good rheological performances, and carrying out an injection molding technology to prepare a body of a yoke iron seat with a required shape; and removing parts of the binder from injection molded body through a solvent degreasing technology, completely removing the binder from the body through a heating decomposition technology, and sintering the binder removed body at 1200-1500DEG C for 1-10h to obtain the yoke iron seat product. The density of a yoke seat soft-magnetic material prepared in the invention is greater than 98%, the magnetic induction intensity B6000 is 1.6-2.0T, the maximum magnetic conductivity is 8-25mH / m, the coercive force is smaller than 120A / m, the resistivity is greater than 20[mu]omega.cm, and the dimension precision of the product is smaller than + / -0.3%.

Owner:UNIV OF SCI & TECH BEIJING

Ultralow-carbon low-cobalt martensitic steel and preparation method thereof

PendingCN114480943AHigh strengthGrain refinementTransportation and packagingMetal-working apparatusSolvent debindingHeat treating

The preparation method comprises the following steps that low-cobalt martensitic steel stainless steel powder and a binder are subjected to mixing and granulation, feed is obtained, the feed is injected into a mold, an injection green body is obtained, solvent degreasing is conducted to obtain a dissolvable blank, warm isostatic pressing treatment is conducted to obtain a pressed green body, and the pressed green body is subjected to heat treatment to obtain the ultra-low-carbon low-cobalt martensitic steel with the ultra-low-carbon low-cobalt martensitic steel with the ultra-low-carbon low-cobalt martensitic steel. According to the preparation method, two times of degreasing are adopted, after the injection blank is obtained through injection molding, a solvent is adopted for degreasing to remove part of the binder, and then the ultra-low-carbon and low-cobalt martensitic steel is obtained through sintering in a vacuum environment, so that the ultra-low-carbon and low-cobalt martensitic steel is obtained. According to the ultra-low-carbon low-cobalt martensitic steel and the preparation method thereof, the low-carbon low-cobalt martensitic steel is subjected to temperature isostatic pressing treatment under the set technological parameter condition to obtain a green body, the inventor finds that the density of the green body can be greatly improved, and the ultra-low-carbon low-cobalt martensitic steel has high density, fine grains and excellent mechanical properties.

Owner:湖南英捷高科技有限责任公司

Sintering method of high-strength and high-plasticity powder titanium alloy

The invention provides a sintering preparation method of a high-strength and high-plasticity powder titanium alloy, and particularly relates to the field of injection molding. The method comprises the following steps: weighing a certain amount of commercially available hydrogenated and dehydrogenated TC4 titanium alloy powder, and carrying out powder activation modification treatment on the powder by adopting an airflow mill; the treated titanium alloy powder and a binder are subjected to mulling and granulation, and feed is obtained; the feed is subjected to injection molding, and a blank is obtained; the obtained blank is subjected to solvent degreasing and thermal degreasing; and finally, a high-vacuum tungsten wire furnace or a high-vacuum molybdenum wire furnace is adopted for high-vacuum sintering at the highest temperature of 950-1050 DEG C for 10-360 min, furnace cooling is carried out, and a titanium alloy sintered product with the tensile strength larger than 950 MPa and the ductility larger than 15% is obtained. By adopting the method, a high-strength and high-plasticity titanium alloy sintered product can be prepared by sintering under a relatively low-temperature condition.

Owner:UNIV OF SCI & TECH BEIJING

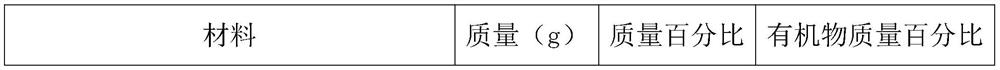

Powder injection molding process

The invention relates to a powder injection molding process. The powder injection molding process is characterized by comprising the following steps: mixing inorganic material powder with mixed organic matters, and extruding and granulating the mixture to form a feed, wherein the organic matters comprise an adhesive, a lubricating dispersant and a coupling agent; feeding the feed into an injection molding machine, and injecting the feed into a mold cavity to form an injection molding blank in a required shape; soaking the injection molding blank into an extraction degreasing solvent for solvent degreasing to remove a part of organic matters, wherein the extraction degreasing solvent is a monoterpene compound; putting the blank without a part of adhesive into a sintering furnace for thermal degreasing and sintering to form a semi-finished product; and performing necessary machining and surface treatment on the semi-finished product to form a final finished product. According to the powder injection molding process, the degreasing rate, sintering density, physical performance and the like of the product meet the requirements, and the powder injection molding process is high in use safety, non-toxic and environment-friendly.

Owner:杭州铭赫科技有限公司

A low-cost powder injection molding process of hydrogenated dehydrogenated titanium powder

The invention relates to titanium alloy molding process, and particularly discloses a powder injection molding process by utilizing low-cost hydrogenated-dehydrogenated titanium powder. The process comprises the following steps: mixing hydrogenated-dehydrogenated titanium powder with alloy element powder, additive powder and an adhesive, mixing and pelletizing to obtain feeds; manufacturing blanks by utilizing an ultrasonic-assisted injection molding method; removing the adhesive in the blanks by utilizing solvent debinding and thermal debinding; finally sintering at high temperature to manufacture finished products. According to the powder injection molding process by utilizing the low-cost hydrogenated-dehydrogenated titanium powder as a raw material, the preparation cost of titanium alloy products is low, and the process is suitable for large-scale industrial production.

Owner:SHENZHEN ELEMENTPLUS MATERIAL TECH CO LTD

A kind of preparation method of rocking block of air conditioner compressor

ActiveCN109277574BLow costHigh tensile strengthTransportation and packagingMetal-working apparatusProcess engineeringSS - Stainless steel

The invention discloses a method for preparing rocking blocks of air-conditioning compressors. The 440C stainless steel powder base material and the binder are mixed and granulated to obtain uniform feeding; and then the feeding is injected into a mold cavity by injection molding technology to obtain The product is green; then the binder in the green body is removed by solvent degreasing and thermal degreasing processes, and sintered and densified, and finally heat-treated to obtain the rocker product of the air conditioner compressor. Compared with the prior art, the air conditioner compressor rocker produced by metal injection molding technology in the present invention has the characteristics of high processing efficiency, high dimensional accuracy, low production cost, and easy production automation, and can produce excellent performance and high quality Stable products, the tensile strength exceeds 850MPa, 60% better than similar products, reaching the international advanced level, and can well meet the needs of customers.

Owner:湖南英捷高科技有限责任公司

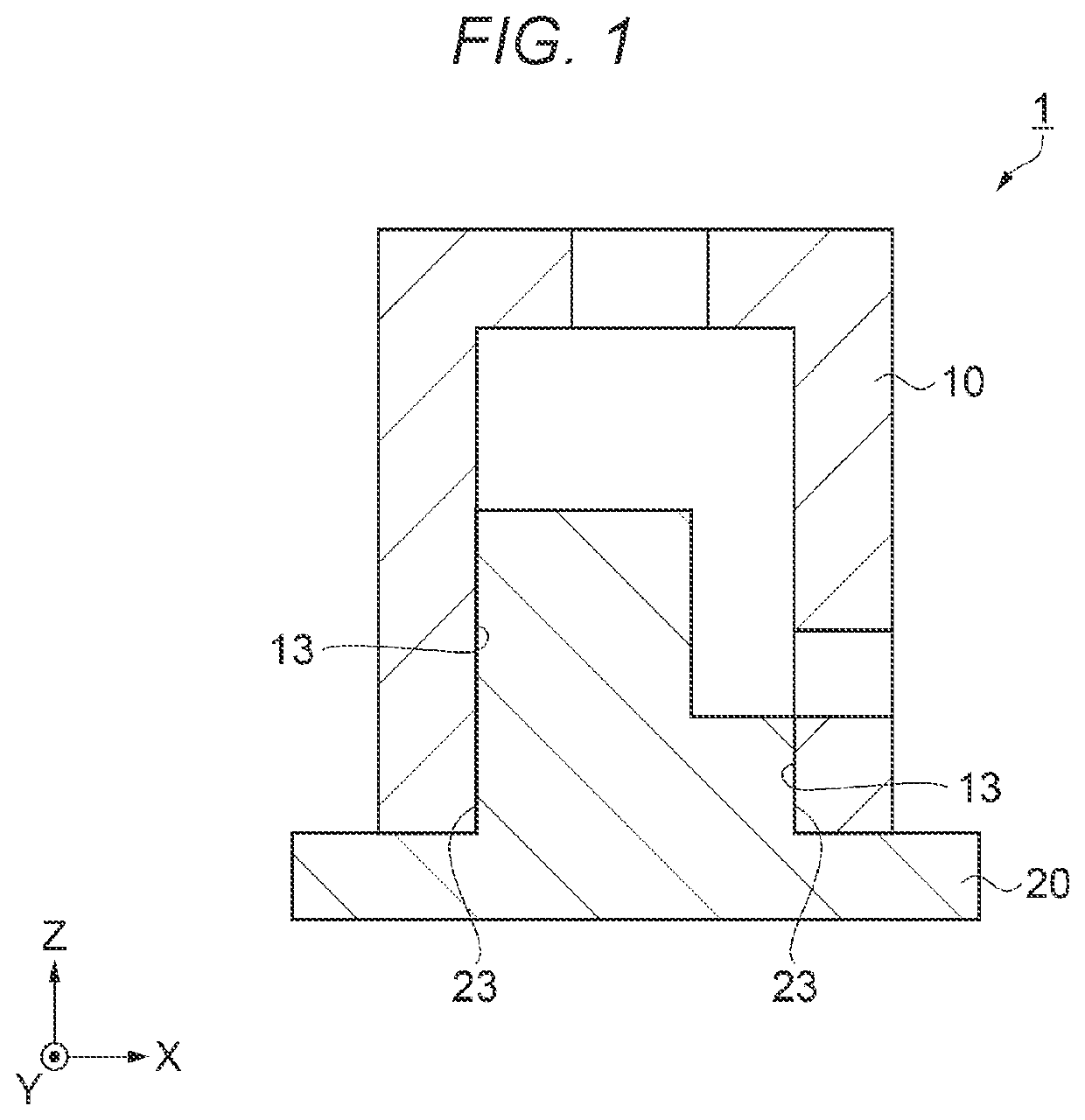

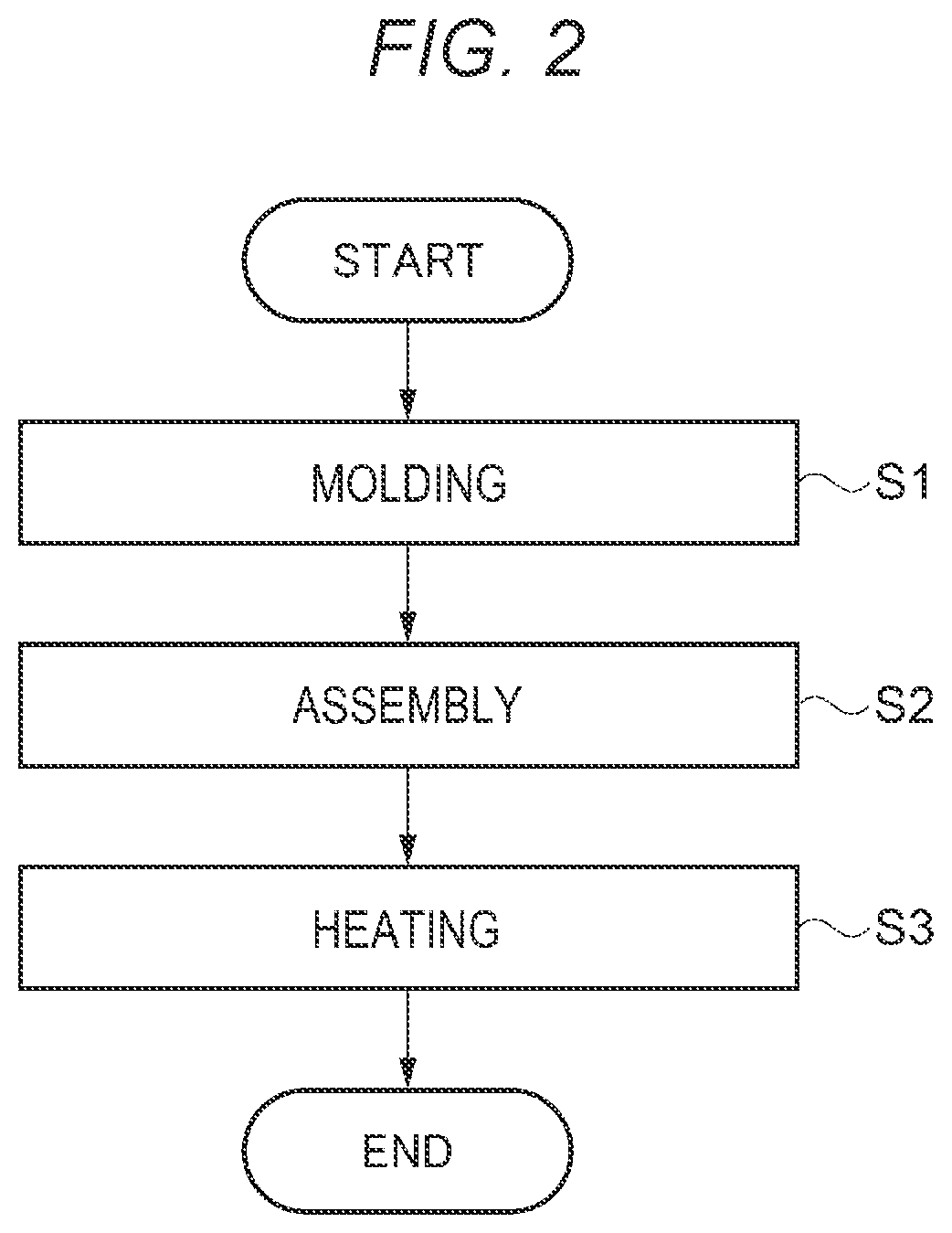

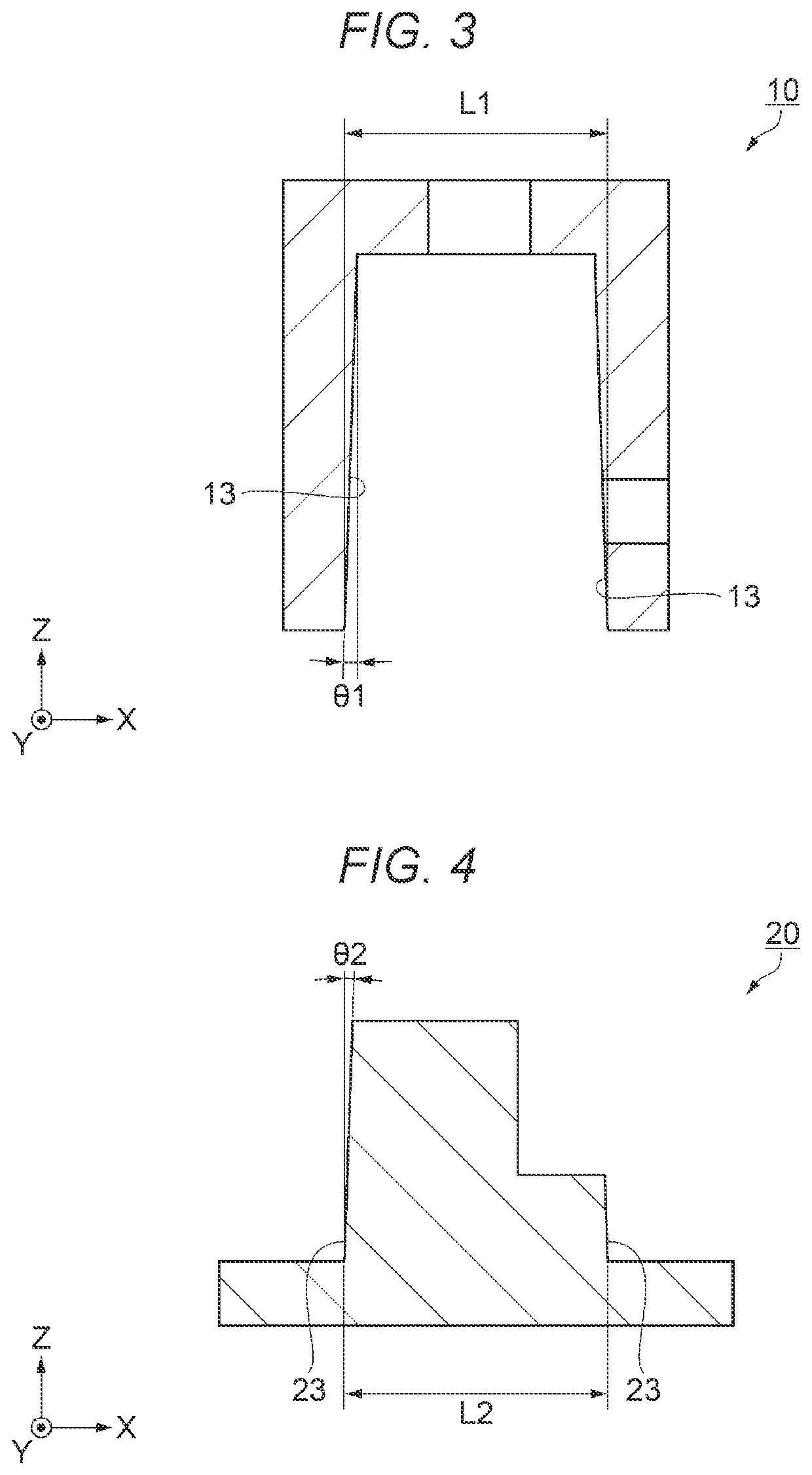

Method For Manufacturing Metal Composite Sintered Body

A method for manufacturing a metal composite sintered body includes: a molding step of injection-molding a first molded product and a second molded product from a kneaded product of a metal powder and a binder; an assembling step of fitting the first molded product to the second molded product without performing a solvent degreasing treatment to form a composite; and a heating step of subjecting the composite to a thermal degreasing treatment and a sintering treatment, in which the first molded product and the second molded product have fitting portions that fit to each other, at least one of the fitting portion of the first molded product and the fitting portion of the second molded product has a tapered shape, in the assembling step, a maximum meshing when the fitting portions are fitted to each other is 0.002 mm or more and 0.010 mm or less, and a content of the binder in the kneaded product is 2 mass % or more and 20 mass % or less with respect to a total amount of the kneaded product.

Owner:SEIKO EPSON CORP

A kind of preparation method of uo2 fuel pellet

ActiveCN109994235BMeet the indicator requirementsHigh surface finishNuclear energy generationReactors manufactureSurface finishFuel cells

The invention belongs to the technical field of nuclear fuel manufacture, and in particular relates to a method for preparing UO2 fuel pellets. The invention comprises the following steps: step 1, preparation of feeding material; step 2, injection molding process; step 3, solvent degreasing; step 4, degreasing and sintering. The invention can realize high-efficiency near-net shape of fuel pellets, reduce cost, obtain uniform density, high dimensional accuracy and high surface finish, and be flexibly applied in new fuel design research.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com