Method For Manufacturing Metal Composite Sintered Body

a metal composite and body technology, applied in the field of metal composite sintered body manufacturing, can solve the problems of reducing workability, difficult to improve the quality of metal composite sintered body, and difficult to handle and reduce workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiments

1. Configuration of Metal Composite Sintered Body

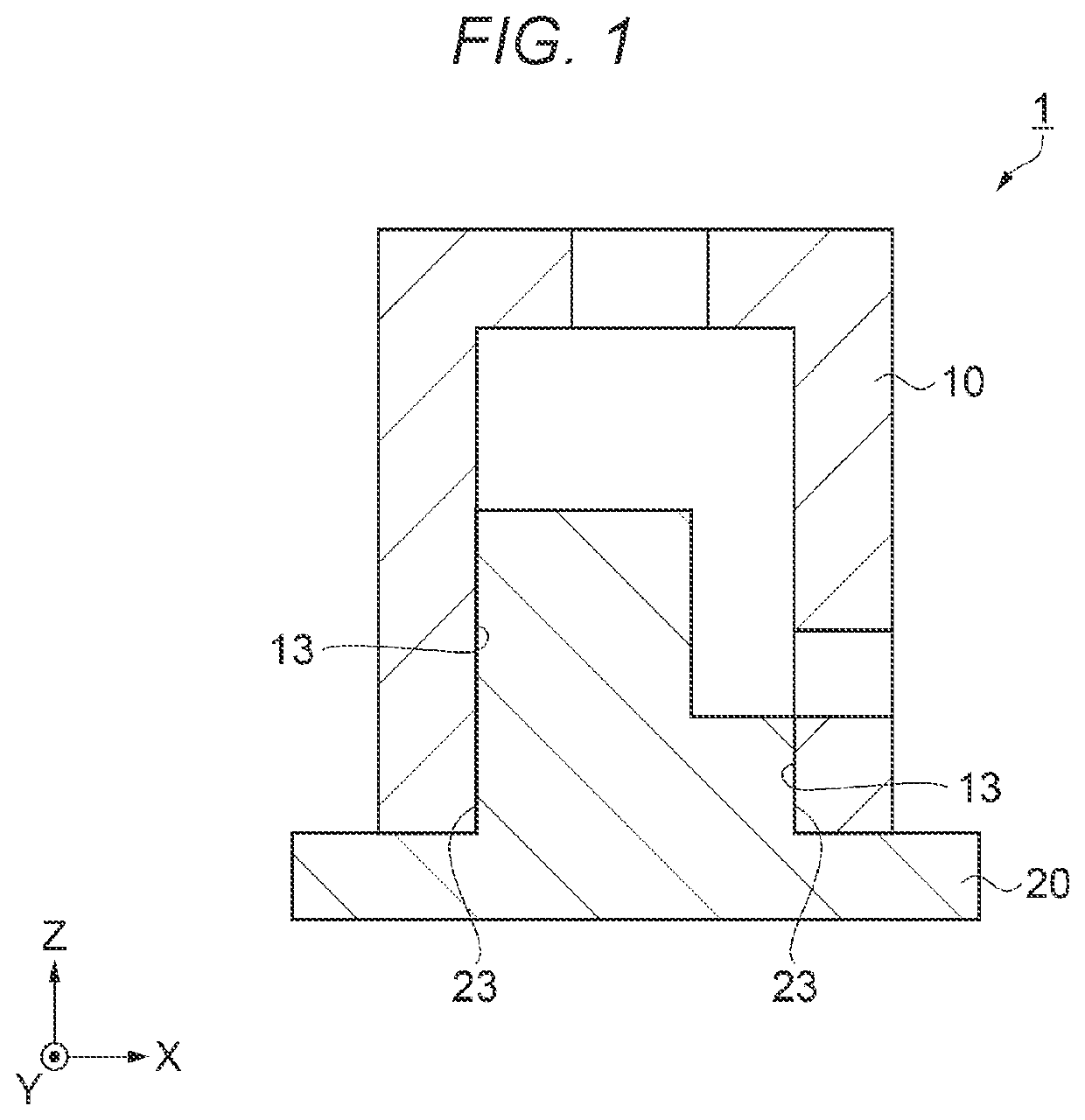

[0011]In the present embodiment, a metal composite sintered body 1 formed of two members, a first molded product and a second molded product, is illustrated. The metal composite sintered body according to the present disclosure is not limited to being formed of two members, and may be formed of three or more members. A shape of the metal composite sintered body according to the present disclosure is not limited to shapes illustrated below. Hereinafter, a configuration of the metal composite sintered body 1 according to the embodiment will be described with reference to FIG. 1.

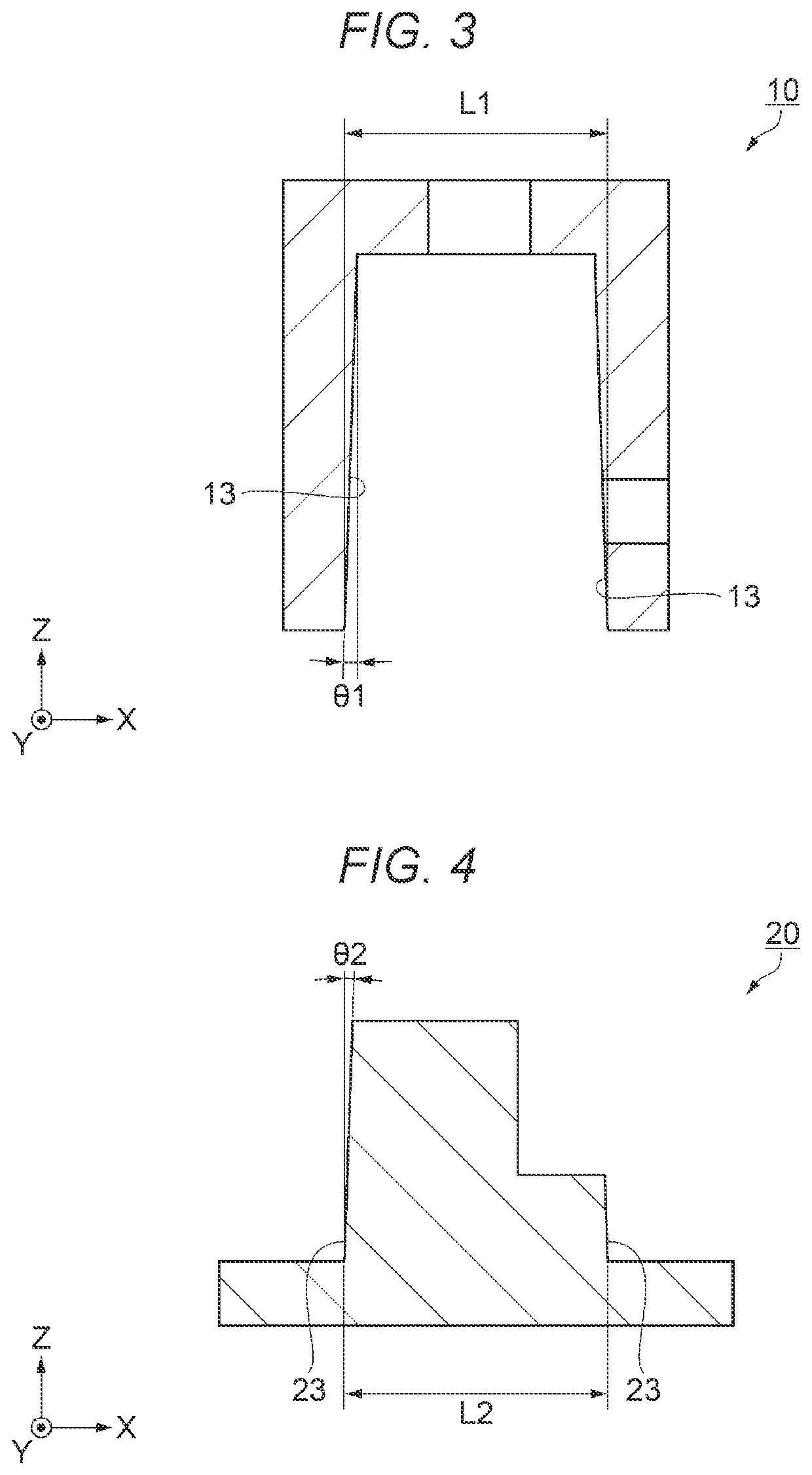

[0012]As shown in FIG. 1, the metal composite sintered body 1 is formed by combining a first molded product 10 and a second molded product 20. The first molded product 10 has a substantially circular cylindrical shape in a plan, and has openings at a lower side, an upper side, and a side surface. The second molded product 20 is formed to have a flat lower side an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com