Turbine blade for high-performance gasoline engine, and preparation method thereof

A technology for turbine blades and gasoline engines, which is applied in the direction of turbines, mechanical equipment, blade support components, etc., can solve the problems of HK30 turbine blades such as large gap in high temperature performance, low production efficiency, and long preparation time, and achieve simple procedures and high production efficiency , The effect of shortening the holding time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A kind of preparation method of turbine blade for high-performance gasoline engine, its process is as follows:

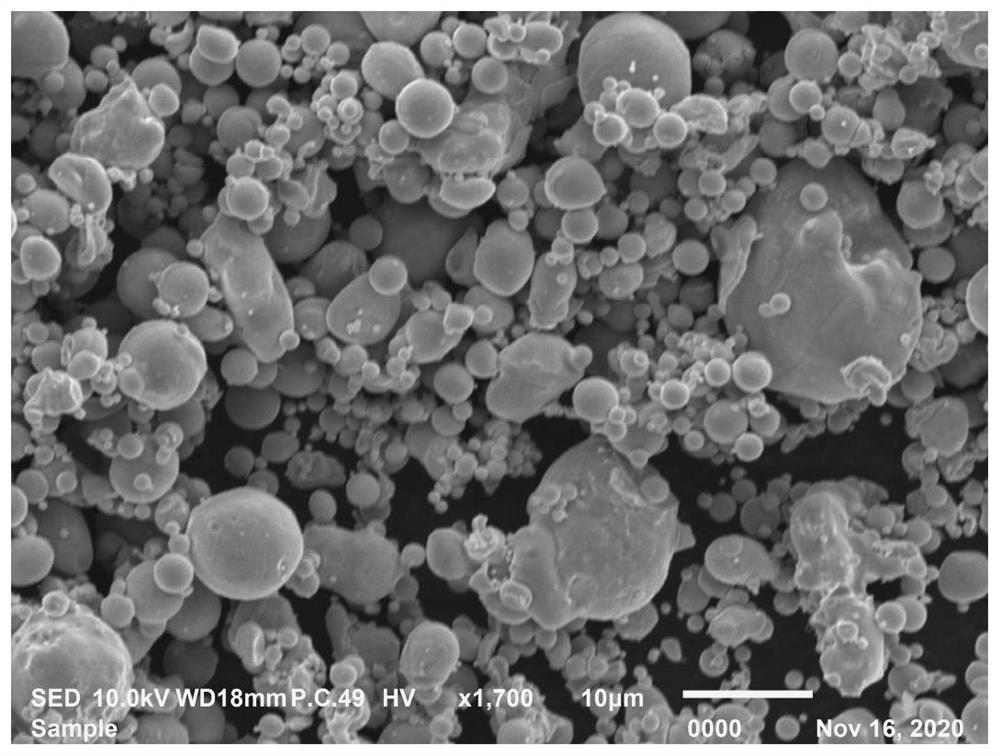

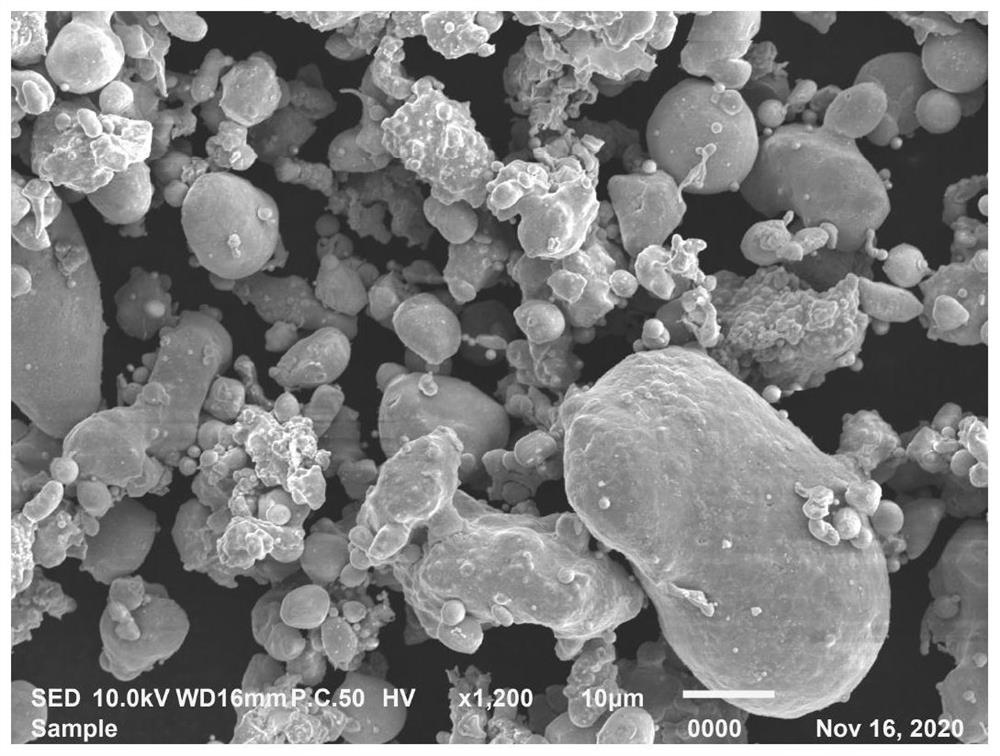

[0047] A. Raw material preparation: the matrix material is mixed with HK30 stainless steel powder with an average particle size of 8 μm and Al powder with an average particle size of 15 μm. The content of Al powder accounts for 0.8% of the total amount of the matrix material. figure 1 and figure 2 SEM images of HK30 stainless steel powder and Al powder respectively;

[0048] B. Preparation of binder: by mass percentage, take 75% of paraffin wax (PW), 17% of polyethylene (PE), and 8% of stearic acid (SA), and mix them in a mixer for 4 hours at a temperature of 120°C. binder;

[0049] C. Preparation of feeding material: mixing and granulating the binder and the base material according to the volume ratio of 43%:57% to make the feeding material. The mixing temperature is 120°C, and the speed of the mixer is 85r / min. The time is 4h;

[0050] D. Injection mol...

Embodiment 2

[0054] A kind of preparation method of turbine blade for high-performance gasoline engine, its process is as follows:

[0055] A. Raw material preparation: the matrix material is mixed with HK30 stainless steel powder with an average particle size of 8 μm and Al powder with an average particle size of 15 μm, and the content of Al powder accounts for 1% of the total amount of the matrix material. figure 1 and figure 2 SEM images of HK30 stainless steel powder and Al powder respectively;

[0056] B. Preparation of binder: by mass percentage, take 80% of paraffin wax (PW), 15% of polyethylene (PE), and 5% of stearic acid (SA), and mix them in a mixer for 2 hours at a temperature of 150°C. binder;

[0057] C. Preparation of feeding material: mixing and granulating the binder and base material according to the volume ratio of 45%:55% to make feeding material. The mixing temperature is 150°C, and the speed of the mixer is 90r / min. The time is 2h;

[0058] D. Injection molding: ...

Embodiment 3

[0062] A kind of preparation method of turbine blade for high-performance gasoline engine, its process is as follows:

[0063] A. Raw material preparation: the matrix material is mixed with HK30 stainless steel powder with an average particle size of 8 μm and Al powder with an average particle size of 15 μm. The content of Al powder accounts for 1.2% of the total amount of the matrix material. figure 1 and figure 2 SEM images of HK30 stainless steel powder and Al powder respectively;

[0064] B. Preparation of binder: according to the mass percentage, take 85% of paraffin wax (PW), 13% of polyethylene (PE), and 2% of stearic acid (SA), and mix them in a mixer for 1 hour at a temperature of 180°C. binder;

[0065] C. Preparation of feeding material: mixing and granulating the binder and base material according to the volume ratio of 40%:60% to make feeding material. The mixing temperature is 180°C, and the speed of the mixer is 100r / min. The time is 1h;

[0066] D. Injecti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com