Sintering method of high-strength and high-plasticity powder titanium alloy

A sintering method and titanium alloy technology, applied in the fields of injection molding and powder metallurgy, can solve the effective regulation of the structure and properties of difficult titanium and titanium alloy parts, the price of high-quality titanium alloy powder remains high, and the performance and cost cannot be balanced. and other problems, to achieve the effect of fine grains, good plasticity and low oxygen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

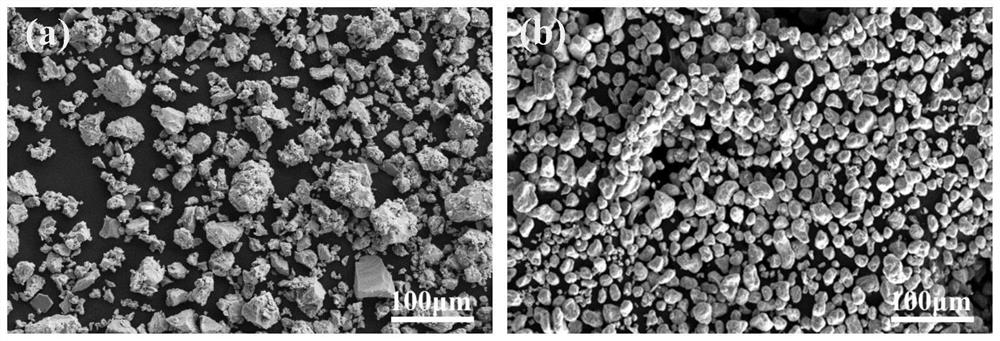

[0030] 1. The raw material powder is a commercially available gas-atomized TC4 powder with a median diameter of 12.7 μm. Weigh 1000 g of the alloy powder and the wax-based binder into an internal mixer according to a volume ratio of 65:35. Mixing and granulating at a speed of 30r / min for 90min to obtain injection molding feed;

[0031] 2. Use an injection molding machine to inject the above feed into the mold to make a stretch rod blank;

[0032] 3. Immerse the stretch rod blank in hexane at a temperature of 50°C and a immersion time of 1440min;

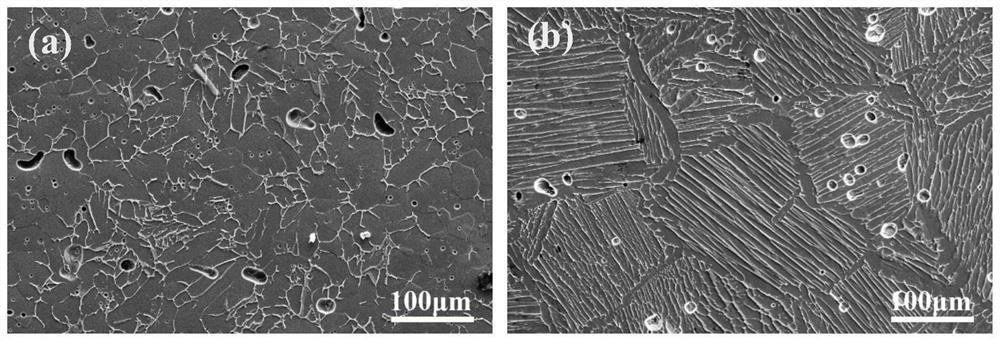

[0033] 4. Put the stretched rod after solvent degreasing into a high vacuum molybdenum wire furnace, and after thermal degreasing, the temperature is raised to 1050 °C at a heating rate of 2 °C / min and vacuum sintered for 120 min to obtain a TC4 titanium alloy stretched rod;

[0034] 5. The mechanical properties of the produced TC4 titanium alloy tensile rod are tested, and the results show that the density is 97.1%, the tensile str...

Embodiment 2

[0036] 1. The raw material powder is a commercially available hydrodehydrogenation TC4 powder with a median diameter of 20.1 μm. Weigh 1000 g of the powder, place the powder in the grinding chamber of the jet mill, fill it with high-purity argon as the protective gas and grind the gas, and the air pressure is 0.8MPa, after 10min treatment, the treated titanium alloy powder was collected.

[0037] 2. Load the treated alloy powder and the wax-based binder into an internal mixer according to a volume ratio of 65:35, mix at a speed of 30r / min at 160°C for 90min and granulate to obtain an injection molding feed;

[0038] 3. Use an injection molding machine to inject the above feed into the mold to make a stretch rod blank;

[0039] 4. Immerse the stretch rod blank in trichloroethylene at a temperature of 40°C and a soaking time of 720min;

[0040] 5. Put the stretched rod after solvent degreasing into a high vacuum molybdenum wire furnace, and after thermal degreasing, the tempera...

Embodiment 3

[0043] 1. The raw material powder is a commercially available gas-atomized TC4 powder with a median diameter of 20.1 μm. Weigh 1000 g of the alloy powder and the wax-based binder into an internal mixer at a volume ratio of 65:35. Mixing and granulating at a speed of 30r / min for 90min to obtain injection molding feed;

[0044] 2. Use an injection molding machine to inject the above feed into the mold to make a stretch rod blank;

[0045] 3. Immerse the stretch rod blank in hexane at a temperature of 70°C for 12 hours;

[0046] 4. Put the stretch rod after solvent degreasing into a high vacuum tungsten wire furnace, and after thermal degreasing, the temperature is raised to 1050 °C at a heating rate of 2 °C / min and vacuum sintered for 120 min to obtain a TC4 titanium alloy stretched rod;

[0047] 5. The mechanical properties of the produced TC4 titanium alloy tensile rod were tested, and the results showed that the density was 99.6%, the tensile strength was 1079MPa, the yield ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com