Method for extracting aluminium oxide from coal ash and producing cement by using waste slag

A technology of alumina and fly ash, which is applied in the field of reducing environmental pollution of pulverized coal furnaces and comprehensive utilization of fly ash, and extracting aluminum hydroxide or alumina, which can solve the problems of difficult control of cement quality, high cost, and large investment. Achieve the effect of realizing low cost and high added value, reducing the content of sulfur dioxide, and reducing the degree of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

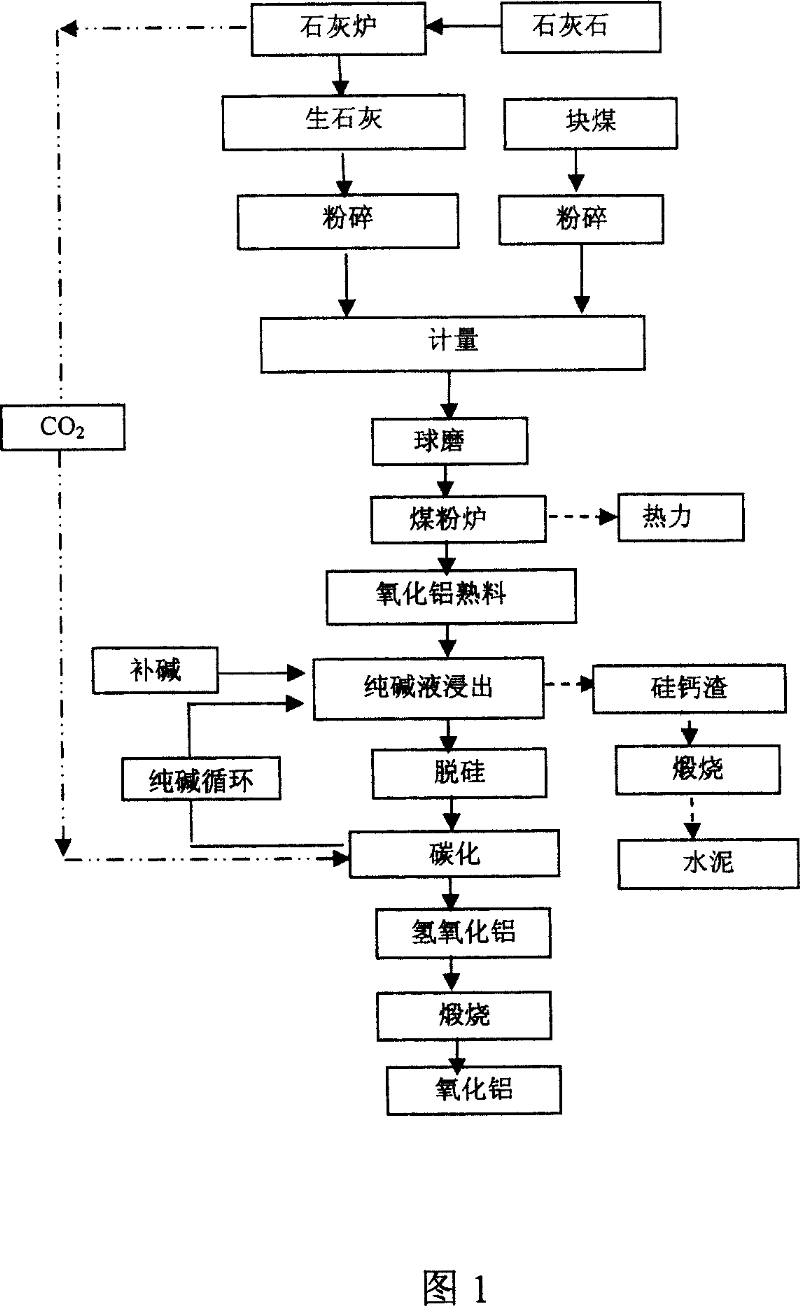

[0036] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0037]Alumina clinker is obtained by using one furnace for dual purposes. One furnace refers to the pulverized coal thermal boiler, and the dual purpose refers to the pulverized coal boiler producing heat and alumina clinker at the same time. The steam is delivered to heat users. The outstanding progress is that according to the ash content and chemical composition of the coal powder, calcareous raw materials and mineralizers are added to the coal, so that the chemical composition of the alumina clinker obtained after the coal blending mixture is burned (Molar ratio) is: CaO / Al 2 o 3 =0.9-1.1, CaO / SiO 2 =1.6-2.2; the consumption of mineralizer is 0-2% (percentage by weight) of calcareous raw material, this coal blending mixture is fully mixed and ground, and its powder particle size should reach less than 100 μ m, this blending The coal mixture powder is sprayed in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com