Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

114results about How to "Reduce decarbonization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Direct steelmaking process by using fine ores, coal and oxygen

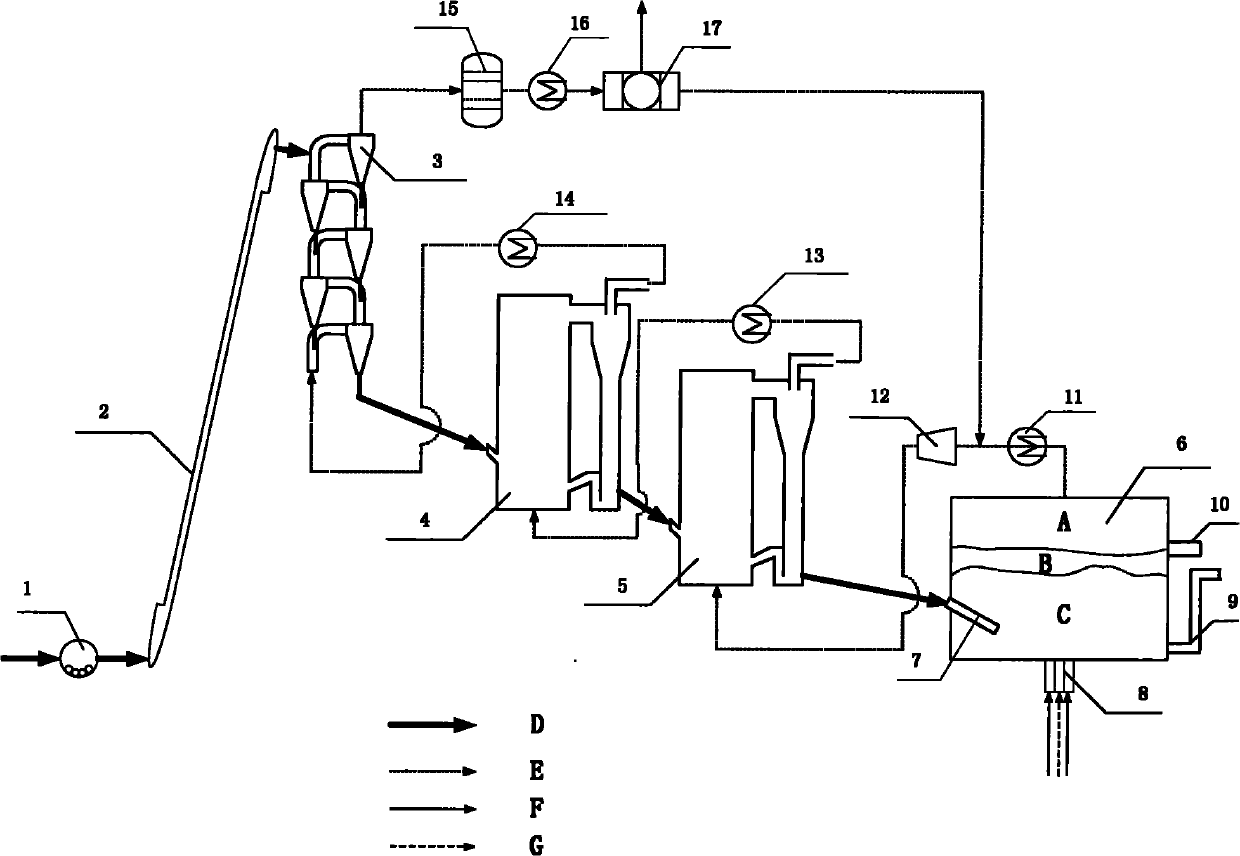

The invention discloses a direct steelmaking process by using fine ores, coal and oxygen. Coal dust and oxygen are blown into a high-temperature melt to produce reducing gas; by utilizing the advantages of gas phase suspension preheating of fine iron ore and high speed and high efficiency of gas phase reduction, the fine iron ore is preheated and reduced respectively in a cyclonic preheater and a recirculating fluidized bed; and the obtained pre-reduced fine iron ore with the metallization rate of over 90 percent is blown into the high-temperature melt to form molten steel. Due to the reduction at lower temperature, the generated pre-reduced fine iron ore achieves less carburization, and less decarbonization is achieved when the finished product molten steel is obtained. The direct steelmaking process simplifies the steelmaking production flow essentially. The direct steelmaking process has the advantages of high productivity, low energy consumption for each ton of steel, equipment and capital investment conservation, full simplification of physical distribution, no temperature loss in the molten iron transporting process, and easy implementation of production continuity and automatic control.

Owner:LAIWU IRON & STEEL GRP

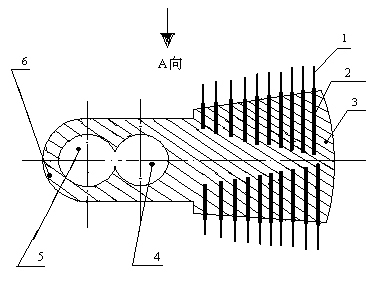

Wear-resistant hammer head of hammer crusher with movable installation position and manufacturing method thereof

InactiveCN101920216AExtended service lifeSimple processFoundry mouldsFoundry coresManganeseStructural engineering

The invention discloses a wear-resistant hammer head of a hammer crusher with movable installation position and a manufacturing method thereof. The hammer head is manufactured by super-high manganese as raw material by lost foam casting. The hammer head comprises an end part (3) and a handle part (6); hard alloy bars (2) are cast in the two working surfaces of the end part (3) of the hammer head; and an first installation hole (4) and an second installation hole two (5) are formed on the handle part (6) of the hammer head at a distance. The hammer head has good strength and toughness and high hardness and wear resistance and is applicable to the crusher hammer head with single magnitude between 500 and 700 N. When a certain length of the end part of the hammer head is worn, the installation position is moved and the hammer head can be continuously used, being equivalent to replace a new hammer head, so that the purpose of prolonging the service life of the hammer head is fulfilled.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

Method for decreasing decarburized layers on surfaces of high-carbon-chromium bearing steel wires

The invention relates to a method for decreasing decarburized layers on surfaces of high-carbon-chromium bearing steel wires. The specific process comprises the steps that steel is molten to obtain molten steel which is subjected to continuous casting to form bearing steel, the bearing steel is subjected to continuous casting to form a bloom, and the bloom is rolled into square hot rolling billet with the section being 160mm*160mm; the surface of the square hot rolling billet is ground, and the grinding amount is 0.5-2mm; the square hot rolling billet is heated in a heating furnace, micro positive pressure control is adopted in the furnace, the pressure in the furnace is 5-40 Pa, the weak oxidizing atmosphere is adopted in the furnace, and the air-fuel ratio is adjusted to enable the oxygen remaining volume in the furnace to be 0-2%; and the spinning temperature is controlled to be 800-850 DEG C, cooling is performed at the rate of 5-10 DEG C / s after spinning to reduce the temperature to 500-600 DEG C, and then slow cooling is performed to obtain hot-rolled wire rods. According to the bearing steel wires obtained through the method, the surfaces are free of fully decarburized layers, and the depth of half decarburized layers is smaller than 50 microns; meanwhile, good component uniformity and internal structure uniformity are achieved, and the product quality requirement of downstream customers can be met; besides, the surface grinding amount of the downstream customers can be reduced, the cost is lowered, and a certain competitive advantage is provided.

Owner:XINGTAI IRON & STEEL

Natural mineral-based high-temperature anti-oxidation decarbonization coating

InactiveCN102786822AGood dispersionImprove high temperature resistanceCoatingsPhysical chemistrySlurry

Owner:NANJING UNIV OF INFORMATION SCI & TECH

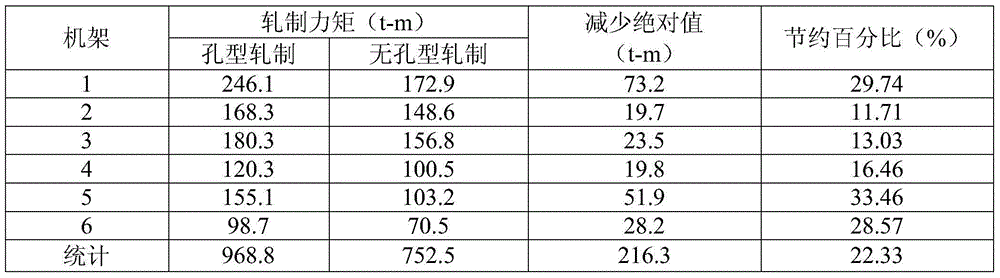

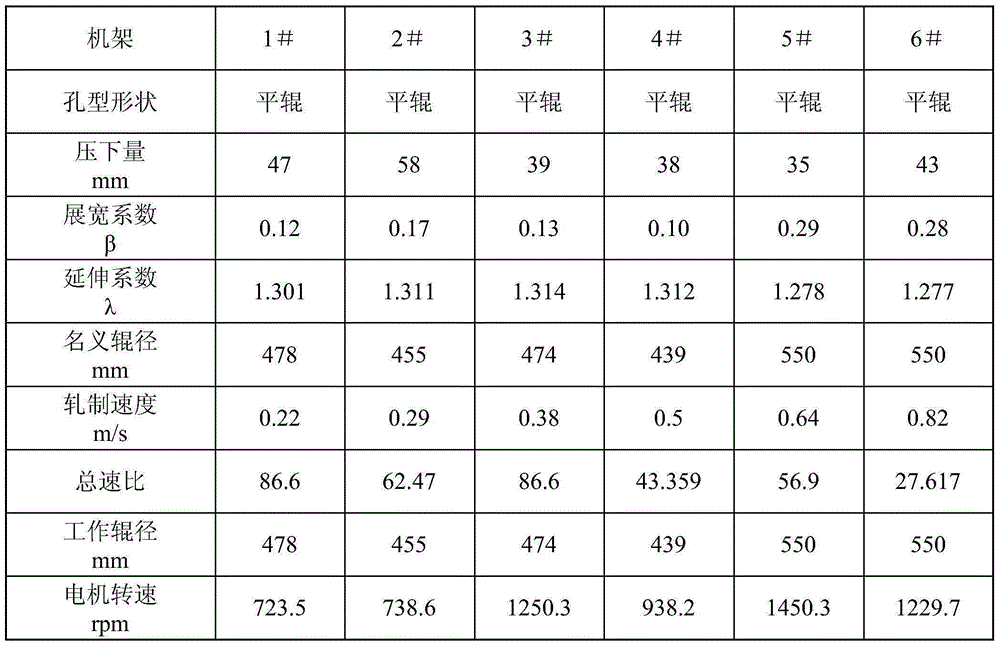

Production process for grooveless rolling of 82B wire rod by high-speed wire mill

ActiveCN104084421ASharedReduce reservesWork treatment devicesMetal rolling arrangementsWire rodEconomic benefits

The invention belongs to the technical field of rod wire deformation processes in metallurgical industry and particularly relates to a production process for grooveless rolling of an 82B wire rod by a high-speed wire mill. The production process aims that special equipment is not required, the processing cost is low, industrialized production is easy to realize, the steel off-square problem of a grooveless rolling production process is solved, the production accident rate is greatly reduced, the product quality is improved, and the economic benefit is increased. The production process adopts the technical scheme as follows: the production process comprises the following steps: (1) heating a 82B steel billet; (2) rolling by a grooveless flat-roll rough rolling unit, wherein in the rolling process, the extension coefficient of each pass is controlled from 1.20 to 1.45, the broadening coefficient ranges from 0.10 to 0.65, and the running speed of the steel billet ranges from 0.20 m / s to 1.04 m / s; (3) entering an intermediate rolling unit and a pre-finishing unit in sequence for rolling; (4) rolling by a finishing unit; (5) cooling by water and entering a wire-feeding machine to obtain the wire rod; (6) cooling by air, winding and transporting, and finally packaging and warehousing to obtain the finished high-speed 82B wire rod.

Owner:西安盛日机电科技有限公司

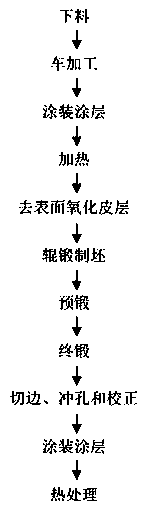

Large-scale locomotive connecting rod forging technology

ActiveCN104057263AReduce depthGuarantee the quality of raw materialsShaping toolsRailway componentsPunchingSurface oxidation

The invention discloses a large-scale locomotive connecting rod forging technology which comprises the steps of blanking, lathing, anti-decarburization coating application, blank heating, surface oxidation layer removal, roll forging of blanks, pre-forging, finish forging, trimming, punching and calibration, anti-decarburization coating application and heat treatment. According to the large-scale locomotive connecting rod forging technology, forming can be achieved through one time of heating only. Compared with the traditional technology that heating needs to be conducted twice or more, the technology has the advantages that surface oxidation and decarburization of a connecting rod are effectively reduced, the mechanical performance of the connecting rod is guaranteed, and time and energy resources are saved. Due to the adoption of roll forging of blanks, speed is high, labor is saved, the consistency of manufactured blanks is high, and time and labor are saved during forging in later periods. Due to the fact that high-temperature-resistant and oxidation-resistant anti-decarburization coating application is conducted twice during the whole technology, the decarburized layer on the surface of a final forged piece is thinner than 0.3 mm, and product quality is improved effectively. Due to the fact that the connecting rod forged piece is vertically hoisted for heat treatment, bending deformation of the forged piece is effectively prevented during heat treatment.

Owner:SICHUAN HAOTE JINGGONG EQUIP CO LTD

Hardening and tempering technology of alloy-steel tube

ActiveCN102676780AStress reliefUniform internal organizationFurnace typesHeat treatment furnacesHydraulic cylinderFree cooling

The invention discloses a hardening and tempering technology of an alloy-steel tube, and through the technology, the hardened and tempered alloy-steel tube is high in intensity and hardness, has good abrasion resistance and high plasticity, bears great pressure, and has small deformation and less decarburization. The technology comprises the following steps of: (1) annealing treatment: warming to 870-880 DEG C at the speed of 20-25 DEG C / minute, keeping the temperature for 35-40 minutes, and then cooling to 500 DEG C below; (2) quenching treatment: warming to 930-935 DEG C at the speed of 5-10 DEG C / minute, keeping the temperature for 50-60 minutes, then cooling rapidly at the speed of 190-200 DEG C / second to 320-325 DEG C, and cooling naturally to 30-40 DEG C; and (3) tempering treatment: warming to 500-510 DEG C at the speed of 5-10 DEG C / minute, then keeping the temperature for 230-240 minutes, and then cooling naturally to room temperature, thus the hardened and tempered alloy-steel tube is high in intensity and hardness, has good abrasion resistance and high plasticity, bears great pressure, and has small deformation and less decarburization. The hardening and tempering technology of the alloy-steel tube provided by the invention is mainly applied to the hardening and tempering of the alloy-steel tube for a hydraulic cylinder barrel.

Manufacturing method for medium-carbon cold forging steel rods and wires

ActiveCN103966411ASame nodularitySame hardnessTemperature control deviceMetal rolling arrangementsHardnessSteel ball

The invention relates to a manufacturing method for medium-carbon cold forging steel rods and wires. The method comprises the following steps: low temperature rolling with a finish rolling temperature of 700 to 750 DEG C; rapid air cooling after rolling through cooling to 450 to 550 DEG C at a speed of no less than 0.5 DEG C / s; rapid induction heating pretreatment through heating to 730 to 750 DEG C at a speed of 5 to 15 DEG C / s and heat preservation for 2 to 3 min; and spheroidizing annealing heat treatment through heating to 760 to 780 DEG C with a furnace, heat preservation for 60 to 80 min, cooling to 680 to 710 DEG C, heat preservation for 80 to 120 min and air cooling out of the furnace. With the method provided by the invention, spheroidizing annealing heat treatment time for medium-carbon cold forging steel balls is substantially shortened by more than 50%, and heat treatment efficiency is greatly improved; obtained medium-carbon cold forging steel has at least a same balling rate and same hardness and cold forging performance compared with current medium-carbon cold forging steel annealed for a long time, and high requirements on cold forging steel in the fastener industry are satisfied.

Owner:BAOSHAN IRON & STEEL CO LTD

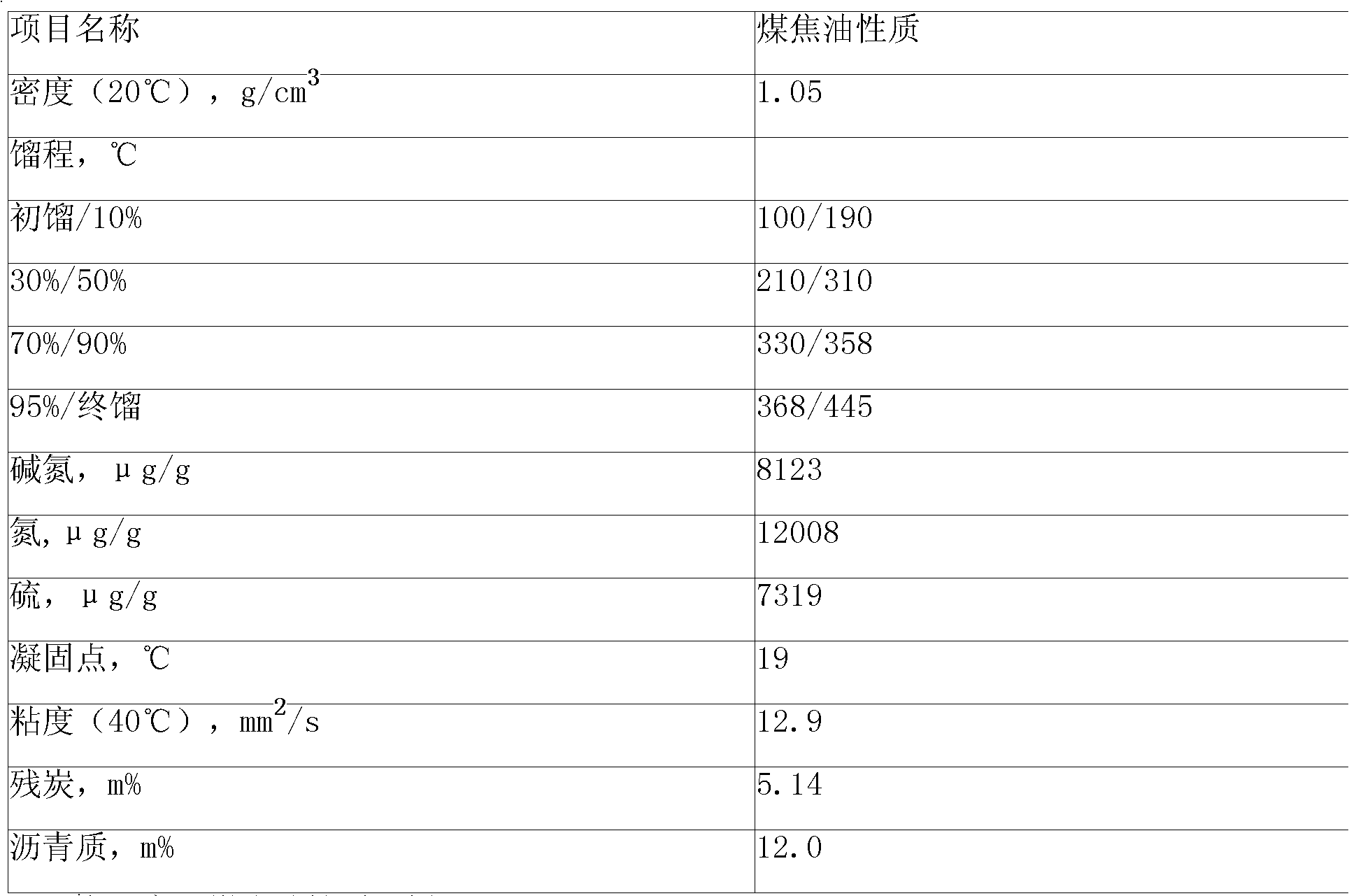

Method for preparing diesel component by catalytic cracking of coal tar light fraction

ActiveCN101629094AExtend your lifeQuality improvementCatalytic crackingChemistryFluid catalytic cracking

The invention discloses a method for preparing a diesel component by catalytic cracking of coal tar light fraction, which comprises the following step: placing a coal tar light fraction in a catalytic cracking device under conditions of a temperature of between 400 and 450 DEG C, a pressure of 0.05and 0.4MPa and an oil gas airspeed of 0.5 to 2.5 hour<-1> to obtain the diesel component. The method has the advantages of simple flow, high conversion rate and stable operation and belongs to the field of coal tar deep processing.

Owner:HANERGY TECH

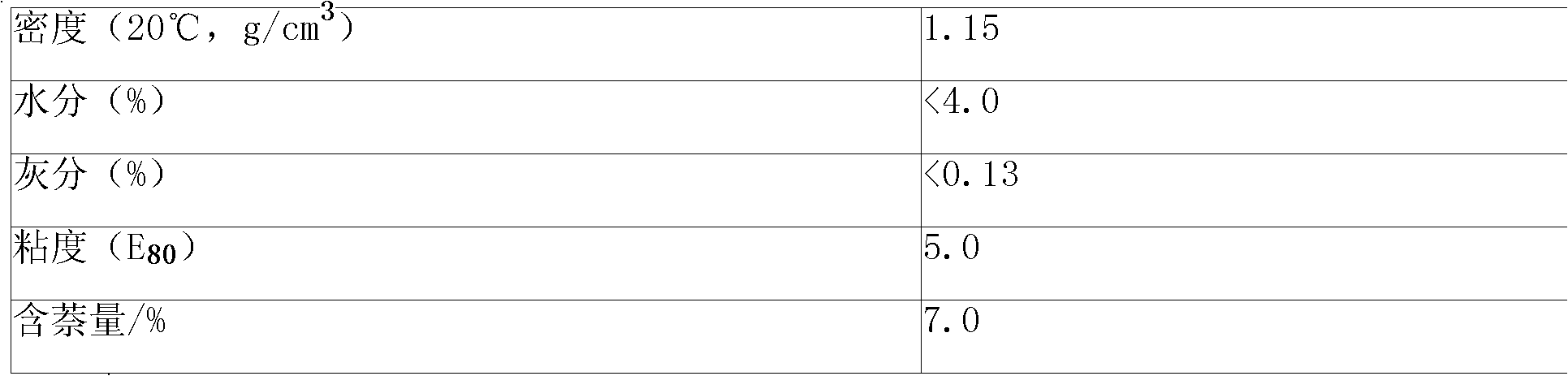

Novel high-strength LPD50 spring steel

ActiveCN107267864ALow antioxidantHigh strengthQuenching devicesLow internal friction springsManufacturing technologyHigh intensity

The invention discloses novel high-strength LPD50 spring steel, and belongs to the field of high-strength spring steel for thermal pressure machining purposes and manufacturing technologies. The novel high-strength LPD50 spring steel is characterized in that the novel high-strength LPD50 spring steel comprises the following components, by mass percent, 0.47-0.53% of C, 0.15-0.35% of Si, 0.75-1.10% of Mn, 0.90-1.20% of Cr, 0.05-0.10% of V, 0.02-0.10% of Nb, 0.15-0.25% of Mo, less than or equal to 0.25% of Cu, less than or equal to 0.25% of Ni, less than or equal to 0.02% of P, less than or equal to 0.015% of S and the balance Fe and unavoidable impurities. The novel high-strength LPD50 spring steel has the excellent characteristics of low carbon removed amount, high strength, high plasticity and toughness, low alloy content and low cost, and can meet the requirements on high stress, high fatigue property, high processing property and high reliability from lightweight flat springs.

Owner:SHANDONG LEOPARD AUTOMOTIVE HLDG

P110 steel level high frequency straight welded pipe manufacturing method

InactiveCN102430901AImprove toughnessImprove resistance to delayed crackingFurnace typesHeat treatment furnacesMedium frequencyEngineering

A P110 steel level high frequency straight welded pipe manufacturing method comprises (1) taking hot-rolled coil as raw material; (2) shaping the coil into a straight seam pipe by continuous shaping techniques, welding the straight seam on the pipe by a high frequency inductive welding machine to produce a primary pipe, and after the welding, timely removing external and internal burrs of the primary pipe; (3) heating the primary pipe removed of burrs by a medium frequency induction furnace to 920-950 degrees centigrade and conveying it to a hot rolling and diameter reducing machine, rolling the primary pipe into pipe blanks with different apertures by hot mechanical rolling; (4) conducting whole-pipe quenching and tempering to the hot roller pipe blank to produce finished pipe; (5) conducting ultrasonic flaw detection and pipe end magnetic powder inspection to the finished pipe. The invention takes low steel level coil as raw material to produce primary pipe, produces pipe blanks with different diameter specifications by the primary pipe with the same specification, and produces oil casing product with high steel level and high performance by low steel level economical pipe blanks. The working efficiency is high. The production cost is low.

Owner:BAOJI PETROLEUM STEEL PIPE

Big-wire diameter suspension helical spring material and preparation method thereof

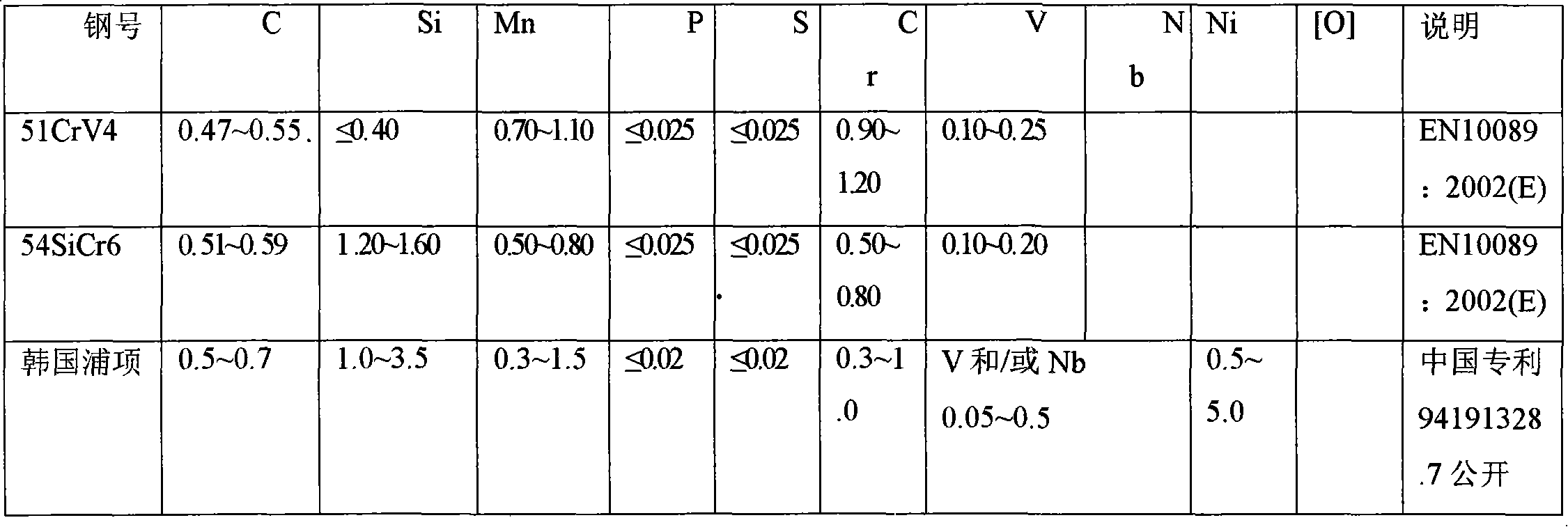

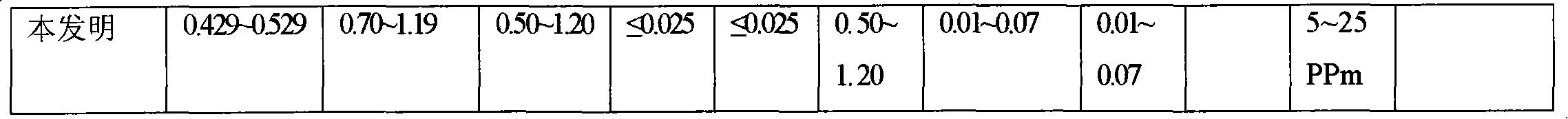

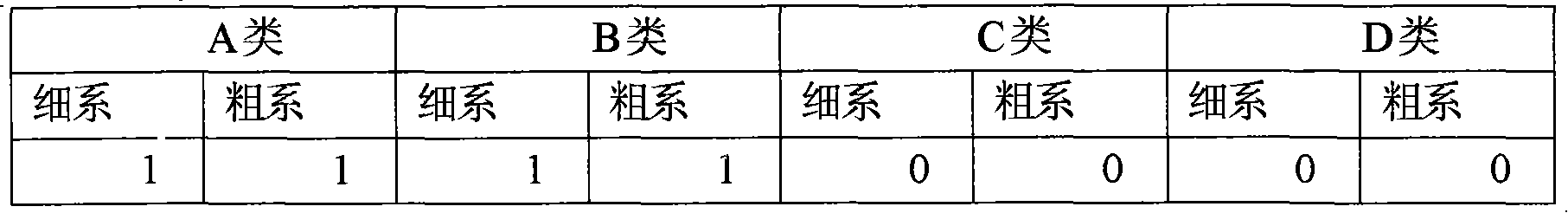

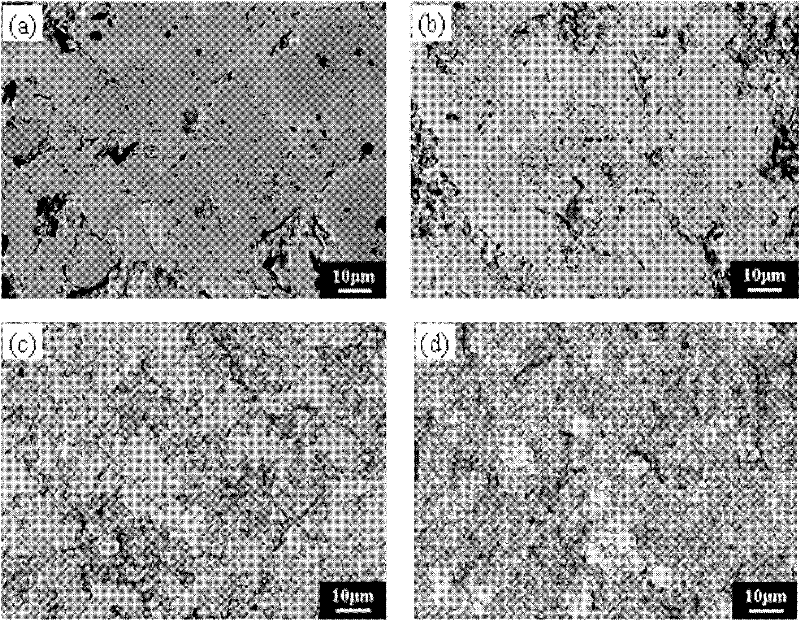

InactiveCN101619418ALow antioxidantLow decarbonization effectFurnace typesHeat treatment furnacesAlloyHigh intensity

The invention relates to a big-wire diameter suspension helical spring material, which comprises the following chemical components in percentage by weight: 0.429 to 0.529 percent of C, 0.70 to 1.19 percent of Si, 0.50 to 1.20 percent of Mn, 0.50 to 1.20 percent of Cr, 0.01 to 0.07 percent of V, 0.01 to 0.07 percent of Nb, less than or equal to 0.025 percent of P, less than or equal to 0.025 percent of S, 5 to 25ppm of O, and the balance of Fe and inevitable impurities. The big-wire diameter suspension helical spring material has technical properties of low decarburization, high strength and high plasticity, has a low alloy content and is a good material for making a helical spring of a suspension having a big wire diameter of a medium or heavy vehicle and also for making a suspension helical spring of a car, a vehicle torsion bar spring and a stock stabilizer, and also a good material used for making a high-strength spring steel wire and an oil tempering spring steel wire.

Owner:孙心红

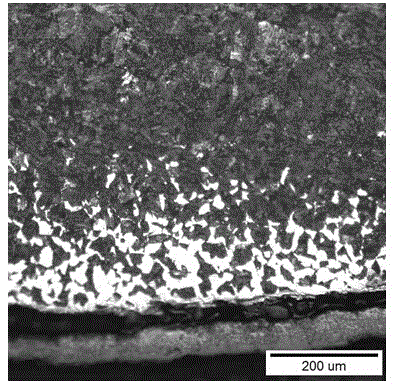

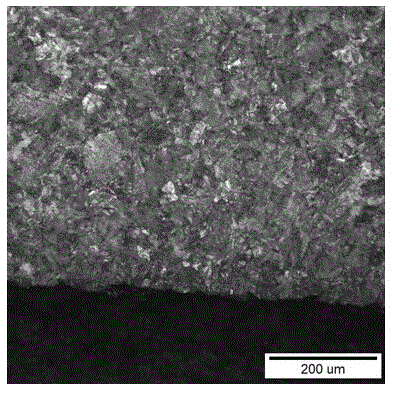

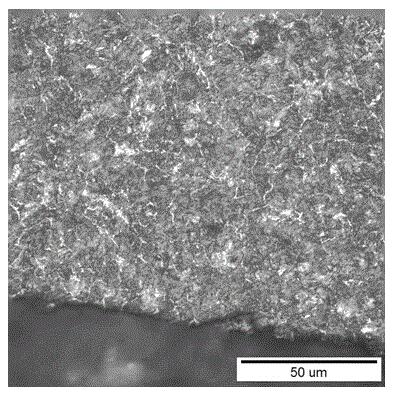

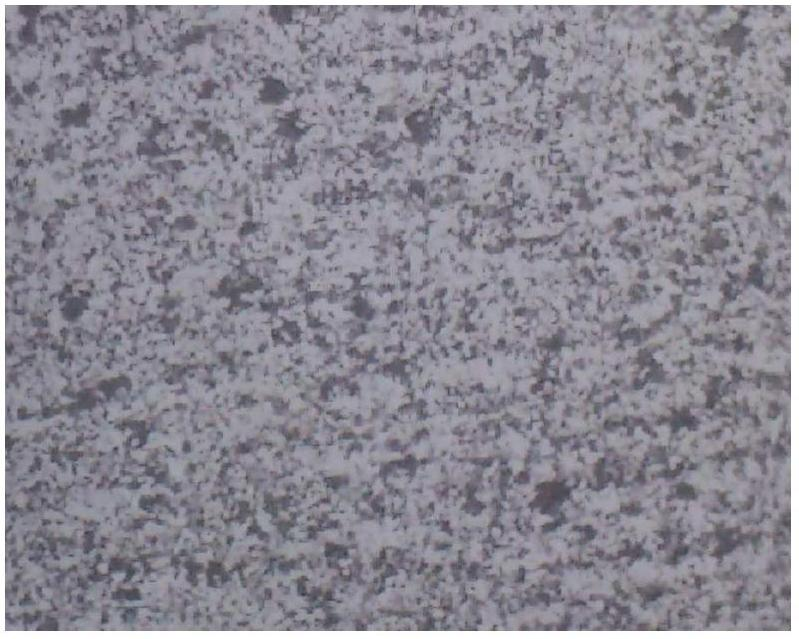

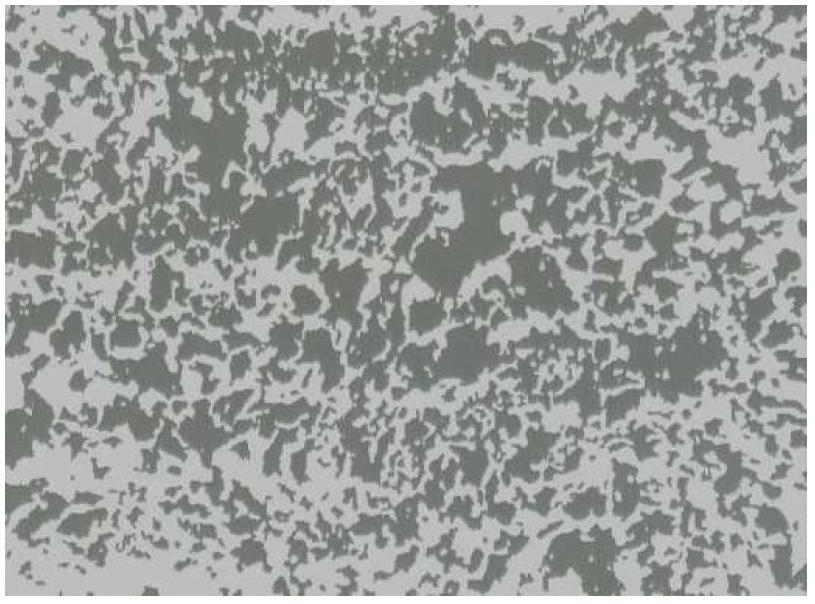

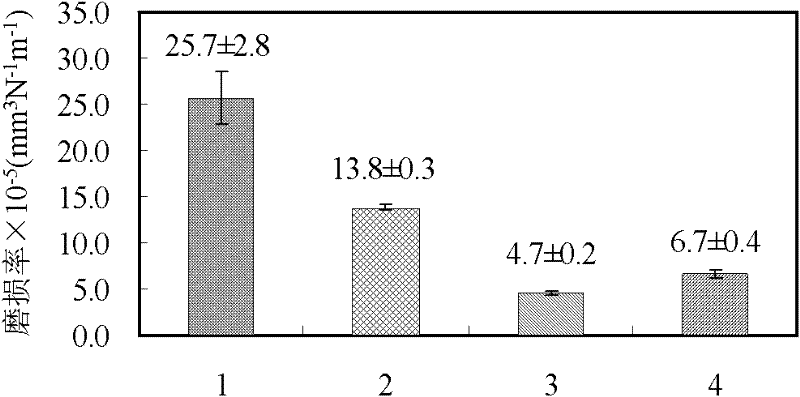

Tungsten carbide cobalt-copper-molybdenum disulfide self-lubricating wear-resistant coating and preparation method thereof

The invention discloses a tungsten carbide cobalt-copper-molybdenum disulfide self-lubricating wear-resistant coating and a preparation method thereof. The preparation method is characterized by comprising the following steps of: preparing tungsten carbide cobalt-copper-molybdenum disulfide composite powder by taking tungsten carbide cobalt, copper and molybdenum disulfide as raw materials and by a sintering crushing method; and obtaining a tungsten carbide cobalt-copper-molybdenum disulfide composite coating by an atmospheric plasma spraying method. In the composite coating, the ratio of tungsten carbide cobalt to copper to molybdenum disulfide is equal to (70-90):(6-18):balance; and the thickness is 200 to 400mu m. Compared with the traditional tungsten carbide cobalt coating, the tungsten carbide cobalt-copper-molybdenum disulfide self-lubricating wear-resistant coating has the advantages that: the friction coefficient and the wear rate of the tungsten carbide cobalt-copper-molybdenum disulfide composite coating are remarkably reduced; and the tungsten carbide cobalt-copper-molybdenum disulfide composite coating is an excellent self-lubricating wear-resistant coating.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Method of preparing high-temperature nickel-based alloy porous material by 3DP (three-dimensional printing) and aftertreatment process

ActiveCN109807320AMeet the needs of different purposesLow costAdditive manufacturing apparatusPore distributionPolyvinyl alcohol

The invention discloses a method of preparing a high-temperature nickel-based alloy porous material by 3DP (three-dimensional printing) and an aftertreatment process. The method comprises the following steps of: step A. mixing powder, to be specific, fully mixing a certain proportion of metal powder such as Ni, Cr, and Fe with polyvinyl alcohol powder; step B. carrying out macroscopic direct pore-forming, to be specific, designing a three-dimensional model being of a porous structure by three-dimensional design software according to the appearance feature, porosity, pore distribution law and pore shape and size design requirements of the porous material; step C. preparing the porous material by 3DP, to be specific, 3DP equipment receives a printing program, and sets printing parameters tostart printing; step D. removing residual powder, to be specific, firstly taking out a rough blank from a powder stack, and then removing the residual powder on the rough blank; step E. debonding andatmosphere sintering treatment, to be specific, sending the rough blank to a muffle surface for debonding and atmosphere sintering; step F. carrying out electrochemical corrosion, to be specific, carrying out electrochemical corrosion treatment on the sintered nickel-based porous material; step G. carrying out cryogenic treatment, to be specific, putting a workpiece in a cryogenic device for cryogenic treatment; and step H. completing the preparation and aftertreatment of the high-temperature nickel-based alloy porous material.

Owner:NANTONG INST OF TECH

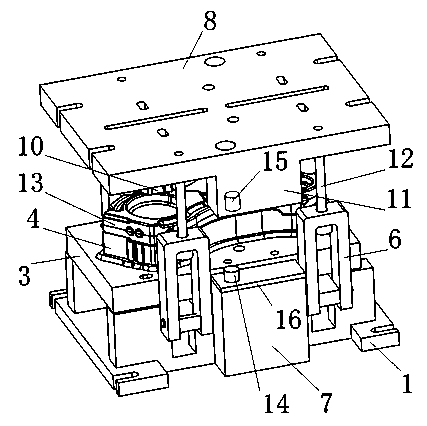

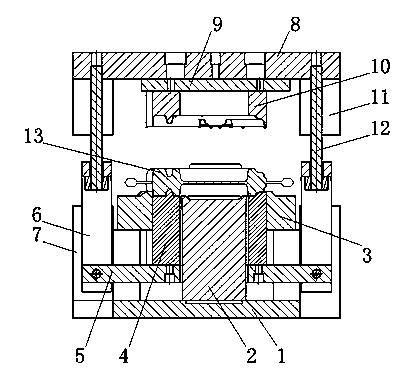

Chord pipe hot molding method and hot press molding mold used for spud legs of marine oil drilling platform

InactiveCN102909247AReduce decarbonizationReduce the phenomenon of growing upShaping toolsOil drillingPetroleum

The invention provides a chord pipe hot molding method and a hot press molding mold used for spud legs of a marine oil drilling platform. With the adoption of the chord pipe hot molding method and the hot press molding mold, the phenomena of oxidization, decarburization and grain growth in the chord pipe hot molding process are reduced. The positioning is accurate, the shape is regular, and the percent of pass can reach 100% during pressure molding.

Owner:XIAN FLIT HEAT TREATMENT

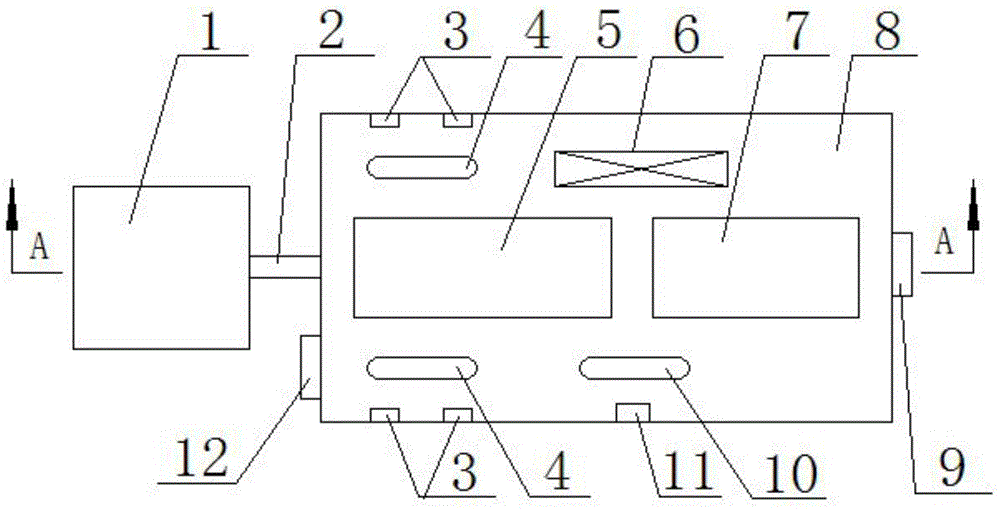

Non-oxidation brazing and thermal treatment device of hard alloy cutting teeth

ActiveCN104400172AAchieving brazing qualityExtend your lifeFurnace typesMetal working apparatusQuenchingManipulator

The invention provides a non-oxidation brazing and thermal treatment device of hard alloy cutting teeth, belongs to the technical field of cutting tools, and mainly solves the problems of the prior art of poor welding quality and thermal treatment effect. The non-oxidation brazing and thermal treatment device comprises a cryogenic box, a nitrogen transporting pipeline, a heating furnace, a quenching tank and a manipulator. The non-oxidation brazing and thermal treatment device is characterized in that the nitrogen transporting pipeline is arranged between the cryogenic box and a working bin, one part of the nitrogen transporting pipeline in the working bin is close to the top wall of the working bin, and oxidation discharge holes formed on the nitrogen transporting pipeline. The heating furnace, the quenching tank and the manipulator are located in the working bin of a sealed structure. A heating operation hole, a heating observation hole, a quenching operation hole and a quenching observation hole are formed at the top of the working bin. A waste gas discharge hole is formed on the lower portion of the working bin or on the side wall close to the bottom. A material inlet is formed on the side wall of one side of the working bin close to the heating furnace, a material outlet is arranged on the side wall of one side of the working bin close to the quenching tank, and a movable sealed device is arranged in the material outlet. The non-oxidation brazing and thermal treatment device reduces energy consumption and saves materials.

Owner:SHANXI LI PU LI TUO COAL PARTS MFG CO LTD

Process for heat treatment of 12Cr1MoVG high pressure tubes after forging

ActiveCN104017976AProduction process economyProduction Technology ScienceFurnace typesHeat treatment furnacesRate limitingHydrogen

The invention relates to a process for heat treatment of 12Cr1MoVG high pressure tubes after forging. After vacuum degassing, [H] contents are detected by online hydrogen determination, so that processes for heat treatment of the 12Cr1MoVG high pressure tubes after forging for are respectively formulated against two conditions that [H] is greater than or equal to 3ppm and [H] is less than 3ppm; a process of hydrogen diffusion and then normalizing is adopted for the 12Cr1MoVG high pressure tube of which [H] content is greater than or equal to 3ppm detected by online hydrogen determination, a rate-limiting cooling stage in the original process is cancelled, the hydrogen diffusion time at 650 DEG C is appropriately prolonged, and temperature rise is directly carried out after hydrogen diffusion is ended so as to carry out normalizing, and the workpiece is hoisted down from a lathe after normalizing and is then subjected to air cooling, so that the annealing time is greatly shortened; after vacuum degassing, except for optimizing according to above process, as for the 12Cr1MoVG high pressure tube of which [H] content is less than or equal to 3ppm detected by online hydrogen determination, a heat insulation stage at 500-650 DEGC as well as hydrogen diffusion annealing and normalizing temperature rise rate limiting stages are not required, and thus the annealing process peroid is further shortened. The invention discloses the process for heat treatment of the 12Cr1MoVG high pressure tubes after forging, which has the advantages that the production peroid is effectively shortened, the productivity of high pressure tubes after forging is increased and the normalizing effect is improved.

Owner:HENAN ZHONGYUAN SPECIAL STEEL EQUIP MFG CO LTD

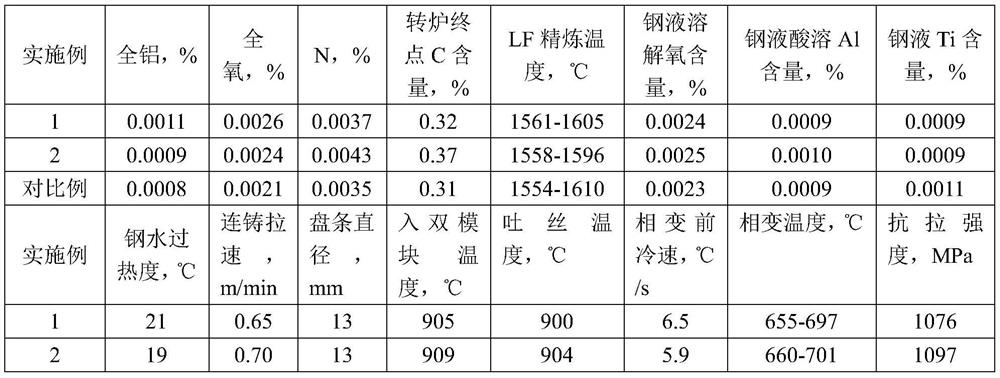

High-strength and high-toughness automobile suspension spring steel and production method thereof

ActiveCN113755761AImprove toughness and mechanical propertiesLow costProcess efficiency improvementWire rodAlloy

The invention relates to the technical field of automobile suspension spring steel, in particular to high-strength and high-toughness automobile suspension spring steel and a production method thereof. The steel comprises the following chemical components in percentage by weight: 0.5%-0.6% of C, 1.2%-1.6% of Si, 0.60%-0.9% of Mn, 0.6%-0.9% of Cr, 0.01%-0.3% of V, less than or equal to 0.015% of P, less than or equal to 0.015% of S, less than or equal to 0.0015% of Ti, 0.0005%-0.0050% of total aluminum, less than or equal to 0.0025% of total oxygen, less than or equal to 0.0050% of N, less than 0.1% of inevitable impurities and the balance of iron. Through brand new low-alloy-content and low-cost chemical component design and in cooperation with appropriate converter smelting, refining, continuous casting, continuous rolling, wire rod rolling, drawing, heat treatment and other processes, the technical problems that the 2000MPa-grade automobile suspension spring steel wire is excessive in strength and insufficient in plasticity and toughness are solved. The tensile strength of the steel can reach 2000 MPa level and 2100 MPa level respectively, and the area reduction rate is larger than or equal to 45%. The spring steel not only has the excellent mechanical properties of high toughness, but also has the advantages of low cost, low decarburization, high surface quality, high purity and excellent fatigue property.

Owner:ANGANG STEEL CO LTD

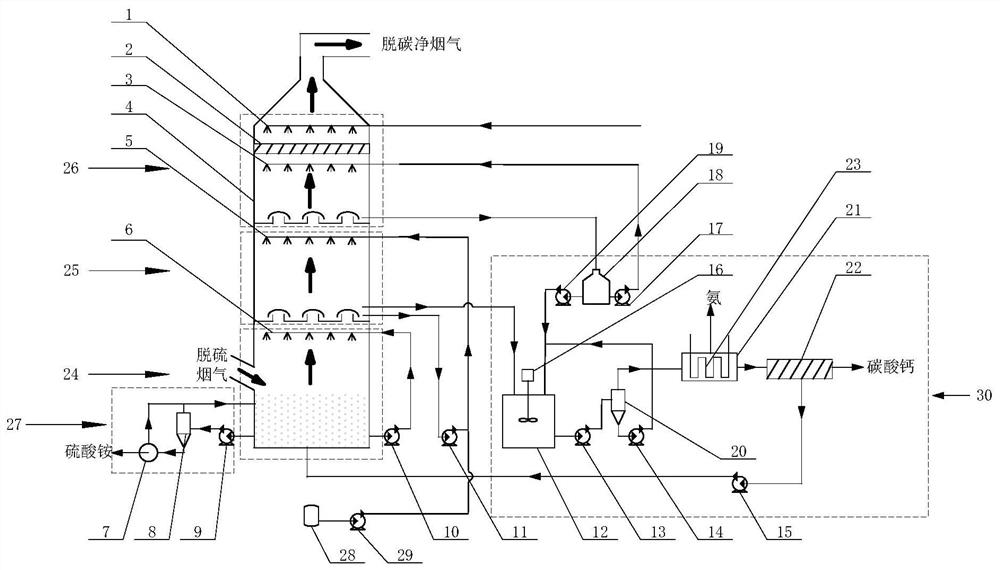

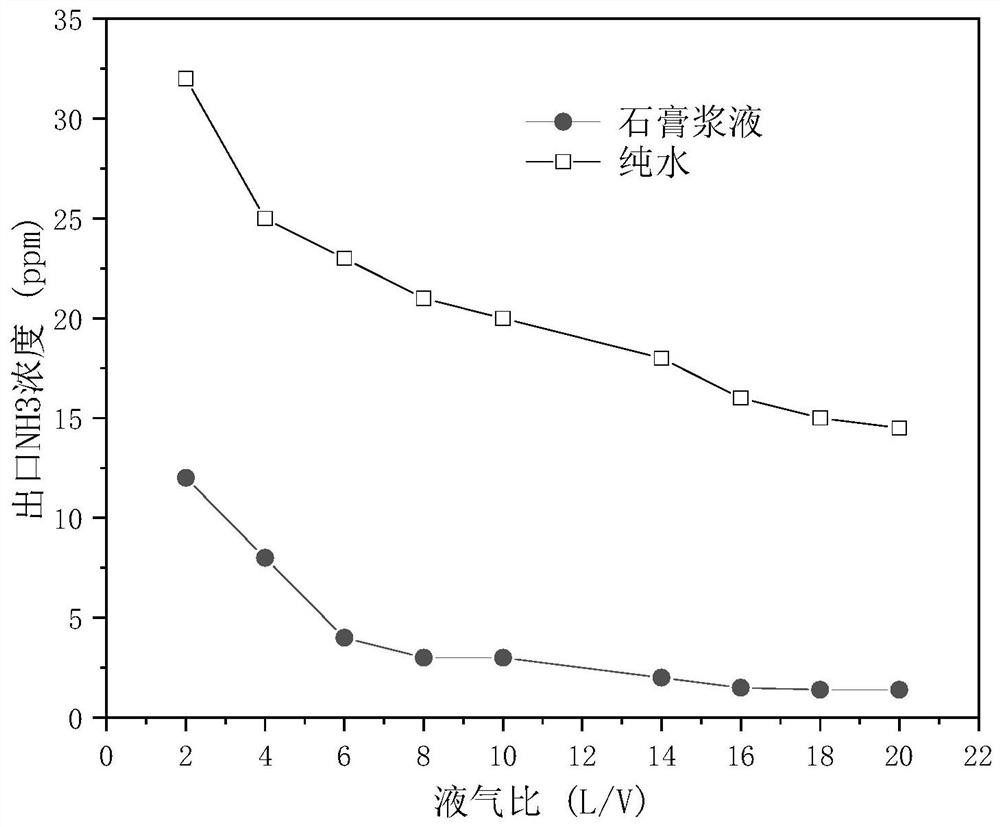

System and method for directly mineralizing carbon dioxide in flue gas by using gypsum

PendingCN113181751AReduce decarbonizationReduce utilization costCalcium/strontium/barium carbonatesGas treatmentPhysical chemistrySlurry

The invention relates to a system and a method for directly mineralizing carbon dioxide in flue gas by using gypsum. An absorption tower can sequentially realize cooling, decarburization and escape ammonia trapping processes of desulfurized flue gas; the bottom of a lower cooling section is provided with a slurry area and is circularly connected with an upper ammonium bicarbonate spraying layer, so that the trapping of the waste heat of the desulfurized flue gas can be realized, and heat is provided for the low-temperature concentration and crystallization of ammonium sulfate slurry; the bottom of a middle decarburization section is provided with an ammonium bicarbonate liquid holding layer, and the ammonium bicarbonate liquid holding layer and the ammonium bicarbonate spraying layer form circulation; ammonia is supplemented through an ammonium bicarbonate spraying layer pipeline, so that continuous decarburization reaction can be carried out on cooled flue gas; and meanwhile, the lower cooling section and the middle decarburization section are separated, and a gypsum spraying layer, a demister, a process water spraying layer, a gypsum liquid holding layer and a gypsum spraying layer which are sequentially arranged on the upper deamination section in the height direction form circulating spraying, and the continuous trapping process of escaping ammonia is achieved. The system is simple in structure, reasonable in design and low in smoke decarburization and utilization cost, and meanwhile, continuous online treatment of a large amount of smoke can be achieved.

Owner:XIAN THERMAL POWER RES INST CO LTD

Method for controlling 16 Mn seamless steel tube blank heating

InactiveCN105886719AReduce oxidation burnReduce burning rateFurnace typesHeat treatment process controlPerformance indexHeating furnace

The invention belongs to the technical field of metal working methods and discloses a method for controlling 16 Mn seamless steel tube blank heating to solve the problem that the performance index of a finished 16 Mn seamless steel tube product is low. The method for controlling 16 Mn seamless steel tube blank heating comprises the steps that an annular heating furnace is adopted for heating a 16 Mn seamless steel tube blank, and the heating process is sequentially divided into a preheating stage, a heating stage and a soaking stage, wherein the heating temperature at the preheating stage is smaller than or equal to 700 DEG C, the heating stage is divided into a low-temperature heating stage and a high-temperature heating stage, the heating temperature at the low-temperature heating stage is larger than or equal to 800 DEG C but smaller than or equal to 1,100 DEG C, the heating temperature at the high-temperature heating stage is larger than or equal to 1,050 DEG C but smaller than or equal to 1,290 DEG C, and the heating temperature at the soaking stage is larger than or equal to 1,260 DEG C but smaller than or equal to 1,300 DEG C. By means of the method, the defect that the yield strength performance index is low is completely eliminated, and the performance percent of pass reaches 100%. The method is suitable for heating of 16 Mn seamless steel tube blanks with various diameter specifications.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

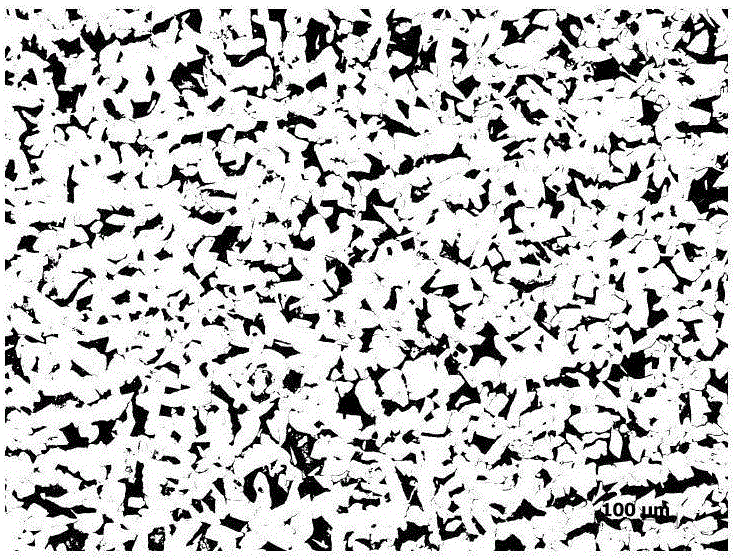

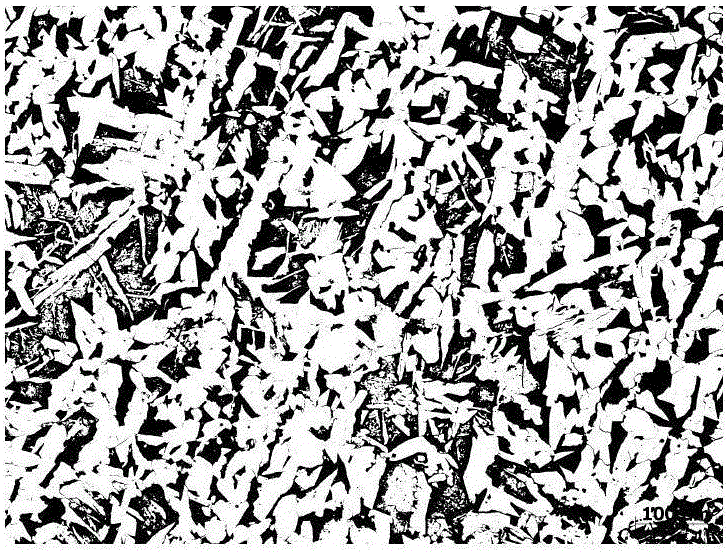

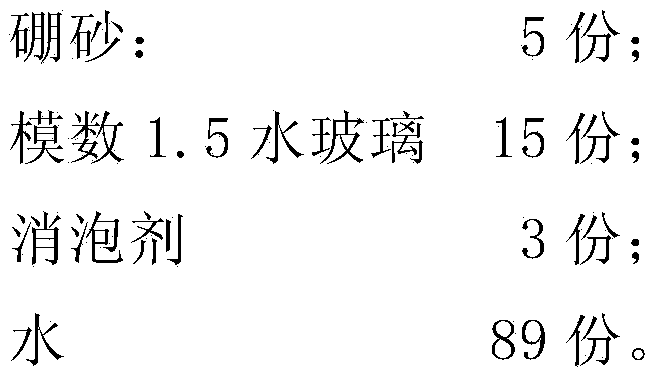

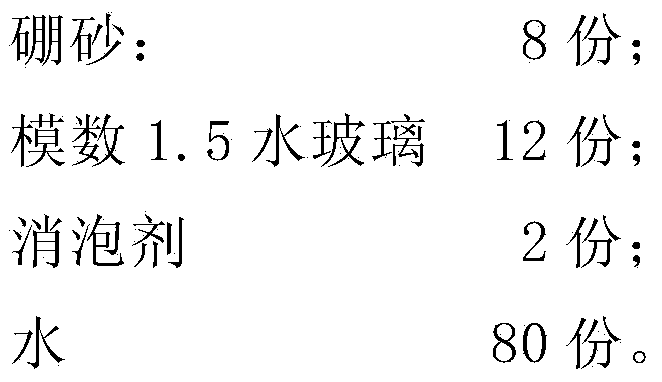

Anti-decarbonizing agent for bearing steel thermal treatment for preparing bearing and preparation method thereof

The invention discloses an anti-decarbonizing agent for bearing steel thermal treatment for preparing a bearing. The anti-decarbonizing agent is prepared from the following raw materials in parts by weight: 5-10 parts of borax, 5-15 parts of water glass with modulus of 1.5, 1-3 parts of defoamer and 72-89 parts of water. The preparation method comprises the following steps: first, heating water to 60-70 DEG C; adding borax to stir and dissolve; adding the defoamer till borax is fully dissolved; and uniformly stirring and gradually adding water glass with modulus of 1.5 to obtain the anti-decarbonizing agent. The anti-decarbonizing agent disclosed by the invention can form a compact chemical protective film on the surface of bearing steel to prevent a decarbonizing layer from being formed on the surface of the bearing steel due to thermal treatment, so that the grinding allowance can be reduced by 20-30%, thereby improving the processing efficiency. As the compact chemical protective film on the surface of a steel product can isolate corrosion of oxygen and water vapor in a put process after thermal treatment, anti-rust treatment is reduced or avoided. The anti-decarbonizing agent disclosed by the invention is particularly suitable for thermal treatment of a mesh belt furnace.

Owner:广德中隆轴承有限公司

Long-fatigue-life strip steel as well as preparation method and application thereof

The invention relates to long-fatigue-life strip steel as well as a preparation method and application thereof, and belongs to the technical field of steel preparation. The long-fatigue-life strip steel is prepared from the following chemical components in percentage by mass: 0.26 to 0.45 percent of C, 0.10 to 0.25 percent of Si, 1.1 to 1.4 percent of Mn, less than or equal to 0.015 percent of P,less than or equal to 0.003 percent of S, 0.015 to 0.08 percent of Al, 0.01 to 0.05 percent of Ti, 0.0010 to 0.0050 percent of B, 0.10 to 0.30 percent of Cr, less than or equal to 0.006 percent of N,and at least one of the following chemical components in percentage by mass: 0.05 to 0.2 percent of Sb, 0.05 to 0.2 percent of Sn, and the balance of Fe and inevitable impurities. A hollow stabilizerbar is prone to surface decarburization in the plurality of heat treatment in the raw material production and follow-up forming process, so that the surface hardness is reduced, and the fatigue life is shortened. The tin / antimony element is prone to enrich on the surface layer of steel to inhibit the diffusion of C from the strip steel, so that decarburization of the surface layer is inhibited. Atleast one of Sb and Sn is added into the chemical components of the material, so that the fatigue life of the final part hollow stabilizer bar is prolonged by reducing surface decarburization of thematerial.

Owner:SHOUGANG CORPORATION +1

Spring steel with performance of low decarburization, high strength and high ductility

InactiveCN106756513ASolve the problem of full decarburization layerThe effect of low decarbonizationAlloyHigh intensity

The invention discloses spring steel with the performance of low decarburization, high strength and high ductility, and belongs to the field of spring steel used for hot press machining. The spring steel comprises the chemical components of, by weight, 0.42-0.52% of C, 0.70-1.10% of Si, 0.50-1.10% of Mn, 0.50-1.1% of Cr, 0.01-0.05% of V, 0.005-0.009% of Nb, no greater than 0.025% of P, no greater than 0.025% of S, 5-25 ppm of [O] and the balance Fe and inevitable impurities. Since a spring material has the technicalperformance of low decarburization, high strength and high ductility and is low in alloy content, the spring steelisan excellent material for manufacturing medium and heavy duty truck large-wire-diameter suspension spiral springs, can also be used for car suspension spiral springs, car torsion rod springs and stabilizer bars, and is also an excellent raw material for high-strength spring steel wires and oil tempering spring steel wires. The spring steel is wide in application and suitable for application and popularization in the industry.

Owner:SHANDONG LEOPARD AUTOMOTIVE HLDG

Turning tool machining technology capable of reducing heat damage and improving tempering quality

InactiveCN104128777AReduce heating deformationDegree of reductionFurnace typesHeat treatment furnacesThermal insulationHardness

The invention discloses a turning tool machining technology capable of reducing heat damage and improving tempering quality. The turning tool machining technology comprises the processes of blank blanking, forging, cutting, heat treatment and grinding in sequence. A blank is W2MoCr4V2Co8 high-speed tool steel. The heat treatment process includes preheating, heating and heat insulation, quenching and tempering in sequence. Preheating is conducted in a staged mode with the temperature gradually increased. An annealing step is further set between the forging step and the cutting step, and according to the annealing step, the forged blank is heated step by step. The turning tool machining technology is simple in circuit, the heat treatment effect is good, the hardness number of the turning tool can be more than 70 HRC, and the good wear resistance and the good heat hardness are achieved.

Owner:CHENGDU HENGTONG ZHAOYE PRECISION MACHINERY

Corrosion-resistant high-strength high-toughness alloy tool steel and heat treatment method and production method thereof

The invention discloses corrosion-resistant high-strength high-toughness alloy tool steel and a heat treatment method and a production method thereof. The corrosion-resistant high-strength high-toughness alloy tool steel comprises the following chemical components of, in percentage by weight, 0.70%-1.00% of C, 0.80%-1.10% of Si, 0.50%-0.80% of Mn, 0.50%-0.80% of Cr, 0.30%-0.50% of Mo, 0.20%-0.40% of V, 0.020%-0.040% of Nb, 0.030%-0.050% of Ti, 0.15%-0.35% of Ni, 0.15%-0.35% of Cu, 0.05%-0.25% of Re, trace amounts of P, S, O and N and the balance Fe and other inevitable impurities, wherein 0.50 W + 0.50 Mo + 0.26 Cr + V + Nb < = 1.5 C. The discloses corrosion-resistant high-strength high-toughness alloy tool steel has good strength, plasticity and toughness, wear resistance, impact resistance and corrosion resistance, and can meet the use requirements.

Owner:MAANSHAN IRON & STEEL CO LTD

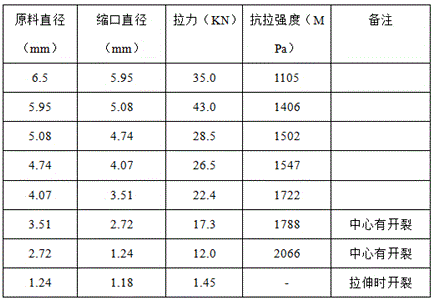

Manufacture process of high-strength welding wires

InactiveCN105983798AGuaranteed smooth productionAvoid crackingDrawing diesFurnace typesWeld lineElectric arc

The invention discloses a manufacture process of high-strength welding wires capable of producing manufacture process of high-strength welding wires with high composite performance. The process comprises following steps: smelting welding wires, performing acid pickling in an off-line manner, pulling and pushing welding wires, plating welding wires with copper and welding welding wires layer by layer. The middle link of the step for pulling and pushing welding wires comprises an annealing process of welding wires. An experiment shows that the annealing process added to the middle link of the step for pulling and pushing welding wires has great advantages. Therefore, the annealing process is selected for production of high-strength welding wires. The high-strength welding wires do not crake during production and smooth production of processes for pulling and pushing welding wires, plating welding wires with copper is ensured. As a result, smooth production of high-strength welding wires is ensured and welding wires produced are featured by being good in cooper plating bonding force and usage performance, stable in arcs and little in weld spatter and attractive in welding line formation.

Owner:KUNSHAN MCC BAOSTEEL WELDING CONSUMABLES

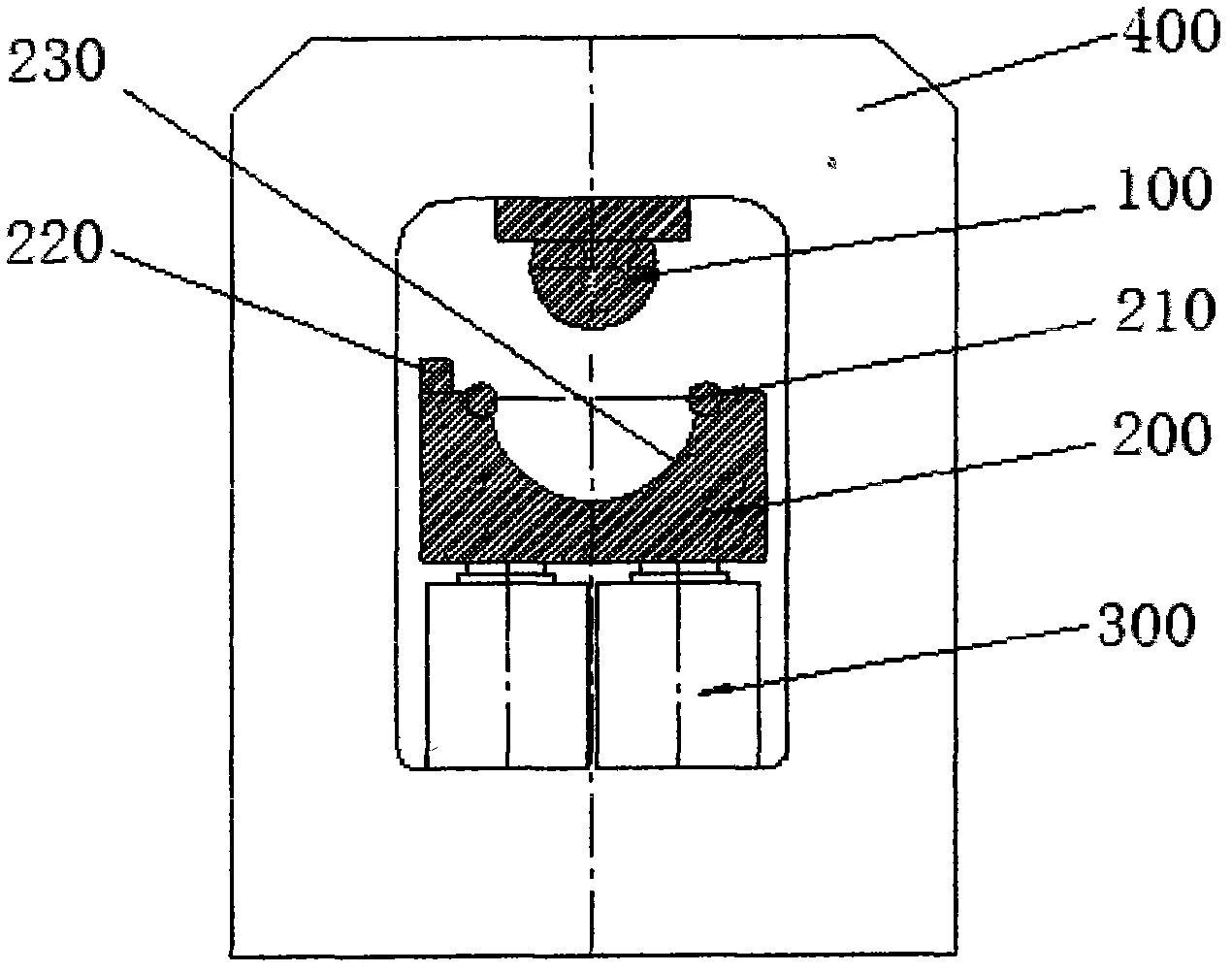

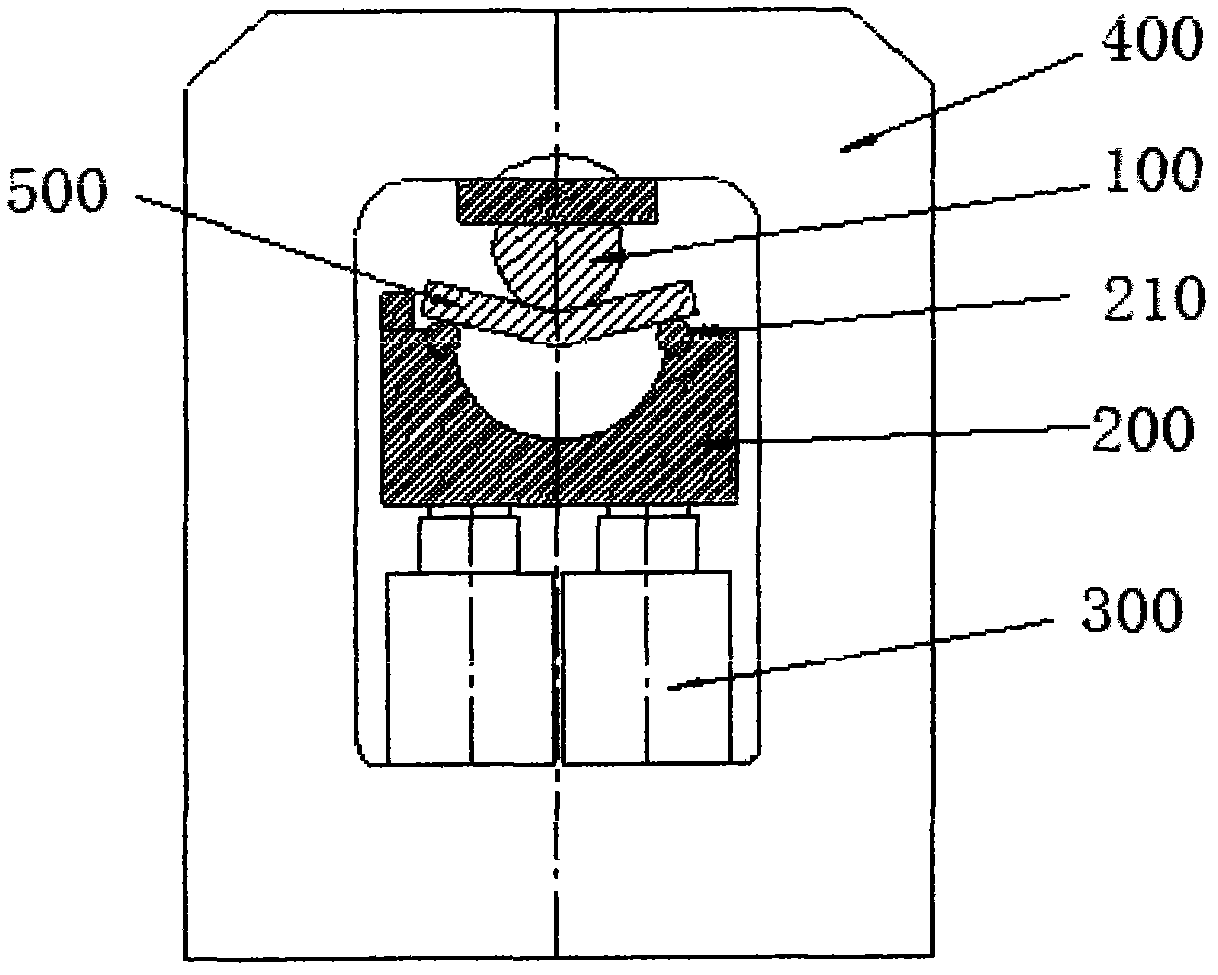

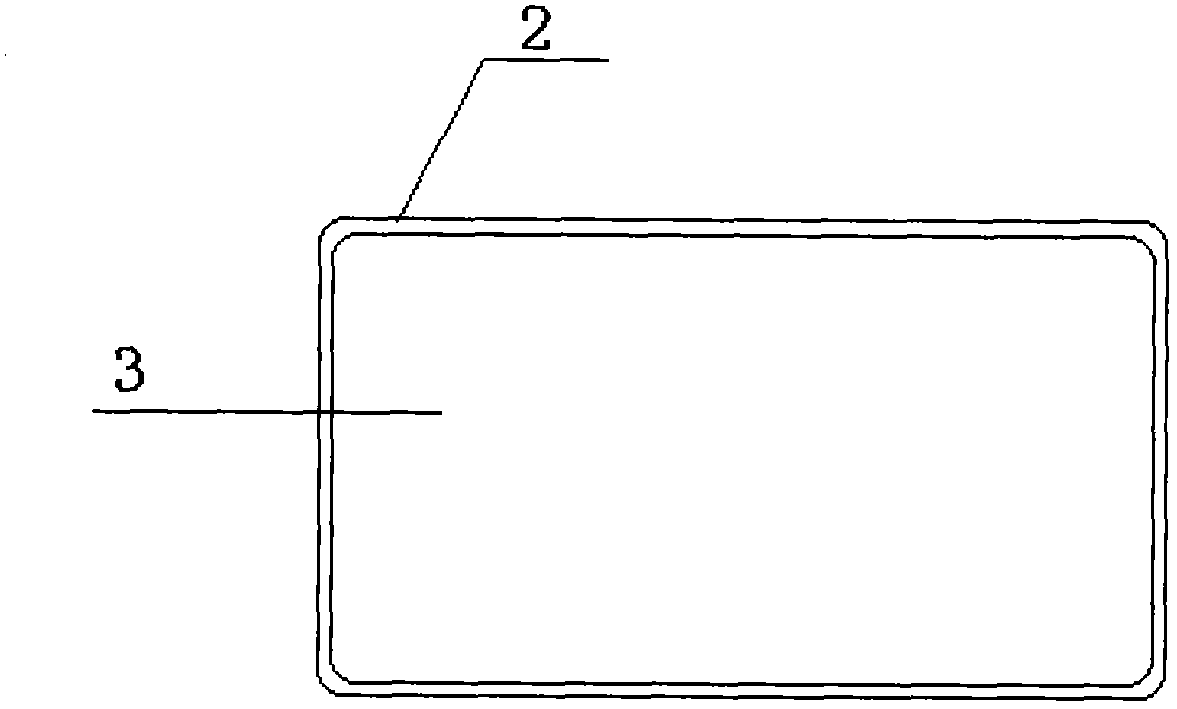

Surface slot blasting sealing method of dewaxed powder metallurgy green ware body

The invention relates to a surface slot blasting sealing method of a dewaxed powder metallurgy green ware body. The method comprises the steps of dewaxing and sintering, the surface of the powder metallurgy green ware body (3) forms a high-density layer (2) before sintering and after dewaxing, and the thickness of the high-density layer is greater than or equal to 0.1mm and less than or equal to 0.5mm. According to the method, as the surface of the powder metallurgy green ware body (3) forms the high-density layer (2) before sintering and after dewaxing, the high-density layer prevents oxygen and water from entering within preset definite time between a sintering procedure and a hot forging procedure, oxidation and decarburization of powder metallurgy finished products are effectively reduced, and quality of the powder metallurgy finished products is improved.

Owner:刘福平

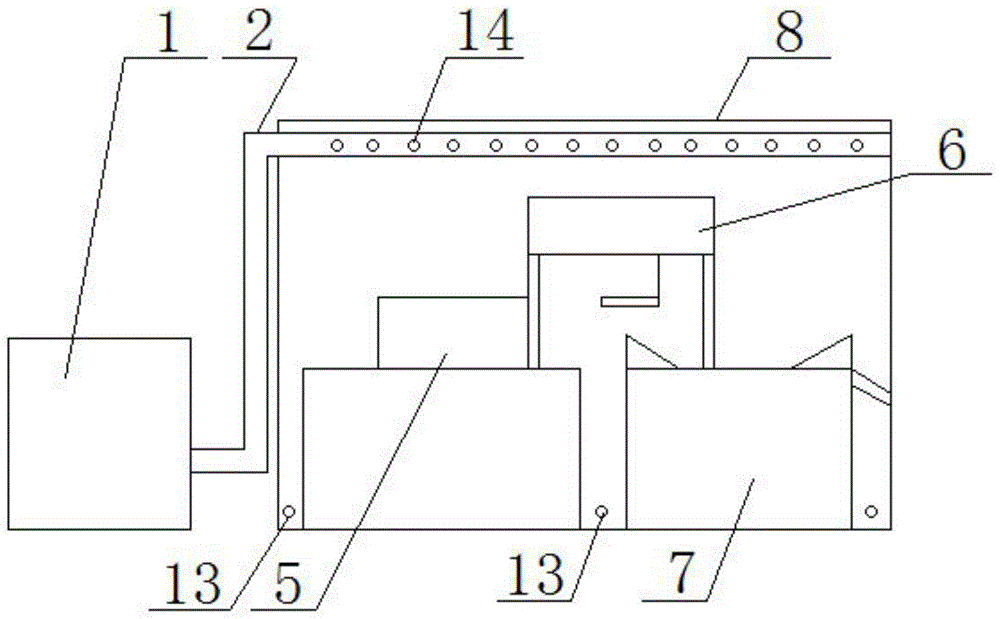

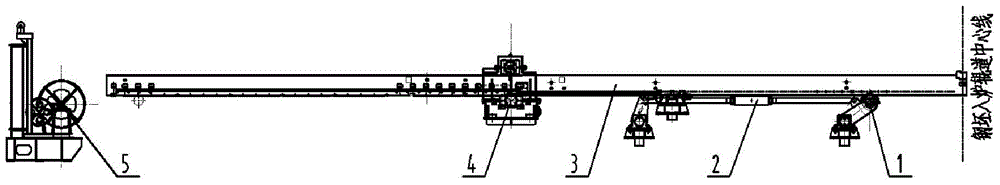

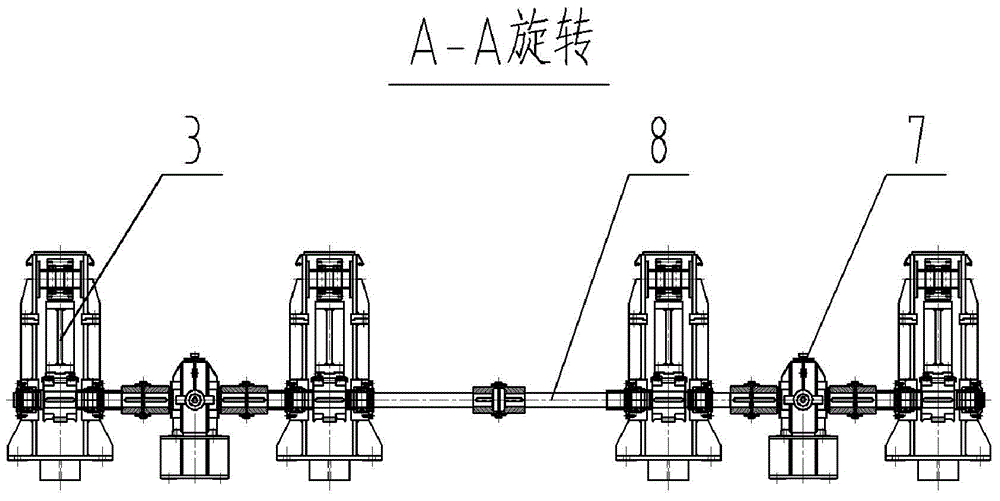

Flexible production device for directly charging high-temperature casting blanks in sequence

ActiveCN104525565AQuality improvementReduce energy consumptionMetal rolling arrangementsHigh carbonEngineering

The invention discloses a flexible production device for directly charging high-temperature casting blanks in sequence and belongs to the technical field of industrial furnaces. The flexible production device for directly charging high-temperature casting blanks in sequence comprises a lifting roller device, a parallel connecting rod mechanism, a steel support arm, a gear case, a cooling water pipe coiling device, a lifting drive device, a translation drive device, a translation drive synchronization shaft, a lifting drive winch, a lifting synchronization shaft and a lifting following winch. The flexible production device for directly charging high-temperature casting blanks in sequence has advantages that the steel blank is only performed with soaking in a heating furnace, the heating time is shortened, the heating furnace output is improved, the heating furnace energy consumption is effectively lowered, the production cost is lowered, and the market competitiveness of the steel product is improved; the hot blank charging steel blank quality is good, the temperature is uniform, and accordingly the production accident is reduced, and the yield is greatly improved; for the high-carbon steel, alloy steel and the like steel, the flexible production device for directly charging high-temperature casting blanks in sequence is good for reducing the surface decarburization of steel blanks and improving the product quality.

Owner:BEIJING SHOUGANG INT ENG TECH

Turning tool manufacturing technology capable of reducing heat damage and facilitating processing

InactiveCN104175083AReduce heating deformationDegree of reductionFurnace typesHeat treatment furnacesManufacturing technologyHardness

The invention discloses a turning tool manufacturing technology capable of reducing heat damage and facilitating processing. The turning tool manufacturing technology comprises steps of workblank blanking, forging, cutting processing, heat treatment and grinding which are performed sequentially, wherein the workblank adopts W2MoCr4V2Co8 high-speed tool steel; the heat treatment comprises steps of preheating, heating and heat insulation, quenching and tempering which are performed sequentially, the preheating is performed by gradually warming by stages, the heating and heat insulation step is that the workblank is further heated to 1,210-1,230 DEG C, and heat insulation is performed for not less than 25 min; and an annealing step is performed between the forging and the cutting processing and is that the forged workblank is heated step by step. The technology has a simple route and small heat damage to a turning tool, the hardness value of the obtained turning tool can be higher than 72 HRC, and the obtained turning tool has good wear resistance and red hardness as well as long service life.

Owner:CHENGDU HENGTONG ZHAOYE PRECISION MACHINERY

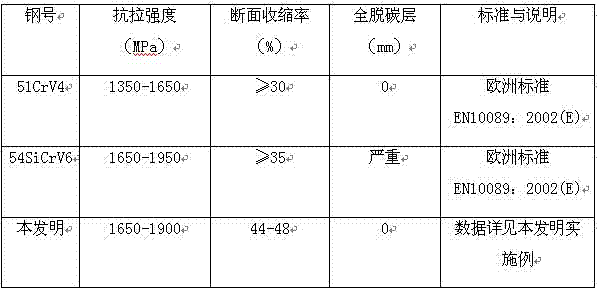

Heating method capable of reducing depth of decarburized layer of GCr15 bearing steel

InactiveCN107460301AStop the spreadReduce thicknessFurnace typesHeat treatment furnacesHeating timeStage ii

The invention discloses a heating method capable of reducing depth of a decarburized layer of GCr15 bearing steel. The heating method comprises the following steps of: preserving the heat of steel billets for 30 minutes at a temperature of 500-600 DEG C in a heat preserving furnace; feeding the steel billets into a step beam type heating furnace to heat in four stages, wherein the temperature at a pre-heating stage is 850-1020 DEG C, a temperature at a heating stage I is 1100-1190 DEG C, heating time of the heating stage I is greater than 35 minutes, a temperature at a heating stage II is 1180-1220 DEG C, a temperature at a uniform-heating stage I is 1180-1220 DEG C, a temperature at a uniform-heating stage II is 1170-1210 DEG C, and heating time from the heating stage II to the uniform-heating stage II is greater than 130 minutes; introducing oxygen gas in a heating process, wherein oxygen gas flow at the pre-heating stage is 80000-90000 m<3> / h, oxygen gas pressure at the pre-heating stage is 8-9 bar, oxygen gas flow at the uniform-heating stage is 140000-150000 m<3> / h, and oxygen gas pressure at the uniform-heating stage is 14-15 bar. The method effectively shortens the heating time, and reduces the depth of the decarburized layer.

Owner:NANJING IRON & STEEL CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com