Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

44results about How to "Production process economy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

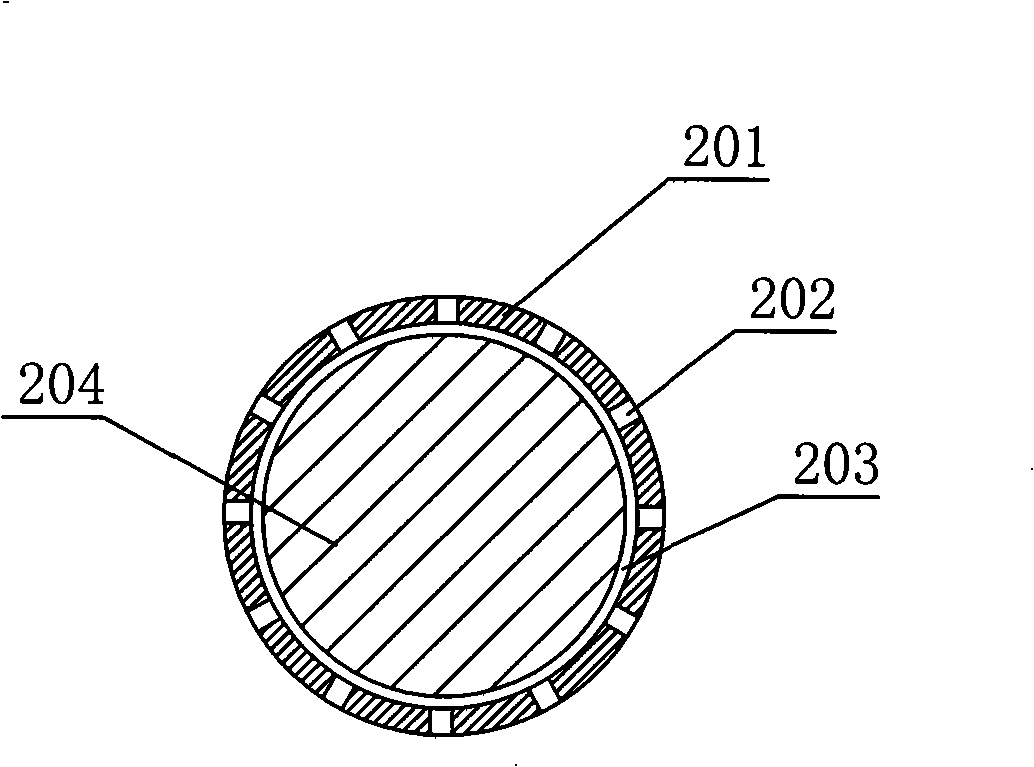

Steel for non-magnetic drilling tool and production method thereof

InactiveCN101597721AMeet the use requirementsProduction process economyChemical compositionMetallurgy

The invention discloses steel for non-magnetic drilling tools and a production method thereof. The steel for non-magnetic drilling tools comprises the following chemical compositions in percentage by weight: Fe, less than or equal to 0.06% of C, 17.00-23.00% of Mn, less than or equal to 0.80% of Si, less than or equal to 0.025% of P, less than or equal to 0.015% of S, 12.00-20.00% of Cr, less than or equal to 1.0% of Mo, 0.20-1.20% of N, less than or equal to 2.30% of Ni and less than or equal to 0.025% of Al, wherein, N equivalent weight=Ni+0.6Mn+0.18Cr+9.69(C+N)-0.11SI2 is greater than or equal to 16. Compared with the prior art, the invention provides an economic and scientific production method with stable austenite so as to be subject to use requirement, production cost requirement and the like. The steel for non-magnetic drilling tools of the invention is also suitable for other applicable fields.

Owner:ZHONGYUAN SPECIAL STEEL

Accumulator electrode with internal particle movable and producing process thereof

InactiveCN101335342AFully automatedProduction process is environmentally friendlyElectrode manufacturing processesElectricityFast charging

The invention relates to a battery electrode with movable internal particles and a preparation method thereof, and pertains to the technical field of the battery electrode. The battery electrode is characterized in that the battery electrode comprises an electrode frame which is arranged in the battery body, movable electrode particles are piled in the electrode frame, the electrode particles are negative particles or positive particles made of solid electrode material, the electrode frame has net-shaped structure and is connectively provided with an input pipeline and an output pipeline which extend out of the battery body, and the electrode frame is connectively provided with an electrode post head. The battery electrode with movable internal particles and the preparation method thereof break through the traditional model in which the battery electrode is fixed in the battery. The electrode particles of the battery electrode can be input into or output from the battery body, can be charged in the battery body and also can be moved out of the battery body to carry out charging and maintenance. The battery electrode has the advantages that the manufacturing automatization of the battery electrode can be realized; the volume and the weight of the battery are reduced; the use performance of the battery is improved; and fast charge is achieved.

Owner:郑力

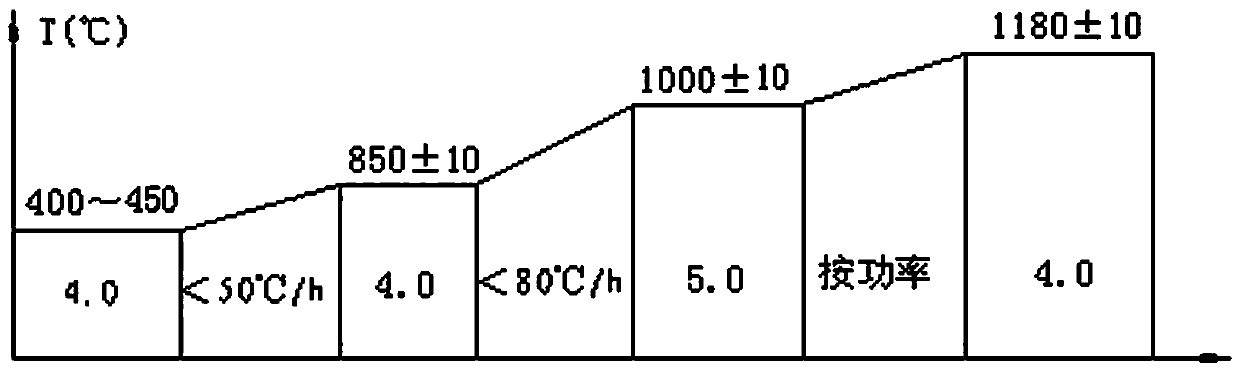

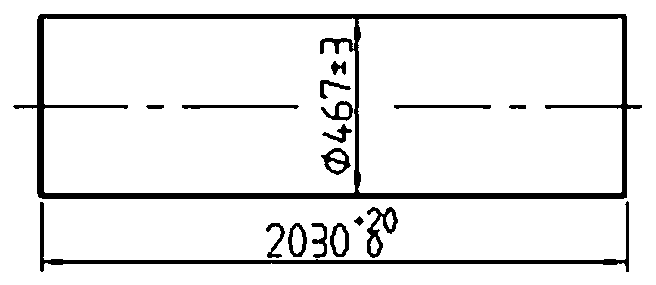

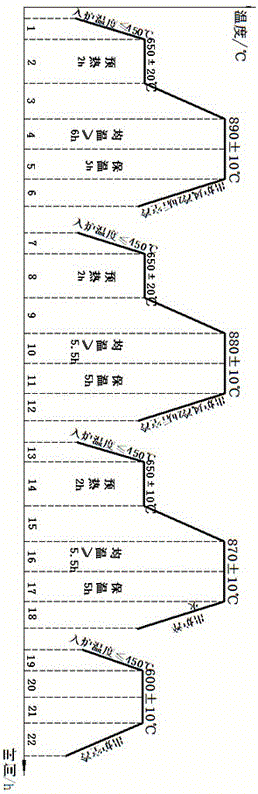

Forging method for large-specification crystallization roller steel forged piece

ActiveCN107617713AImprove forgeabilityImprove toughnessEngine componentsHeating/cooling devicesDeformation controlToughness

The invention relates to a forging method for a large-specification crystallization roller steel forged piece. The forging method comprises the steps that a raw material is fed into a furnace and thensubjected to heat preservation at the temperature of 400-450 DEG C, the temperature is increased to 850+ / -10 DEG C at the rate of no greater than 50 DEG C / h, then preserved, then increased to 1000+ / -10 DEG C at the rate of no greater than 80 DEG C / h, afterwards increased to 1180+ / -10 DEG C and preserved, and the piece is discharged out of the furnace and forged, specifically, the upsetting speedis controlled during forging, the piece is forged on an upper flat anvil being 700 mm wide and a lower V-shaped anvil of 135 degrees while being subjected to drawing deformation, the rolling reductionof the first pass is controlled to be 30-50 mm, the rolling reduction of the second pass is controlled to be 50-80 mm, then main deformation of high rolling reduction is conducted, the rolling reduction of each pass is 120-150 mm, the anvil stagger amount of each pass is at least 50 mm, and forging deformation is in a pulling impact or pushing impact mode; and nicking is conducted after the pieceis drawn to be of a certain dimension, a hammer is changed to perform forging deformation on upper and lower flat anvils being 700 mm wide, pushing impact forging is conducted from the end portion tothe inside, deformation control is conducted in a half anvil feeding mode with small rolling reduction, forging cracking and end surface pits can be avoided, the problems of post-forging coarse grains and unqualified ultrasonic exploration can be solved, and the requirements for texture, strength and toughness after tempering can be met.

Owner:HENAN ZHONGYUAN SPECIAL STEEL EQUIP MFG CO LTD

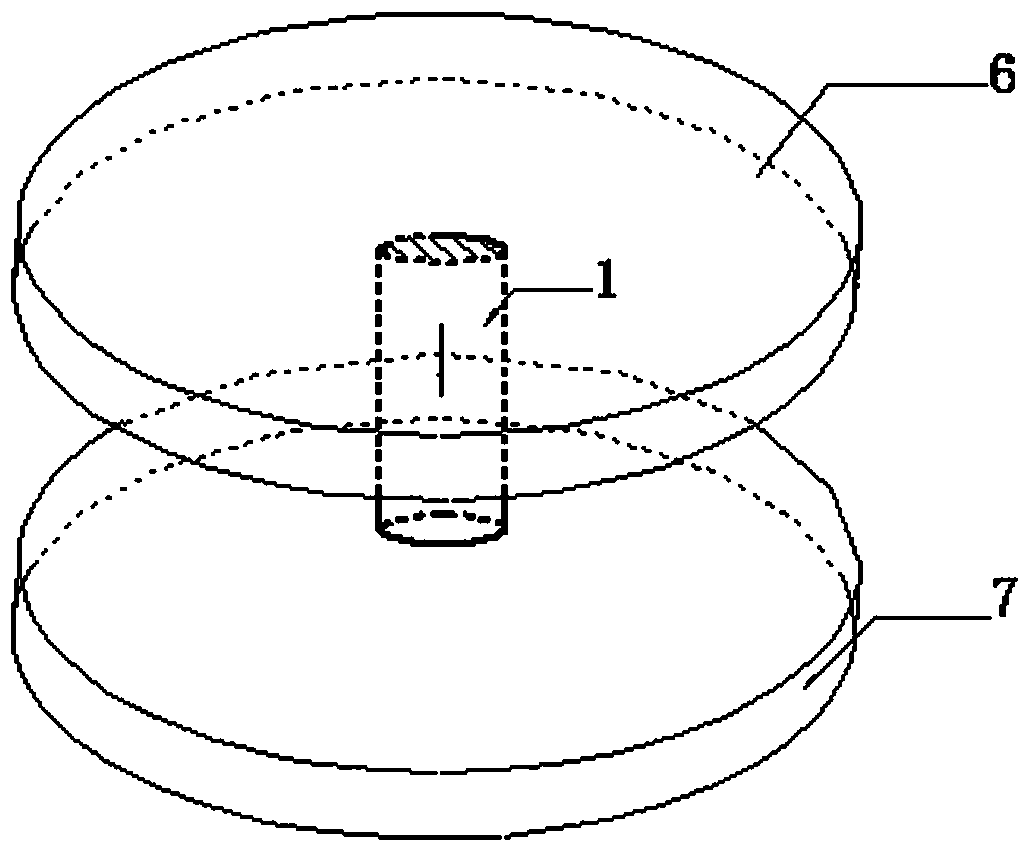

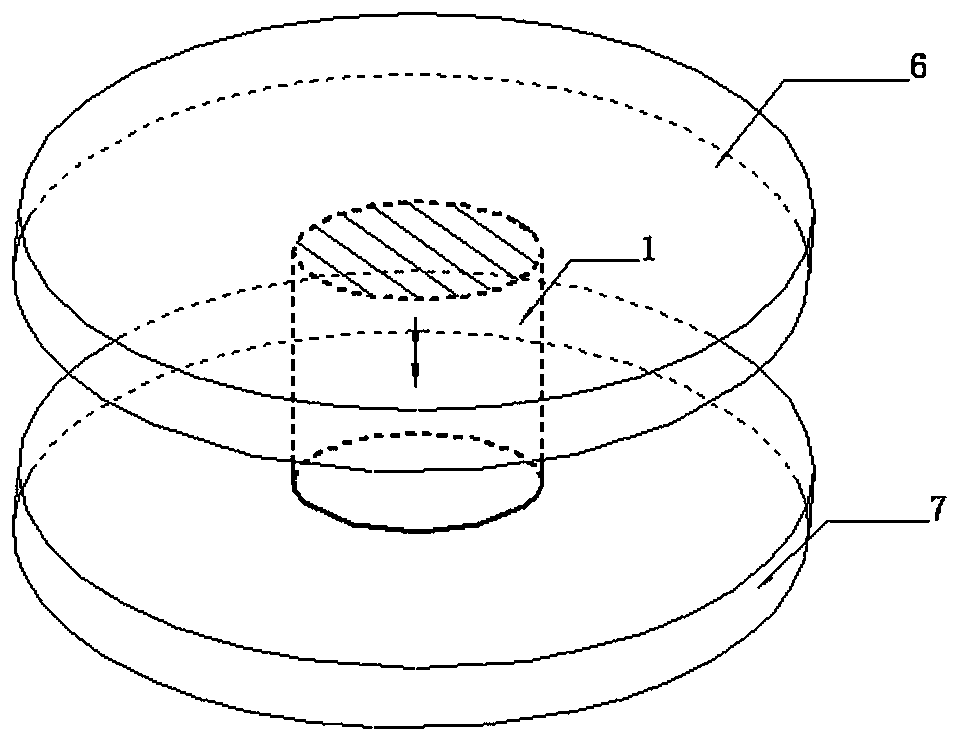

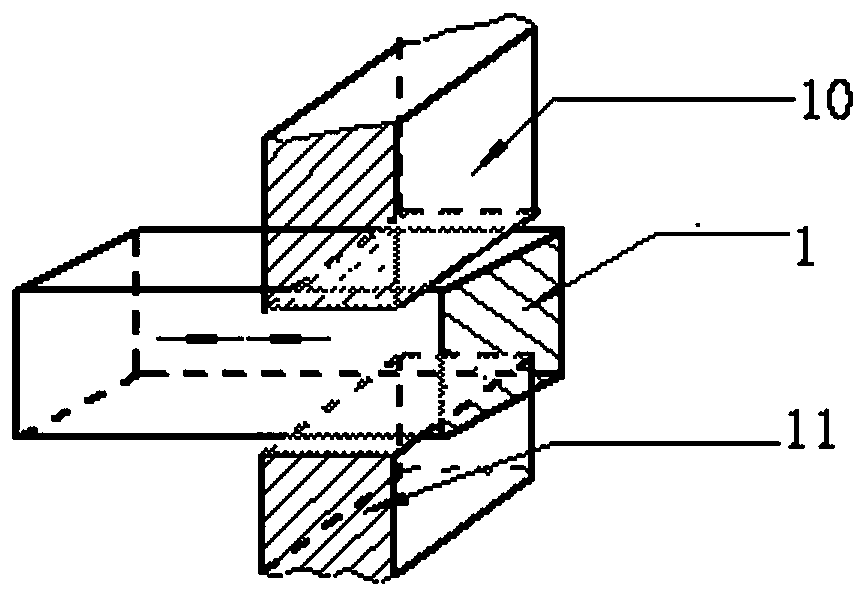

Forging method capable of efficiently, integrally and uniformly compacting deformation

InactiveCN108465762AImprove forgeabilityImprove forging efficiencyMetal-working apparatusIngotDeformation Problem

The invention relates to a forging method capable of efficiently, integrally and uniformly compacting deformation, and the forging method can uniformly refine compacting deformation and the structureof a large forged piece product. The forging method is characterized in that special upper and lower wide plates are adopted for upsetting and forging a forged piece, so that forging main deformationis completed; then, finishing forming is performed on upper and lower anvils; a special wide plate is utilized for integrally forging, so that forging permeability is greatly improved, and the problemthat forging deformation is uneven at positions such as each hammer head, and a joint of the hammer heads during upper and lower anvil forging is also overcome, and therefore, the inner part of the forged piece is forged thoroughly and compacted, and a uniform fine grain structure is obtained; upset electroslag ingots are mainly deformed on upper and lower wide plates, and integral once formationis performed until design dimensions at every pass in a wide plate forging process, and reduction is controlled to be 25%-40%; the electroslag ingots are integrally forged until deformed to the designed dimensions between upper and lower flat plates after being turned over by 90 degrees, and 700mm-wide upper and lower nails are adopted for forging and forming so as to conveniently erecting angles, so that the uneven forging deformation problem of the hammer head during main deformation is avoided, forging permeability is improved, anvil replacing times are reduced, forging time is saved by about 1 / 2, forging production efficiency is improved, production cost is reduced, and product quality stability is high.

Owner:HENAN ZHONGYUAN SPECIAL STEEL EQUIP MFG CO LTD

Oxidation desulfuration method based on modified MCM-41 anchored heteropolyacid catalyst

InactiveCN102134508AEasy to prepareHigh catalytic activityMolecular sieve catalystsTreatment with plural serial refining stagesFiltrationRoom temperature

Owner:SHANDONG UNIV

Reaction-type crab-flavor essence and preparation method thereof

The invention provides a reaction-type crab-flavor essence and a preparation method thereof. The preparation method comprises the following steps: taking the leftovers, such as crab legs and crab pincers and the like as raw materials; carrying out pretreatment and enzymolysis, combining other ingredients and adopting a corresponding preparation process to prepare into the crab-flavor essence. The obtained crab-taste essence has aromatic crab flavor, fresh mouthfeel and high truth degree, reduces the cost, and solves the problems of wasting and polluting the proteins of the crab leftovers.

Owner:TIANJIN CHUNFA BIO TECH GRP

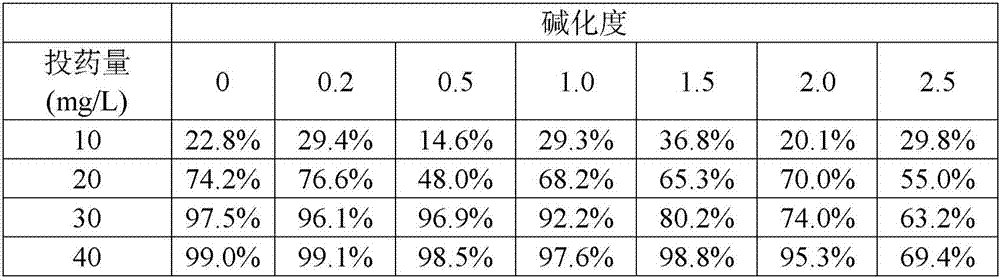

Preparation method of polymerizing zirconium tetrachloride type inorganic macromolecular coagulant and application thereof

InactiveCN107151030AHigh removal rateImprove coagulation efficiencyWater/sewage treatment by flocculation/precipitationZirconium halidesChemical industryWater supply

The invention discloses an inorganic polymer coagulant for water treatment and a preparation method thereof. The inorganic macromolecule coagulant is polymerized zirconium tetrachloride, which uses zirconium tetrachloride and concentrated lye as raw materials, and slowly adds the concentrated lye to the zirconium tetrachloride solution to obtain different suitable alkalization degrees, concentrated alkali The dropwise addition process is controlled to be completed within 3 hours, and then the stirring is continued for 3-5 hours until the solution becomes a colorless and transparent liquid. The inorganic polymer coagulant provided by the invention has the advantages of good product stability, strong adsorption and bridging ability to colloidal substances, good coagulation effect, wide application range, etc., and can be widely used in water supply, wastewater treatment, papermaking, textile printing and dyeing , Daily chemicals and other fields, and has a good water treatment effect. The method of the invention has the characteristics of simple and convenient process, economy, speed and the like.

Owner:UNIV OF SCI & TECH OF CHINA

Iron-rich cooled agglomerated pellet and manufacturing technology and purpose of iron-rich cooled agglomerated pellet

ActiveCN103627897AGuaranteed StrengthGuaranteed ingredientsManufacturing convertersManufacturing technologySlag

The invention belongs to the technical field of comprehensive resource utilization and relates to an iron-rich cooled agglomerated pellet, and a manufacturing technology and a purpose of the iron-rich cooled agglomerated pellet. The invention aims at providing the manufacturing technology of the iron-rich cooled agglomerated pellet, which has the advantages of good pelletizing performance, strong knock resistance, improved pulverization situation and high metallic iron yield. The manufacturing technology comprises the steps of (1) predrying, (2) mixing, (3) pelleting, and (4) natural drying. The key improvements of the technology are (1) selection of a binding agent and (2) a natural airing mode. The iron-rich cooled agglomerated pellet prepared by the technology can be used for replacing scrap steel to be applied to a steel converter for smelting. After enrichment sludge replaces the scrap steel, the heat adjustment of the converter is more flexible in comparison with the scrap steel, a slag state in a process is good, slag comes fast, dephosphorization and desulfuration effects are stable, and the total iron yield is 89.29% and reaches an expected level. Compared with the scrap steel, the production technology is superior, and the price is lower.

Owner:PANGANG GRP PANZHIHUA STEEL & VANADIUM

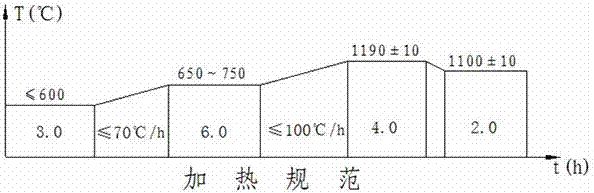

Forging process for steel forging piece for 2Cr11Mo1VNbN steam turbine blade

InactiveCN106903246AImprove toughnessImprove forgeabilityForging press drivesEngine componentsSteam turbine bladeIngot

The invention relates to a forging process for a steel forging piece for a 2Cr11Mo1VNbN steam turbine blade. The forging process comprises the following steps of: during heating before forging, controlling a charging temperature to not exceed 600 DEG C, controlling a low-temperature temperature rise rate to not exceed 70 DEG C / h, preserving heat for 6-8 hours at a temperature of 650-750 DEG C, and heating to 1190 + / -10 DEG C at temperature rising speed not exceeding 100 DEG C / h, cooling to 1100 + / - 10 DEG C after preserving the heat for 4-6 hours at a temperature of 1190 + / -10 DEG C, and tapping and forging after preserving the heat for 2-4 hours; during forging, adopting a A-B-clamping-jaw transverse pulling forging mode or a pushing forging mode through a precision forging machine, clamping the tail end of an ingot after loading, and enabling a dead head end to face towards a chuck B. In order to overcome the defects that a steel structure, produced in the prior art, for the 2Cr11Mo1VNbN steam turbine blade is high in sigma-ferrite content, is extremely liable to crack during forging, and is severely affected in strength and toughness, the invention provides the forging process for the steel forging piece for the 2Cr11Mo1VNbN steam turbine blade, and the forging process solves the cracking problem of the steel forging piece for the 2Cr11Mo1VNbN steam turbine blade, meets the strength and toughness requirements, reduces machining allowance and improves production efficiency.

Owner:HENAN ZHONGYUAN SPECIAL STEEL EQUIP MFG CO LTD

Process for heat treatment of 12Cr1MoVG high pressure tubes after forging

ActiveCN104017976AProduction process economyProduction Technology ScienceFurnace typesHeat treatment furnacesRate limitingHydrogen

The invention relates to a process for heat treatment of 12Cr1MoVG high pressure tubes after forging. After vacuum degassing, [H] contents are detected by online hydrogen determination, so that processes for heat treatment of the 12Cr1MoVG high pressure tubes after forging for are respectively formulated against two conditions that [H] is greater than or equal to 3ppm and [H] is less than 3ppm; a process of hydrogen diffusion and then normalizing is adopted for the 12Cr1MoVG high pressure tube of which [H] content is greater than or equal to 3ppm detected by online hydrogen determination, a rate-limiting cooling stage in the original process is cancelled, the hydrogen diffusion time at 650 DEG C is appropriately prolonged, and temperature rise is directly carried out after hydrogen diffusion is ended so as to carry out normalizing, and the workpiece is hoisted down from a lathe after normalizing and is then subjected to air cooling, so that the annealing time is greatly shortened; after vacuum degassing, except for optimizing according to above process, as for the 12Cr1MoVG high pressure tube of which [H] content is less than or equal to 3ppm detected by online hydrogen determination, a heat insulation stage at 500-650 DEGC as well as hydrogen diffusion annealing and normalizing temperature rise rate limiting stages are not required, and thus the annealing process peroid is further shortened. The invention discloses the process for heat treatment of the 12Cr1MoVG high pressure tubes after forging, which has the advantages that the production peroid is effectively shortened, the productivity of high pressure tubes after forging is increased and the normalizing effect is improved.

Owner:HENAN ZHONGYUAN SPECIAL STEEL EQUIP MFG CO LTD

Plywood with twist resistance and high strength and manufacturing method thereof

InactiveCN102514053AWide range of applicationsProduction process economyLaminationLamination apparatusWater circulationEnvironmental resistance

The invention discloses a plywood with twist resistance and high strength and a manufacturing method thereof and belongs to the field of plywoods. The plywood comprises multiple layers of single plates, wherein the textures of adjacent single plates are mutually vertical; and a binding layer is arranged between the adjacent single plates and is a formaldehyde-free hot melt film. The manufacturing flow of the plywood comprises the following steps of: selecting the single plates; drying the single plates until the water content of the single plates is less than 12 percent; sloping the single plates; combining the single plates; pre-pressing the single plates; performing hot rolling on the single plates; cooling the single plates (cold water circulation); puttying the single plates; setting the thickness and sanding the plates; sawing sides of the single plates; coating a masking agent on the single plates; performing cold pressing (0.67MPa); veneering; performing hot rolling; and sawing sides. The plywood has the beneficial effects that: the bonding strength is high and passes a bonding strength test of I type of man-made board / phenolic glue (WBP) level and I type of man-made board; the plywood does not contain formaldehyde, is highly environment-friendly and is high in bonding strength; a glue coater is not required, so the traditional glue coating process is thoroughly changed; pollution caused by cleaning the glue coater is avoided; the production process is simple; the labor is saved; and the defect of short water activity period of the traditional liquid glue is overcome.

Owner:XUZHOU ANLIAN WOOD

Preparation method of reactive crab-taste essence

The invention provides a preparation method of a reactive crab-taste essence, which is characterized by comprising the following steps of: carrying out pretreatment and enzymolysis on leftovers comprising crab legs, crab claws and the like, then compounding leftovers with other auxiliary materials and adopting corresponding preparation processes to prepare the crab-taste essence. The obtained essence has the advantages of thick crab taste, delicious taste and high reality, simultaneously reduces cost and solves the problems of protein waste and pollution of crab leftovers.

Owner:TIANJIN CHUNFA BIO TECH GRP

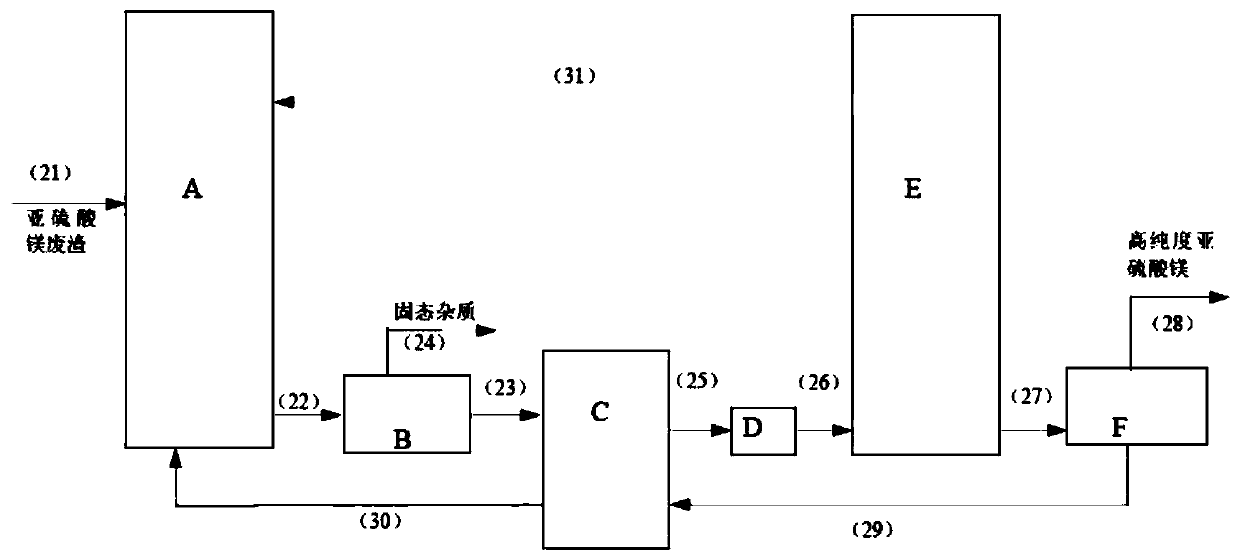

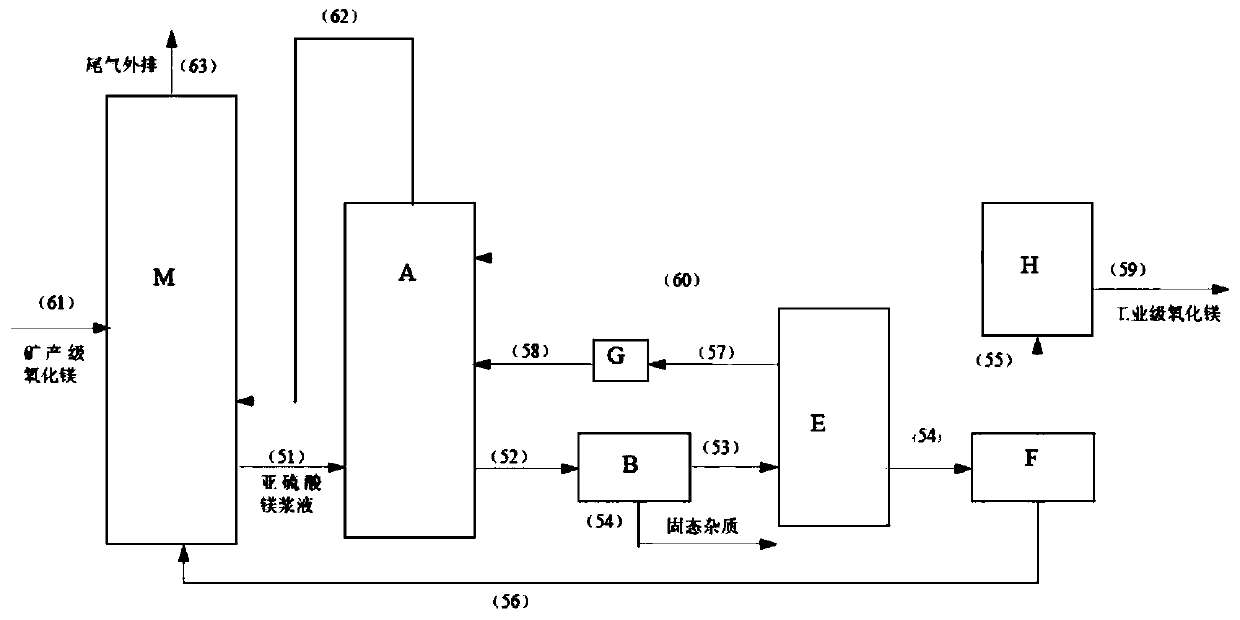

Production method of high-purity magnesium sulfite

PendingCN110844926AHigh recovery rateSolve Oxidation ProblemsMagnesium sulfitesMagnesiaHydrogen SulfateMagnesium bisulfite

The invention relates to a production method of high-purity magnesium sulfite. The production method comprises the following steps: introducing sulfur dioxide gas into magnesium sulfite slurry to obtain a magnesium bisulfite solution, removing solid-phase impurities in the magnesium bisulfite solution, decomposing magnesium bisulfite into sulfur dioxide and magnesium sulfite crystals in a heatingor / and pressure reducing way, and recovering the magnesium sulfite crystals, wherein sulfur dioxide gas is reused for the acidification reaction of the magnesium sulfite slurry. Considering from the perspective of flue gas desulfurization, the method has the beneficial effects that the problems of high flue gas desulfurization cost and incapability of comprehensively utilizing desulfurization products of the existing magnesium method flue gas desulfurization are solved, mineral-grade magnesium oxide is converted into industrial-grade magnesium oxide through the desulfurization process, and value-added recycling of flue gas desulfurization is realized. Considering from the perspective of industrial-grade magnesium oxide production, the method has the beneficial effect of creating a high-purity magnesium oxide production process which is low in production cost, high in product quality and less in three-waste pollution.

Owner:江苏联慧资源环境科技有限公司

Method for manufacturing power cables

InactiveCN103137266AProduction Technology ScienceProduction process economyCable/conductor manufactureCross-linkProduct inspection

The invention relates to a method for manufacturing power cables. The method comprises the steps of wire drawing, softening, stranded wire pressing, cross-linking three-layer co-extrusion, copper strip three-layer wrapping, cabling, distance sleeve extrusion, sheath installation, sheath extruding and printing or installed sheath spark testing, finished product inspection and packaging. The method for manufacturing power cables has the advantages that produced power cables are ensured to be safe and reliable, and a production process is scientific and economic.

Owner:SHANGHAI PEOPLE ELECTRICAL APPLIANCE GROUP

Production technology for producing pulullan by fermenting aureobasidium pullulans

InactiveCN107641634AProduction process economyEfficient production processFungiMicroorganism based processesBiotechnologyPullulan

The invention discloses a production technology for producing pulullan by fermenting aureobasidium pullulans. The production technology comprises the following steps: culturing seeds; preparing a seedculture medium; preparing a potato dextrose agar culture medium, a first-grade seed culture medium, a second-grade seed culture medium and a third-grade seed culture medium respectively; carrying outactivated culture on the seeds; inoculating an aureobasidium pullulans strain slant single bacterial colony to a first-grade seed shake flask and carrying out shake flask activation; inoculating an activated seed culture solution into a new second-grade seed culture shake flask according to the volume percent concentration of 1 percent to 20 percent and carrying out amplified culture; then inoculating the seed culture solution subjected to the amplified culture into a third-grade seed shake flask according to the volume percent concentration of 1 percent to 20 percent and culturing to obtaina seed culture solution to be fermented; inoculating the seed culture solution to be fermented into a fermentation tank filled with a fermentation culture medium and carrying out fermentation cultureto obtain the pulullan. The production technology disclosed by the invention has the advantages that the source of the raw materials is wide and the production cost is reduced, and has the effects ofeconomical efficiency, high efficiency and energy saving.

Owner:北京艾普希隆生物科技有限公司

Forging control method for uniformly refining grain sizes of forgings

ActiveCN110684885ASolve the coarse grainSolve the mixed crystal problemMixed crystalIndustrial engineering

The invention relates to a forging control method for uniformly refining grain sizes of forgings. Special forging control and furnace return heating modes are adopted in the forging process of large forgings, so that the surface and heart temperatures of the forgings tend to be consistent, the heart structures of the forgings are totally transformed, and the internal structures of the large forgings are uniformly refined; the before-forging high-temperature heating is adopted; after first heating number upsetting and lengthening forging, the forgings are cooled in air to reach a certain temperature; after the internal and external surface temperatures of the forgings tend to be consistent, the forgings are returned to the high-temperature furnace for heating; after second heating number upsetting and lengthening, the forgings are cooled in air to reach a certain temperature; after the internal and external surface temperatures of the forgings tend to be consistent, the forgings are returned to the low-temperature furnace for heating; the forgings are discharged from the furnace for forging after insulation in the low-temperature furnace by a period of time; and the forging controlmethod can uniformly refine the internal structures of the large forgings under the condition of not increasing the production cost, solves the difficulties of coarse crystals and mixed crystals of the large forgings, greatly reduces the production cost, shortens the production period, and is high in mechanical performance index of the forgings, long in service life and more economical and scientific in production process.

Owner:HENAN ZHONGYUAN SPECIAL STEEL EQUIP MFG CO LTD

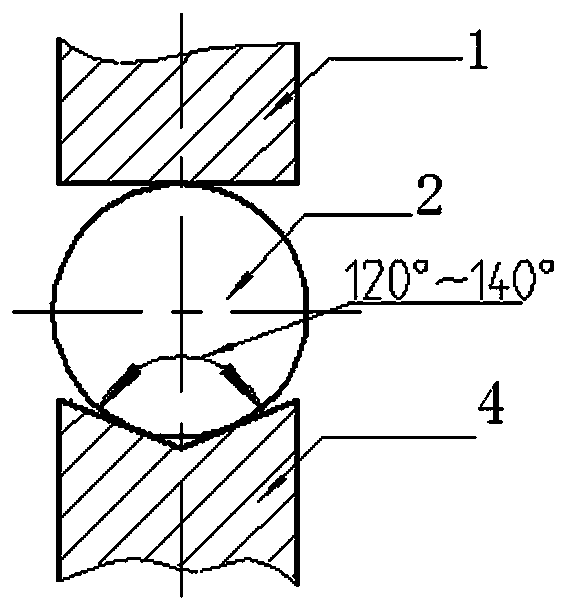

Forging method capable of avoiding general looseness of hollow part forged through continuous casting blank with small deformation amount

InactiveCN108723268AReduce manufacturing costLoose Conformity GuaranteeForging/hammering/pressing machinesStressed stateMetal

The invention relates to a forging method capable of avoiding general looseness of a hollow part forged through a continuous casting blank with small deformation amount. Under the insufficient deformation amount, special upper flat and lower V anvil forging is adopted to replace upper and lower flat anvil forging, the stress state of the blank and the flowing direction of metal are changed, the metal deforming characteristics are changed, and the outer layer metal deforming amount is increased; the continuous casting blank is heated and then fed into an oil press machine, the oil press machineadopts an upper flat and lower V anvil for forging, a precision forging machine is adopted for forging forming, after forging, annealing, inspection, ultrasonic flaw detection and discharging are carried out, through the forging method, general looseness of hollow part products like a corrugated roller produced by the continuous casting blank is avoided, production efficiency is improved, comprehensive production cost is reduced, and the product quality stability is high.

Owner:HENAN ZHONGYUAN SPECIAL STEEL EQUIP MFG CO LTD

Core-shell structure loaded tungsten composite catalyst, preparation method and application thereof

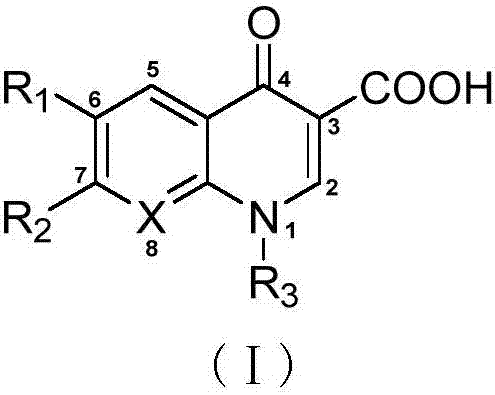

ActiveCN107469828AReduce processing costsEasy to operateOrganic chemistryHeterogenous catalyst chemical elementsRecyclable catalystQuinolone

The invention discloses a core-shell structure loaded tungsten composite catalyst, a preparation method and application thereof. Existing synthesis of the main rings of quinolone drugs mostly has the defects of long synthesis steps, tedious operation, large amount of three wastes, high cost, etc. Fe3O4 colloid and SiO2 / Fe3O4 composite nanoparticles are prepared to prepare a magnetic separation core-shell loaded tungsten composite catalyst WO3 / SiO2 / Fe3O4 used for catalytic synthesis of quinolone compounds. The invention provides an efficient quinolone compound preparation method with magnetically separable and recyclable catalyst. The catalyst prepared by the method provided by the invention can be reutilized in preparation of quinolone compounds, still maintains the original activity and is free of inactivation phenomenon, not only greatly improves the production efficiency, but also reduces environmental pollution.

Owner:HANGZHOU NORMAL UNIVERSITY +1

Green and efficient heterogeneous catalyst for compounding 2,4-di-tert-butylphenol

InactiveCN106975517AImprove catalytic performanceSolution to short lifeOrganic chemistryOrganic compound preparationSolid acidCatalytic effect

The invention relates to a green and efficient heterogeneous catalyst for compounding 2,4-di-tert-butylphenol. The catalyst is a porous solid acid resin catalyst with high specific surface area. Phenol and isobutene are taken as reaction raw materials for producing 2,4-di-tert-butylphenol under a catalytic effect of the nontoxic harmless green solid acid resin catalyst. The catalyst provided by the invention is used for replacing a carclazyte catalyst in the present production, can be repeatedly reused, has the characteristics of long service life, is capable of greatly reducing the production cost of the catalyst, is capable of greatly reducing the solid waste generated by disposable use of the carclazyte catalyst and can realize the greening of the production process. Meanwhile, the heterogeneous catalyst for compounding 2,4-di-tert-butylphenol provided by the invention is simply separated, recycled and reused, the separating time of the present carclazyte catalyst is greatly shortened and the production efficiency is obviously increased.

Owner:TONGJI UNIV

Preparation method of hydroxyapatite supported heteropolyacid salt catalyst for catalytic oxidation desulfurization

PendingCN110124741AConducive to loadImprove adhesionOrganic-compounds/hydrides/coordination-complexes catalystsRefining with oxygen compoundsCatalytic oxidationRoom temperature

The invention belongs to the technical field of environmental protection, and particularly relates to a preparation method of a hydroxyapatite supported heteropolyacid salt catalyst for catalytic oxidation desulfurization. An ionic solution is prepared from a chloride and a nitrogen-containing compound, then hydroxyapatite is bonded with the ionic solution, and finally, heteropolyacid reacts withthe hydroxyapatite bonded ionic solution to obtain the hydroxyapatite supported heteropolyacid salt catalyst. The prepared catalyst is used for catalytic oxidation desulfurization, and the catalytic oxidation desulfurization comprises the following steps: mixing an oil product with the catalyst according to a ratio, sequentially adding an ionic liquid and an oxidizing agent according to a proportion under a certain temperature and a normal pressure condition, carrying out a reaction, and then carrying out cooling to room temperature to remove thiophene sulfur-containing compounds in the oil product. Compared with a method using a conventional catalyst, the method has the advantages that the desulfurization condition is mild, desulfurization can be carried out in a low-concentration hydrogen peroxide (0.5%-5%) system, and the desulfurization effect in the oil product is good.

Owner:HAINAN NORMAL UNIV

Connector for hermetic compressors

InactiveCN103842652AEasy to installProduction process economyPositive displacement pump componentsPumpsEngineeringVALVE PORT

Owner:WHIRPOOL SA

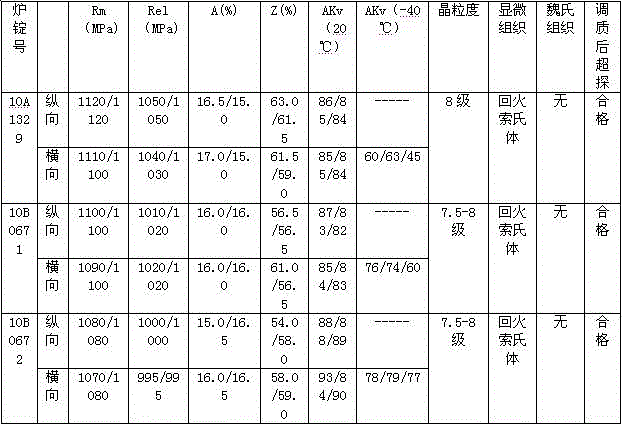

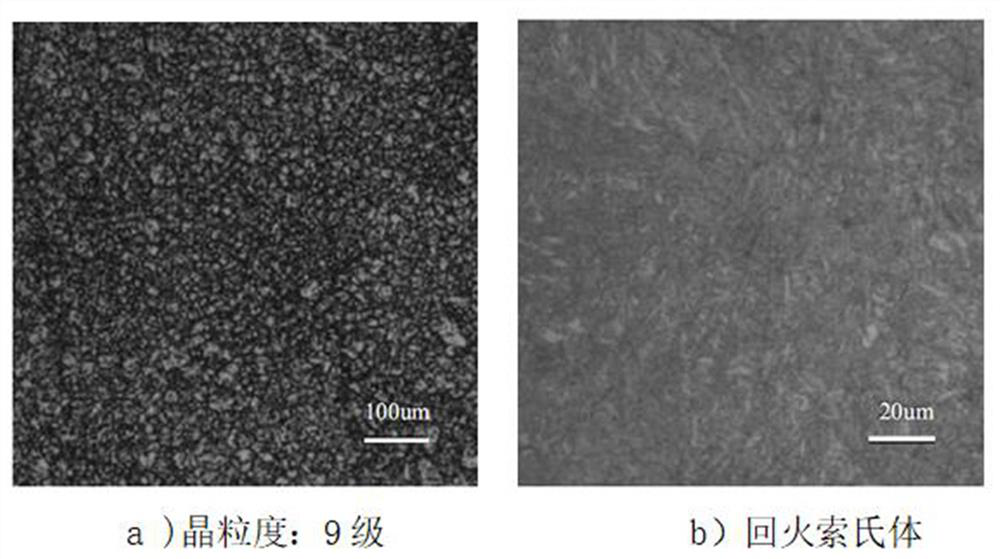

A processing method for grain refinement of crnimov high pressure steel forgings

ActiveCN103981347BHigh low temperature impact toughnessFine grain sizeProcess efficiency improvementTemperature controlChemical composition

Owner:HENAN ZHONGYUAN SPECIAL STEEL EQUIP MFG CO LTD

Preparation device and method of methyl 3-methyl-2-butenoate

PendingCN112409174AGood yieldReduce usageOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsIndustrial scaleMethyl methacrylate

The invention discloses a device and a method for preparing methyl 3-methyl-2-butenoate. The self-design device comprises a reaction kettle, a reaction reflux and distillation condenser, a rectifyingkettle, a rectifying tower section and a rectifying tower top condenser, the reaction kettle is connected with the reaction reflux and distillation condenser through a pipeline; the reaction reflux and distillation condenser is connected with the rectification kettle through a pipeline; the rectifying kettle is connected with the rectifying tower section; the top of the rectifying tower section isconnected with the rectifying tower top condenser through a pipeline; the rectifying tower top condenser is connected with the reaction kettle through a pipeline. According to the method, the ionic liquid is used as a catalyst for esterification reaction of methyl 3-methyl-2-butenoate, on the base of the self-designed preparation device, the reaction process is carried out synchronously with separation of methyl 3-methyl-2-butenoate and (or) water, an ionic liquid catalyst is repeatedly used for five times, and the average yield of the reaction is 90.7%. The invention provides a safe, economic, green and environment-friendly preparation device and method for industrial scale production of methyl 3-methyl-2-butenoate.

Owner:浙江丽晶化学有限公司

Preparation method and application of polyamide-amine dendrimer polymer immobilized heteropoly acid catalyst

InactiveCN108295879AEfficient removalMild reaction conditionsOrganic-compounds/hydrides/coordination-complexes catalystsRefining with oxygen compoundsDendrimerHeteropoly acid

The invention belongs to the crossing field of deep processing of petrochemical oil products and environmental protection technology, and particularly relates to a preparation method and an application of a polyamide-amine dendrimer polymer immobilized heteropoly acid catalyst. The method comprises the steps as follows: adding a polyamide-amine dendrimer polymer to deionized water, and performingheating and stirring; dissolving heteropoly acid in deionized water to prepare a solution and dropwise adding a polyamide-amine dendrimer polymer solution, controlling the temperature, and performingintense stirring and dialyzing and separating to prepare the polyamide-amine dendrimer polymer immobilized heteropoly acid catalyst. Compared with the traditional catalyst, when applied to oxidative desulfurization, the catalyst prepared with the method has the advantages that the desulfurization condition is mild, desulfurization can be performed in the hydrogen peroxide system with lower concentration (0.5%-5%), the decomposition rate of hydrogen peroxide is low, and the desulfurization effect in oil products is good.

Owner:HAINAN NORMAL UNIV

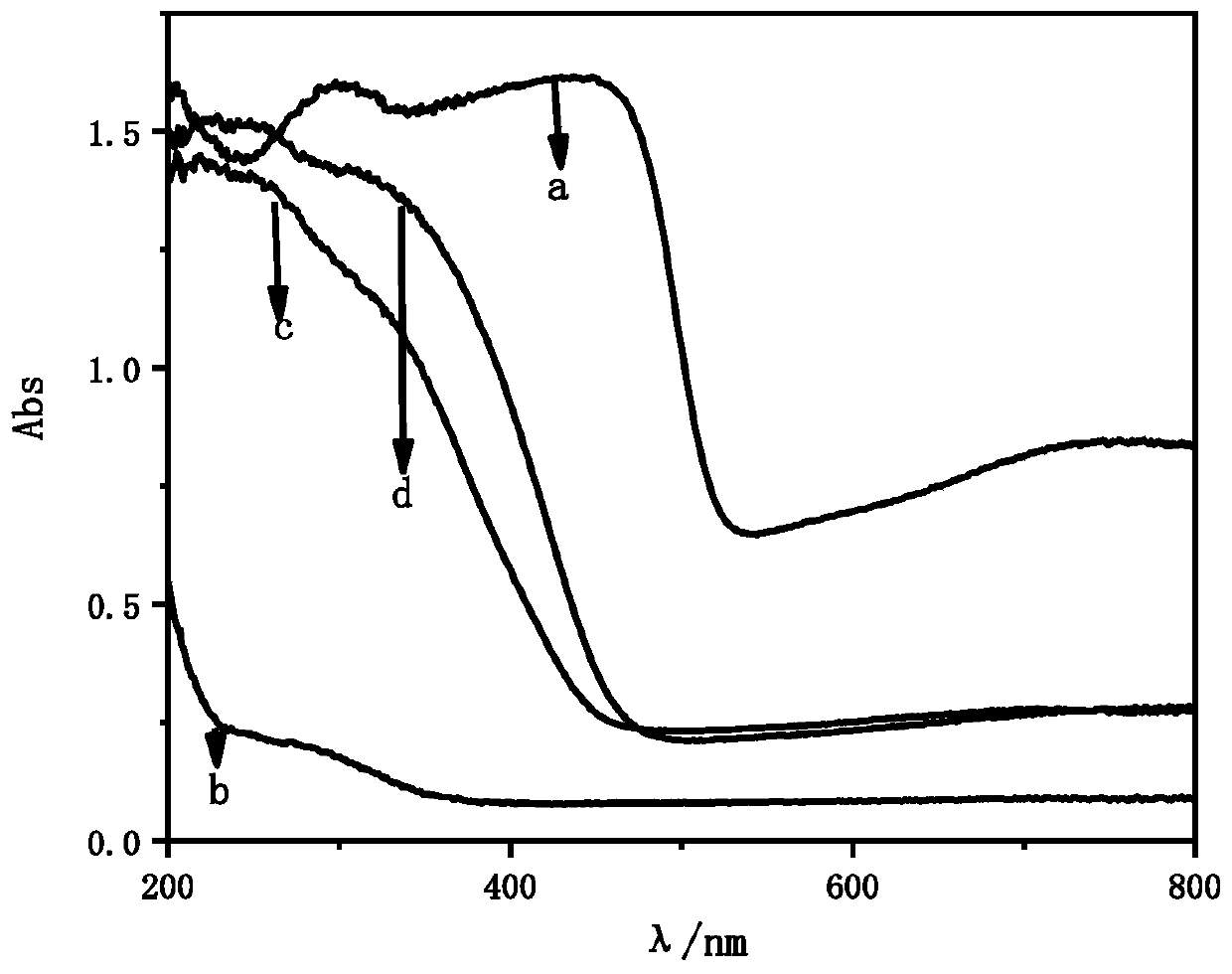

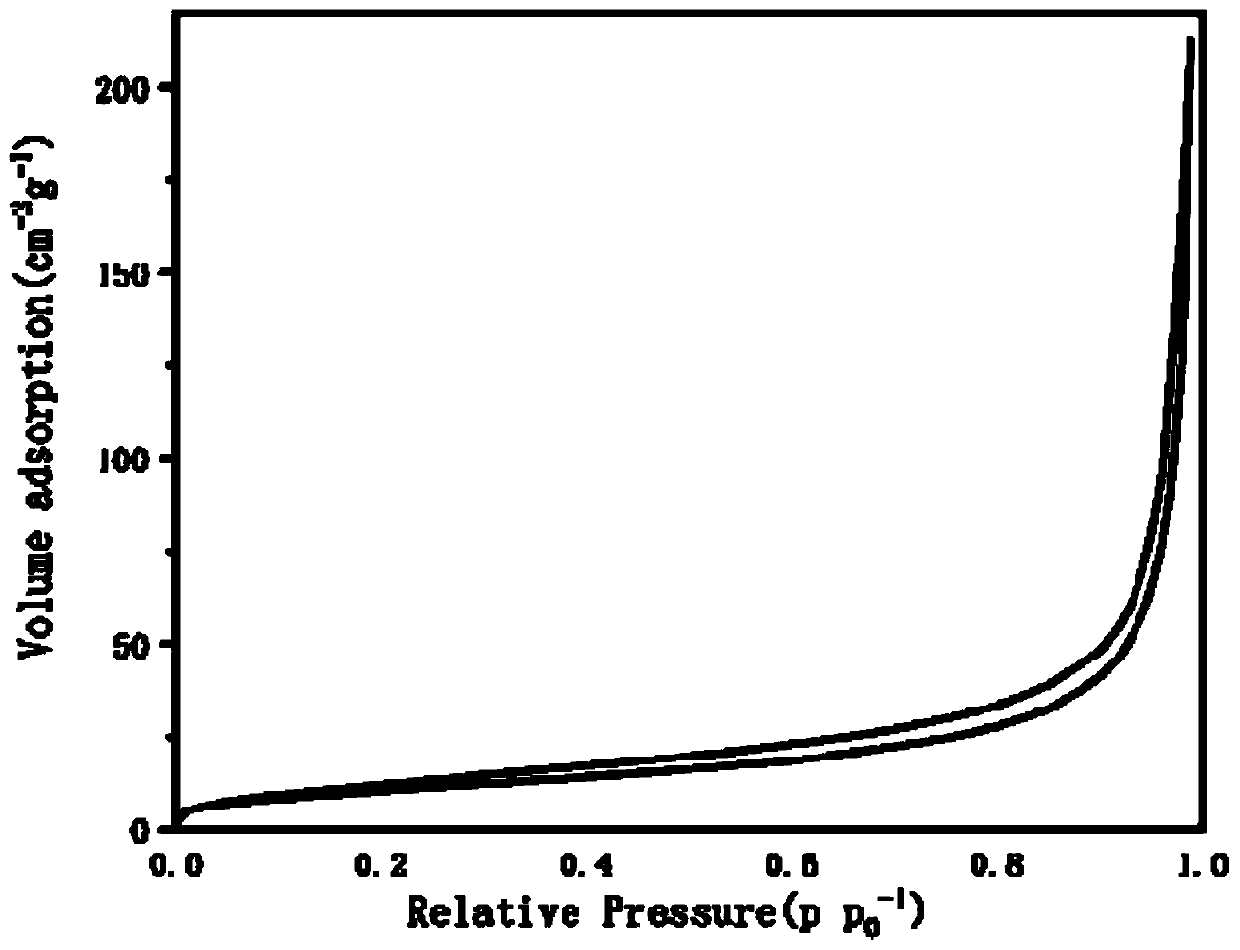

Oxidation desulfuration method based on modified MCM-41 anchored heteropolyacid catalyst

InactiveCN102134508BEasy to prepareHigh catalytic activityMolecular sieve catalystsTreatment with plural serial refining stagesFiltrationRoom temperature

The invention discloses an oxidation desulfuration method based on modified MCM-41 anchored heteropolyacid catalyst, adopting hydrogen peroxide as oxygenant and modified MCM-41 anchored heteropolyacid as catalyst. The method comprises the following steps: proportionally mixing oil with acetonitrile solvent, proportionally adding the mixture of the oxygenant and the catalyst at certain temperature and normal pressure, cooling to room temperature after reaction, naturally layering, obtaining desulphurized oil products at the upper layer of oil phase, separating the catalyst in the lower layer (namely the acetonitrile phase) through filtration, and recycling. Compared with the traditional process, the method has the advantages of low production process, high safety of operation under normal pressure, strong desulfuration capability, saving of oxygenant and low production cost, and achieves efficient, economic and environment-friendly production process.

Owner:SHANDONG UNIV

Forging Control Method for Uniformly Refining the Grain Size of Forgings

ActiveCN110684885BNo abnormal grain growthTransform Uniform ThinningEngineeringIndustrial engineering

The invention relates to a forging control method for uniformly refining the grain size of forgings. For the forging process of large forgings, a special forging control and furnace heating method are adopted to make the temperature of the surface and core of the forging tend to be consistent, so that the structure of the core of the forging is completely Transformation, to achieve uniform refinement of the internal structure of large forgings, adopt high temperature heating before forging, after the first fire upsetting and elongation forging, air cool the forgings to a certain temperature, so that the temperature of the inner and outer surfaces of the forgings tends to be consistent, and then return to the high temperature furnace for heating; After the second fire upsetting and drawing, the forging is air-cooled to a certain temperature, and after the temperature of the inner and outer surfaces of the forging tends to be consistent, it is heated in a low-temperature furnace; Without increasing production costs, the internal structure of large forgings is evenly refined, which solves the problem of coarse grains and mixed crystals in large forgings, greatly reduces production costs and shortens the production cycle. Forgings have high mechanical properties and long service life. Production The process is more economical and scientific.

Owner:HENAN ZHONGYUAN SPECIAL STEEL EQUIP MFG CO LTD

Forging and heat treatment method of large size 20simn spindle

ActiveCN110257617BImprove forgeabilityUniform mechanical propertiesMetal-working apparatusFurnace typesPhysical chemistryEngineering

The invention discloses a method for forging and heat treatment of a large-sized 20SiMn main shaft. After the steel ingot is raised to 1200°C-1250°C according to a special process, the pre-pressing tongs are carried out first, and then returned to the furnace for heat preservation. After the heat preservation is completed, two upsetting and two Pull forming, the drawing process adopts WHF method, and the reduction amount of each pass is controlled at 18% to 22%. The flange forming adopts the principle of JTS forging method, and the deformation amount reaches 7%, which ensures the reasonable and effective compaction effect; after forging Air-cooled to 350℃~400℃, and then processed by special double normalizing + tempering heat treatment process, and air-cooled after two times of normalizing; improved the coarse grain clutter and performance of forgings, and improved the large-scale 20SiMn spindle overall product quality.

Owner:HENAN ZHONGYUAN SPECIAL STEEL EQUIP MFG CO LTD

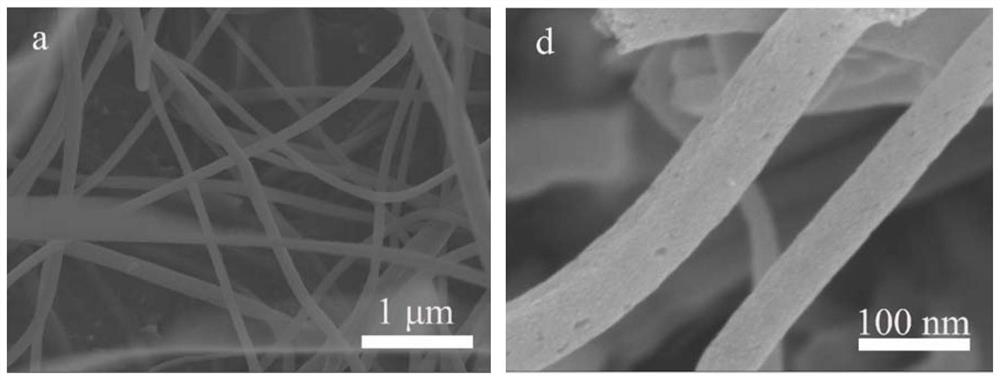

Preparation method and application of nanofiber loaded heteropolyacid salt catalyst

PendingCN113893878ALarge specific surface areaIncrease the active siteOrganic-compounds/hydrides/coordination-complexes catalystsTreatment with plural serial refining stagesO-Phosphoric AcidPtru catalyst

The invention belongs to the crossing field of environmental protection technology and oil chemical deep processing industry, and particularly relates to a preparation method and application of a nanofiber loaded heteropolyacid salt catalyst. The preparation method comprises the following steps: mixing MoO3 and V2O5, adding into deionized water, carrying out condensing reflux heating to 100 DEG C, continuously stirring, adding phosphoric acid, stirring, and drying to obtain an H5PMo10V2O40 catalyst; carrying out electrostatic spinning by taking a mixed solution of polyacrylonitrile and melamine as a carrier to obtain nanofibers; and calcining in oxygen, introducing argon, and calcining for 2 hours to obtain the nanofiber loaded heteropolyacid salt catalyst. The catalyst is used for catalytic oxidation desulfurization, and has obviously improved desulfurization benefit.

Owner:HAINAN NORMAL UNIV

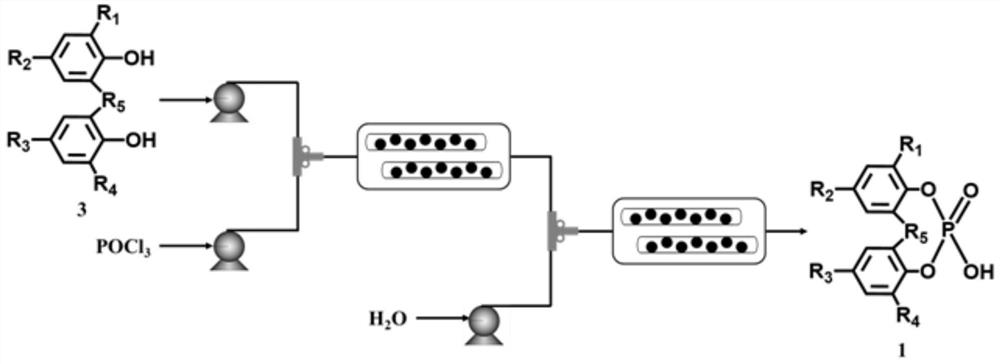

Continuous preparation method of substituted diaryl phosphate compound

PendingCN113896745ASolve the blockageHigh yieldGroup 5/15 element organic compoundsContinuous reactorPhosphate

The invention discloses a continuous preparation method of a substituted diaryl phosphate compound, which comprises the steps disclosed in the invention; the preparation method of the substituted diaryl phosphate compound in a continuous reactor provided by the invention has the characteristics of short reaction time, mild reaction conditions, high purity, few byproducts, high yield, large output and the like, the utilization rate of raw materials is very high, the technical process is more green, environment-friendly, economical and efficient, the product yield is up to 99% or above, and the product purity is up to 99.9% or above.

Owner:EAST CHINA UNIV OF SCI & TECH +1

Forging control method of large-specification stepped shaft component

The invention relates to a forging control method of a large-specification stepped shaft component. A forging drawing design is optimized, and a steel ingot is subjected to scarfing and shoulder cutting treatment before forging, so that a riser material is prevented from extending to a steel ingot body during forging production; special before-forging air-cooling temperature control heating is made, so that temperature stress and structural stress of the low-carbon steel ingot are overcome, the surface crack problem of a forge piece is avoided, the rejection rate is reduced, and the machiningallowance is reduced; a special tool is utilized to carry out notch design, firstly, triangular iron is used for nicking, and then a special narrow block is used for notch deformation, so that the material stripping problem at a step is reduced, and the problem that process materials are added due to wide anvil deformation of the notch is solved; and during forming deformation, narrow anvil forging is adopted, a square-octagon-hexadecagon-circle forging deformation mode is utilized in the small step deformation process, and the feeding amount of each time is controlled to be 0.6-0.85 time of the height of a blank before pressing, so that the eccentric problem is avoided, the machining allowance is reduced, the material utilization rate is improved, the production cost is reduced, and the product quality is stable.

Owner:HENAN ZHONGYUAN SPECIAL STEEL EQUIP MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com