Accumulator electrode with internal particle movable and producing process thereof

A production method and battery technology, which are applied in battery electrodes, electrode manufacturing, circuits, etc., can solve the problems of bulky plates, complex processes, and shortened battery life, achieving economical production processes, light volume and weight, and improved efficiency. The effect of using performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings of the description.

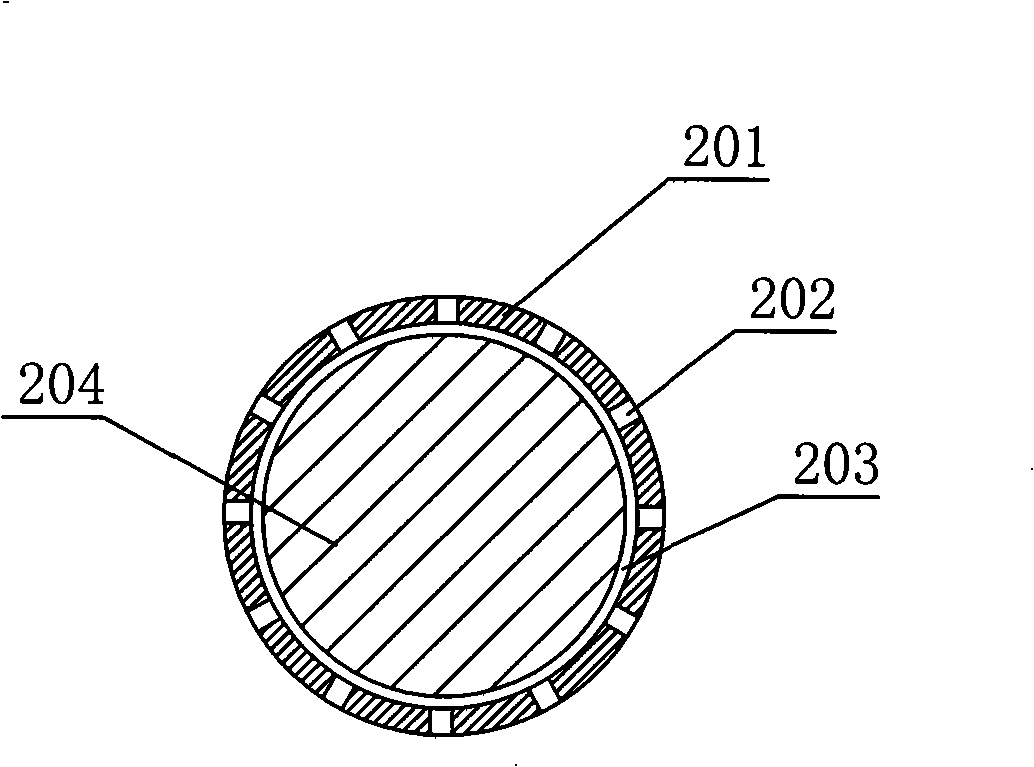

[0032] As shown in the figure, the battery electrode with movable internal particles includes an electrode frame 1 installed in the battery body, and movable electrode particles 2 are accumulated in the electrode frame 1, and the electrode particles 2 are cathode particles made of solid electrode materials. Or anode particles, the electrode frame 1 is a mesh structure, the electrode frame 1 is connected with an input pipe 3 and an output pipe 4 protruding from the battery body, and the electrode frame 1 is also connected with an electrode terminal 5 . Described input pipeline 3, output pipeline 4 have upward or downward inclination angle, are provided with input gate 3a, output gate 4a respectively on it, and the pipe diameter of input pipeline 3, output pipeline 4 can make 3-4 The size of the electrode particles 2 passing through at the same time, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com