Tungsten carbide cobalt-copper-molybdenum disulfide self-lubricating wear-resistant coating and preparation method thereof

A technology of tungsten carbide cobalt: copper, tungsten carbide cobalt, which is applied in the field of tungsten carbide cobalt-copper-molybdenum disulfide self-lubricating wear-resistant coating and its preparation field, to achieve the effect of improving friction and wear performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

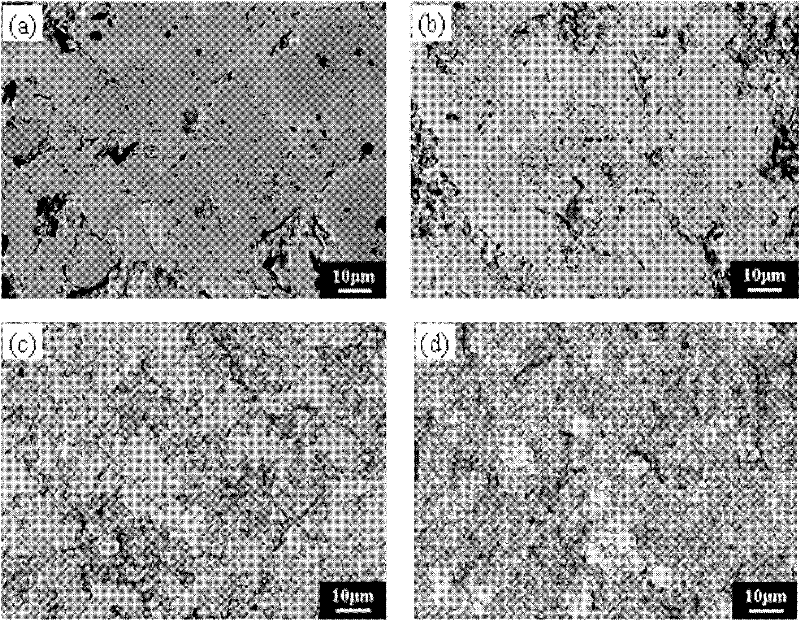

[0041] The powder for atmospheric plasma spraying is 70wt.%WC-Co-18wt.%Cu-12wt.%MoS 2 Powder, spraying base material is A3 low carbon steel plate. Before atmospheric plasma spraying, SiC sand particles are used to pre-process the surface of the sprayed substrate. After pretreatment, the atmospheric plasma spraying system is used for spraying within two hours. With argon as the main gas, hydrogen as the auxiliary gas, the gas flow rates of argon and hydrogen are 50 slpm and 3 slpm respectively; when argon is used as the powder feeding gas, the powder feeding gas flow is 5 slpm, and the powder feeding rate is 14 rpm; used in the spraying process The current is 400A, the voltage is 55V, the spraying distance is 100mm, and the spraying is 25 times. The thickness of the prepared coating is about 250 μm.

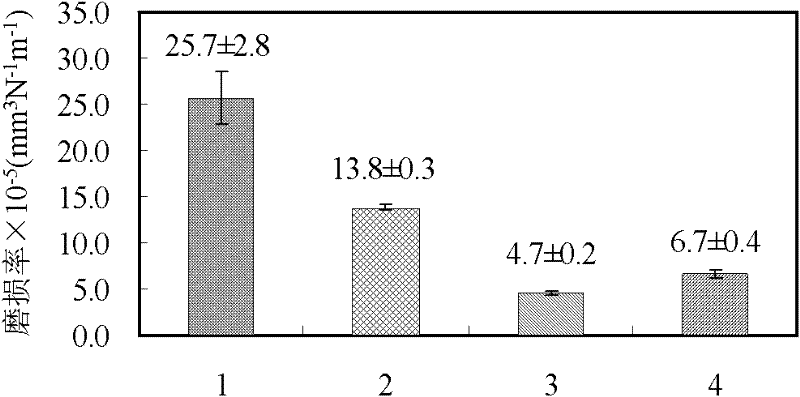

[0042] 70wt.%WC-Co-18wt.%Cu-12wt.%MoS 2 The friction coefficient of the coating is about 0.05, and the wear rate is about (6.7±0.4)×10 -5 mm 3 N -1 m -1 , While the friction coeffic...

Embodiment 2

[0044] The gas flow rates of the main gas and auxiliary gas of the atmospheric plasma spraying in Example 1 were changed to 75 slpm and 3 slpm, respectively, and the other experimental conditions were the same. The resulting 70wt.%WC-Co-18wt.%Cu-12wt.%MoS 2 The friction coefficient of the coating is about 0.07, and the wear rate is about (7.3±0.5)×10 -5 mm 3 N -1 m -1 , While the friction coefficient of the traditional WC-Co coating is about 0.42, and the wear rate is about (25.7±2.8)×10 -5 mm 3 N -1 m -1 . The friction coefficient and wear rate of the composite coating have been significantly improved.

Embodiment 3

[0046] The current of atmospheric plasma spraying in Example 1 was changed to 450A, and the other experimental conditions were the same. The resulting 70wt.%WC-Co-18wt.%Cu-12wt.%MoS 2 The friction coefficient of the coating is about 0.08, and the wear rate is about (6.4±0.3)×10 -5 mm 3 N -1 m -1 , While the friction coefficient of the traditional WC-Co coating is about 0.42, and the wear rate is about (25.7±2.8)×10 -5 mm 3 N -1 m -1 . The friction coefficient and wear rate of the composite coating have been significantly improved.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com