Big-wire diameter suspension helical spring material and preparation method thereof

A coil spring and suspension technology, which is applied in the field of large-diameter suspension coil spring materials for thermal processing and its preparation, can solve the problems of reduced decarburization tendency, low decarburization, and high material cost, so as to improve material strength and increase The effect of grain refinement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

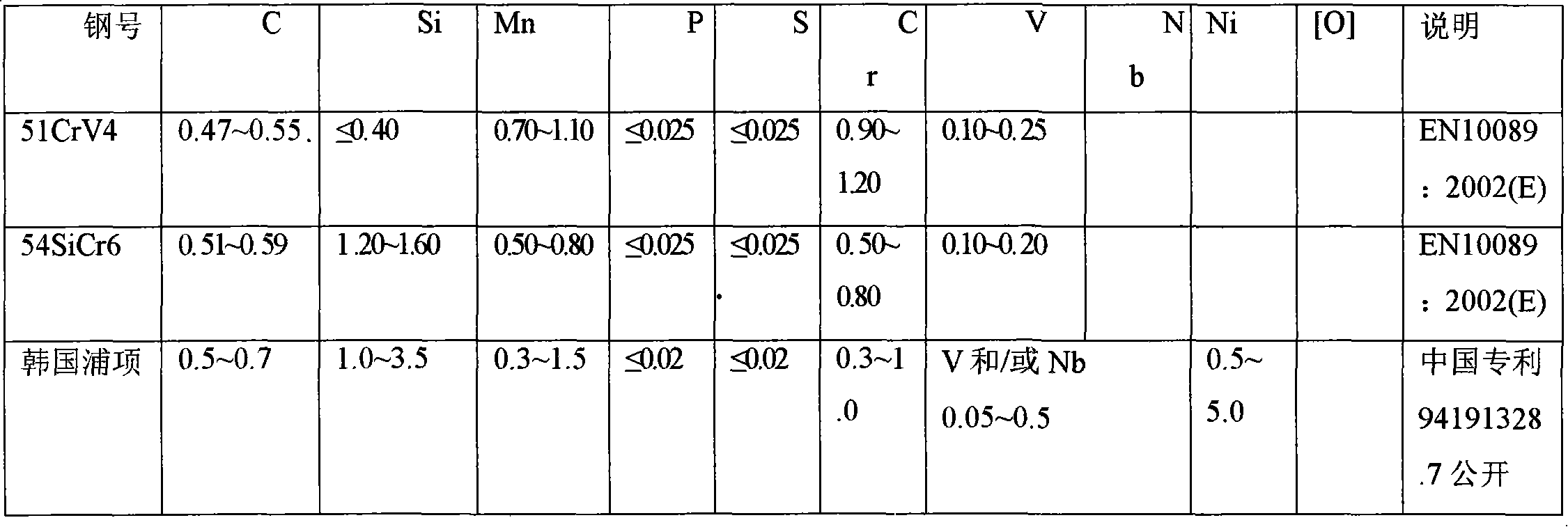

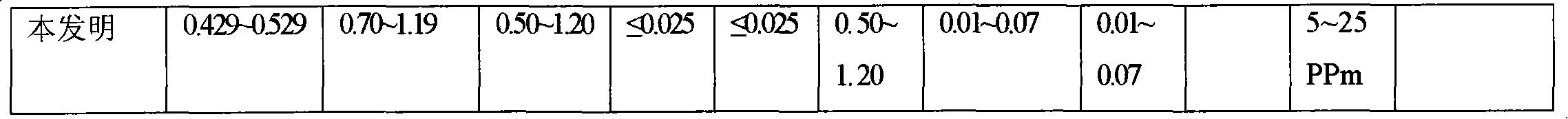

[0046] 1) The chemical composition ratio (Wt%) of the material in Example 1 is shown in Table 5, and the balance is Fe and unavoidable impurities.

[0047] table 5

[0048] C

Si

mn

P

S

Cr

V

Nb

[O]

0.50

0.94

0.84

0.018

0.006

0.97

0.03

0.03

14ppm

[0049] 2) The metallurgical production process of the material of embodiment 1 is: according to the above 1) material composition (Wt%) batching, industrial production electric furnace smelting, furnace outer ladle refining and degassing treatment, mold casting, billet opening, pickling, grinding , rolling.

[0050] 3) The hot-rolled material of the material of Example 1: Φ16-Φ35.

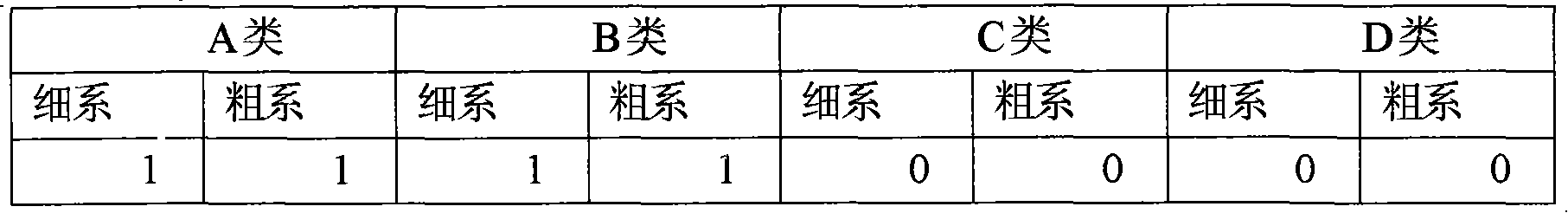

[0051] 4) metallographic examination of the full decarburization layer depth, grain size and non-metallic inclusions of the material in Example 1:

[0052] Φ16 hot-rolled material, fully decarburized layer depth = 0mm, grain size 8.

[005...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| reduction of area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com