Wear-resistant hammer head of hammer crusher with movable installation position and manufacturing method thereof

A technology of hammer crusher and installation location, which is applied in the direction of manufacturing tools, casting molding equipment, casting mold components, etc. It can solve the problems that the material is difficult to meet the wear resistance toughness, the manufacturing process is complicated, and the combination is not firm, so as to solve the problem of production The effect of harsh environment, simple process and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

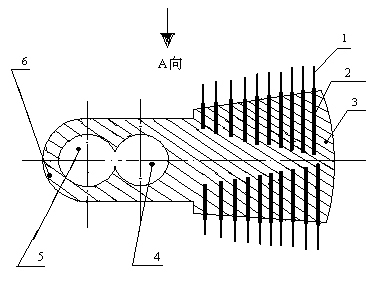

[0015] Embodiment 1: The production unit weight is the tup of 500N, and this tup adopts super high manganese steel to form through lost foam casting, and tup comprises end 3 and handle 6, and two work in the end 3 of tup The hard alloy rod 2 is inlaid on the surface, and there are No. 1 installation hole 4 and No. 2 installation hole 5 at a certain distance on the shank 6 of the hammer head; wherein, the mass fraction of the chemical composition of the ultra-high manganese steel is: C 1.14 %, Si 0.48%, S 0.04%, P 0.05%, Mn 17.82%, Cr 2.17%, MO 0.42%, V 0.17%, Ti 0.12%, RE 0.21%, Fe 77.38%; The two working surfaces of 3 are inlaid with YG20 hard alloy rod 2. The alloy rod is a purchased part with a diameter of 4mm. The mass fraction of its chemical composition is: WC 80%, binder 20%, and its performance is: density / t.m -3 13.4~13.8, bending strength / Mpa 2400~2480, hardness (HRA) 80~83.5.

[0016] The manufacture method of hammer head of the present invention, this manufactu...

Embodiment 2

[0017]Embodiment 2: the production of a hammer head with a unit weight of 600N, the hammer head adopts ultra-high manganese steel through lost foam casting, the hammer head includes an end 3 and a handle 6, and two working parts at the end 3 of the hammer head The hard alloy rod 2 is inlaid on the surface, and there are No. 1 installation hole 4 and No. 2 installation hole 5 at a certain distance on the handle 6 of the hammer head; wherein, the mass fraction of the chemical composition of the ultra-high manganese steel is: C 1.19 %, Si 0.56%, S 0.04%, P 0.06%, Mn 18.64%, Cr 2.48%, MO 0.52%, V 0.21%, Ti 0.15%, RE 0.24%, Fe 75.91%; The two working surfaces are inlaid with YG20 hard alloy rod 2. The alloy rod is a purchased part with a diameter of 4.5 mm. The mass fraction of its chemical composition is: WC 80%, binder 20%, and its performance is: density / t.m. -3 13.4~13.8, bending strength / Mpa 2400~2480, hardness (HRA) 80~83.5.

[0018] The manufacture method of hammer head ...

Embodiment 3

[0019] Embodiment 3: produce the hammer head that unit weight is 700N, this hammer head adopts ultra-high manganese steel to form through lost foam casting, hammer head comprises end 3 and shank 6, two working parts at the end portion 3 of hammer head Hard alloy rod 2 is inlaid on the surface, and there are No. 1 installation hole 4 and No. 2 installation hole 5 at a certain distance on the handle 6 of the hammer head; wherein, the mass fraction of the chemical composition of ultra-high manganese steel is: C 1.23 %, Si 0.66%, S 0.05%, P 0.06%, Mn 19.24%, Cr 2.76%, MO 0.58%, V 0.23%, Ti 0.19%, RE 0.29%, Fe 74.71%; The two working surfaces are inlaid with YG20 cemented carbide rod 2. The alloy rod is a purchased part with a diameter of 5mm. The mass fraction of its chemical composition is: WC 80%, binder 20%, and its performance is: density / t.m -3 13.4~13.8, bending strength / Mpa 2400~2480, hardness (HRA) 80~83.5.

[0020] The manufacture method of hammer head of the present in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com