Hardening and tempering technology of alloy-steel tube

An alloy steel pipe, quenching and tempering technology, used in manufacturing tools, furnaces, heat treatment equipment, etc., can solve the problems of low section shrinkage, low tensile strength, cracking and deformation of steel pipes, and achieve uniform internal structure of the material and fast cooling speed. , the effect of high pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

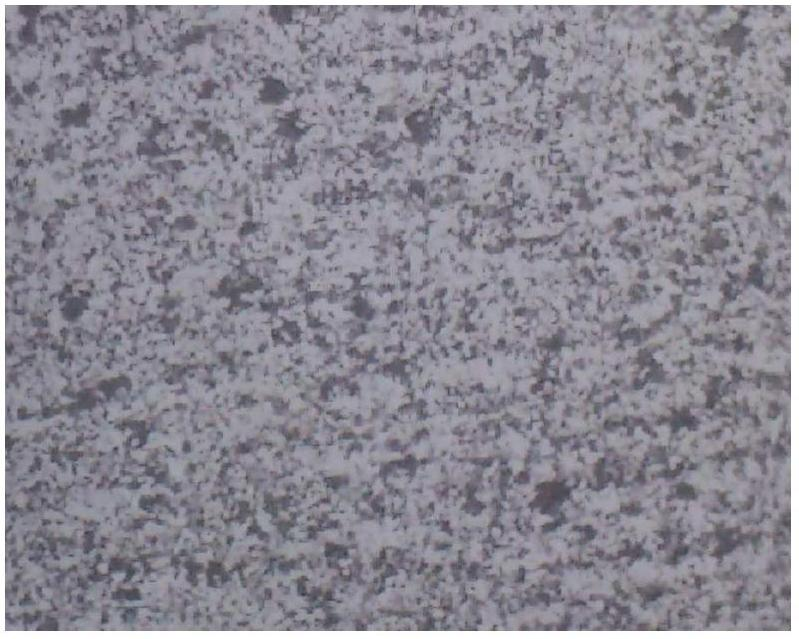

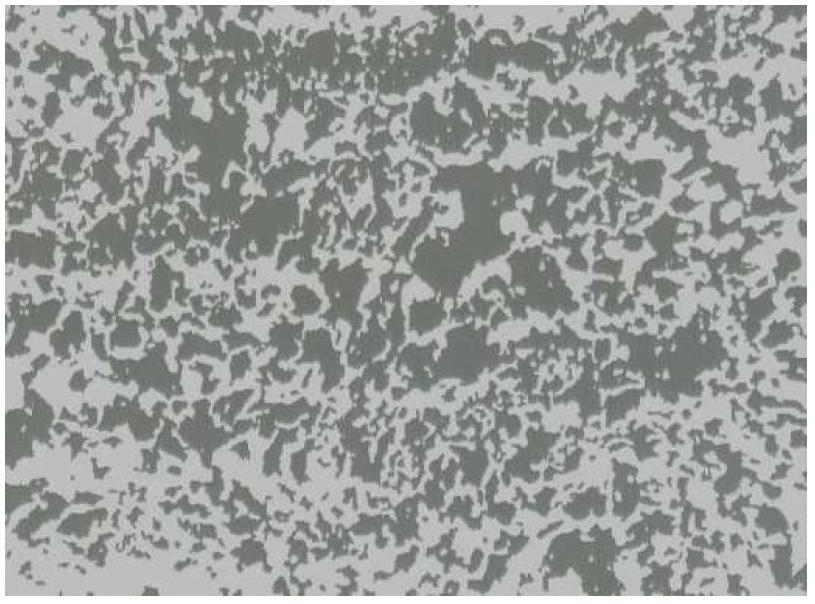

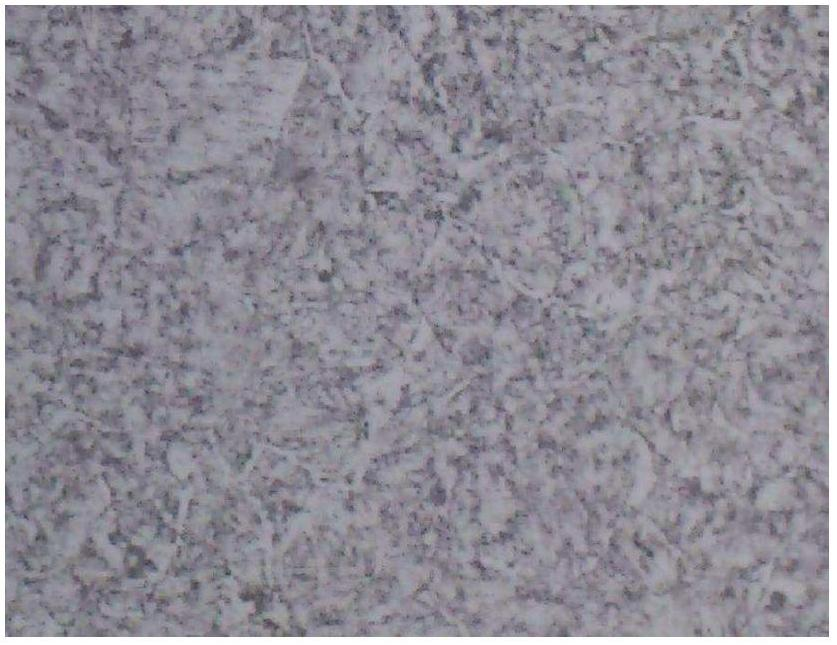

[0110] The alloy steel pipes commonly used to make hydraulic cylinders (in terms of mass percentage, its composition contains: 0.24-0.32% carbon, 1.1-1.4% silicon, 1.1-1.4% manganese, 0.07-0.12% vanadium, Phosphorus content ≤ 0.035%, sulfur content ≤ 0.035%, chromium content ≤ 0.3%, nickel content ≤ 0.3%, copper content ≤ 0.3%) as an example, describe the specific implementation of the present invention in detail.

[0111] First, anneal the perforated and drawn alloy steel pipe (tube blank of the hydraulic cylinder), and the specific steps are: heat up to 870-880°C at a speed of 20-25°C / min, then keep warm for 35-40°C After 10 minutes, first cool down to below 500°C at a rate of ≤15°C / min, and then cool down to room temperature;

[0112] Then, carry out quenching treatment, the specific steps are: after heating up to 930-935°C at a speed of 5-10°C / min, keep it warm for 50-60 minutes, and then, use the method of salt water spraying, heat the temperature at 190-200°C After rapi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com