Fusion reduction iron-smelting method for directly using concentrate powder

A concentrate powder, direct technology, applied in the field of molten iron production, smelting reduction ironmaking, can solve problems such as erosion of furnace lining, achieve the effect of reducing heat load, easy to realize, and reduce the burden of reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

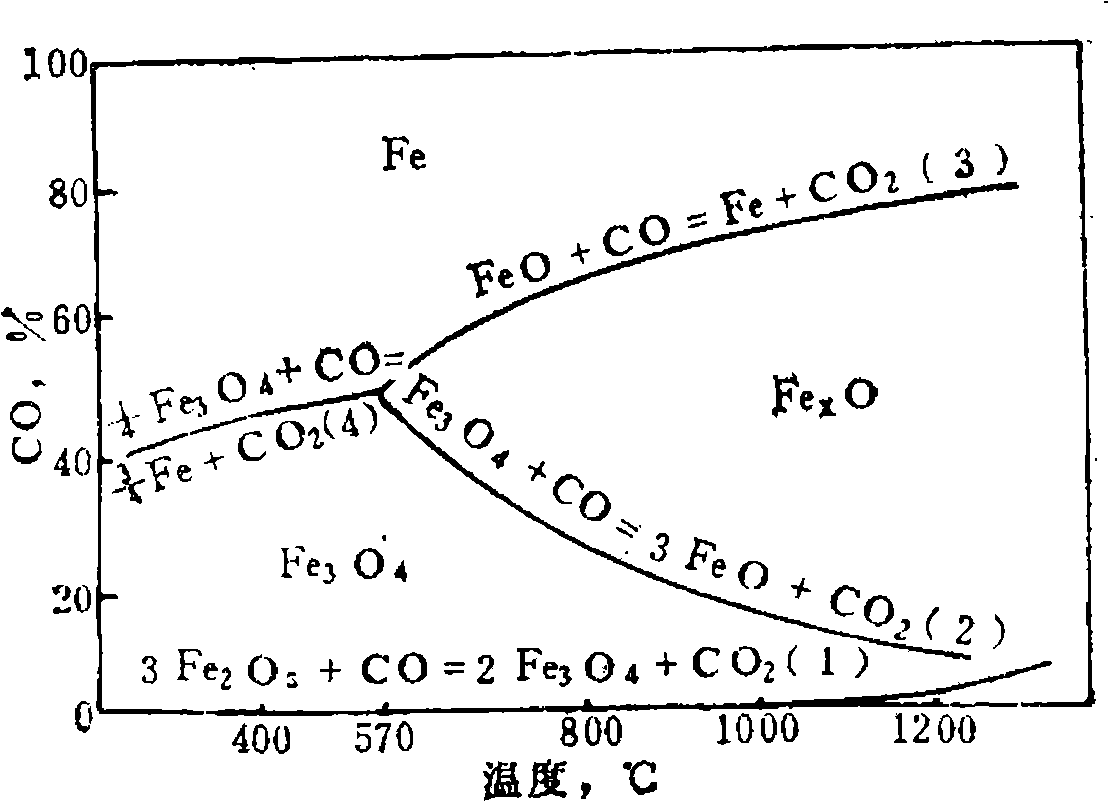

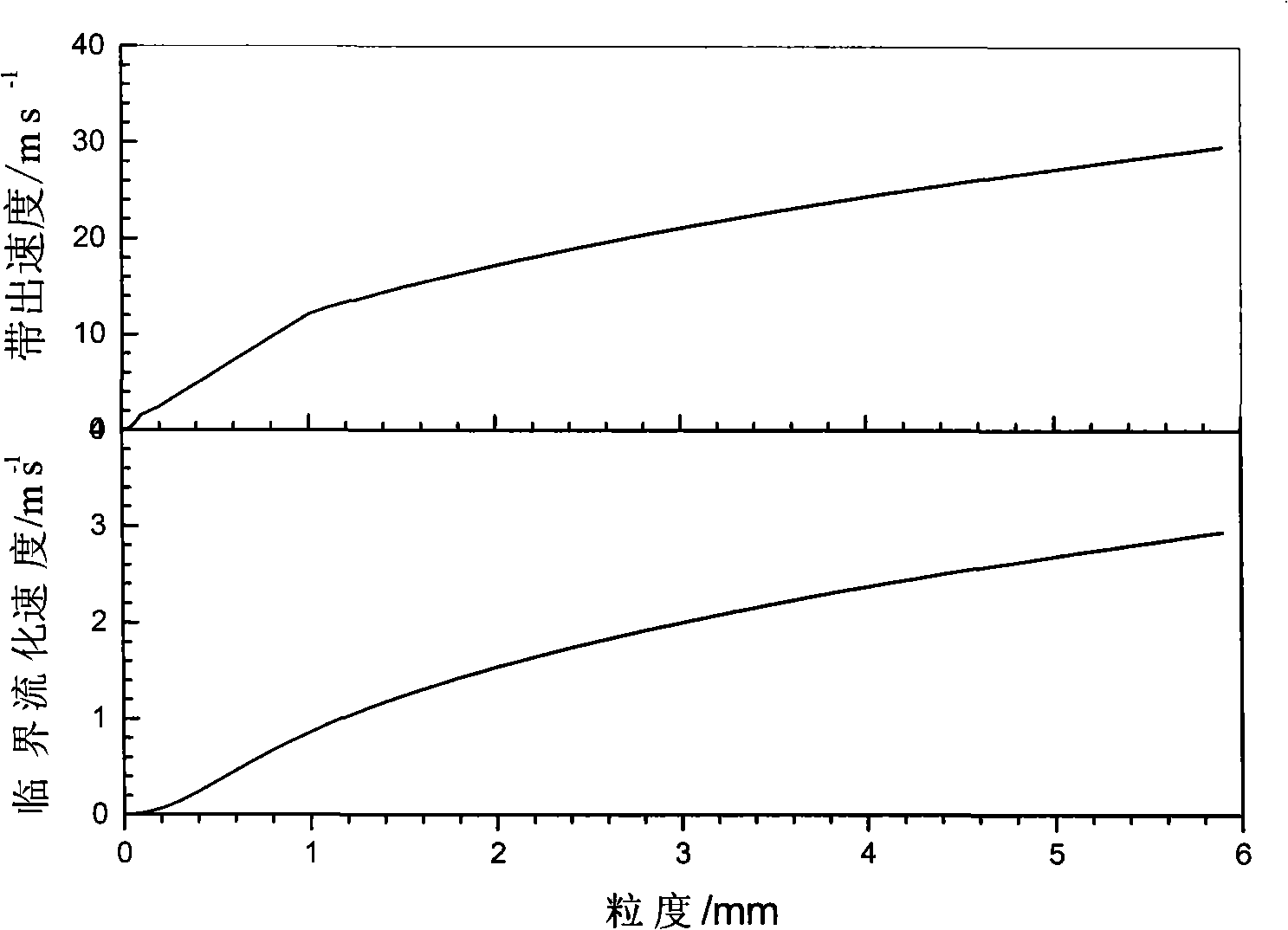

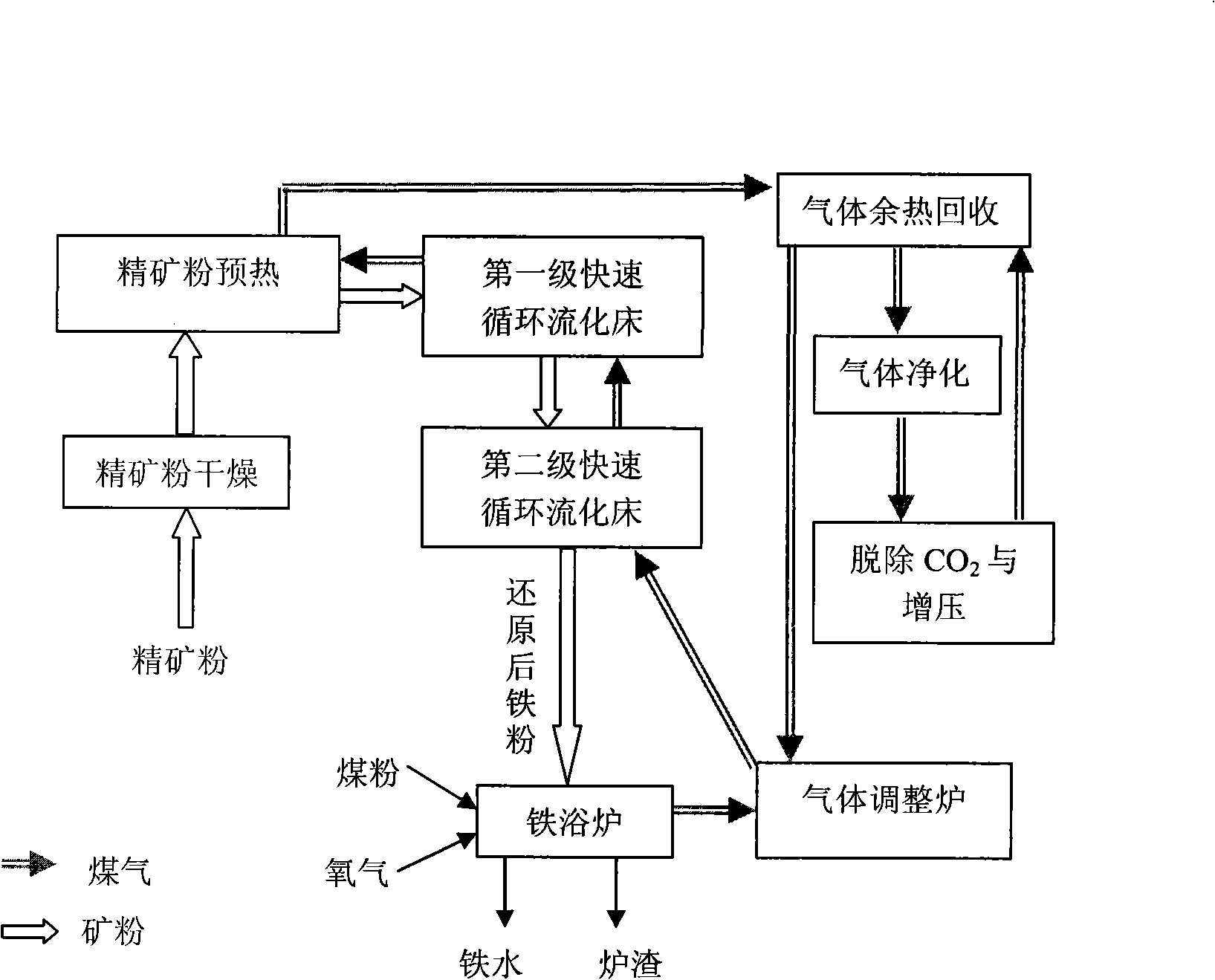

[0041] The iron ore powder used in the embodiment of the present invention is magnetite concentrate powder and Australian mineral powder (see Table 1 for composition). The Australian mineral powder is crushed and its average particle size is 0.3mm. The total carbon in the used coal powder is 85%, and the ash content is 12%. Process equipment includes iron bath furnace, drum dryer, preheating device (rapid circulating fluidized bed), 2-stage rapid circulating fluidized bed pre-reduction reaction device, gas adjustment furnace, heat exchange device, dehydration and dust removal device, VPSA, gas Supercharger, coal-oxygen spray gun system, oxygen supply system (using oxygen cylinders), PLC automatic control system, etc., see the process flow image 3 . The experimental output is 1t of molten iron / h, the temperature of molten iron is controlled at 1450°C±20°C, and the temperature of slag is controlled at 1500±20°C. The implementation process parameters and results are shown in T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com