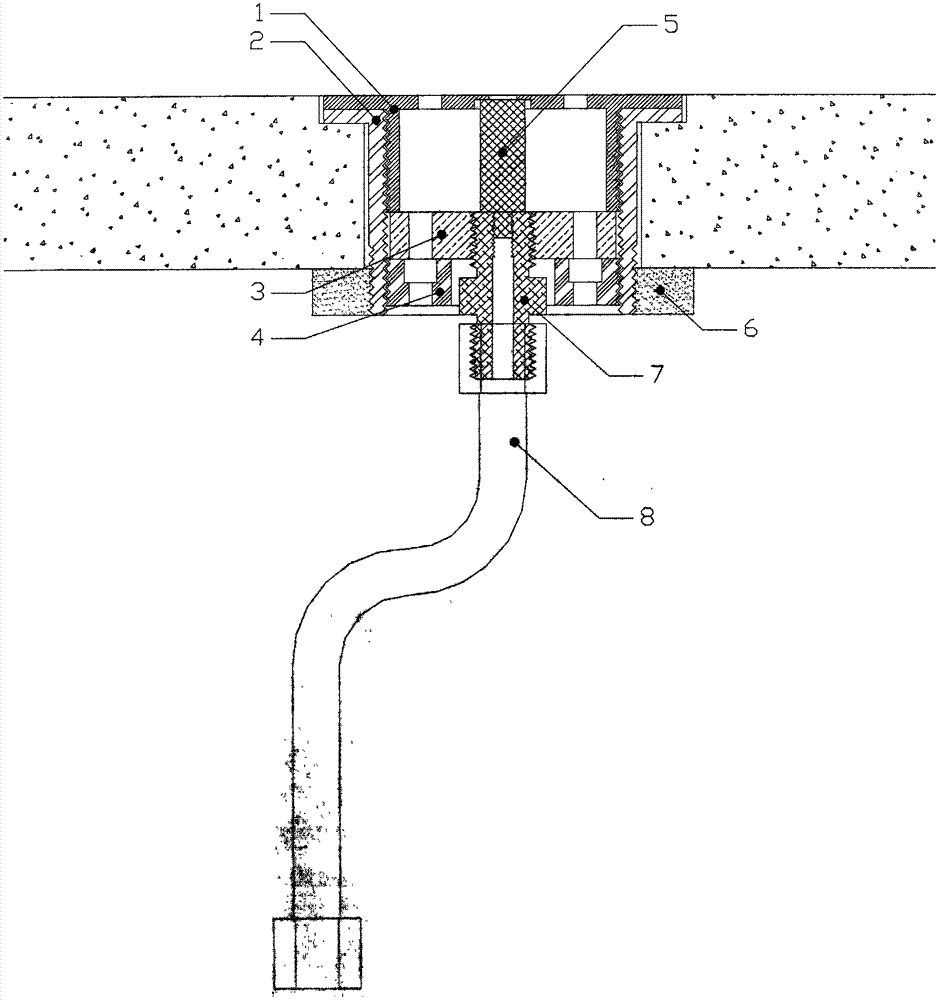

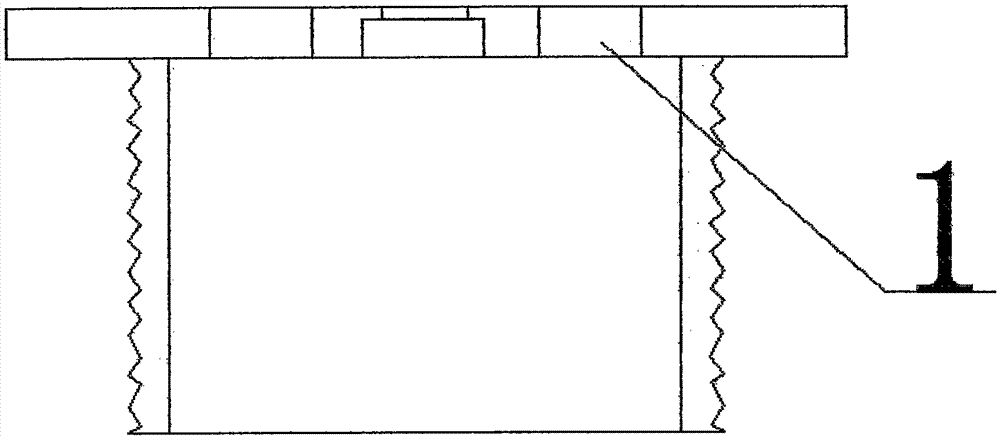

Atomizing and water filling terminal mounted in match with paved plate

A pavement board and water passage technology, which is applied in spraying devices, liquid spraying devices, etc., can solve the problems of tourists kicking and tripping injuries, weak water passing ability, stepping and falling off, etc., to achieve simple and convenient operation, improve water passing capacity, and load bearing powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

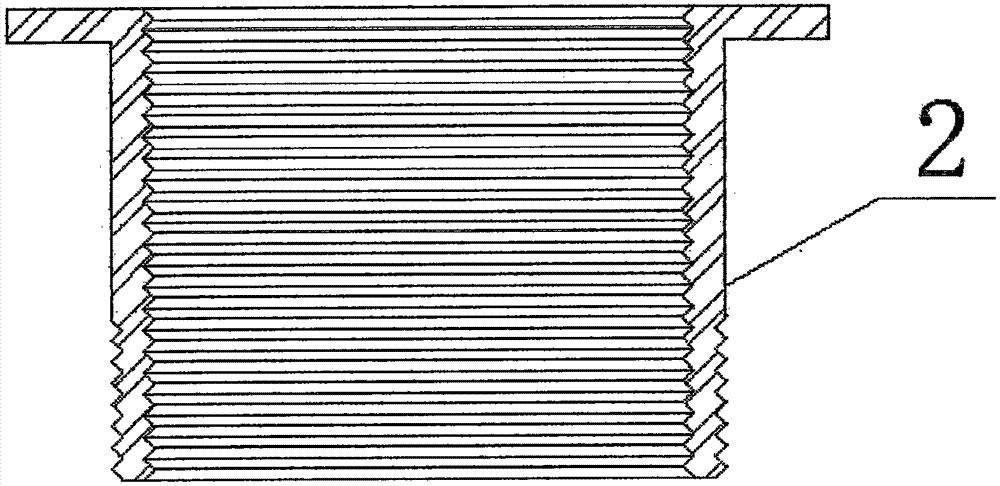

[0020] Specific implementation mode, when using the present invention, since the center of the top cover is provided with an atomization hole, the periphery of the atomization hole is provided with a water hole, the center of the centering plate is provided with a threaded hole, and the periphery of the threaded hole is provided with a water hole, through which The water hole forms a complete water flow path through the atomization nozzle and the atomization pipeline, so the water flows through the atomization pipeline to the atomization nozzle, and then sprays out, and the liquefied water flows back through the water hole to atomize again, which can Effectively save water resources.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com