Cooling tower water inflow anti-blockage cleaning facilitating mechanism

An anti-clogging and cooling tower technology, applied in the direction of water shower cooler, damage protection, filter regeneration, etc., can solve the problems of a large number of impurities in the pipeline, troublesome handling, waste of time, etc., and achieve the effect of strengthening the filtering effect and enhancing the effect of water passage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

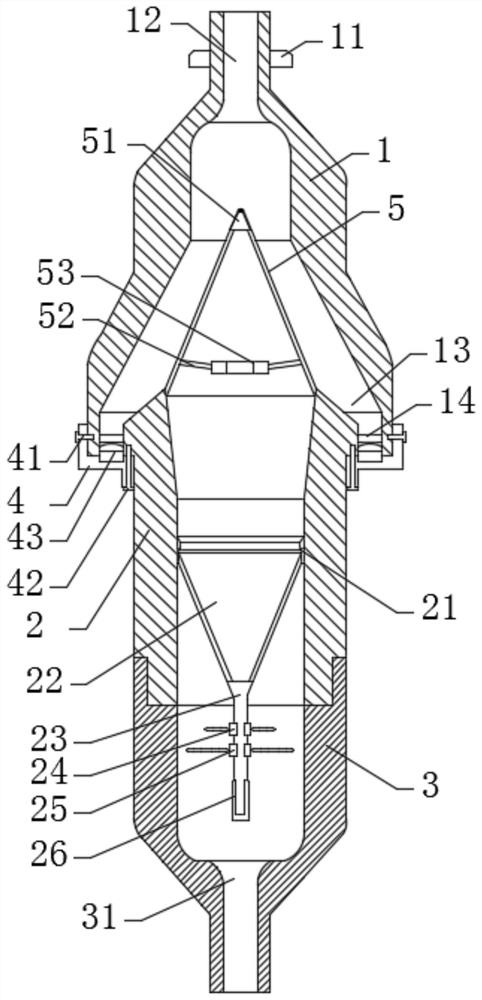

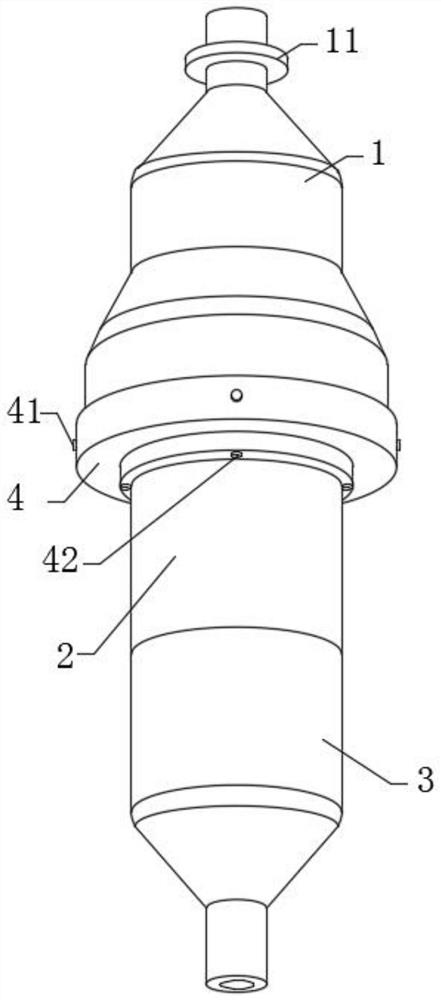

[0028] see Figure 1-4 , the present invention provides a technical solution: a cooling tower water inlet anti-clogging and easy-cleaning mechanism, including: a first connection port 1, a water inlet 12 is opened at the center of the top of the first connection port 1, and the first connection port 1 is provided with a water inlet 12 at the center of the top. An inner hole 13 is opened inside the connection port 1 .

[0029] The central tube 2, the outer top of the central tube 2 is welded to the inner wall of the inner hole 13 through the connecting frame 14, and a steel wire filter 5 is welded at one end of the central tube 2, and the steel wire filter 5 is tapered Structure; the central pipe 2 and the first connecting port 1 communicate with each other.

[0030] Wherein, through the connection structure of the central pipe 2 and the first connection port 1, and the setting of the steel wire filter 5, it is convenient to discharge the clogged impurities during use, wherein...

Embodiment 2

[0043] see Figure 1-4 , the present invention provides a technical solution: a cooling tower water inlet anti-clogging and easy-cleaning mechanism, including: a first connection port 1, a water inlet 12 is opened at the center of the top of the first connection port 1, and the first connection port 1 is provided with a water inlet 12 at the center of the top. An inner hole 13 is opened inside the connection port 1 .

[0044] The central tube 2, the outer top of the central tube 2 is welded to the inner wall of the inner hole 13 through the connecting frame 14, and a steel wire filter 5 is welded at one end of the central tube 2, and the steel wire filter 5 is tapered Structure; the central pipe 2 and the first connecting port 1 communicate with each other.

[0045] Wherein, through the connection structure of the central pipe 2 and the first connection port 1, and the setting of the steel wire filter 5, it is convenient to discharge the clogged impurities during use, wherein...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com