Manipulator paw based on stepping motor

A technology of stepping motors and manipulators, applied in the field of intelligence, can solve problems such as expensive prices and complex structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

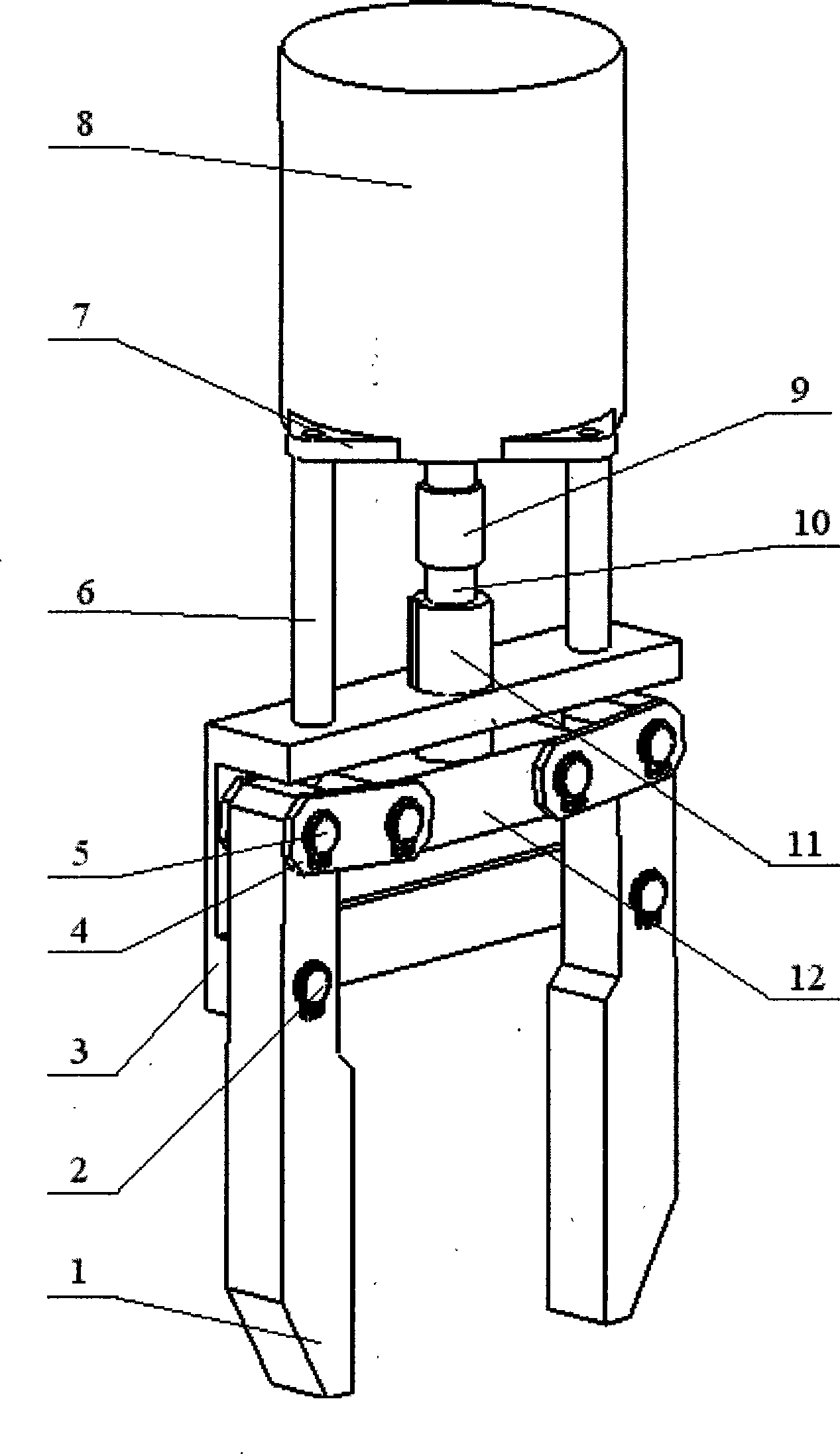

[0014] Embodiment: In the accompanying drawings, the stepper motor 8 is connected to the finger base plate 3 through the motor connection sleeve 6, the gripper device is hinged on the finger base plate 3, and the stepper motor 6 is connected to the gripper device through a lead screw 10. The claw device includes a claw push plate 12, a finger bottom plate 3, a connecting plate 4, a finger 1 and a finger shaft, the upper end of the finger 1 is hinged with the claw push plate 12 through the connecting plate 4 and the finger shaft A5, and the finger 1 is symmetrically located on Claw push plate 12 both sides. The claw push plate 12 is connected with the lead screw 10, and the middle part of the finger 1 is hinged with the finger bottom plate 3 through the finger shaft B2.

[0015] The output end of the stepping motor 8 is provided with a stepping motor fixing plate 7, one end of the motor connection sleeve 6 is fixed on the stepping motor fixing plate 7, and the other end is fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com