Crank-slider type vane oscillating mechanism and straight-wing propeller comprising same

A technology of straight-wing propeller and swing mechanism, applied in the direction of rotary propeller, etc., can solve the problems of high working noise, inconvenient use of hydraulic system, and poor real-time action response.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

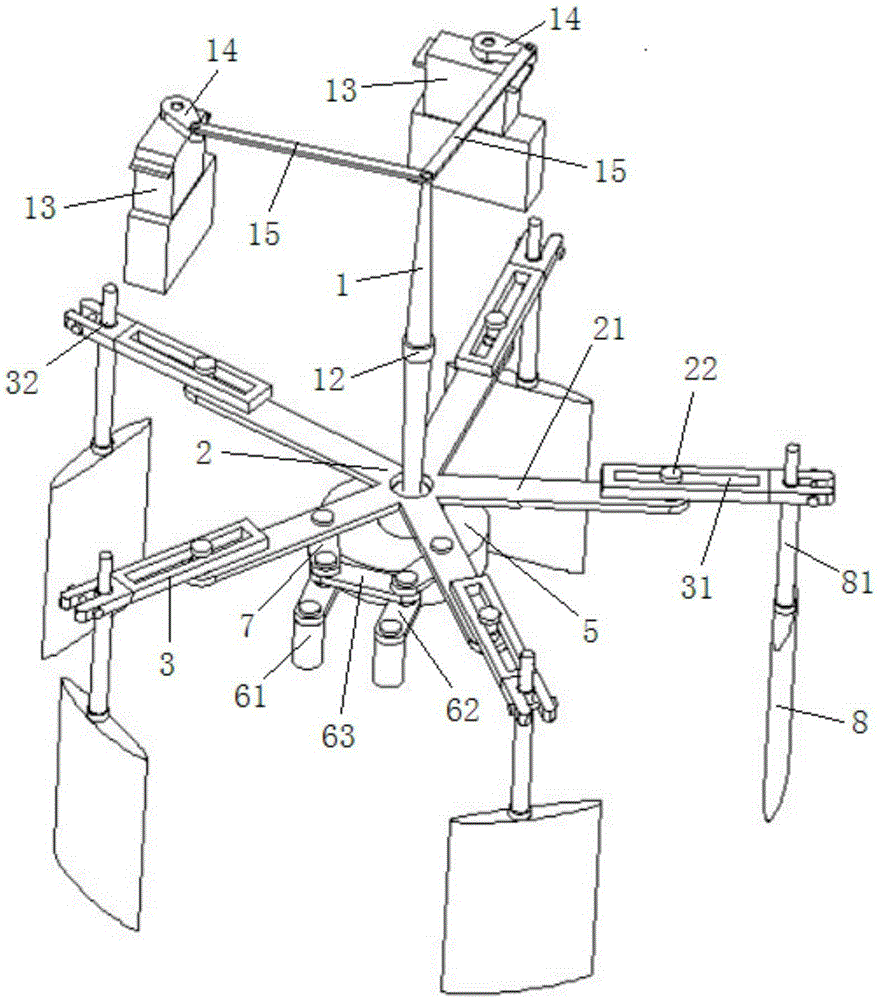

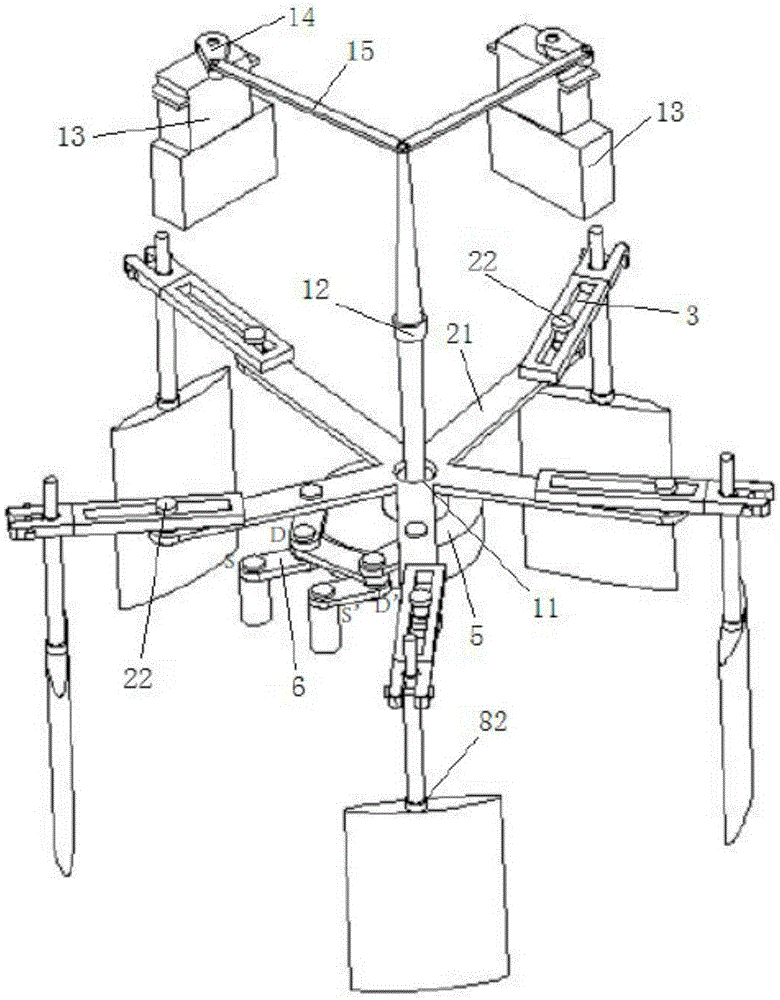

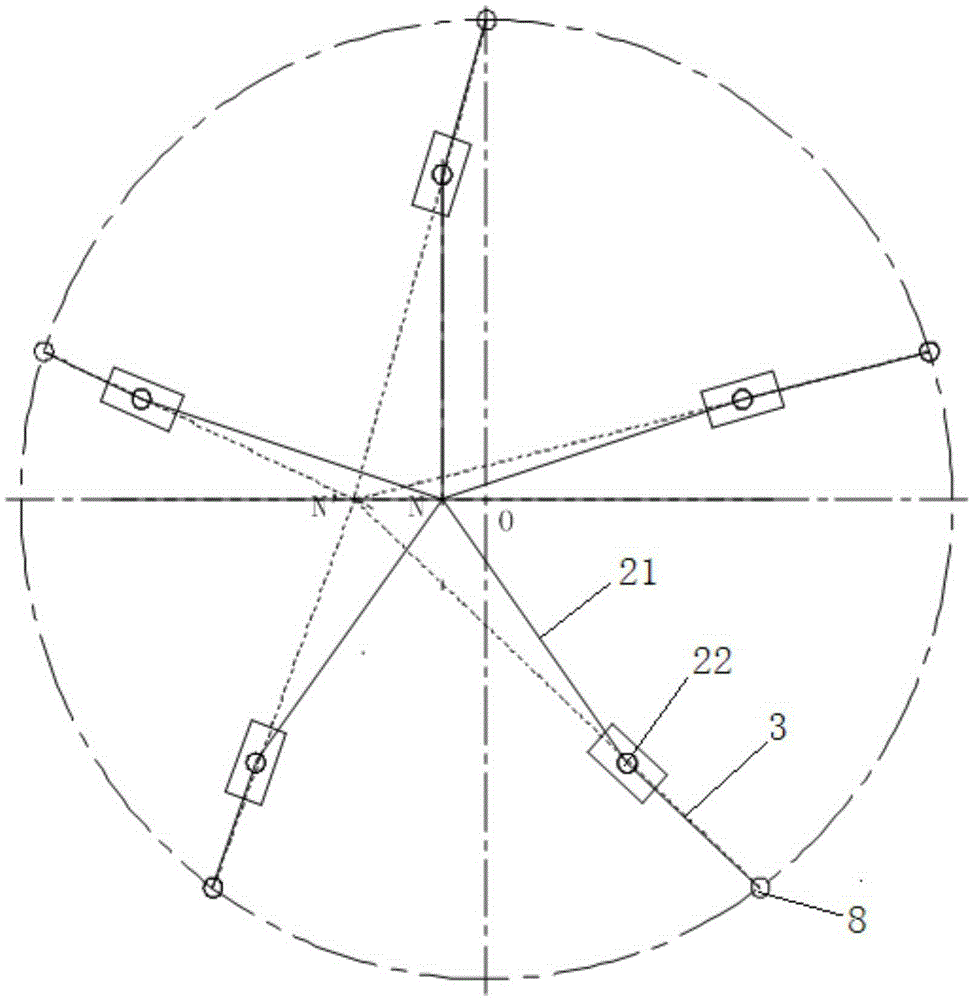

[0024] Such as figure 1 , figure 2 shown, combined with Figure 5, a slider crank type blade swing mechanism, including a control rod 1, a connecting frame 2, a guide rod 3, a boss 5 fixed on a rotary disk 4 and a supporting frame structure 6, two adjacent arms connected to the connecting frame 2 21 and the connecting rod 7 between the supporting frame structure 6, the connecting frame 2 has at least two equal-length frame arms 21 arranged at equal intervals in a radial shape, and the outer ends of each frame arm 21 are correspondingly connected to a longitudinally opened long slot 31 equal length guide rods 3, the outer end of each frame arm 21 has a slider 22 sliding along the long groove 31 of the guide rod 3, the outer end of each guide rod 3 is perpendicular to the main shaft 81 of a blade 8 Specifically, the outer end of the guide rod 3 is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com