Automatic feeding pastry slicer

An automatic feeding and slicing machine technology, which is applied in the division/slicing of baked food, metal processing, etc., can solve the problems of low production efficiency and low automation level, and achieve the effect of guaranteed effect, fast and efficient slicing, and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

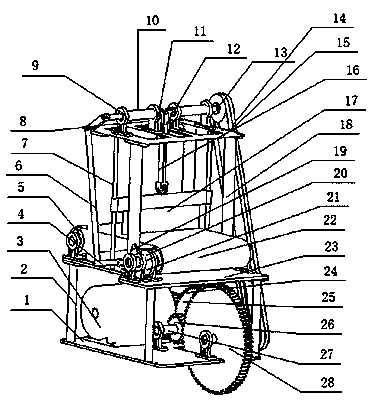

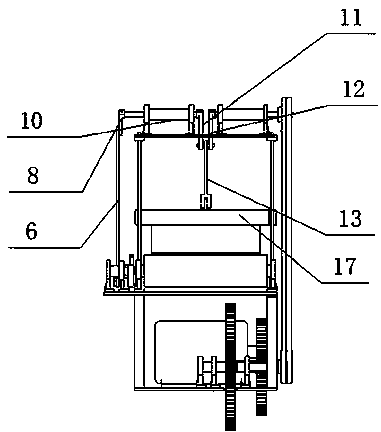

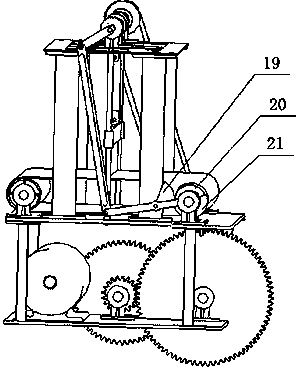

[0015] Implementation mode one: if Figures 1 to 3 As shown, the structure of the automatic feeding pastry slicer of the present embodiment is: comprise crank slider slicing mechanism, crank rocker feeding mechanism and power unit, crank slider slicing mechanism comprises crank connecting shaft 10, cutter crank and cutter 17 , the crank connecting shaft drives the cutter crank II 12 and the cutter crank I 11 to make a turnover motion, and the cutter crank II 12 and the cutter crank I 11 drive the cutter 17 to move up and down through the cutter connecting rod 16 to complete slicing; the crank rocker The feeding mechanism includes a feeding crank 8, a feeding connecting rod 6, a feeding connecting rod 4 and a transmission device. The crank connecting shaft 10 drives the feeding crank 8 to make a turnover movement, and the feeding crank 8, the feeding connecting rod 6 and the feeding rocker 4 form a crank rocker. One end of the feeding rocker 4 is connected with the friction whe...

Embodiment approach 2

[0016] Implementation mode two: if Figures 1 to 3 As shown, the structure of the automatic feeding pastry slicer of the present embodiment is: comprise crank slider slicing mechanism, crank rocker feeding mechanism and power unit, crank slider slicing mechanism comprises crank connecting shaft 10, cutter crank and cutter 17 , the crank connecting shaft drives the cutter crank II 12 and the cutter crank I 11 to make a turnover motion, and the cutter crank II 12 and the cutter crank I 11 drive the cutter 17 to move up and down through the cutter connecting rod 16 to complete slicing; the crank rocker The feeding mechanism includes a feeding crank 8, a feeding connecting rod 6, a feeding connecting rod 4 and a transmission device. The crank connecting shaft 10 drives the feeding crank 8 to make a turnover movement, and the feeding crank 8, the feeding connecting rod 6 and the feeding rocker 4 form a crank rocker. One end of the feeding rocker 4 is connected with the friction whe...

Embodiment approach 3

[0017] Implementation mode three: if Figures 1 to 3 As shown, the structure of the automatic feeding pastry slicer of the present embodiment is: comprise crank slider slicing mechanism, crank rocker feeding mechanism and power unit, crank slider slicing mechanism comprises crank connecting shaft 10, cutter crank and cutter 17 , the crank connecting shaft drives the cutter crank II 12 and the cutter crank I 11 to make a turnover motion, and the cutter crank II 12 and the cutter crank I 11 drive the cutter 17 to move up and down through the cutter connecting rod 16 to complete slicing; the crank rocker The feeding mechanism includes a feeding crank 8, a feeding connecting rod 6, a feeding connecting rod 4 and a transmission device. The crank connecting shaft 10 drives the feeding crank 8 to make a turnover movement, and the feeding crank 8, the feeding connecting rod 6 and the feeding rocker 4 form a crank rocker. One end of the feeding rocker 4 is connected with the friction w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com