Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

111 results about "Crash box" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A Crash box is a sound effect device which reproduces a crash or collision sound effect. Commonly used in theatre and plays, they consist of a large metal or wood crate in which, glassware, china crockery, wood blocks and/or other delicate objects are placed. The items may or may not be broken. Crash boxes can usually be used multiple times, until the objects inside of them become so broken that they no longer give the desired effect. They can then be reloaded with more breakable objects and re used. Crash boxes are used to recreate the sounds of a crash, collision or glass breakage in theatre. To recreate the sound effects, crash boxes are dropped from a height backstage. They can also be shaken to create a gentler sound effect. A crash box is generally preferred to a recorded sound effect because it is perceived as more realistic.

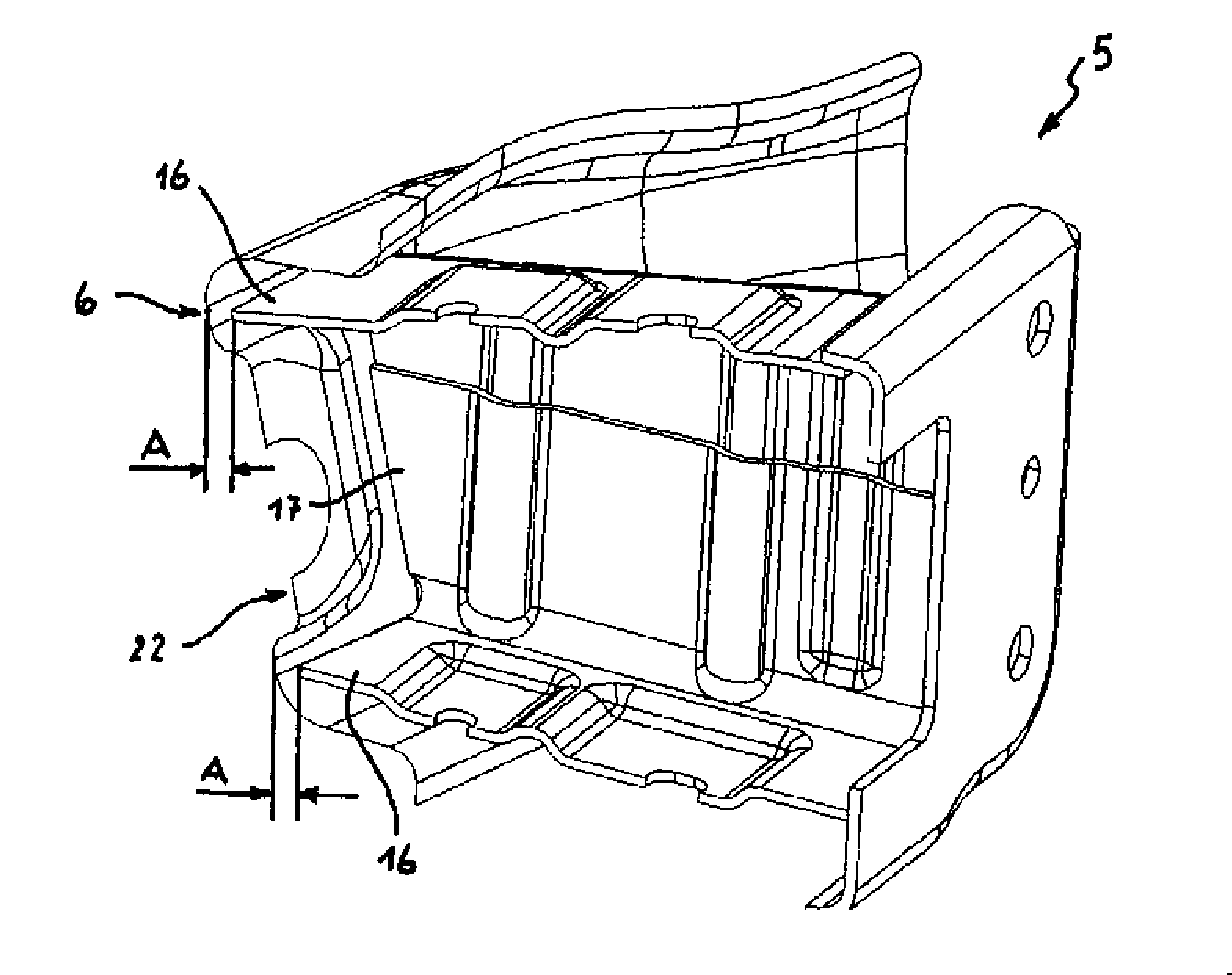

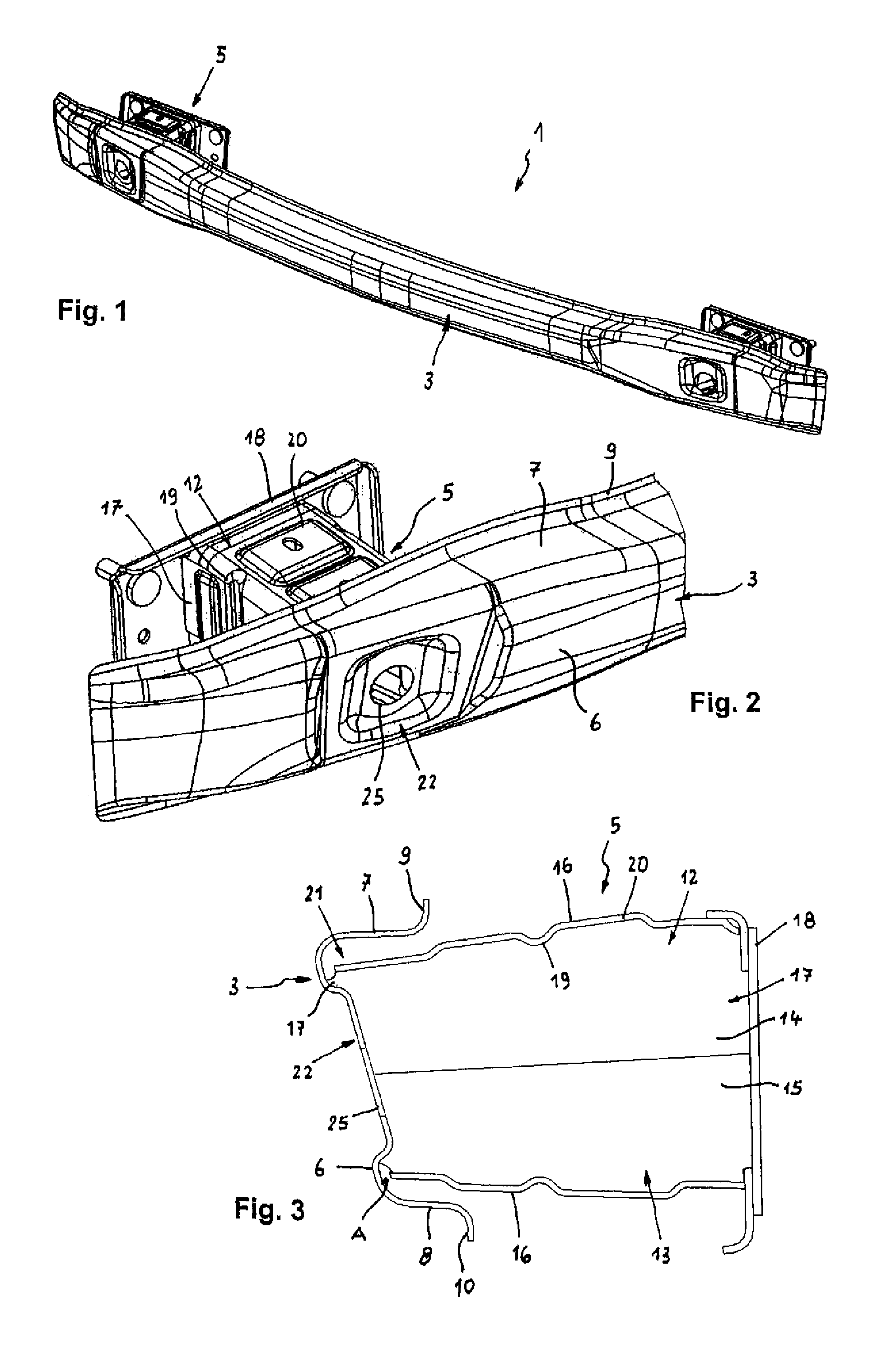

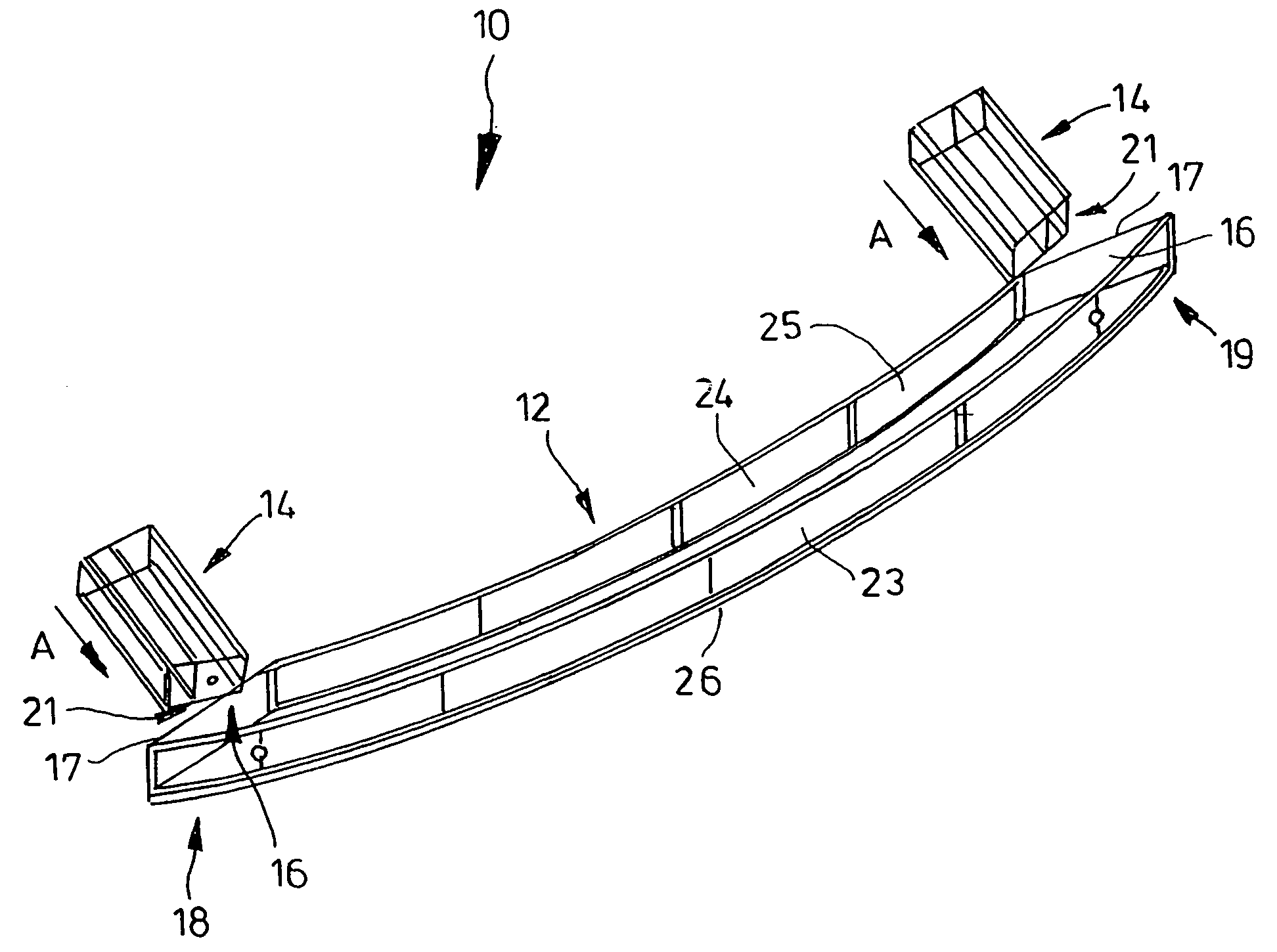

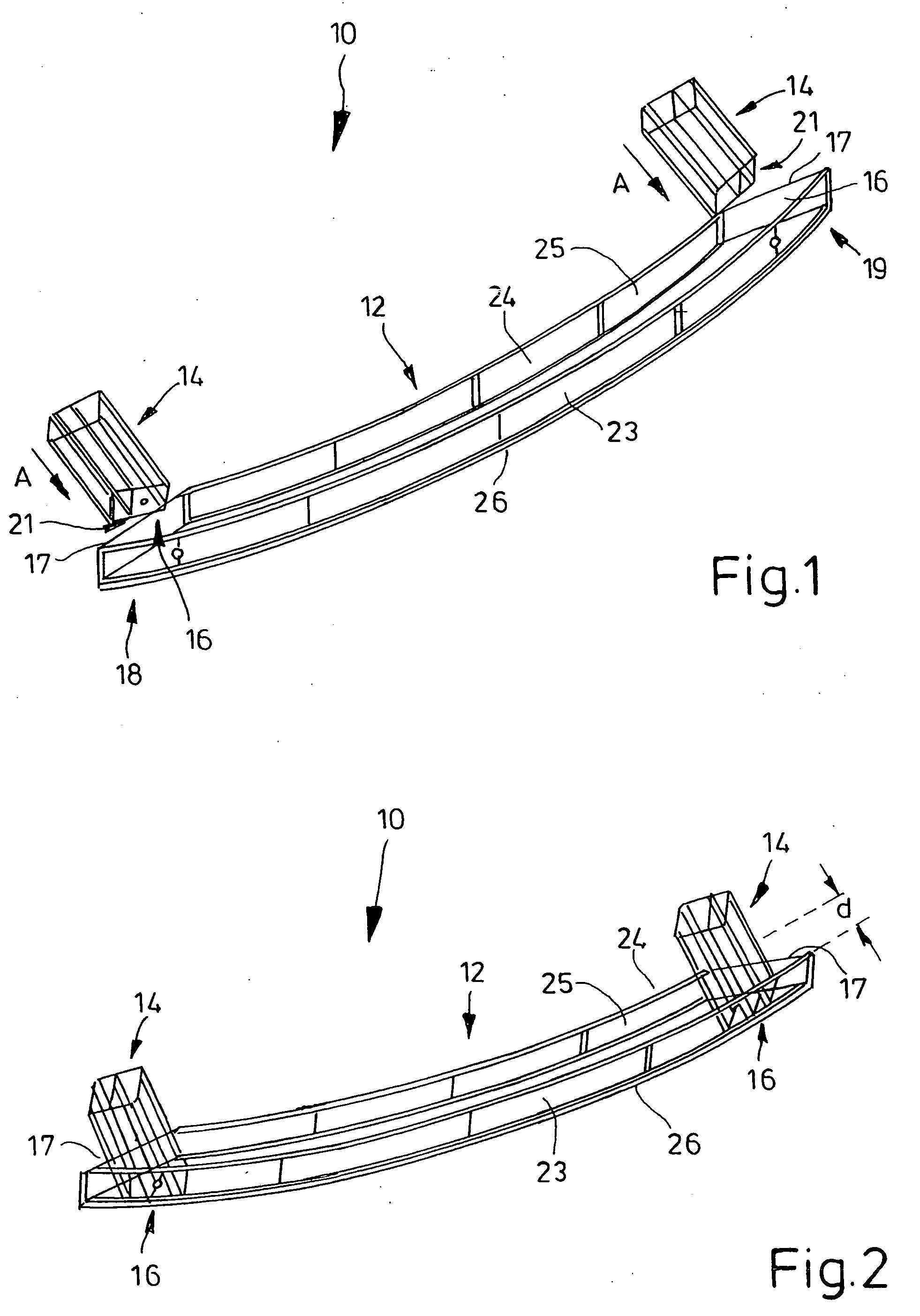

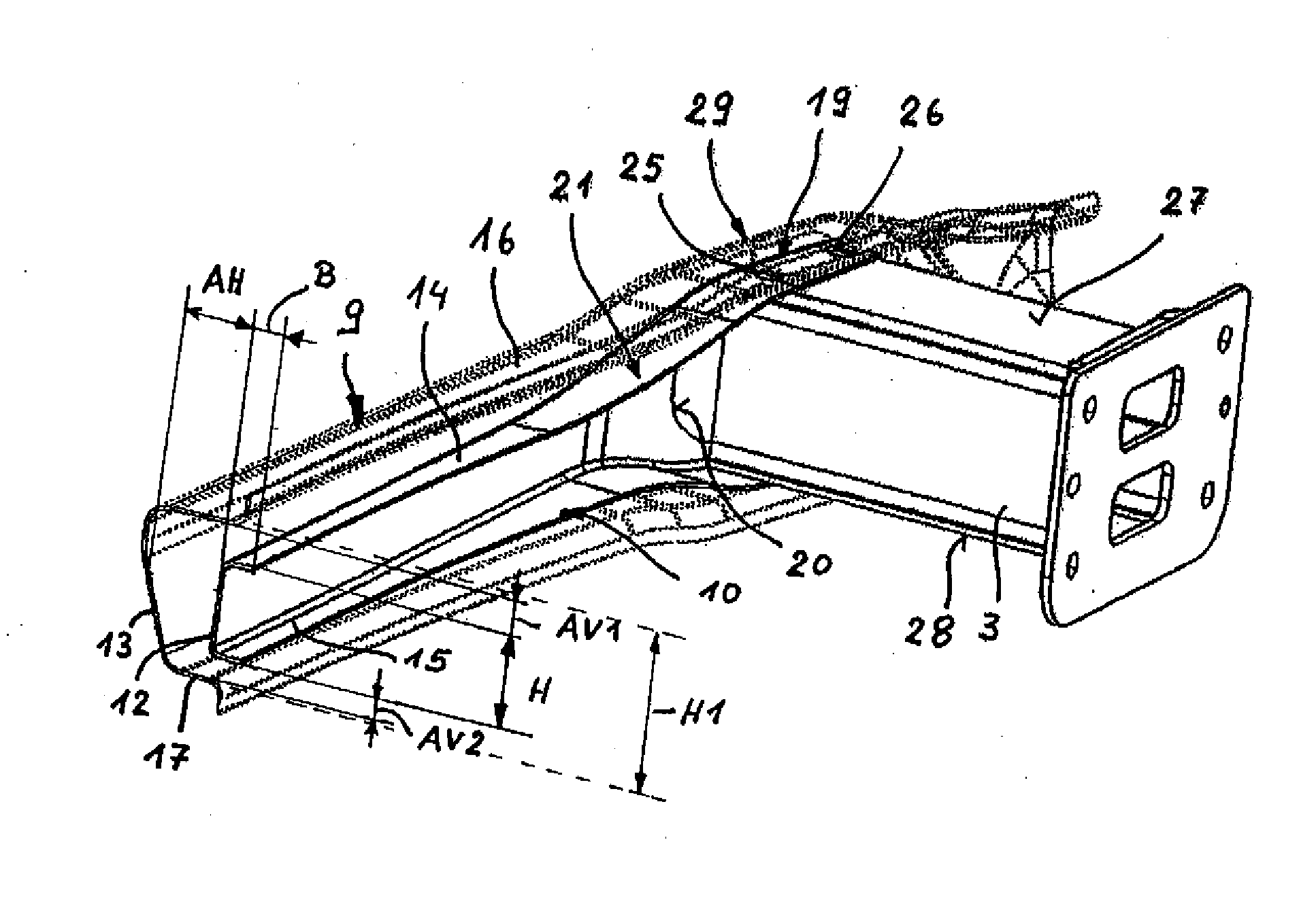

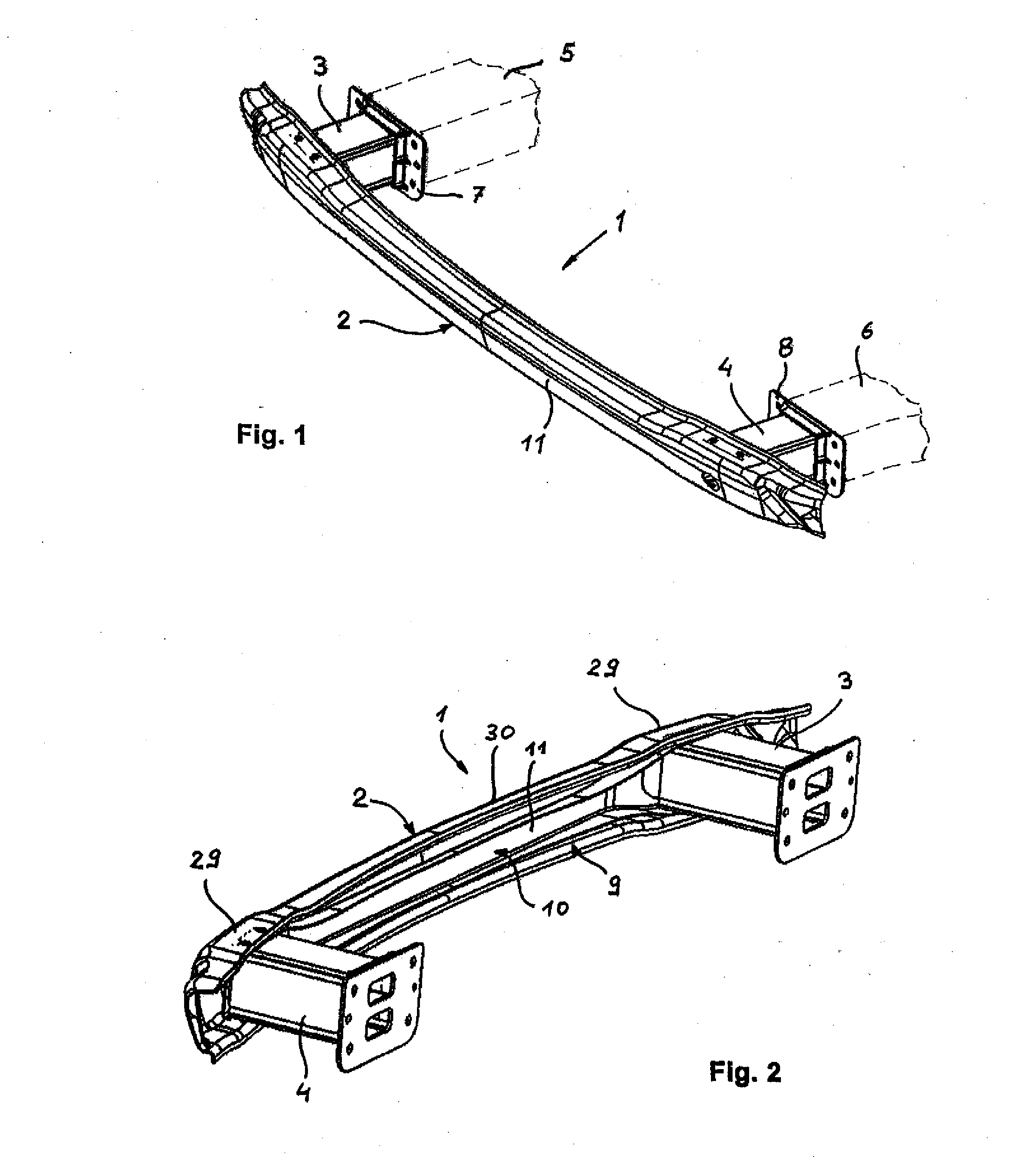

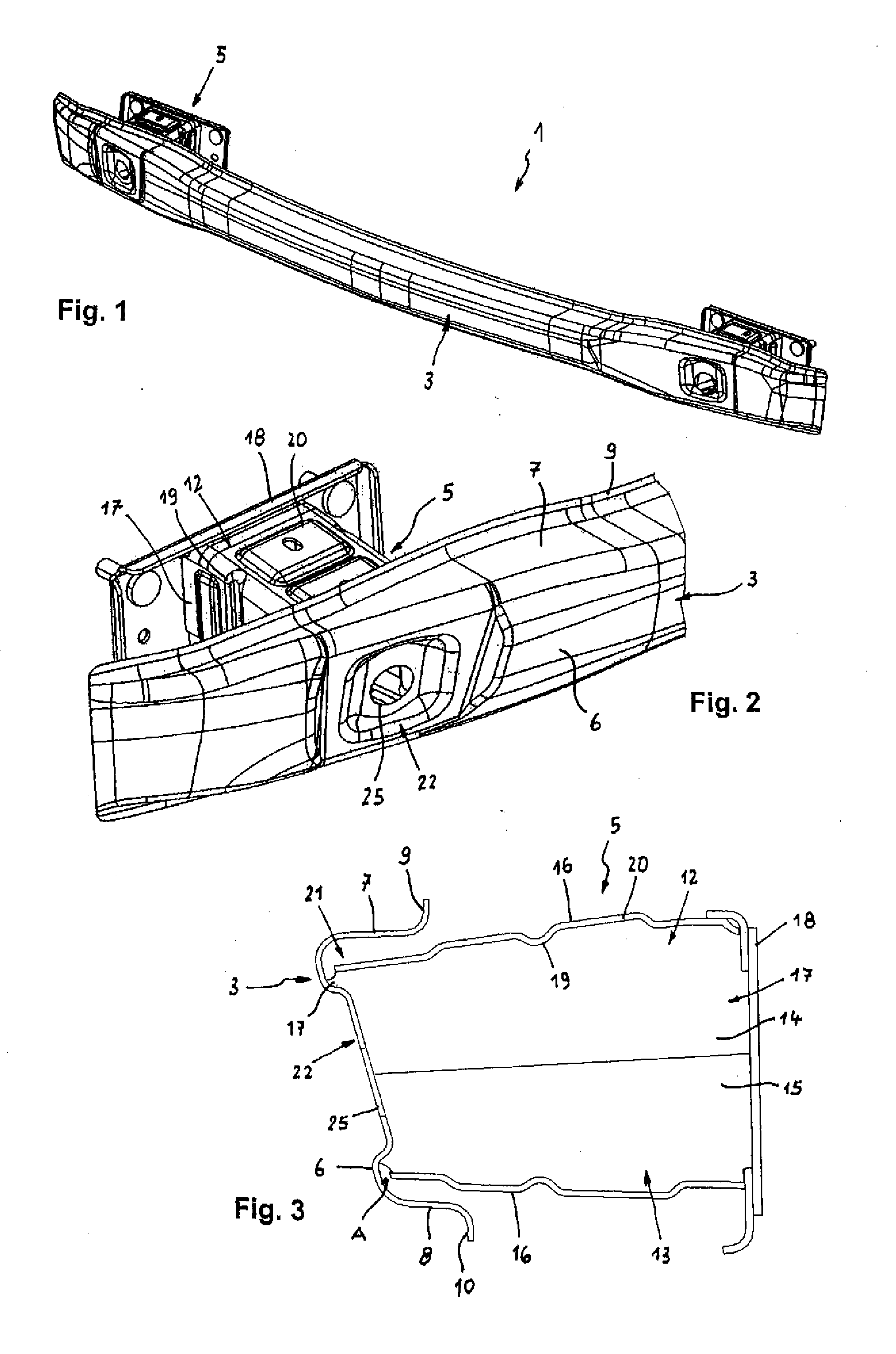

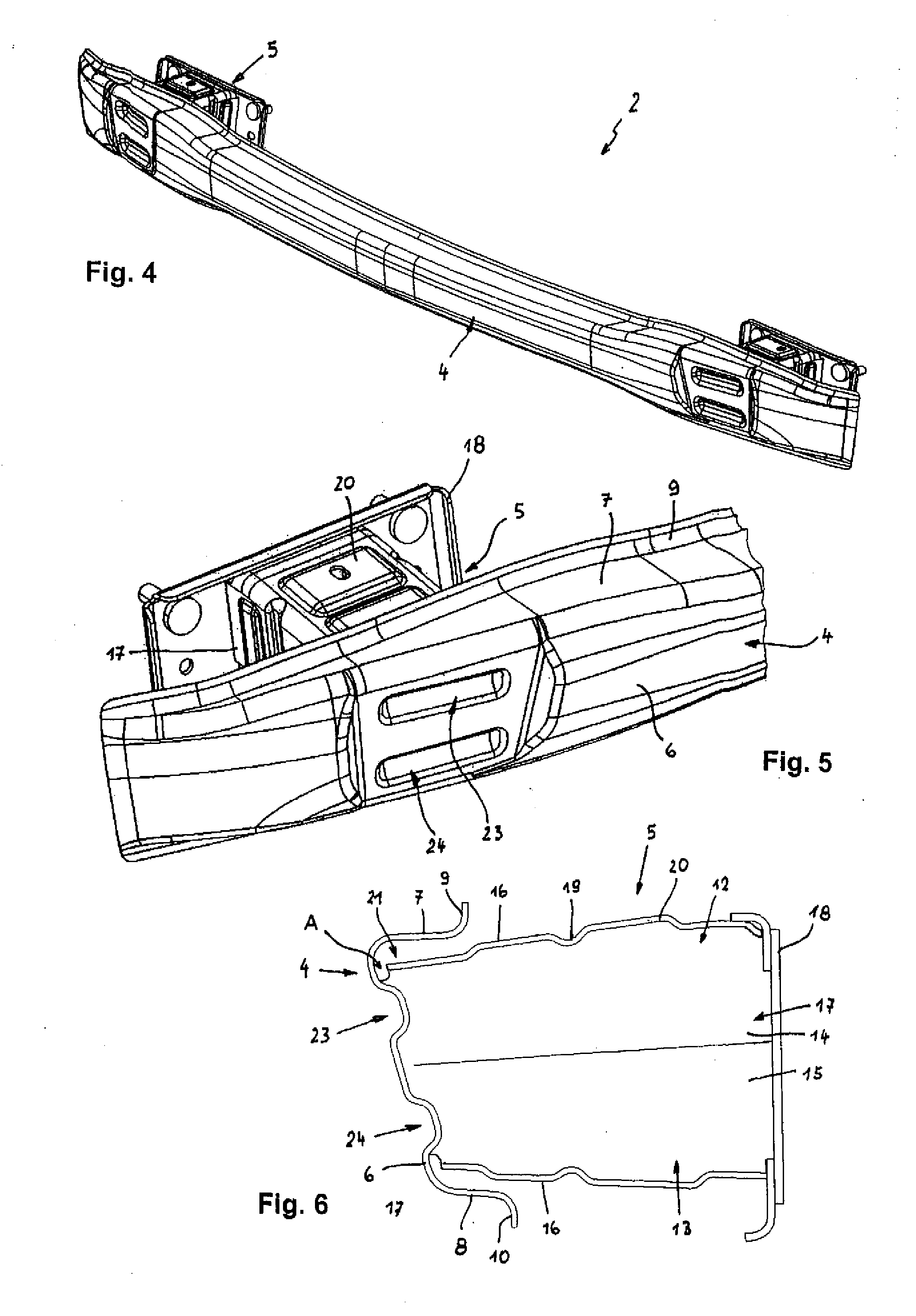

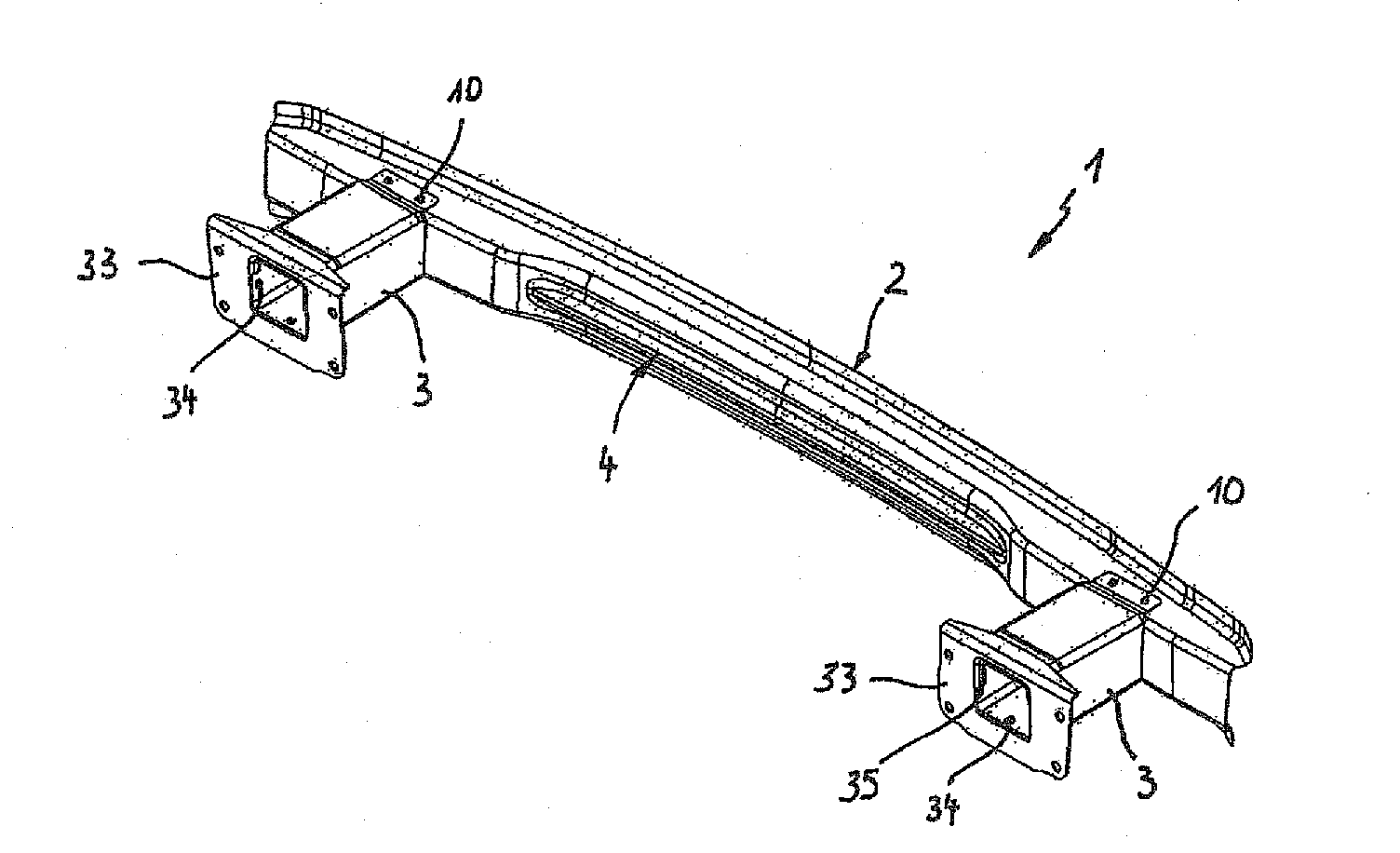

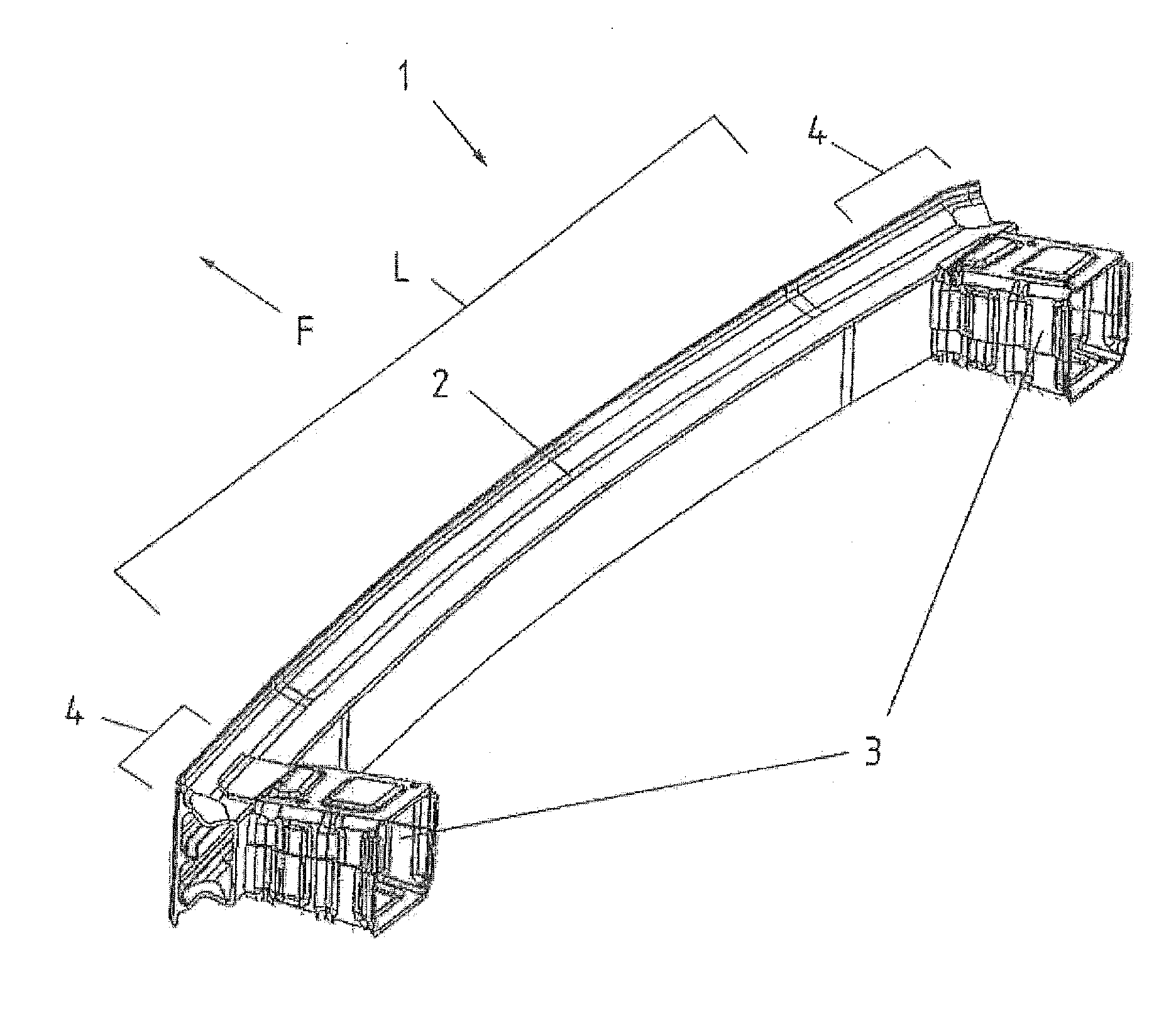

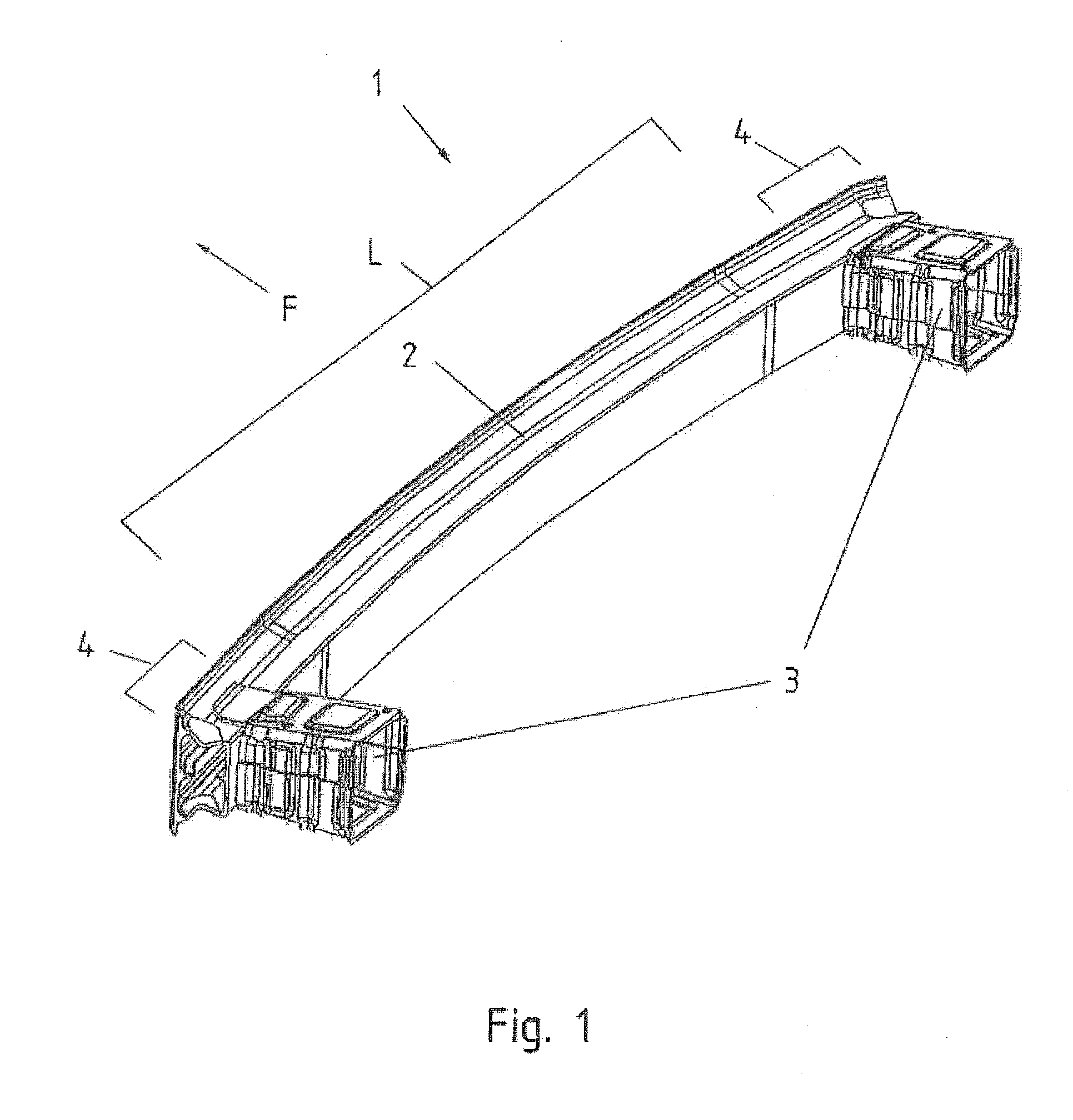

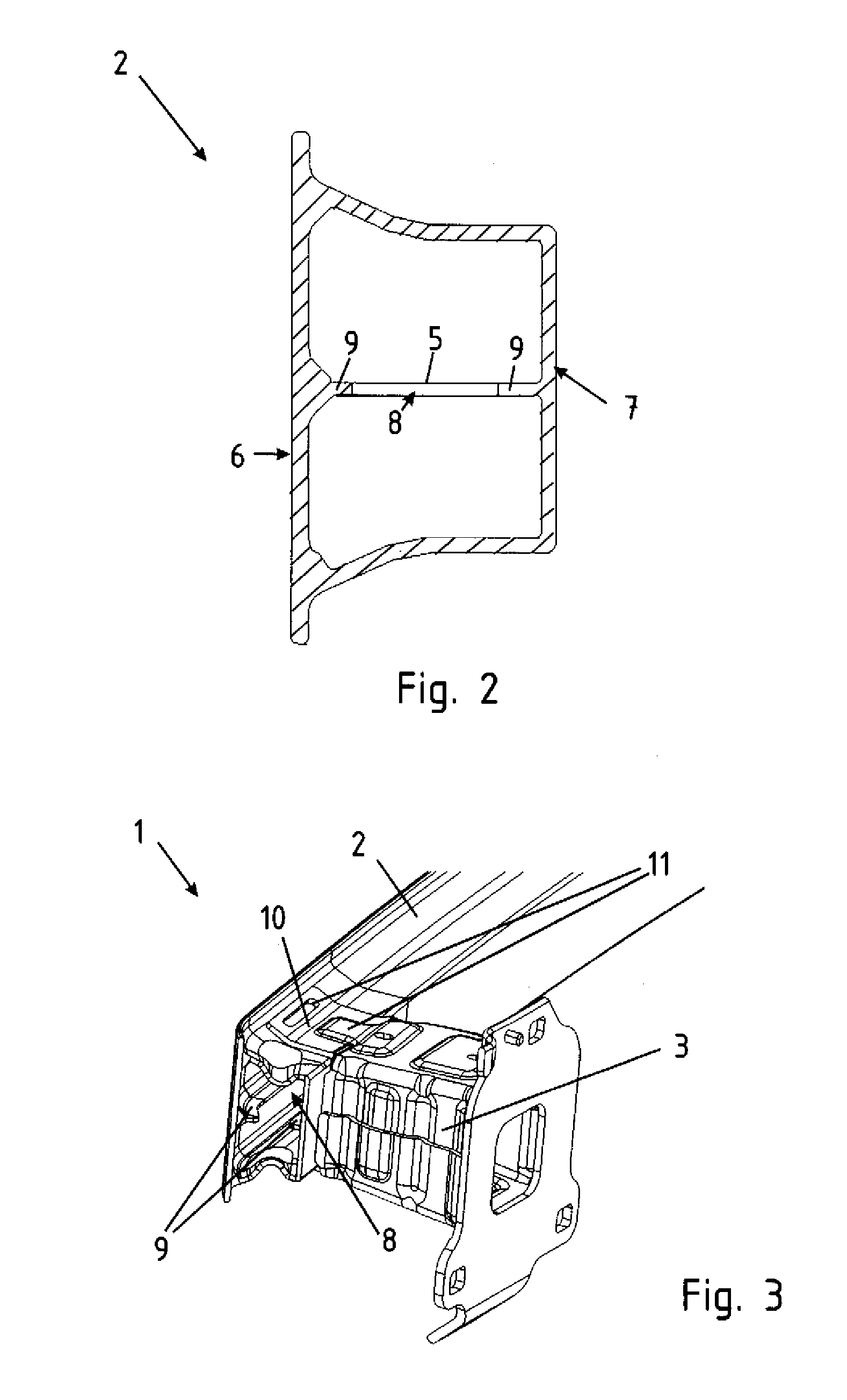

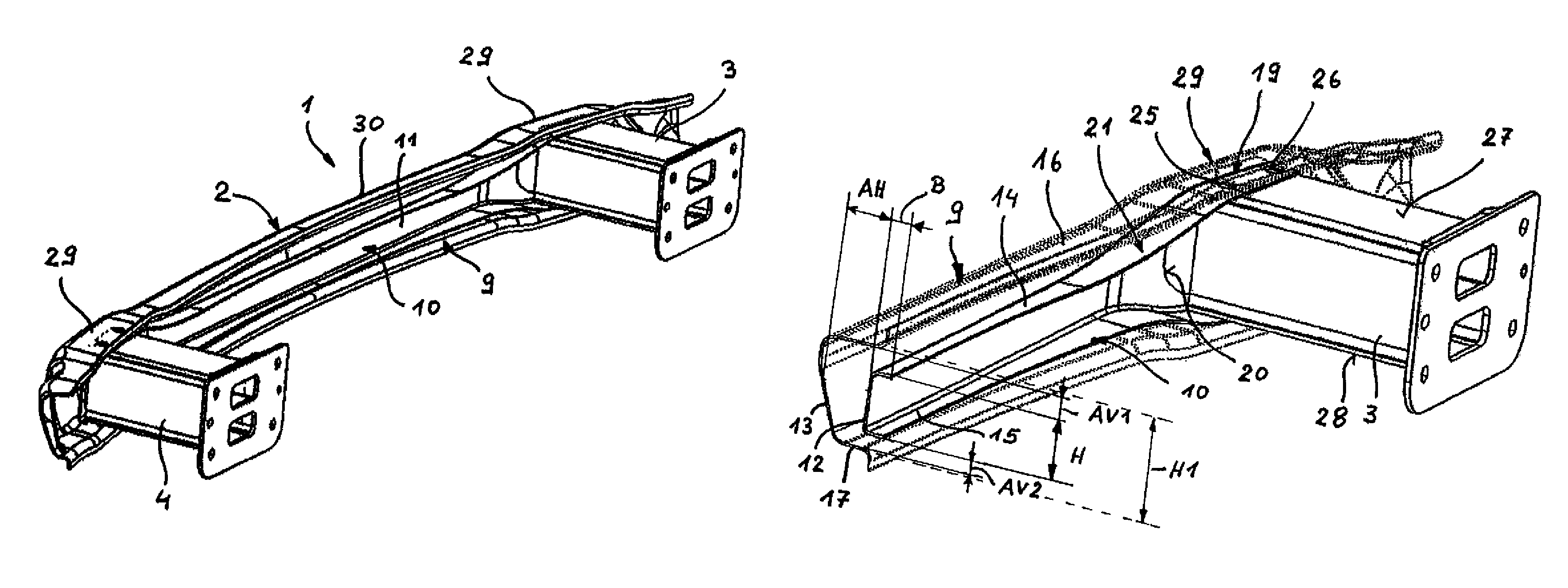

Bumper for a motor vehicle

A bumper for a motor vehicle includes a cross member disposed transversely to side rails of a motor vehicle frame and having a U-shaped cross section with a wall and two legs extending from opposite ends of the wall. The cross member is supported via integral crash boxes against the side rails. Each crash box has a cross member proximal end which abuts against the wall of the cross member, and includes vertical legs and horizontal legs to define a casing-like configuration. The wall of the cross member is formed in an area of the cross member proximal end of the crash box with a depression which extends in a direction of the crash box, with the vertical legs of the crash box joined at the cross member proximal end to the wall of the cross member, and with the horizontal legs of the crash box spaced from the wall of the cross member by a distance.

Owner:BENTELER AUTOMOBILTECHNIK GMBH

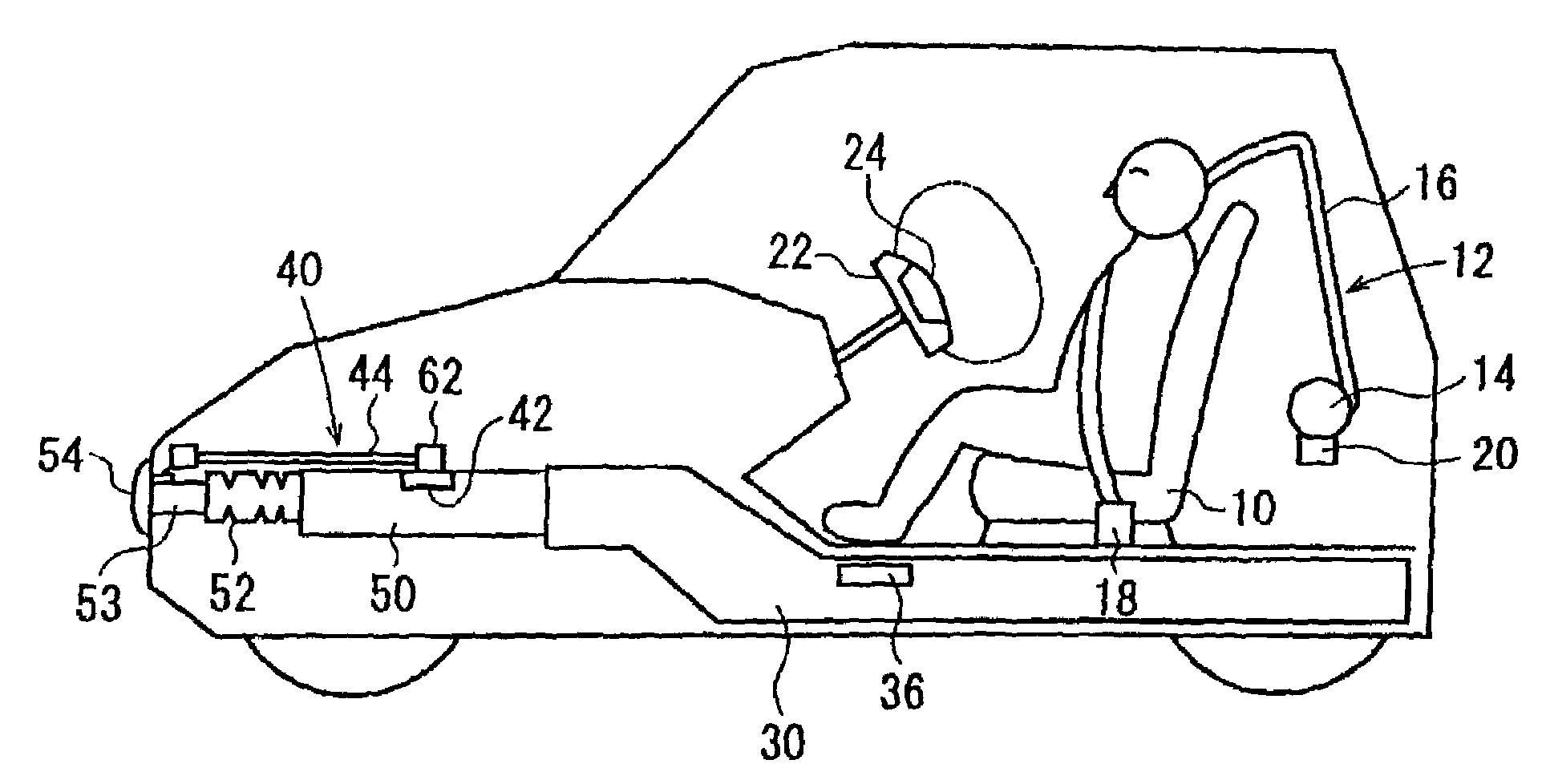

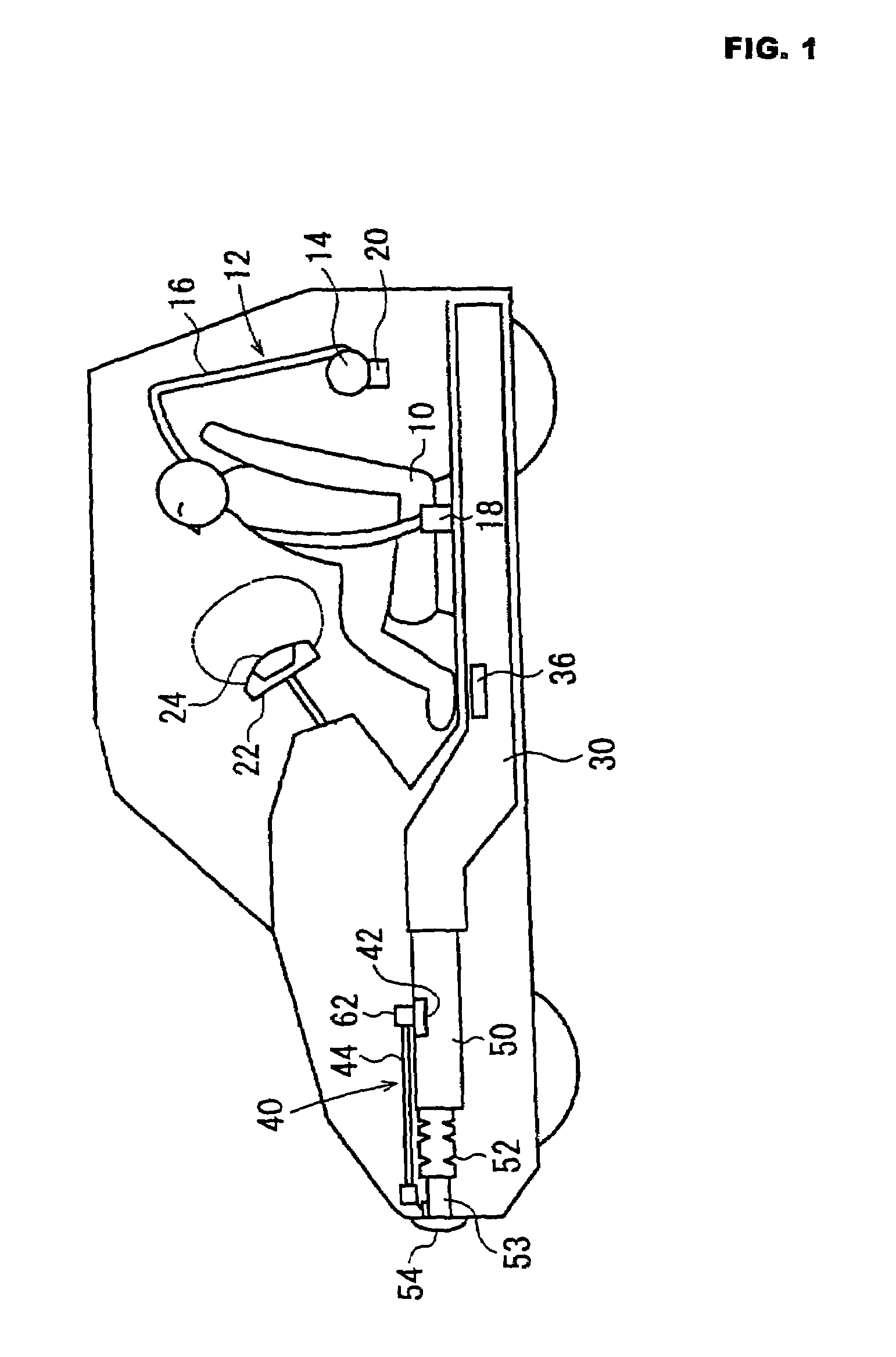

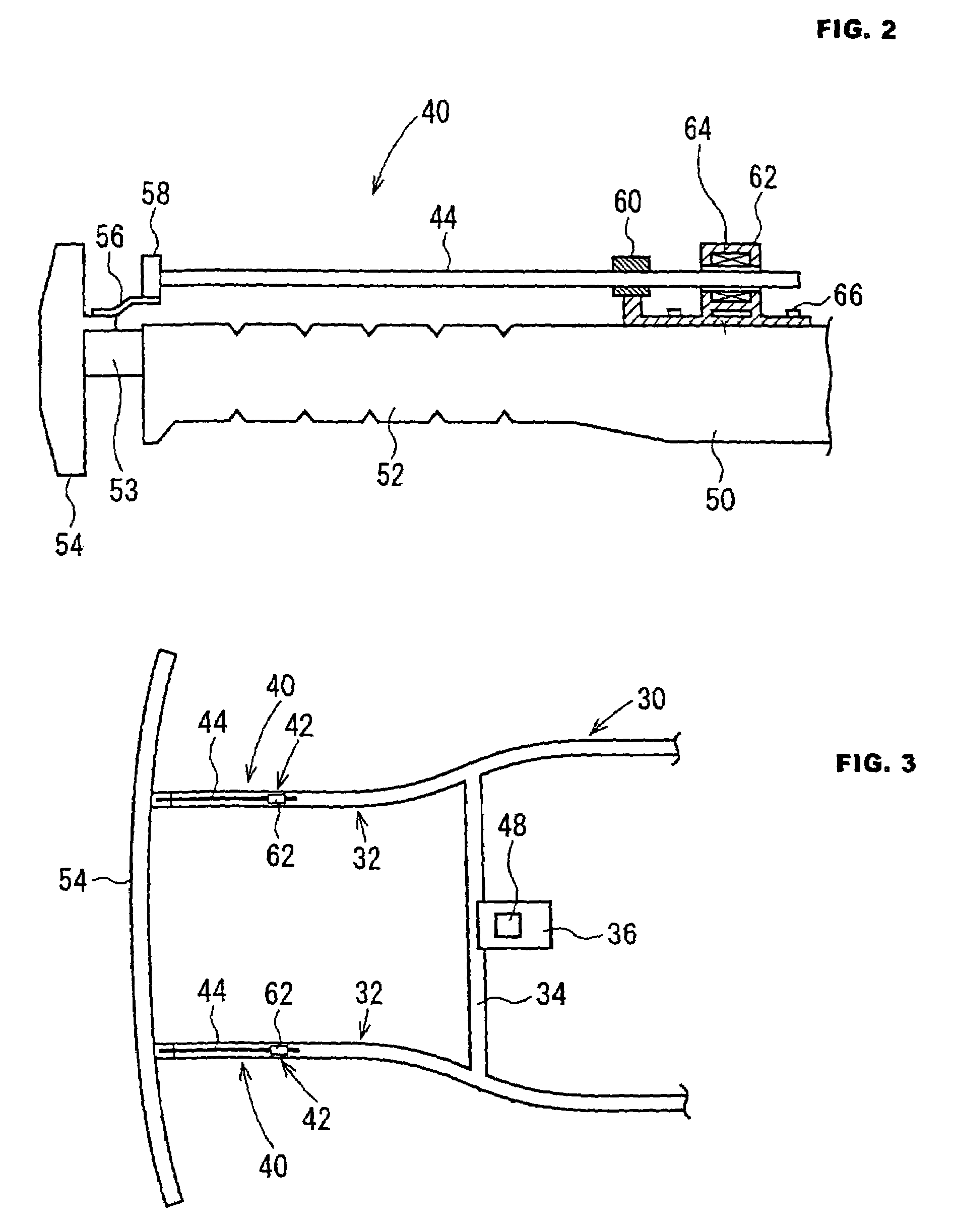

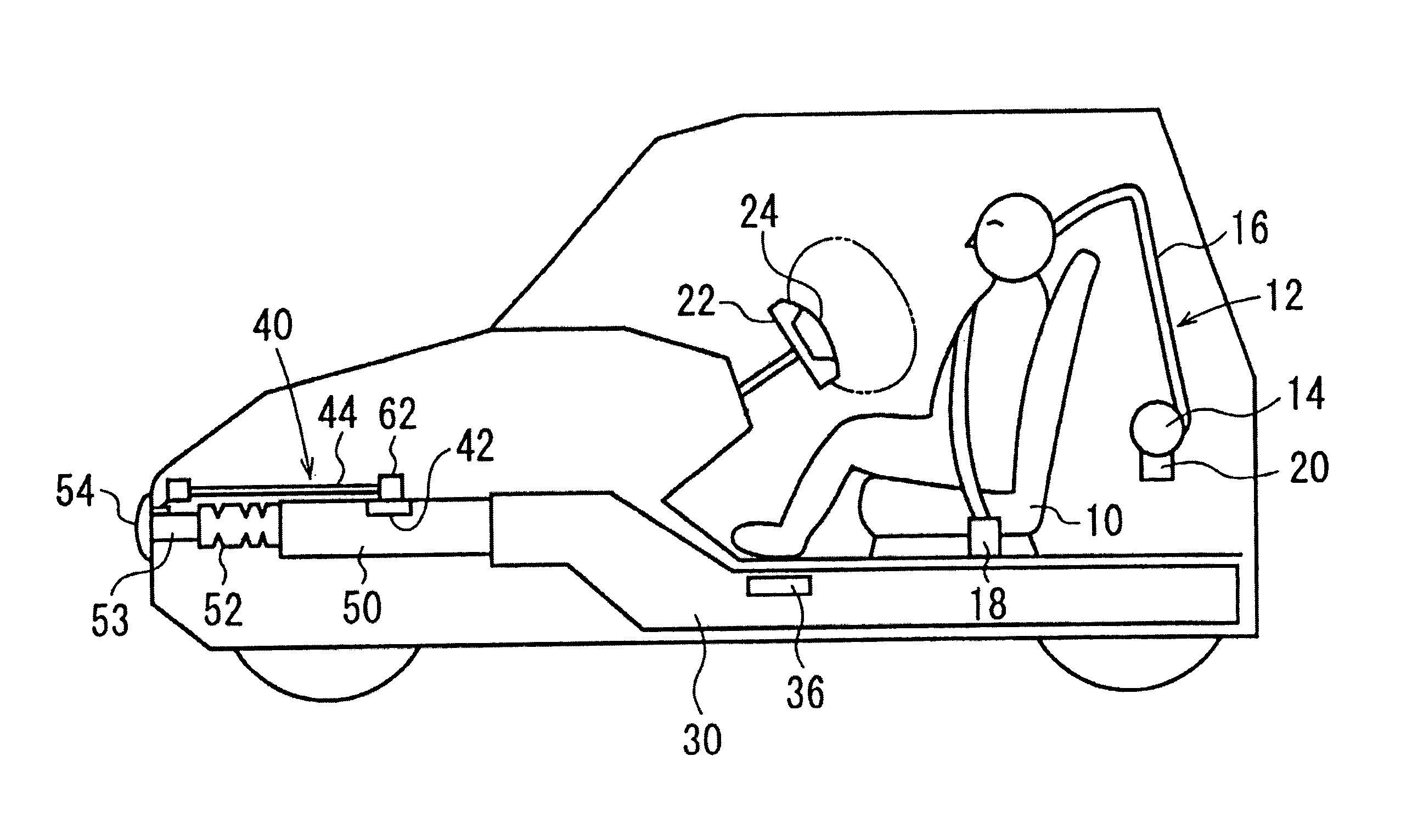

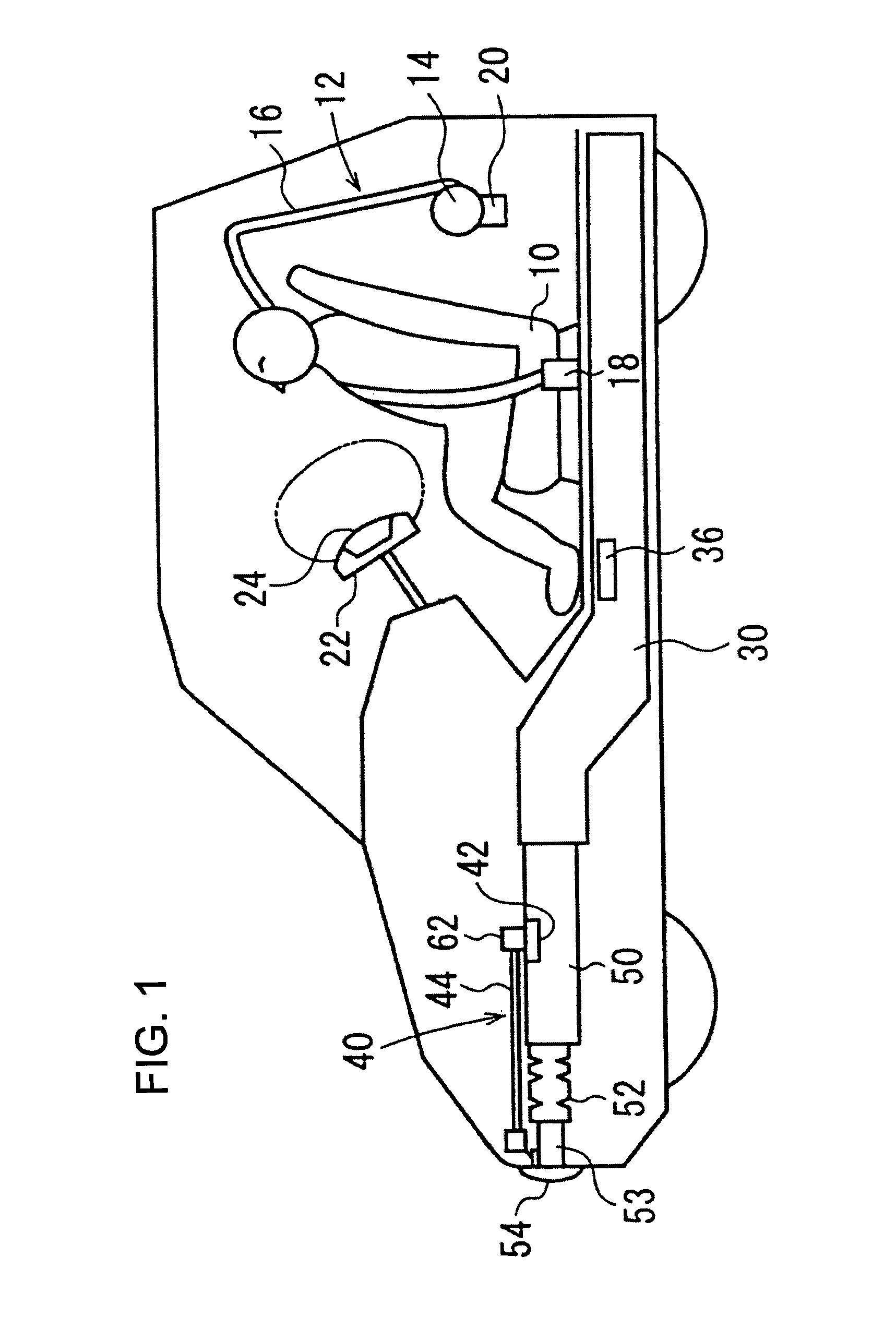

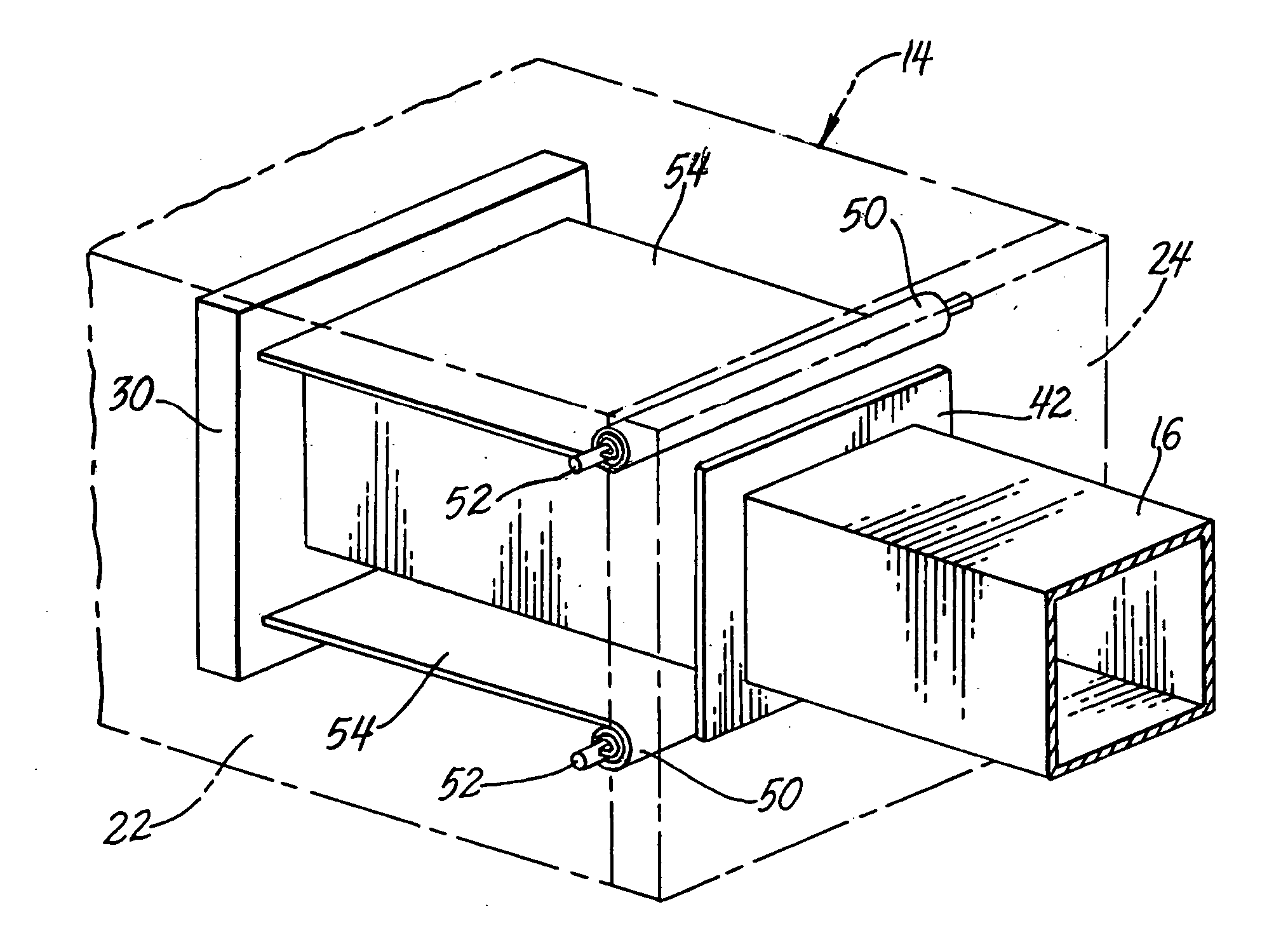

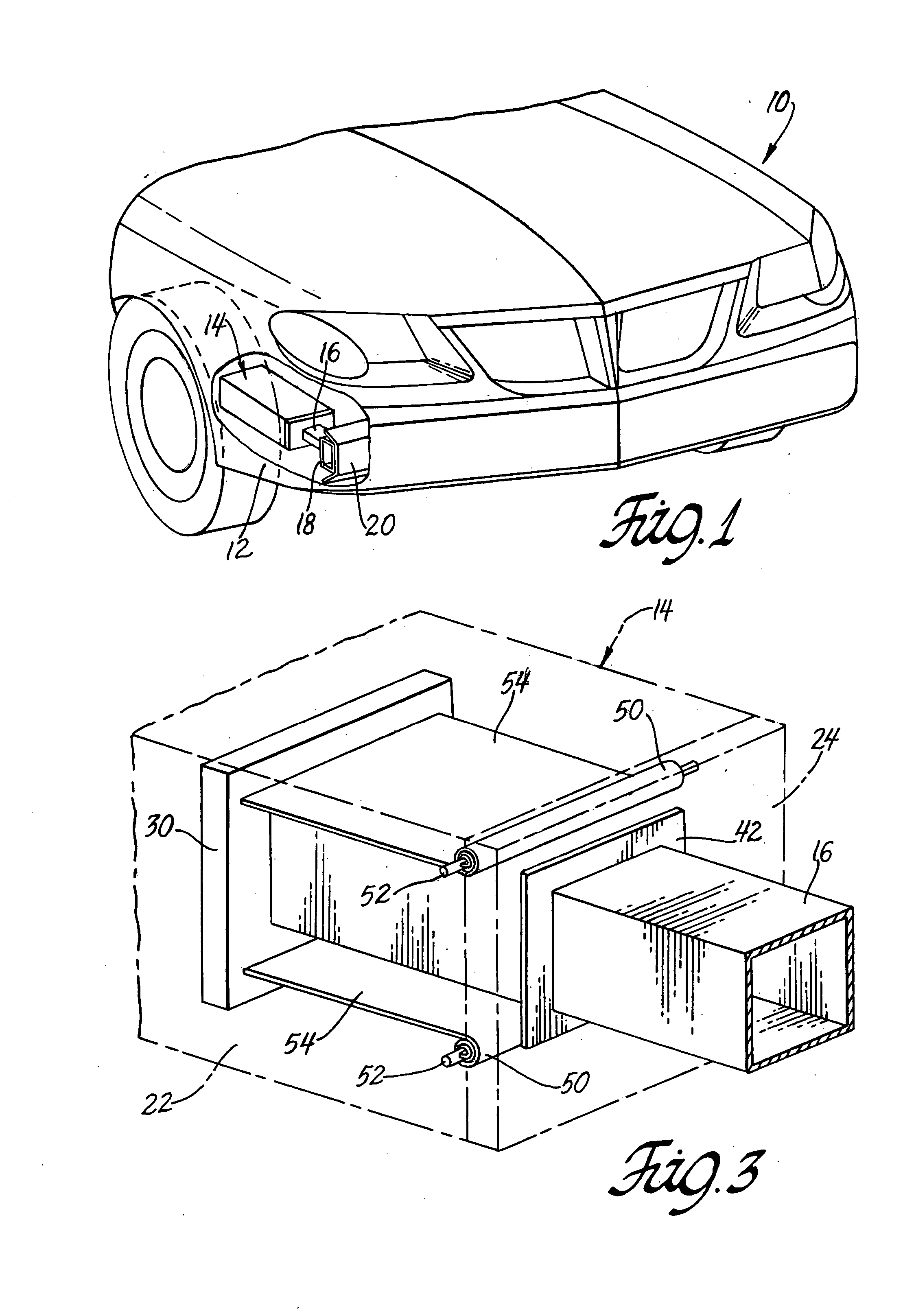

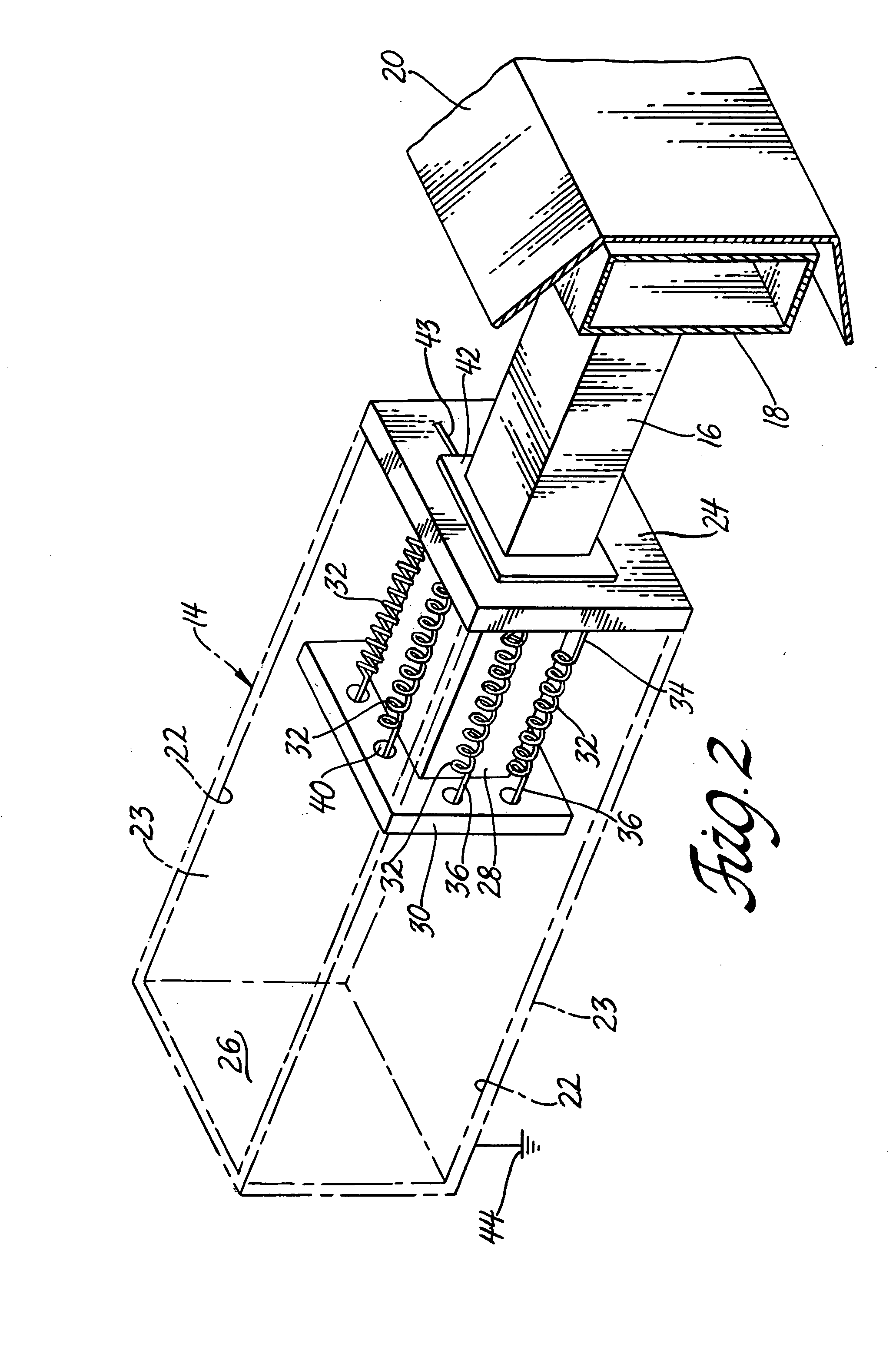

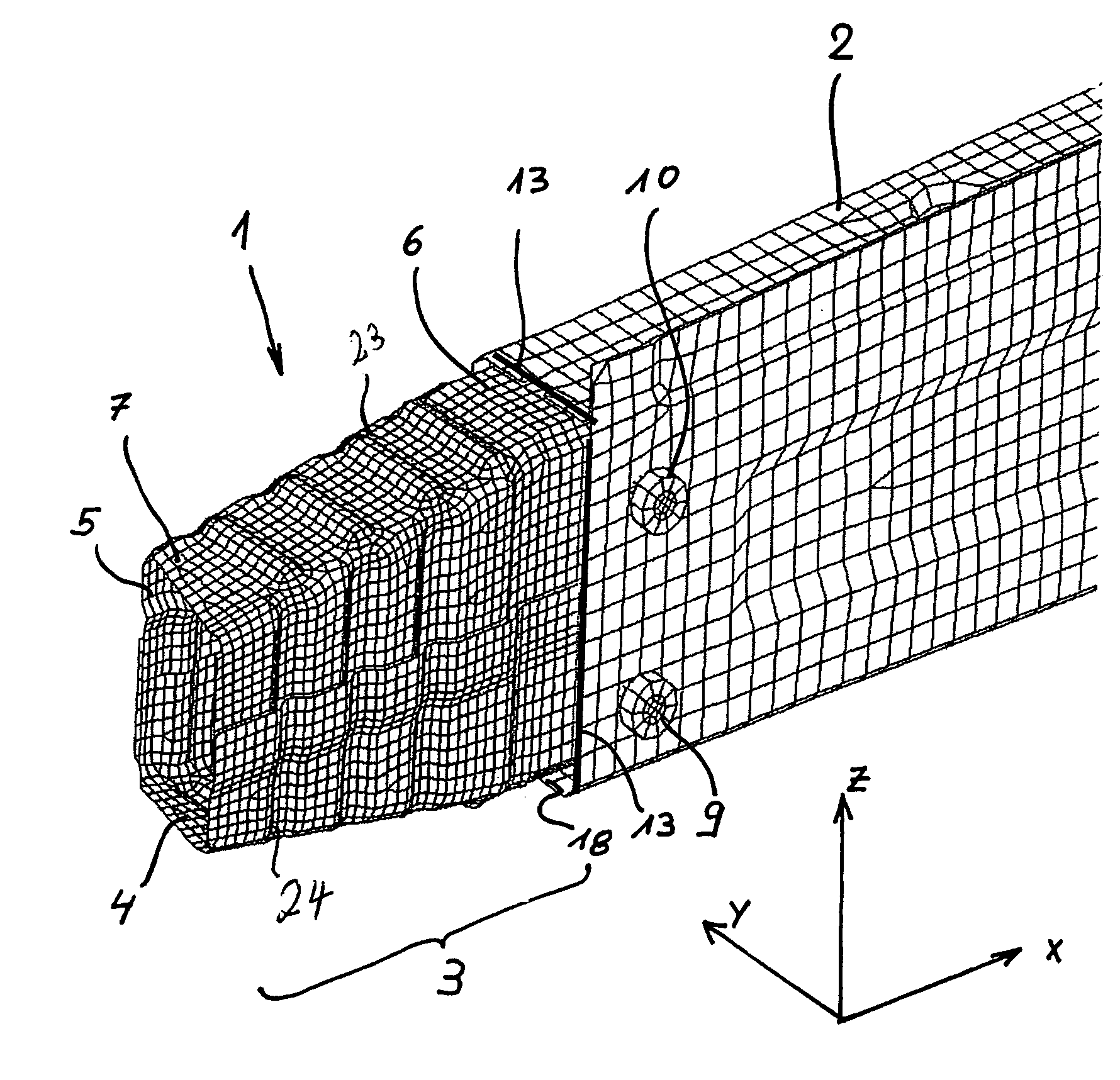

Collision detecting device and passive safety system

InactiveUS7137472B2Improve accuracyDigital data processing detailsAcceleration measurementCrash boxMagnetic detector

A collision detecting device providing the accurate and early determination of a collision with a vehicle or the like and a passive safety system using this collision detecting device. A low-rigid portion and a crash box are arranged ahead of the high-rigid portion in a front portion of a frame. The front end of a rod is fixed to a bumper. The rod is inserted into a magnetic detector disposed on the high-rigid portion. In the rod, a number of magnets are aligned in the longitudinal direction of the rod such that their N poles and S poles are alternatively arranged. As a vehicle collides, the crash box is first deformed so that the rod moves backward, whereby a collision can be detected before large acceleration is generated.

Owner:TAKATA CORPORATION

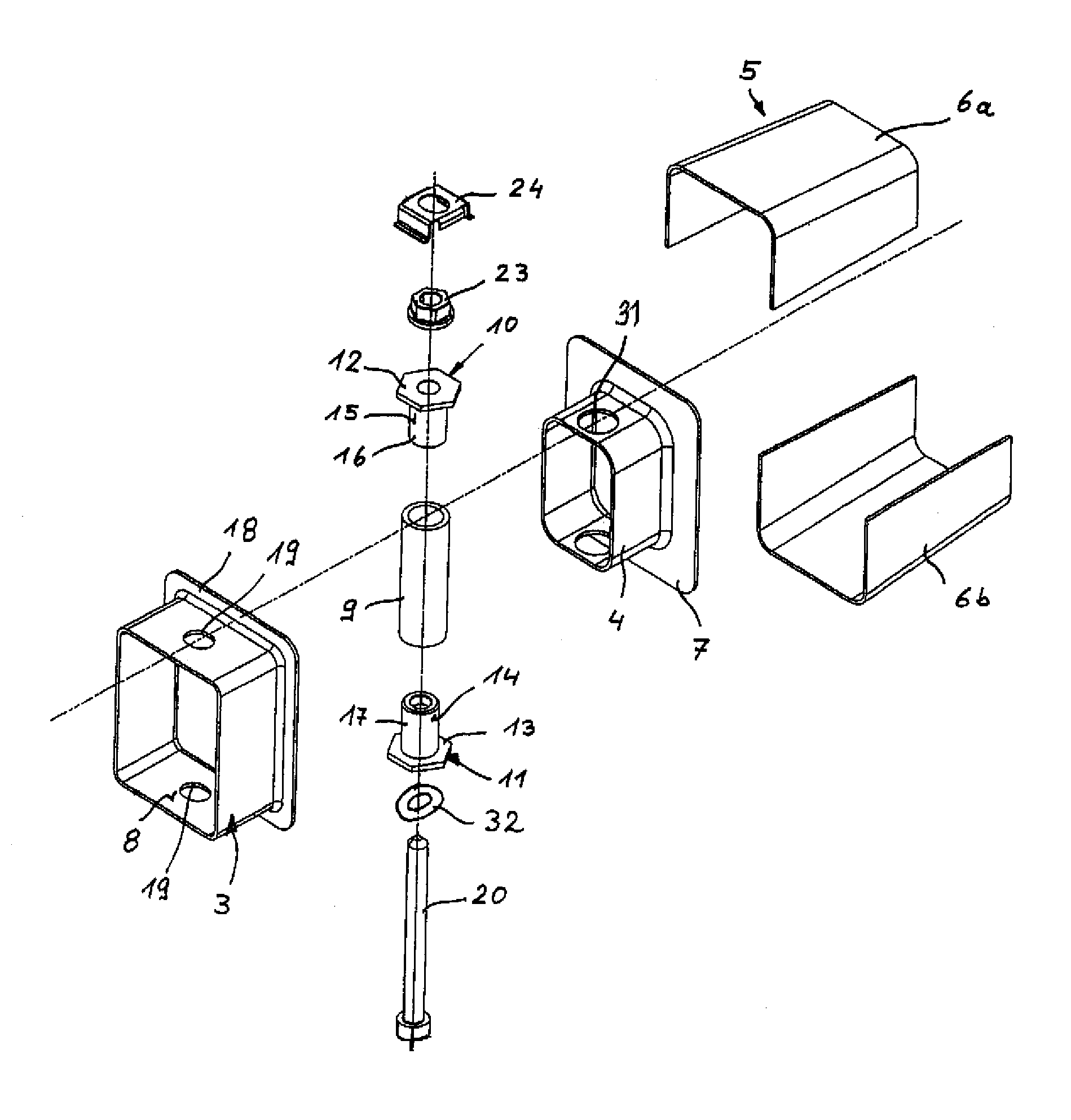

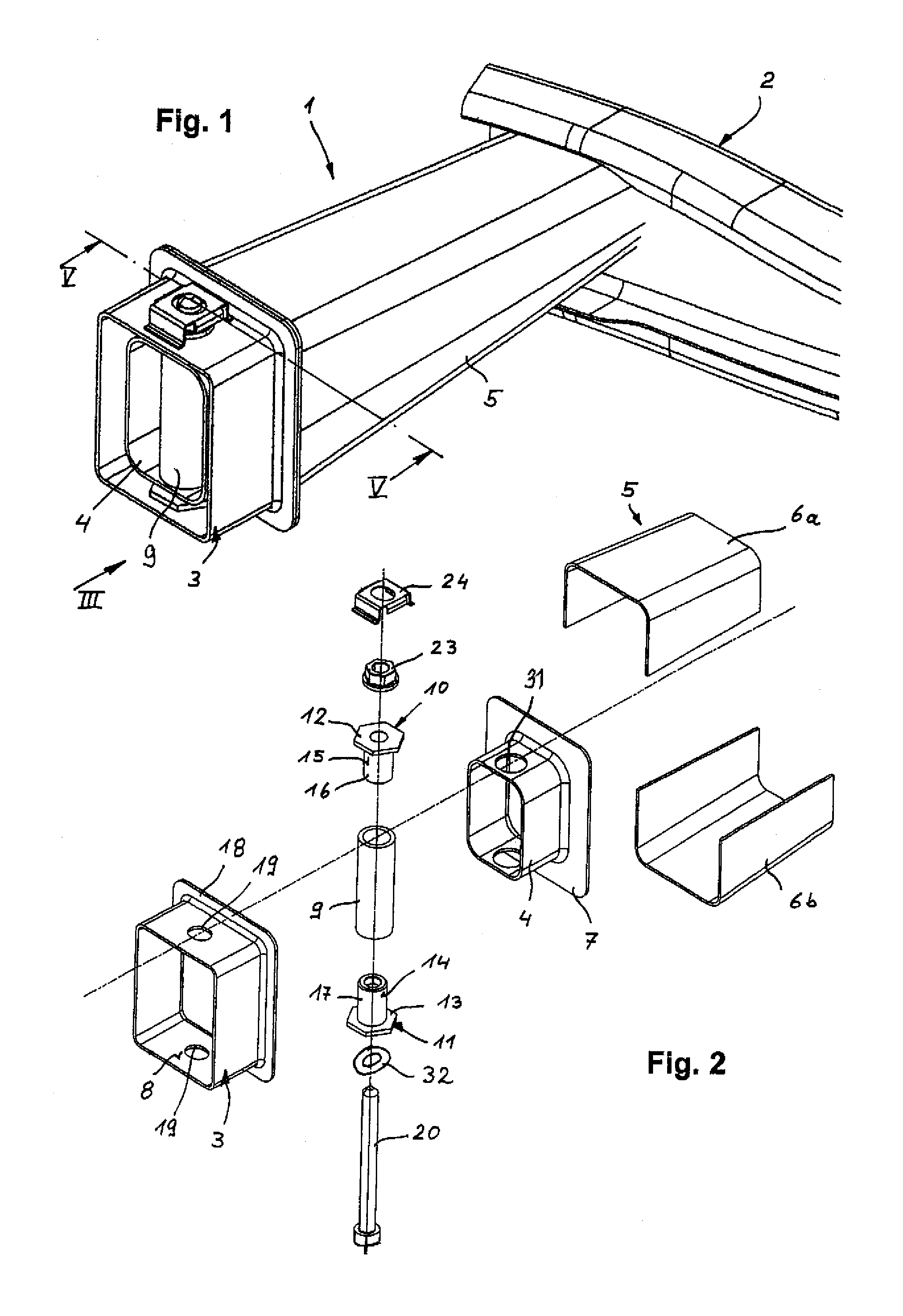

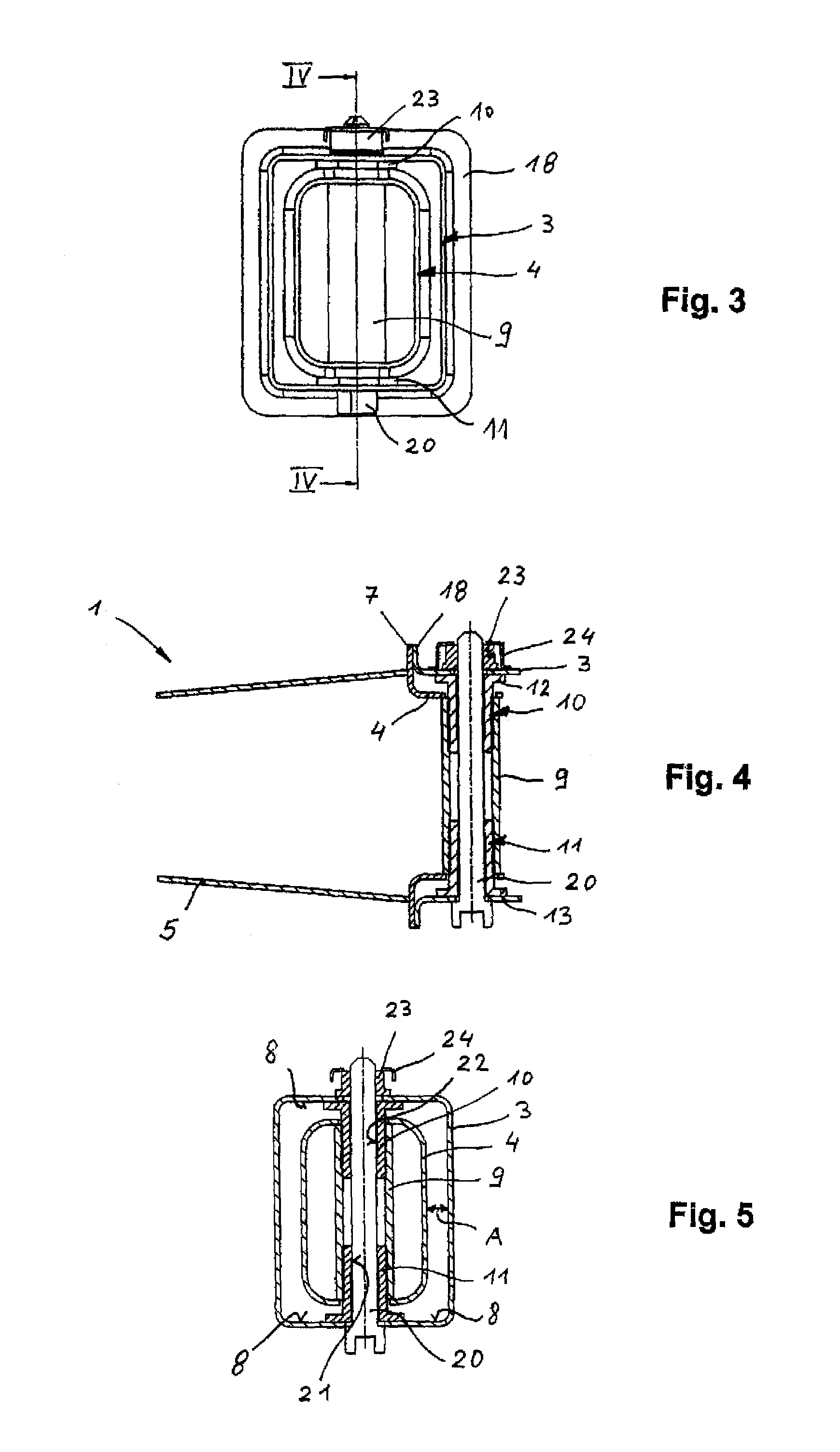

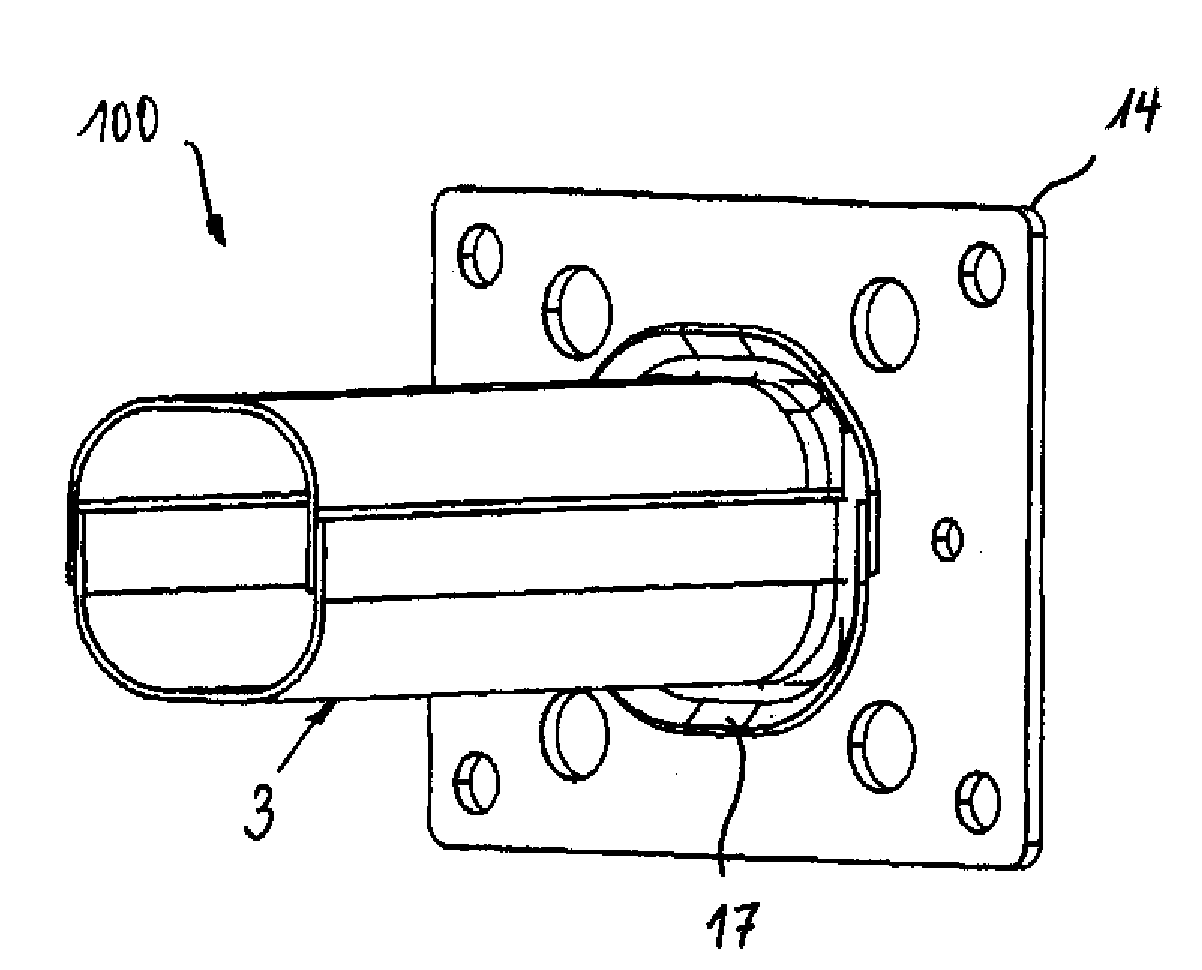

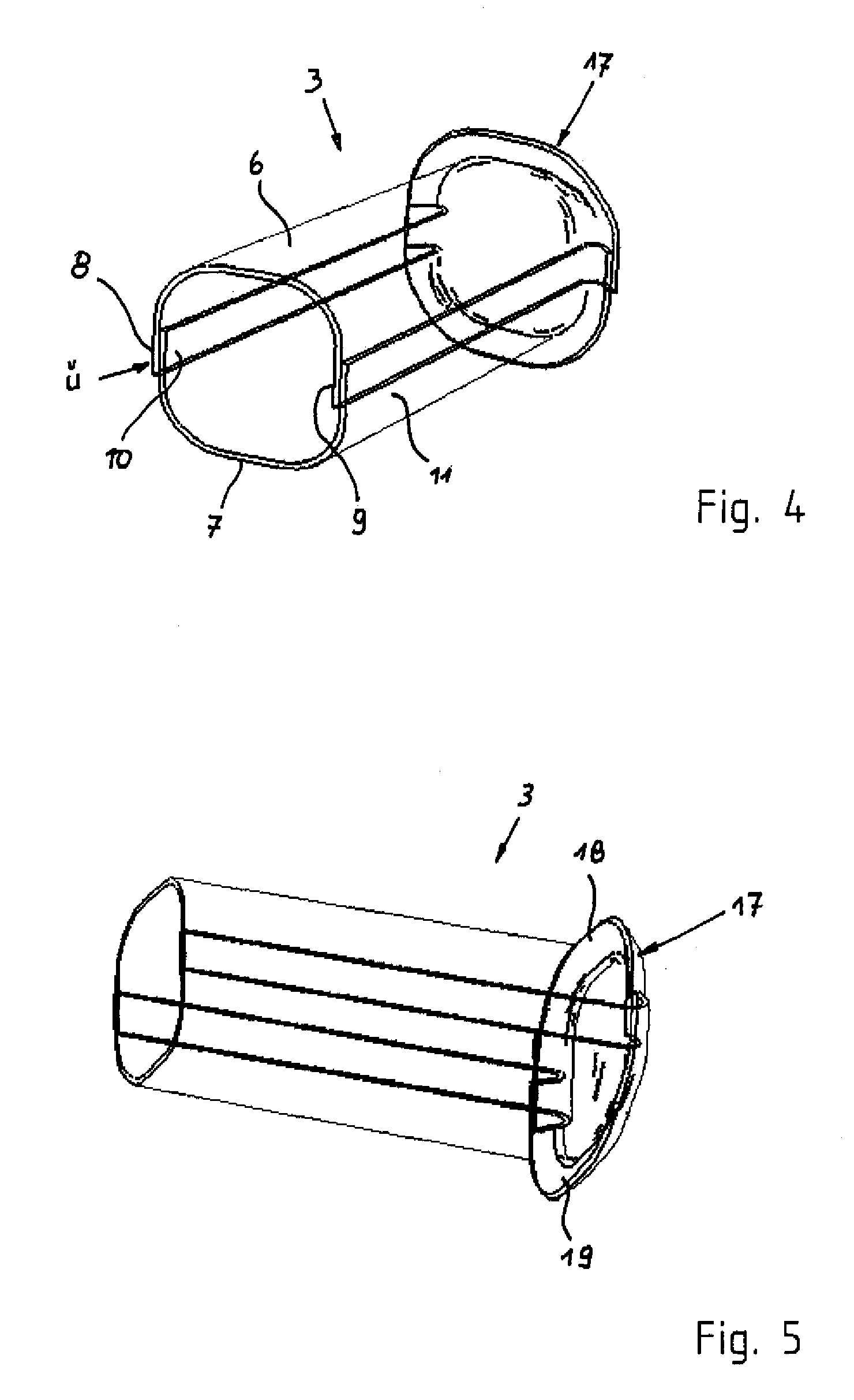

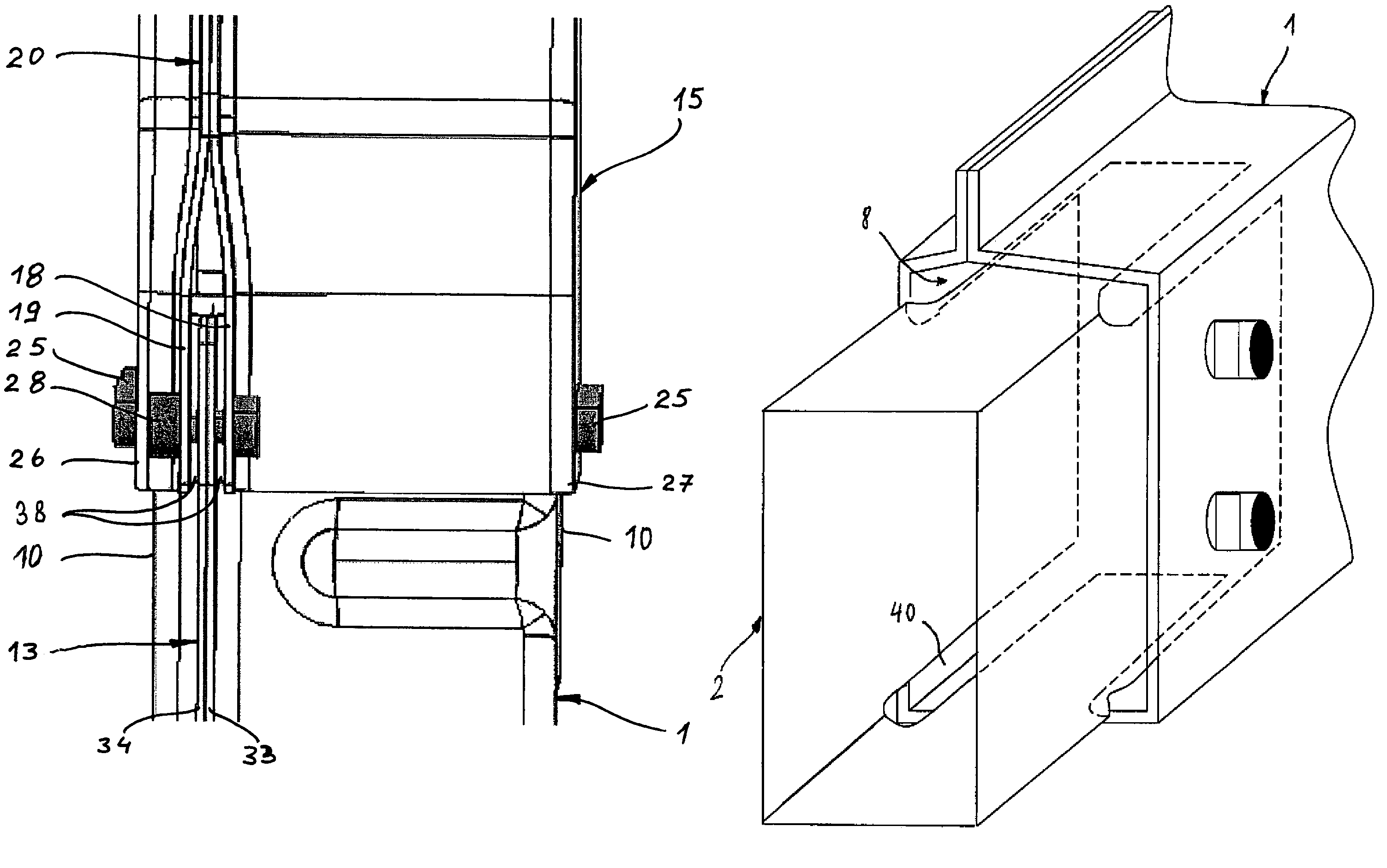

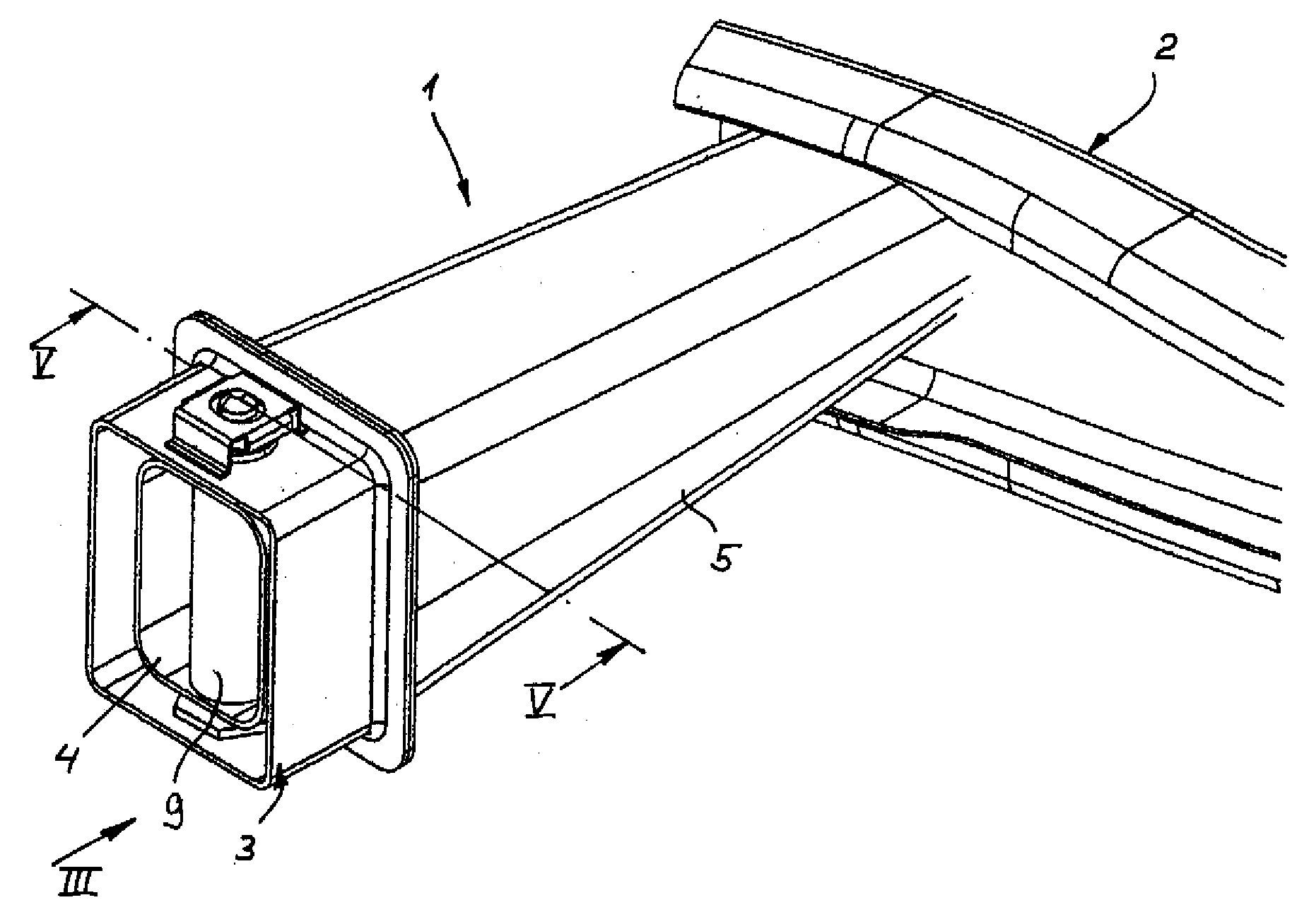

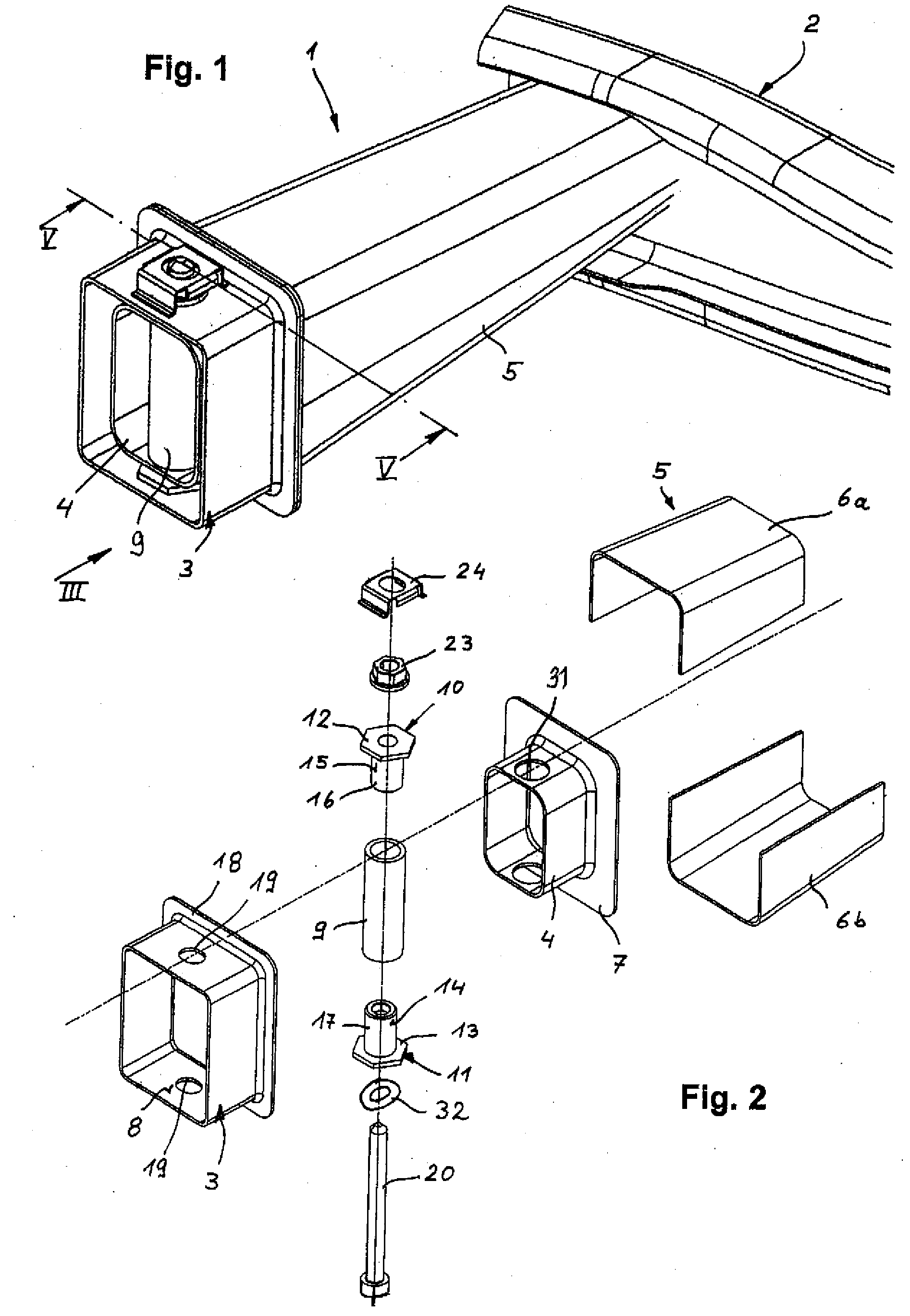

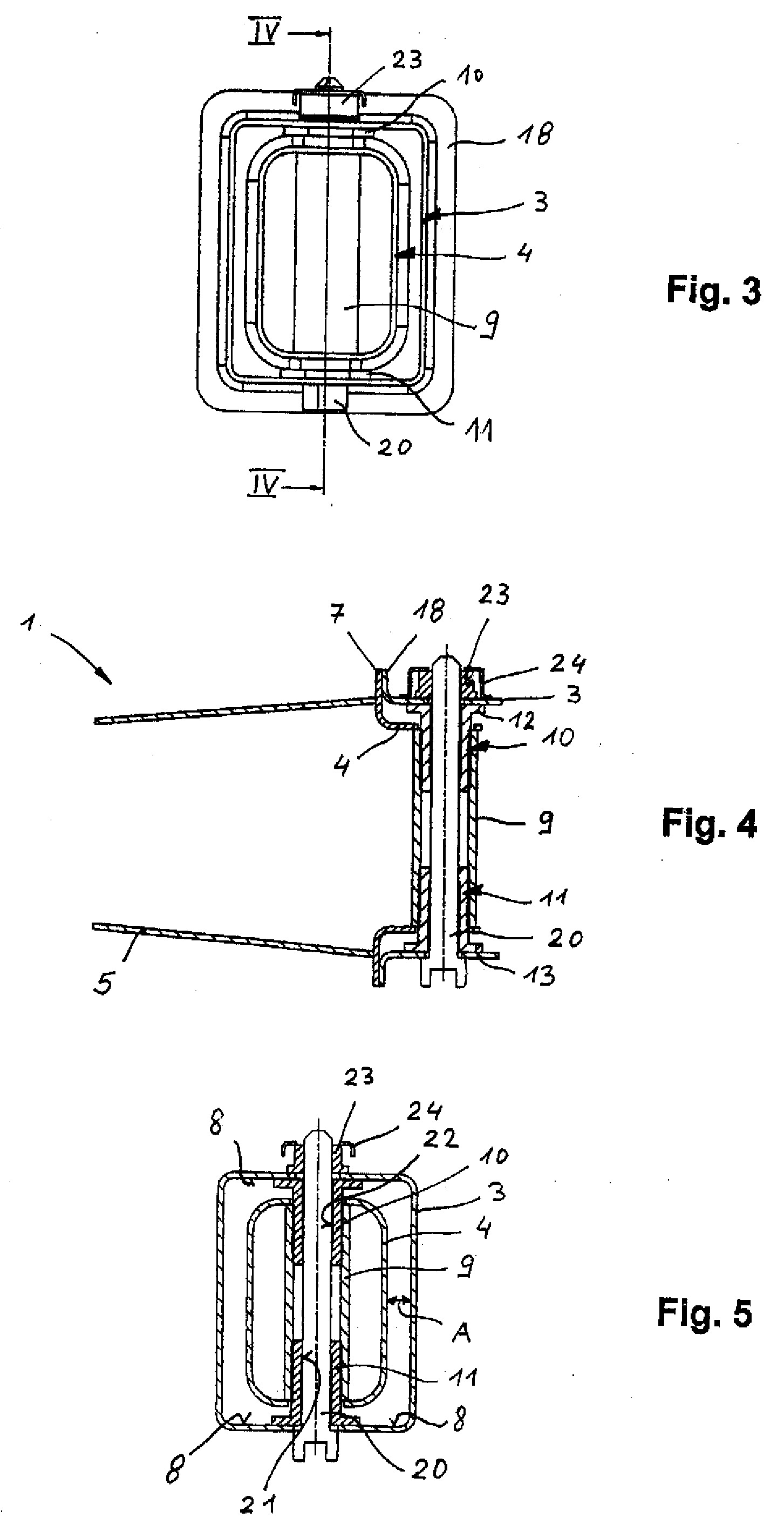

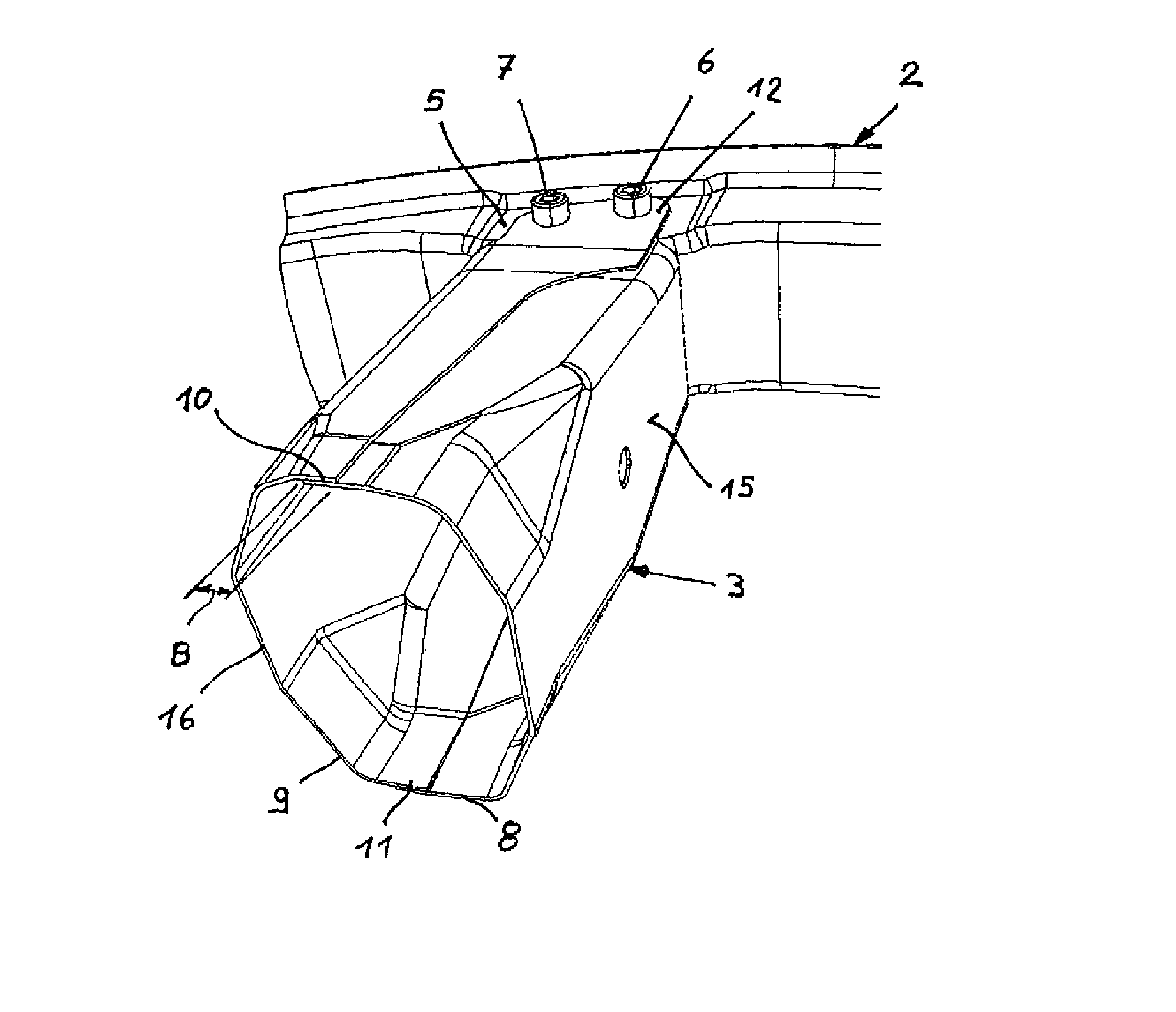

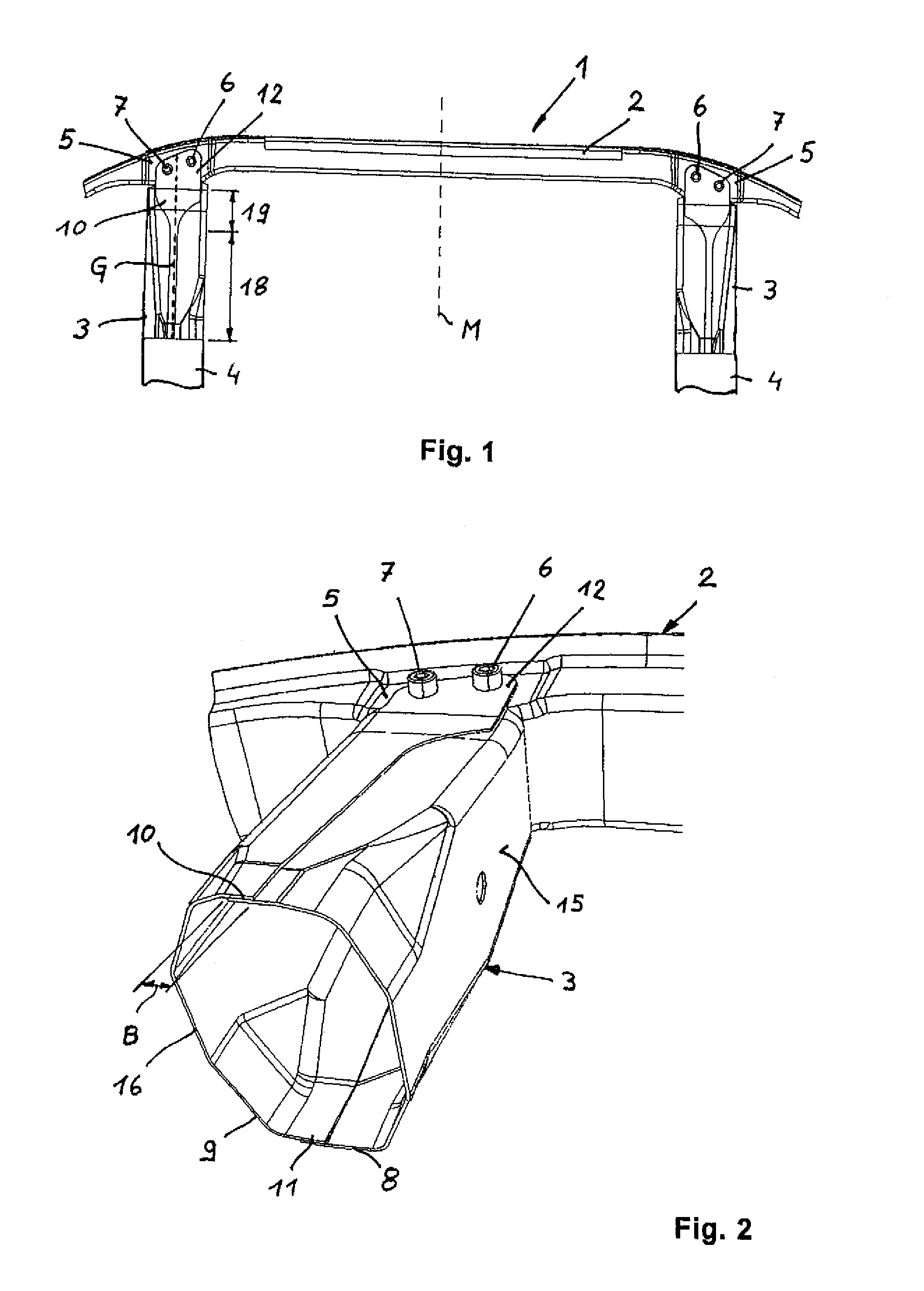

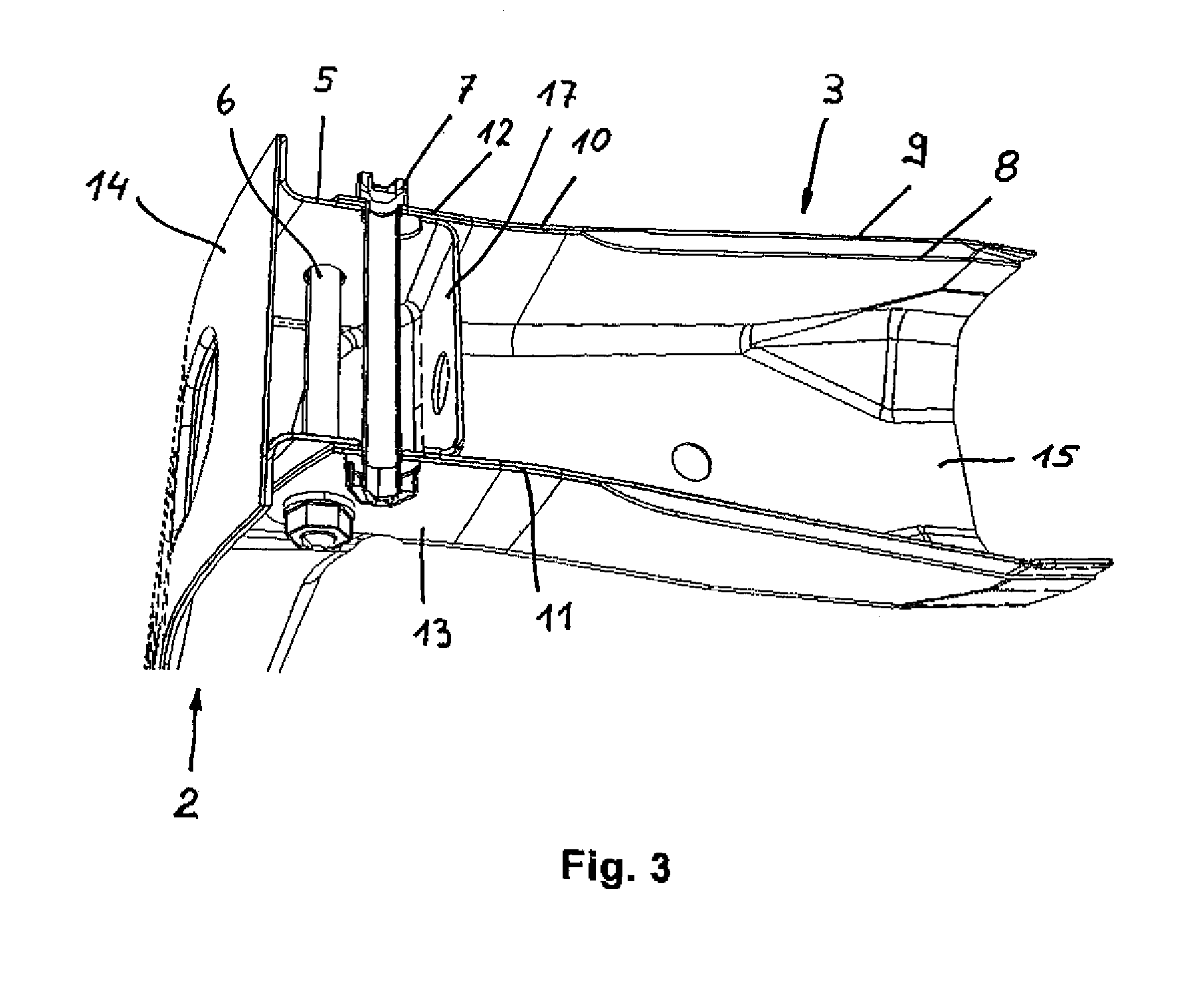

Crash box

InactiveUS7188877B2Easy to assembleAvailable installation spaceWashersUnderstructuresMobile vehicleEngineering

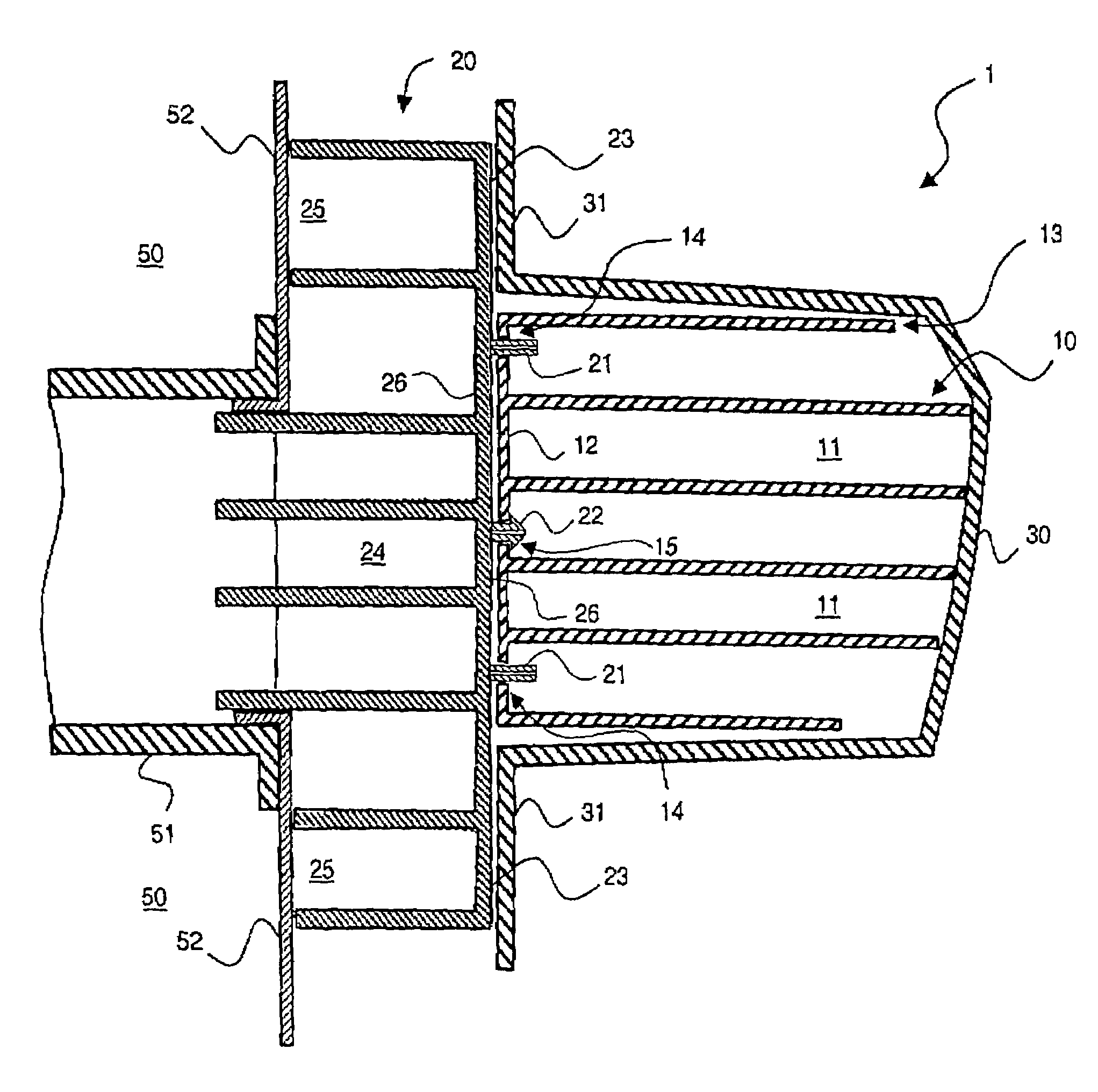

A crash box for a motor vehicle includes an attachment portion which engages a longitudinal member of the motor vehicle and is secured thereto by at least one screw bolt which extends through a spacer sleeve. The spacer sleeve is securely fixed to the attachment portion and has two threaded portions of opposite pitch. Inserted from opposite sides of the spacer sleeve are tolerance compensating bolts, which are each provided with an inner rotary catch for interaction with an outer thread of the screw bolt. When the screw bolt is screwed in, the tolerance compensating bolts are thus moved apart until abutting against opposite inside wall surfaces of the longitudinal member. The screw bolt engages hereby a nut on an outside of the longitudinal member so that the attachment portion is now held without clearance on the longitudinal member by a head portion of the screw bolt and one of the tolerance compensating bolts, and by the other one of the tolerance compensating bolts and the nut.

Owner:BENTELER AUTOMOBILTECHNIK GMBH

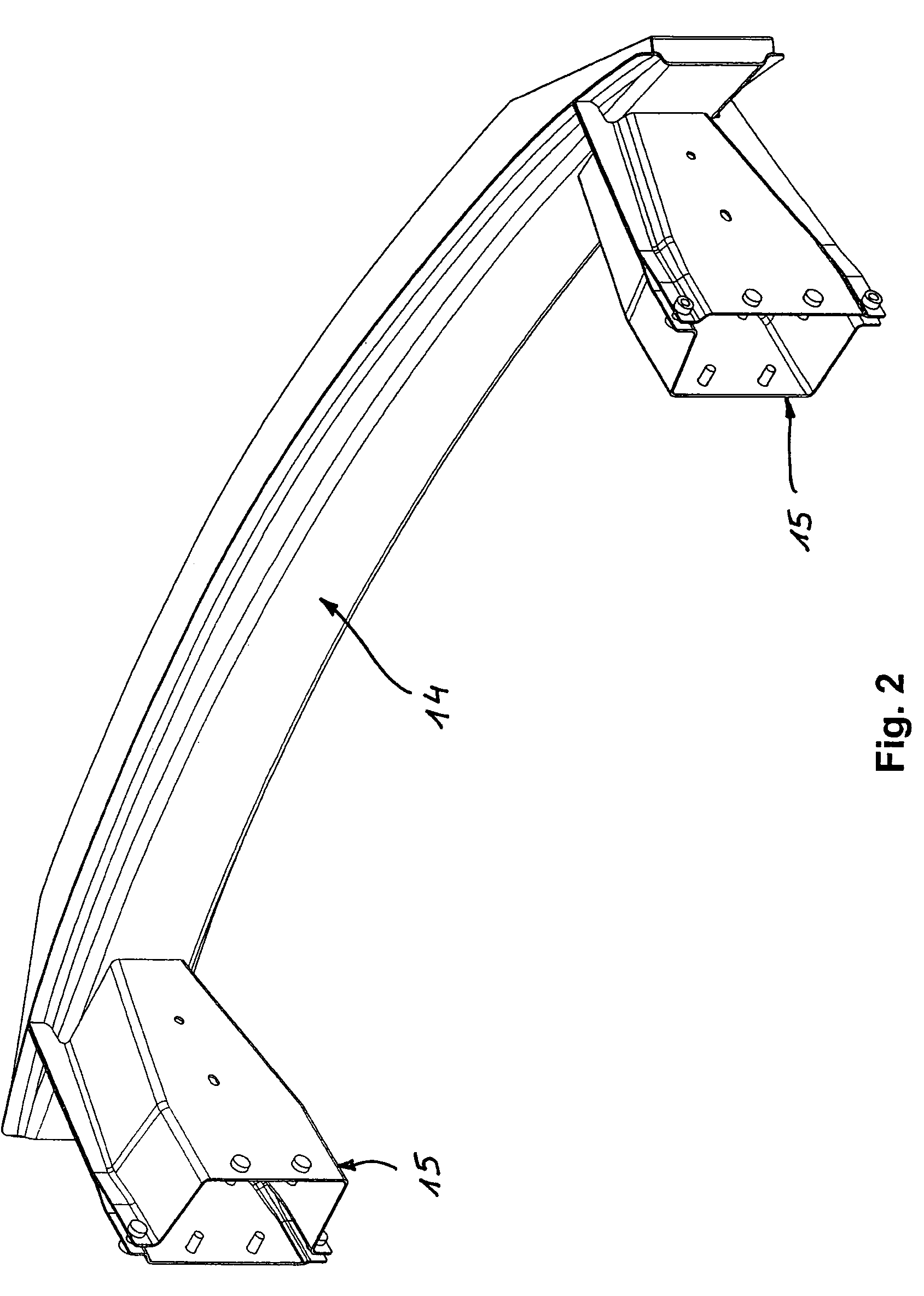

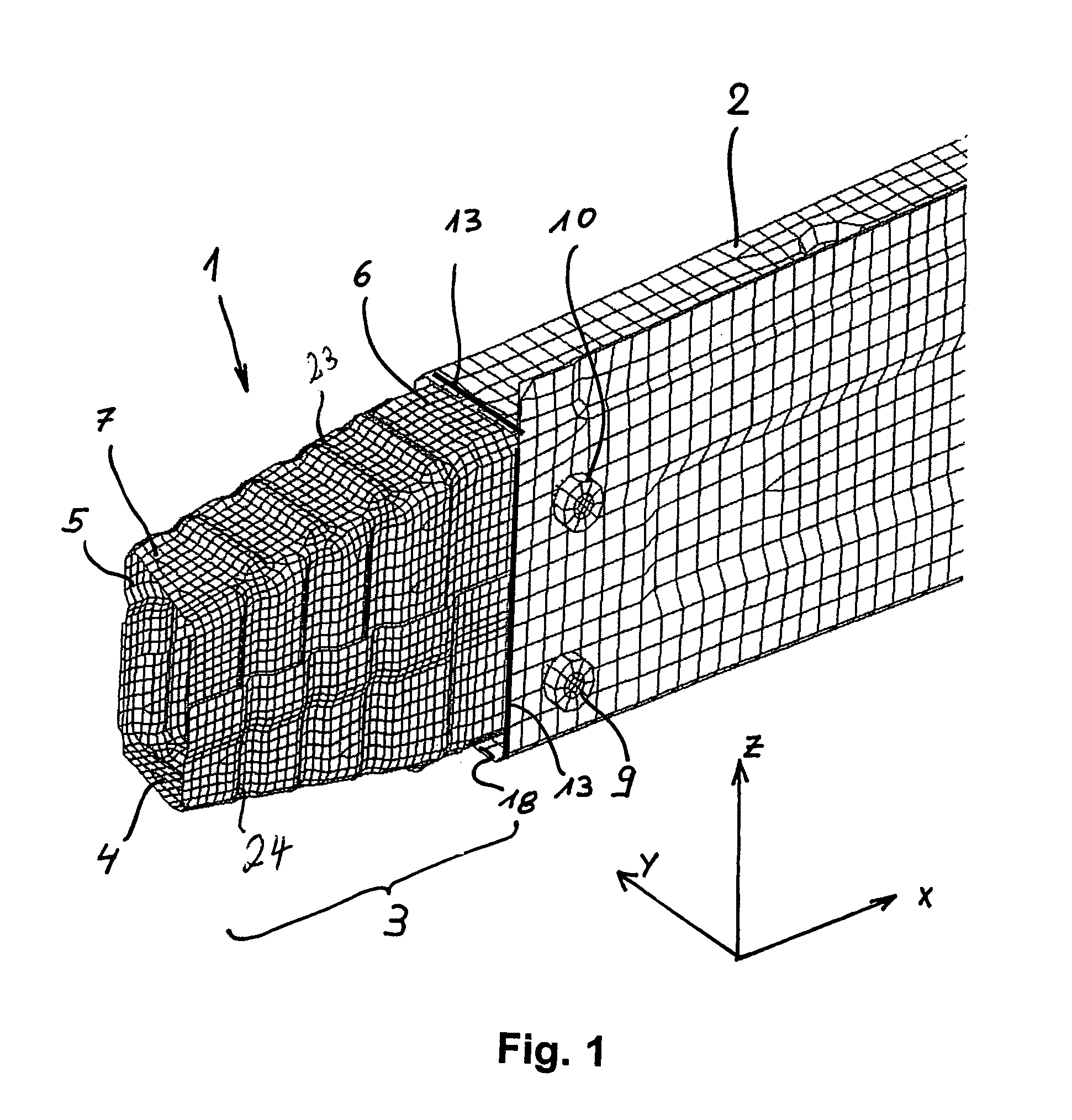

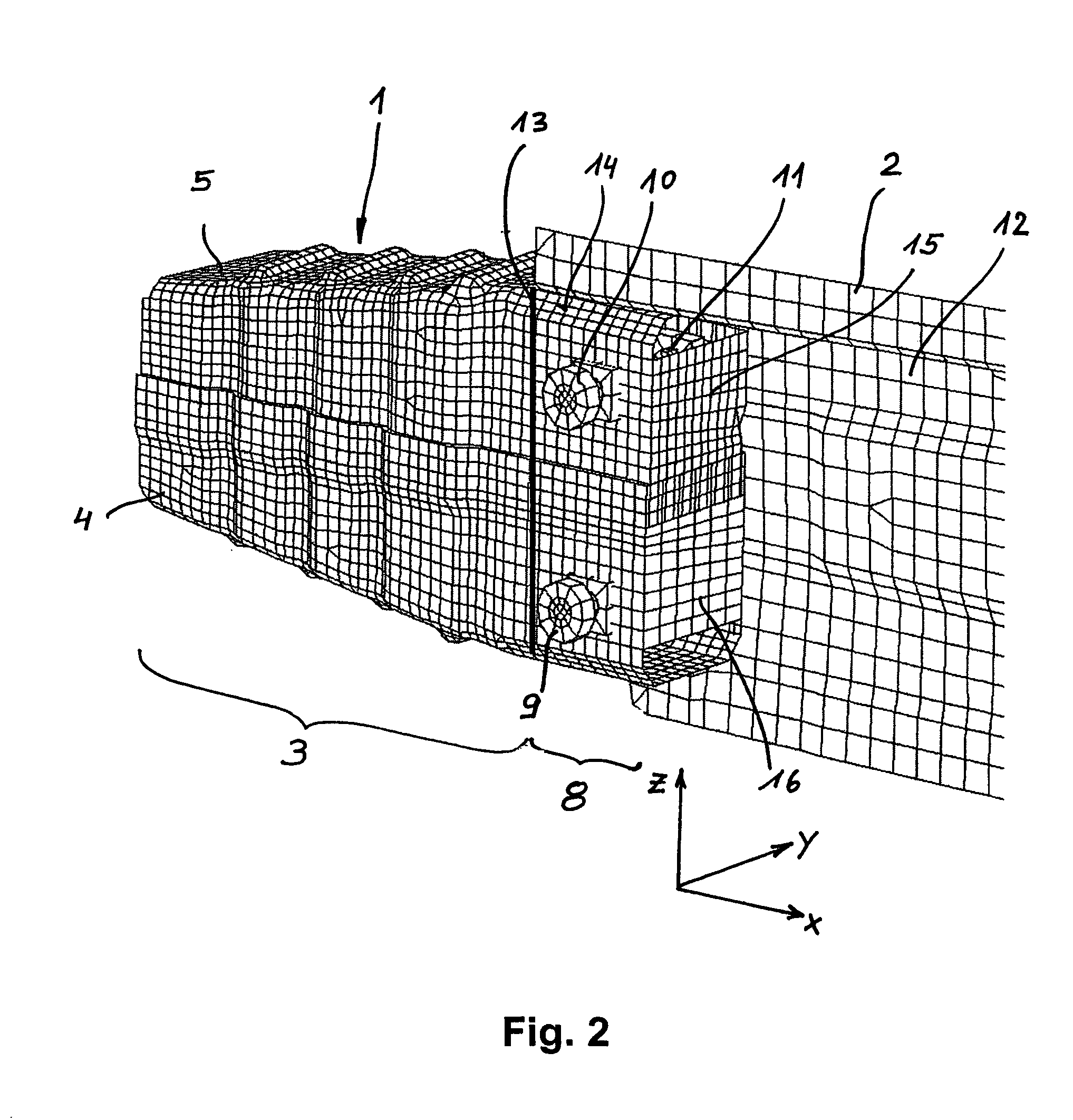

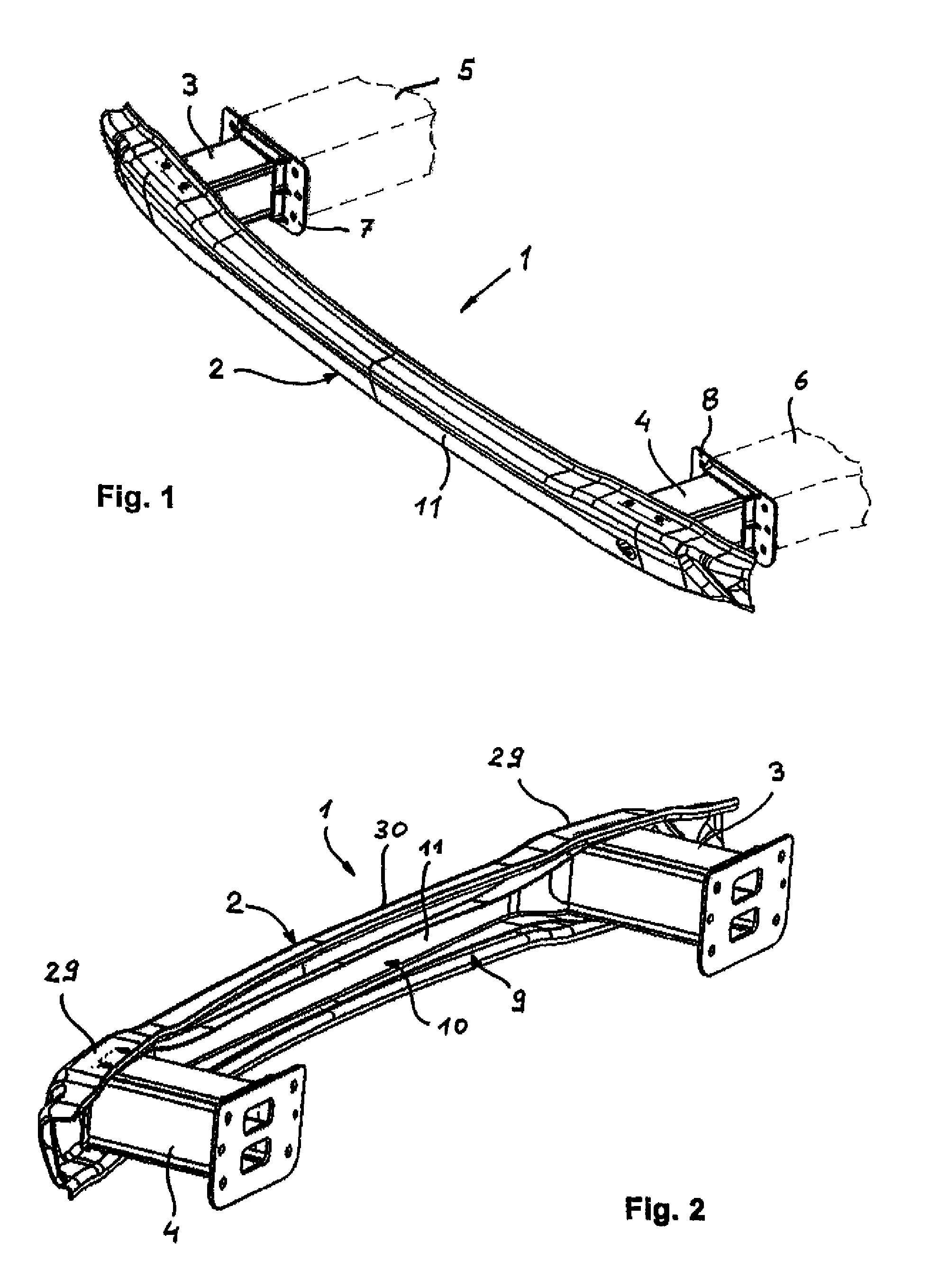

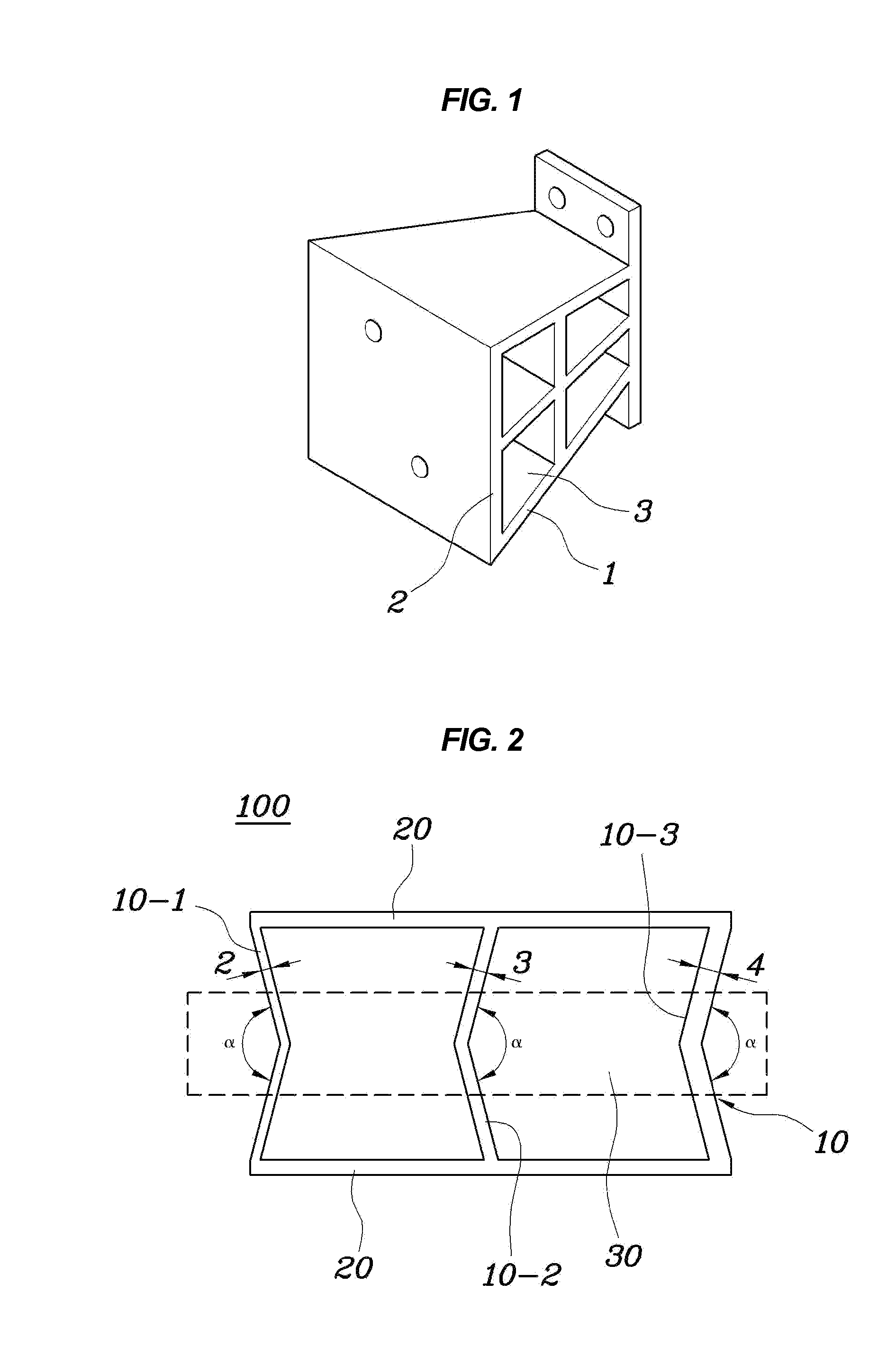

Bumper system

A bumper having crash-boxes accommodated at least in part by space in a hollow cross beam section. As a result, when impact due to collision occurs, deformation of the crash-box takes place early, so that for the same outer dimensions of the bumper longer crash-boxes can be employed. This is of advantage as the energy absorbed by the compression of the cross beam is small in relation to the mass employed and the distance traversed compared with the that achieved with crash-boxes. The capacity to absorb energy exhibited by the proposed bumper is therefore greater than that achieved by conventional bumpers.

Owner:ALCAN TECH & MANAGEMENT LTD

Bumper assembly for a vehicle and corresponding vehicle comprising said bumper assembly

A bumper assembly for a vehicle and the corresponding vehicle comprising said bumper assembly are described. The assembly comprises: at least two crash boxes; a cross member made of a first plastic material which, during use, extends over a distance at least corresponding to that between the crash boxes; and at least two substantially indeformable connecting devices connected to said cross member for rigidly fixing said cross member to said chassis of the vehicle, wherein said at least two substantially indeformable connecting devices are connected to the cross member at positions corresponding to the crash boxes. In a preferred embodiment, the crash boxes and the connecting devices are made of plastic material.

Owner:VM PLASTICS

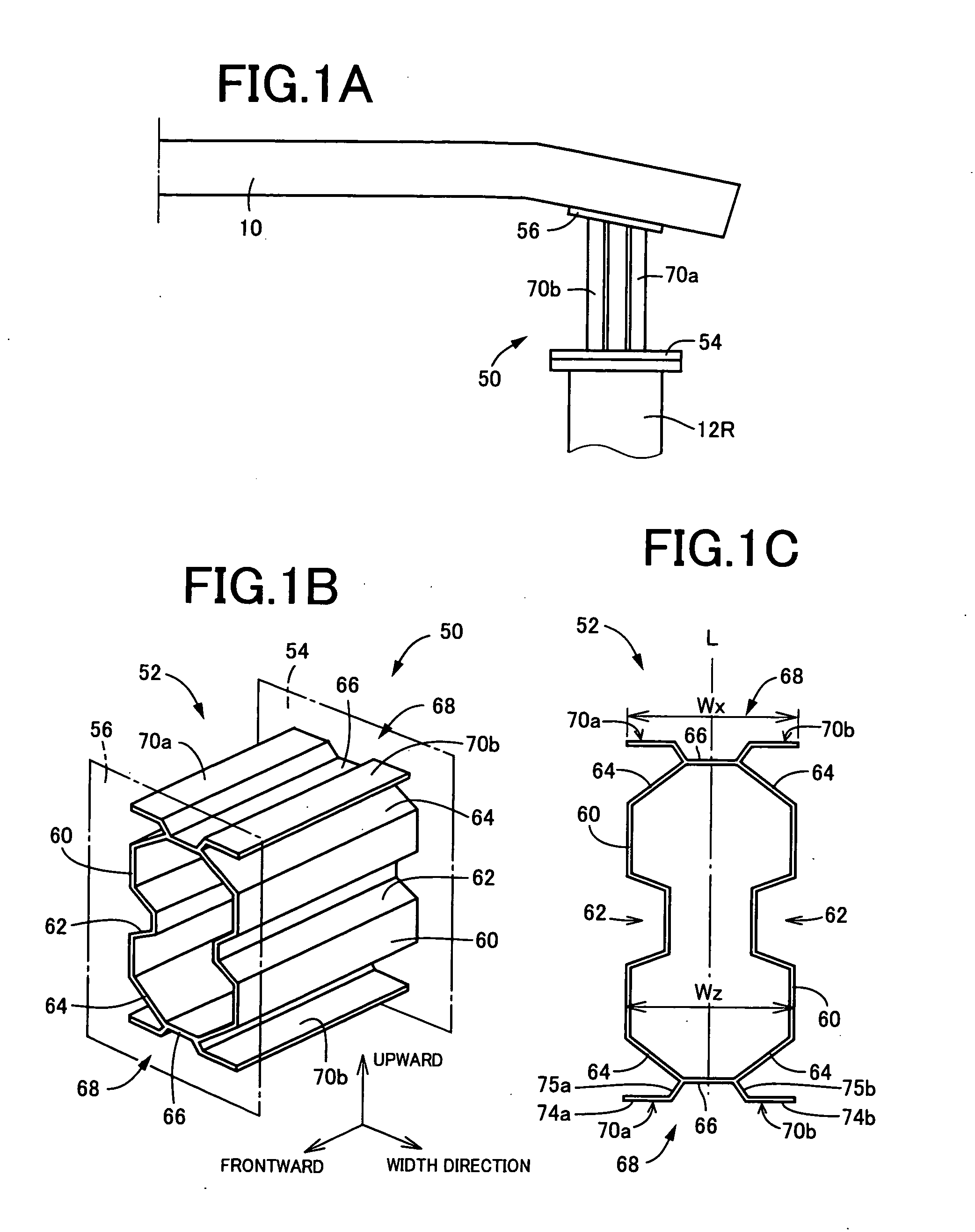

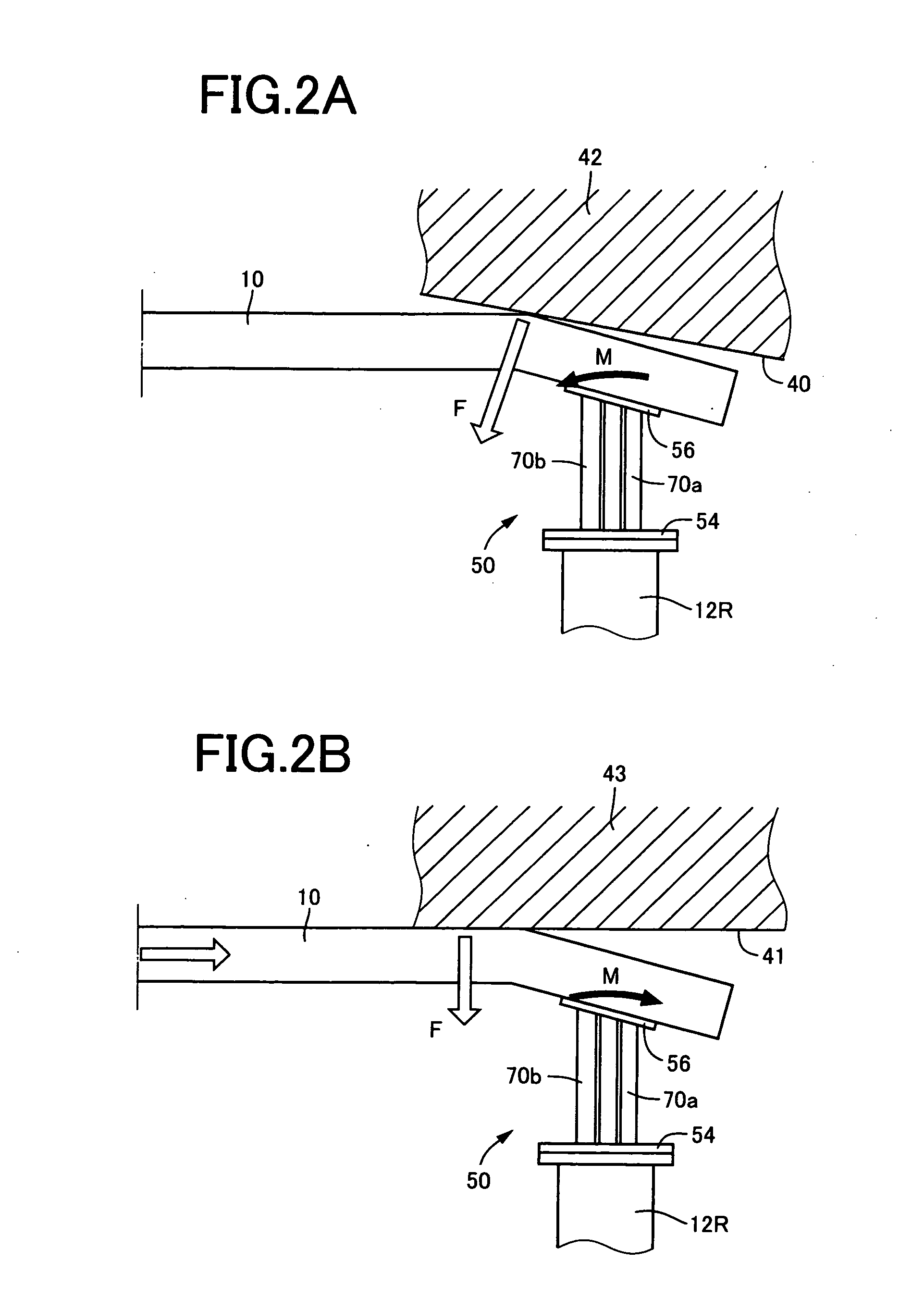

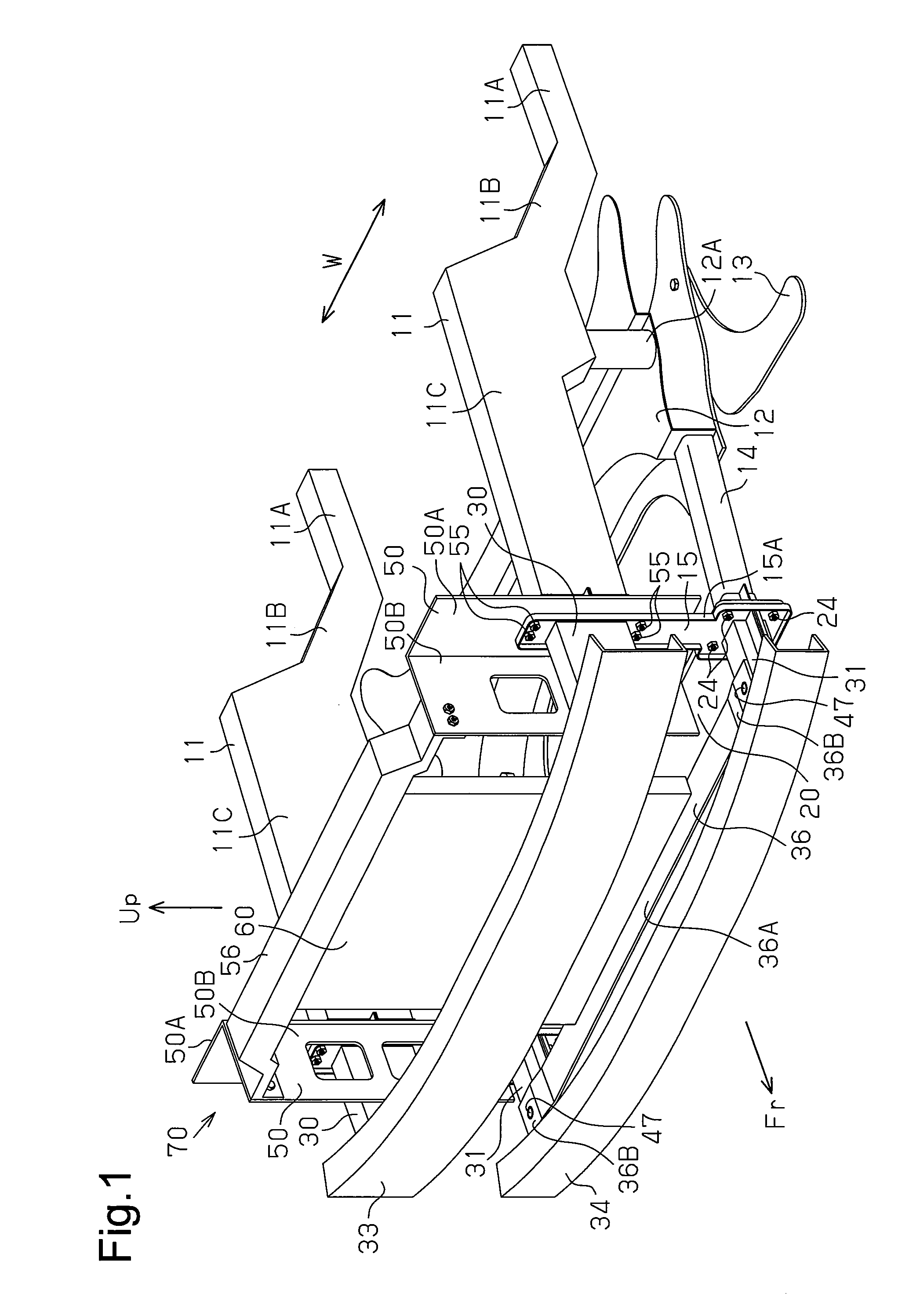

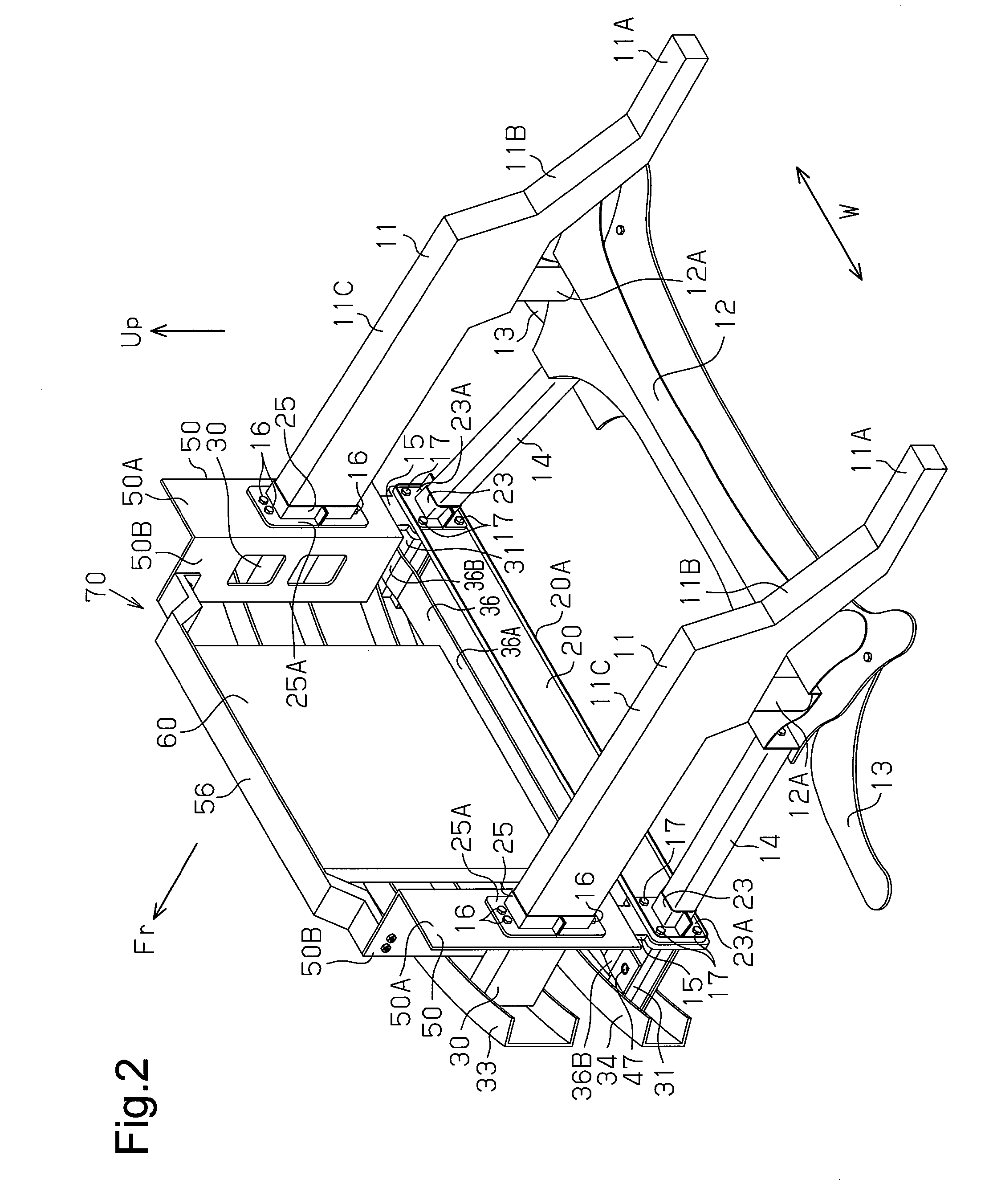

Impact absorbing member for vehicle

InactiveUS20100164238A1Less mounting spaceExcellent impact absorbing performance stablyElastic dampersBumpersFlangeCrash box

Flanges (68) are provided on outer sides (in an upper-lower direction) of a pair of narrow side walls (66) of a crash box (50). Each of flanges (68) is provided to be connected to the narrow side wall (66) at the central portion thereof, and the both lateral portions thereof (wing-like flanges (70a, 70b)) extend parallel to the narrow side walls (66) and in the opposite directions relative to each other. Therefore, even when an impact load is applied to the crash box (50) in an oblique direction of the vehicle, owing to disposition of the flanges (68) the crush box (50) is suppressed from lateral falling, so that excellent impact-absorbing property is stably obtained. Because the flanges (68) are formed parallel to the narrow side walls (66), the impact absorbing member can be appropriately prevented from the lateral falling resulted from the impact load acting in an oblique direction of the vehicle, and can be compactified in size. As a result, mountability on a vehicle is improved.

Owner:TOYODA IRON WORKS CO LTD

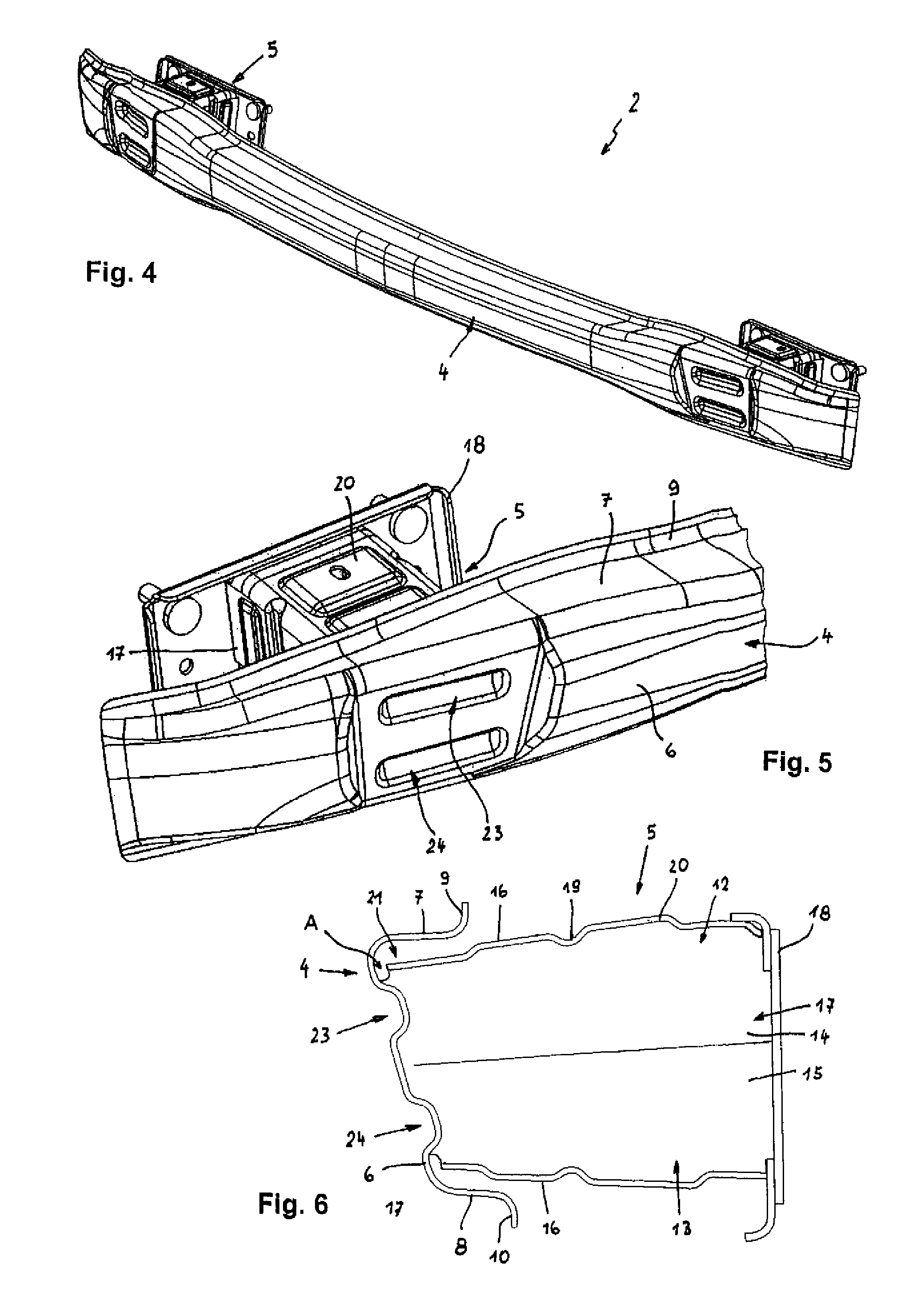

Bumper for a motor vehicle

A bumper for a motor vehicle includes a cross member which is disposed transversely to side rails of a motor vehicle frame and connected to the side rails via crash boxes. The cross member has a C-shaped cross section and includes an outer shell member and an inner shell member. The inner shell member is constructed as tension link which is made of a material having a tensile strength that is greater than the tensile strength of a material of the outer shell member.

Owner:BENTELER AUTOMOBILTECHNIK GMBH

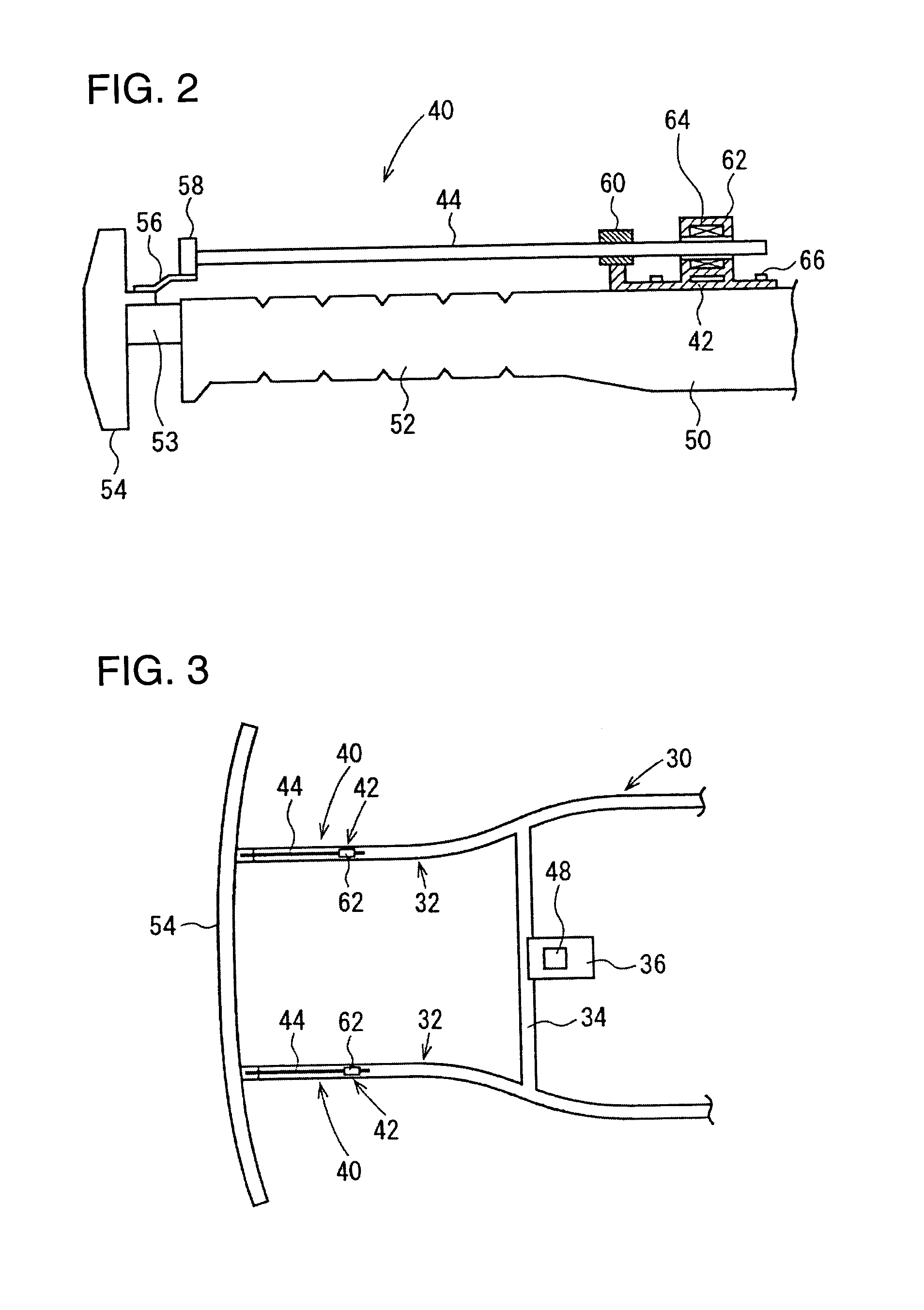

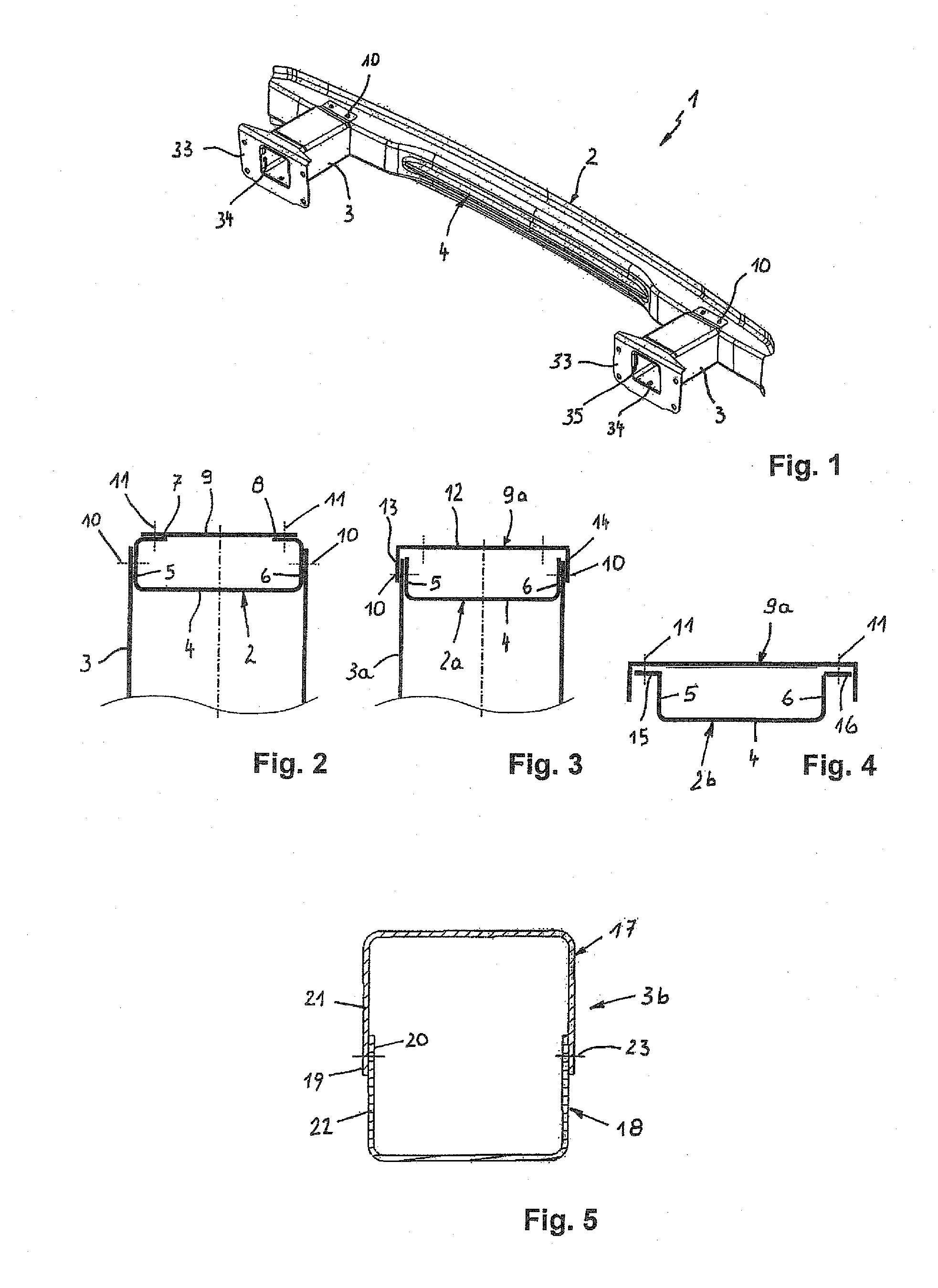

Crash box

InactiveUS20060033363A1Reduce weightAdd supportVehicle seatsSteering linkagesEnergy absorptionEngineering

A crash box for installation between a longitudinal member and a bumper cross member of a motor vehicle, includes a sheet metal body having a deformation member which extends anteriorly of an end surface of the longitudinal member and whose maximum crumpling capability defines the energy absorption of the crash box. In prolongation of the deformation member is an attachment member which is engaged in the longitudinal member and detachably secured by bolts therein. Formed in a transition zone between the deformation member and the attachment member, is a stop which is configured in the form of an outwardly directed material protuberance or outwardly directed thickened area of the sheet metal body and bearing against the end surface of the longitudinal member.

Owner:BENTELER AUTOMOBILTECHNIK GMBH

Bumper for a motor vehicle

A bumper for a motor vehicle includes a cross member disposed transversely to side rails of a motor vehicle frame and having a U-shaped cross section with a wall and two legs extending from opposite ends of the wall. The cross member is supported via integral crash boxes against the side rails. Each crash box has a cross member proximal end which abuts against the wall of the cross member, and includes vertical legs and horizontal legs to define a casing-like configuration. The wall of the cross member is formed in an area of the cross member proximal end of the crash box with a depression which extends in a direction of the crash box, with the vertical legs of the crash box joined at the cross member proximal end to the wall of the cross member, and with the horizontal legs of the crash box spaced from the wall of the cross member by a distance.

Owner:BENTELER AUTOMOBILTECHNIK GMBH

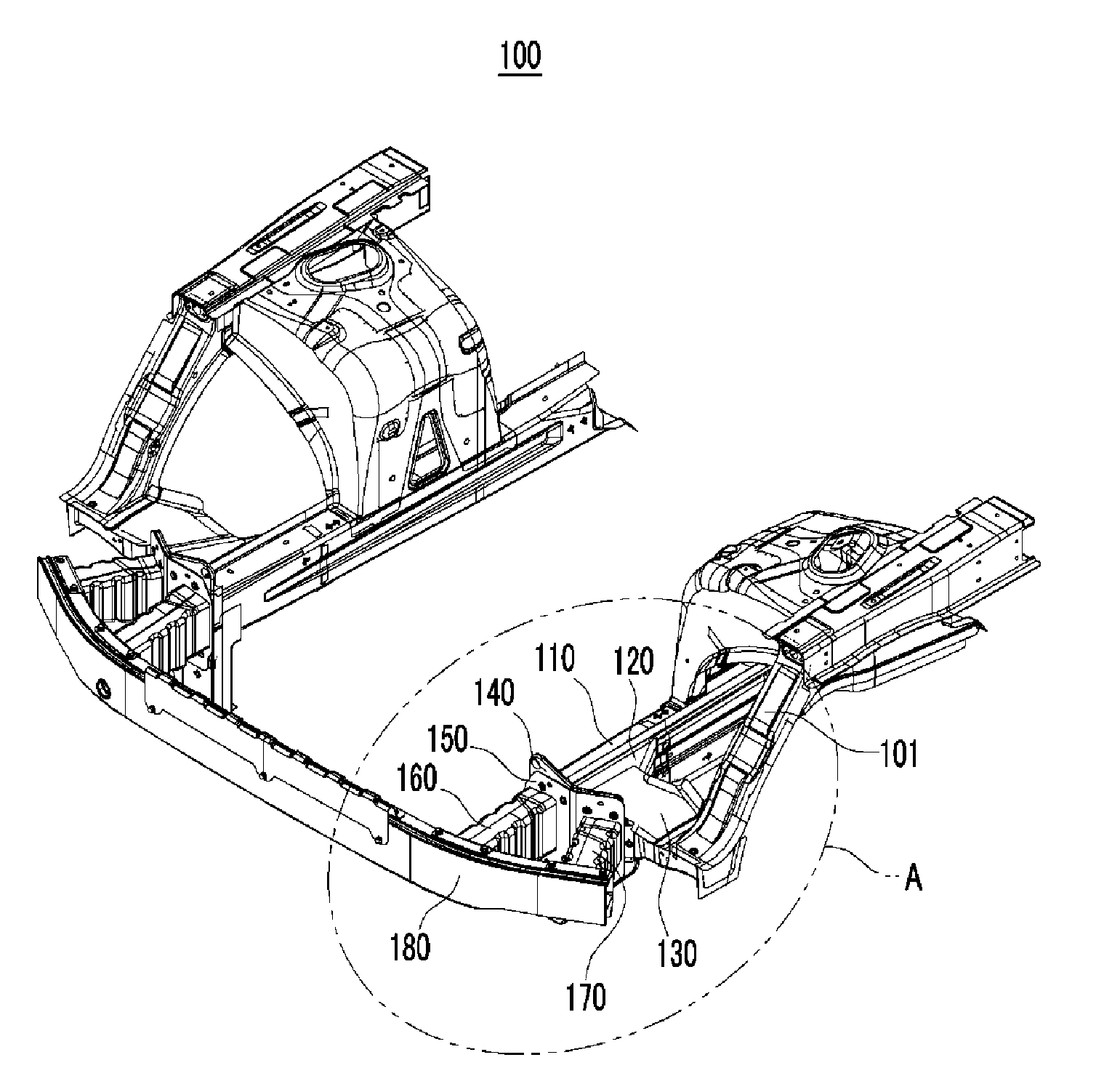

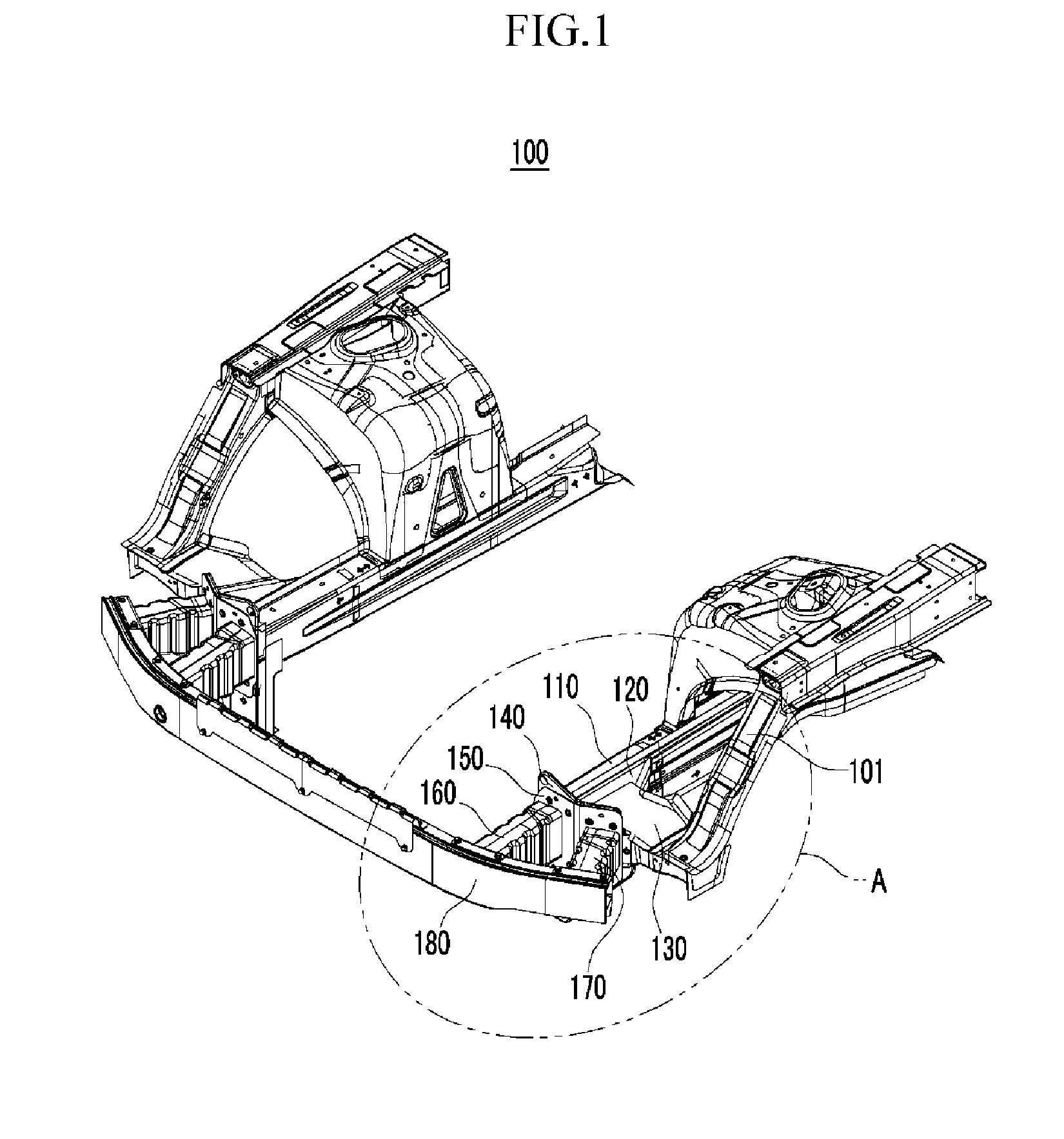

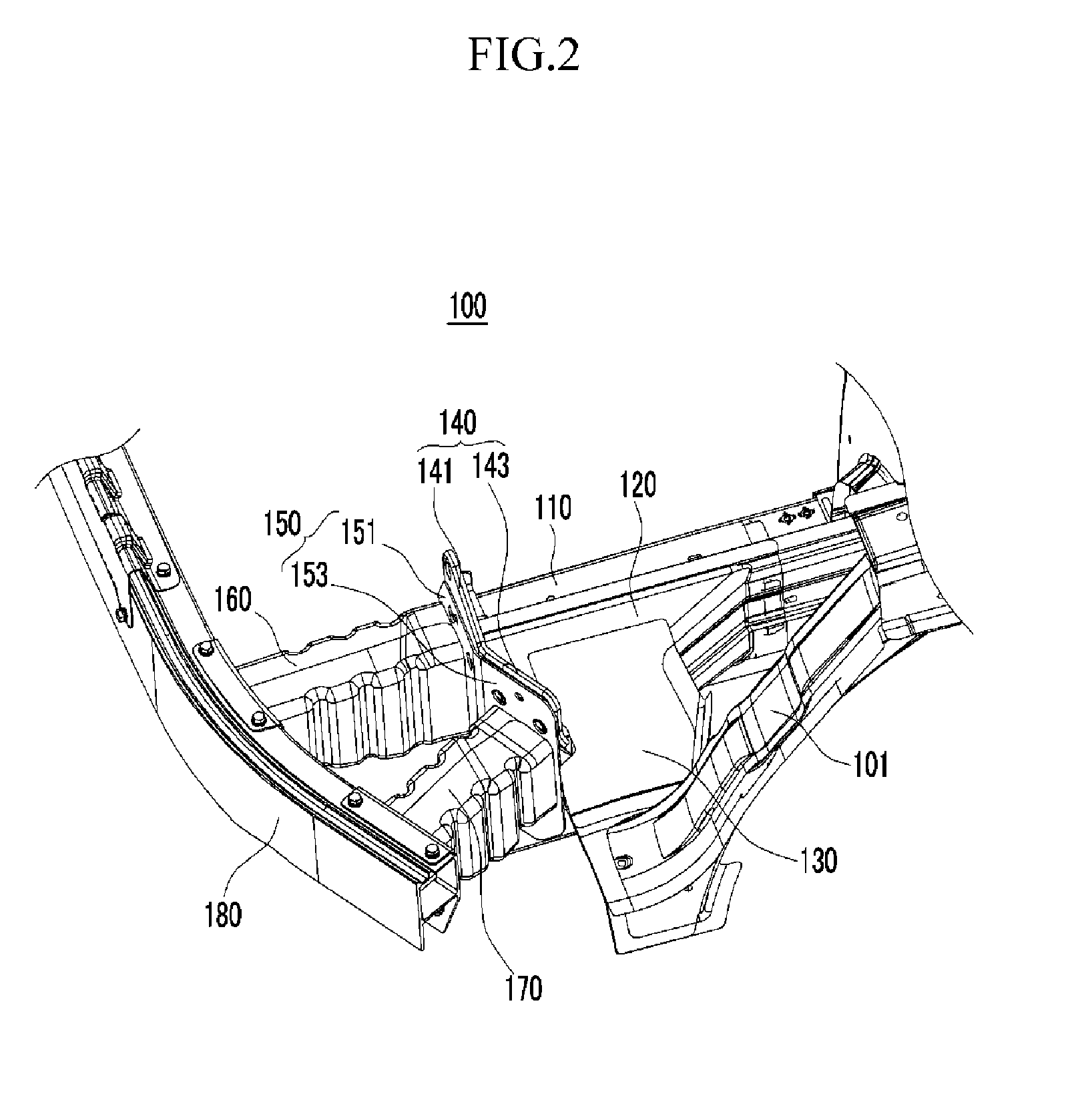

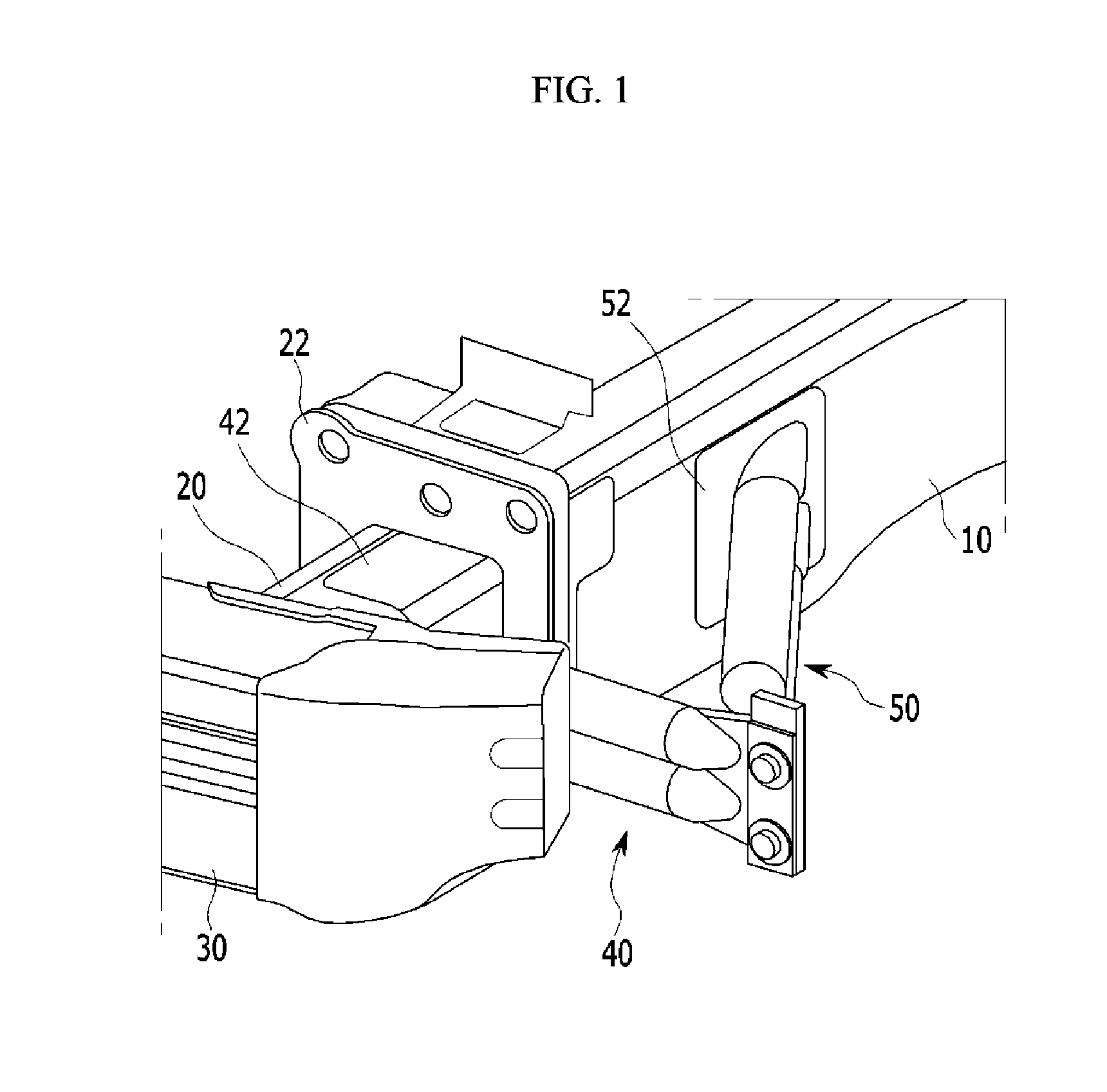

Bumper assembly for vehicle

A bumper assembly for vehicle may include a first side member disposed in each of both sides of a vehicle body in a longitudinal direction thereof, a second side member coupled to an external surface of the first side member, a fender member having one side coupled to an external side of the second side member, a member flange connected to front ends of the first and second side members respectively, a mounting flange coupled with the member flange, a first crash box having a rear end connected to the mounting flange, a second crash box having a rear end connected to the mounting flange, and a bumper beam having both distal sides, each of which may be coupled to front ends of the first and second crash boxes.

Owner:HYUNDAI MOTOR CO LTD +1

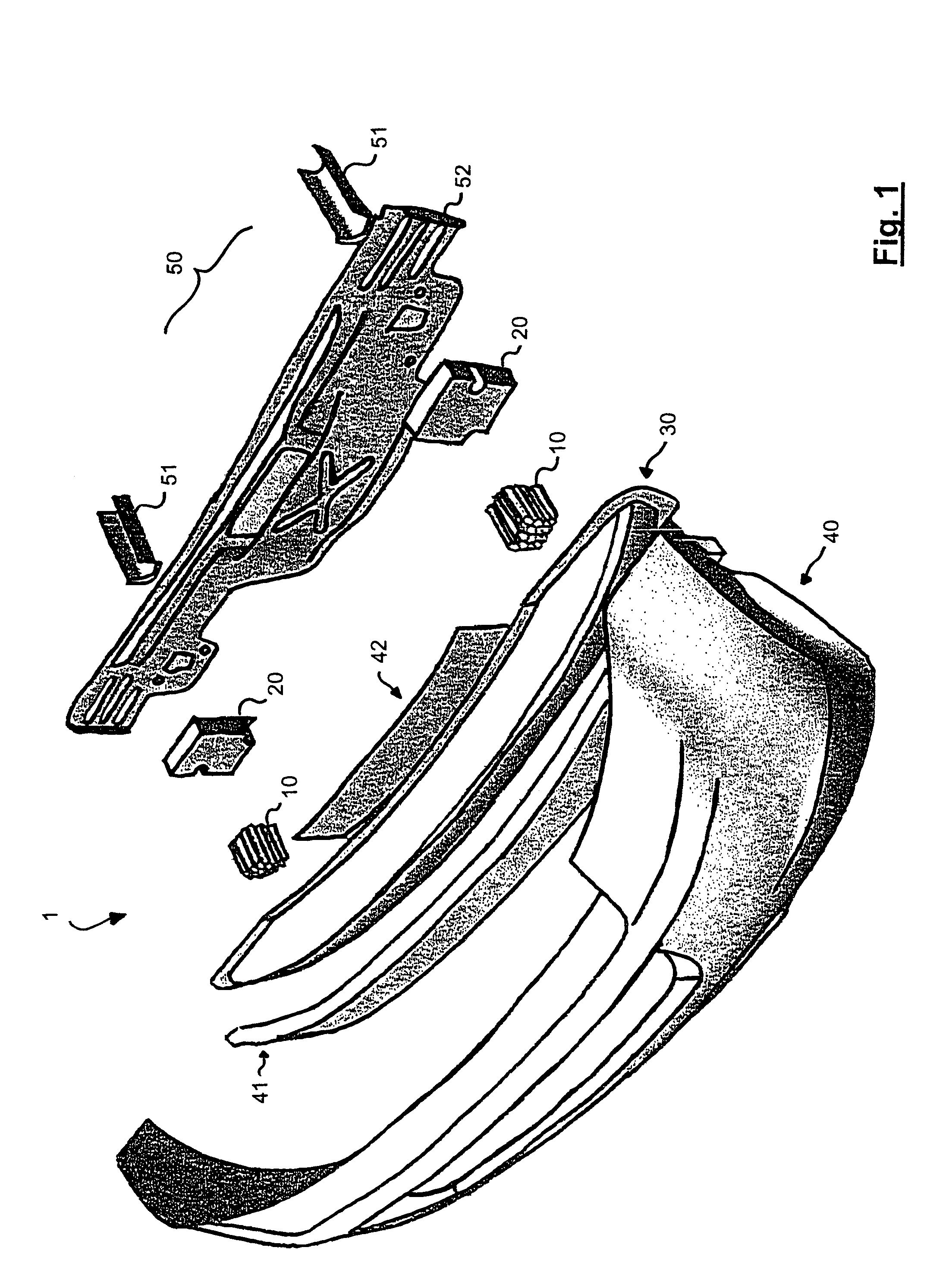

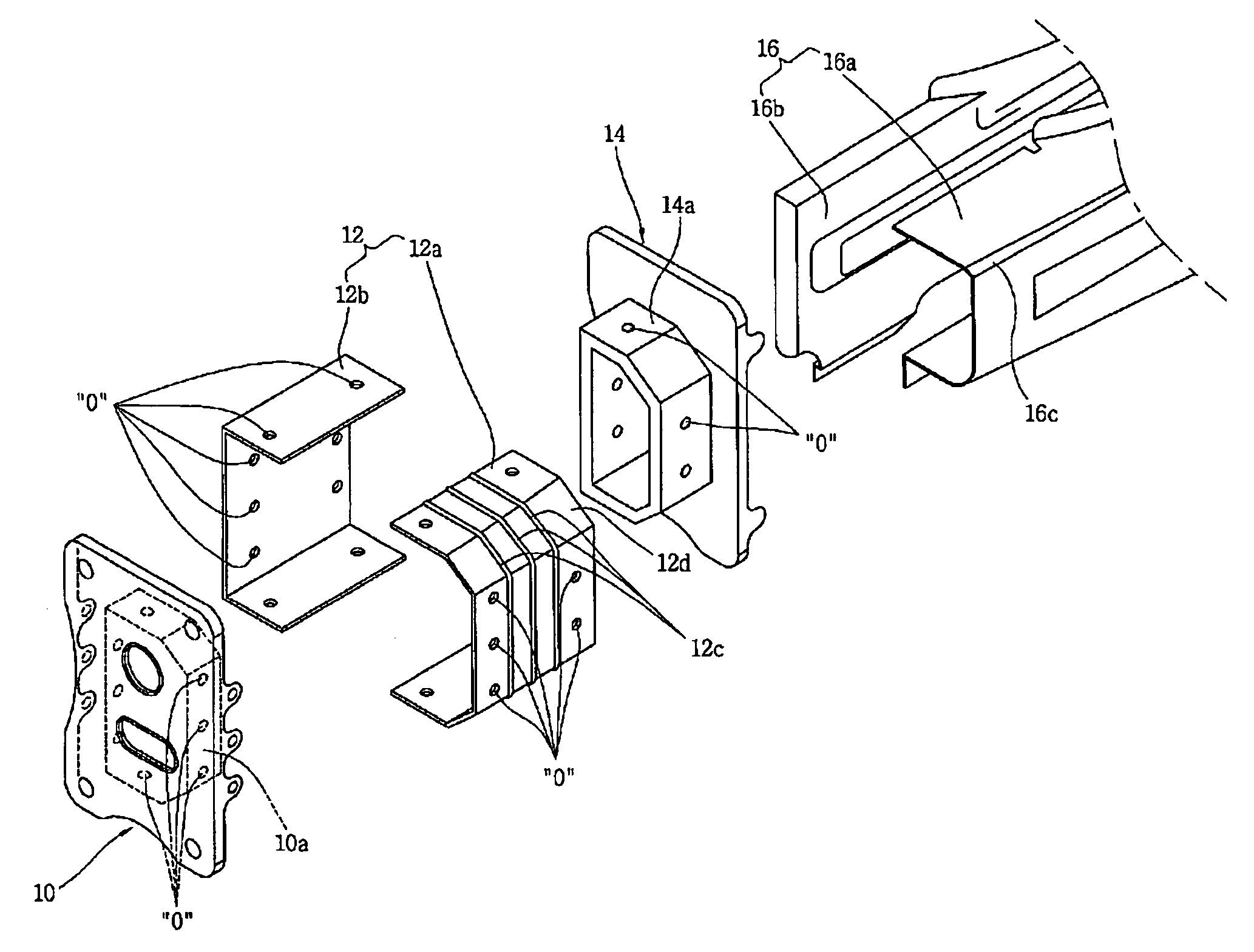

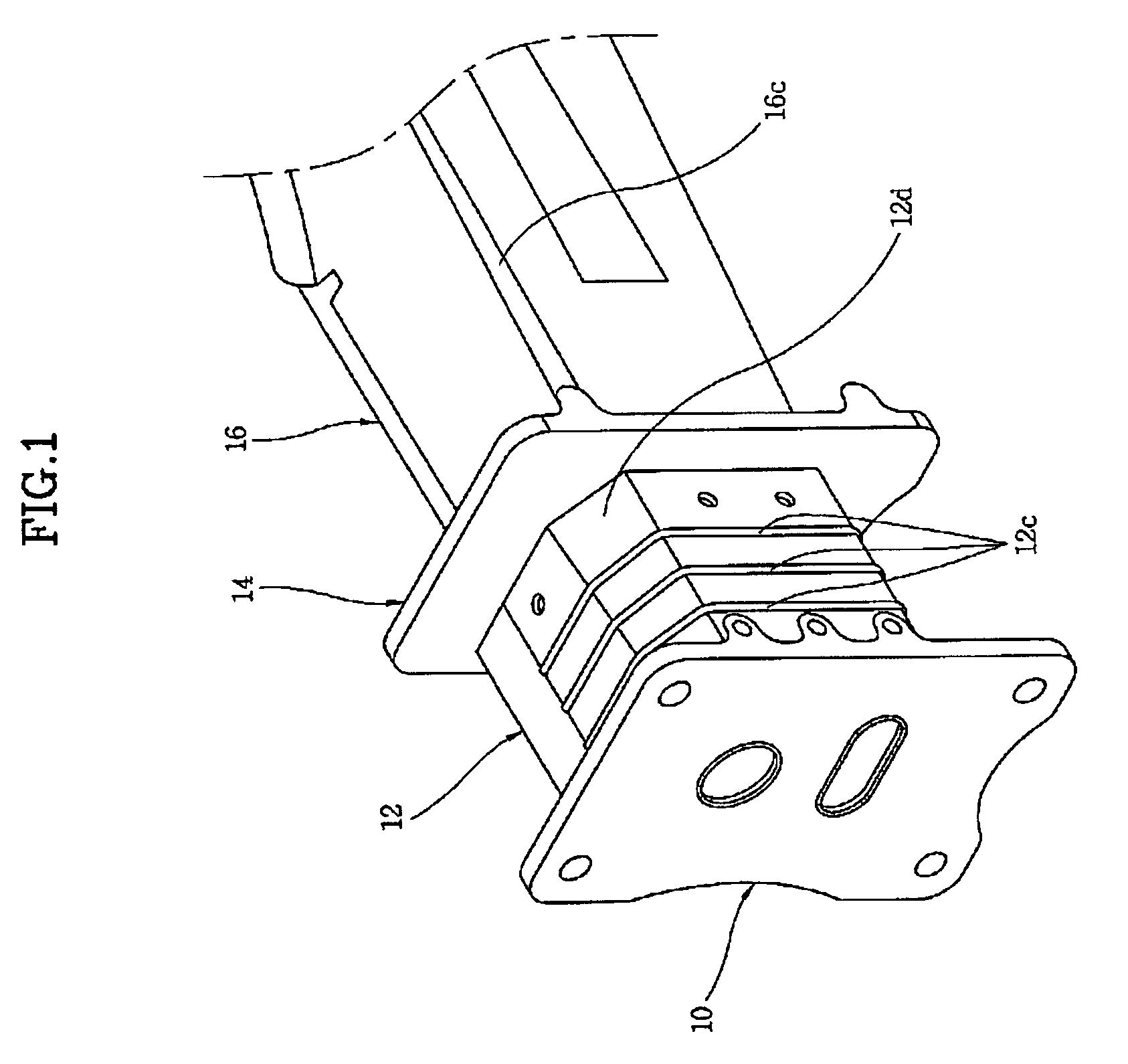

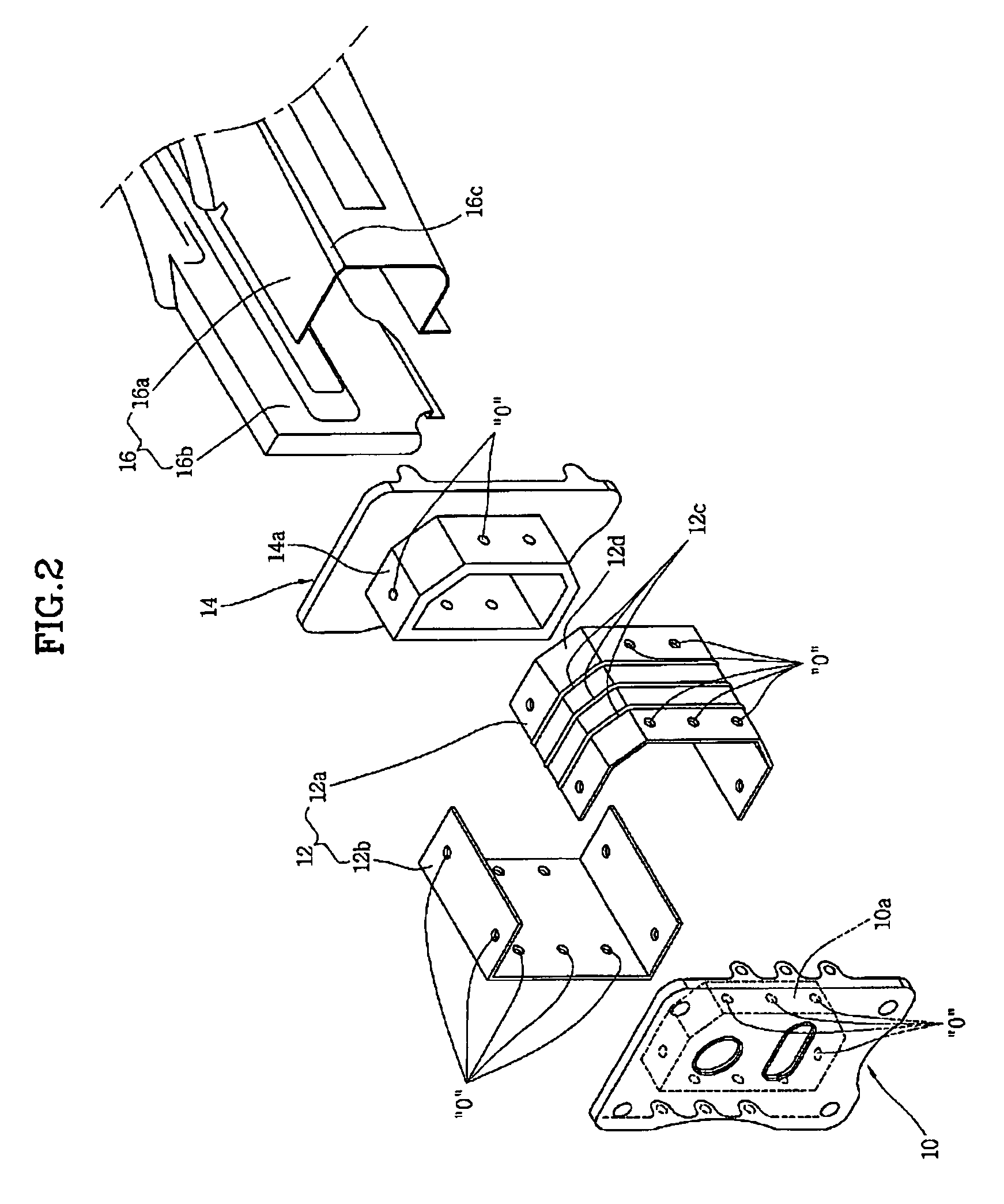

Front structure for car body

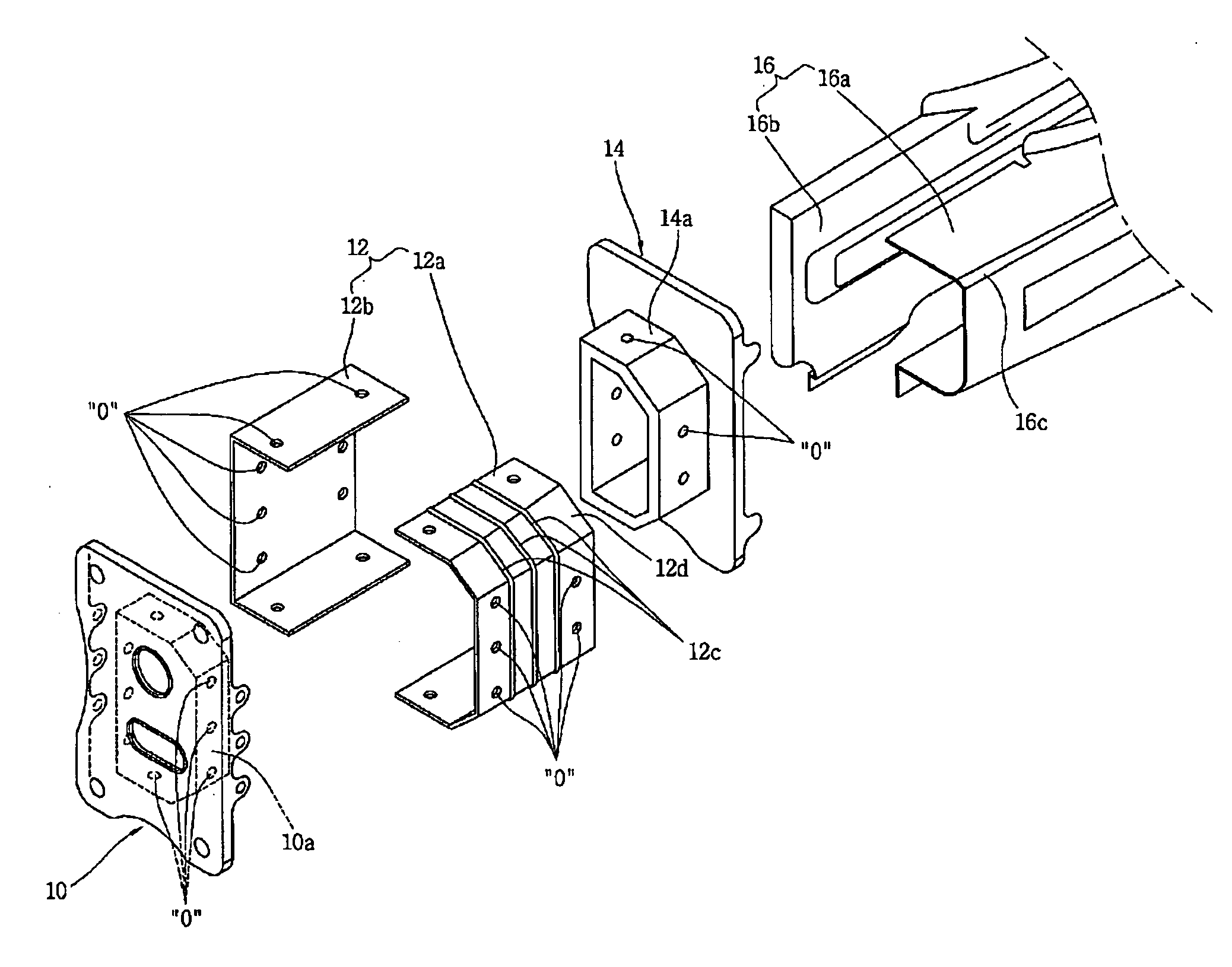

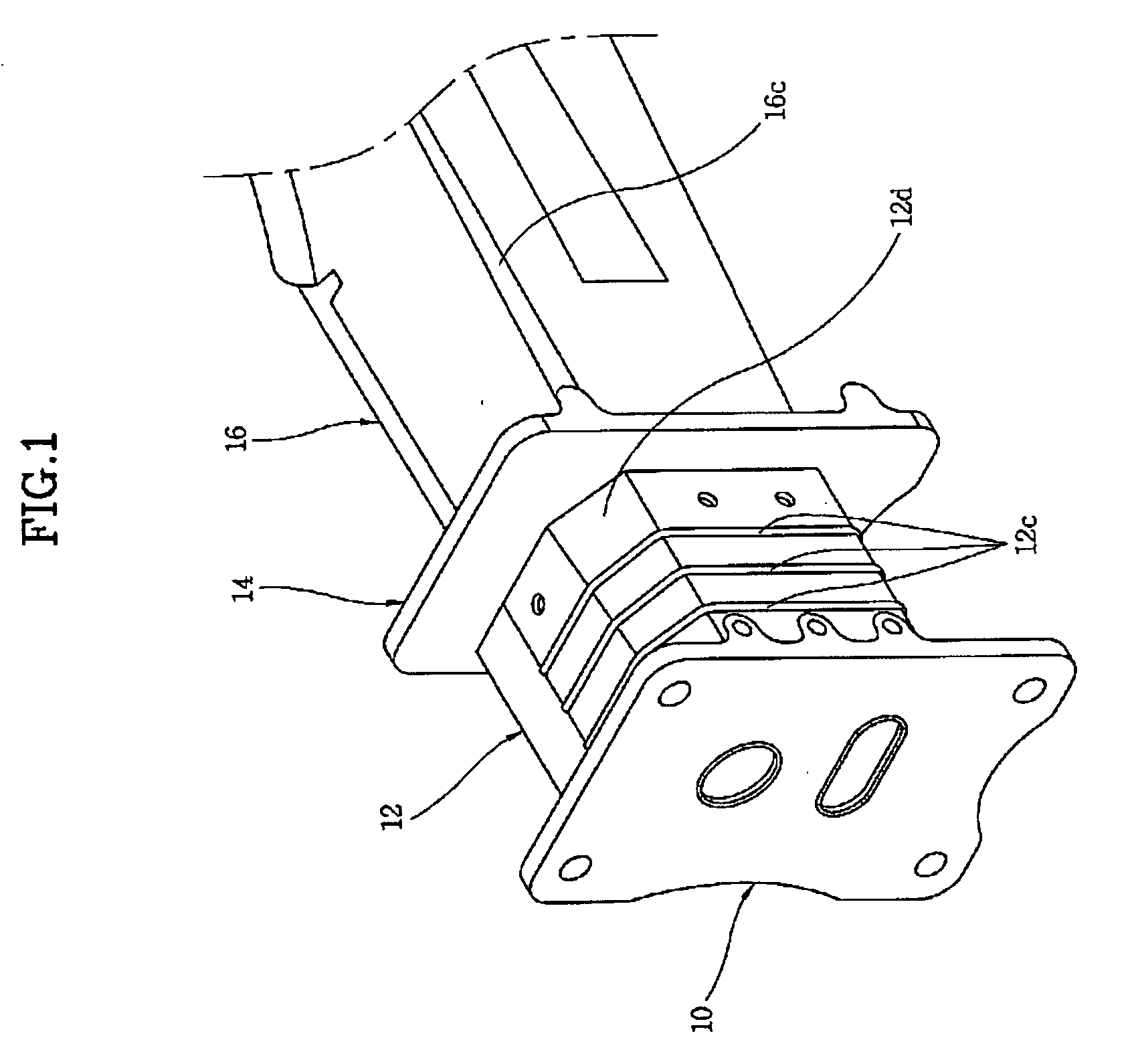

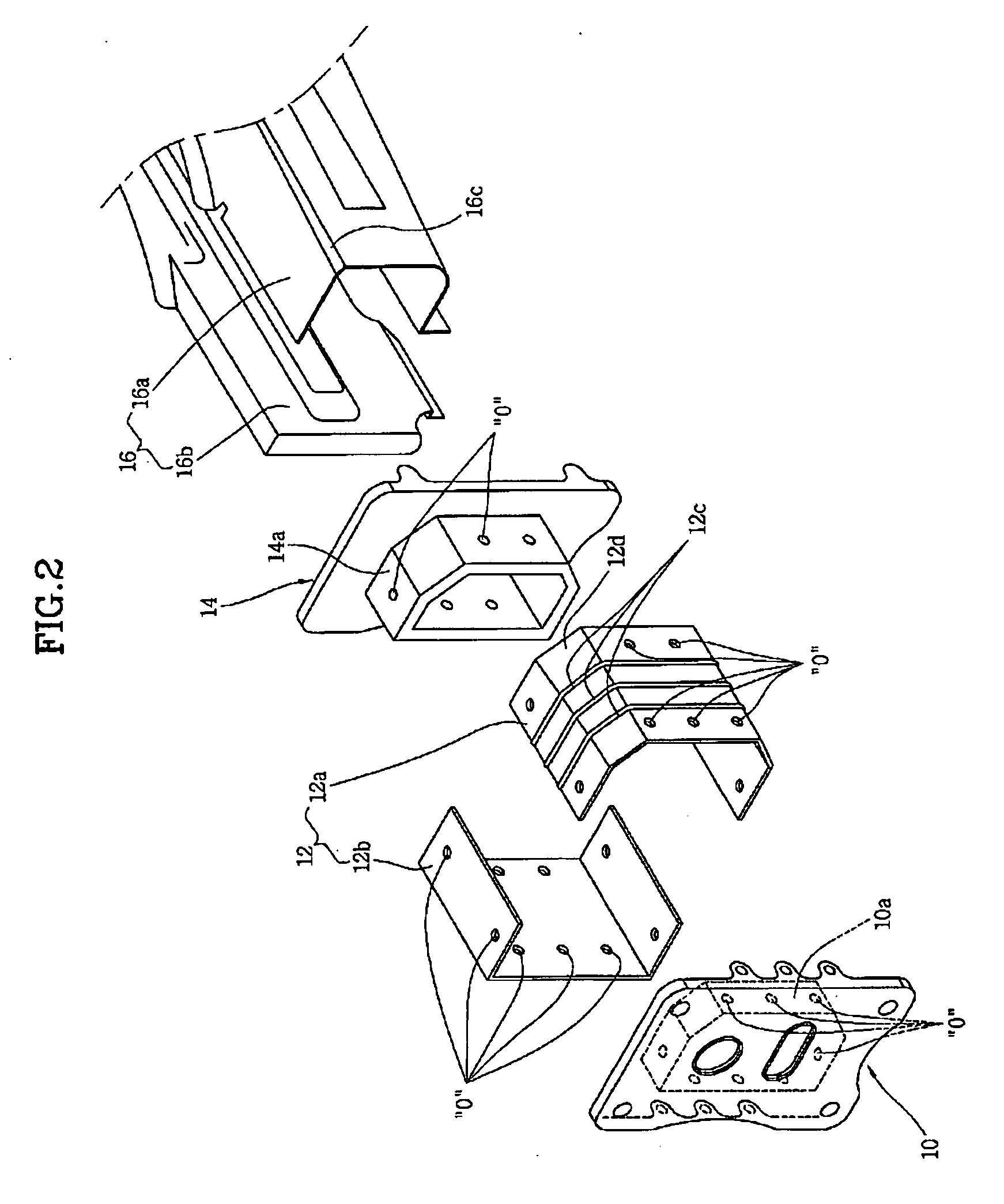

A front structure for a car body that reduces time and cost to repair a car body after a collision by localizing damage in low-speed collisions to a crash box mounted in a space between a front bumper and a side member and making the car body deform always in a predetermined mode in the collisions. A front structure for a car body may include a first connecting bracket supporting the left and right rear of a front bumper, a crash box joined to the rear of the first connecting bracket, a second connecting bracket joined to the rear of the crash box, and a front side member joined to the rear of the second connecting bracket. The crash box includes an inner member and an outer member, which are curved and separated from each other, so as to extend in the longitudinal direction of the vehicle and have a closed cross section. The inner member has a plurality of bead-shaped protrusions that are formed across the inner member and longitudinally spaced from each other.

Owner:HYUNDAI MOTOR CO LTD

Front structure for car body

A front structure for a car body that reduces time and cost to repair a car body after a collision by localizing damage in low-speed collisions to a crash box mounted in a space between a front bumper and a side member and making the car body deform always in a predetermined mode in the collisions. A front structure for a car body may include a first connecting bracket supporting the left and right rear of a front bumper, a crash box joined to the rear of the first connecting bracket, a second connecting bracket joined to the rear of the crash box, and a front side member joined to the rear of the second connecting bracket. The crash box includes an inner member and an outer member, which are curved and separated from each other, so as to extend in the longitudinal direction of the vehicle and have a closed cross section. The inner member has a plurality of bead-shaped protrusions that are formed across the inner member and longitudinally spaced from each other.

Owner:HYUNDAI MOTOR CO LTD

Collision detecting device and passive safety system

A collision detecting device providing the accurate and early determination of a collision with a vehicle or the like, and a passive safety system using this collision detecting device. A low-rigid portion and a crash box are arranged ahead of a high-rigid portion in a front portion of a frame. The front end of a rod is fixed to a bumper. The rod is inserted into a magnetic detector disposed on the high-rigid portion. In the rod, a number of magnets are aligned in the longitudinal direction of the rod such that their N poles and S poles are alternatively arranged. As a vehicle collides, the crash box is first deformed so that the rod moves backward, whereby a collision can be detected before large acceleration is generated.

Owner:TAKATA CORPORATION

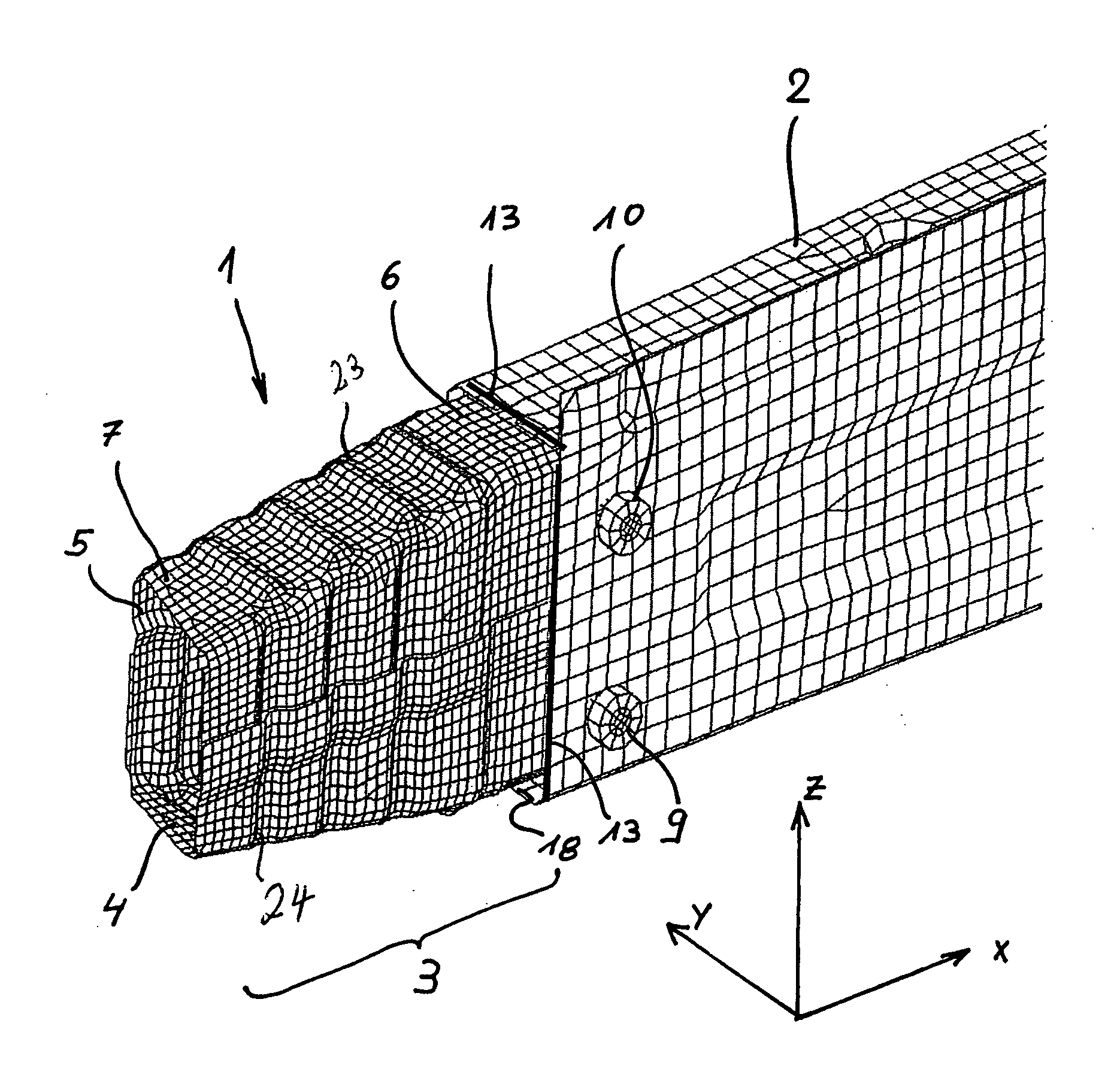

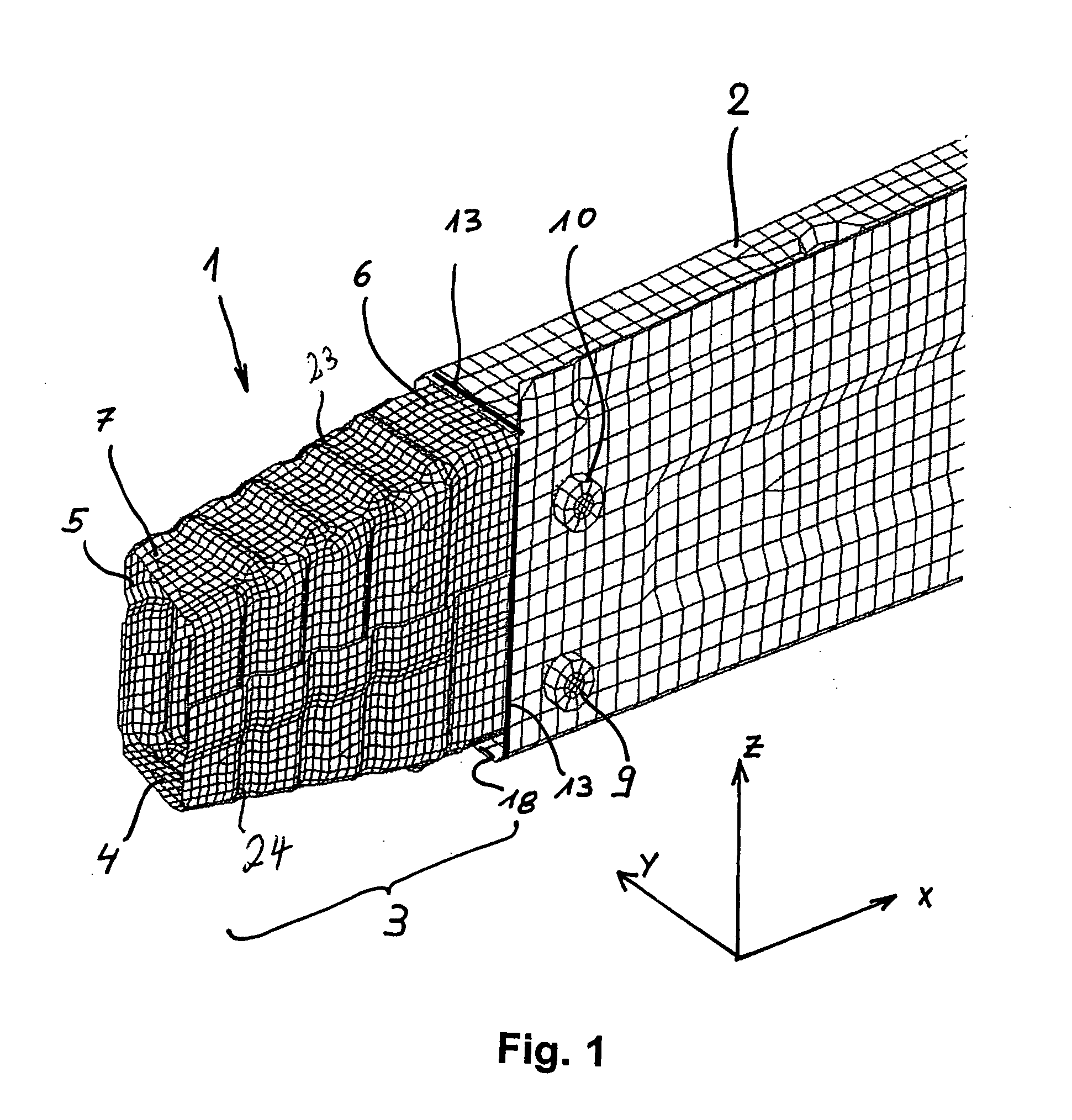

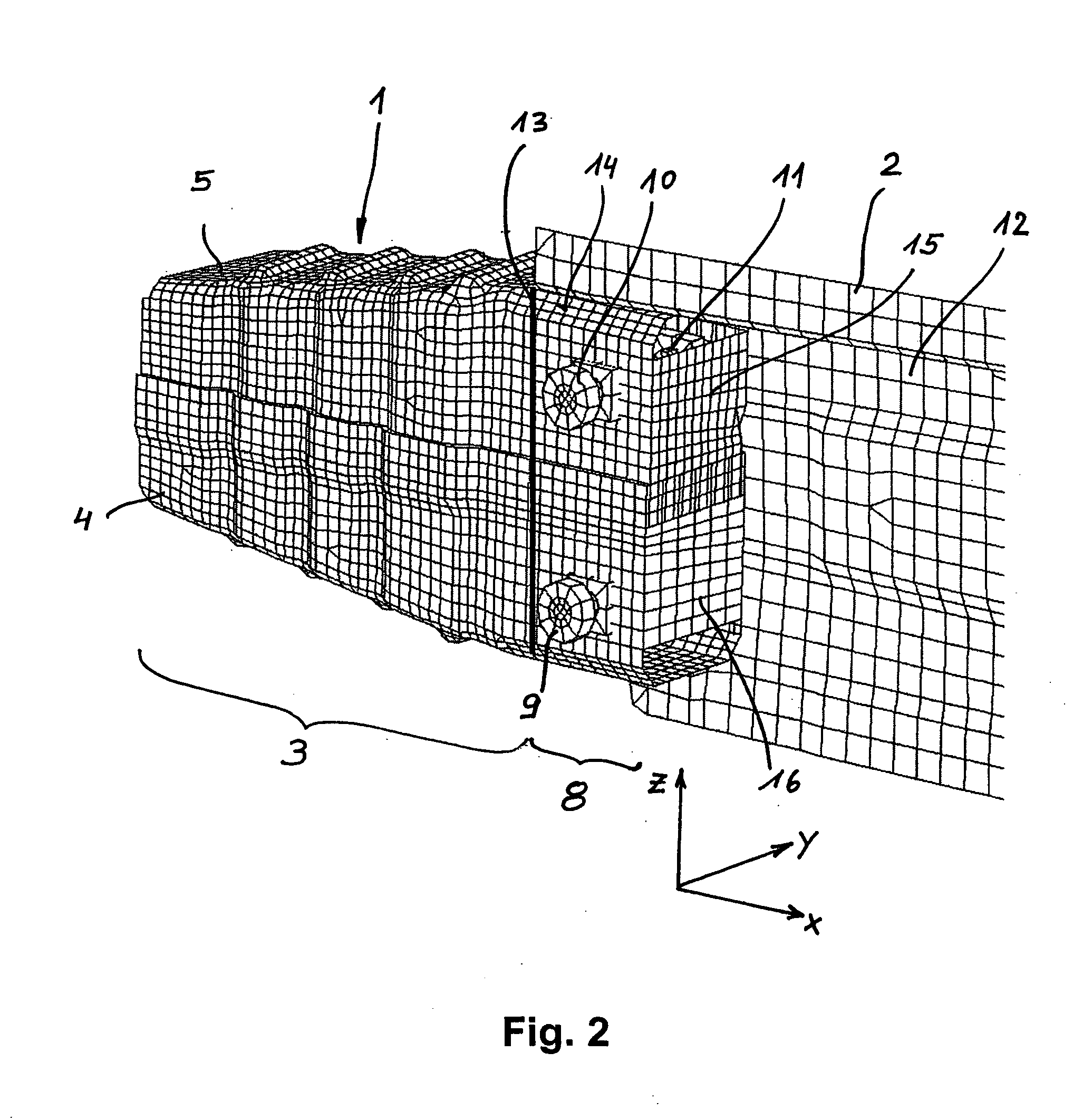

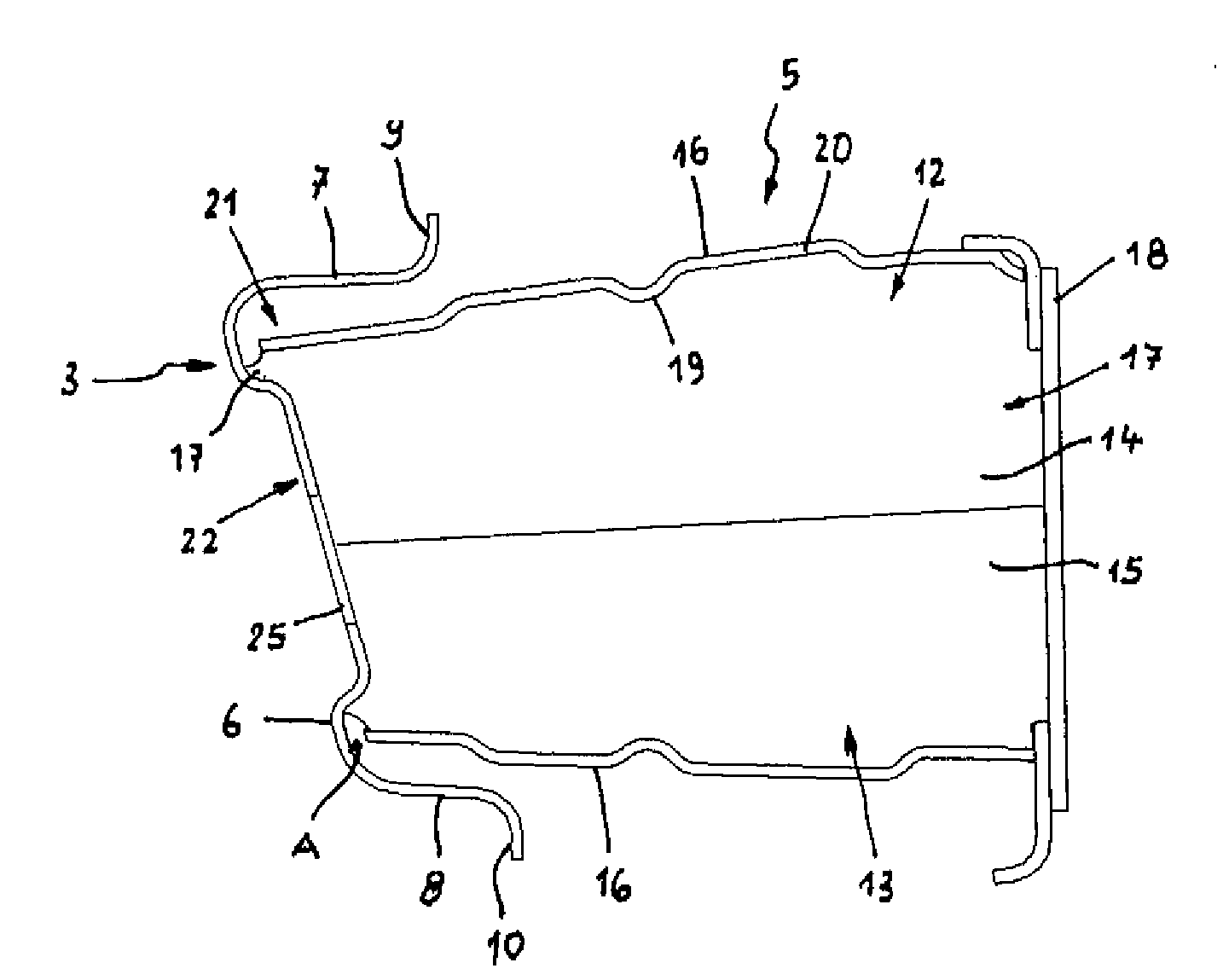

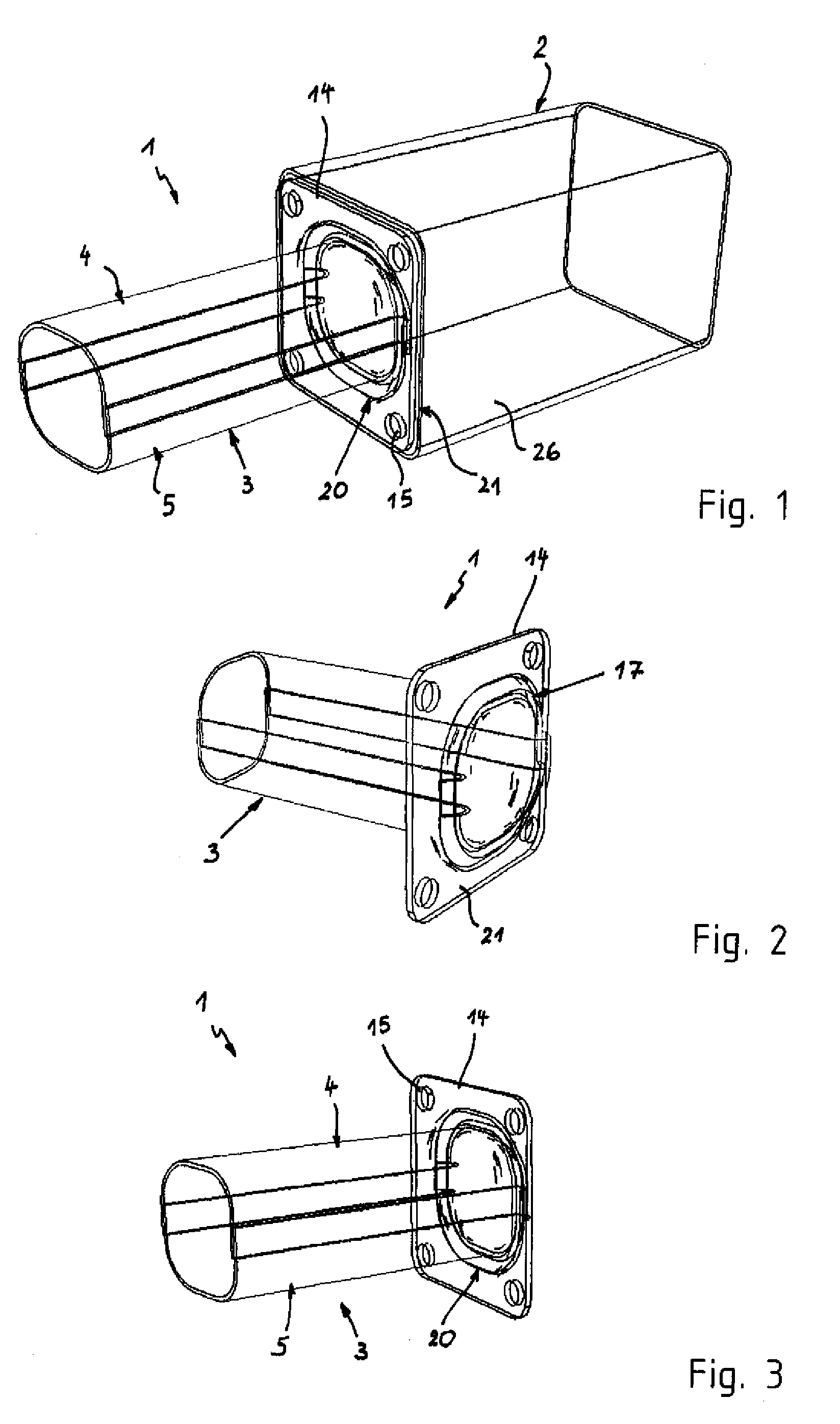

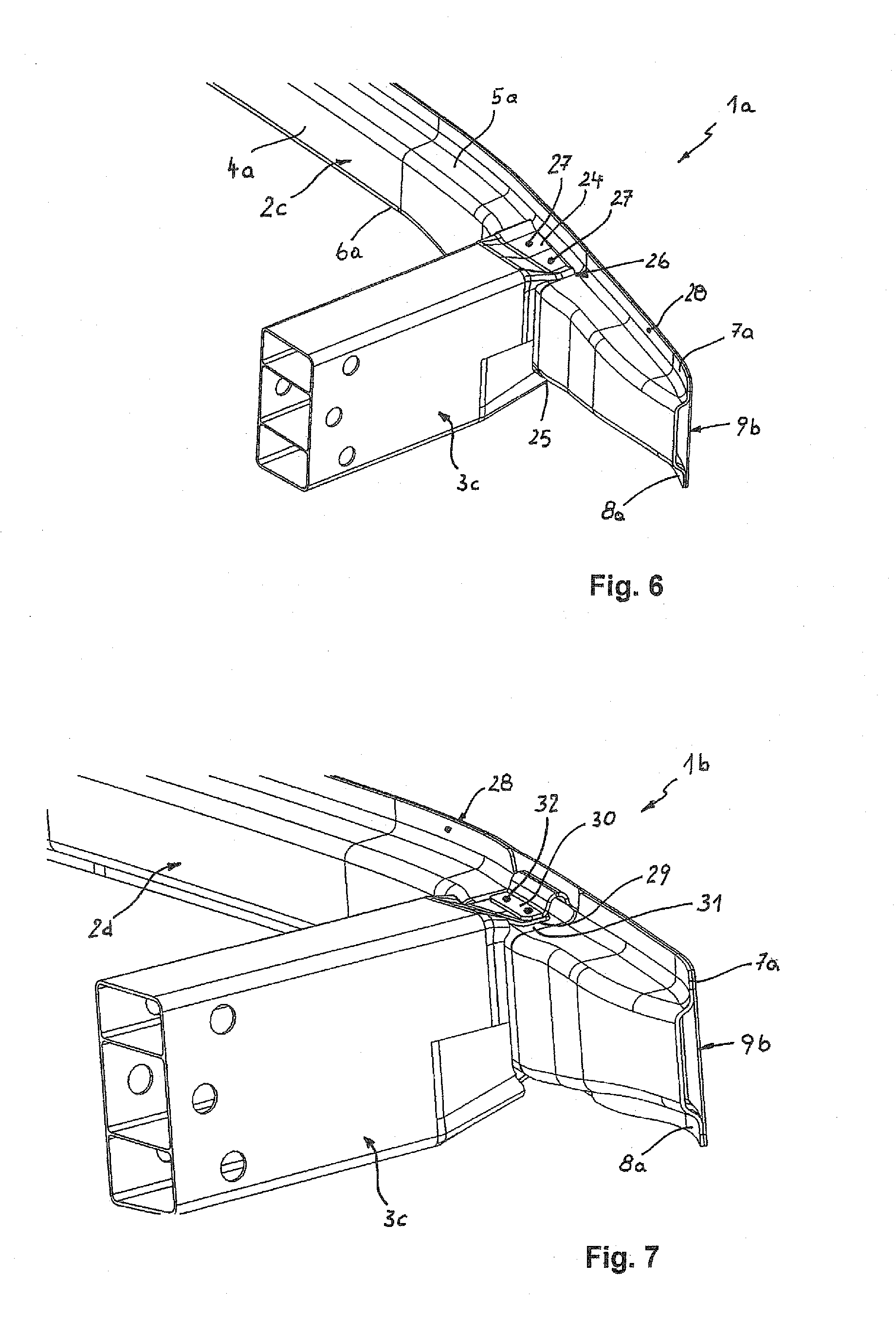

Crash box and bumper for a motor vehicle

InactiveUS20080224487A1Adjustable stiffnessPositively affects deformationBumpersMobile vehicleMotor vehicle part

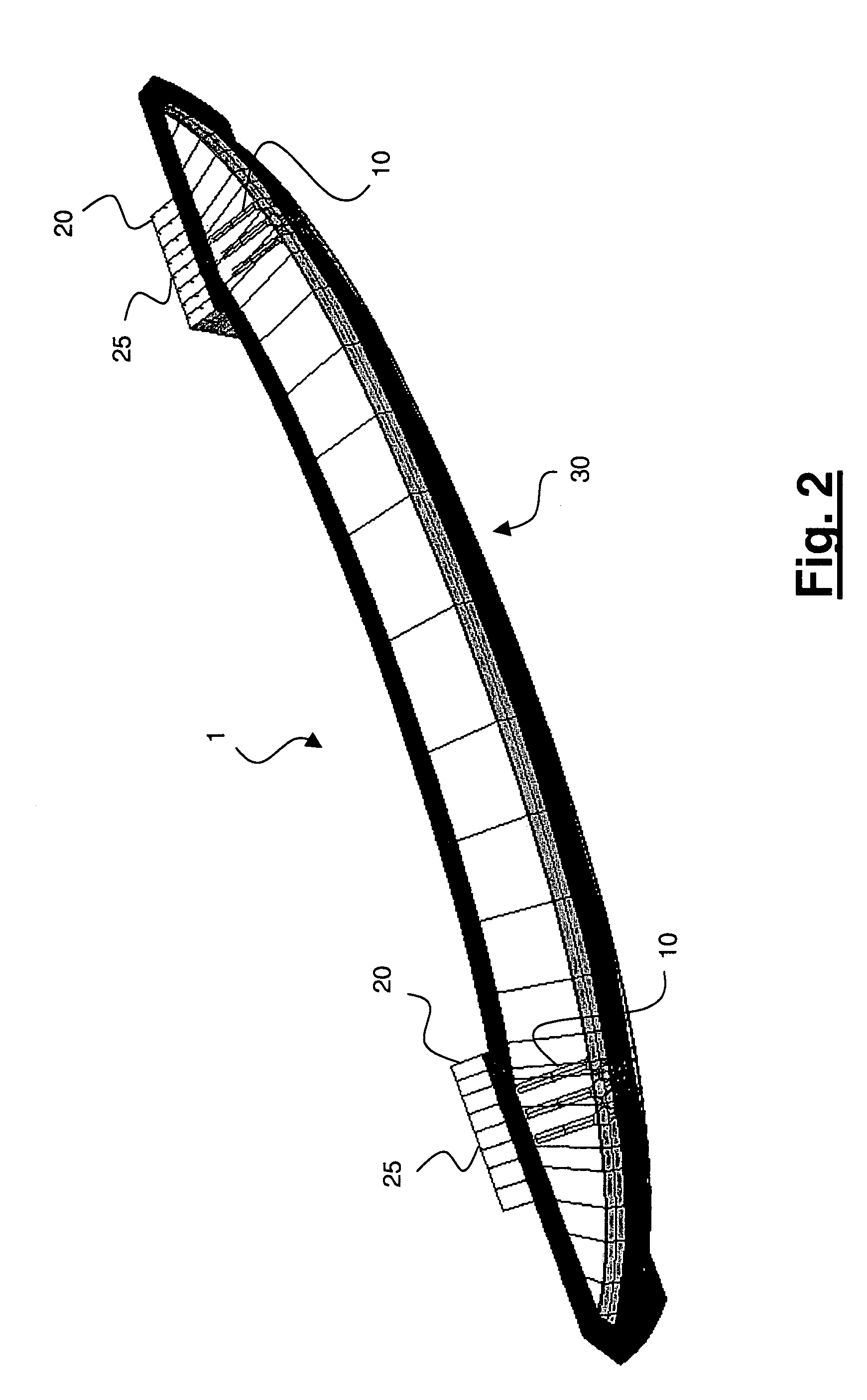

A crash box for placement between a bumper beam and a side rail of a motor vehicle includes a longitudinal profile made of two U-shaped shells having overlapping ends sized to realize a material doubling for increasing side stiffness and to suit the side stiffness to a load level. A flange plate is provided on a side-rail-proximal end of the longitudinal profile and has an opening for passage of the longitudinal profile. The side-rail-proximal end of the longitudinal profile is configured with a collar which is turned outwards. The collar rests against the flange plate and is joined with the flange plate. In the event of a collision, the longitudinal profile of the crash box is moved into the side rail as the longitudinal profile folds into the side rail starting from the flange plate, while the side-rail-proximal end of the longitudinal profile remains secured to the flange plate.

Owner:BENTELER AUTOMOBILTECHNIK GMBH

Tunable, healable vehicle impact devices

ActiveUS20050104391A1Low costLarge energy absorption capacityBumpersShock absorbersLow speedEnergy absorption

An impact absorbing device for a vehicle uses a shape memory material that can be heated to repair deformation from a relatively low speed, low energy impact and its stroking force and energy absorption can be tuned by heating. The shape memory material is suitably used in a crash box having an inserted impact absorbing ram, the box being placed, for example, between a bumper and strong body member. The shape memory material is attached to the box and ram for absorbing energy as the ram is driven into the box. Heating means is provided to repair or tune the shape memory material.

Owner:GM GLOBAL TECH OPERATIONS LLC

Bumper structure for a motor vehicle

A bumper structure for a motor vehicle includes a cross member, and a crash box placed between the cross member and a longitudinal member, with the crash box having an attachment zone. Bolts extend through walls of the attachment zone and the longitudinal member for securing the crash box to the longitudinal member by forcing the attachment zone against the wall of the longitudinal member. The attachment zone undergoes hereby locally an elastic or plastic deformation for realizing a self-centered disposition of the crash box in relation to the longitudinal member. The walls of the attachment zone and the longitudinal member extend at a tolerance distance before the crash box is secured to the longitudinal member.

Owner:BENTELER AUTOMOBILTECHNIK GMBH

Crash box

Owner:BENTELER AUTOMOBILTECHNIK GMBH

Bumper for a motor vehicle

InactiveUS20100194125A1High corrosion potentialReduce manufacturing costBumpersVehicle frameEngineering

A bumper for a motor vehicle includes a cross member which is disposed transversely to a side rail of a motor vehicle frame. A crash box is incorporated between the cross member and the side rail, with set bolts being provided to join the crash box to the cross member in the absence of prepunching.

Owner:BENTELER AUTOMOBILTECHNIK GMBH

Crash box

A crash box for a motor vehicle includes an attachment portion which engages a longitudinal member of the motor vehicle and is secured thereto by at least one screw bolt which extends through a spacer sleeve. The spacer sleeve is securely fixed to the attachment portion and has two threaded portions of opposite pitch. Inserted from opposite sides of the spacer sleeve are tolerance compensating bolts, which are each provided with an inner rotary catch for interaction with an outer thread of the screw bolt. When the screw bolt is screwed in, the tolerance compensating bolts are thus moved apart until abutting against opposite inside wall surfaces of the longitudinal member. The screw bolt engages hereby a nut on an outside of the longitudinal member so that the attachment portion is now held without clearance on the longitudinal member by a head portion of the screw bolt and one of the tolerance compensating bolts, and by the other one of the tolerance compensating bolts and the nut.

Owner:BENTELER AUTOMOBILTECHNIK GMBH

Bumper structure

Owner:BENTELER AUTOMOBILTECHNIK GMBH

Bumper system

A bumper system includes a crossbeam having ends constructed to form attachment zones, and two crash boxes which are secured to side rails of a motor vehicle and coupled to the attachment zones, respectively. The crossbeam has a front wall, a rear wall, and an inner wall which extends between the front and rear walls along a major length of the crossbeam. The inner wall is hereby recessed to leave a gap in the area of the attachment zones.

Owner:BENTELER AUTOMOBILTECHNIK GMBH

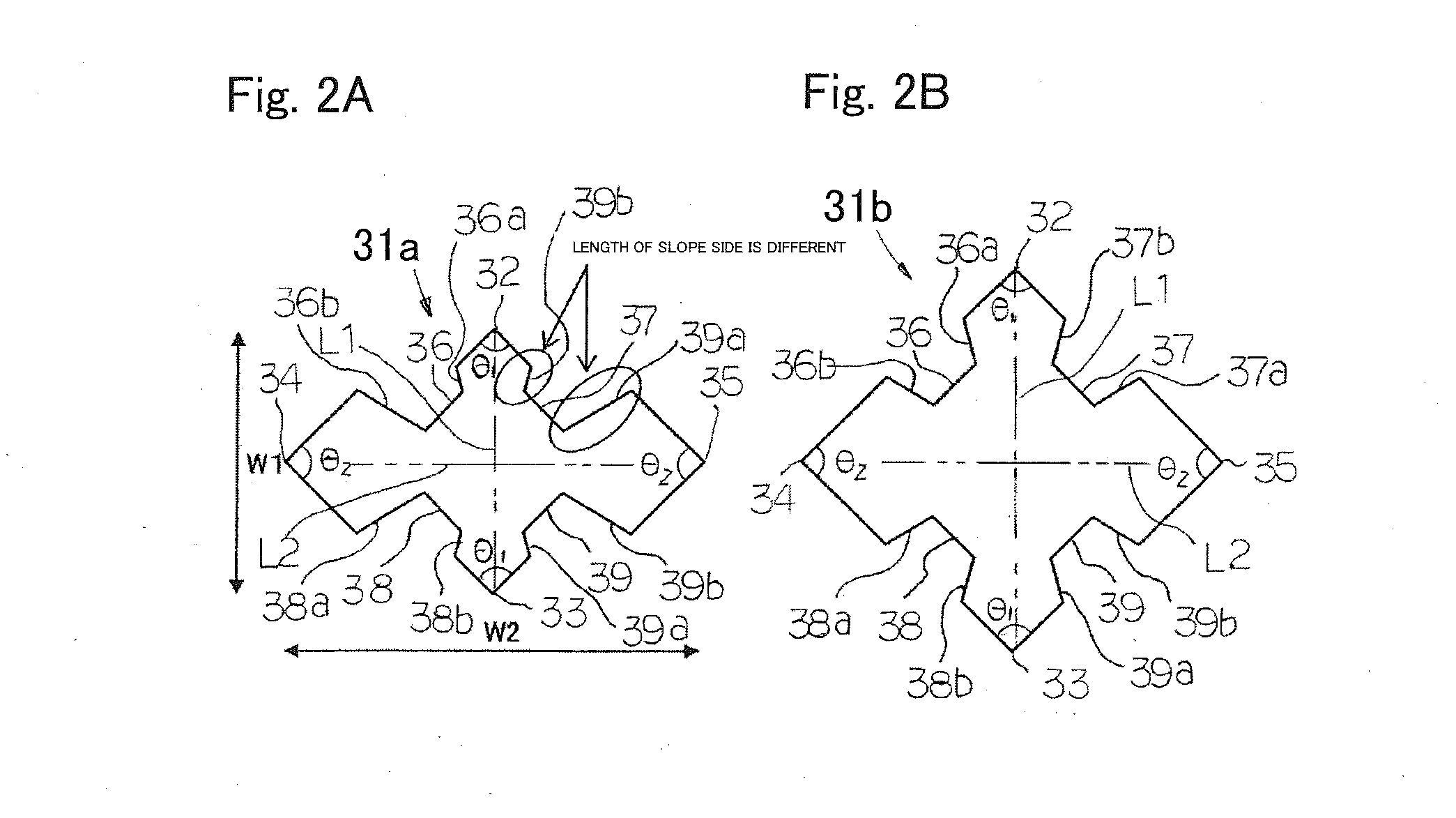

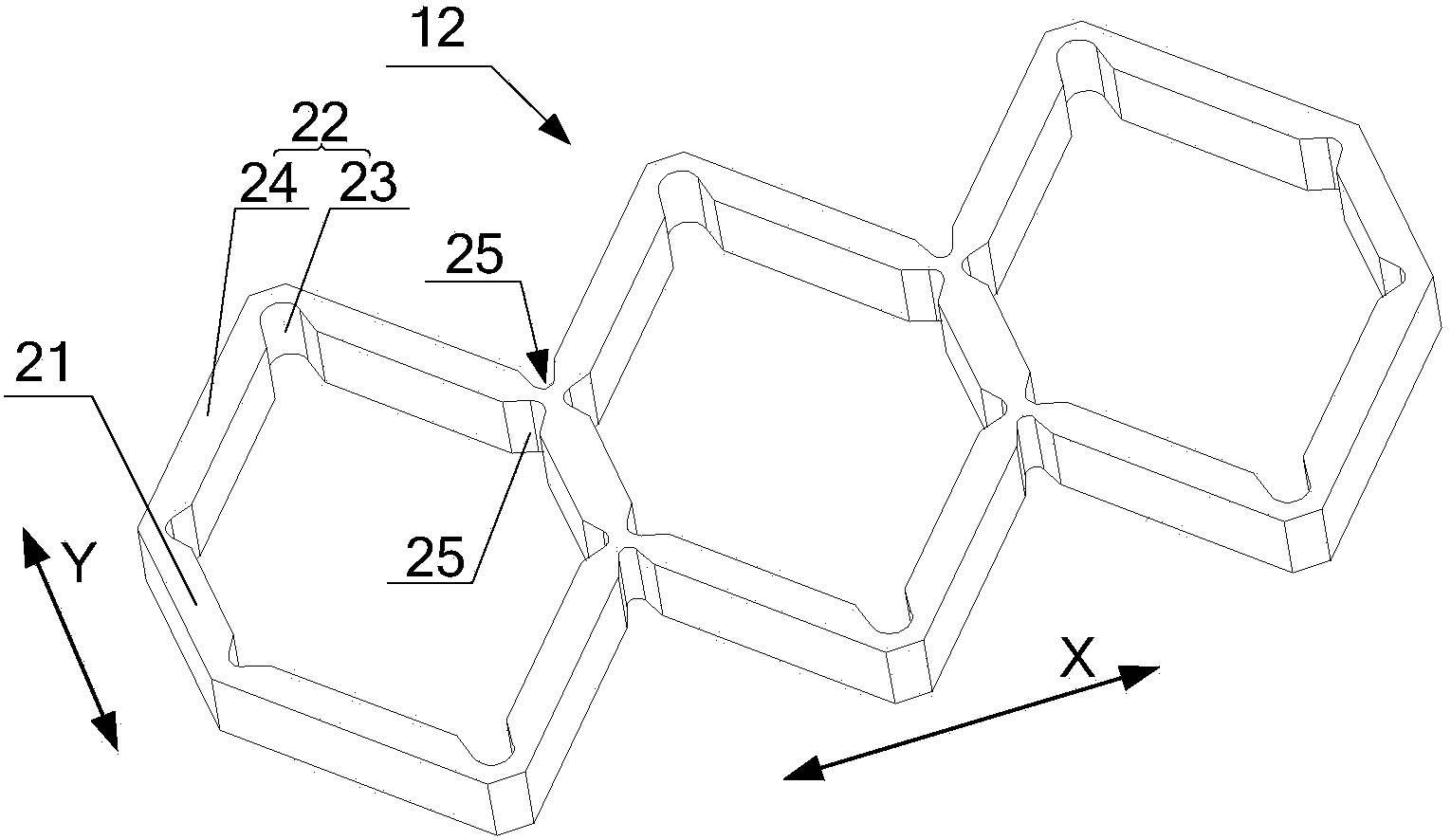

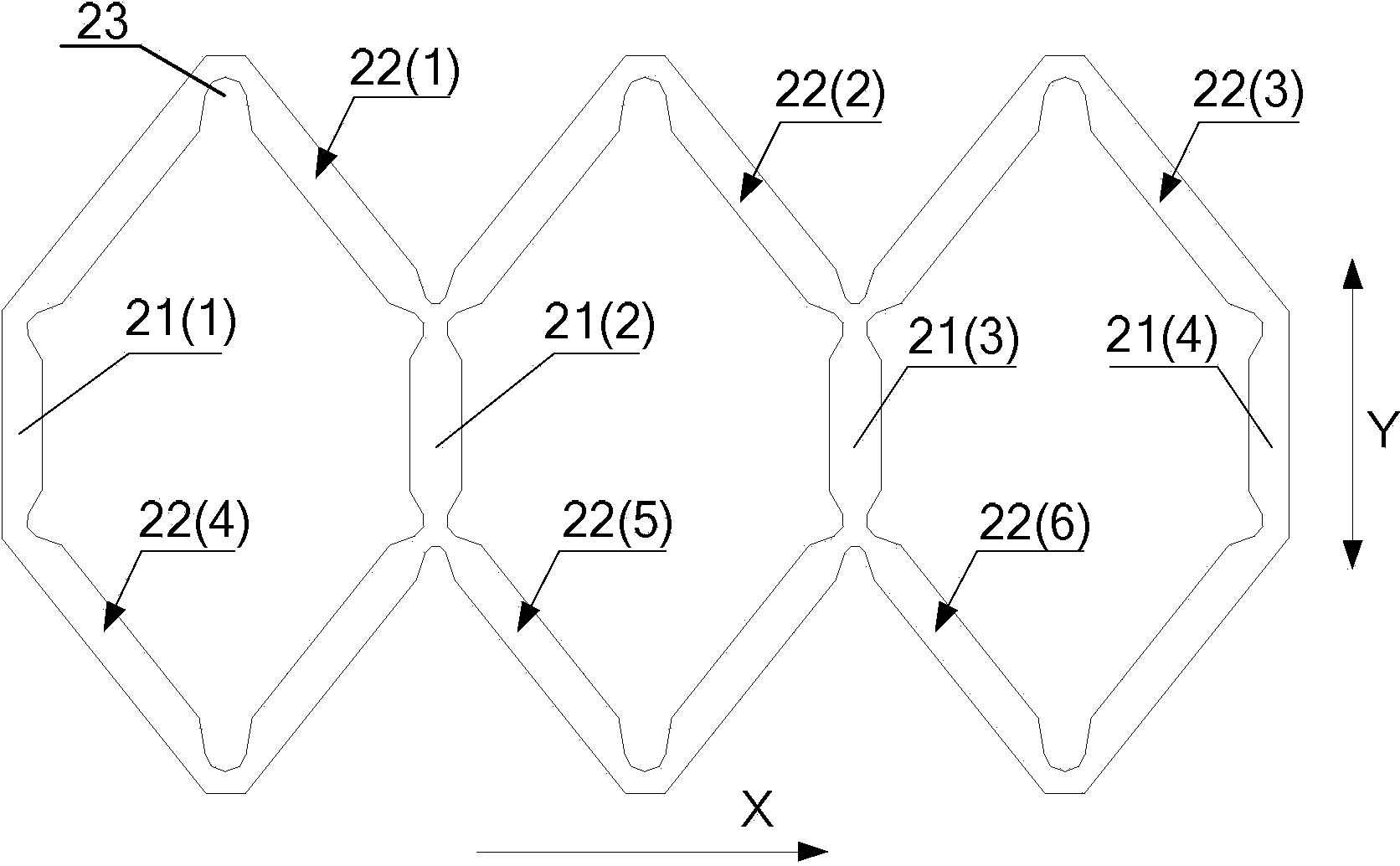

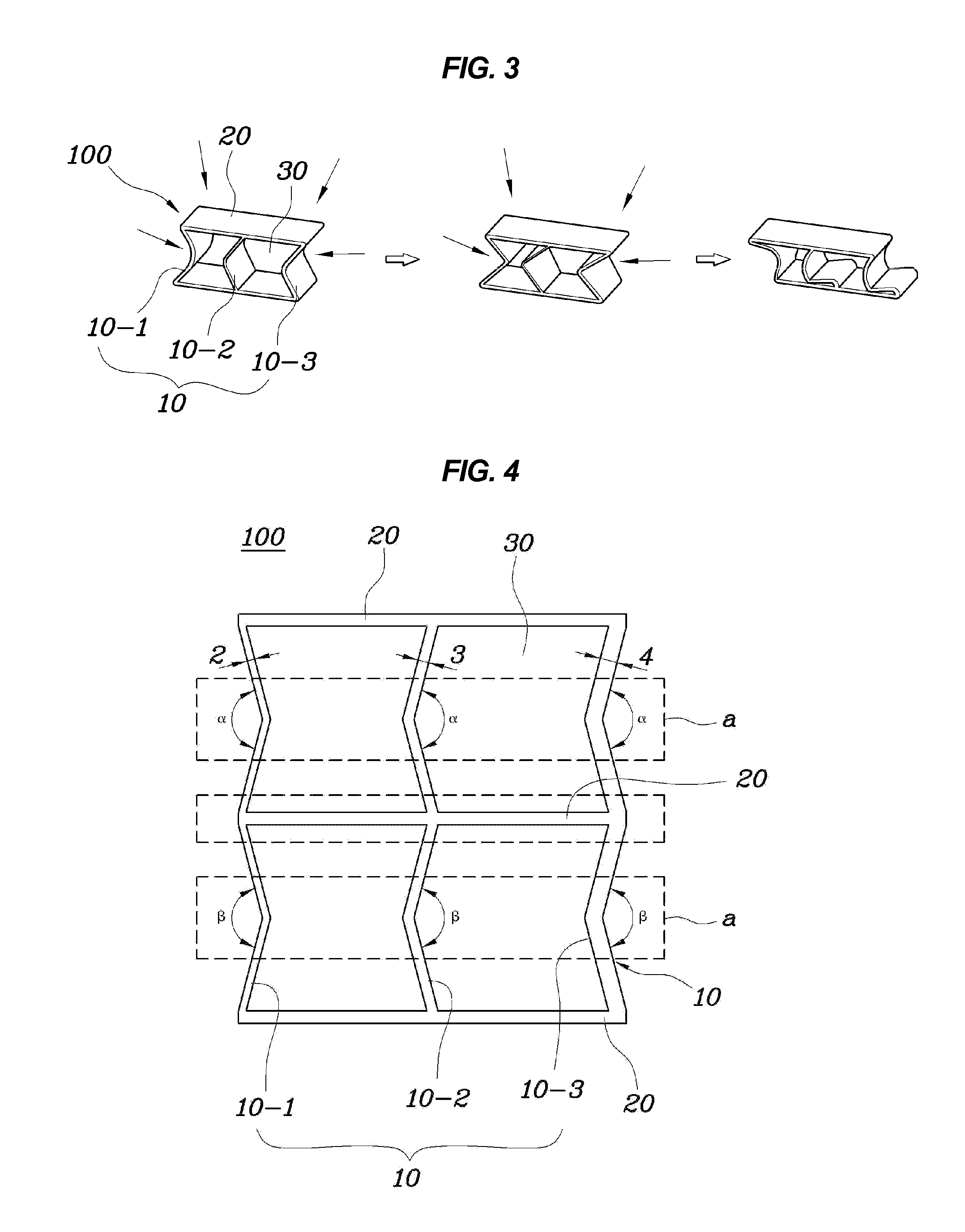

Crash box and automobile chassis

ActiveUS20150197206A1Improve deformationCross-sectional shape may be constantElastic dampersBumpersAngular degreesEngineering

Provided is a crash box having improved robustness, wherein an angle of the pair of corner portions is set to 90° or larger and 150° or smaller, an angle of the another pair of corner portions is set to 30° or larger and 90° or smaller, one or more inwardly convex trench portions extending in a longitudinal direction are provided, a cross-sectional peripheral length of the tubular body in the one end side is shorter than a cross-sectional peripheral length of the tubular body in the other end side, an aspect ratio between the longest one and the shortest one of diagonal lines of a polygon changes depending on a position on the axial direction of the tubular body, and overall sides on the cross section in the one end are formed in parallel to the opposite sides on the cross section in the other end.

Owner:NIPPON STEEL CORP

Bumper for a motor vehicle

Owner:BENTELER AUTOMOBILTECHNIK GMBH

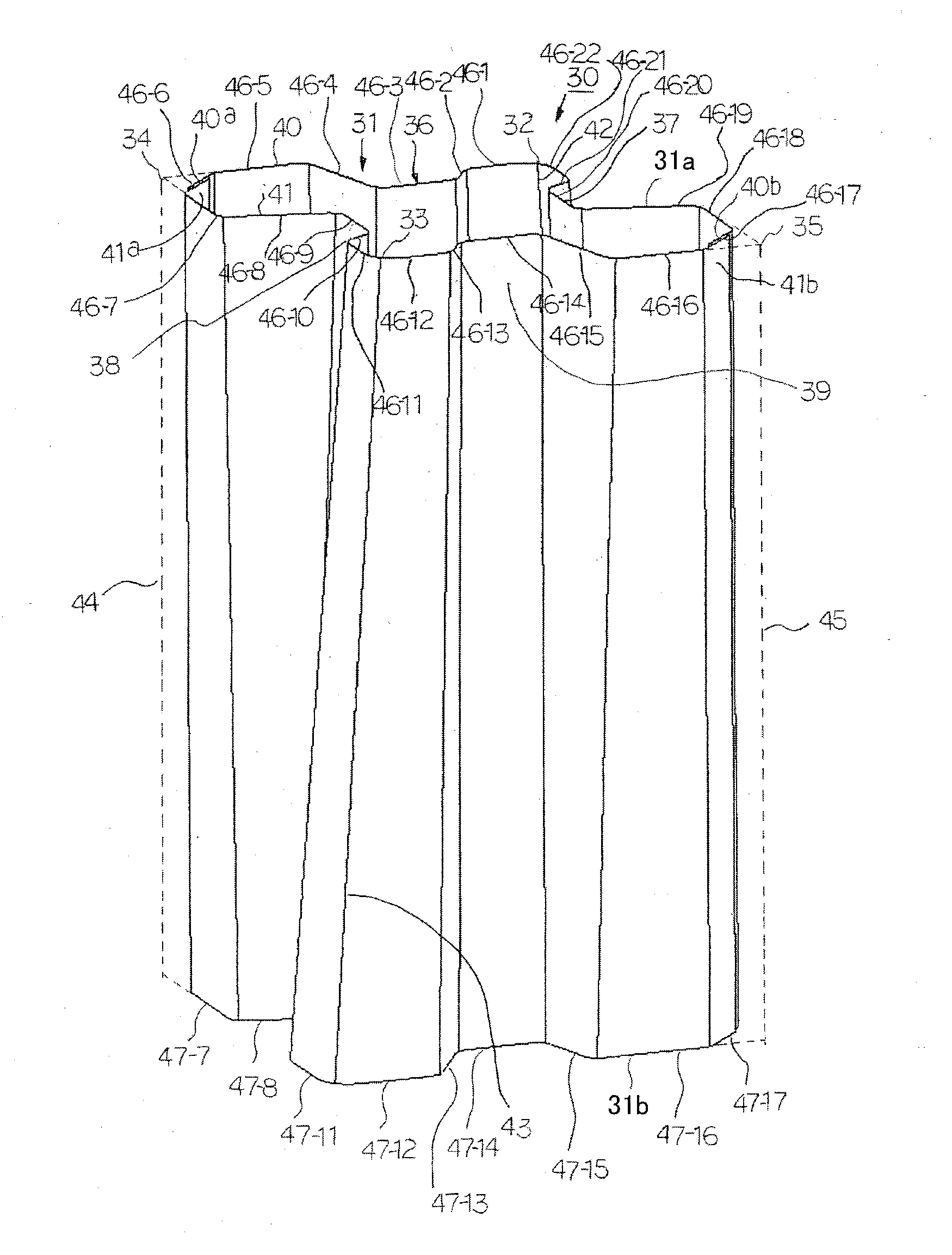

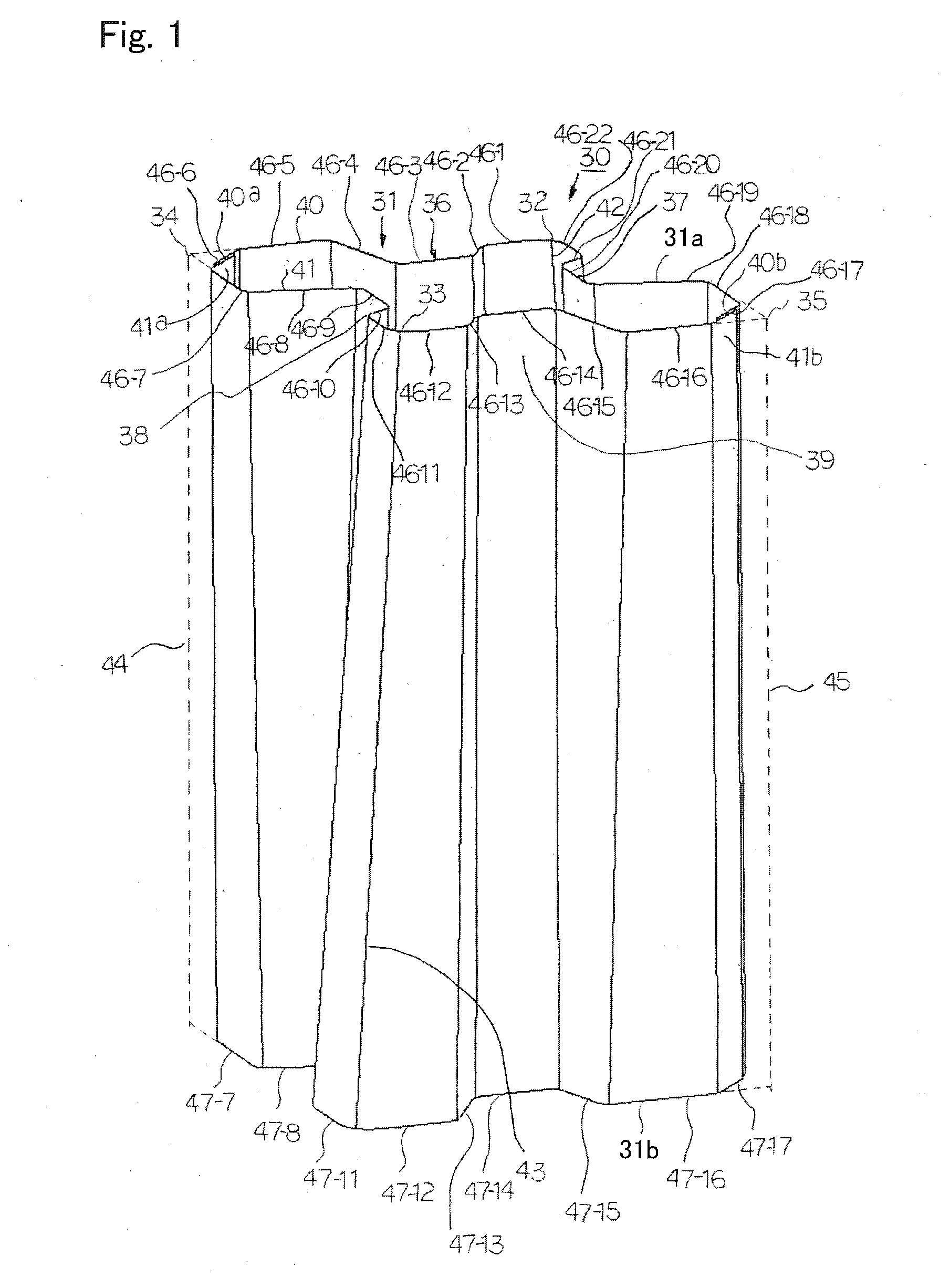

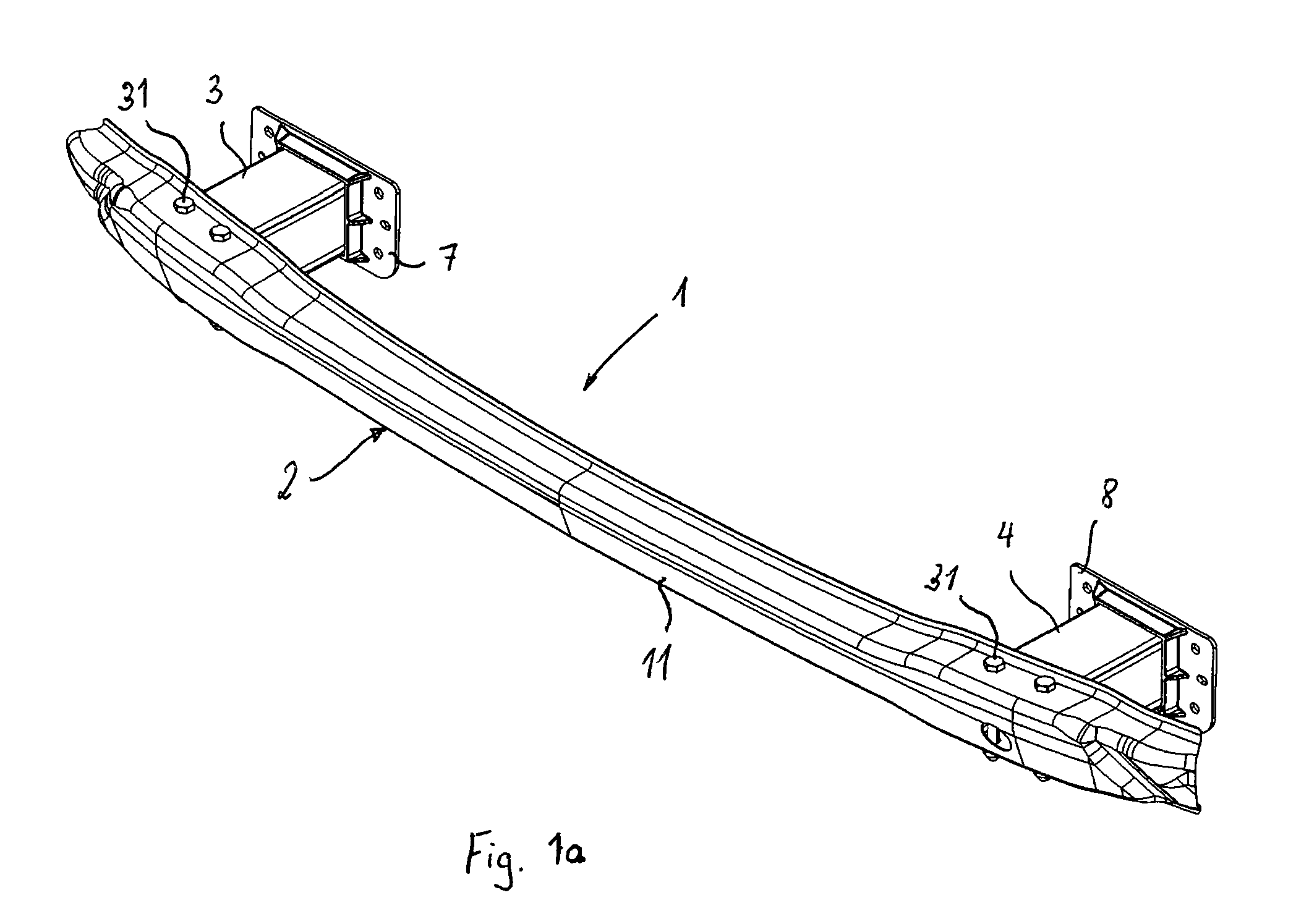

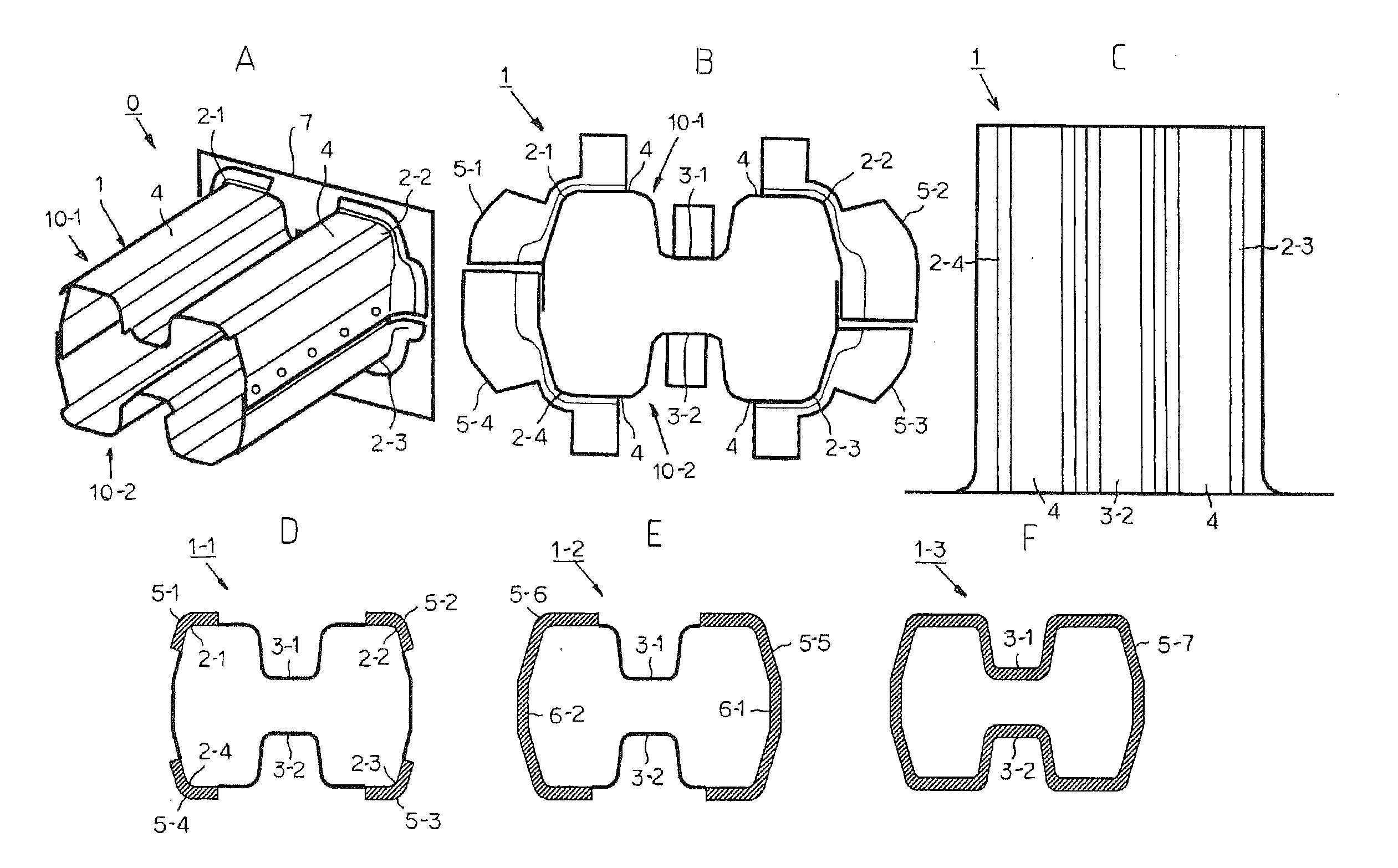

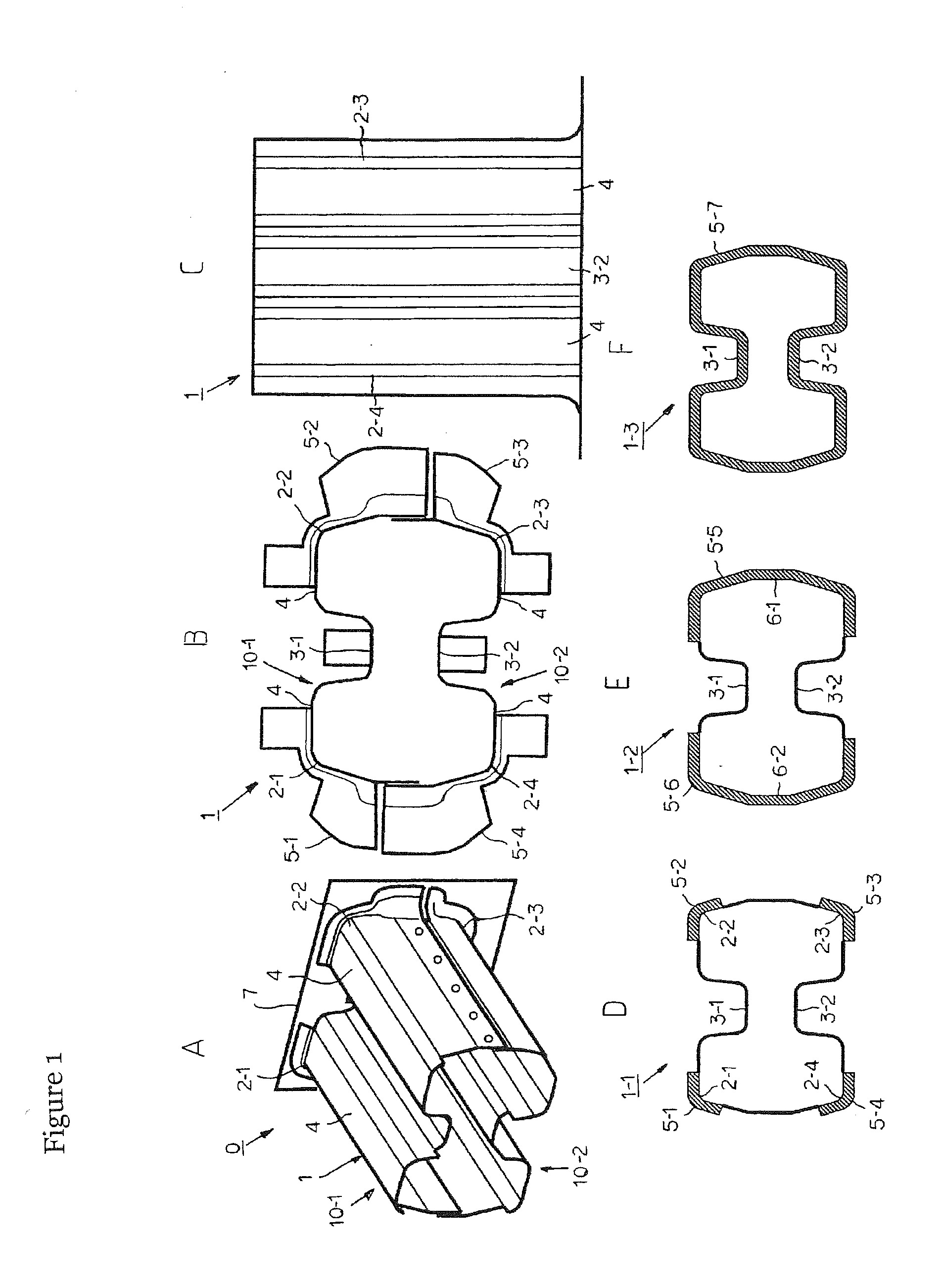

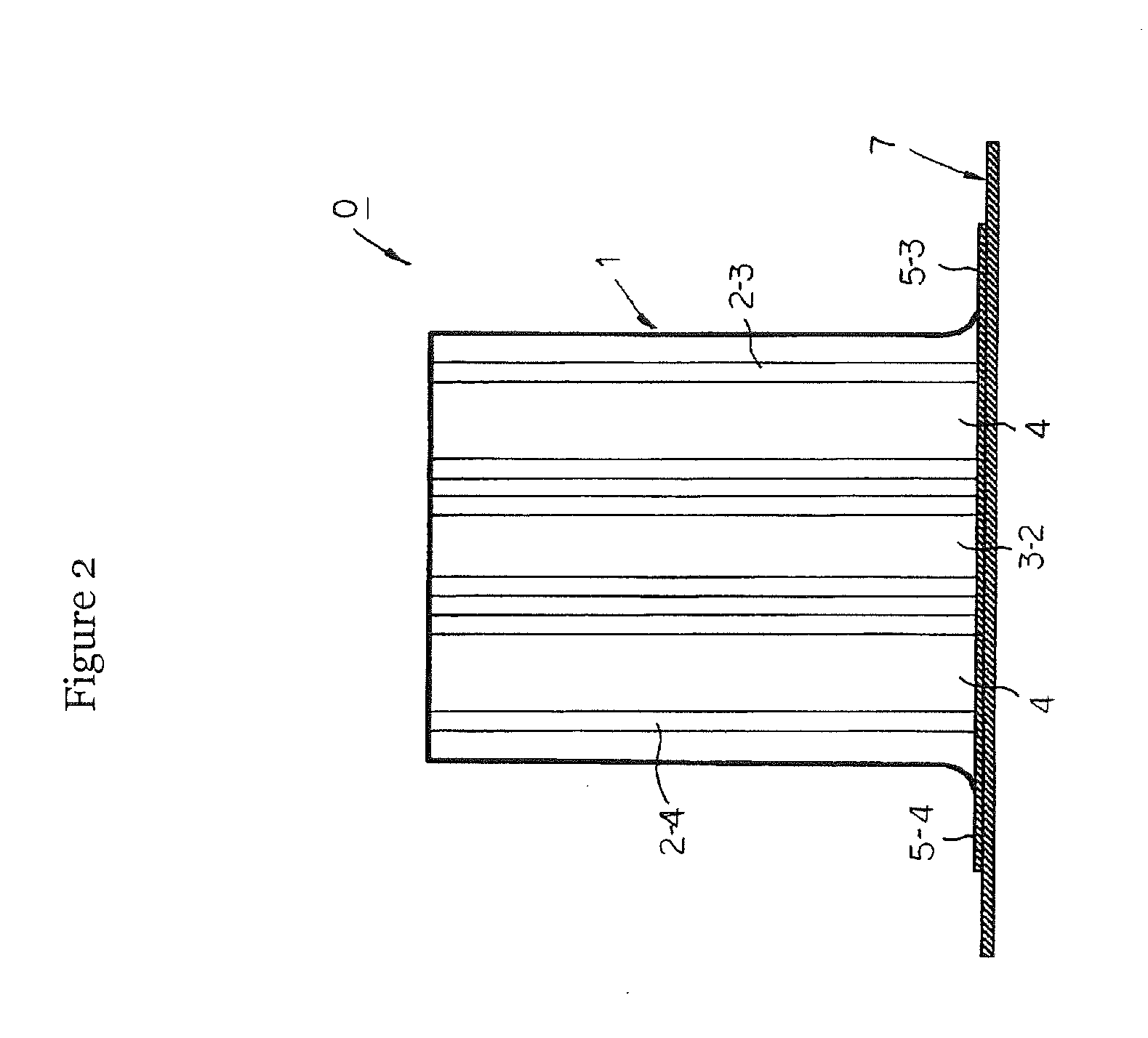

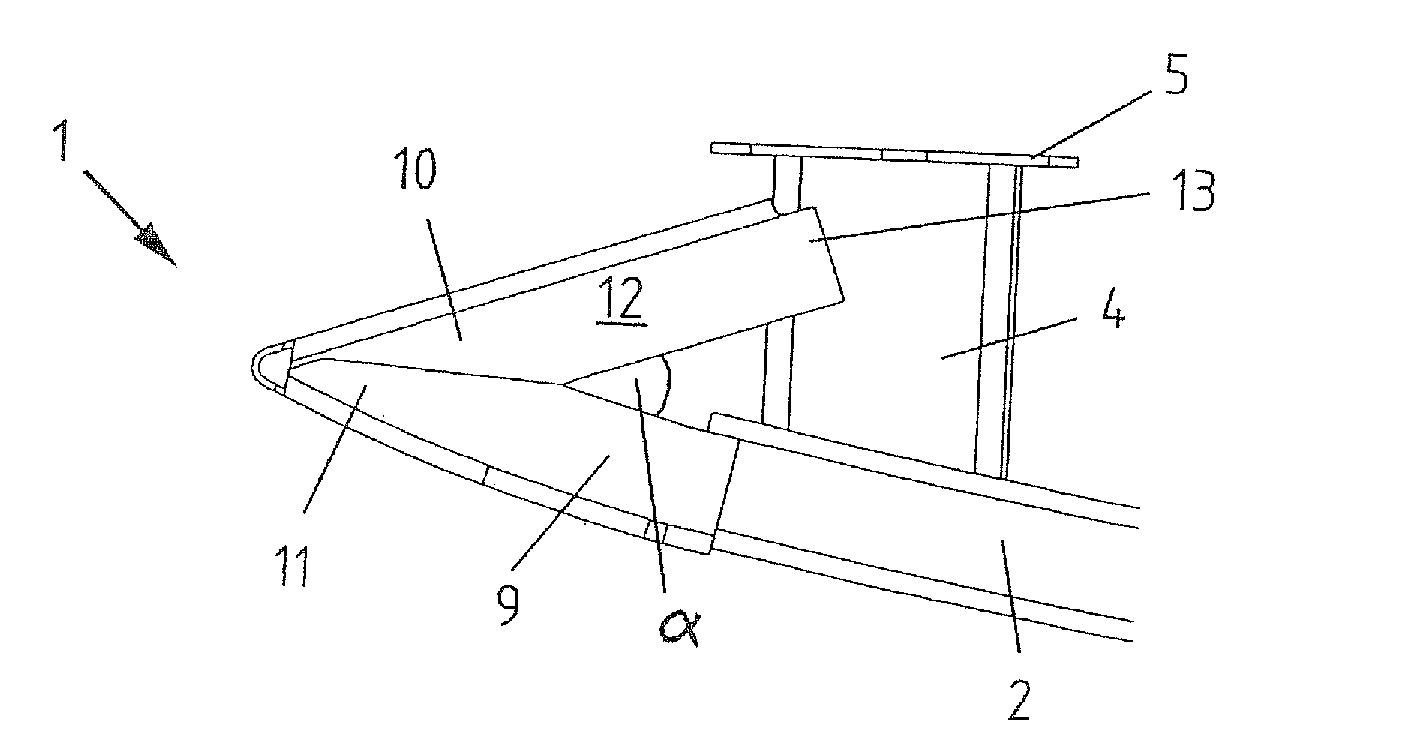

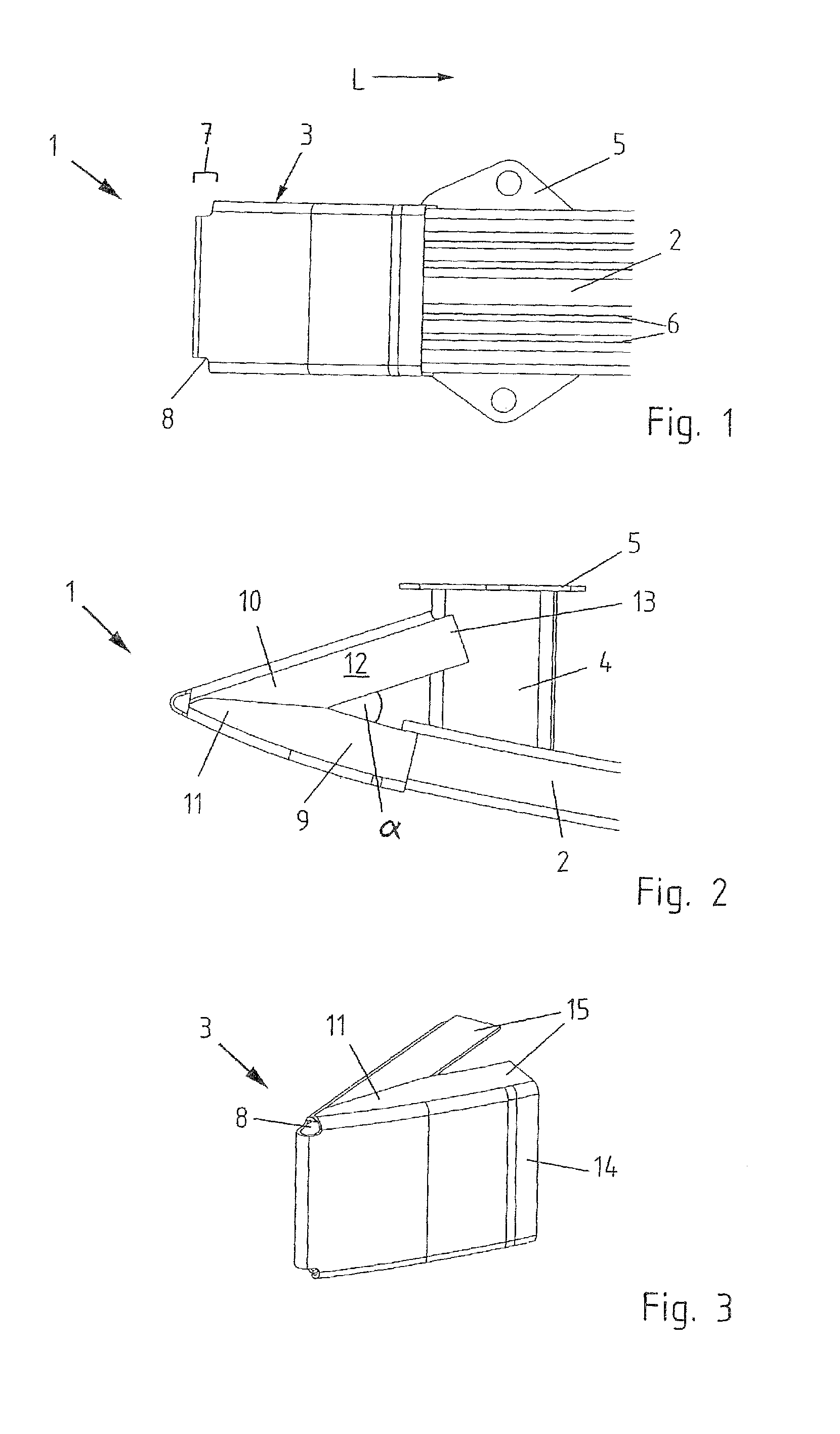

Crash box and method for producing the same

ActiveUS20160221521A1High strengthAvoid it happening againUnderstructuresArc welding apparatusEngineeringFlange

A crash box has excellent axial crushing performance and in which, even if the sheet thickness of a tubular body constituting the crash box is smaller than 1.4 mm, good welding can be performed with the tubular body butted against a set plate. The crash box (1) having a metallic longer-length tubular body and a method for producing the crash box are provided. The tubular body has a basic cross-sectional shape that is a flat polygon surrounded by a plurality of ridges (2-1 to 2-4) extending in a longitudinal direction and a plurality of side wall portions (4), includes one or more groove portions (3-1 and 3-2) on side wall portions (4) on long sides substantially parallel to the major axis direction of the cross section that extend in longitudinal direction, and includes outward flanges (5-1 to 5-4) in an end portion in the longitudinal direction.

Owner:NIPPON STEEL CORP

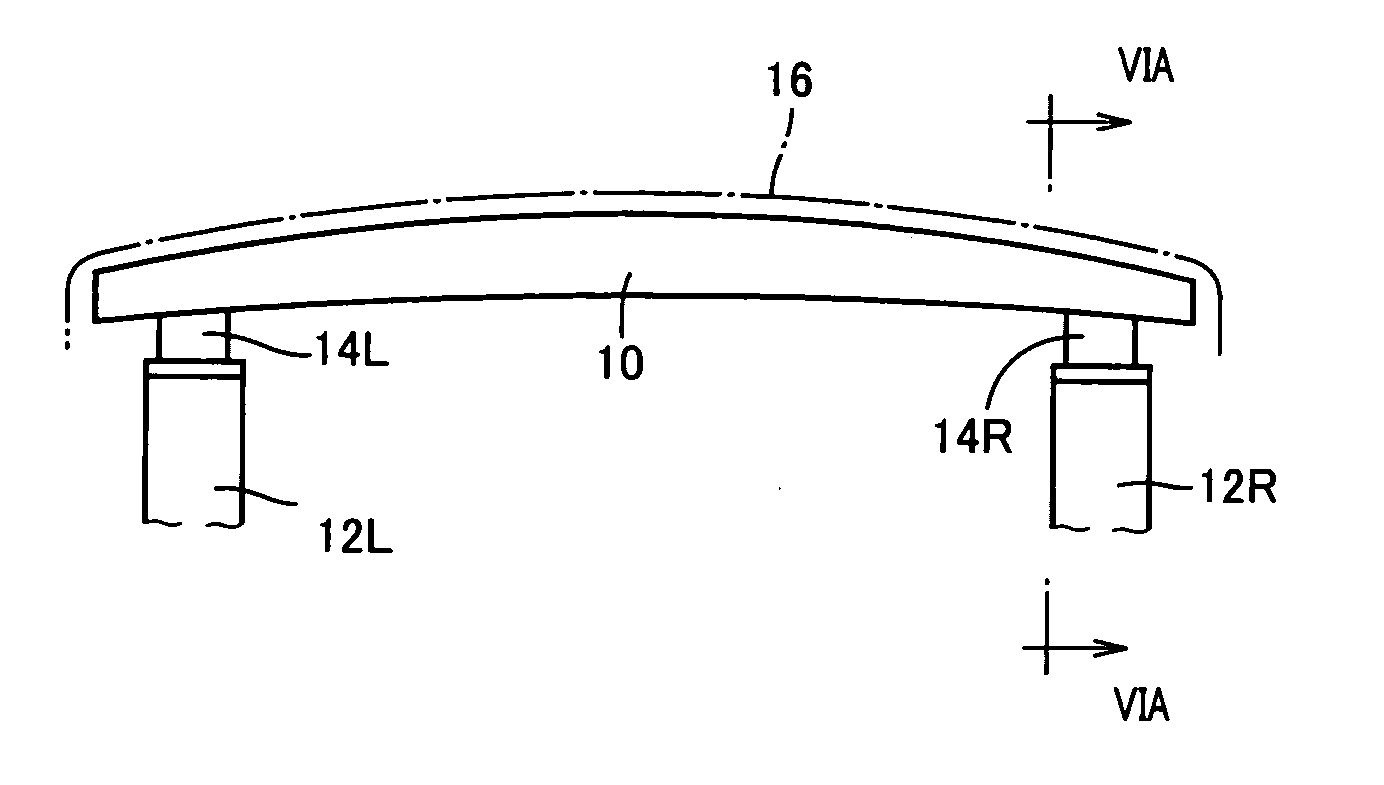

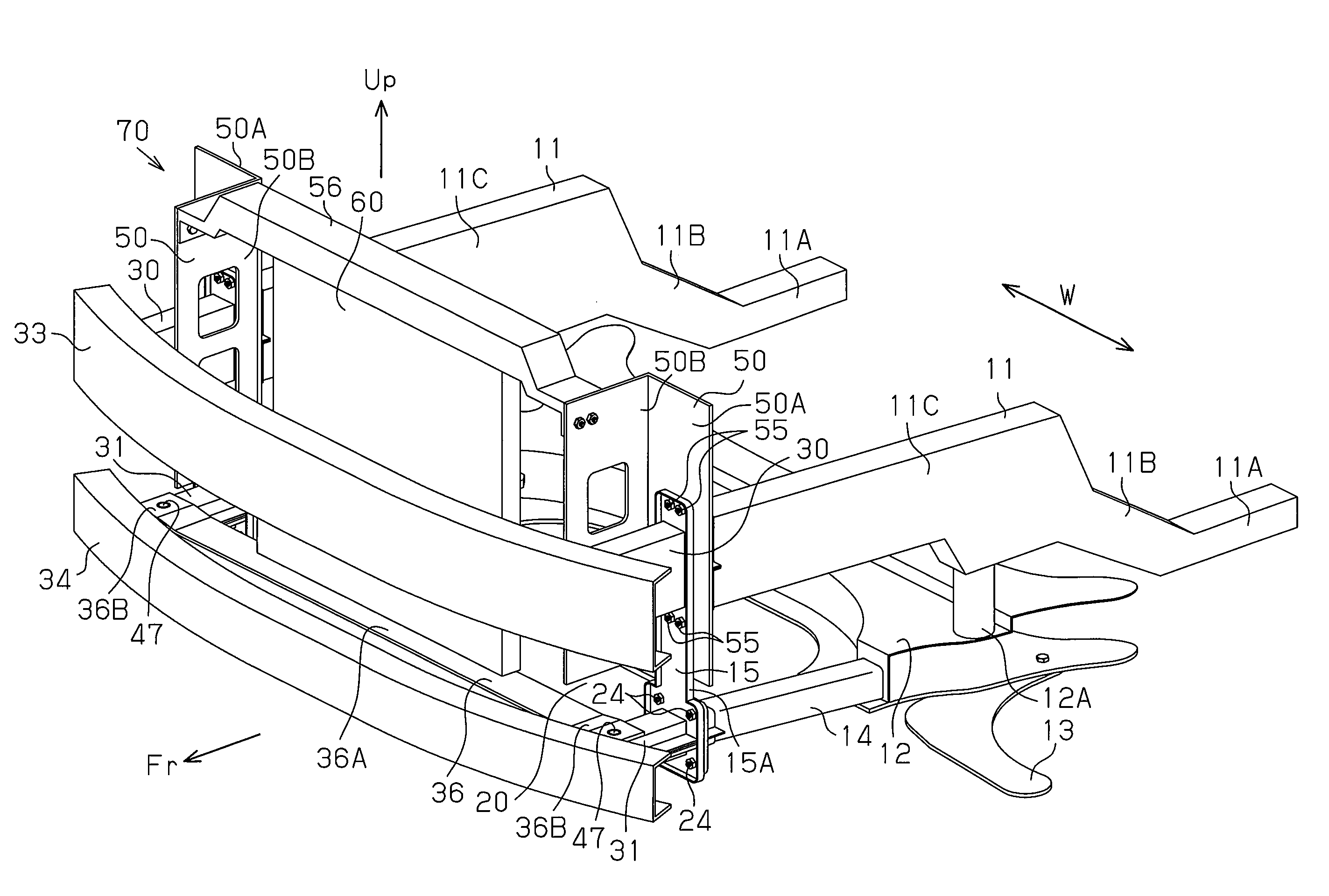

Front structure of vehicle body

InactiveUS20150251613A1Increases collision load absorption efficiencyImprove absorption efficiencyVehicle seatsUnderstructuresEngineeringCrash box

A front structure of a vehicle body includes a first bumper reinforcement extending in a lateral direction of the vehicle body. A second bumper reinforcement extends in the lateral direction of the vehicle body below the first bumper reinforcement. Two first crash boxes are coupled to the two ends of the first bumper reinforcement. Two second crash boxes are coupled to the two ends of the second bumper reinforcement. Two vertical posts are coupled to the rear ends of the first and second crash boxes. Two side frames are coupled to the two vertical posts opposite to the first crash boxes. Two lower members are coupled to the two vertical posts opposite to the second crash boxes. A lower support member couples the second crash boxes to each other and forms a lower portion of a radiator support.

Owner:TOYOTA JIDOSHA KK

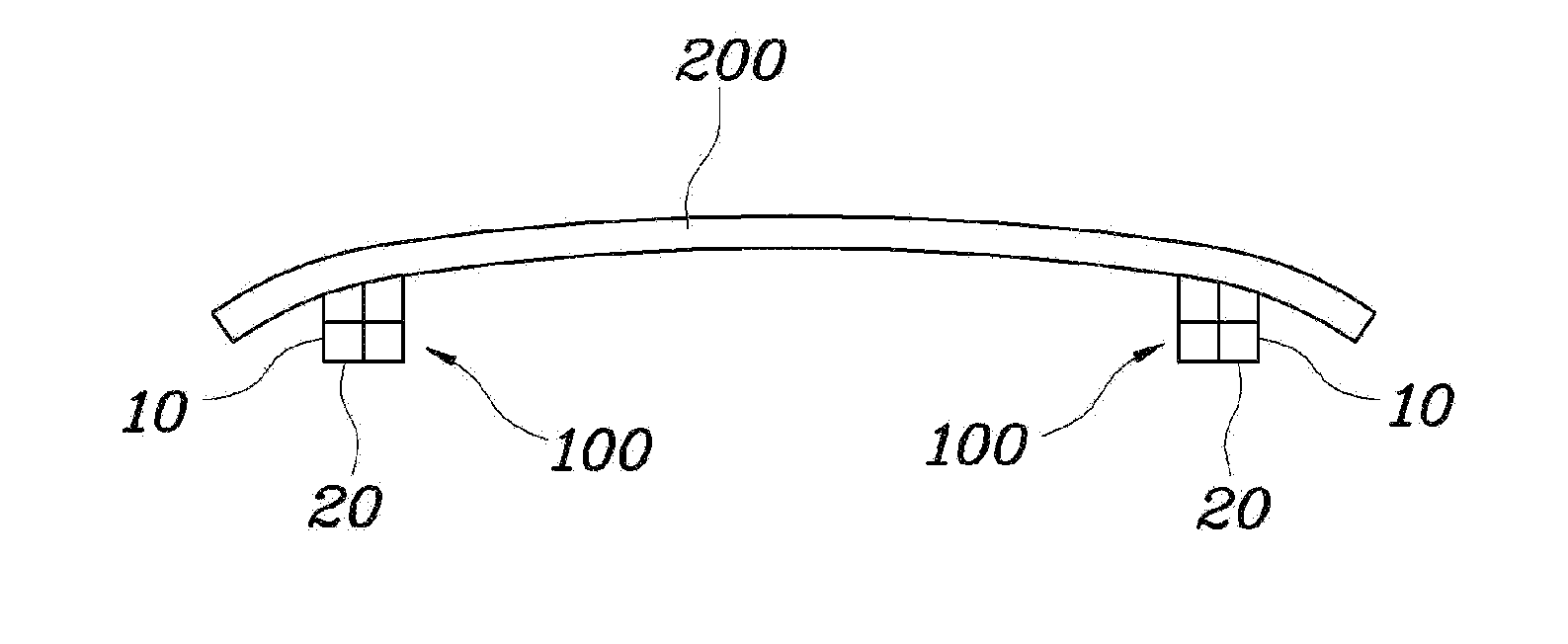

Automobile bumper arrangement and modular bumper system

ActiveUS8414041B2Accelerate absorption and transferPromote absorptionVehicle seatsDashboardsModularityEngineering

An automobile bumper arrangement includes a crossbeam coupled to side rails of an automobile via crash boxes, wherein the crossbeam has extensions disposed at end sections which are laterally supported on a corresponding crash box. A modular bumper system has a crossbeam, an extension and a crash box coupled to a side rail of an automobile, wherein the crossbeam has a standardized length and a vehicle-specific width of a bumper can be attained by varying the length of the extension.

Owner:BENTELER AUTOMOBILTECHNIK GMBH

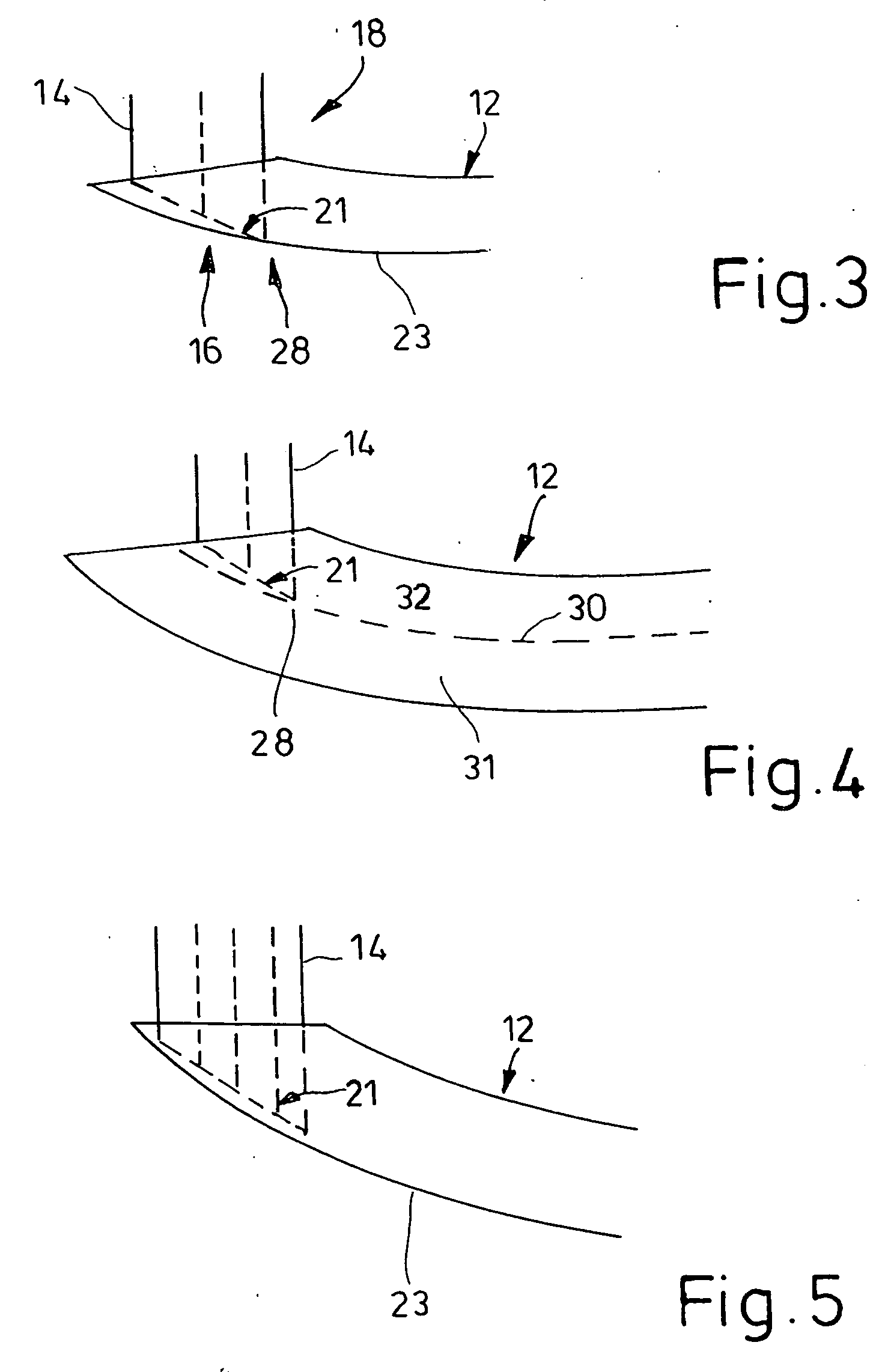

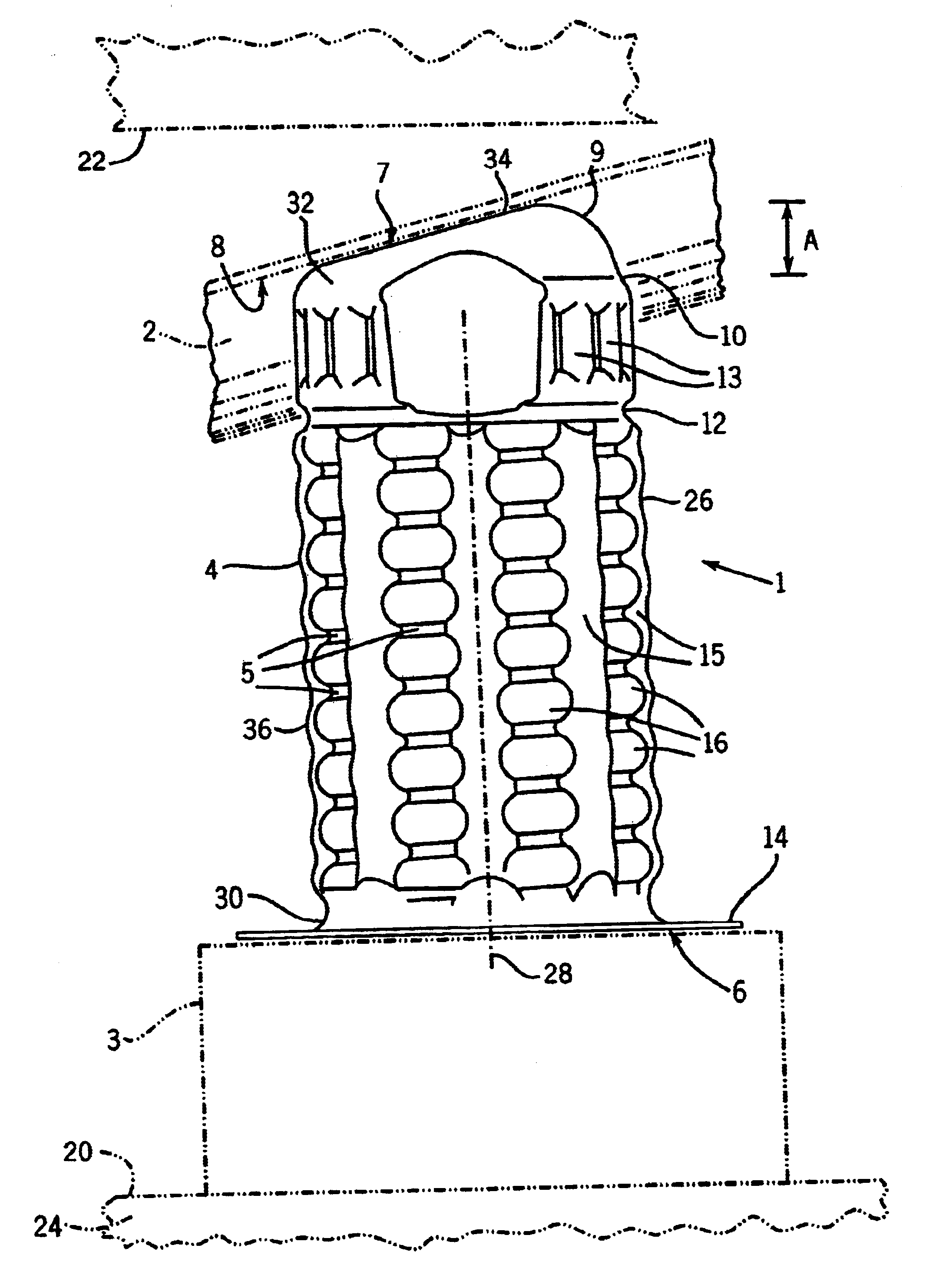

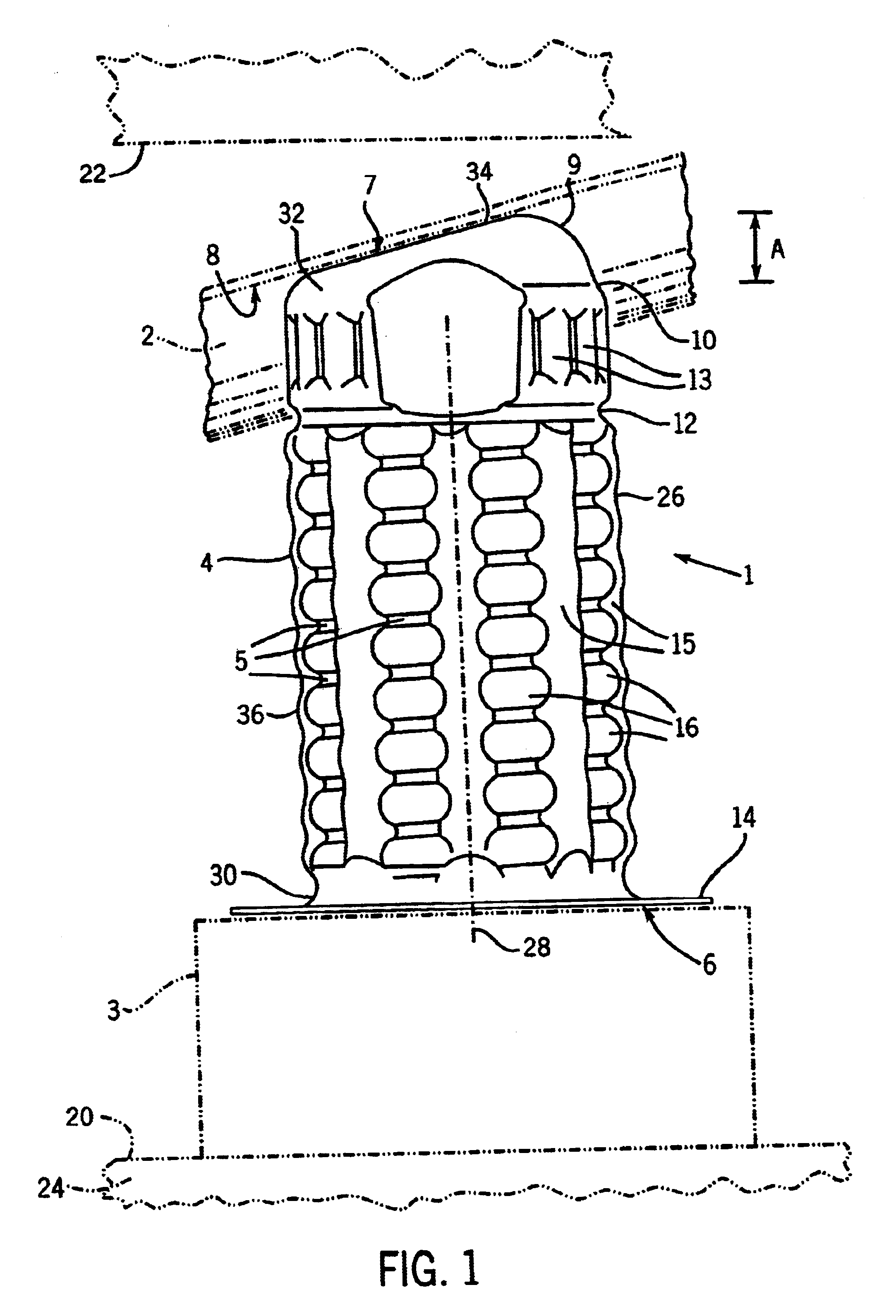

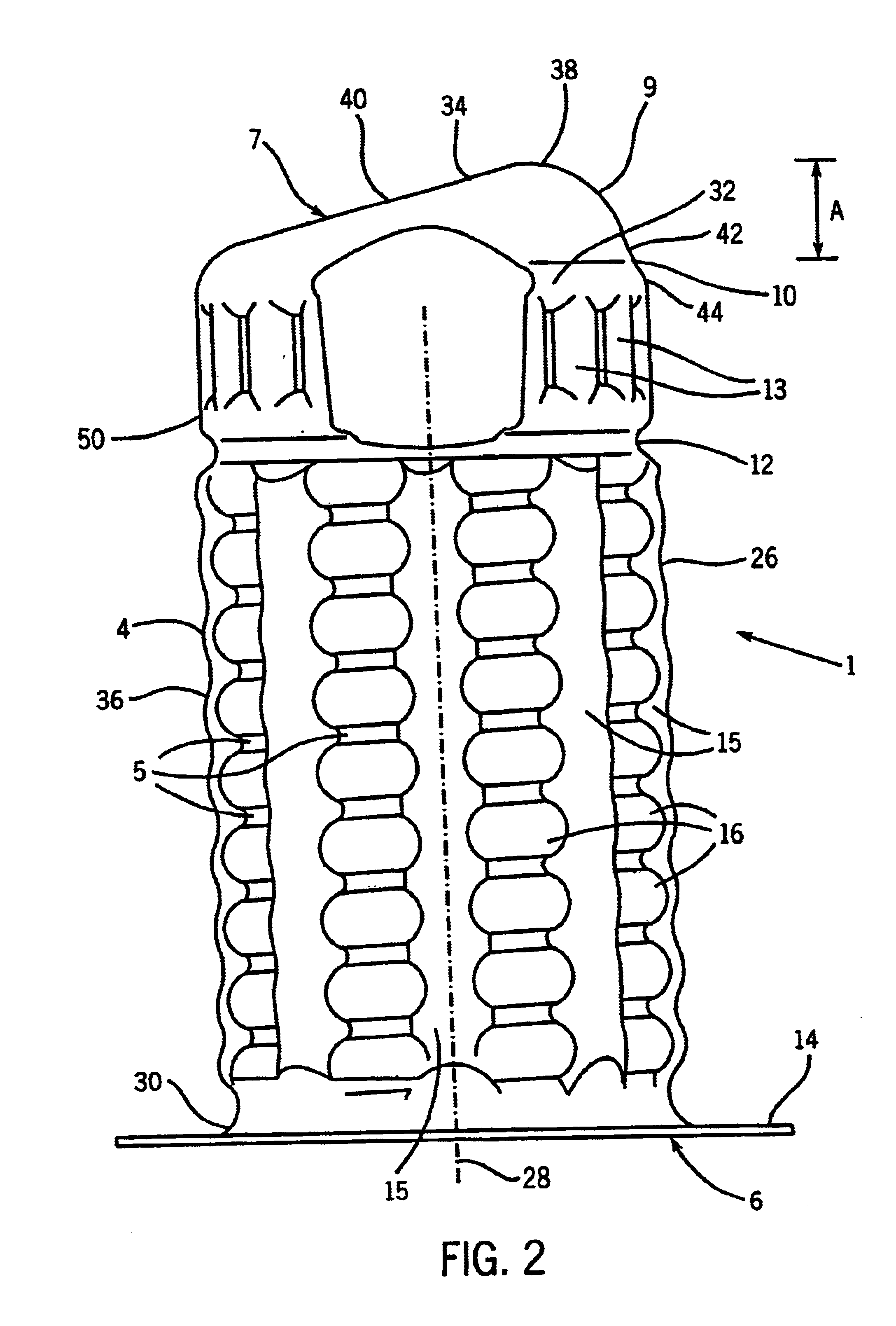

Crash box collision damper for motor vehicle

InactiveUS6672438B2Minimizing replacement frequencyReserved functionPedestrian/occupant safety arrangementElastic dampersLeading edgeEngineering

An automotive crashbox damper member (26) has a sequenced pre-collapse surface (34) providing sequential energy absorbing compression such that at application of longitudinal (28) force, longitudinal compression initially occurs at the pre-collapse surface (34), prior to compression of the remainder (36) of the crashbox damper member (26). In one embodiment, the pre-collapse surface (34) is a mounting surface (7) beveled (40) in roof-like fashion to a frontmost leading edge (38) over the end (32) of the crashbox damper member (26). In another embodiment, the pre-collapse surface (34) is a mounting surface (7) formed as an arched cap (11) in the form of a spherical segment over the end (32) of the crashbox damper member (26).

Owner:WAGON AUTOMOTIVE

Automobile crash box

The invention discloses an automobile crash box, relates to automobile accessories and provides an energy absorbing device which is uniform in deformation and good in crash energy absorbing effect. The automobile crash box in the embodiment comprises a tubular crash box body, one end of the crash box body is provided with a front mounting plate connected with an anticollision beam of an automobile, and the other end of the same is provided with a rear mounting plate connected with a longitudinal beam of the automobile. The side wall of the crash box body is provided with crumple grooves recessed inwardly, and at least one guide plate is fixed on at least one side wall of the crash box body and provided with a weakening structure corresponding to the crumple grooves. When automobiles crash, the weakening structures of the guide plates can deform and guide the crumple grooves to crumple and absorb energy. The automobile crash box is mainly applied to automobiles.

Owner:GREAT WALL MOTOR CO LTD

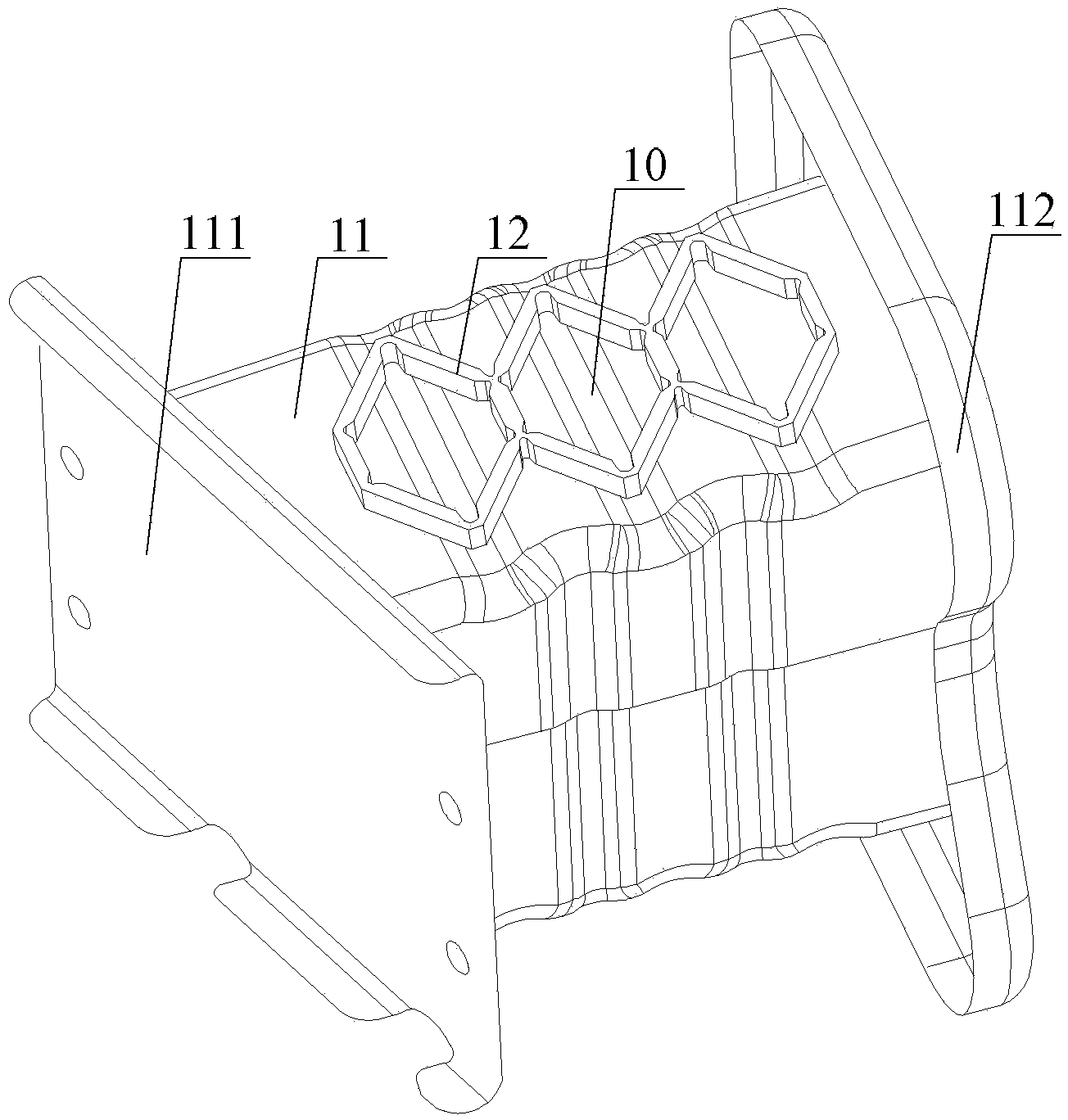

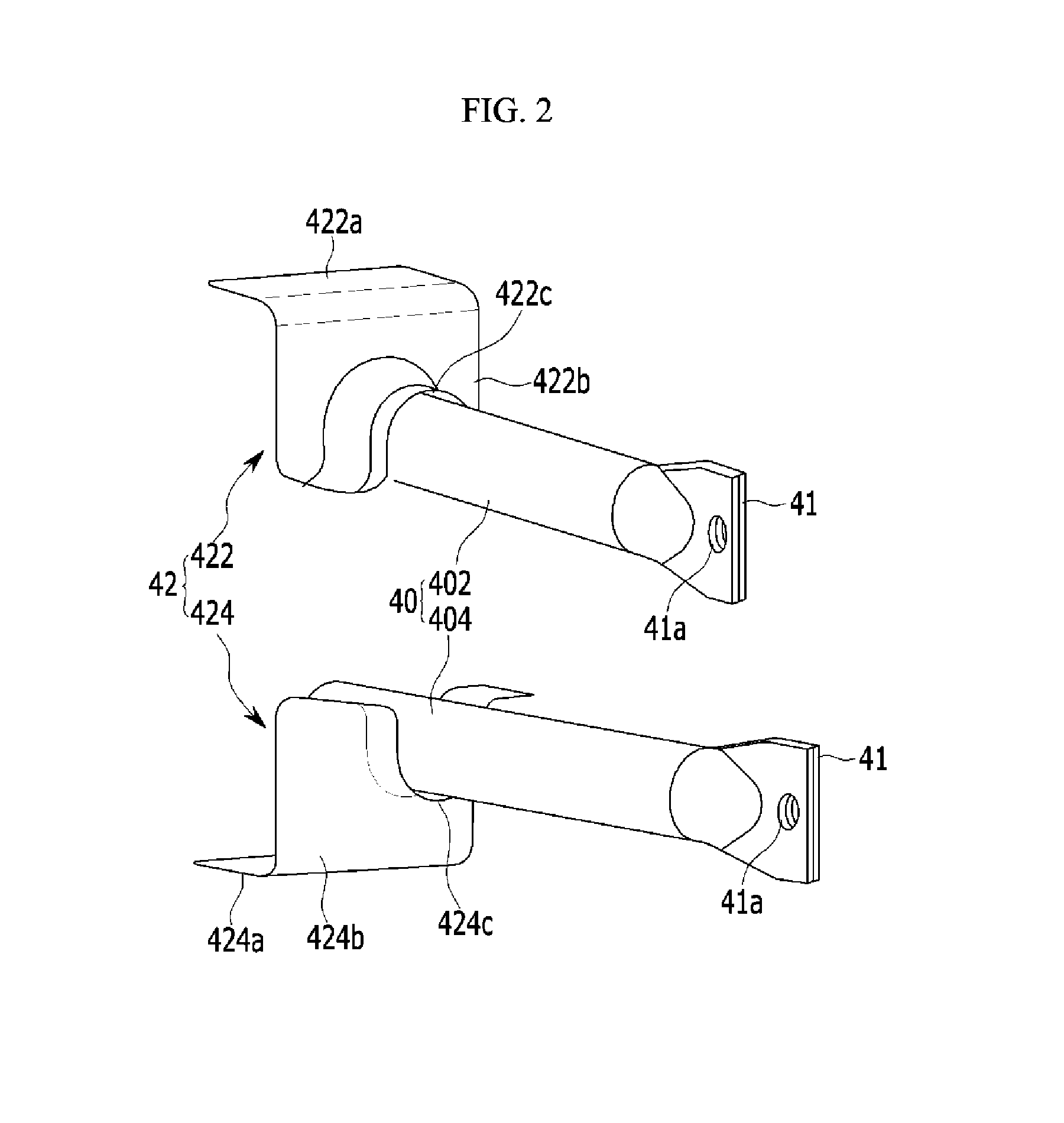

Crash box of bumper for vehicle

ActiveUS20120139273A1Reduce weightIncrease the collision energyBumpersShock absorbersEngineeringCrash box

A crash box of a bumper for a vehicle is provided in the bumper to absorb collision energy produced in a collision. The crash box is constructed such that upper and lower horizontal partitions and a plurality of vertical partitions are connected to each other to form a lattice structure having a plurality of hollow portions, and each of the vertical partitions is formed to be bent at a middle portion thereof. A vertical partition located at the outermost position of the hollow portions forming the lattice structure is bent towards the inside of the crash box, and a vertical partition provided in a middle portion of the crash box is bent to the outside or inside of the vehicle.

Owner:HYUNDAI MOTOR CO LTD +2

Vehicle body reinforcing structure for coping with small overlap collision

ActiveUS9272678B2Comprehensive performance is smallEnergy efficiencyUnderstructuresSuperstructure subunitsEngineeringMechanical engineering

A vehicle body reinforcing structure for coping with a small overlap collision may include front side members which may be extended in a longitudinal direction of a vehicle and disposed at left and right sides in a width direction of the vehicle, a crash box which is installed to a front end of the front side member in the longitudinal direction of the vehicle and absorbs and reduces impact when receiving the impact to be deformed, a bumper beam which is disposed in front of the crash box in the longitudinal direction of the vehicle, coupled to the crash box, and extended in the width direction of the vehicle, and a reinforcing member which is coupled to both the crash box and the front side member, and protrudes outside of the bumper beam in the width direction of the vehicle to transfer an impact energy to the front side member.

Owner:HYUNDAI MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com