Vertical intelligent force measurement support

An intelligent, vertical technology, applied in the direction of measuring force, measuring devices, measuring instrument components, etc., can solve problems such as unsuitable for mass use, unsatisfactory technical performance, high cost, etc., to achieve test automation and remote monitoring, structure Simple, low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

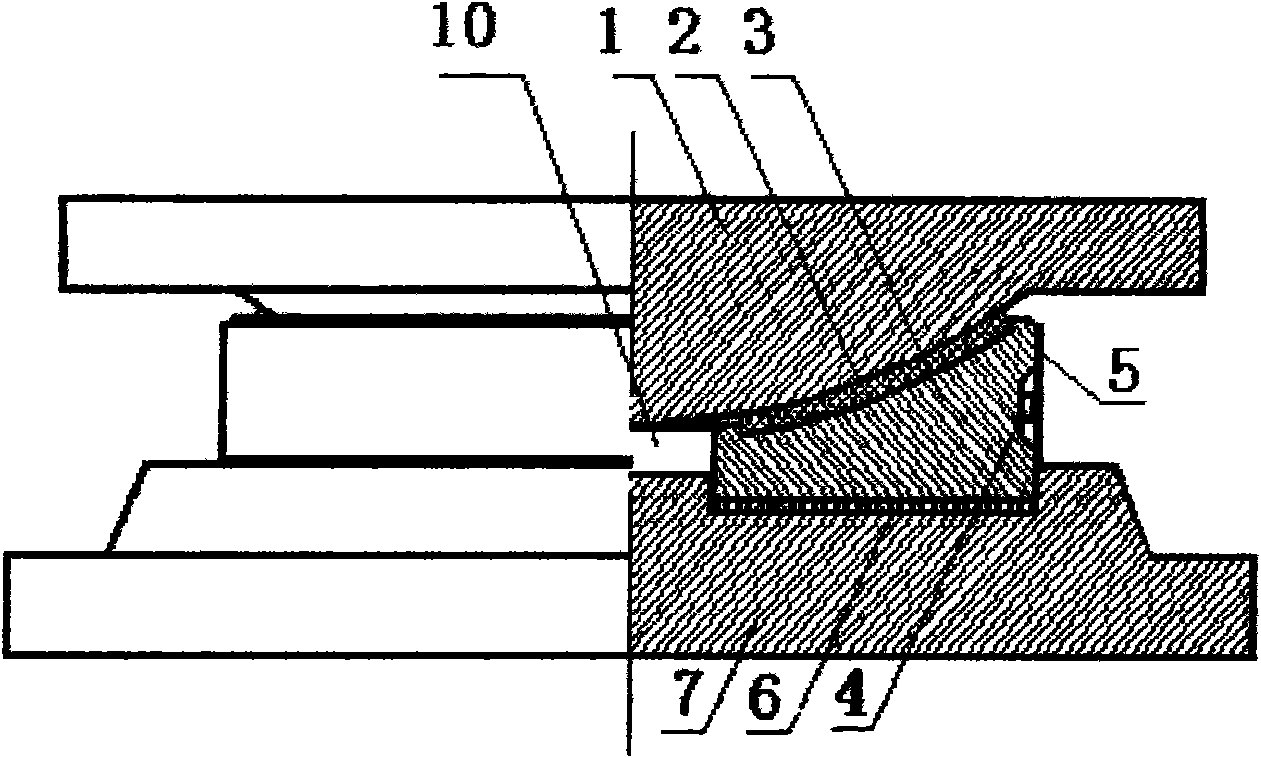

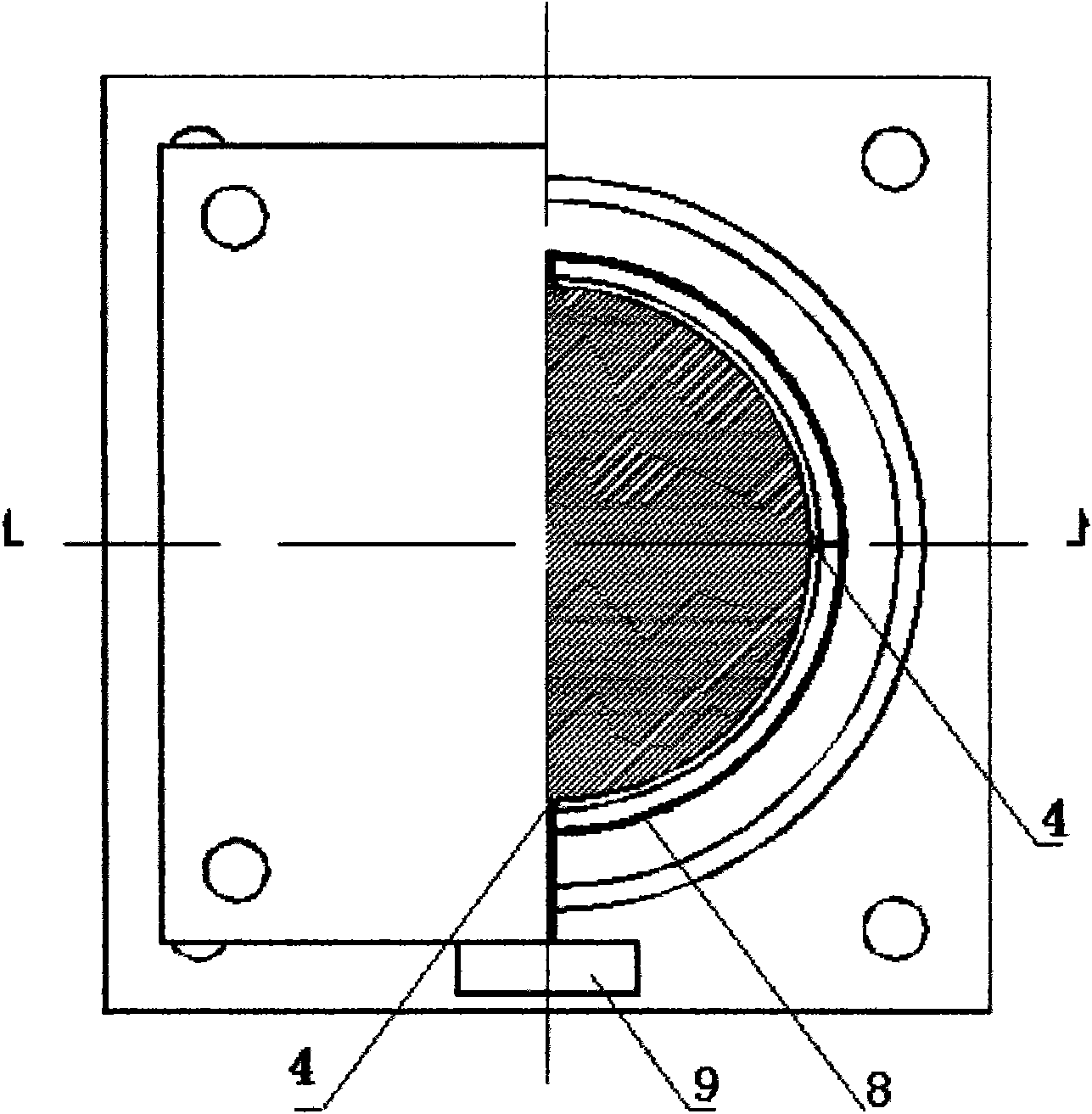

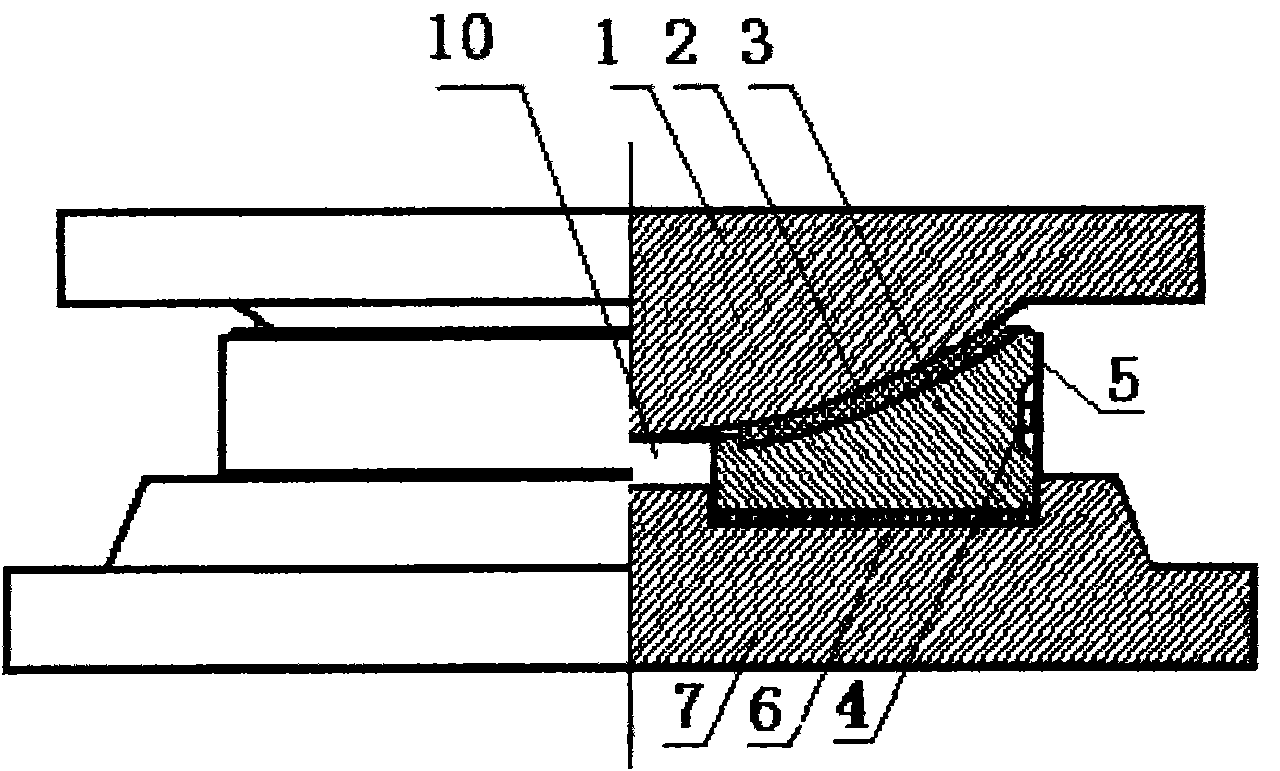

[0021] Combine below figure 1 and figure 2 , the present invention is further described:

[0022] Such as figure 1 As shown, an intelligent vertical force-measuring support is composed of an upper pendulum 1, an upper friction-reducing layer 2, a lower hem 3, a resistance strain element 4, a sealing cover 5, a lower friction-reducing layer 6, a base 7, and connecting wires 8 , and a data acquisition module 9 is formed.

[0023] The top surface of the upper pendulum 1 is flat, and there are bolt holes connected to the structure at the four corners. The bottom surface of the upper pendulum 1 is a convex spherical surface; Cylindrical, bottom 3 center has circular hole 10. An upper anti-friction layer 2 is arranged between the upper hem 1 and the lower hem 3, and the upper anti-friction layer 2 is in spherical contact with the upper hem 1 and the lower hem 3 respectively.

[0024] The bottom surface of hem 3 and the upper support surface of base 7 can be plane or spherical,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com