Silicon-fluorine modified styrene-acrylic emulsion and preparation method thereof

A styrene-acrylic emulsion and silicon-fluorine modification technology, which is applied in the field of silicon-fluorine modified styrene-acrylic emulsion and its preparation, can solve the problems of high interfacial tension, poor initial viscosity, difficulty in applying high-end products, etc., and achieve improved roughness and improved The effect of contact angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Provide a kind of preparation method of silicon fluorine modified styrene-acrylic emulsion, comprise the following steps:

[0028] The first step: mix nonylphenol polyoxyethylene ether and sodium lauryl sulfate in a mass ratio of 3:2 to prepare an emulsifier, add three quarters of the emulsifier to deionized water, and stir to dissolve;

[0029] Step 2: Add butyl acrylate, styrene, and acrylic acid mixed monomers to S1, and stir vigorously for 30 minutes to make a pre-emulsion;

[0030] The third step: dissolve the initiator ammonium persulfate into an appropriate amount of water to form an initiator solution;

[0031] Step 4: In a 250mL four-necked bottle equipped with a reflux condenser, an electric stirrer, a constant pressure dropping funnel and a thermometer, add an appropriate amount of sodium bicarbonate, deionized water and the remaining quarter of the emulsifier, and heat up to 60°C, add part of the initiator solution in S3, drop 1 / 5 of the pre-emulsion in S2 ...

Embodiment 2

[0034] Provide a kind of preparation method of silicon fluorine modified styrene-acrylic emulsion, comprise the following steps:

[0035] The first step: Mix nonylphenol polyoxyethylene ether and sodium lauryl sulfate uniformly in a mass ratio of 3:2 to prepare an emulsifier, and add the emulsifier and a certain amount of sodium bicarbonate into the Add a certain amount of deionized water to the 250mL four-necked flask with a stirrer, a constant pressure dropping funnel and a thermometer and stir to dissolve;

[0036] Step 2: Raise the temperature to about 60°C, add part of the initiator ammonium sulfate, then drop in about 1 / 5 of the mixed monomer of butyl acrylate, styrene and acrylic acid within 30 minutes, and keep it warm at 75-80°C to the liquid turns blue;

[0037] Step 3: Mix vinyltriethoxysilane into the remaining 4 / 5 butyl acrylate, styrene, acrylic acid mixed monomer, drop the mixed monomer and the remaining initiator ammonium sulfate solution into the flask within...

Embodiment 3

[0039] Vinyltriethoxysilane is added after the other monomers are dropped, and the other procedures are the same as those in the examples, and will not be repeated here.

[0040] 1. Based on the silicon-fluorine modified styrene-acrylic emulsion prepared in Examples 1-3, the influence of the amount of silicon monomer and the way of addition on the water absorption of the latex film was studied:

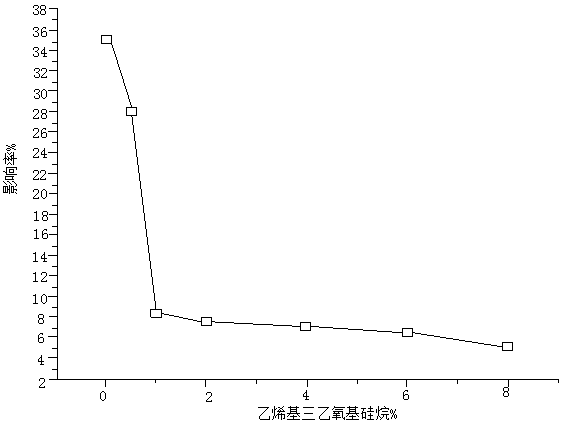

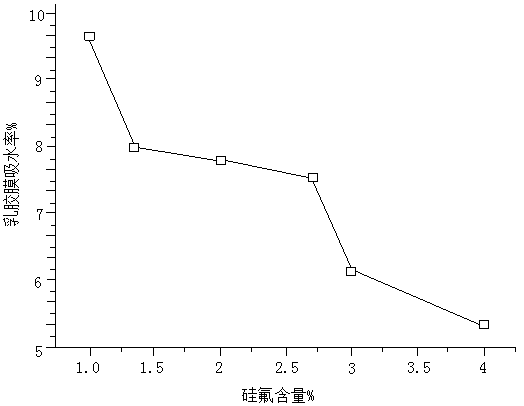

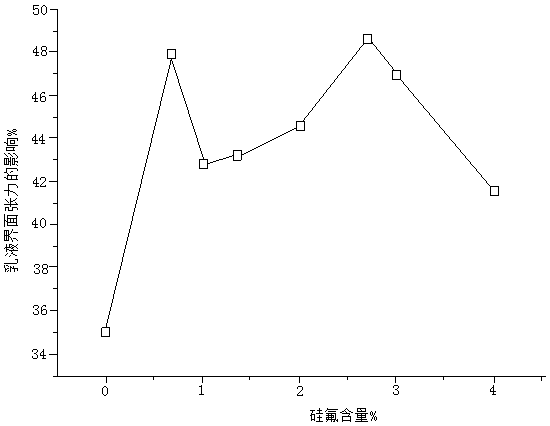

[0041] see figure 1 , when other reaction conditions remain unchanged, the effect of the amount of vinyltriethoxysilane on the water absorption of the latex film is determined by figure 1It can be seen that changing the amount of vinyltriethoxysilane has a significant impact on the water absorption of the latex film; in the preparation process of embodiment 1 and embodiment 2, adding vinyltriethoxysilane can well improve The water resistance of latex film; but when adopting embodiment 3 to add organosilicon monomer method, after adding vinyltriethoxysilane, the water absorption rate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com