Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

78 results about "TRICAPRYLYL CITRATE" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Waterproof rubber material

InactiveCN105384989AImprove thermal conductivityImprove conductivityPolyethylene glycolMaterials science

The invention discloses a waterproof rubber material. The waterproof rubber material is prepared from the following raw materials by weight: 7 to 8 parts of polyethylene glycol terephthalate, 3 to 4 parts of trioctyl citrate, 1 to 2 parts of rosin, 24 to 27 parts of polyacrylonitrile, 1 to 2 parts of sodium diacetate, 12 to 13 parts of graphite, 3 to 4 parts of fly ash bead, 0.7 to 1 part of sodium dodecyl sulfate, 42 to 55 parts of liquid acrylonitrile-butadiene rubber, 0.6 to 1 part of methacrylic acid, 52 to 60 parts of acrylonitrile-butadiene rubber, 20 to 255 parts of butadiene styrene rubber, 5 to 6 parts of nanometer silica sol, 3 to 4 parts of tetramethyl-thiuram disulfide, 2 to 3 parts of diglycol, 6 to 8 parts of VAE emulsion, 14 to 16 parts of activated clay, 5 to 7 parts of barium titanate, 7 to 9 parts of magnesium hydroxide and 0.2 to 0.3 part of calcium propionate. The waterproof rubber material prepared in the invention has good waterproof performance and acid resistance, oil resistance and flame retardation performance, can perfectly meet requirements of production and is worth popularization.

Owner:安徽创奇乐智能游乐设备有限公司

Photoresist detergent composition

InactiveCN101750914AEasy to cleanImprove solubilityPhotosensitive material processingMetallic materialsSemiconductor chip

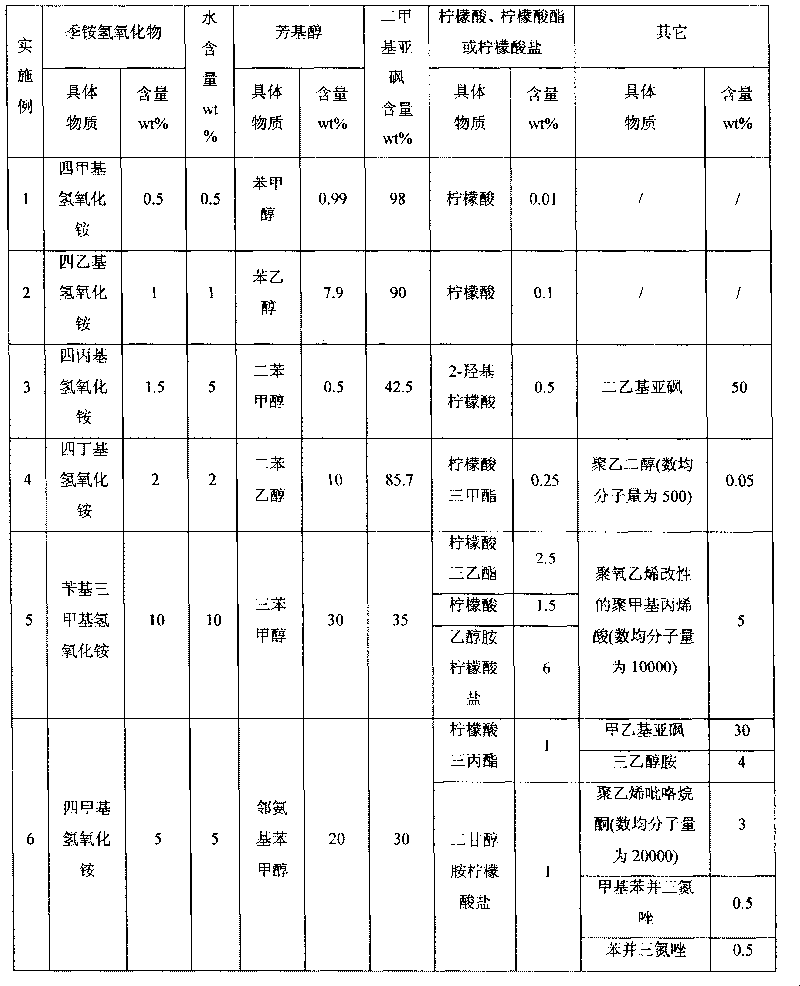

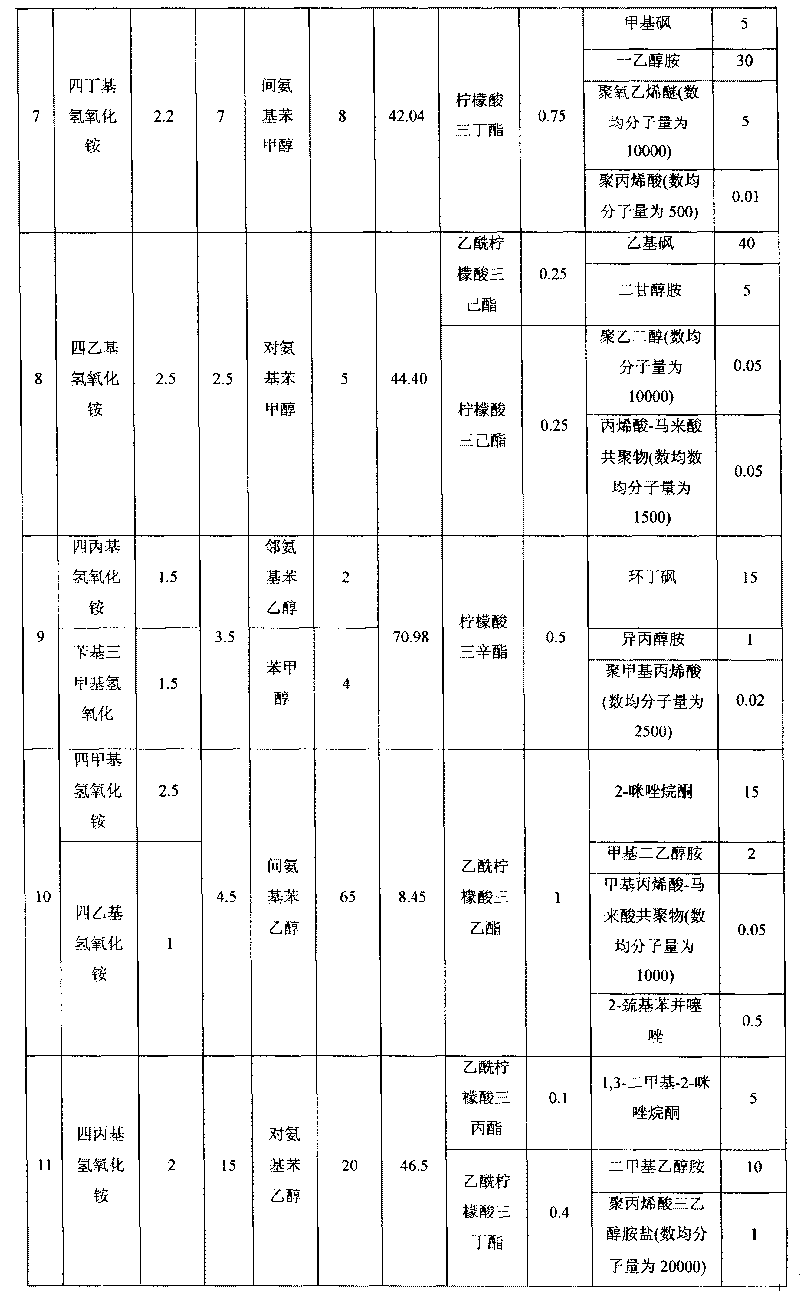

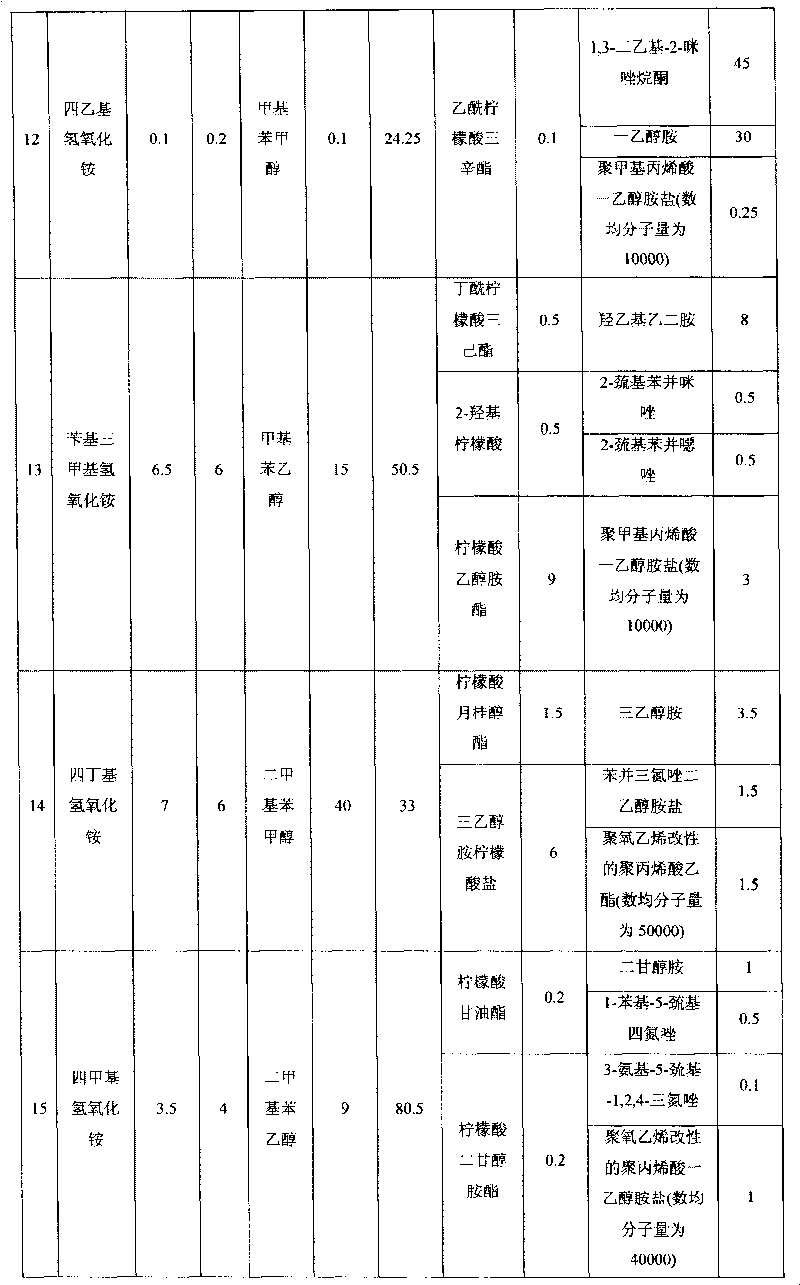

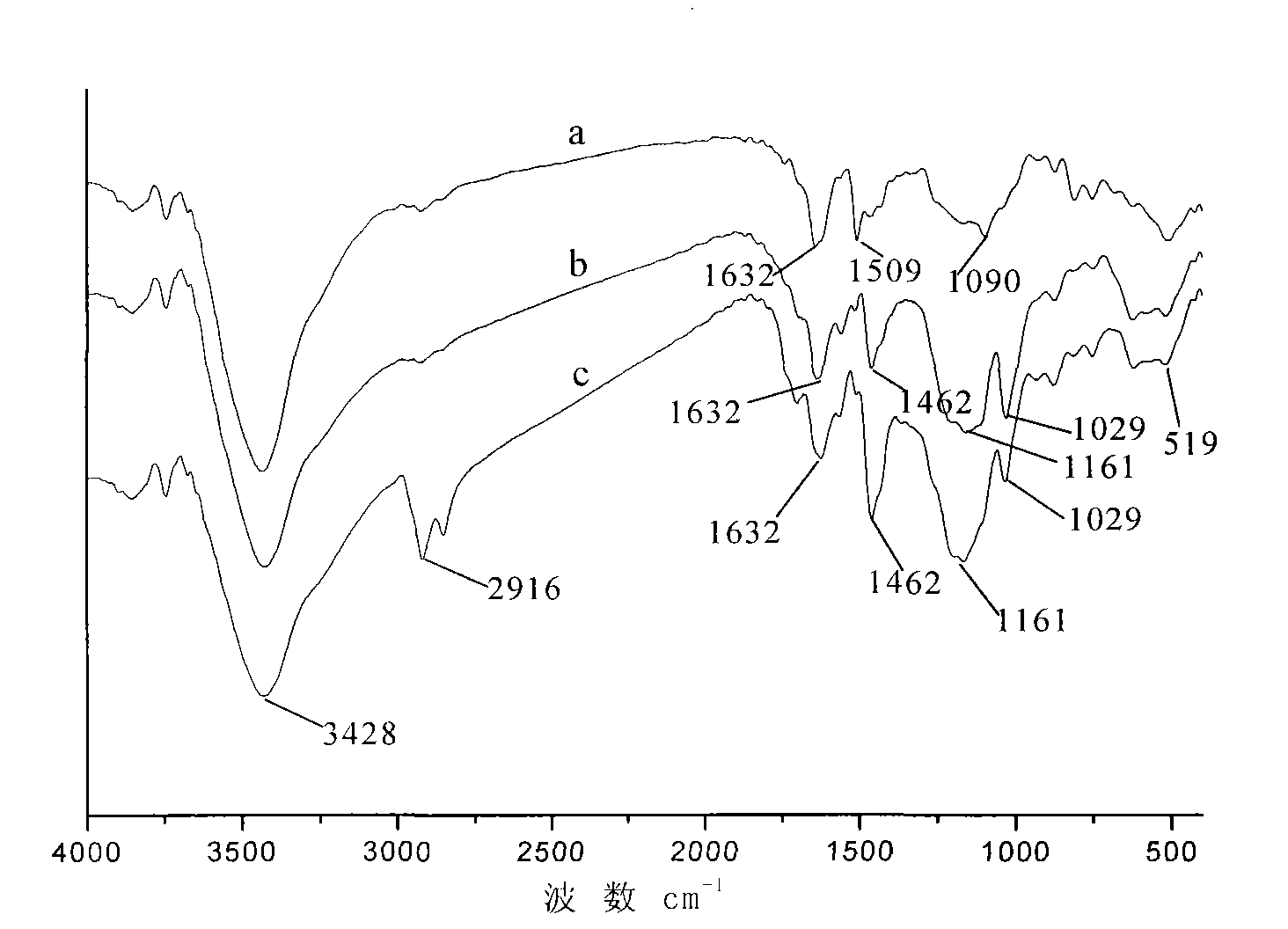

The invention discloses a photoresist detergent composition, which comprises quaternary ammonium hydroxides, water, aromatic alcohol, dimethyl sulfoxide, and at least one corrosion inhibitor selecting from citric acid, tricaprylyl citrate and citrate. The photoresist detergent composition can also comprise a polar organic cosolvent, a surface active agent and / or other corrosion inhibitors. The photoresist detergent composition can remove the photoresist (particuarly thick film negative photoresist) with the thickness of over 20 mu m on the metals, metal alloys or dielectric medium substrates, and other etching residues; and meanwhile, the composition has low causticity to the metals such as aluminum, copper and the like and the nonmetallic materials such as silicon dioxide and the like, thus, the composition has good application prospect in the micro-electronics fields such as semiconductor chip cleaning, and the like.

Owner:ANJI MICROELECTRONICS (SHANGHAI) CO LTD

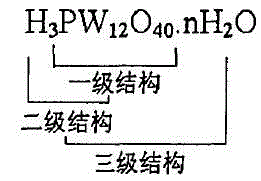

Sulfonated phenolic resin and preparation and application as catalyst thereof

InactiveCN101550223ALarge specific surface areaSuitable reaction spaceOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsTRICAPRYLYL CITRATECITRATE ESTER

The invention provides sulfonated phenolic resin. Firstly, phenolic resin is synthesized by raw materials of phenol and formaldehyde, and then the phenolic resin is sulfonated under proper conditions, thus obtaining the sulfonated phenolic resin. The catalytic activity center of the prepared phenolic resin is sulfonic group, and good thermal stability of the phenolic resin ensures that the acid activity center can play the catalyst role fully, thus deciding that the sulfonated phenolic resin is an acid catalyst with excellent properties. The sulfonated phenolic resin catalyst is used in the catalytic synthesis reaction of trioctyl citrate and tributyl citrate, and the result shows that the esterification rate of the tributyl citrate is 99 percent and that the esterification rate of the trioctyl citrate is more than 96.0 percent.

Owner:NORTHWEST NORMAL UNIVERSITY

Environment-friendly type PVC (polyvinyl chloride) synthetic leather and production method thereof

InactiveCN104278539AImprove breathabilityReduce potential threatsSynthetic resin layered productsTextiles and paperPolyamidePolyvinyl chloride

The invention discloses environment-friendly type PVC (polyvinyl chloride) synthetic leather. The environment-friendly type PVC synthetic leather is prepared from the following raw materials in parts by weight: 30-60 parts of polyvinyl chloride resin SG-5 (PVCSG-5), 15-30 parts of polyvinyl chloride resin SG-8 (PVCSG-8), 10-15 parts of egg shell powder, 3-6 parts of rice bran, 2-5 parts of rice husk, 2-4 parts of wollastonite powder, 0.2-0.5 part of aluminum oxide, 40-70 parts of trioctyl citrate, 15-30 parts of trimethyl citrate, 1-2 parts of isopropanolamine, 0.5-1 parts of lactose, 0.2-0.5 part of calcium chloride, 0.5-1.5 parts of dioctyl sodium sulfosuccinate, 1-2 parts of turkey red oil, 0.5-1 part of polyamide epichlorohydrin, 5-10 parts of pigment and 5-10 parts of modifying additives. The PVC synthetic leather uses agricultural wastes as filling materials, is environmentally-friendly, can improve the air permeability and toughness and is suitable for practical production use, and energy can be saved.

Owner:ANHUI HUIAN ARTIFICAL LEATHER

Photoresist detergent composition

InactiveCN101750911AEasy to cleanImprove solubilityOrganic detergent compounding agentsNon-surface-active detergent compositionsSemiconductor chipMetallic materials

The invention discloses a photoresist detergent composition, which comprises quaternary ammonium hydroxides, water, alkyl glycol ether with 3 to 18 alkyl glycol carbon atoms, dimethyl sulfoxide, and at least one corrosion inhibitor selecting from citric acid, tricaprylyl citrate and citrate. The photoresist detergent composition can also comprise a polar organic cosolvent, a surface active agent and / or other corrosion inhibitors. The photoresist detergent composition can remove the photoresist (particularly thick film negative photoresist) with the thickness of over 20 mu m on the metals, metal alloys or dielectric medium substrates, and other etching residues; and meanwhile, the composition has low causticity to the metals such as aluminum, copper and the like and the nonmetallic materials such as silicon dioxide and the like, thus, the composition has good application prospect in the micro-electronics fields such as semiconductor chip cleaning, and the like.

Owner:ANJI MICROELECTRONICS (SHANGHAI) CO LTD

Method for synthesizing trioctyl lemon acid

InactiveCN101245008AReduce dosageNo pollution in the processOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsTRICAPRYLYL CITRATECITRATE ESTER

The invention discloses a method for synthesizing trioctyl citrate, which adopts critric acid and n-octanol as reactants, in the process of ester synthesis, naphthalene sulfonic acid methylal is used as catalyst; after the reaction, the catalyst is filtered out from the materials left after the reaction, and after water washing, caustic washing and distillation, trioctyl citrate can be gained from filter liquid; the method has the advantages that, first, the high yield is high and is about 97.5 to 99.6 percent; second, the catalyst is cheap, and the amount of catalyst which takes up 0.1 to 2.0 percent of the total weight of reaction materials is little; third, the reaction conditions are mild, and the reaction time is short; fourth, the catalyst can be used repeatedly and fifth, no environmental pollution exists.

Owner:EAST CHINA NORMAL UNIVERSITY

Radiation-resisting cable material and preparation method thereof

InactiveCN103613882AGood physical and mechanical propertiesImprove flame retardant performancePlastic/resin/waxes insulatorsMicrocrystalline waxPolyetherimide

The invention discloses a radiation-resisting cable material and a preparation method thereof. The radiation-resisting cable is prepared from the following raw materials in parts by weight: 70-80 parts of SG-4 type PVC (Polyvinyl Chloride) resin, 25-35 parts of polyetherimide, 10-15 parts of ABS (Acrylonitrile Butadiene Styrene), 10-15 parts of magnesium hydrate, 5-10 parts of Phenoxycyclotriphosphazene, 8-12 parts of acetyltrioctylcitrate, 3-5 parts of microcrystalline wax, 4-8 parts of coumarone resin, 5-10 parts of calcium phosphate, 3-6 parts of epoxy octyl stearate, 10-15 parts of calcined clay, 4-8 parts of composite filler, 6-12 parts of precipitated barium sulphate, 0.5-1 part of imarcaptoacetate dioctyltin, 1-2 parts of zinc stearate, 3-6 parts of titanium dioxide, 0.3-0.5 part of a light stabilizer 622, 0.2-0.4 part of a light stabilizer 1084 and 0.5-0.8 part of an antioxidant 264. The cable material disclosed by the invention is excellent in physical and mechanical property, flame retardant property, radiation resistance property and electric property, is capable of working in severe environments in nuclear power plants, is long in service life, and can be widely applied to cables in match with wires in the nuclear power plants.

Owner:立宝莱科技股份有限公司

Heat-resistant insect-proofing polyurethane foam gap filling material

The invention discloses a heat-resistant insect-proofing polyurethane foam gap filling material comprising the raw materials: polyurethane, a styrene-acrylic emulsion, acrylic ester, diphenol propane, xylene, microlite, light calcium carbonate, diatomite, lindane, a talcum powder, zeolite, titanium dioxide, a talcum powder, a cellulose powder, magnesium oxide, nano calcium carbonate, a lamellar-structural mica powder, glass fiber, carbon fiber, quick lime, quartz sand, activated carbon, dichlorinated sodium isocyanurate, sodium potassium tartrate, fumaric acid, glutamine, inulin, borneol, acetyl trioctyl citrate, petroleum sodium sulfonate, sodium lauroyl glutamate, silicone oil, styrene, methyl triethoxysilane, a thickening agent, a silane coupling agent and a foaming agent. The heat-resistant insect-proofing polyurethane foam gap filling material has excellent heat resistant performance and insect-proofing performance.

Owner:CHUZHOU GLOBAL POLYURETHANE TECH CO LTD

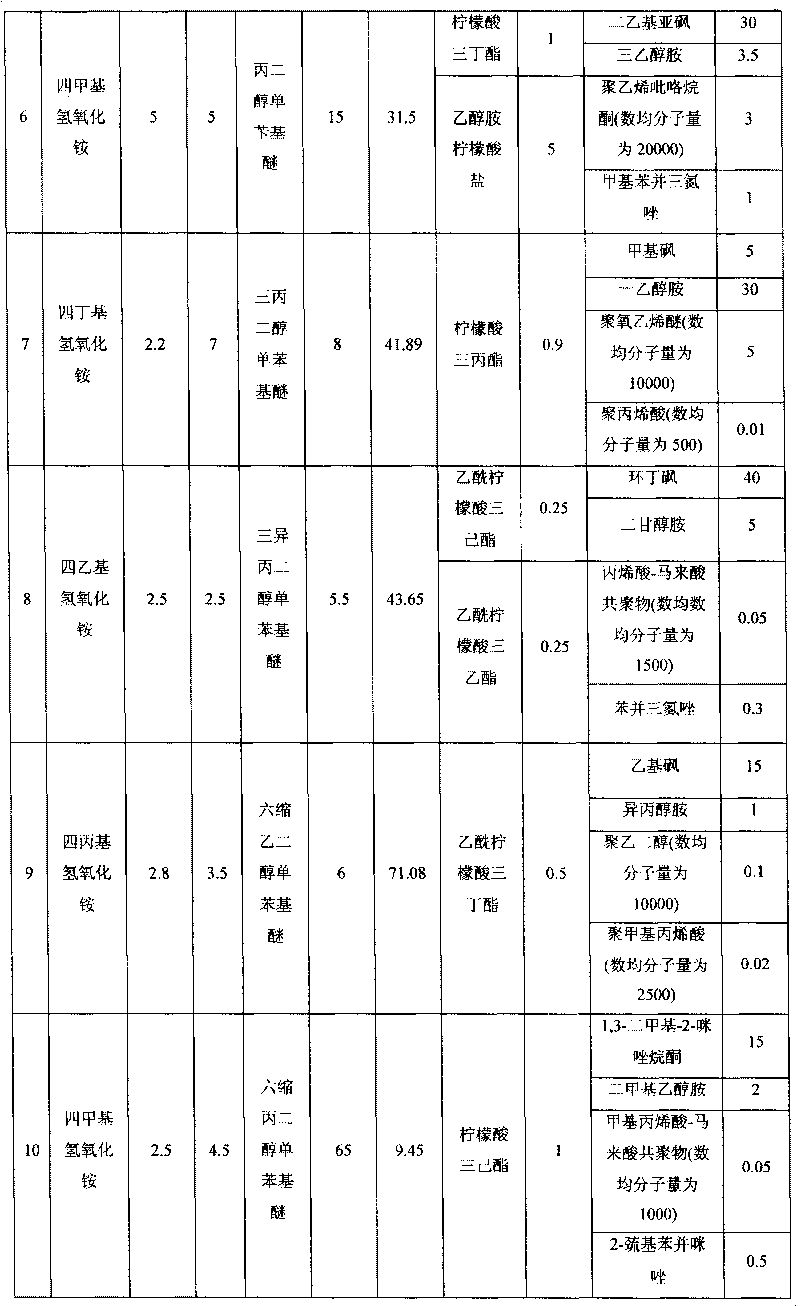

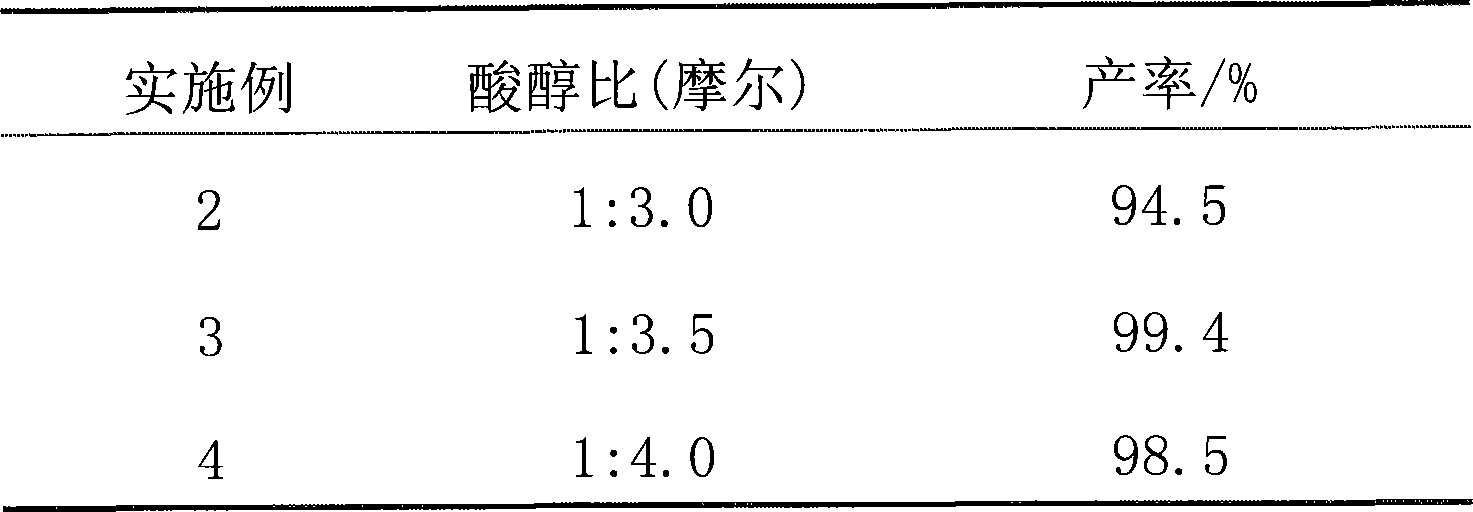

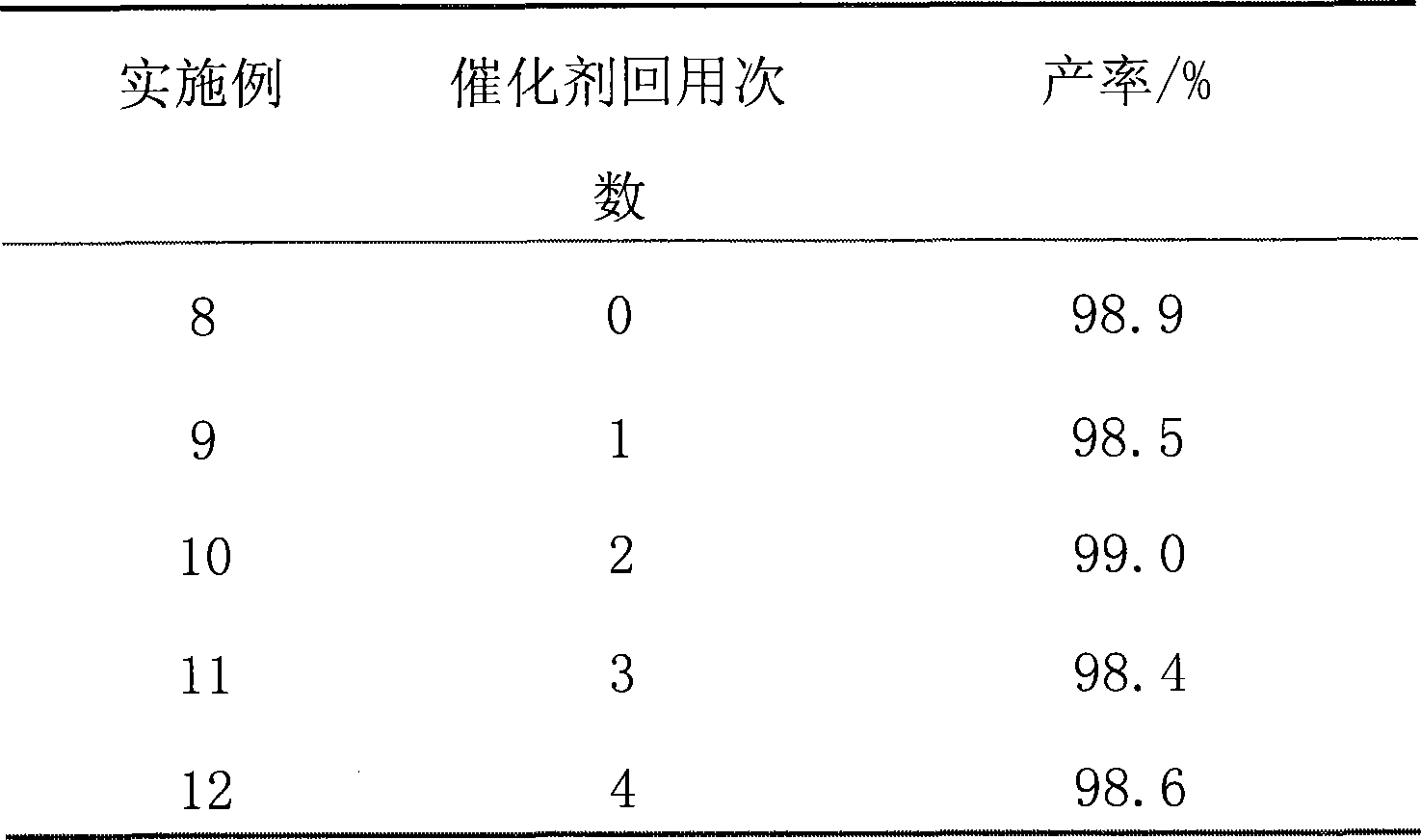

Synthetic method of medicinal acetyl trioctyl citrate

ActiveCN104355995AIncrease profitLow costMolecular sieve catalystsOrganic compound preparationTRICAPRYLYL CITRATEAcetic anhydride

The invention discloses a synthetic method of medicinal acetyl trioctyl citrate, in particular to a method for catalytic synthesis of acetyl trioctyl citrate by using of mesoporous zeolite supported heteropolyacid. The synthetic method comprises the following steps: (1), citric acid and n-caprylic alcohol are used as raw materials, mesoporous zeolite supported heteropolyacid is used as catalyst, after complete reaction, the obtained reaction mixture layers naturally, and n-caprylic alcohol and water in the mixture are distilled out under reduced pressure directly to obtain a crude product; (2), adding acetic anhydride into the crude product obtained in step (1), after complete reaction, the reaction mixture is left to stand for layering, the substance in the upper layer is subjected to distillation under reduced pressure to obtain a coarse product, and the coarse product is refined and purified to obtain the finished product of acetyl trioctyl citrate. The method provided by the invention is mild in reaction condition and short in reaction time; the same catalyst is used in the reaction of two steps and can be reused, so that the method is suitable for industrial production; besides, the product esterification rate is high, the product yield is high, the quality is good, and the microbial limit is controlled effectively.

Owner:HUNAN ER KANG PHARMA

White emulsion with improved water-resistant performance

InactiveCN108676526AImprove water resistanceHigh bonding strengthNon-macromolecular adhesive additivesGraft polymer adhesivesAdditive ingredientCarvacryl acetate

The invention relates to the technical field of an adhesive, in particular to white emulsion with improved water-resistant performance. The white emulsion is prepared from the following ingredients ofpolyvinyl acetate, vinyl acetate, polyvinyl alcohol, glycol, water-resistant modified starch, dibutyl phthalate, vinyl versatate, an emulsifier, an initiator, lyophobic filling materials, a plasticizer, N-hydroxymethyl acrylamide and water, wherein the lyophobic filling materials are mixed inorganic filling materials of nanometer calcium carbonate, roasted kaolin and montmorillonite subjected tohydrophobic modification; the emulsifier is sodium dodecyl benzene sulfonate or sodium oleate; the plasticizer is tributyl citrate or acetyl trioctyl citrate; the initiator is one kind of materials from potassium peroxodisulfate, ammonium persulfate and hydrogen peroxide. The white emulsion has the advantages that the bonding performance is good; the curing time is shorter; the water-resistant performance is excellent; tackless cannot easily occur in the damp environment.

Owner:HEFEI GUANGMIN BUILDING MATERIAL CO LTD

Sound insulation composite material of bamboo fibrofelt and polypropylene and preparing method thereof

ActiveCN101770773AImprove adhesionImprove sound insulation performanceSynthetic resin layered productsSound producing devicesTRICAPRYLYL CITRATEPolypropylene

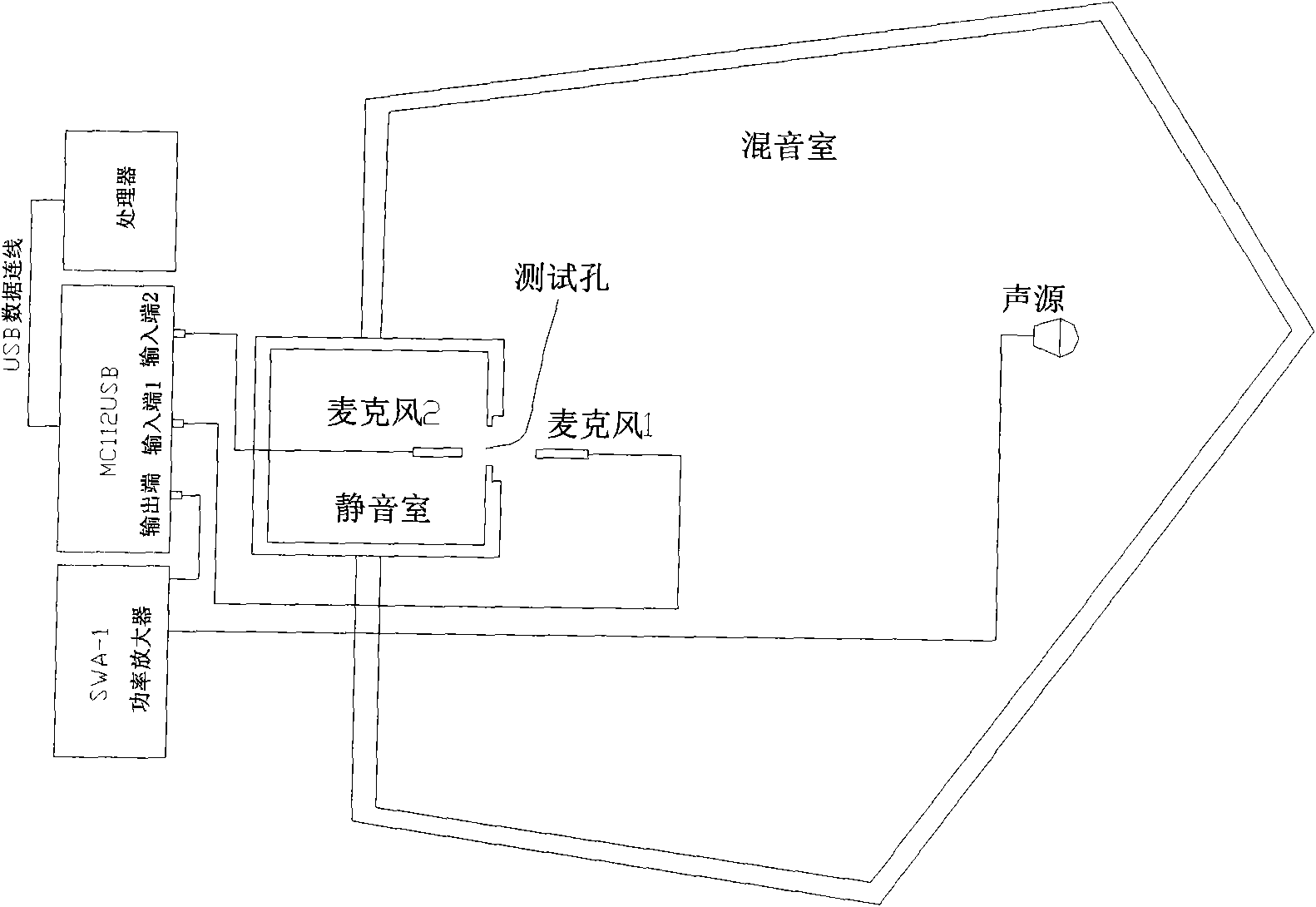

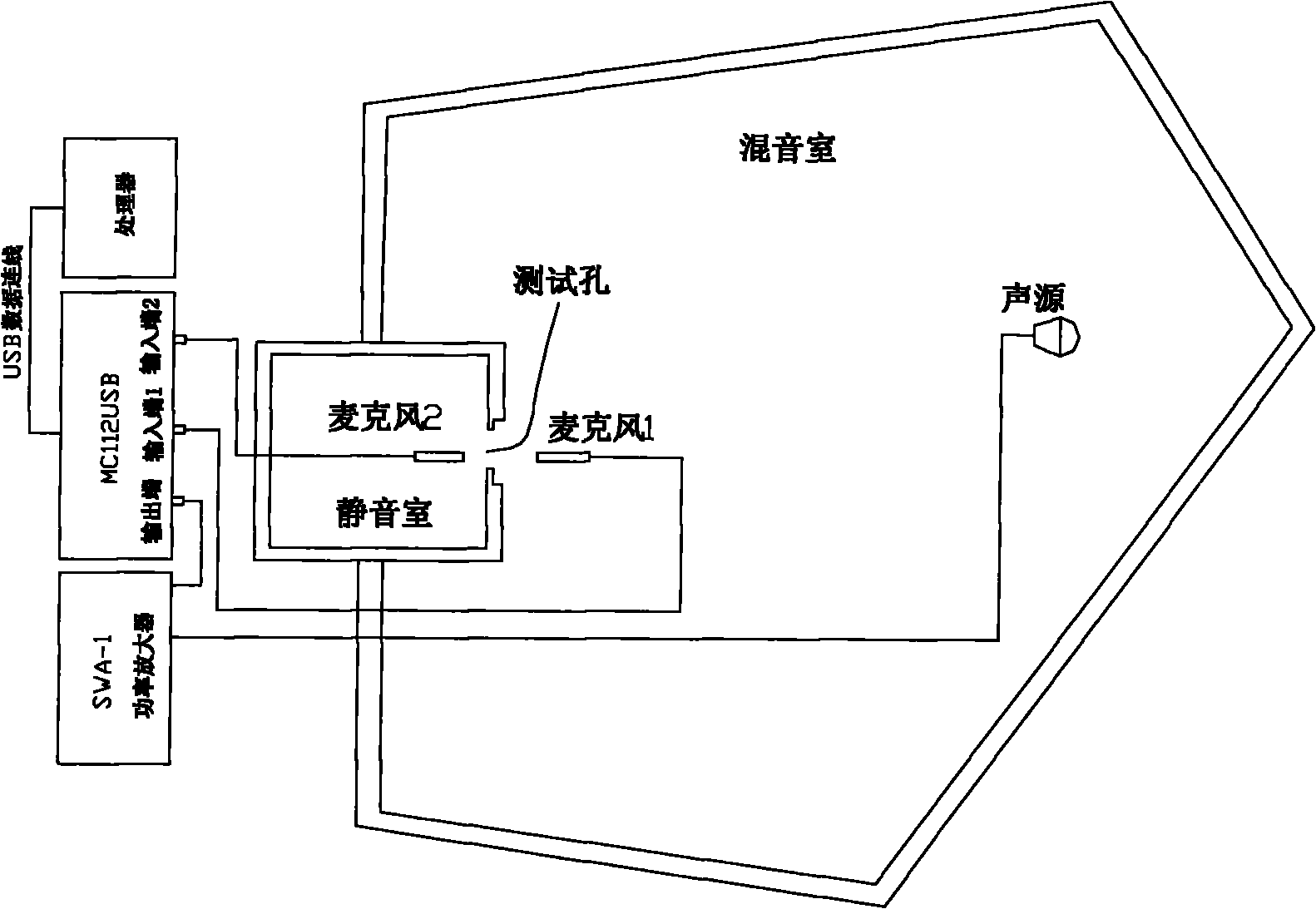

The present invention relates to a sound insulation composite material of bamboo fibrofelt and polypropylene and a preparing method thereof. The material is prepared from 50 to 70% by weight of bamboo fibrofelt mixture and 30 to 50% by weight of polypropylene mixture. The hot press forming technique of the material comprises the following steps: bamboo fibrofelt is first processed by tricaprylyl citrate with a proper technique, and the bamboo fibrofelt processed is immersed by polypropylene mixture prepared and molded by hot pressing. The sound insulation composite material of bamboo fibrofelt and polypropylene has the advantages of good sound and heat insulation properties, relatively small material shrinkage and torsion, high size stability and good processability. The properties of the material obviously reach the properties of the existing sound insulation composite material of fiber reinforced resin. The material can be broadly used in the industry of automobiles, buildings, ships, home decoration, industrial packaging, etc for replacing early sound insulation materials, such as glass fiber composite materials. The preparing method of the sound insulation composite material of bamboo fibrofelt and polypropylene is simple in techniques and can be realized by conventional equipment.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Al-pillared paligorskite modified solid acid catalyst and preparation and application thereof

InactiveCN101406842APhysical/chemical process catalystsOrganic compound preparationTRICAPRYLYL CITRATECITRATE ESTER

The invention provides an al-pillared palygorskite modified solid acid catalyst, which is obtained by taking palygorskite raw soil (PGS) as a carrier, preparing al-pillared palygorskite (Al-PGS) by an ion exchange method and then modifying the Al-PGS through SO4<2->. The larger specific surface area of palygorskite can effectively improve the effective active acid site of the acid catalyst in catalytic reaction; meanwhile, the acid catalyst can be better contacted with reaction substrates in the catalytic reaction through good adsorption performance of palygorskite clay, so as to be the acid catalyst which is good in performance and takes the palygorskite as the carrier. When the al-pillared palygorskite modified solid acid catalyst (SO4<2-> / Al-PGS) is used for the catalytic synthesis reaction of trioctyl citrate, the esterification rate of the trioctyl citrate is 99.1 percent. The catalyst still has good catalytic activity after the catalyst is continuously used for five times, thereby showing that the catalyst is worthy to be reclaimed.

Owner:NORTHWEST NORMAL UNIVERSITY

High temperature resistant and wear resistant rubber material for oil sealing

The invention discloses a high temperature resistant and wear resistant rubber material for oil sealing. The rubber material comprises the following raw materials in parts by weight: 50 to 70 parts of hydrogenated nitrile rubber, 30 to 50 parts of fluororubber, 10 to 20 parts of polytetrafluoroethylene, 40 to 60 parts of composite filling material, 10 to 20 parts of microencapsulated red phosphorus, 5 to 15 parts of zinc borate, 20 to 30 parts of ammonium polyphosphate, 15 to 25 parts of acetyl trioctyl citrate, 1 to 3 parts of benzoyl peroxide, 0.2 to 0.4 part of dibutyl tin dilaurate, 0.3 to 0.5 part of promoter D, 0.1 to 0.2 part of promoter ZDC, 1 to 2 parts of Ca / Zn composite stabilizer, 1 to 2 parts of dibutyl tin dichloride, 1 to 2 parts of rare earth stabilizer, 0.2 to 0.4 part of anti-aging agent MB, 0.2 to 0.4 part of anti-aging agent 445, and 2 to 4 parts of montan wax; wherein the composite filling material comprises aerosil, modified molybdenum disulfide, modified graphite, and modified silicon carbide.

Owner:宁国天运橡塑制品有限公司

Heat-resistant anticorrosion cable

InactiveCN105585782AImprove heat resistanceImprove corrosion resistanceInsulated cablesInsulated conductorsElastomerInsulation layer

The invention discloses a heat-resistant anticorrosion cable. The heat-resistant anticorrosion cable comprises a conducting wire, a high-temperature-resistant insulation layer covering the conducting wire, a shielding layer covering the high-temperature-resistant insulation layer and a protection layer covering the shielding layer, wherein the protection layer is prepared from the following raw materials: EPDM, silicone rubber, ethylene-acrylic elastomer, fluororubber, modified diatomite, modified white carbon black, ferric oxide, acetyl trioctyl citrate, 2-ethyl hexyl ester of epoxidized soybean oil, zinc borate, magnesium hydroxide, expansible graphite, maleic anhydride grafted compatilizer, sulfur, 2,5-dimethyl-2,5-di(tert-butylperoxy)hexane, triallyl cyanurate, Ca / Zn composite stabilizer, antioxidant 1010, anti-aging agent 264 and polyethylene wax. The heat-resistant anticorrosion cable is good in corrosion resistance and good in heat resistance.

Owner:繁昌县菲德通讯材料设计有限公司

Radiation-resistant cable insulation material for nuclear power plant

InactiveCN104672628AEvenly dispersedImprove radiation resistanceRubber insulatorsEthyl butyrateTert butyl

The invention discloses a radiation-resistant cable insulation material for a nuclear power plant. The radiation-resistant cable insulation material comprises the following raw materials in parts by weight: 100-120 parts of EPDM, 70-80 parts of fluorinated silicone rubber, 30-40 parts of polyimide, 10-20 parts of ETFE, 20-30 parts of lead oxide, 20-40 parts of rare earth oxide, 15-25 parts of zinc oxide, 5-15 parts of boron nitride, 18-22 parts of titanium nitride, 10-15 parts of organic bentonite, 35-45 parts of mica powder, 2-3 parts of di-(di-octyl phosphite) tetraisopropyl titanate, 2-5 parts of 3,3-bi-(tert-butyl peroxide) ethyl butyrate, 0.4-1 part of sulfur powder, 0.5-1 part of TAIC, 0.8-1.4 parts of HVA-2, 2-4 parts of sodium cinnamate, 4-6 parts of magnesium oxide, 2-5 parts of acetyl trioctyl citrate, 3-6 parts of stearic acid, 2-5 parts of anti-aging agent 1010-A and 1-2 parts of anti-aging agent D-503-4,2-(2'-hydroxyl-3',5'-tert-amyl phenyl) benzotriazole.

Owner:ANHUI SPECIAL CABLE GRP

Anti-aging damping rubber material

The invention discloses an anti-aging damping rubber material. Raw materials of the anti-aging damping rubber material contain, by weight, 40-60 parts of butadiene styrene rubber, 30-50 parts of cis-butadiene rubber, 10-20 parts of ethylene propylene diene monomer, 55-65 parts of a composite filler, 0.5-0.7 part of 3-aminopropyltriethoxysilane, 20-30 parts of melamine phosphate, 10-15 parts of expansible graphite, 10-20 parts of acetyl trioctyl citrate, 10-20 parts of acetyl tributyl citrate, 0.4-0.6 part of dicumyl peroxide, 0.2-0.3 part of stearic acid, 0.1-0.2 part of zinc oxide, 0.1-0.3 part of a promoter CZ, 1-3 parts of a rare earth stabilizer, 1-3 parts of a Ca / Zn compound stabilizer, 0.2-0.4 part of an anti-ageing agent, 0.1-0.3 part of an anti-fatigue agent PL and 2-4 parts of silicone powder. The anti-aging damping rubber material of the invention has good damping performance and good ageing resistance.

Owner:宁国市开源橡塑汽车零部件有限公司

LDPE (low-density polyethylene) antibacterial plastic and preparation method thereof

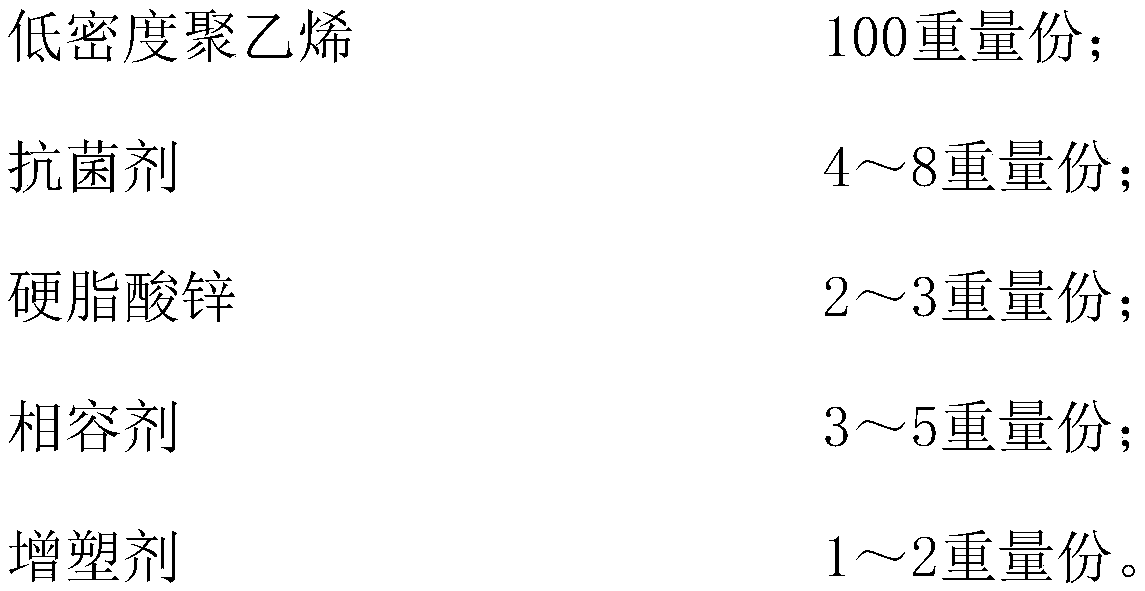

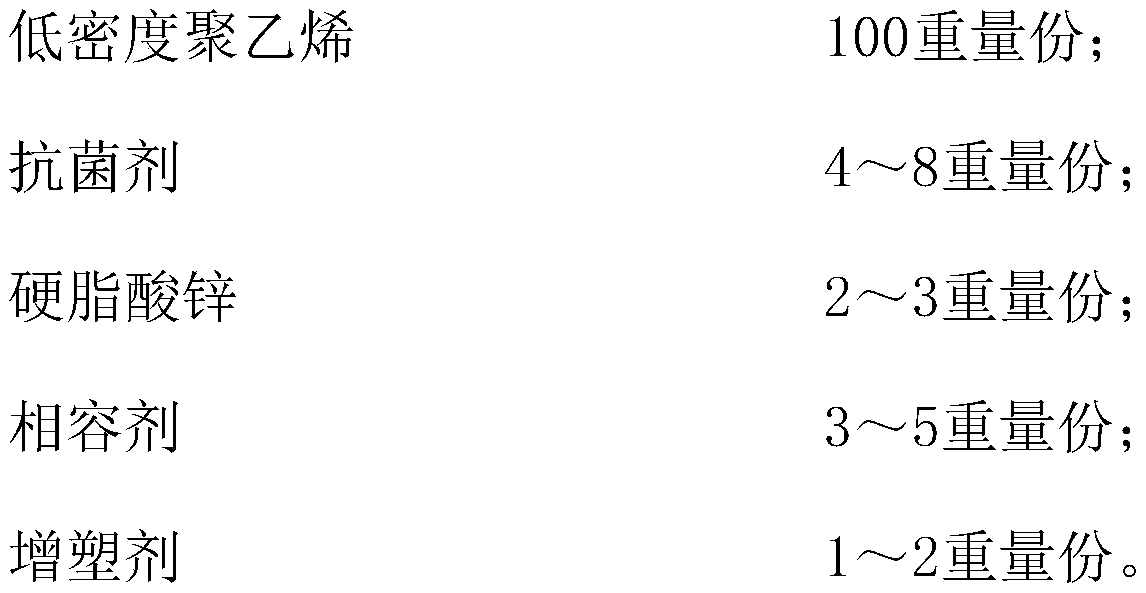

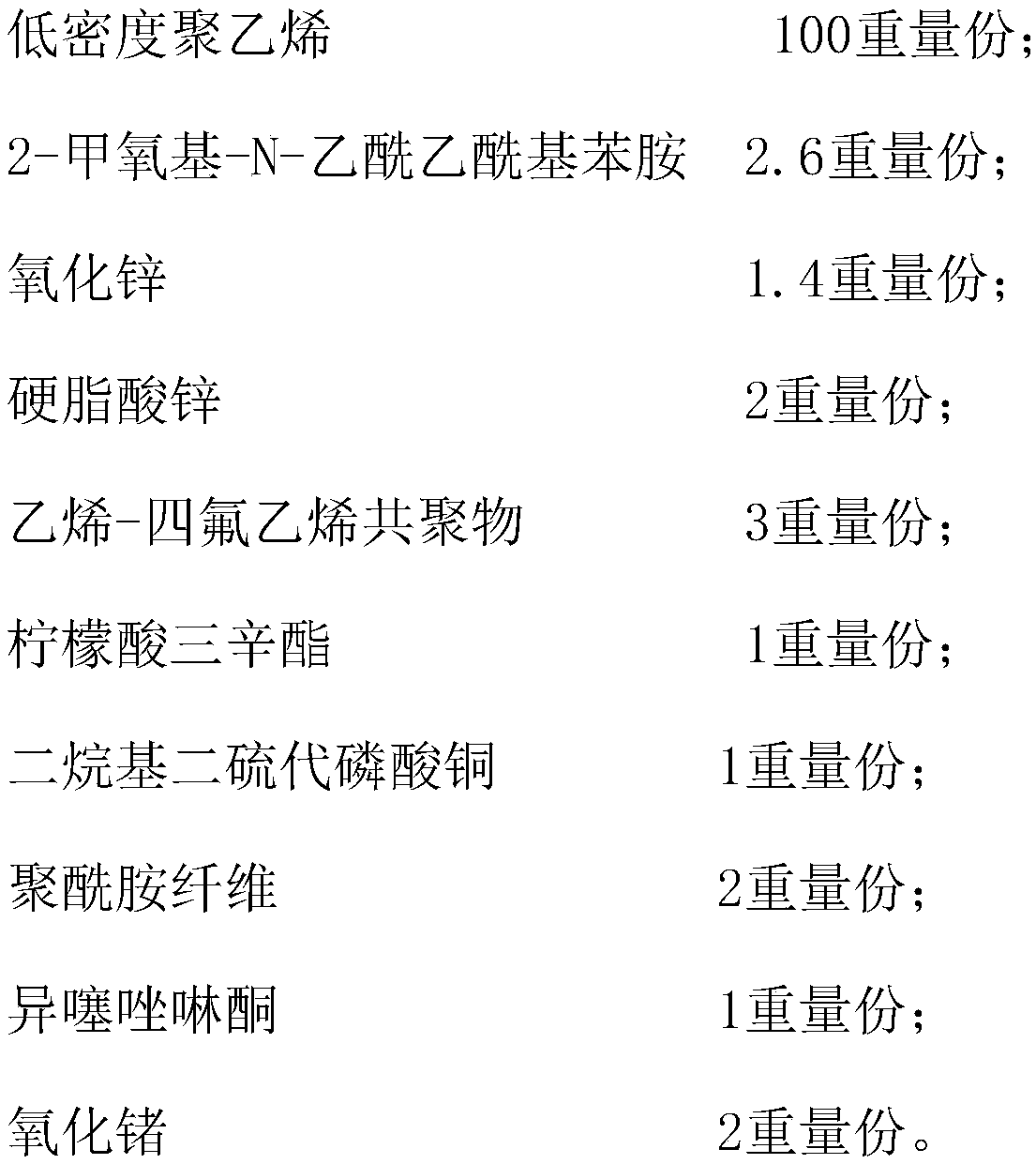

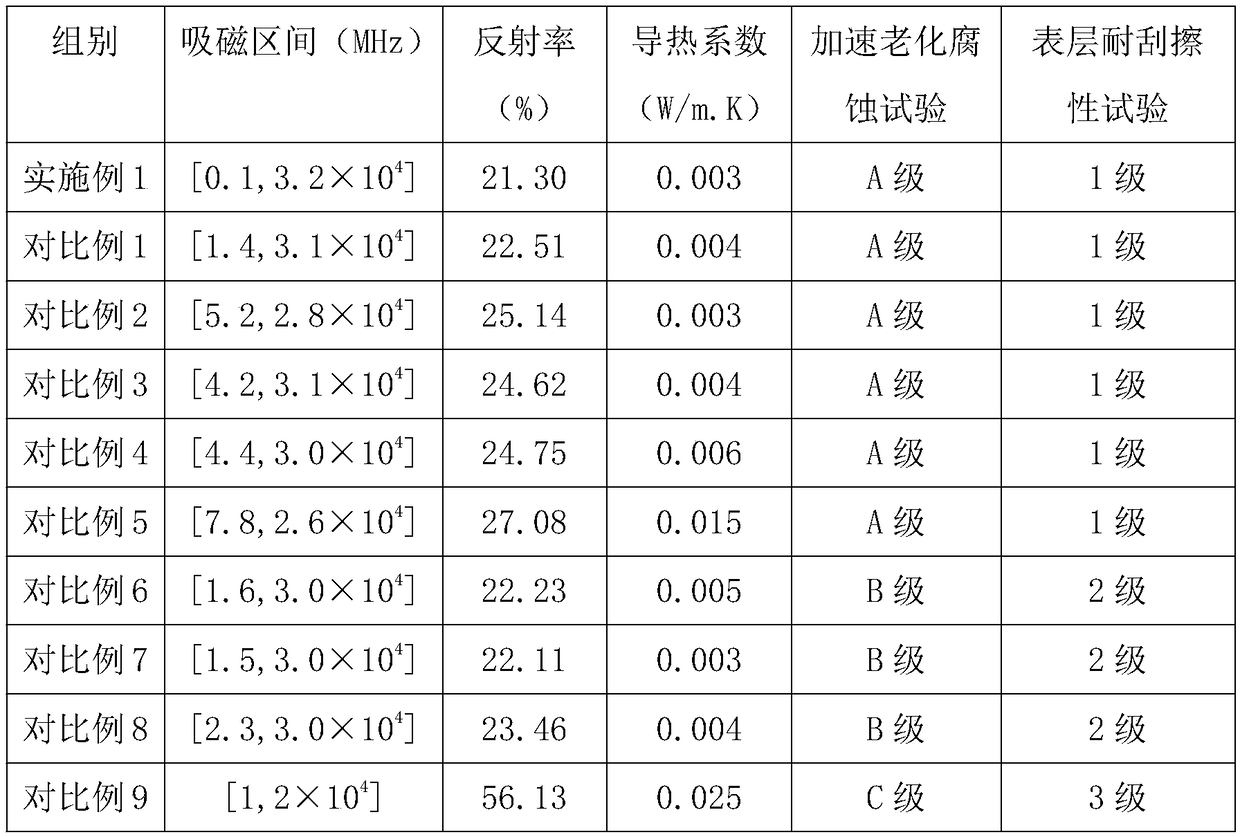

The invention discloses LDPE (low-density polyethylene) antibacterial plastic, which is mainly prepared from the following raw materials in parts by weight: 100 parts of LDPE, 4-8 parts of an antibacterial agent, 2-3 parts of zinc stearate, 3-5 parts of a compatilizer and 1-2 parts of a plasticizer. The LDPE antibacterial plastic adopts 2-methoxy-N-acetoacetyl aniline and zinc oxide as the antibacterial agent, and through reasonable compatibility, the best pathogenic microorganism killing effect and growth inhibiting effect can be achieved; the LDPE is used as a main body, and the zinc stearate can improve the thermostability of the LDPE; an ethylene-tetrafluoroethylene copolymer is used as the compatilizer; the flexibility and easy-processing performance of the LDPE are improved by addingacetyl trioctyl citrate; the antioxidant performance of the LDPE is improved by adding dialkyl copper dithiophosphate; mechanical properties, heat resistance, abrasion resistance, chemical resistance, flame retardance and easy-processing performance of the LDPE are improved by adding polyamide fibers.

Owner:NANTONG YIXUAN IND DESIGN CO LTD

Water-blocking and oil-blocking fully degradable plastic film used for food packaging and preparation method thereof

InactiveCN105001459ASmall particle sizeExcellent gas barrier propertiesPolycaprolactoneBUTYL LACTATE

The invention discloses a water-blocking and oil-blocking fully degradable plastic film used for food packaging. The water-blocking and oil-blocking fully degradable plastic film is characterized by being prepared from, by weight, 60-65 parts of corn starch, 7-9 parts of nano-montmorillonite, 0.6-0.7 part of peanut oil, 1.2-1.4 parts of tetrabutyl titanate, 12-14 parts of ramie sticks, 30-35 parts of poval, 9-12 parts of polycaprolactone, 12-15 parts of trioctyl citrate, 2.5-3 parts of sodium alginate, 3-5 parts of calcium carbonate, 2-3 parts of butyl lactate and 1-1.5 parts of sodium trimetaphosphate. Poval of the appropriate amount is added to be matched with the starch-based material, then the trioctyl citrate and the butyl lactate are added to be blended, the melting point of the poval can be reduced, which is more beneficial for industrial production, the strength and flexibility are improved, and the prepared film is solid and durable; the plastic film can be applied to food packaging and cleaning bags and the like and be fully degraded and therefore is worthy of large-area popularization.

Owner:TONGLING FOUNDER PLASTICS TECH

Pipe for municipal ecological garden greening drainage construction

The invention relates to a pipe for municipal ecological garden greening drainage construction. The pipe is prepared from the following components: copper powder, ethylenediamine, acetone, butantriol, magnesium oxide, chloroprene rubber, titanium dioxide, wollastonite powder, polyethylene polyamine, novolac epoxy resin, sodium lauroyl sarcosine, sodium hydrogen sulphite, rosin resin, ethylene bisstearamide, benzidine, polyoxyethylene monolaurate, phosphonitrilic chloride trimer, acrylic resin, sodium stearate, dilauryl thiodipropionate, acetyl trioctyl citrate, dibasic lead stearate, castor oil, bisphenol-A diglycidyl ether and metallocene polyethylene. According to the pipe, a plurality of ingredients are mixed with one another to form a novel compound toughening and reinforcing system; the toughness, rigidity and elasticity modulus performance indexes are good; the anti-aging performance and the using performance of a product are greatly improved; the pipe has a good corrosion resisting effect, good comprehensive performance and a good using effect.

Owner:龚灿锋

Citric acid mixed ester production method

PendingCN112209824ANo precipitationHigh activityOrganic compound preparationCarboxylic acid esters separation/purificationTRICAPRYLYL CITRATEPtru catalyst

The present invention relates to the technical field of plasticizers, and discloses a citric acid mixed ester production method, which comprises the steps of: an esterification process; a neutralizingand washing process; a steam stripping process; and a filtration process. According to the citric acid mixed ester production method, concentrated sulfuric acid is adopted as a catalyst, the catalystactivity is high, the reaction temperature is low, the reaction speed is high, the catalyst cost is low, the esterification synthesis temperature is controlled within 145 DEG C, it is ensured that the color number of the produced mixed citrate product is within 45, the market use requirement is met, and by adjusting the added butanol according to the market requirement, tetrabutyl citrate, dibutyl-octyl citrate, monobutyl dioctyl citrate and trioctyl citrate in different proportions can be obtained according to the octanol proportion, it is ensured that the produced citric acid mixed ester does not have the phenomena of precipitation and oil seepage in the using process, meanwhile, the using requirements of production of different customers are met, an intermittent esterification processis adopted, the operation elasticity is high, the strain capacity is high, and market requirements can be met.

Owner:山东朗晖石油化学股份有限公司

Modified organic glass with excellent toughness and preparing method thereof

The invention discloses modified organic glass with excellent toughness. The modified organic glass is prepared from methyl methacrylate, modified polybutyl acrylate, blocked type polyether F-68, benzoyl peroxide, triethylene glycol, hydroxyethyl methylacrylate, dibutyltin dilaurate, toluene diisocyanate, hexamethylene diisocyanate, azodiisobutyronitrile, ethylene propylene terpolymer, polyvinylbutyral, mercaptopropionic acid, hydroxypropyl methyl cellulose, trioctyl citrate, hexamethylphosphoric triamide, polyaspartic acid, isopropylxanthic disulfide, calcined kaolin, a silane coupling agent KH-570 and nanosilicon dioxide. The invention further provides a preparing method of the modified organic glass with the excellent toughness. The prepared modified organic glass has excellent toughness.

Owner:安徽亚克力实业有限公司

Environment-friendly cement expanding agent

The invention discloses an environment-friendly cement expanding agent and belongs to the technical field of concrete addition agents. The expanding agent is prepared from, by weight, 15-20 parts of acetyl trioctyl citrate, 1-3 parts of phenethyl cumenyl phenol polyoxyethylene ether, 5-15 parts of alunite, 2-6 parts of aluminum-oxygen clinker, 10-30 parts of calcium sulphoaluminate, 4-12 parts of aluminum slag, 1-5 parts of calcium carbonate powder, 4-12 parts of nanometer aluminum titanate fibers and 8-16 parts of pitchstone ore sand. The environment-friendly cement expanding agent is high in expansion rate, low in alkalinity content and capable of improving the concrete performance, concrete cracking is prevented, meanwhile, leakage is reduced, the strength is improved, the price is low, the production process is simple, the cost is low, and the expanding agent is suitable for large-scale production.

Owner:王嘉文

Rubber material for processing automobile wiper blade

The invention discloses a rubber material for processing an automobile wiper blade, and belongs to the technical field of automobile parts. The rubber material is prepared from, by weight, 60-65 parts of nitrile butadiene rubber, 15-20 parts of ethylene-propylene-diene monomer rubber, 15-20 parts of polyacrylic acid, 10-15 parts of coal gangue powder, 8-12 parts of sea-foam stone powder, 6-10 parts of hydrogenated rosin, 6-10 parts of dimethicone, 5-8 parts of polyethylene wax, 4-6 parts of sulfated castor oil, 4-6 parts of bonding agent, 3-5 parts of trioctyl citrate, 2-4 parts of oleamide, 1-2 parts of magnesium hydrate and 0.1-0.2 part of rare earth. The rubber material has excellent abrasive resistance and excellent weather resistance, the service life is long, the glass attaching performance is good, glass can not be scratched in use, and functionality is high. As the bonding agent is added, the bonding performance of raw materials can be further improved, and rubber mixing and vulcanizing are convenient.

Owner:安徽振海重工机械有限公司

Degradable plastic

InactiveCN106189145AHigh tensile strengthHigh elongation at breakLow-density polyethyleneLinear low-density polyethylene

The invention discloses a degradable plastic which is prepared from polylactic resin, modified poly-beta-hydroxybutyric acid PHB, diisononyl phthalate DINP, unsaturated polyester resin, pea albumen powder, oxidized corn starch, alkaline hargil, calcium carbonate, ramie, linear low density polyethylene grafted maleic anhydride, gamma-glycidoxy propyl trimethoxy silane, methyl methacrylate butadiene styrene copolymer, aluminium potassium sulfate, tricaprylyl citrate, ethylene-vinyl acetate copolymer, ethylene bis oleamide, diphenylmethane diisocyanate, antimycotic antibacterial agent, degradation agent, antioxidant, stabilizing agent, flame retardance, smoke inhibitor, thickening agent, softening agent and ultraviolet light absorber. The degradable plastic has good tensile strength and elongation at break, is good in impact resistance, low in hydroscopicity and good in light transmission, can be completely degraded into carbon dioxide and water after 136-140 days, and no harm is produced to environment.

Owner:冯可发

High temperature-resistant full-degradable plastic film and preparation method thereof

The invention discloses a high temperature-resistant full-degradable plastic film. The high temperature-resistant full-degradable plastic film is prepared from following raw materials, by weight, 60 to 65 parts of corn starch, 7 to 9 parts of nano montmorillonite, 0.6 to 0.7 part of peanut oil, 1.2 to 1.4 parts of tetrabutyl titanate, 12 to 14 parts of ramie straw, 30 to 35 parts of polyvinyl alcohol, 12 to 15 parts of trioctyl citrate, 1 to 2 parts of 2,6-tributyl-4-methyl benzol, 2 to 4 parts of polyimide, 4 to 6 parts of nano cerium oxide, and 2 to 3 parts of liquid silicon. According to a preparation method, the prior art is modified, the obtained preparation method is convenient for operation, and is beneficial for realization of industrial large-scale production; the raw materials are easily available; the obtained high temperature-resistant full-degradable plastic film possesses high temperature resistance and water resistance, is suitable to be taken as industrial packaging materials, and food packaging materials, can be made into clean bags, and is solid and durable; degradation can be realized under natural conditions after discarding; and no pollution is caused.

Owner:TONGLING FOUNDER PLASTICS TECH

Lubricant automotive windscreen washer fluid

InactiveCN104845778AExcellent decontaminationImprove the lubrication effectOther chemical processesSurface-active non-soap compounds and soap mixture detergentsControl theoryMaterials science

The invention discloses a lubricant automotive windscreen washer fluid. The lubricant automotive windscreen washer fluid is prepared from the following raw materials in parts by weight: 6-8 parts of expansile graphite, 10-18 parts of polyphenol, 12-16 parts of trioctyl citrate, 2-3 parts of polyoxyethylene lauryl ether, 4-6 parts of sodium metaborate, 10-20 parts of carnauba wax, 4-7 parts of beewax, 3-7 parts of triethanolamine oleate, 2-4 parts of sodium hydroxide, 4-7 parts of organic nano-montmorillonite, 3-5 parts of aluminum oxide, 4-7 parts of straight-chain paraffin, 2-5 parts of a rust remover and 4-9 parts of ethylene glycol. The lubricant automotive windscreen washer fluid has the beneficial effects that the fluid has the excellent functions of decontaminating, preventing freezing and preventing corrosion, is extremely excellent in lubricity, can be used for effectively reducing friction, and has a great significance to the driving safety.

Owner:QINGDAO KANGTAIXIN ENVIRONMENTAL PROTECTION TECH

Heat-proof insect preventing modified polyurethane thermal insulation composite board

InactiveCN106046758AImprove tensile propertiesImprove wear resistanceClimate change adaptationBuilding componentsPotassium sodium tartrateCement board

The invention discloses a heat-proof insect preventing modified polyurethane thermal insulation composite board which comprises a gypsum board layer, a thermal insulation board layer and a cement board layer sequentially arranged from inside to outside, wherein the thermal insulation board layer is prepared from the following raw materials: modified polyurethane, a styrene-acrylic emulsion, acrylate, polyvinylidene fluoride resin, organic silicon resin, microlite, light calcium carbonate, kieselguhr, chlorinated paraffin, talc powder, zeolite, titanium dioxide, talc powder, cellulose powder, magnesium oxide, nano calcium carbonate, mica powder, glass fiber, carbon cellulose, quicklime, quartz sand, active carbon, sodium dichloroisocyanurat, potassium sodium tartrate, fumaric acid, glutamine, inulin, borneol, trioctyl acetylcitrate, petroleum sodium sulfonate, sodium lauroyl glutamate, silicone oil, styrene, methyl triethoxy silane, a thickening agent, a silane coupling agent and a foaming agent. The heat-proof insect preventing modified polyurethane thermal insulation composite board disclosed by the invention has excellent heat resistance and insect preventing property.

Owner:ANHUI GUANGYAN NEW MATERIAL TECH

Flame retardant polyurethane sealant

ActiveCN104327785ANon-flammableImprove flame retardant performanceNon-macromolecular adhesive additivesOther chemical processesSilicon dioxidePhenol

The invention discloses a flame retardant polyurethane sealant. The flame retardant polyurethane sealant comprises polyurethane resin, a flame retardant, a coupling agent, filler, a plasticizer and a dispersant, wherein the flame retardant is 2,2-bis(3,5-dibromo-4-hydroxyphenyl) propane; the coupling agent is di(octyl phenol polyoxyethylene ether) phosphide; the filler is silicon dioxide; the plasticizer is acetyl trioctyl citrate; the dispersant is polyethylene wax. The flame retardant polyurethane sealant is prepared from the polyurethane resin, the flame retardant, the coupling agent, the filler, the plasticizer and the dispersant; the prepared flame retardant polyurethane sealant is unlikely to combust, good in flame resistance, ageing-resistant, convenient to process, stable in quality and low in cost.

Owner:佛山市元通胶粘实业有限公司

Corrosion-resistant engineering polymer material and preparation method thereof

The invention discloses a corrosion-resistant engineering polymer material and a preparation method thereof. The material is prepared from the following components in parts by weight: 18-23 parts of polyether ether ketone resin, 7-11 parts of polyacrylonitrile, 5-8 parts of polytrifluorochloroethylene, 4-7 parts of polyvinyl cinnamate, 4-6 parts of polyethylene glycol dimethacrylate, 4-5 parts of glycidyl neodecanoate, 6-7 parts of polyglycerol polyricinoleate, 4-5 parts of chlorohydrin rubber, 5-8 parts of trioctyl citrate and 3-4 parts of calcium nitride. The preparation method comprises the following steps: (1) adding the components into a stirring machine to be mixed and stirred; (2) performing melt extrusion on the uniformly stirred components obtained in the step (1), pelletizing, and cooling to obtain the corrosion-resistant engineering polymer material. The prepared corrosion-resistant engineering polymer material is resistant to acid and alkali, as well as bending, and wide in the application range.

Owner:苏州凯欧曼新材料科技有限公司

Wall body coating composition

InactiveCN108624159AEasy to prepareGood compatibilityAntifouling/underwater paintsPaints with biocidesFiberCross-link

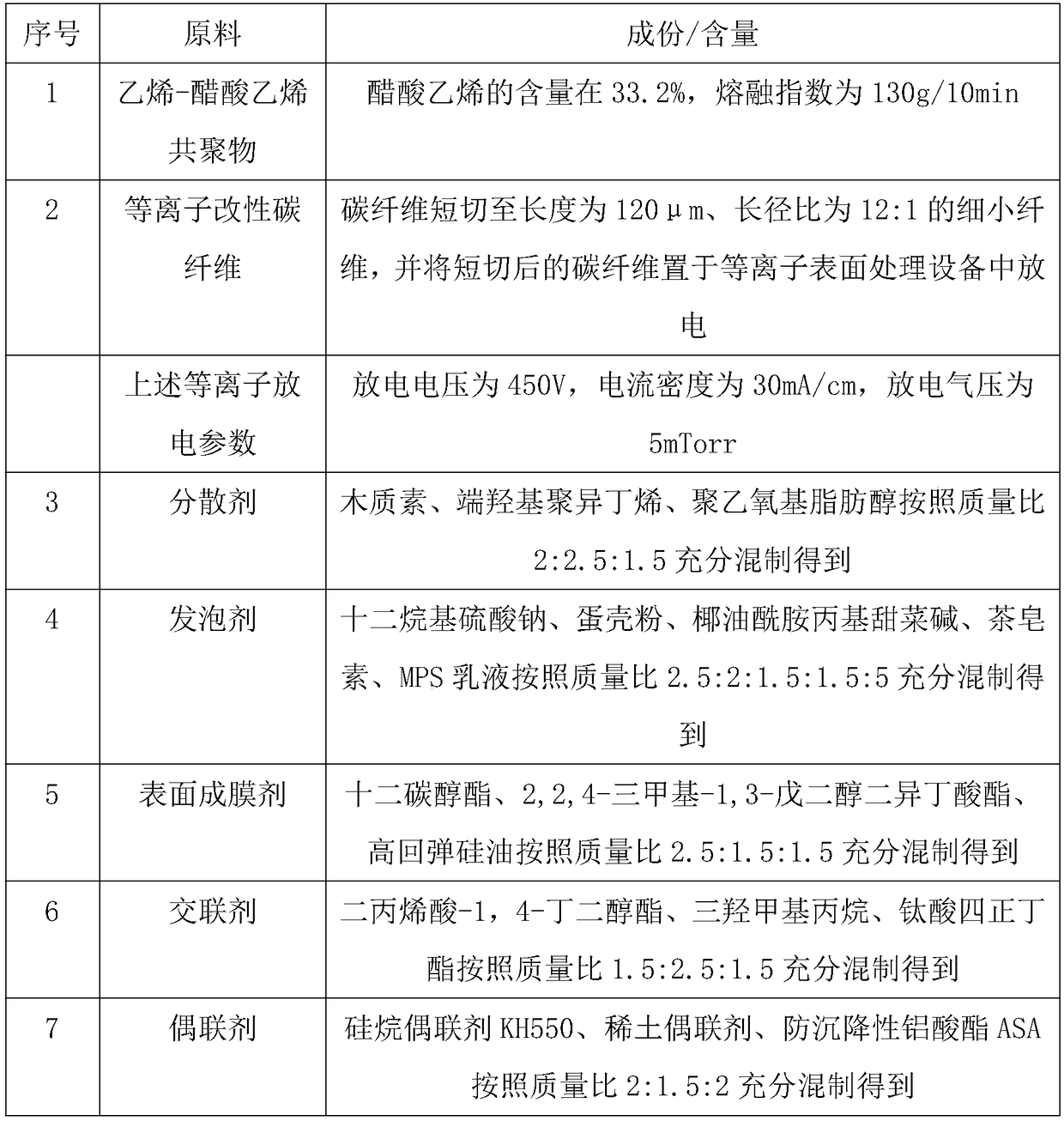

The invention discloses a wall body coating composition and relates to the technical field of coatings. The wall body coating composition consists of the following raw materials: a styrene-acrylic emulsion, a vinyl-vinyl acetate copolymer, plasma-modified carbon fibers, niobium and yttrium ore powder, porous basalt, chlorite, expanded graphite, Wudalianchi volcanic gray matters, ITO powder, acetyltrioctyl citrate, diacetone acrylamide, cyclohexanol, magnetized water, a dispersing agent, a foaming agent, a surface film forming agent, a cross-linking agent and a coupling agent. The wall body coating composition disclosed by the invention is simple to prepare, green and environmentally-friendly, has excellent durability and functionality and solves the problem of environmental pollution caused by electromagnetic wave energy transfer and radiation to a certain extent, thereby greatly reducing the interference damage of electromagnetic waves to surrounding equipment and a human body.

Owner:合肥谦尧建筑装饰工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com