Sound insulation composite material of bamboo fibrofelt and polypropylene and preparing method thereof

A composite material and bamboo fiber technology, applied in the direction of chemical instruments and methods, sound-emitting devices, synthetic resin layered products, etc., to achieve good sound insulation, good processability, and small shrinkage and distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

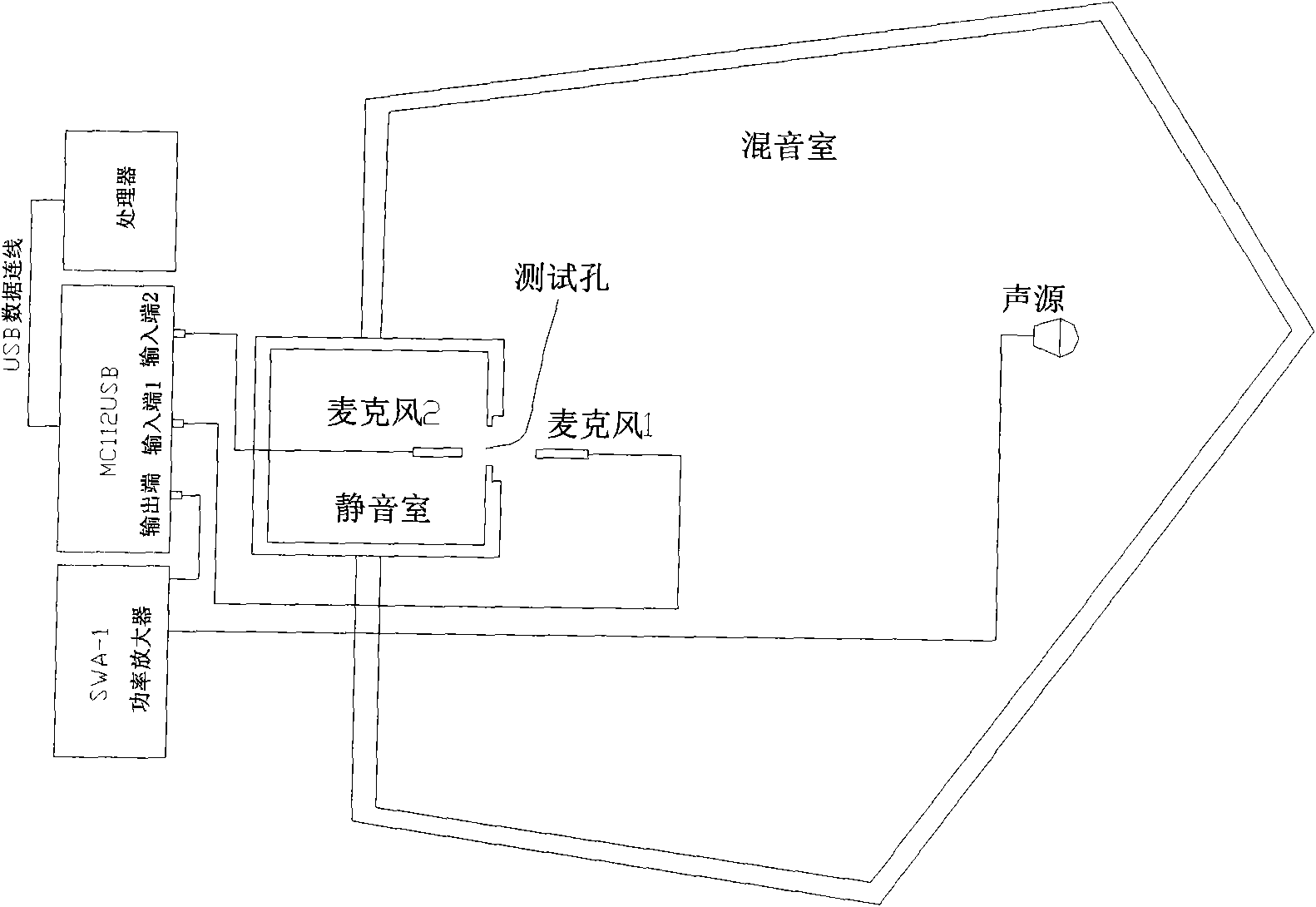

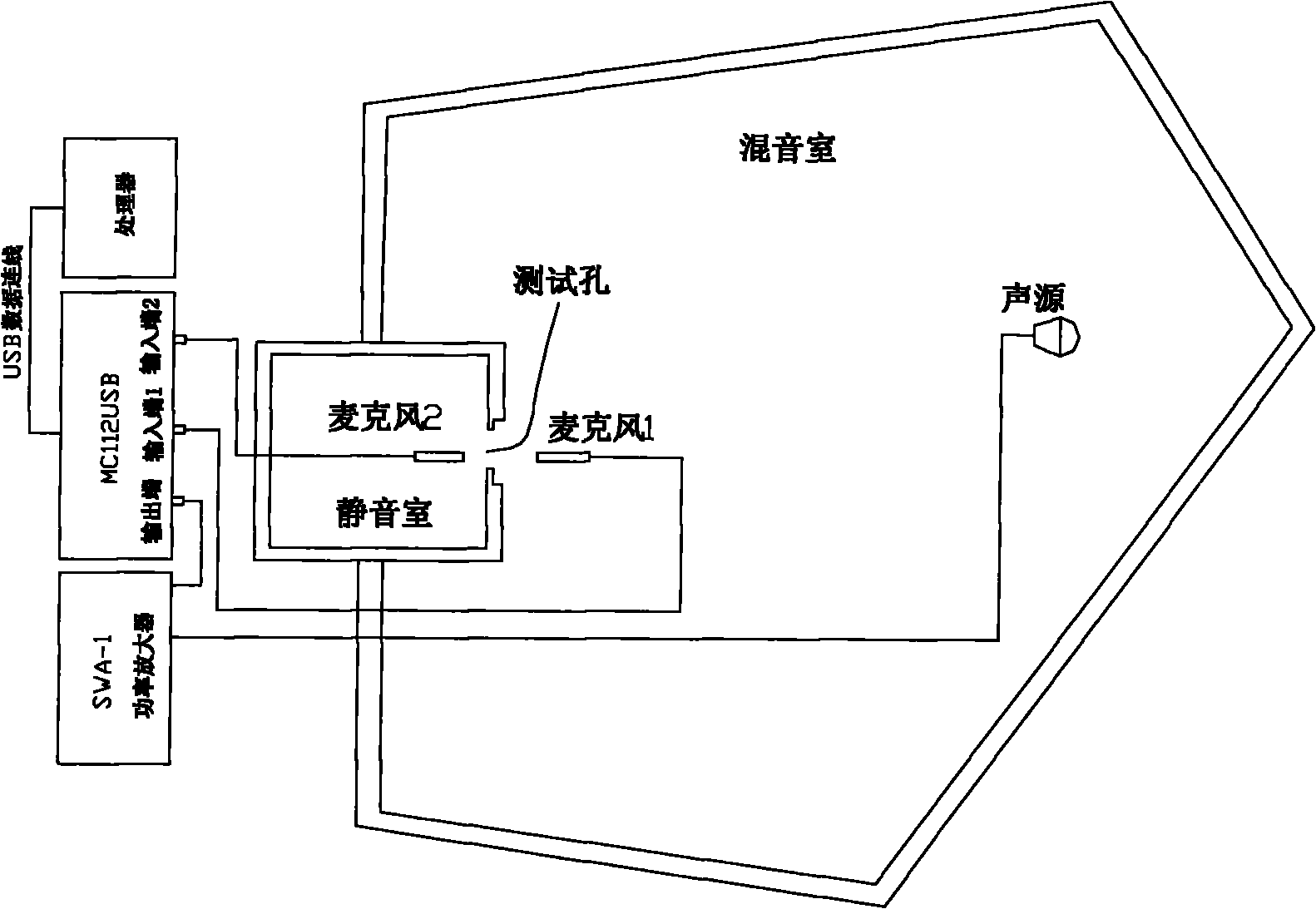

Method used

Image

Examples

Embodiment 1

[0021] The average length of bamboo fiber is 15mm, the average fineness is 500μm, and the surface density is 1.5kg / m 2 Bamboo fiber felt, put it in an oven at 110°C to dry for 20 minutes, take it out and cool to room temperature; then press the bamboo fiber felt every 0.1m 2 Coat 15g of tributyl citrate, evenly coat tributyl citrate on the surface of the bamboo fiber felt, and then spread it on a flat vulcanizer for 30 minutes at normal temperature and pressure at 2MPa, and then take it out under normal pressure. Place it down for 30min to obtain the bamboo fiber felt mixture.

[0022] The average molecular weight is 300,000 and the specific gravity is 0.8g / cm 3 The isotactic polypropylene powder, tributyl citrate and epoxidized soybean oil were uniformly mixed in proportions of 43.2%, 54.3% and 2.5% by weight respectively to obtain a polypropylene mixture.

[0023] The polypropylene mixture is evenly coated on the surface of the bamboo fiber felt mixture, wherein the bamboo...

Embodiment 2

[0038] The average length of bamboo fiber is 27mm, the average fineness is 400μm, and the surface density is 2.7kg / m 2Bamboo fiber felt, put it in an oven at 120°C to dry for 15 minutes, take it out and cool to room temperature; then press the bamboo fiber felt every 0.1m 2 Coat 18g of triethyl citrate, evenly coat triethyl citrate on the surface of the bamboo fiber felt, and then spread it on a flat vulcanizer for 20 minutes at normal temperature and pressure at 3MPa, and then take it out under normal pressure. Place it down for 45min to obtain the bamboo fiber felt mixture.

[0039] The average molecular weight is 400,000 and the specific gravity is 1.0g / cm 3 The isotactic polypropylene powder, tributyl citrate and epoxidized soybean oil were uniformly mixed in proportions of 31%, 65% and 4% by weight respectively to obtain a polypropylene mixture.

[0040] The polypropylene mixture is evenly coated on the surface of the bamboo fiber felt mixture, wherein the bamboo fiber ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com