Heat-resistant anticorrosion cable

A corrosion-resistant and cable technology, applied in the direction of insulating cables, cables, circuits, etc., can solve the problems of high temperature resistance and corrosion resistance that cannot meet the requirements, so as to promote the formation of cross-linked vulcanization and cross-linked networks, and increase high temperature resistance and mechanical strength, the effect of increasing compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

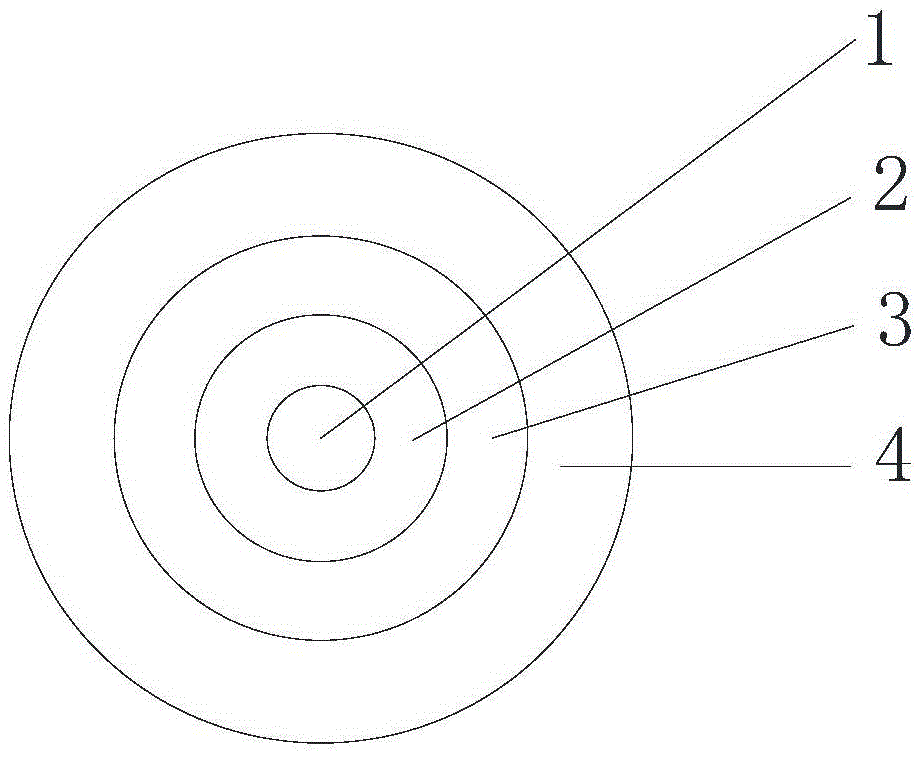

[0021] A heat-resistant and corrosion-resistant cable, comprising a wire, a high-temperature-resistant insulating layer covering the wire, a shielding layer covering the high-temperature-resistant insulating layer, and a protective layer covering the shielding layer;

[0022] Among them, the raw materials of the protective layer include by weight: 50 parts of EPDM rubber, 30 parts of silicone rubber, 10 parts of ethylene acrylate rubber, 20 parts of fluororubber, 15 parts of modified diatomite, and 25 parts of modified white carbon black. 1 part of ferric oxide, 30 parts of acetyl trioctyl citrate, 20 parts of epoxy octyl soybean oleate, 30 parts of zinc borate, 10 parts of magnesium hydroxide, 20 parts of expandable graphite, maleic anhydride graft phase 0.1 parts of solvent, 0.6 parts of sulfur, 251 parts of bismuth, 0.6 parts of triallyl cyanurate, 4 parts of Ca / Zn composite stabilizer, 10100.4 parts of antioxidant, 2640.3 parts of anti-aging agent, 4 parts of polyethylene w...

Embodiment 2

[0027] A heat-resistant and corrosion-resistant cable, comprising a wire, a high-temperature-resistant insulating layer covering the wire, a shielding layer covering the high-temperature-resistant insulating layer, and a protective layer covering the shielding layer;

[0028] Among them, the raw materials of the protective layer include by weight: 70 parts of EPDM rubber, 15 parts of silicone rubber, 15 parts of ethylene acrylate rubber, 15 parts of fluororubber, 25 parts of modified diatomite, and 15 parts of modified white carbon black. 3 parts, 3 parts of ferric oxide, 20 parts of acetyl trioctyl citrate, 30 parts of epoxy octyl soybean oleate, 20 parts of zinc borate, 15 parts of magnesium hydroxide, 10 parts of expandable graphite, maleic anhydride graft phase 0.3 parts of solvent, 0.4 parts of sulfur, 252 parts of bismuth, 0.4 parts of triallyl cyanurate, 6 parts of Ca / Zn composite stabilizer, 10100.2 parts of antioxidant, 2640.5 parts of anti-aging agent, 2 parts of polyet...

Embodiment 3

[0033] A heat-resistant and corrosion-resistant cable, comprising a wire, a high-temperature-resistant insulating layer covering the wire, a shielding layer covering the high-temperature-resistant insulating layer, and a protective layer covering the shielding layer;

[0034] Among them, the raw materials of the protective layer include by weight: 55 parts of EPDM rubber, 25 parts of silicone rubber, 11 parts of ethylene acrylate rubber, 18 parts of fluororubber, 18 parts of modified diatomite, and 22 parts of modified white carbon black. 1.5 parts of ferric oxide, 27 parts of trioctyl acetyl citrate, 23 parts of epoxy octyl soybean oleate, 28 parts of zinc borate, 11 parts of magnesium hydroxide, 18 parts of expandable graphite, maleic anhydride graft phase 0.15 parts of solvent, 0.55 parts of sulfur, 251.3 parts of bismuth, 0.55 parts of triallyl cyanurate, 4.5 parts of Ca / Zn composite stabilizer, 10100.35 parts of antioxidant, 2640.35 parts of anti-aging agent, 3.5 parts of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com