Photoresist detergent composition

A cleaning agent and composition technology, applied in the field of photoresist cleaning agent composition, can solve the problems of insufficient cleaning ability of thick film photoresist, harmful environment, strong corrosion of semiconductor wafer pattern and substrate, etc., and achieve corrosion inhibition Dark spots, corrosion inhibition, and environmental protection effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~26

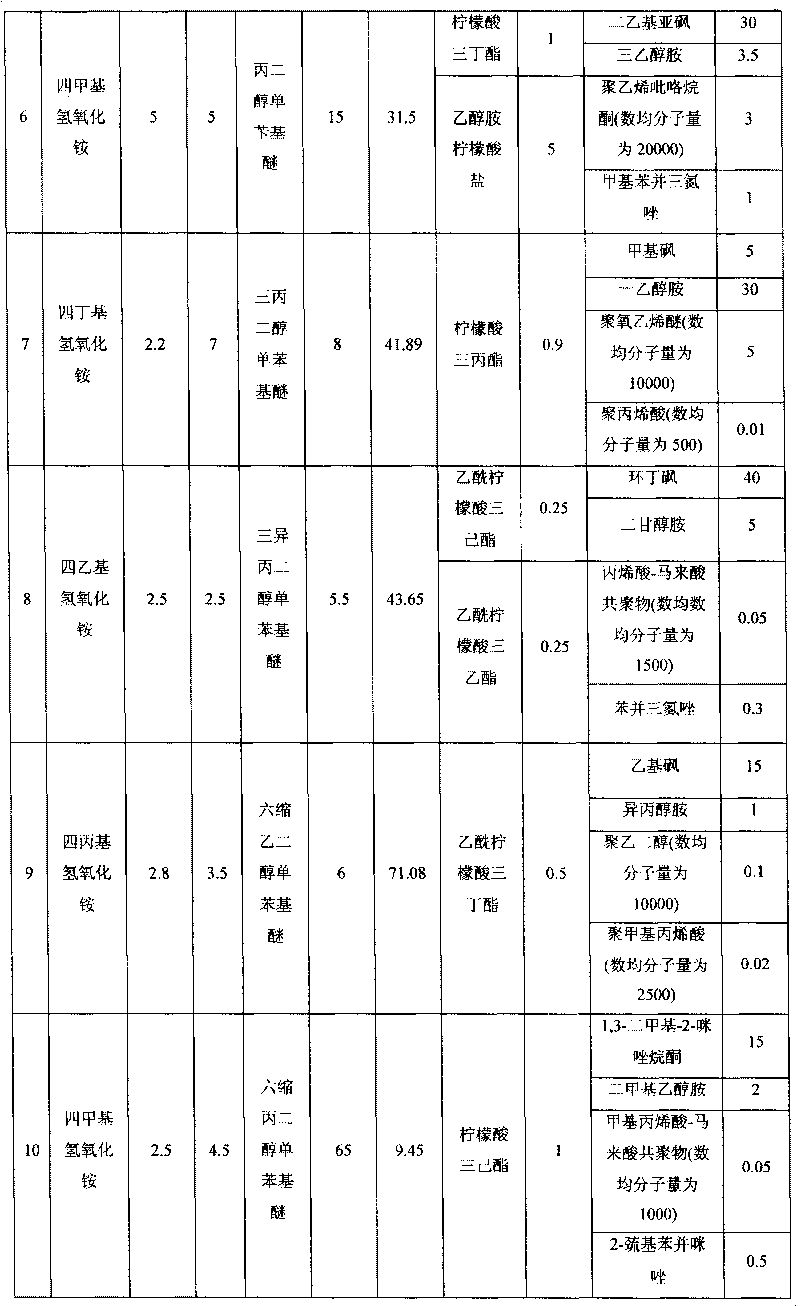

[0043] Table 1 shows the formulations of the photoresist cleaning composition examples 1 to 26 of the present invention. According to the components listed in Table 1 and their contents, simply mix them uniformly to prepare the cleaning compositions.

[0044] Table 1 Photoresist cleaning agent composition embodiment 1~26 of the present invention

[0045]

[0046]

[0047]

[0048]

[0049]

[0050]

[0051] The beneficial effects of the present invention will be further described below through preferred effect embodiments of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com