Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

53results about How to "Reduce potential threats" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

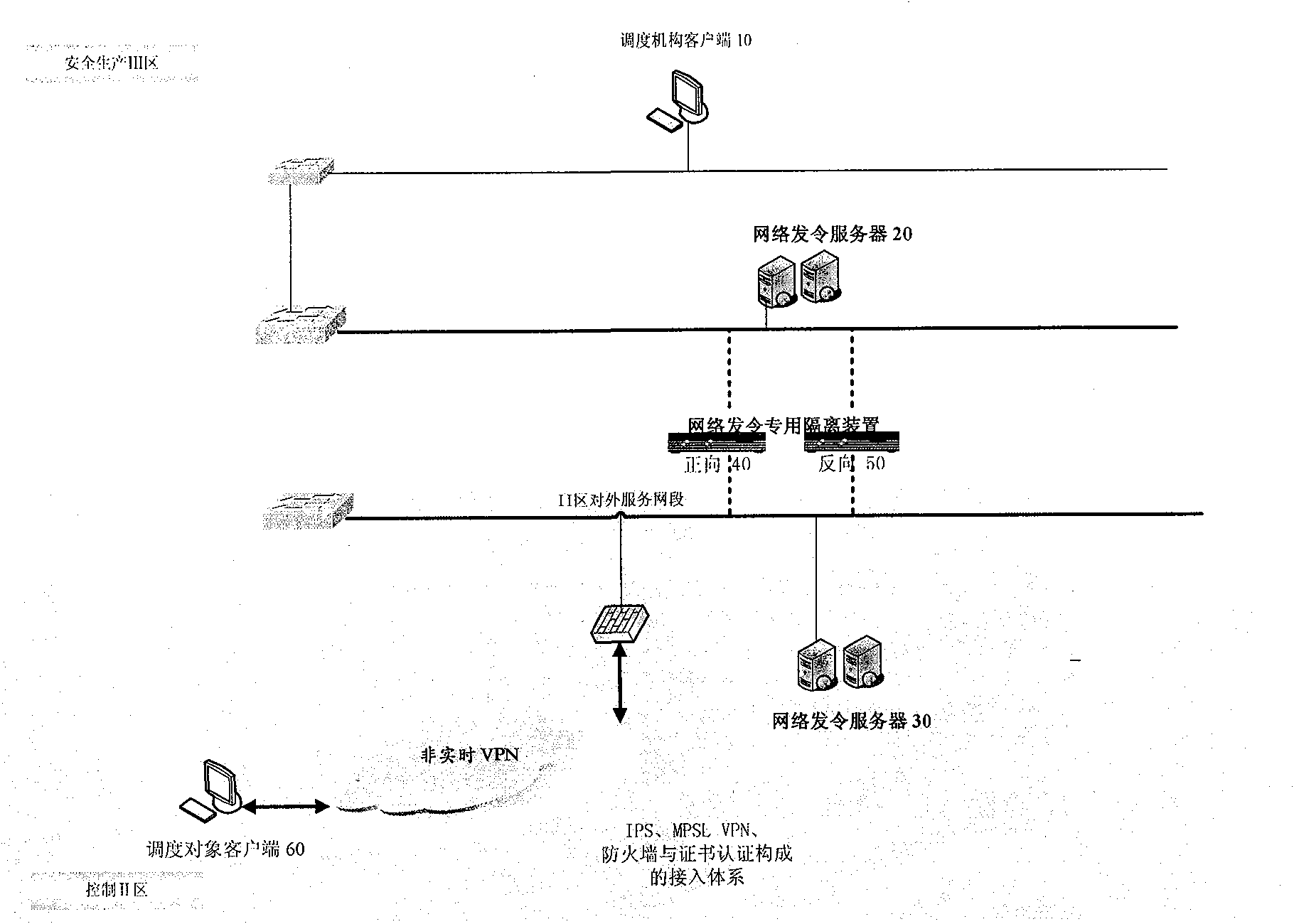

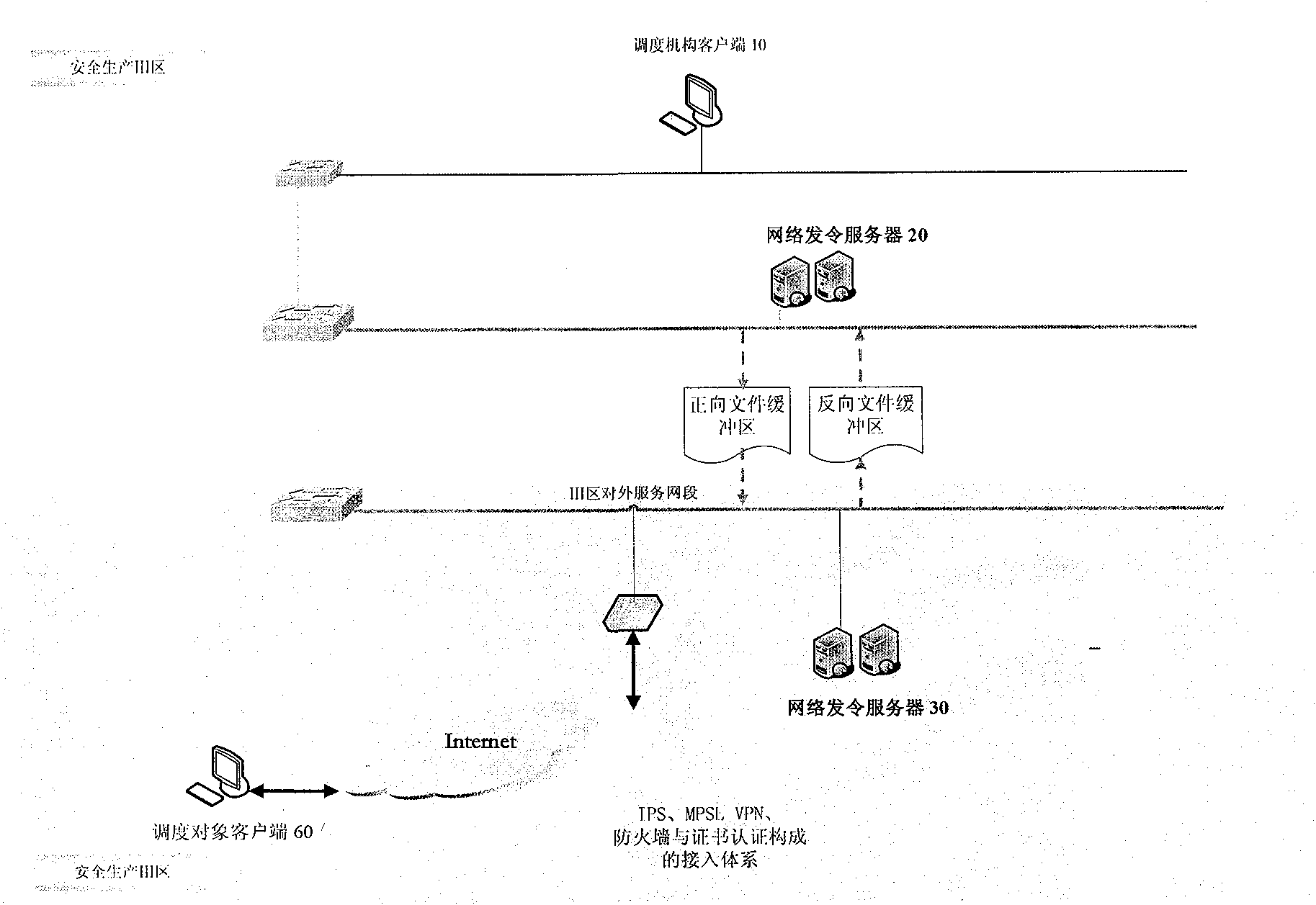

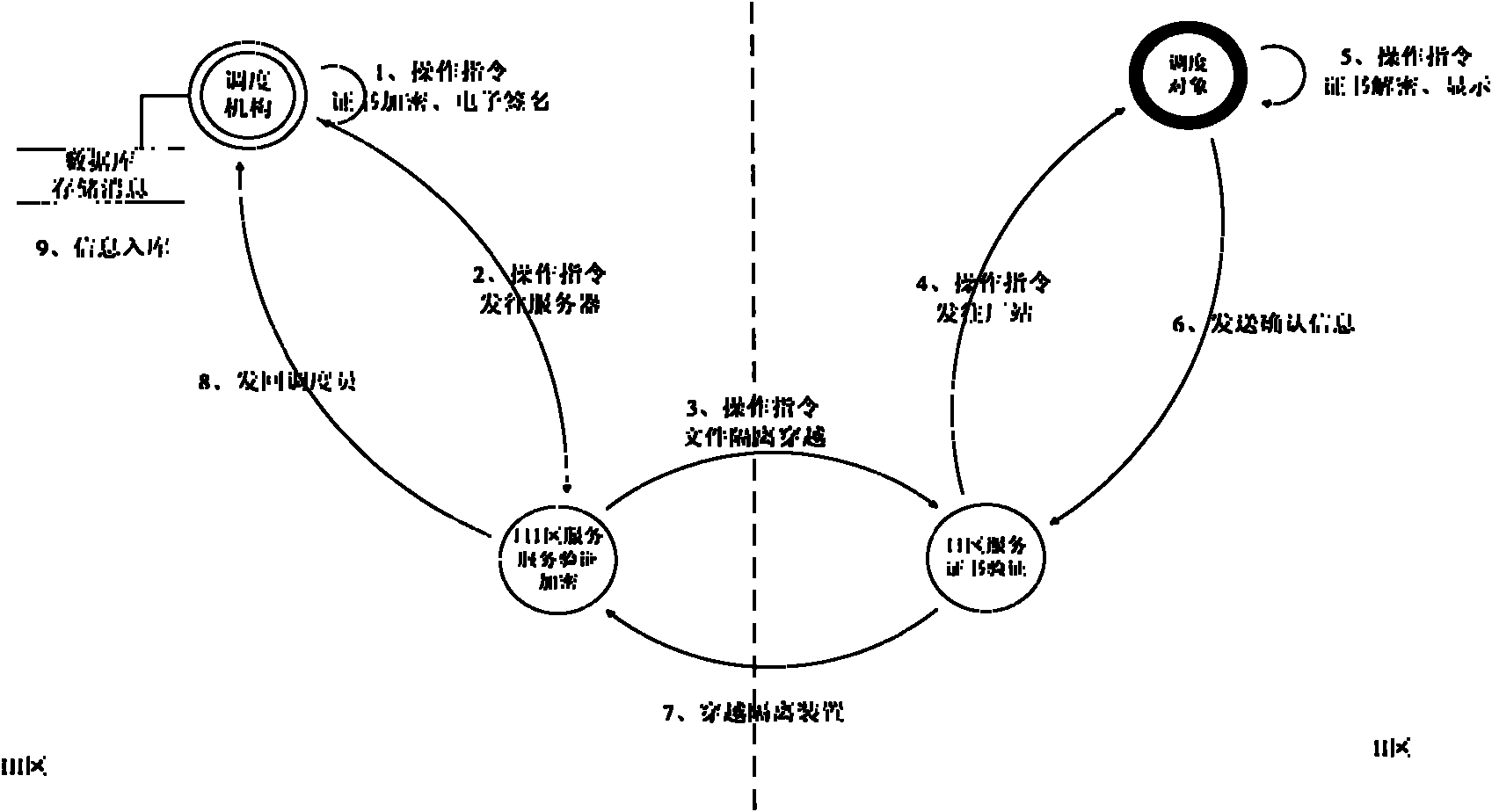

Power grid dispatching intelligentized and instruction informationized working platform

ActiveCN102097859AEasy to changeReduce potential threatsCircuit arrangementsInformatizationPower grid

The invention relates to an intelligentized and instruction informationized power grid dispatching system and an intelligentized and instruction informationized power grid dispatching method. The system and the method provide an improved power grid dispatching running mode. The power grid dispatching system comprises a dispatching mechanism client for intelligently ticketing, safety-checking, sending and receiving a dispatching instruction, a network instruction sending server which is positioned in a safety production region III and communicates with a network instruction sending server positioned in a control region II to perform safety checking on communication data, response to service requests of the dispatching mechanism client and a dispatching object client, store the service data and realize forwarding of the data, a network instruction sending server which is positioned in the control region II and communicated with the dispatching object client to perform safety checking on the communication data, forward the service request of the dispatching object client and realize forwarding of the data, and a dispatching object client for receiving the dispatching instruction from the dispatching object client, replying the dispatching instruction, submitting a work application and reporting a working conference.

Owner:GUANGDONG POWER GRID POWER DISPATCHING CONTROL CENT

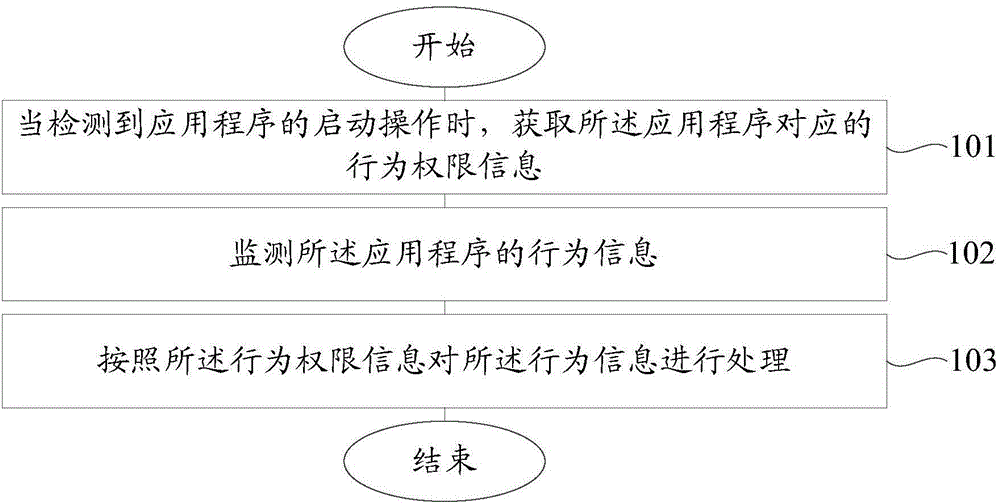

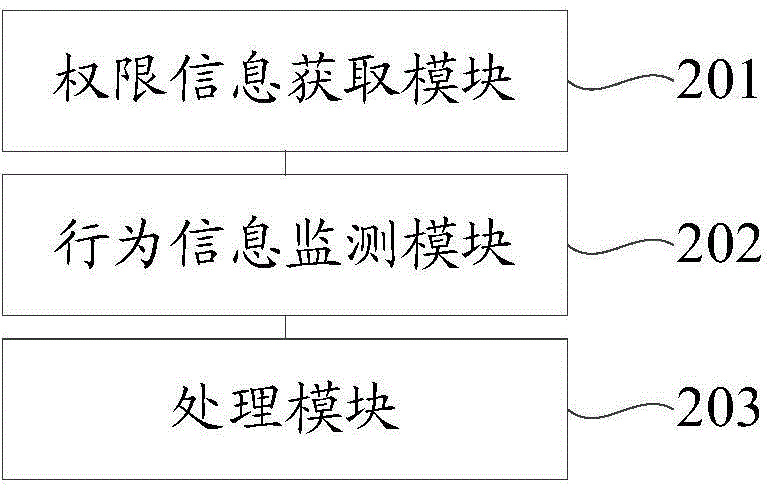

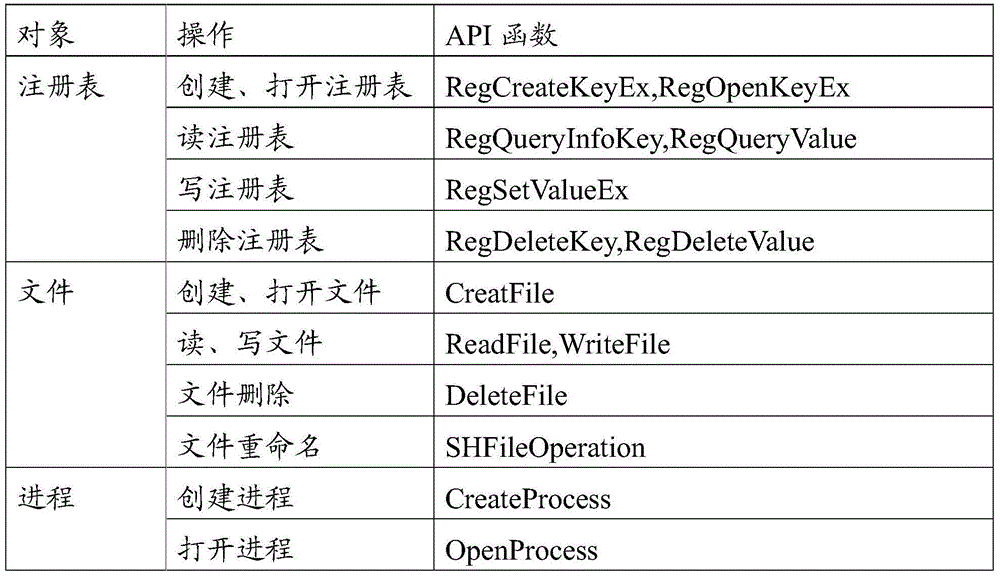

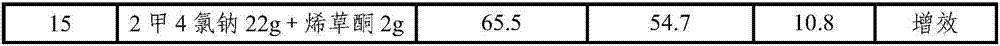

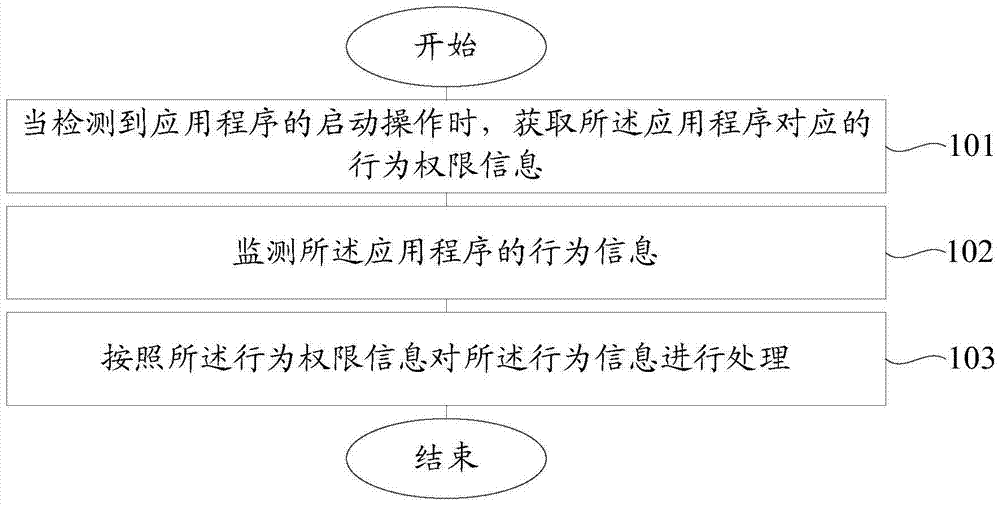

Behavior processing method and device based on application program

InactiveCN104484599AAvoid Monitoring VulnerabilitiesRealize fine-grained permission controlDigital data authenticationPlatform integrity maintainanceGranularityApplication software

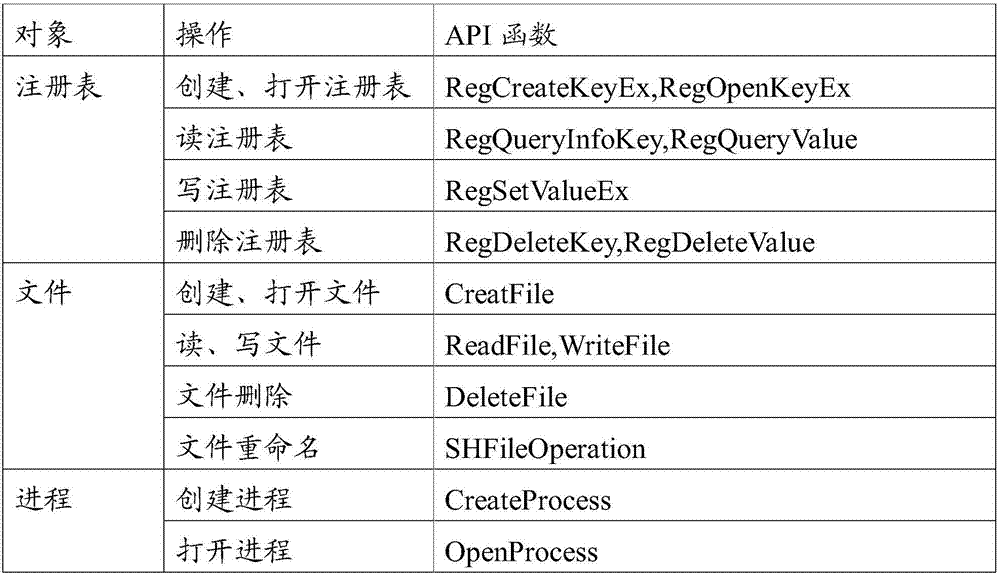

The embodiment of the invention provides a behavior processing method and device based on an application program. The method comprises the following steps that after the starting operation of the application program is detected, the behavior permission information corresponding to the application program is obtained; the behavior information of the application program is monitored; the behavior information is processed according to the behavior permission information. According to the embodiment of the invention, the behavior permission information is configured for the behavior, the single behavior is used as the permission unit, the application program is monitored, the monitoring vulnerability caused by configuring the unified permission for the application program by a blacklist and a whitelist is avoided, the fine granularity permission control is realized, the protection intensity is enhanced, the potential threat is reduced, and the false alarm rate can also be reduced.

Owner:BEIJING QIHOO TECH CO LTD +1

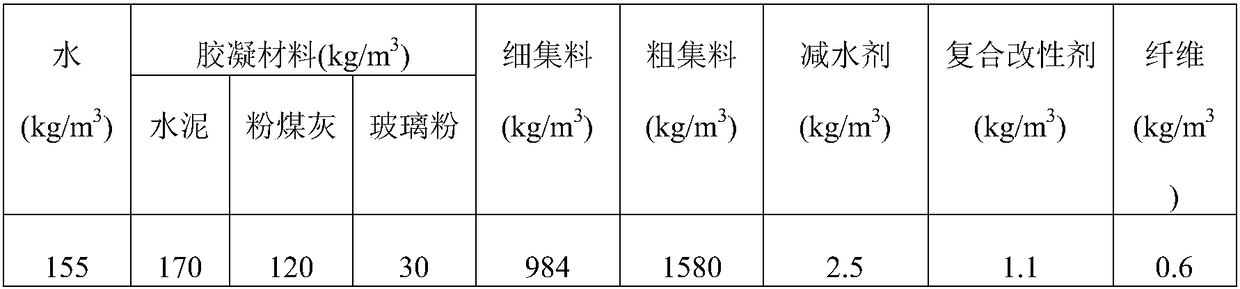

Crack-resistant anti-radiation mass concrete based on waste glass and preparation method thereof

The invention discloses crack-resistant anti-radiation mass concrete based on waste glass. The mass concrete comprises the following components: 140-160kg / m<3> of water, 100-300kg / m<3> of cement, 30-100kg / m<3> of a glass powder, 50-180kg / m<3> of fly ash, 800-1100kg / m<3> of fine aggregates, 1400-2000kg / m<3> of coarse aggregates, 0.35-1.9 kg / m<3> of a composite modifier, 2.1-7.8kg / m<3> of a water reducing agent and 0.6-1.2kg / m<3> of fibers, wherein the coarse aggregate is prepared by mixing barite and lead glass; the fine aggregate is prepared by mixing borosilicate glass sand and barite sand. The prepared crack-resistant anti-radiation mass concrete is excellent in working performance, mechanical property, cracking resistance, durability and shielding effects; moreover, the waste glass containing lead, boron and the like can be efficiently recycled, and the crack-resistant anti-radiation mass concrete has obvious economic and environmental benefits.

Owner:CHINA STATE CONSTR READY MIXED CONCRETE CO LTD

Anti-microbial synthetic leather and preparation method thereof

InactiveCN105155293AReduce potential threats to the environment and humansImprove the finishTextiles and paperChemistryTitanium oxide

The invention relates to an anti-microbial synthetic leather and a preparation method thereof. The anti-microbial synthetic leather is prepared from the following components by weight: 35 to 50 parts of thermoplastic polyurethane, 20 to 35 parts of diisocyanate, 15 to 25 parts of melamine copolymer resin, 7 to 9 parts of a nanometer titanium oxide-Ag anti-microbial agent, 3 to 5 parts of an auxiliary agent, 4 to 8 parts of honey and 1 to 3 parts of elm powder. The synthetic leather has wear resistance, moisture permeability and air permeability, reduces potential threat to the environment and the human body, can improve smoothness and cold-thermal fatigue performance, and has enhanced air permeability and moisture permeability, actual leather feel, wear resistance and service life.

Owner:ZHEJIANG JINSHANG SYNTHETIC LEATHER

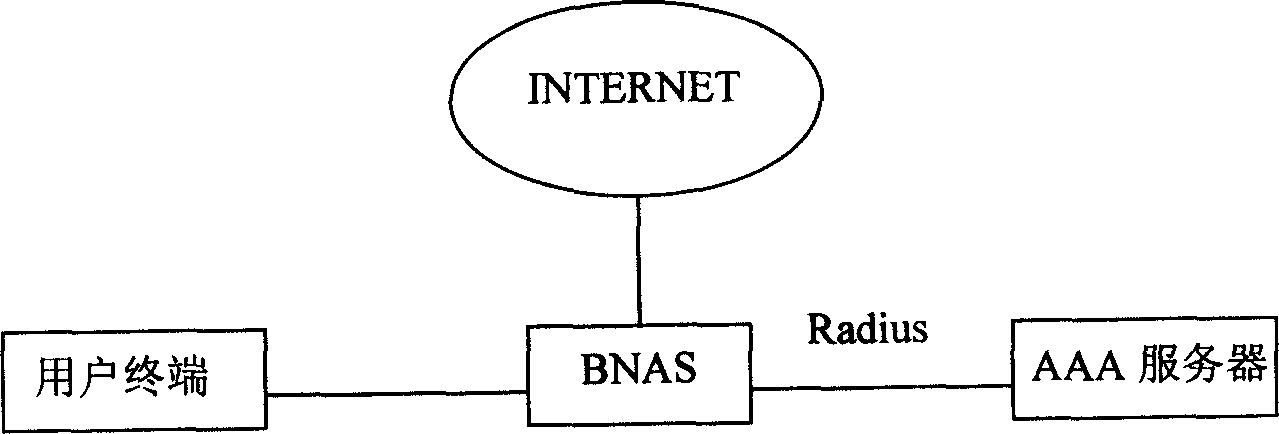

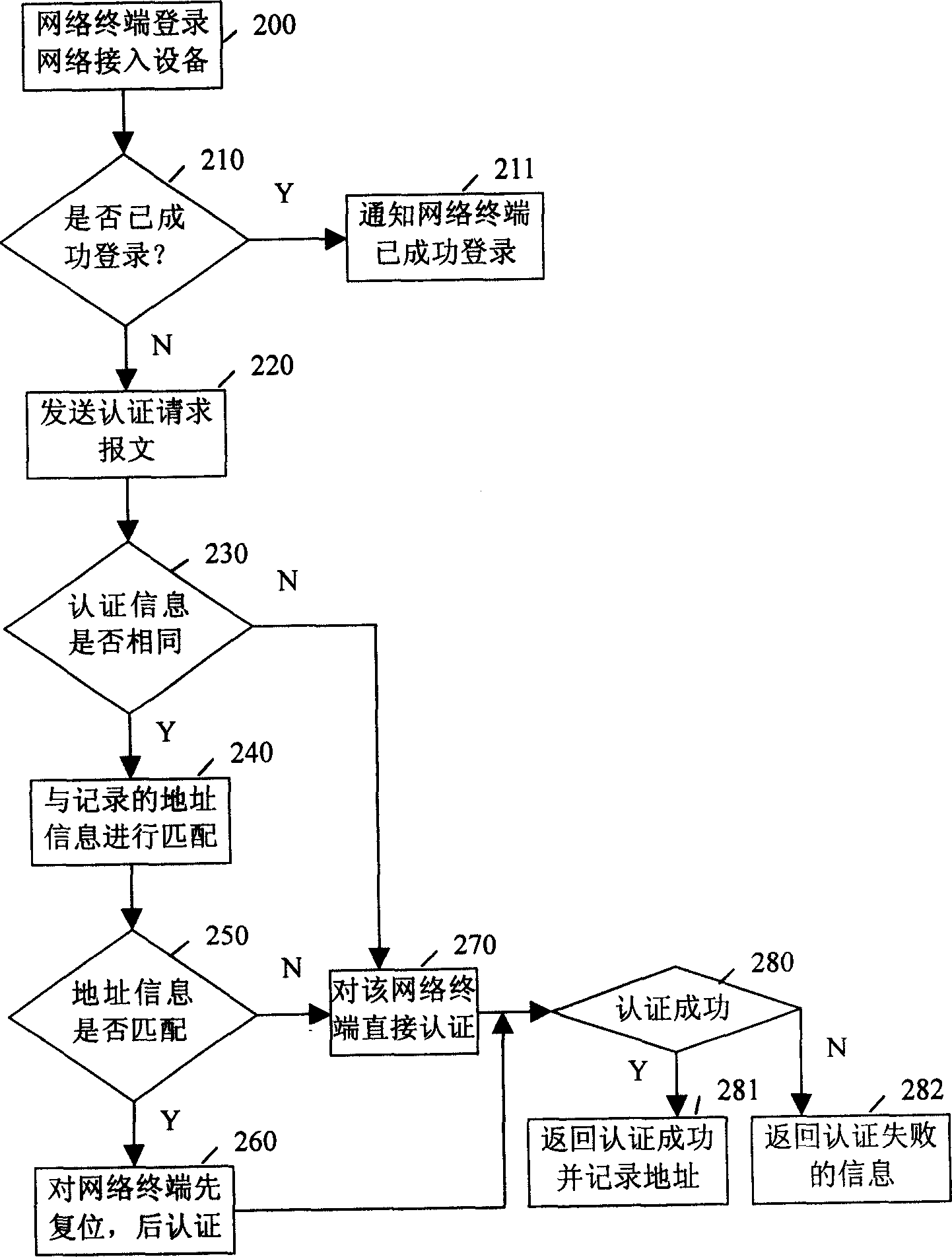

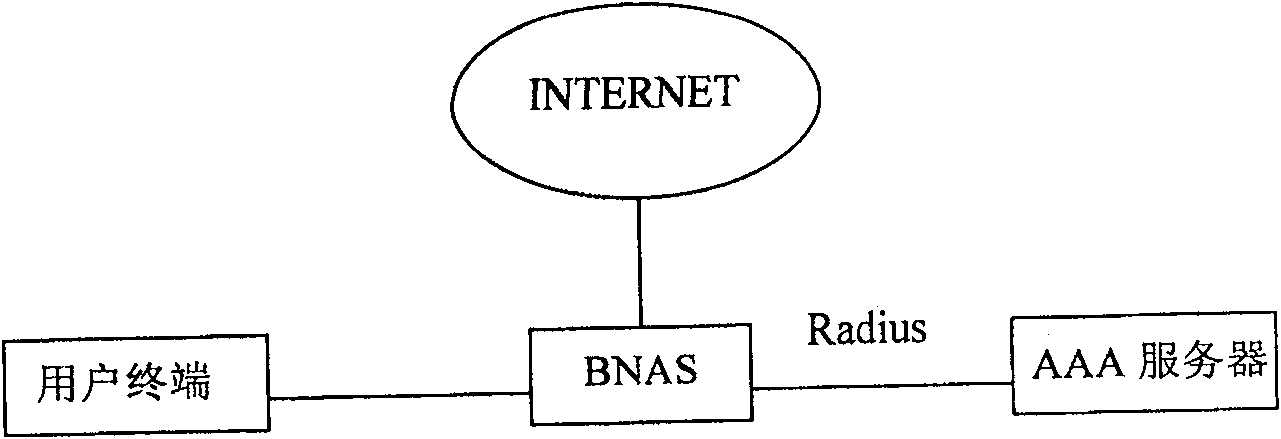

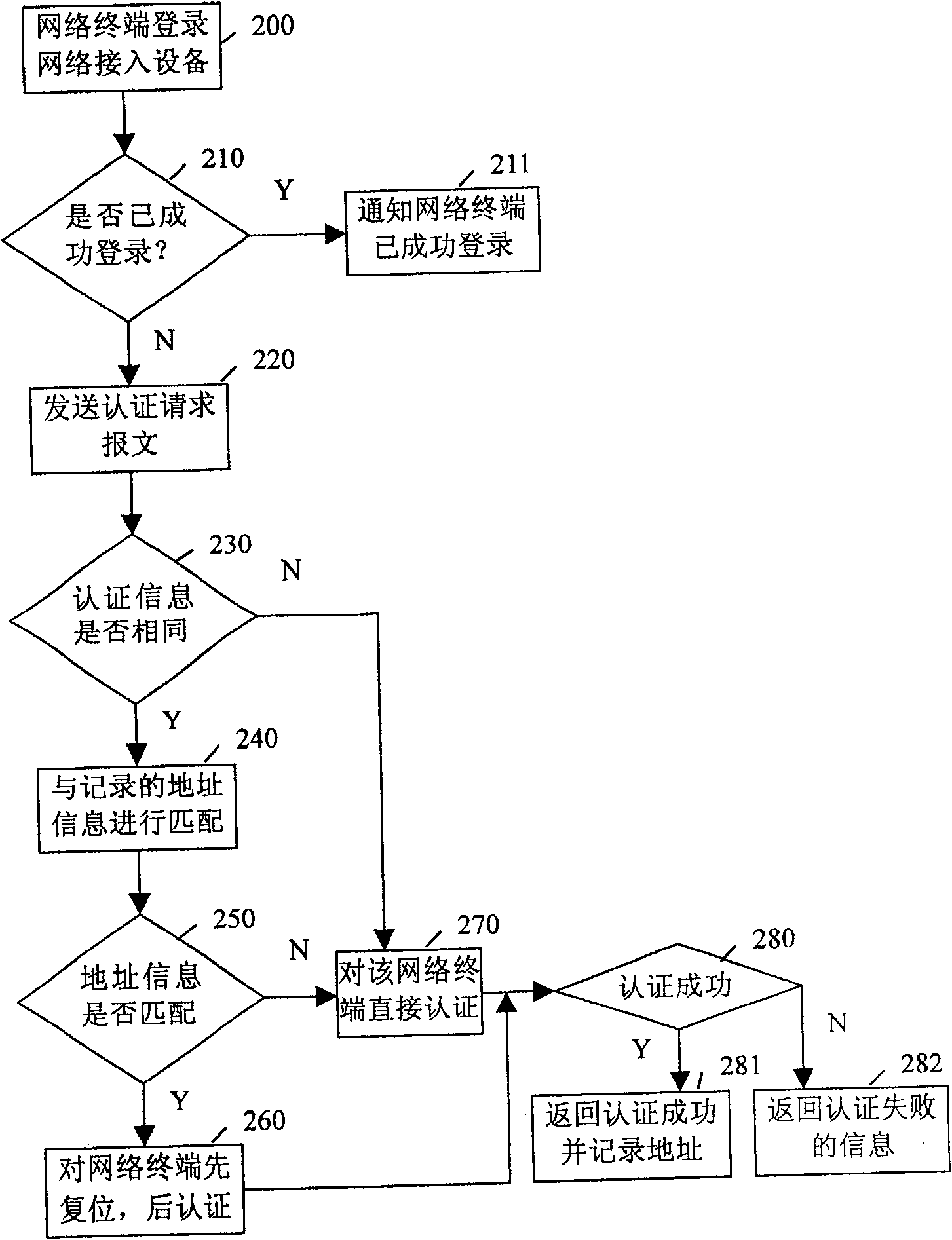

Authentication processing method for broadband network

ActiveCN1642081AAuthentication normalAvoid misjudgmentUser identity/authority verificationNetwork terminationComputer hardware

The invention supplies a method to process identification in wide band network. Its core is that: recording the address data of the online network terminal; when receiving the identification request text from network terminal, capturing the address information of the terminal; comparing the information with the recorded information and record the terminal that matched the recorded address information; taking identification to the network terminal according to the identification request text of network terminal that matched with the address information. The invention improves the reliability of identification process, decreases the potential threat of the network device.

Owner:HUAWEI TECH CO LTD

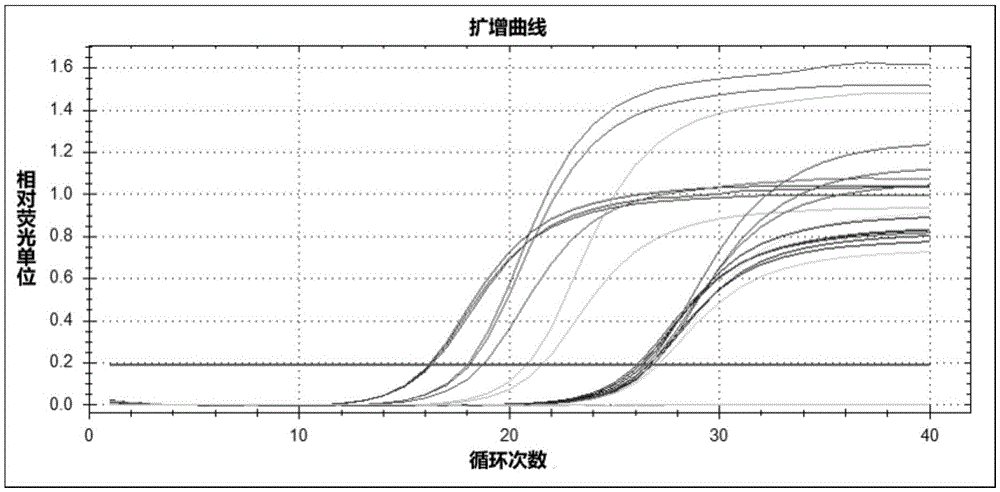

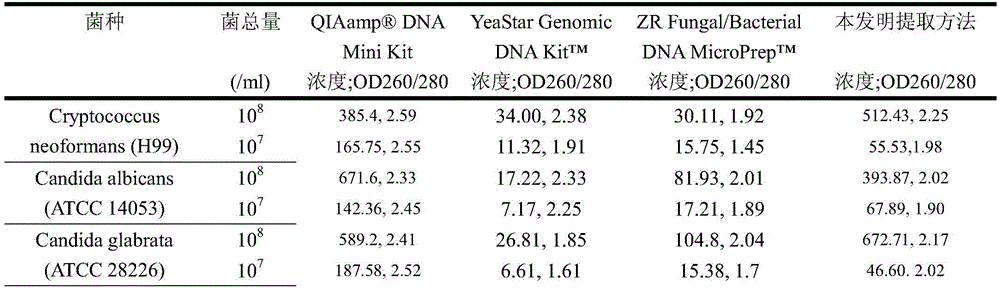

Instrument-free yeast-like fungus DNA extraction method used for nucleic acid amplification

ActiveCN105624152AGood cracking effectShorten the timeMicrobiological testing/measurementDNA preparationSyringeBiology

The invention relates to the field of fungi molecular biology, in particular to an instrument-free yeast-like fungus DNA extraction method used for nucleic acid amplification. According to the method, two yeast wall breaking methods, namely, the chemical lysis method and the enzymatic lysis method, are ingeniously integrated, DNA extraction is completed within 1.5-3 hours through the combination with a suction device, a filter device and a nucleic acid extraction syringe without power supply devices, and the method is the only efficient instrument-free yeast-like fungus DNA extraction method at present. The extraction method has the advantages of being rapid, simple, convenient to use, sensitive, free of toxin, low in cost and the like, and can be suitable for most yeast-like fungi.

Owner:SECOND MILITARY MEDICAL UNIV OF THE PEOPLES LIBERATION ARMY +1

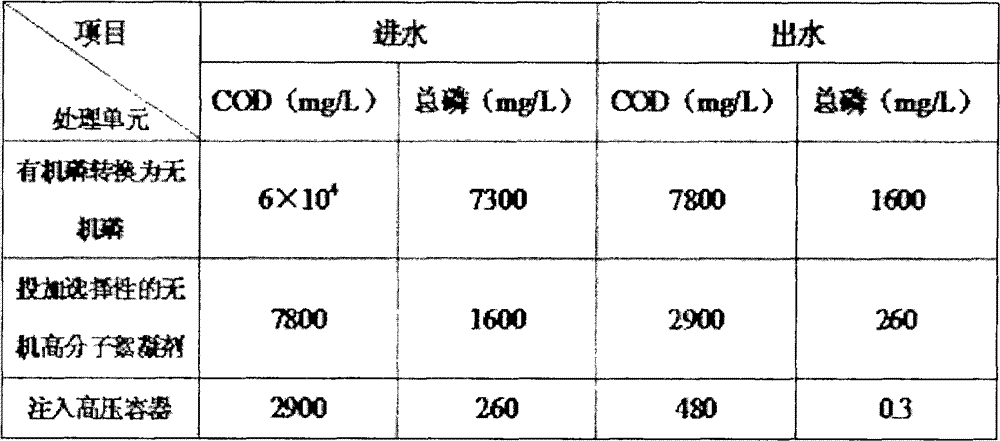

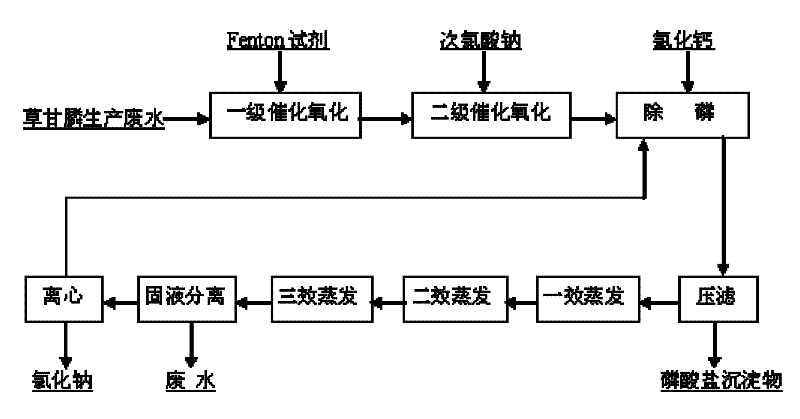

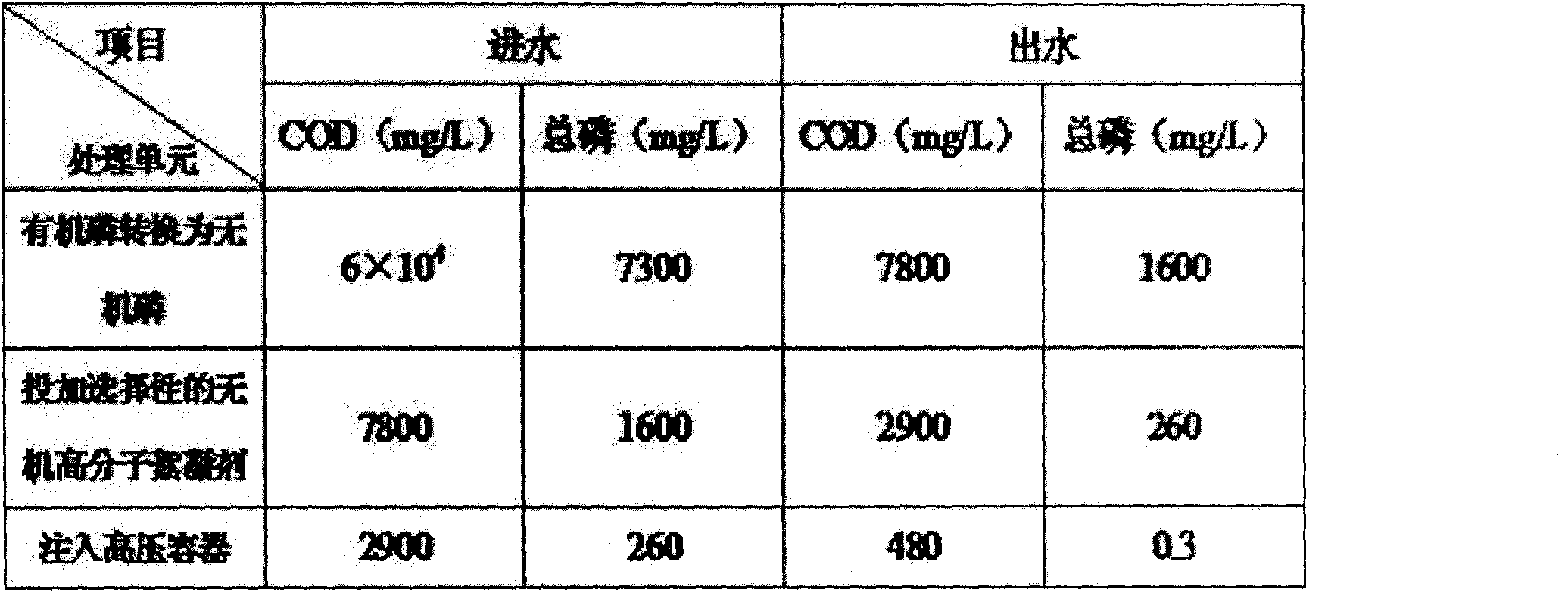

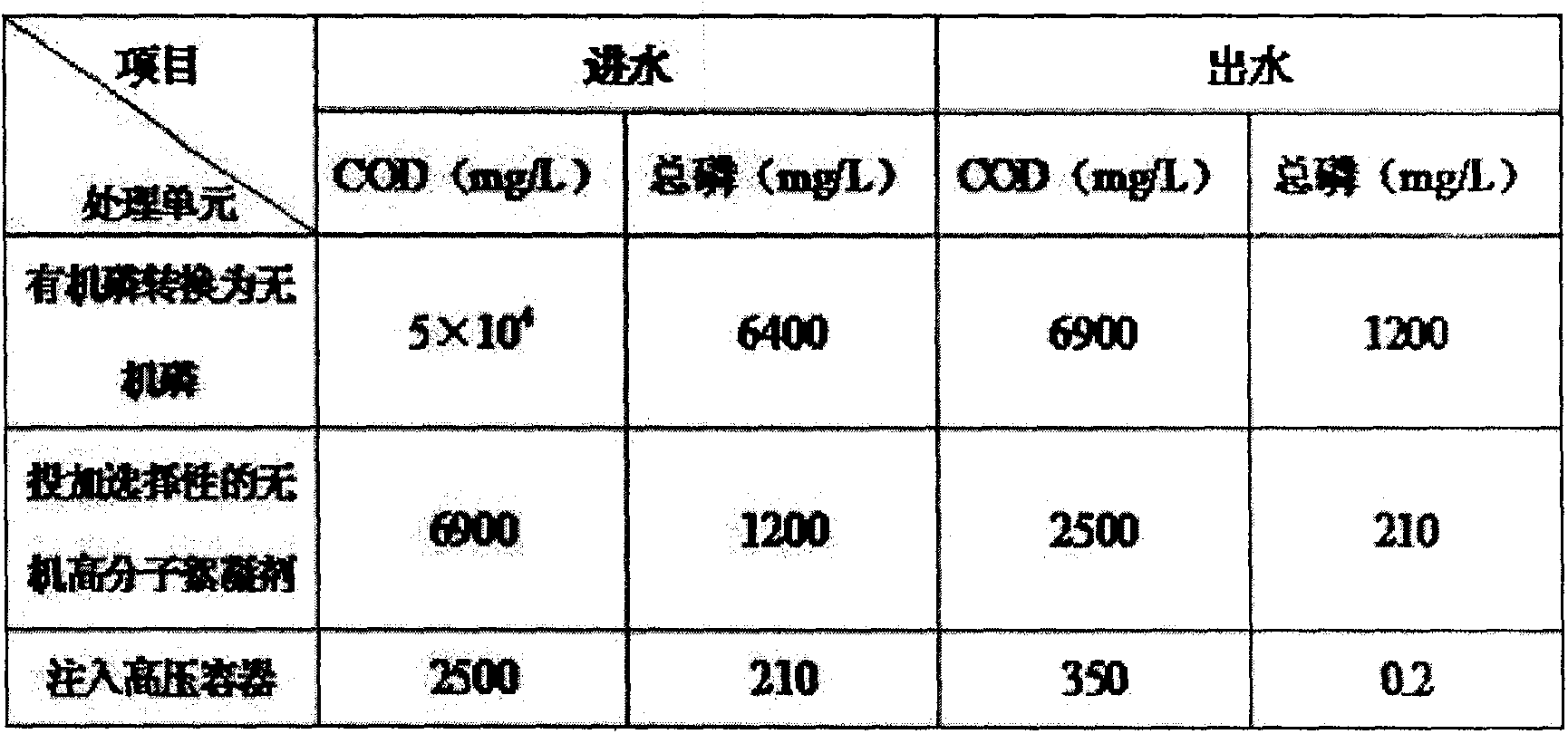

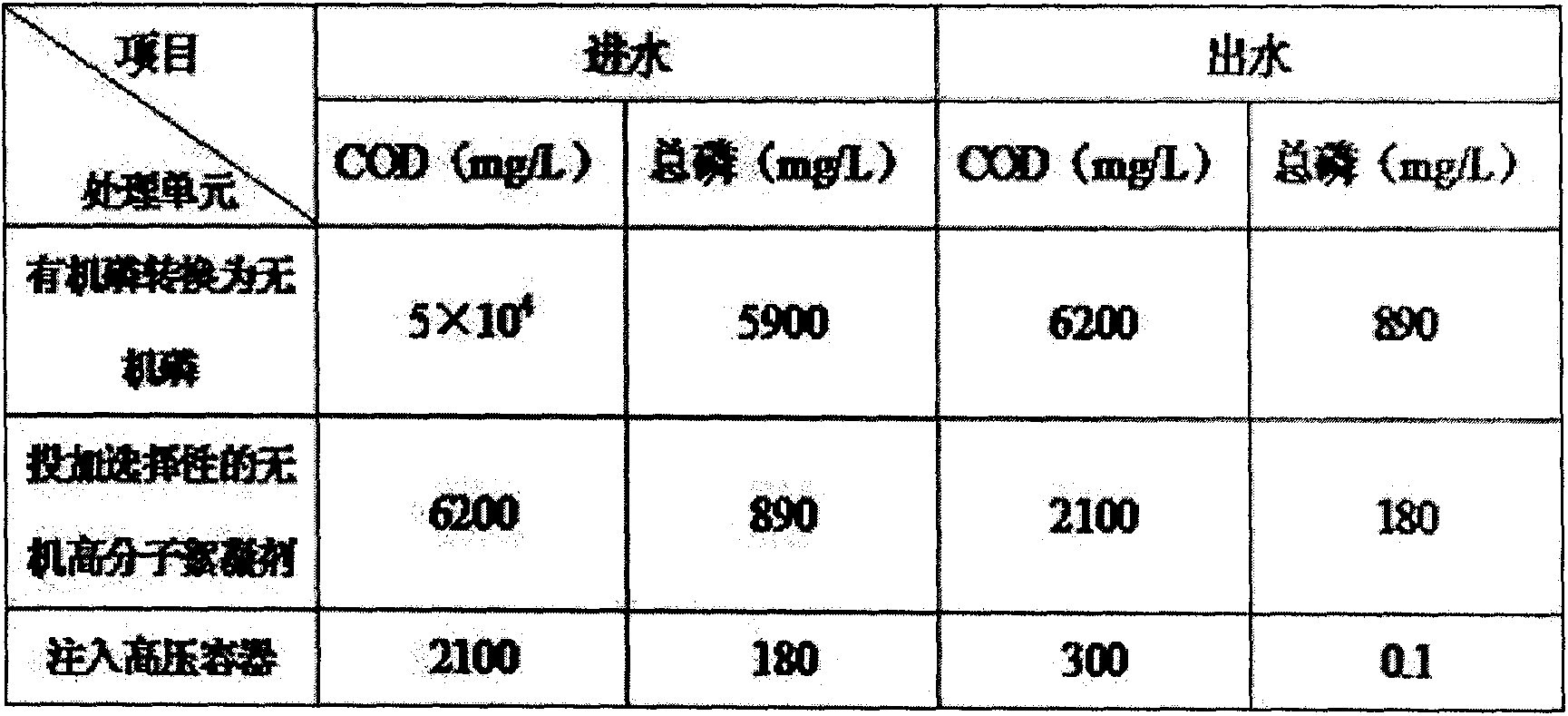

Method for removing high concentration phosphorus in glyphosate wastewater

InactiveCN102775012AReduce potential threatsMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationSlagEnvironmental chemistry

The invention discloses a method for removing high concentration phosphorus in glyphosate wastewater. The method comprises the following steps: adding a reducing agent to the glyphosate wastewater firstly, then adding hydrolytic enzyme and coenzyme to convert organic phosphorus into inorganic phosphorus; then using alkali to adjust PH and adding inorganic polymer flocculant for flocculating settling; adding sodium hypochlorite, polyethylene succinic acid and glycerol to the settled wastewater, injecting the wastewater into a high pressure vessel and drumming air into the vessel to maintain the total pressure in the range of 5.0-6.0MPa; finally, open a container channel to release the wastewater into a pond to form white mist foam. A layer of greasy substance generated in the upper part of the pond can be removed by a slag adhering machine. The method provided by the invention does not have to convert organic phosphorus into inorganic phosphorus through the hydrolysis of hydrolytic enzyme and coenzyme at the high pressure and high temperature condition, the inorganic polymer flocculant added has selectivity. The method provided by the invention can reduce the concentration of phosphorus in glyphosate wastewater to 0.5mg / L or less. And the removal efficiency of phosphorus can reach more than 99.9%.

Owner:CHANGZHOU UNIV

Method for purifying and synthesizing hexagonal boron nitride in synthetic cubic boron nitride tailings

InactiveCN106829889AIncrease profitReduce potential threatsNitrogen compoundsMicrowaveHexagonal boron nitride

The invention belongs to the field of synthesis of cubic boron nitride and in particular relates to a method for purifying and synthesizing hexagonal boron nitride in synthetic cubic boron nitride tailings. The method for purifying and synthesizing the hexagonal boron nitride in the synthetic cubic boron nitride tailings is characterized by being realized through the following steps: carrying out ball milling and thinningrefining; shaking to remove one part of impurities; drying at low temperature; conveying materials into a furnace body of continuous tunnel type microwave drying equipment; meanwhile, introducing mixed gas of oxygen and air into the furnace body, so as to remove carbon impurities; removing the residual impurities through diluted acid; adding the materials, the diluted acid and pure water into a reaction kettle and stirring and heating; after sufficiently reacting, obtaining materials without the impurities; washing with the pure water; neutralizing and washing with the pure water to obtain the pure hexagonal boron nitride. According to the method provided by the invention, a solid waste material, namely the hexagonal boron nitride, is purified to obtain a useful material through physical and chemical methods, so that the utilization of the raw material is greatly improved, and potential threats, caused by the solid waste material, on to the environment are also reduced.

Owner:ZHENGZHOU ZHONGNAN JETE SUPERABRASIVES

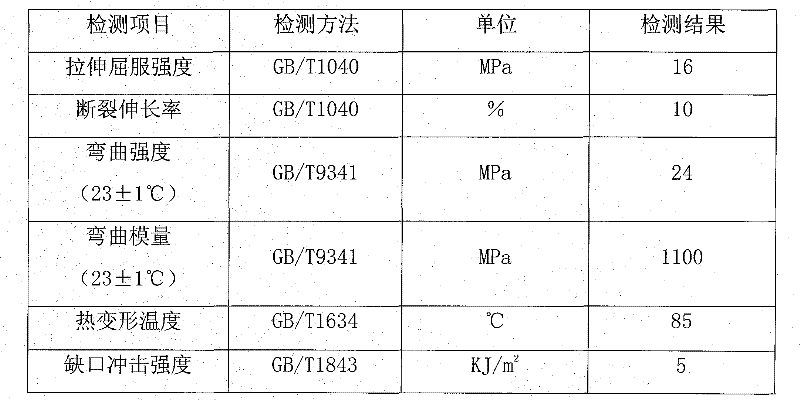

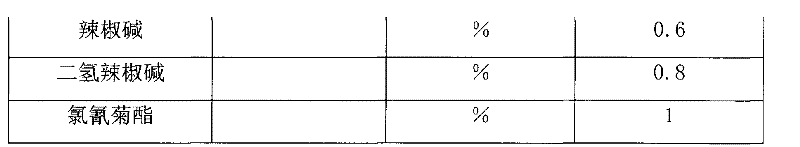

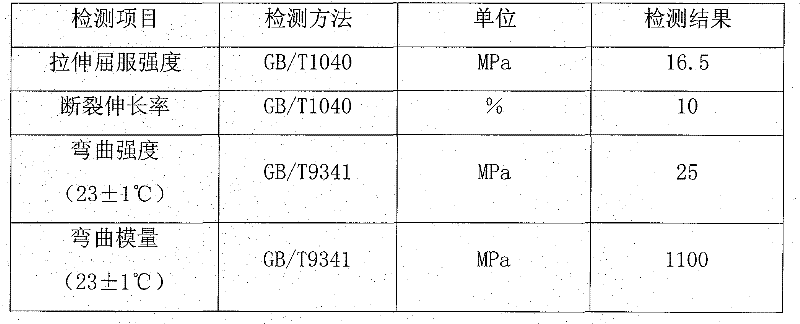

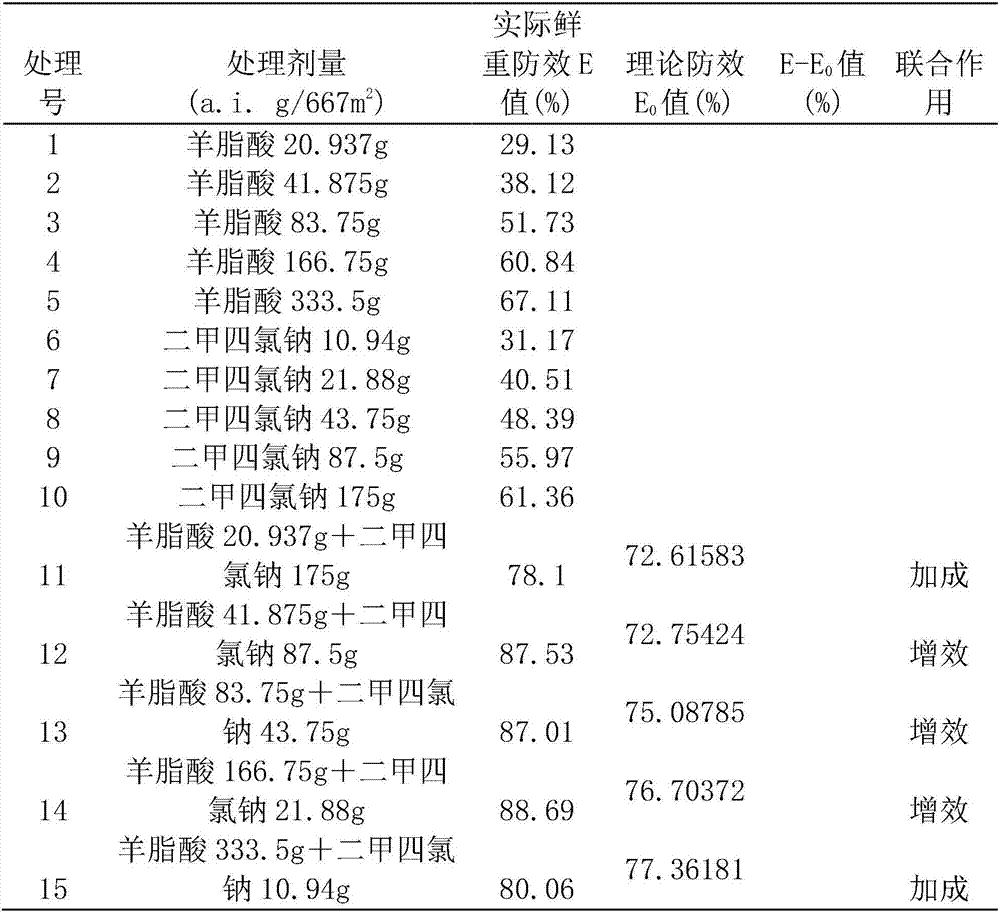

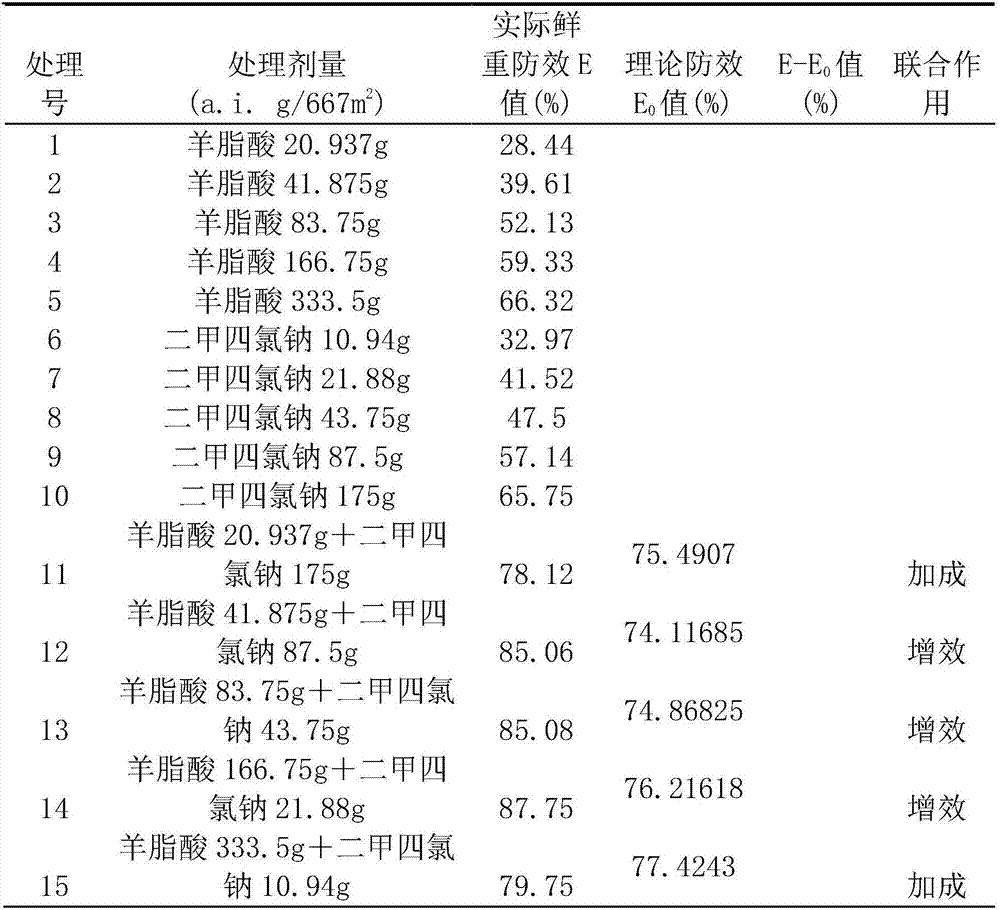

Ratproof and termiteproof material

The invention discloses a ratproof and termiteproof material, which comprises the following components in percentage by weight: 80 to 85 percent of polypropylene, 8 to 20 percent of glass fiber, 0.6 to 2 percent of capsaicine, 0.8 to 2 percent of dihydrocapsaicine and 1 to 2.5 percent of cypermethrin. Because the capsaicine, the dihydrocapsaicine and the cypermethrin can generate strong odor irritating both olfactory sensation and taste sensation of mice and insects, the ratproof and termiteproof material can effectively prevent the bite and encroachment of mice and termites and is particularly suitable to manufacture civil engineering members used outdoors for a long period of time such as filling sacks and fixing buckles used in barrier building; a built barrier has less potential threat and high safety factor and passes experimental verification; and the mechanical property of the ratproof and termiteproof material is identical to that of ordinary polypropylene materials and does not influence the quality of products manufactured by the material.

Owner:CHONGQING DANHAI IND

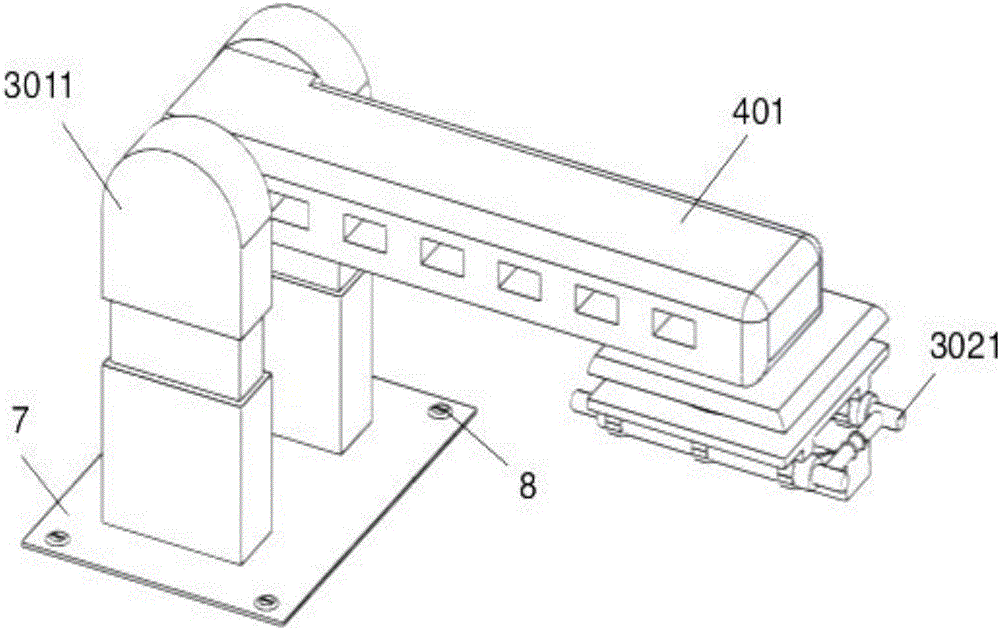

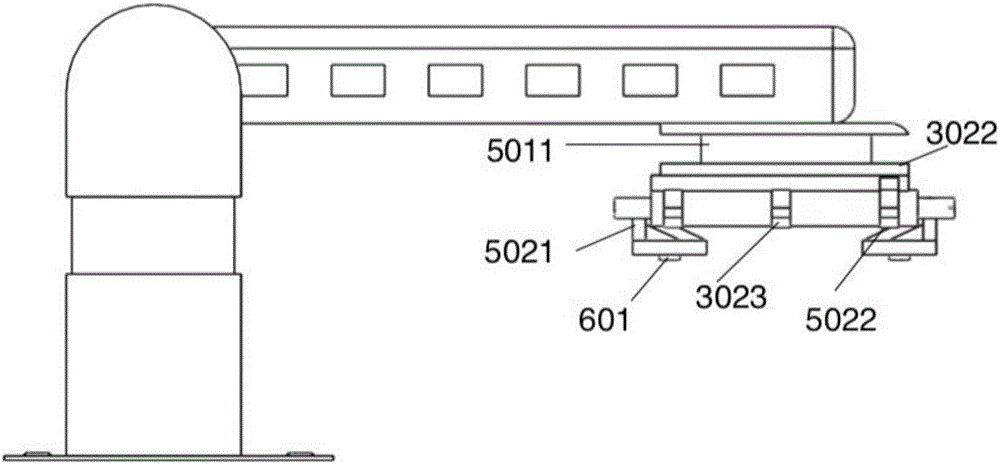

IGBT module structure reliability testing device having video monitoring function

ActiveCN106324468AAvoid long runsReduce lossesSemiconductor operation lifetime testingSemiconductor characterisationVideo monitoringComputer module

The invention relates to an IGBT module structure reliability testing device having a video monitoring function. The IGBT module structure reliability testing device comprises a power supply module, a telescopic module, an intelligent control module, a sliding module, a rotating module, and an acquisition module. The power supply module is connected with other modules to provide electric energy. The intelligent control module is connected with the telescopic module, the sliding module, the rotating module, and the acquisition module to realize a test control function. The IGBT module structure reliability testing device is advantageous in that the design is reasonable; the constant changing of the internal chip, the solder layer, and the copper layer of the IGBT module during a testing process is acquired by adopting a visual sensor; the corresponding changing of the corresponding parts is determined, and the gradual changing of the internal structure of the IGBT is discovered, and after the IGBT loses efficacy, the part causing the failure of the IGBT is determined.

Owner:HEBEI UNIV OF TECH

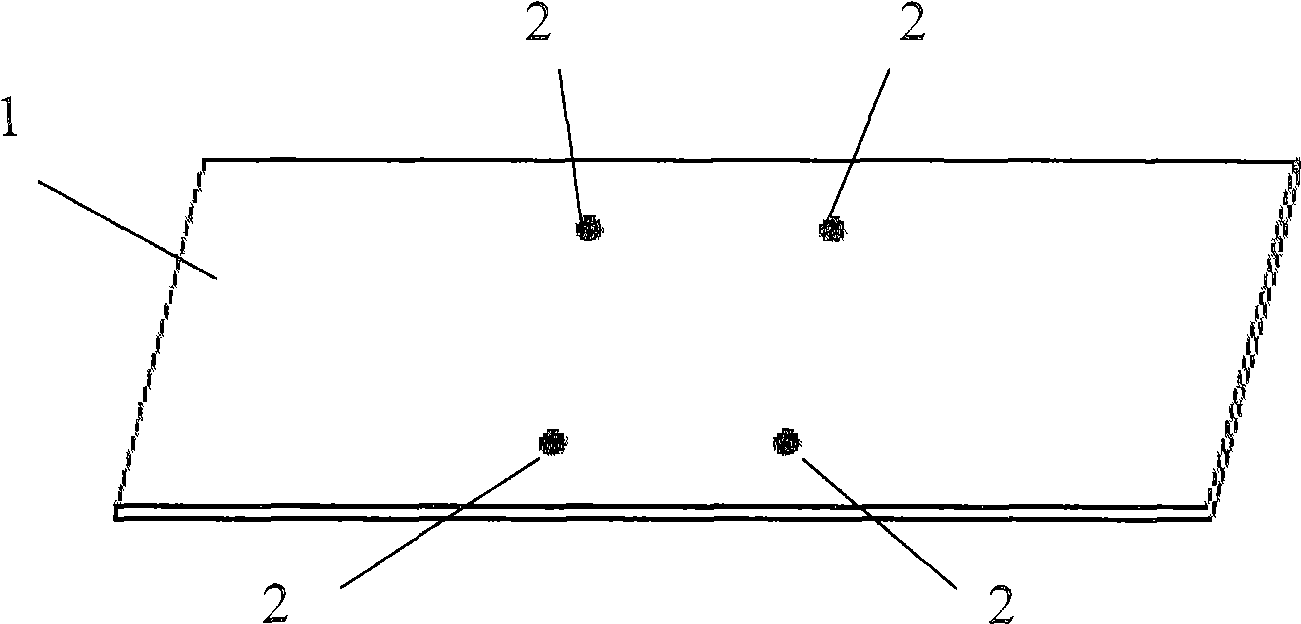

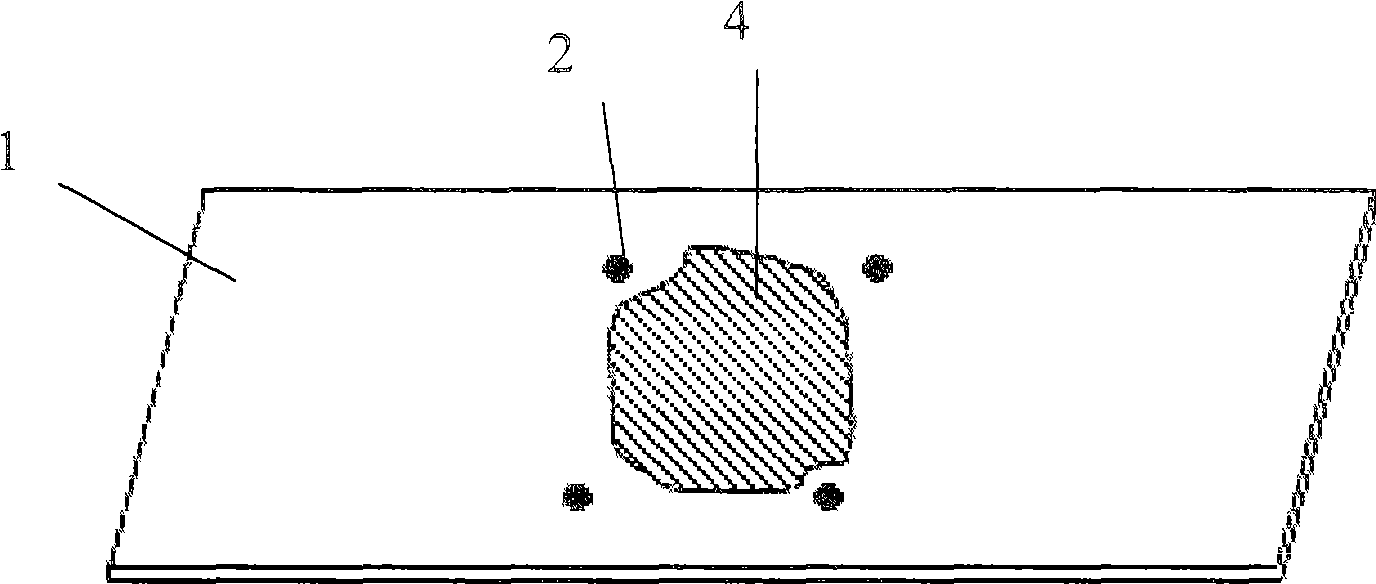

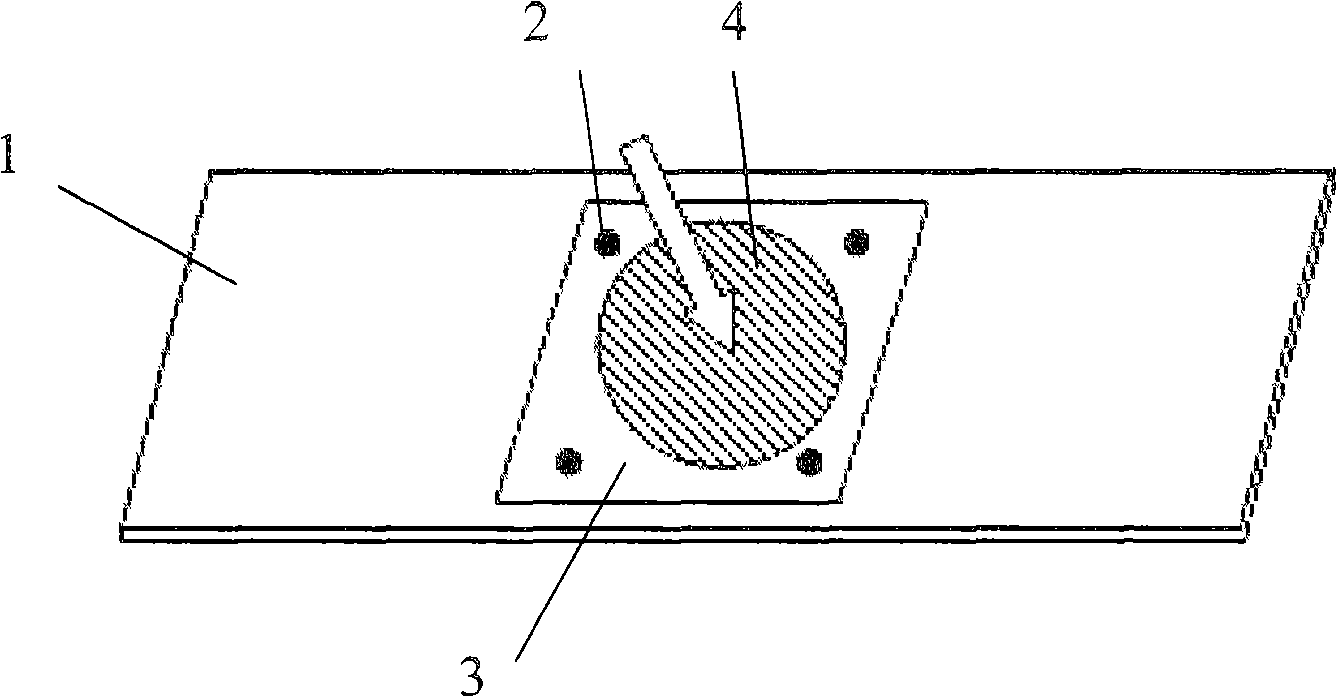

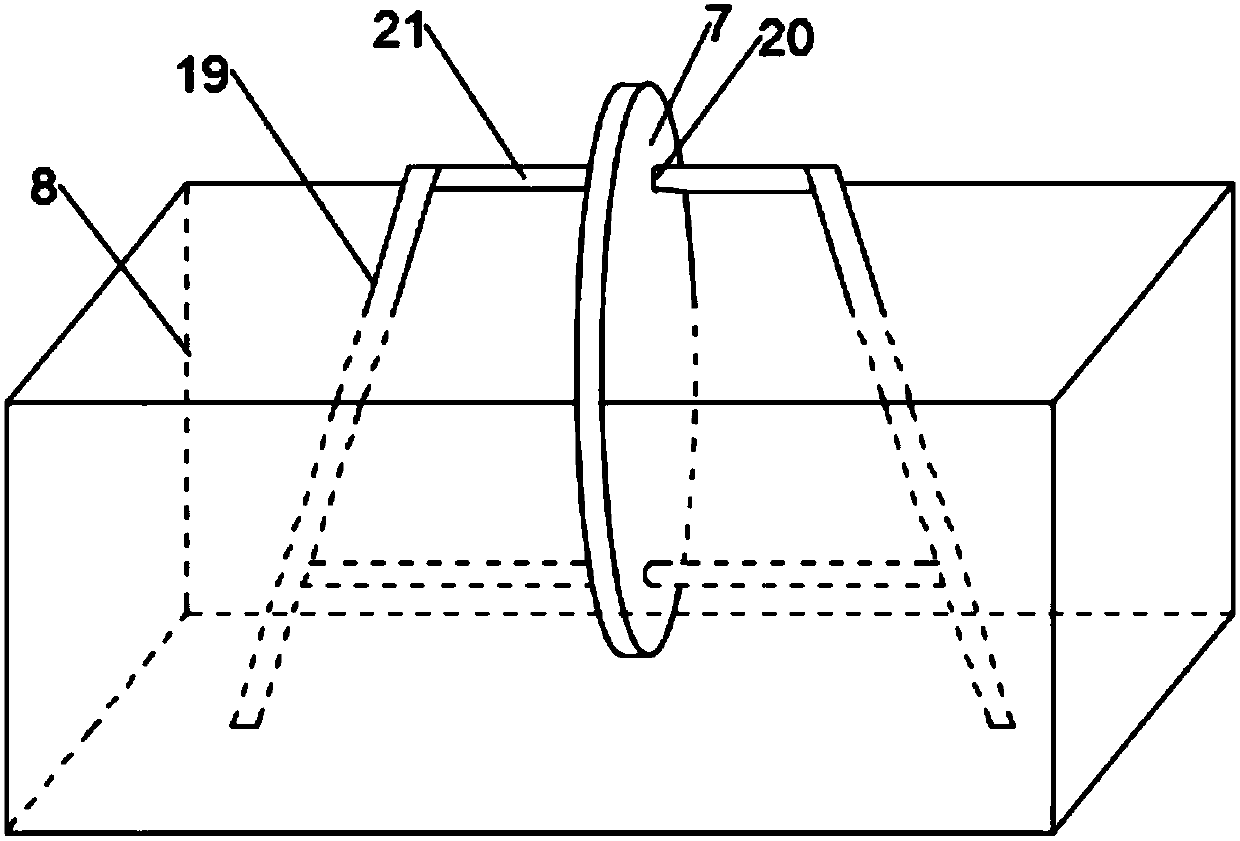

Visible component counting pool, its production method and use method

ActiveCN101477024AAchieve freedom of controlEasy to getIndividual particle analysisBiological testingVisual field lossBiochemical engineering

The invention relates to a counting cell for physical components, which comprises a bottom solid phase supporting plane (1), and three or more than three supporting components (2) for controlling counting depth are arranged on the bottom solid phase supporting plane. A manufacturing method thereof comprises the following steps: cleaning the supporting components; drying the supporting components; fully and evenly mixing high vacuum silicone ester and the supporting components according to a volume ratio of 2-15:1; and arranging the supporting components on the bottom solid phase supporting plane to form at least three supporting points. A using method comprises the following steps: adding samples (4) to be tested among the supporting components on the bottom solid phase supporting plane of the counting cell; covering the samples by a cover plate (3), and pressing the cover plate to the lowest position; and placing the counting cell below the microscope to count, wherein a computing formula comprises that: the density of the physical components is equal to average physical component number of each visual field divided by a product of the height of the supporting components multiplying the visual field area of the microscope. The counting cell has the advantages of low cost, simple manufacture, convenient use and long valid period, and can reduce threat of infectious samples to health by once use.

Owner:BRED LIFE SCI TECH

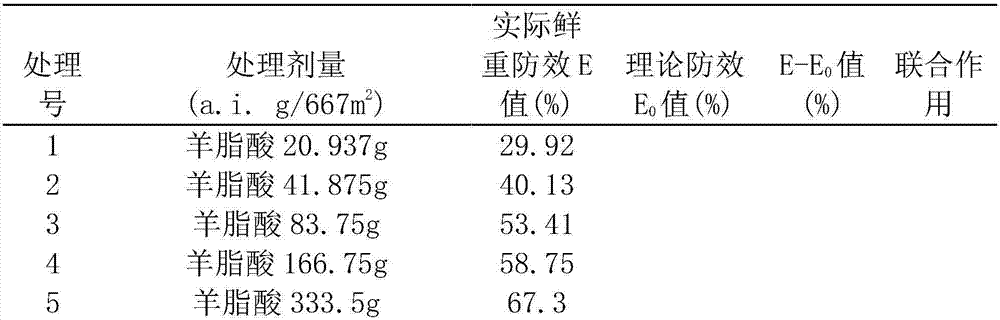

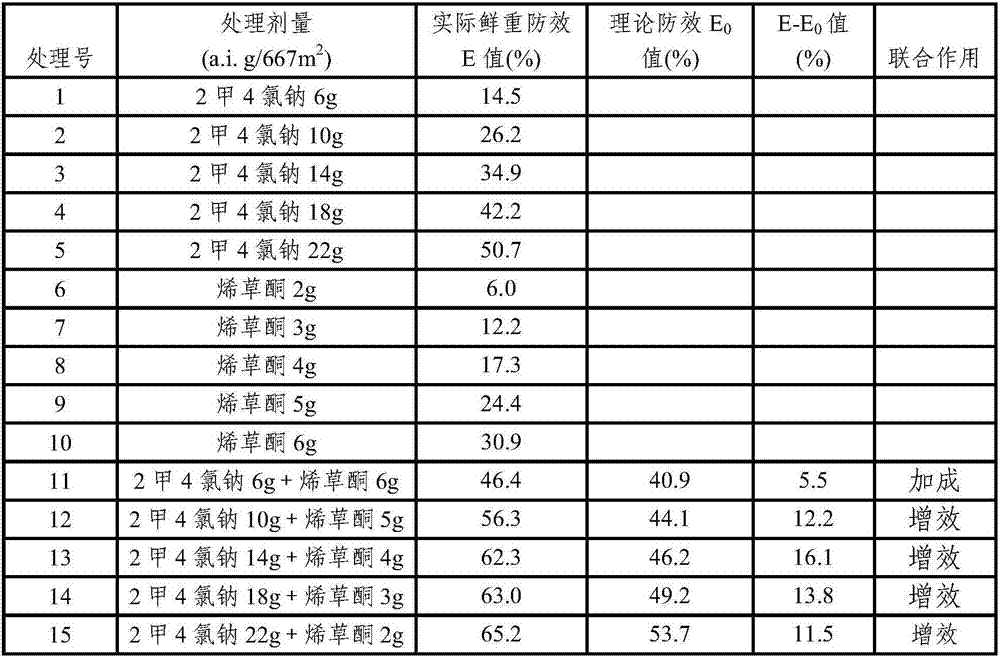

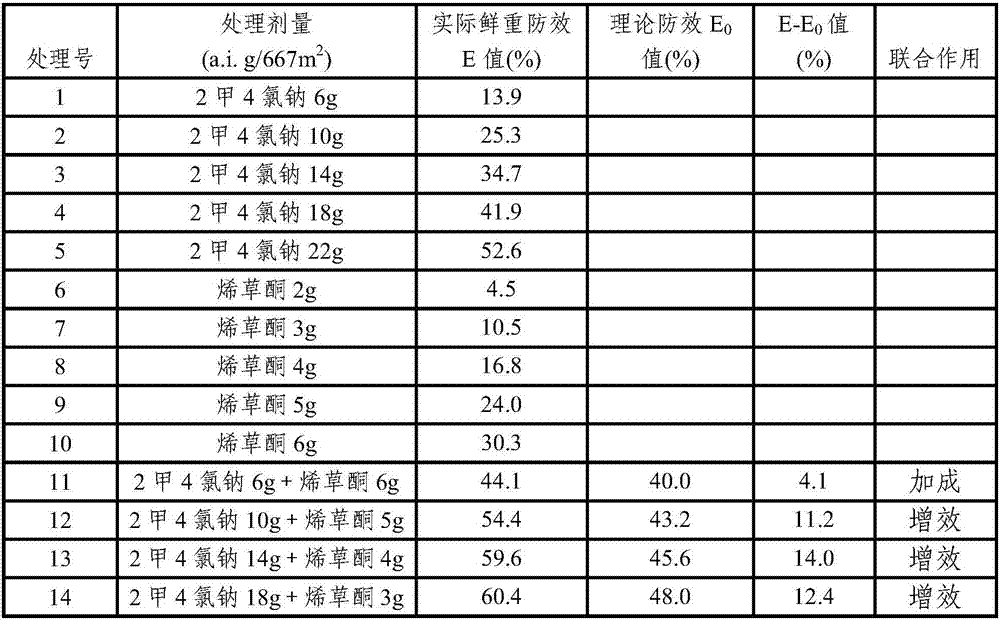

Composition containing MCPA-Na and cyclohexenone herbicide

The invention discloses a composition containing MCPA-Na and a cyclohexenone herbicide. The composition contains the effective ingredients of MCPA-Na and the cyclohexenone herbicide, wherein the mass ratio of MCPA-Na to the cyclohexenone herbicide is (1-10): (10:1); the preferential mass ratio of MCPA-Na to the cyclohexenone herbicide is (1-6): (6:1); the most preferential mass ratio of MCPA-Na to the cyclohexenone herbicide is (1-6): 1. The composition can adopt any one preparation formulation accepted by pesticides, and has a very good synergistic effect within a certain proportion range; compared with that of a single herbicide, the weeding effect of the composition is remarkably improved; meanwhile, the herbicide consumption and the cost are reduced, herbicide residues are reduced, and the potential threats of the pesticides to the environment are relieved.

Owner:HUNAN AGRI BIOTECH RES CENT +1

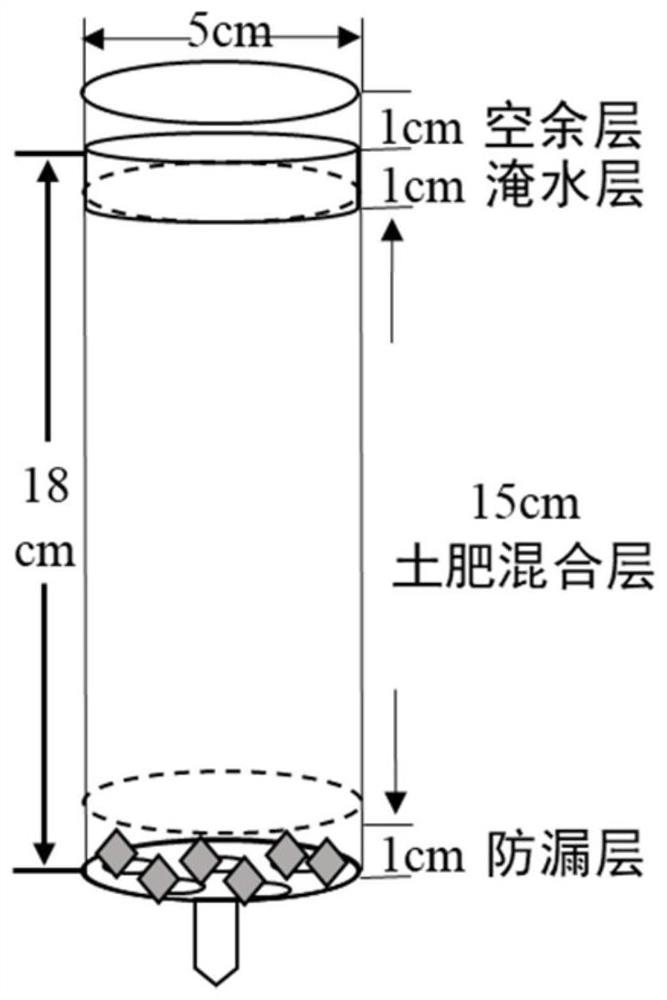

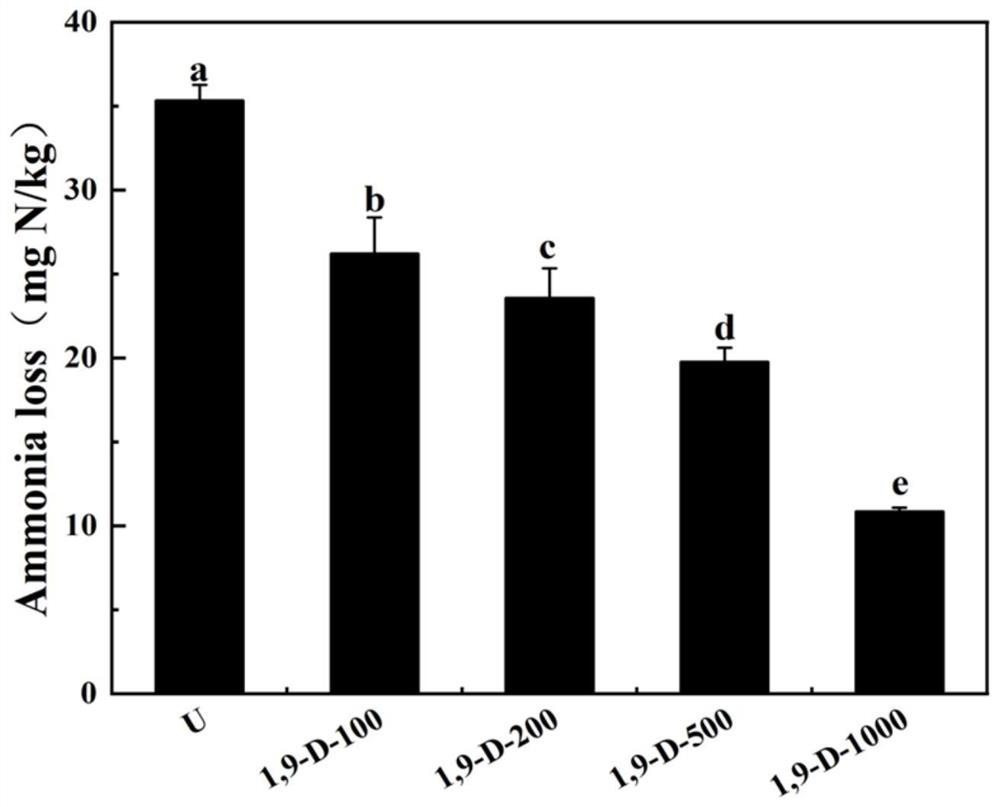

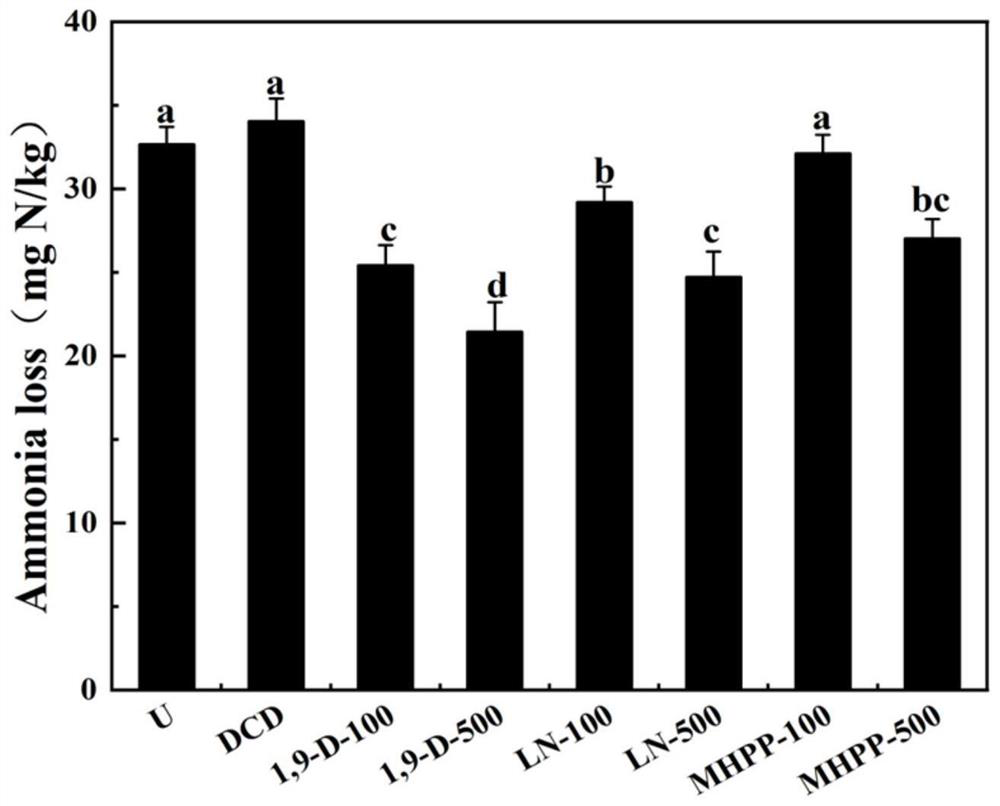

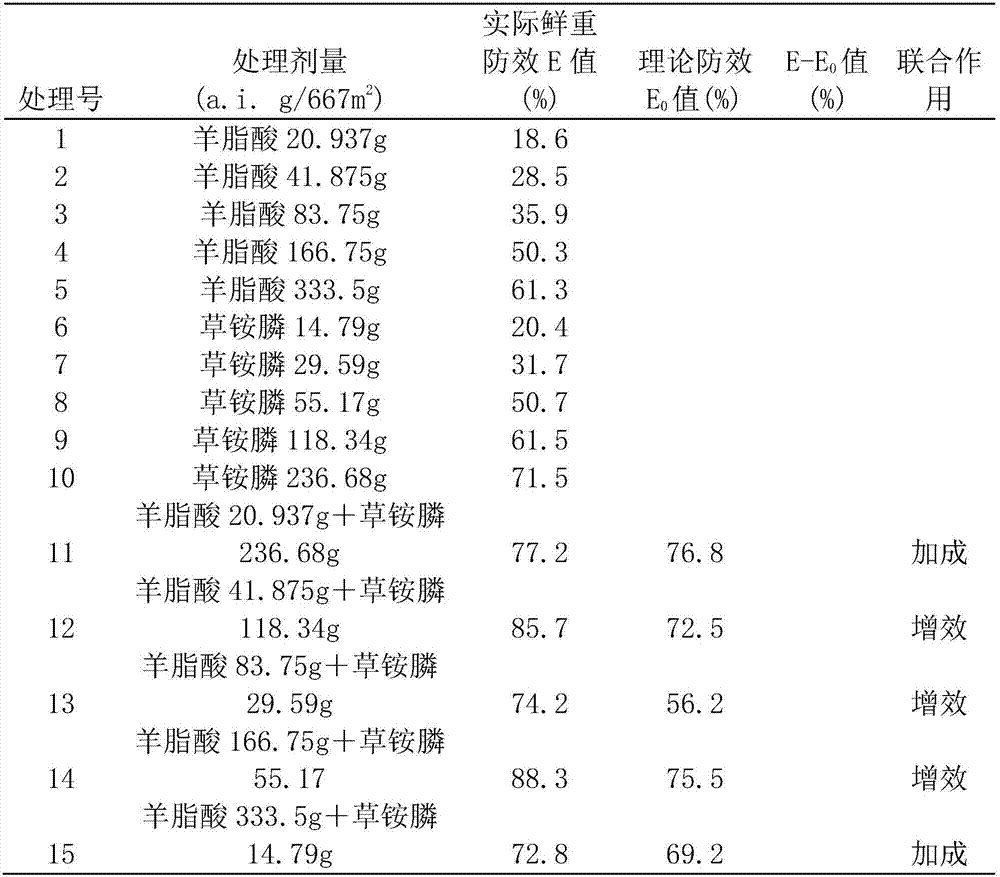

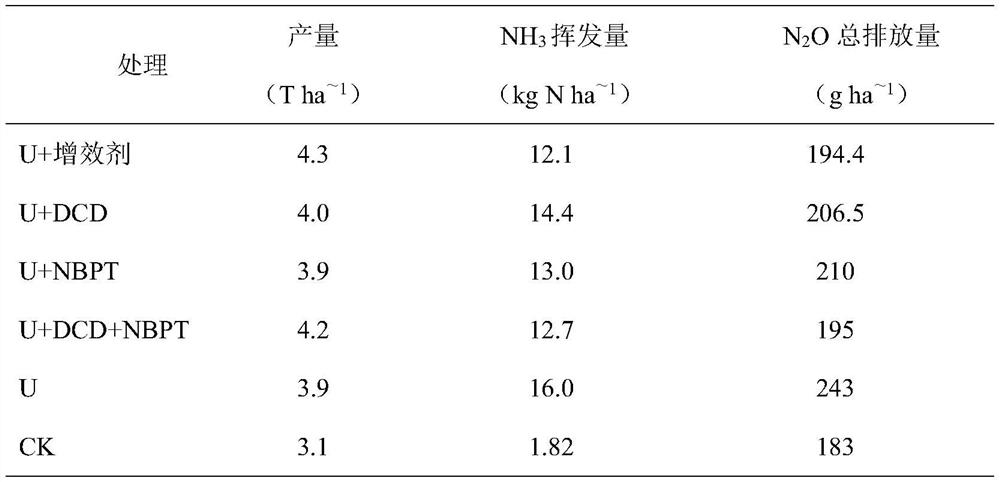

Application of 1, 9-decanediol in inhibition of soil ammonia volatilization

ActiveCN114230416AInhibit nitrificationInhibit ammonia volatilizationAgriculture gas emission reductionUrea compound fertilisersSoil sciencePlant roots

The invention discloses application of 1, 9-decanediol in inhibition of soil ammonia volatilization. The invention finds that 1, 9-decanediol has a bidirectional regulation effect, not only can significantly inhibit soil ammonia volatilization, but also can effectively inhibit the nitrification process of nitrogen, and 1, 9-decanediol, as a fat-soluble substance, has high stability in soil and is not easy to separate from a nitrogen fertilizer under the synergistic interaction effect. The 1, 9-decanediol serving as the plant root exudates also has the advantages of being green, safe and free of pollution, so that the application field of the 1, 9-decanediol is widened, and a new method and thought are provided for improving the industrial application value of the 1, 9-decanediol.

Owner:INST OF SOIL SCI CHINESE ACAD OF SCI

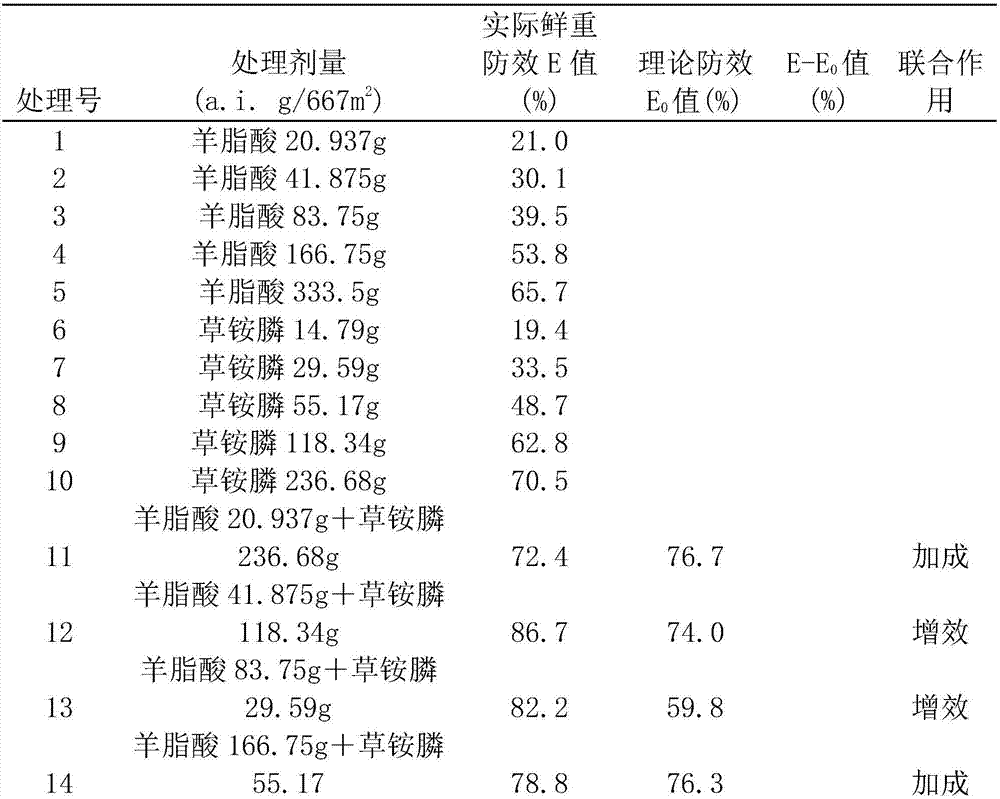

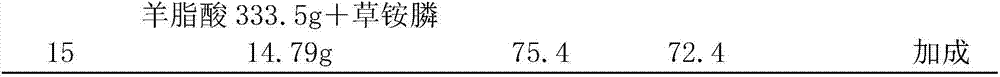

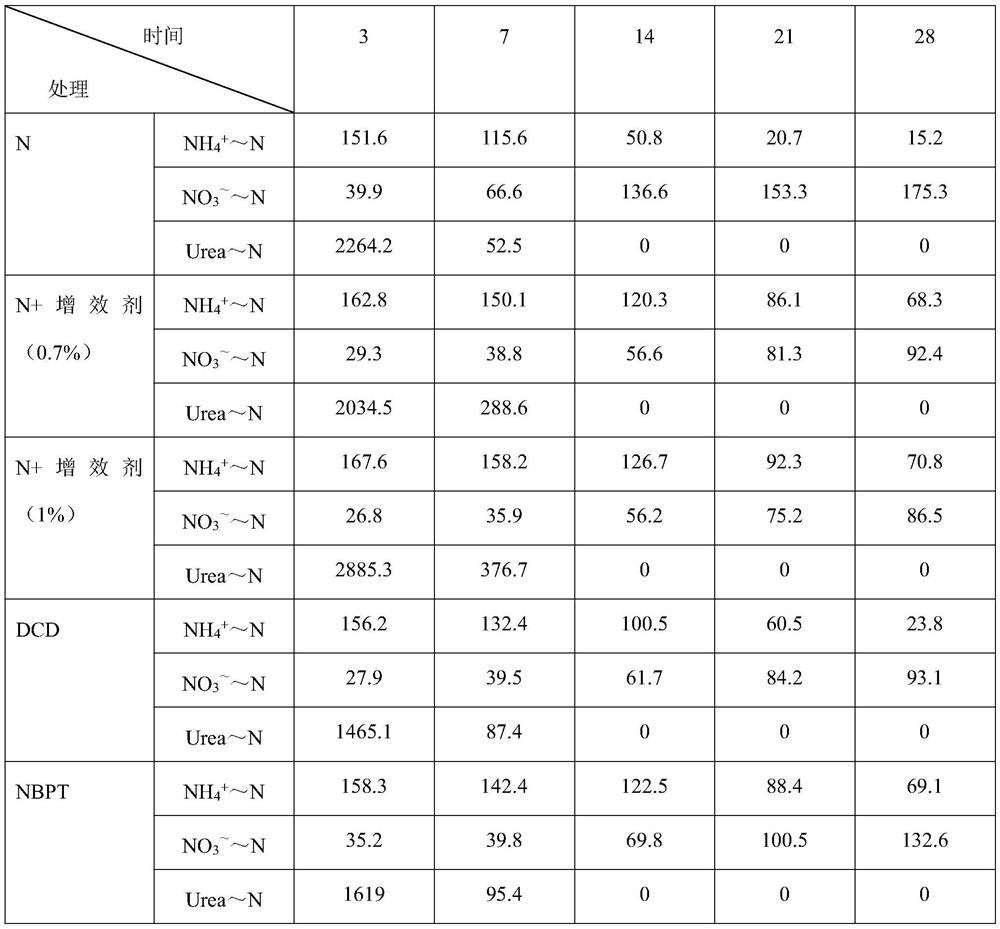

Herbicide composition containing caprylic acid and glufosinate and application of herbicide composition

InactiveCN107950567AReduce dosageLow costBiocideAnimal repellantsEcological environmentActive component

The invention discloses a herbicide composition containing caprylic acid and glufosinate and an application of the herbicide composition. Main active components of the herbicide composition include the caprylic acid and the glufosinate. The dosage form of the herbicide composition can be any pesticidally acceptable dosage form. The herbicide composition achieves good synergistic effects within a certain ratio range, the weeding effect of the composition is improved as compared with that of single dosage, residues of herbicides are decreased, and the potential threat of the herbicides to ecological environments is relieved.

Owner:HUNAN AGRI BIOTECH RES CENT

Application of 2-cyclopentenone-containing compound as synergist of nitrogen-containing fertilizer

InactiveCN113024328AWith two-way control functionAvoid hydrolysisAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersBenzoic acidUrease enzyme

The invention provides a synergist using a 2-cyclopentenone-containing compound as a nitrogen-containing fertilizer. The synergist comprises the components by weight: 5-25 parts of benzoic acid, 3-20 parts of 2-cyclopentenone, 1-30 parts of dihydrojasmonone, 10-60 parts of glycerol and 20-55 parts of yeast liquid powder. The novel synergist is applied to the nitrogen-containing fertilizer, and the nitrogen-containing fertilizer can be prepared. The addition amount of the synergist in the nitrogen-containing fertilizer is 0.1-1% of the nitrogen content in the fertilizer. The preparation method comprises the following steps: a first method comprising the steps of spraying and wrapping the synergist on the surface layer of the fertilizer; a second method comprising the steps of mixing with a grain-level powdery nitrogen fertilizer, and granulating the nitrogen fertilizer to form a stable fertilizer; a third method comprising the steps of adding into a urea production system to form urea; and a fourth method comprising the steps of spraying and granulating ammonium phosphate. The synergist has a bidirectional regulation function, can inhibit hydrolysis of urea to play a role in urease inhibition, can delay conversion from ammonium nitrogen to nitrate nitrogen to play a role in nitrification inhibition, and also has the advantages of good action effect, environmental protection and the like.

Owner:沈阳中科新型肥料有限公司

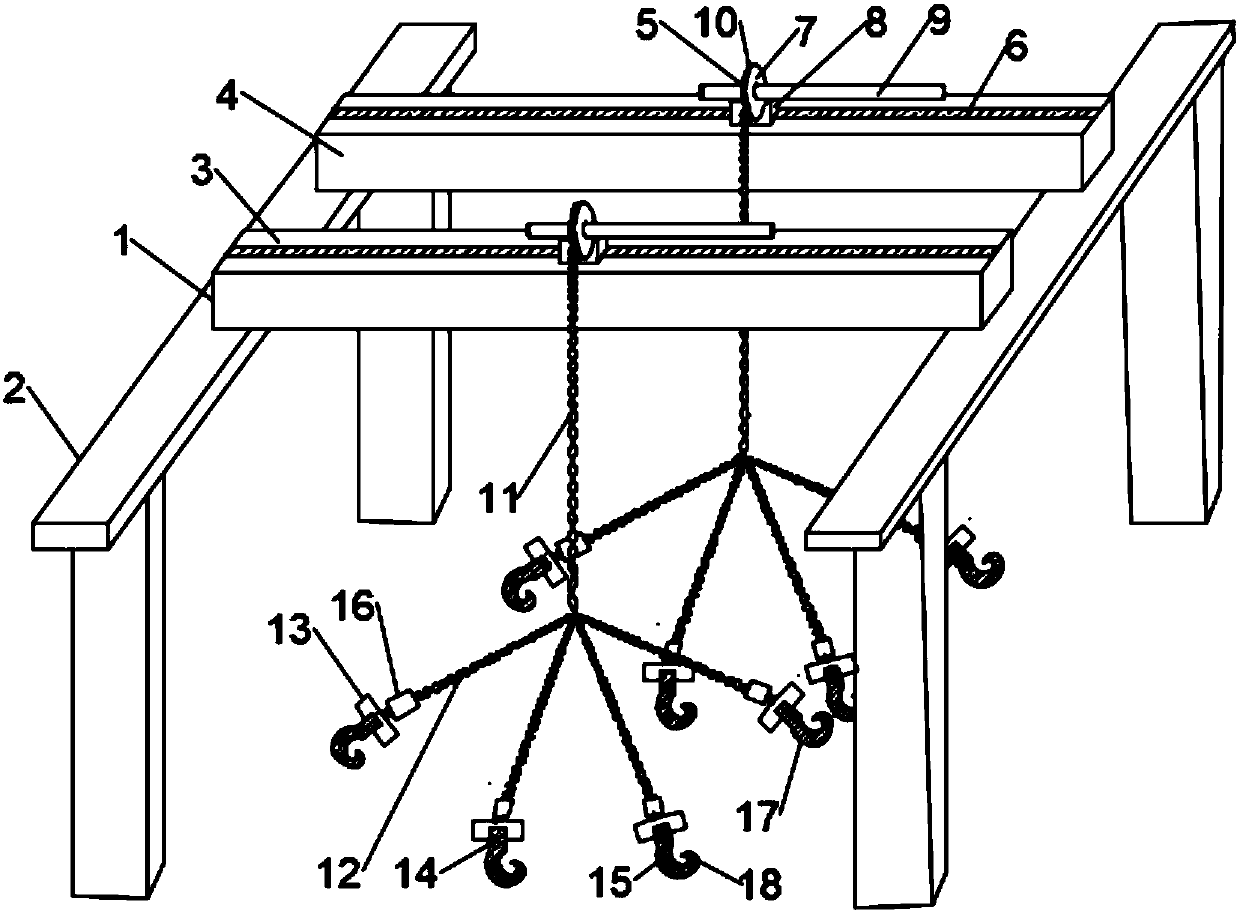

Lifting appliance special for bridge type crane

InactiveCN107686059AImprove work efficiencyImprove stabilityTravelling cranesTrolleysLeather beltEngineering

The invention discloses a lifting appliance special for a bridge type crane. The lifting appliance comprises a bridge and an overhead part. The bridge comprises a main beam and an auxiliary beam whichare each of a box-type structure, traction devices are arranged on the upper surfaces of the main beam and the auxiliary beam correspondingly and comprise tracks and rolls, and the tracks are weldedto the upper surfaces of the main beam and the auxiliary beam. Sliding blocks are arranged above the tracks and can move along the tracks transversely. The rolls are arranged at the upper ends of thesliding blocks, the centers of the rolls are provided with rotary shafts, and one ends of the rotary shafts are connected with motors through belts. Grooves are formed in the outer surfaces of the rolls, the interiors of the grooves are wound with steel wire ropes, and one ends of the steel wire ropes extend to the lower end of the bridge. A plurality of branches are arranged at the lower ends ofthe steel wire ropes, the top ends of the branches and the steel wire ropes are hinged together, and the bottom ends of the branches are provided with hanging rings. The hanging rings are connected with hangers through screws. The structure is simple, operation is easy and convenient, the function of material hanging can be achieved, the problems put forward by the background technology can be effectively solved, and the lifting appliance is worth popularizing.

Owner:ANHU WUHU CHANGJIANG JACK UP EQUIP CO LTD

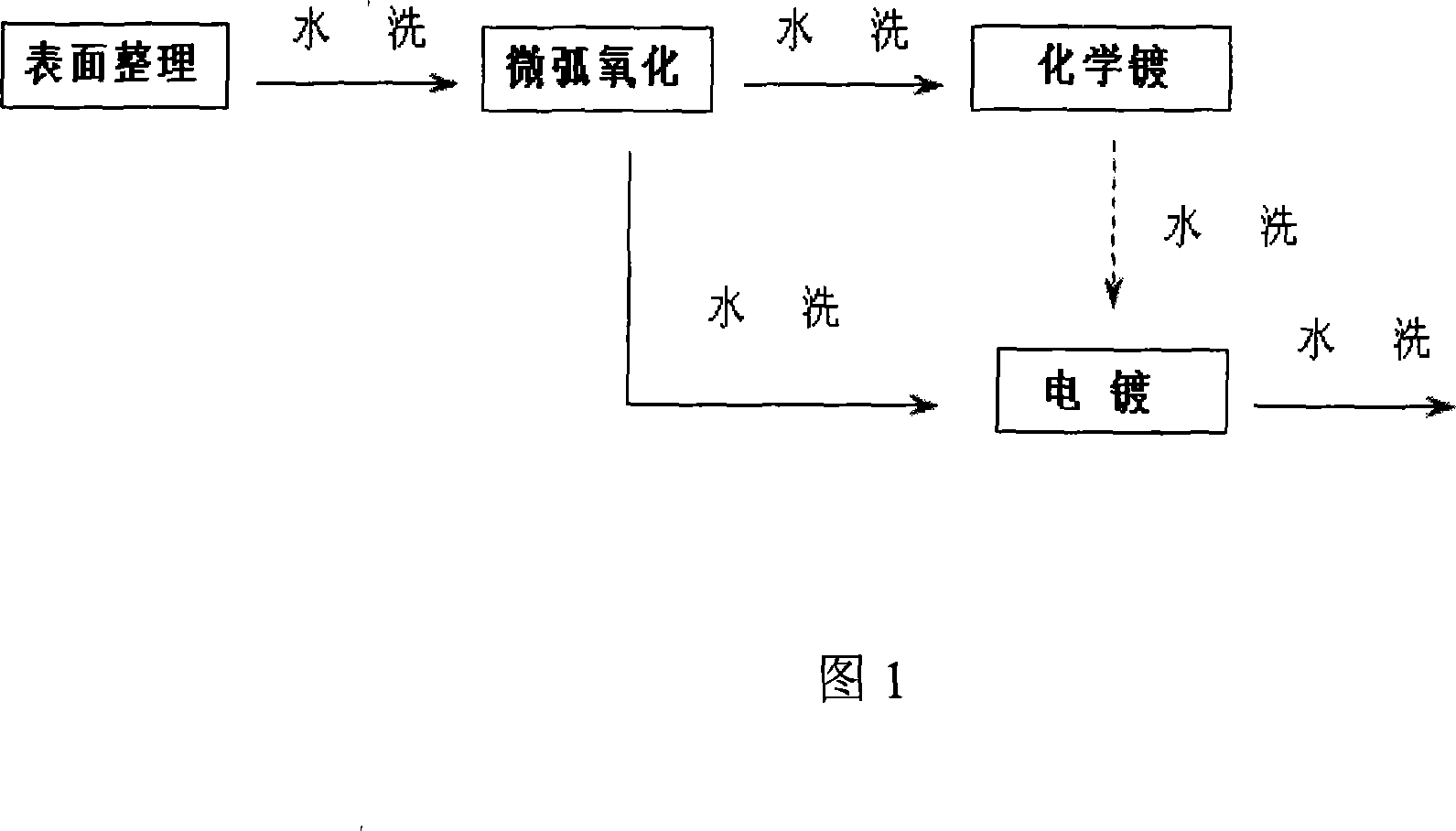

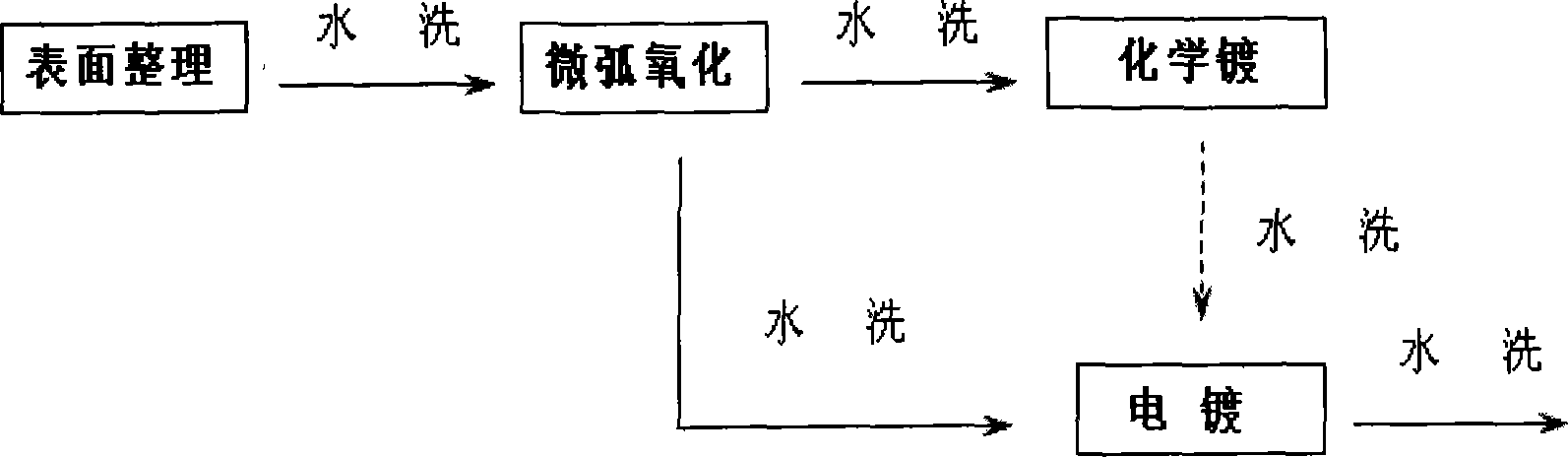

Method for preparing magnesium and magnesium alloy surface coating

InactiveCN101161866BSolving Plating ProblemsAvoid quality problemsAnodisationLiquid/solution decomposition chemical coatingWater basedPorosity

The present invention discloses a magnesium and magnesium alloy surface cladding preparation method which comprises the following procedures: a) the surface is cleaned up; b) electrolyte for micro-arc oxidation is a water-based solution, wherein, the concentration of sodium fluoride is between 1 g / L and 40 g / L; the concentration of sodium phosphate is between 1 g / L and 100 g / L; the sodium fluoride and the sodium phosphate can be used separately or in a combined way, or sodium hydroxide with the concentration between 0.05 g / L and 10 g / L is further added to use; c) the surface is treated bychemical plating and / or d) electroplating; water cleaning is only required among the procedures. The invention based on the knowledge of the related mechanism of plating technology and micro-arc oxidation technology makes the best of the advantages in particular that the micro-arc oxidation ceramic film has the characteristics of corrosion resistance and porosity, and combines the surface ceramictechnology and the surface alloy technology organically and solves the problems of complex working procedures, high cost, large pollution, imperfect effect, etc., in the prior plating art. With the method provided by the invention, a cladding with uniformity, smoothness, a compact structure and excellent performance can be achieved.

Owner:SOUTH CHINA UNIV OF TECH

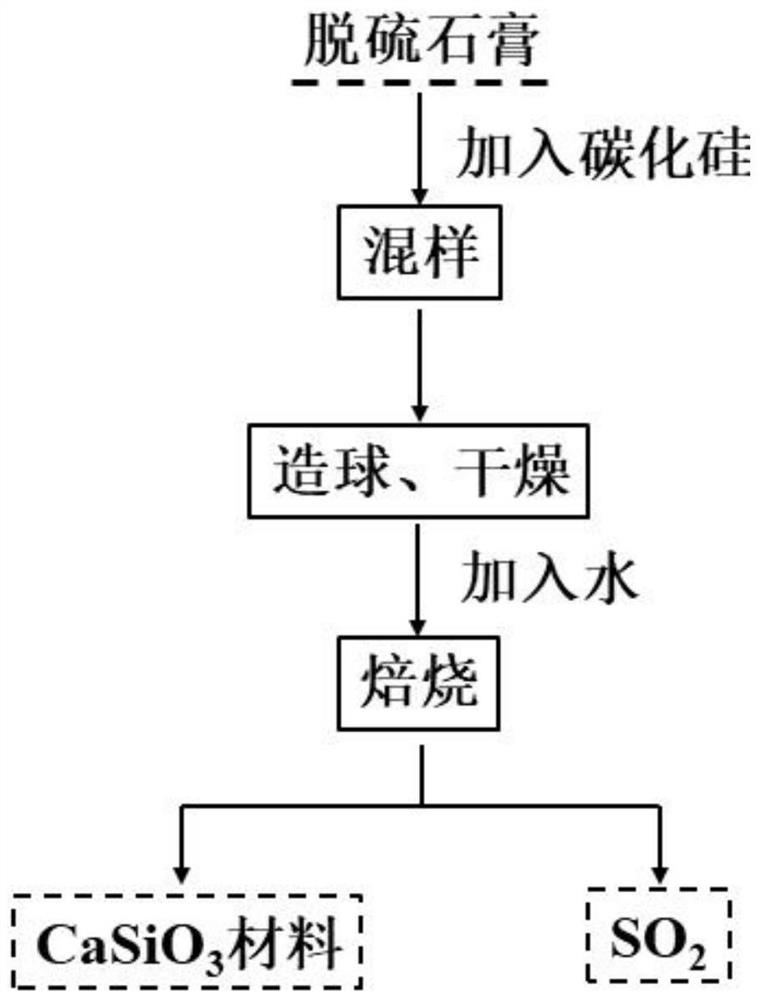

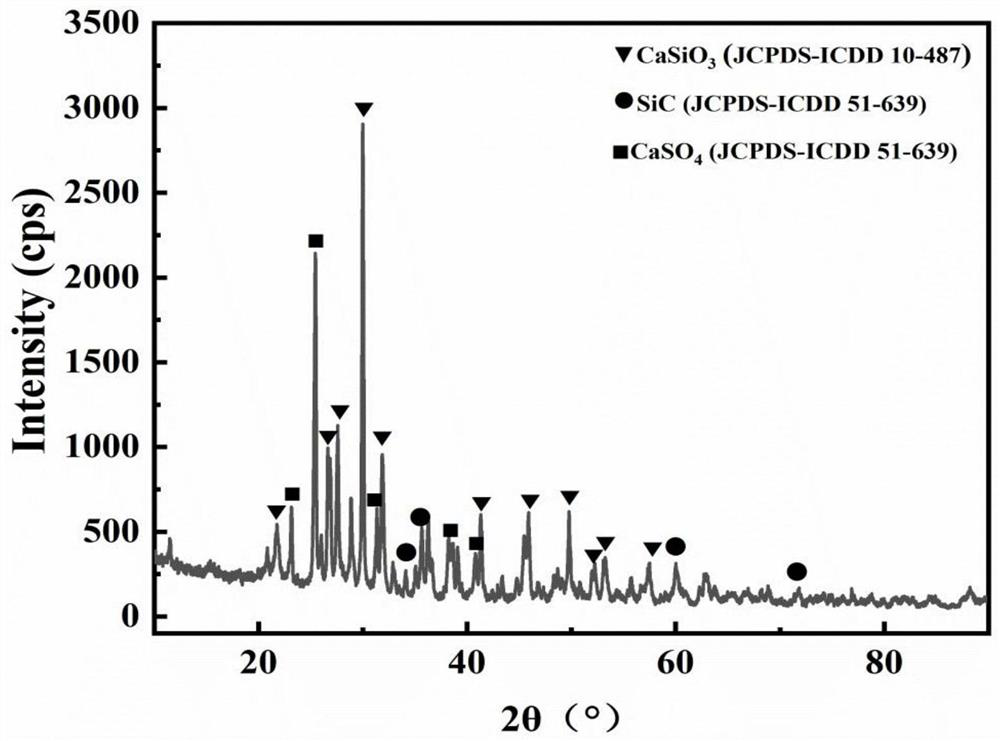

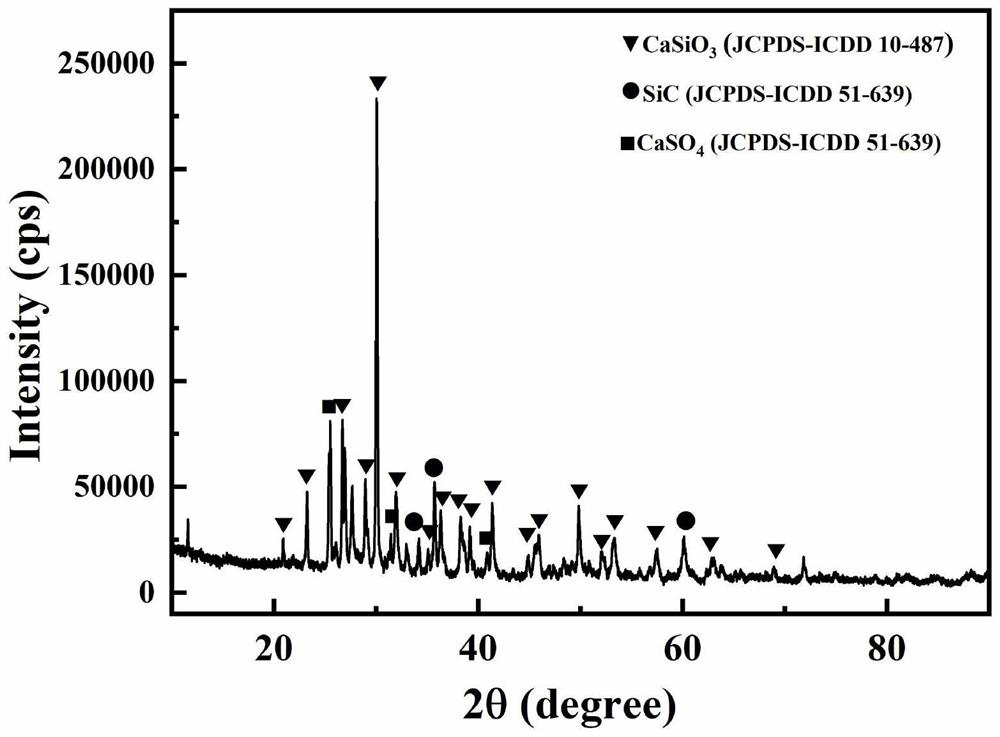

Method for preparing calcium silicate from desulfurized gypsum

PendingCN114873599ALower decomposition temperatureReduce processing energy consumptionAlkaline-earth metal silicatesCalcium silicateCarbide silicon

The invention provides a method for preparing calcium silicate from desulfurized gypsum, and relates to the technical field of solid waste resourceful treatment. The preparation of calcium silicate is realized by taking desulfurized gypsum as a raw material through the steps of drying, mixing, pelletizing, roasting and the like. By utilizing silicon carbide, the decomposition temperature and treatment energy consumption of the desulfurized gypsum are remarkably reduced, meanwhile, the requirement on production equipment is reduced, calcium silicate which can be used as a building material is obtained, and efficient recovery of sulfur resources in the desulfurized gypsum is realized.

Owner:UNIV OF SCI & TECH BEIJING

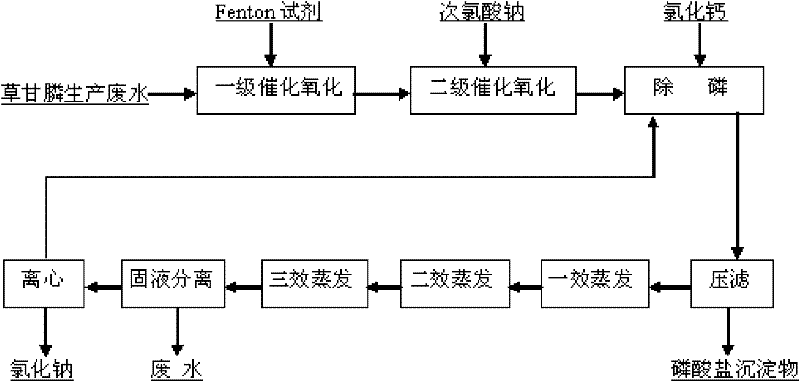

Pretreatment method for glyphosate industrial waste water

InactiveCN101671089BReduce potential threatsQuality improvementMultistage water/sewage treatmentNature of treatment waterPretreatment methodIndustrial waste water

A pretreatment method for glyphosate industrial waste water relates to the technical field of the treatment method for the industrial waste water from pesticides. The invention provides the pretreatment method for the glyphosate industrial waste water, which can remove glyphosate, sodium chloride and reduce COD cr value. The pretreatment method can effectively remove the vast majority of sodium chloride and glyphosate in the glyphosate industrial waste water by adopting steps such as adjusting Ph value, catalytic oxidation, calcification phosphorus removal, triple effect evaporation crystallized sodium chloride removal and the like, and greatly reduces COD cr value; the pretreated waste water can be discharged into a follow-up biochemical treatment system for biochemical treatment, thus causing waste water to be discharged after reaching standards, being beneficial to the protection of the environment and having good social benefits.

Owner:FUJIAN SANNONG GROUP

Method for removing high concentration phosphorus in glyphosate wastewater

InactiveCN102775012BReduce potential threatsMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationHigh concentrationSlag

The invention discloses a method for removing high concentration phosphorus in glyphosate wastewater. The method comprises the following steps: adding a reducing agent to the glyphosate wastewater firstly, then adding hydrolytic enzyme and coenzyme to convert organic phosphorus into inorganic phosphorus; then using alkali to adjust PH and adding inorganic polymer flocculant for flocculating settling; adding sodium hypochlorite, polyethylene succinic acid and glycerol to the settled wastewater, injecting the wastewater into a high pressure vessel and drumming air into the vessel to maintain the total pressure in the range of 5.0-6.0MPa; finally, open a container channel to release the wastewater into a pond to form white mist foam. A layer of greasy substance generated in the upper part of the pond can be removed by a slag adhering machine. The method provided by the invention does not have to convert organic phosphorus into inorganic phosphorus through the hydrolysis of hydrolytic enzyme and coenzyme at the high pressure and high temperature condition, the inorganic polymer flocculant added has selectivity. The method provided by the invention can reduce the concentration of phosphorus in glyphosate wastewater to 0.5mg / L or less. And the removal efficiency of phosphorus can reach more than 99.9%.

Owner:CHANGZHOU UNIV

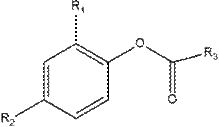

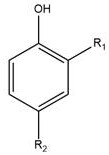

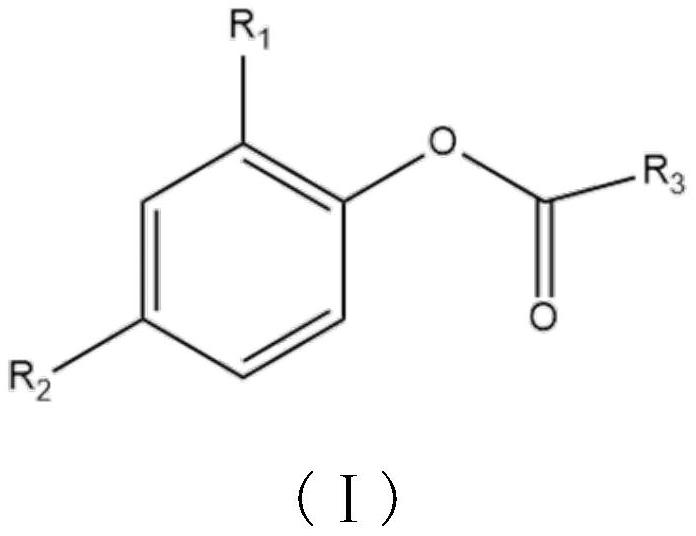

Preparation and Application of Herbicidal Compounds with Different Substituents of Phenol Esters

ActiveCN108935467BGood control effectReduce dosageBiocidePreparation from carboxylic acid halidesPhenolToxicology

The invention provides preparation of a phenolic ester herbicidal compound with different substituents, and applications. The structure contained by the herbicidal compound is shown as a general formula (I); and in the general formula (I), R1 represents -NO2, -Br, -Cl, -F, -SO3H or -CN, R2 represents -CH3, -NO2, -Br, -Cl, -F, -SO3H, -CN or -SO3NH2, and R3 represents C6-C12 alkyl or C6-C8 alkenyl.The herbicidal compound can effectively reduce the using amount and costs of herbicides, so that residuals can be reduced, and potential threats of pesticide to environments can be mitigated.

Owner:HUNAN AGRI BIOTECH RES CENT

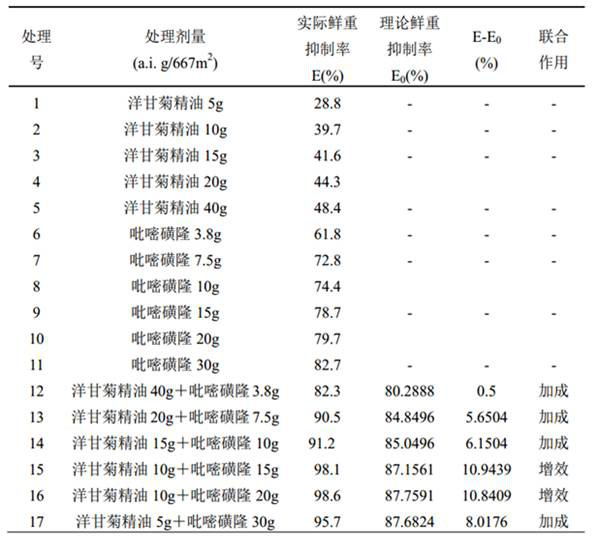

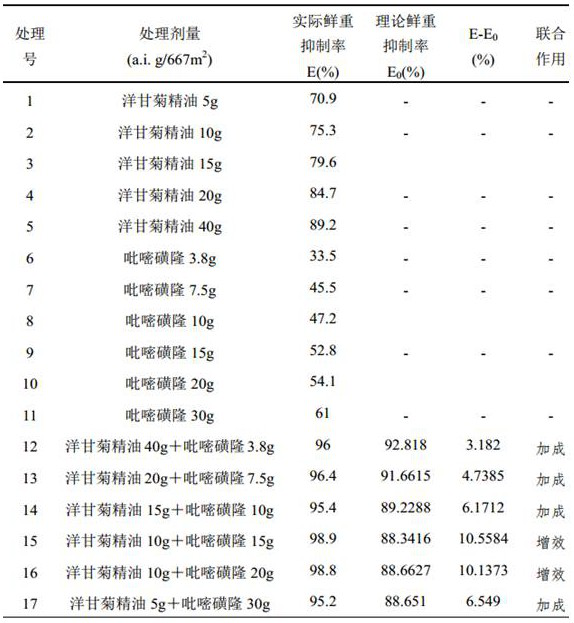

A herbicide composition containing chamomile essential oil and pyrazosulfuron-methyl and its application

Owner:HUNAN AGRI BIOTECH RES CENT

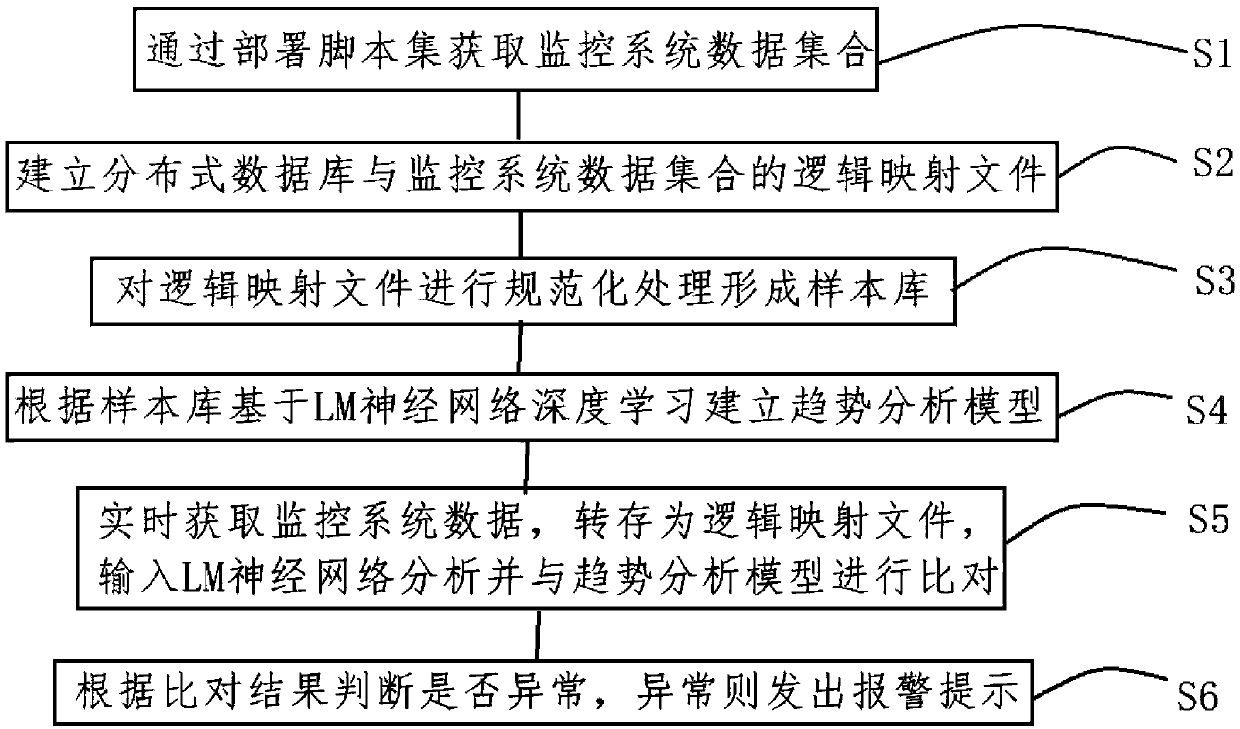

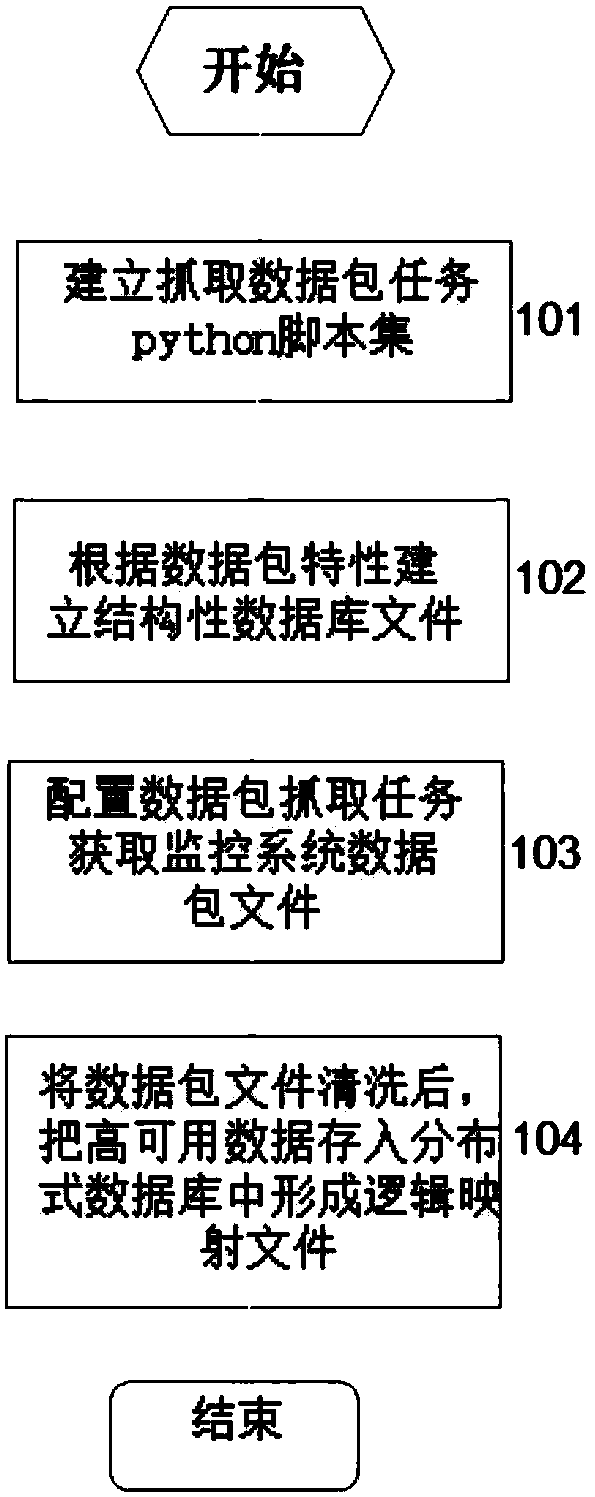

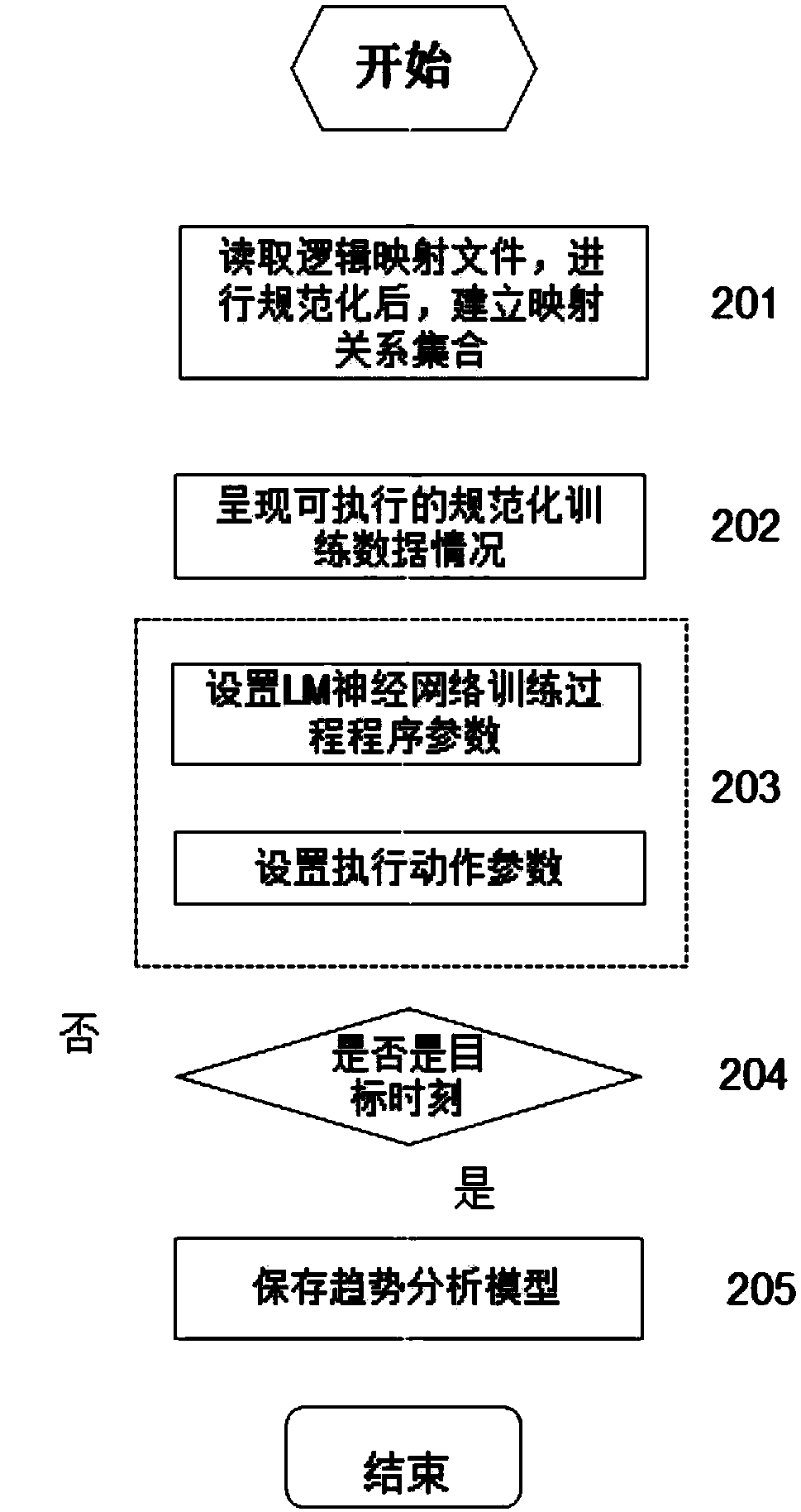

Coal mine monitoring system safety early warning method based on LM neural network

ActiveCN110891039AReduce potential threatsImprove the ability of security early warningNeural architecturesTransmissionNeural network analysisData science

The invention discloses a coal mine monitoring system safety early warning method based on an LM neural network. The method comprises the following steps of acquiring a monitoring system data set by deploying a script set; establishing a logic mapping file of the distributed database and the monitoring system data set; normalizing the logic mapping file to form a sample library; establishing a trend analysis model based on LM neural network deep learning according to the sample library; acquiring monitoring system data in real time, transferring the monitoring system data into a logic mappingfile, inputting the logic mapping file into an LM neural network for analysis, and comparing the logic mapping file with the trend analysis model; judging whether abnormity occurs or not according toa comparison result, and if abnormity occurs, giving an alarm prompt.According to the invention, a safety early warning function can be realized for the monitoring system, potential threats caused byhuman participation are reduced, early sensing of network data situation changes of the monitoring system is realized, the safety early warning capability is improved, and the operation and maintenance cost of the protection system is reduced.

Owner:CCTEG CHINA COAL RES INST

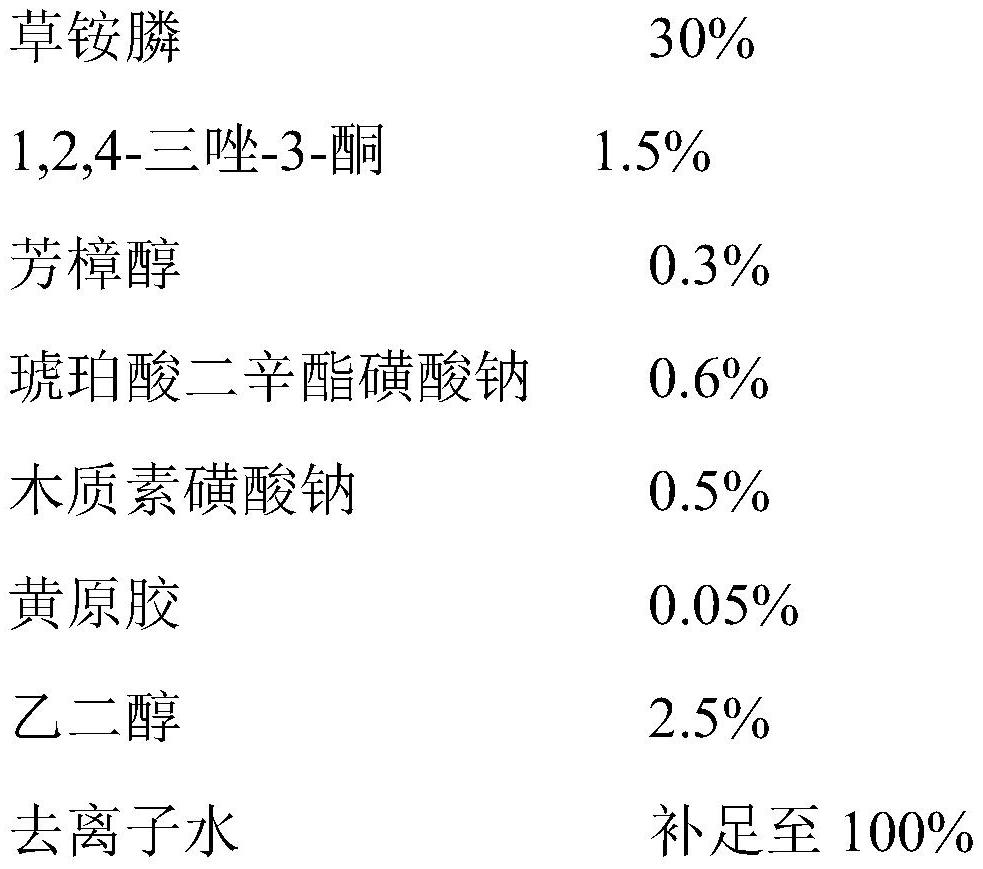

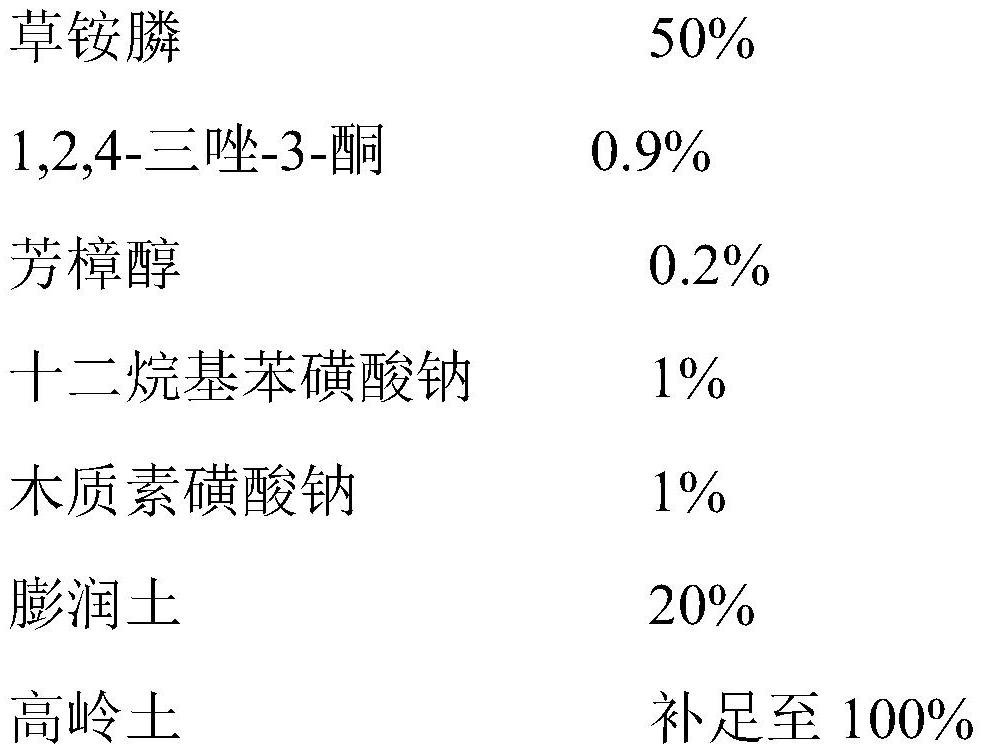

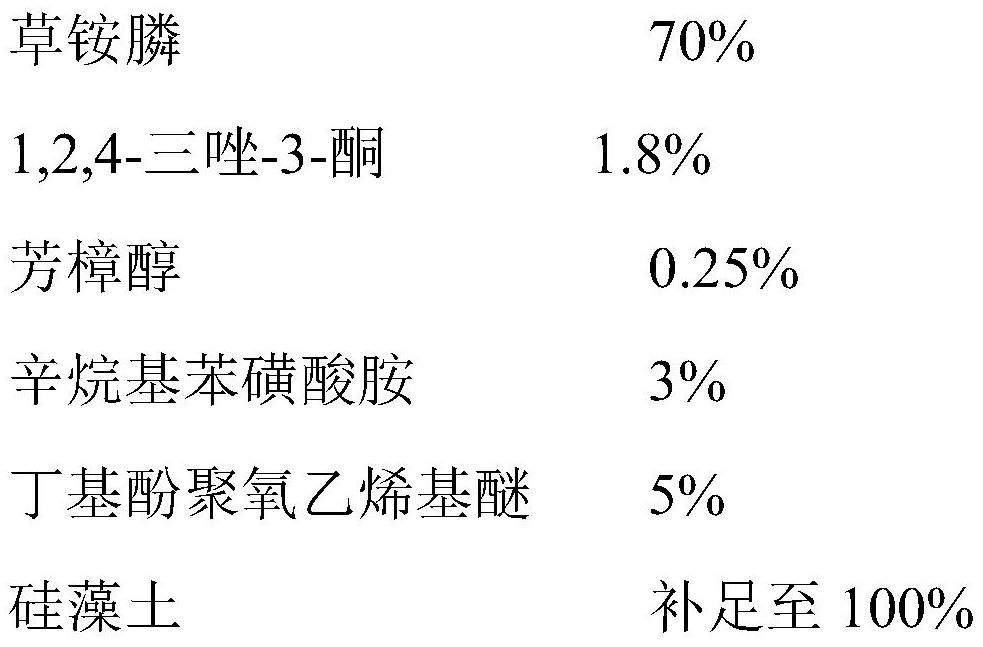

A kind of synergistic herbicidal composition and its preparation and application

The invention discloses a synergistic herbicidal composition and its preparation and application. The synergistic herbicidal composition consists of glufosinate-ammonium, 1,2,4-triazol-3-one, linalool and optional adjuvants. The herbicidal composition can promote the absorption and conduction of effective ingredients by weeds, so that the onset time is significantly shortened, the weeds are not easy to turn green after the onset of effects, the biological activity of glufosinate-ammonium for killing weeds is significantly improved, and at the same time resistance to weeds Grass has a good control effect. While increasing the herbicidal effect of glufosinate, it can reduce the unit dosage and use frequency of glufosinate, thereby reducing the pollution of glufosinate to the environment and slowing down the resistance of weeds to glufosinate. It is of great significance to the comprehensive management of weed resistance.

Owner:WANHUA CHEM GRP CO LTD

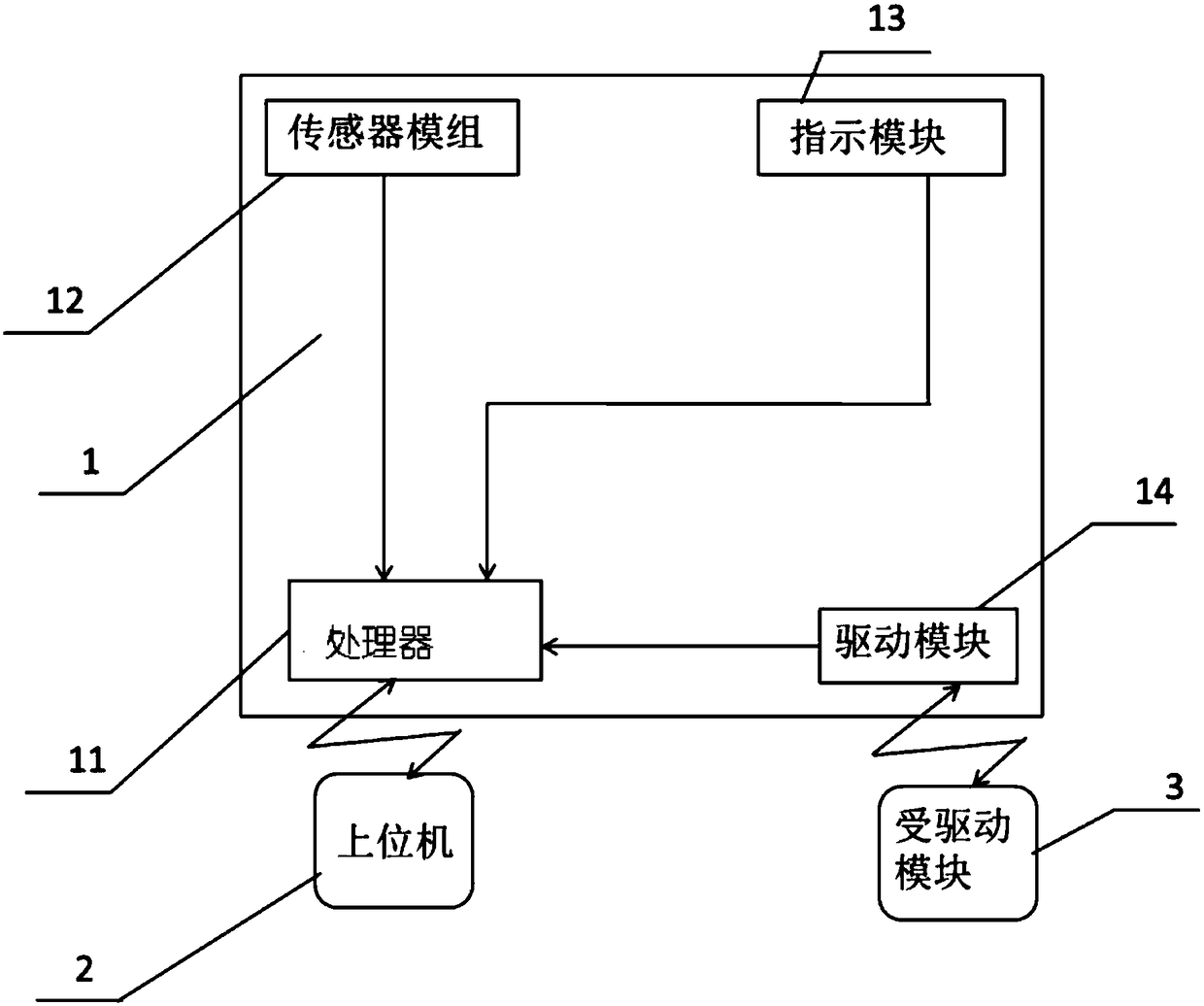

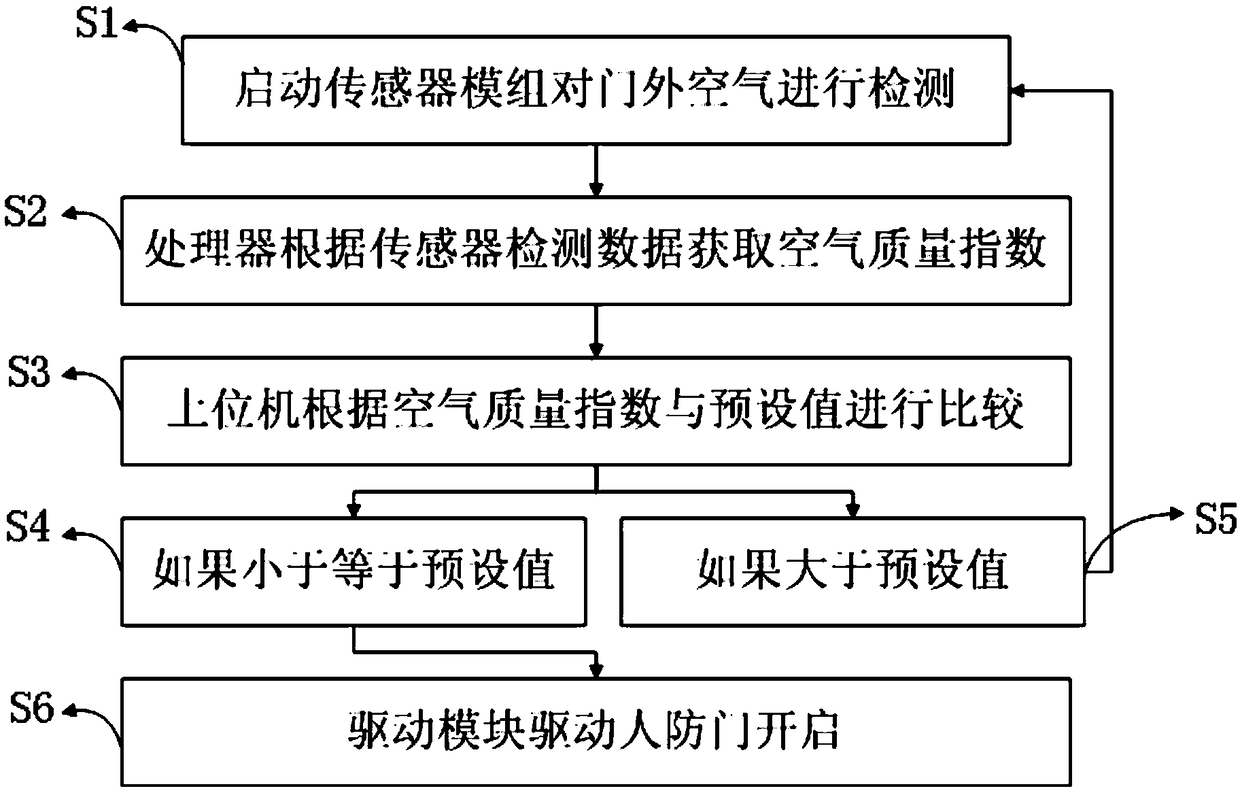

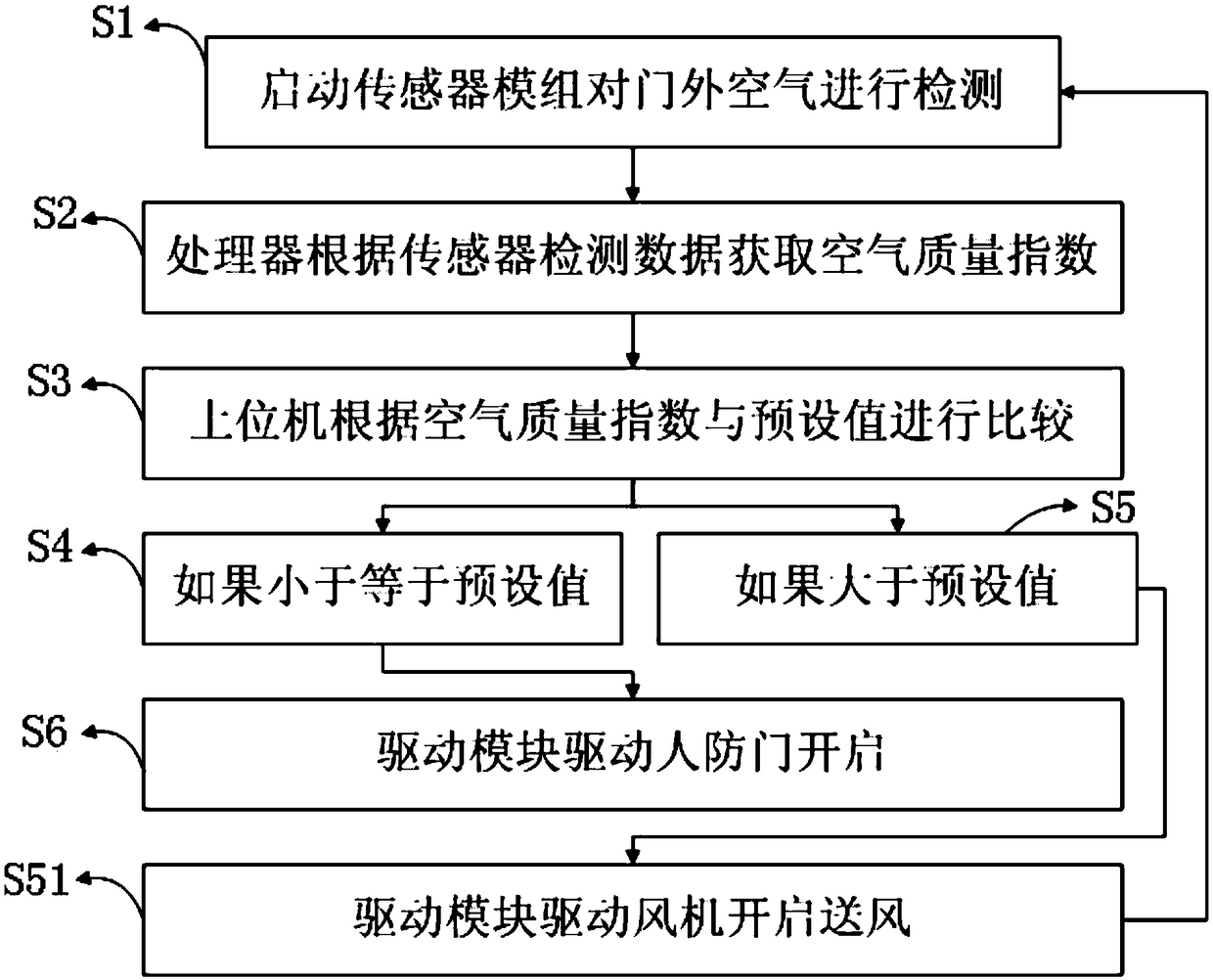

On-line monitoring control system and method for external environment of civil air defense door

InactiveCN108765663AReduce potential threatsImprove securityPump controlIndividual entry/exit registersEnvironmental safetyControl system

The invention relates to an on-line monitoring control system and method for external environment of a civil air defense door. The on-line monitoring control system and method are used for an electriccivil air defense door. The system comprises a sensor module, a processor, an upper computer and a driving module, wherein the sensor module is used for acquiring environmental information outside the civil air defense door; the processor is used for acquiring the civil air defense door outside environmental information collected by the sensor module, processing the environmental information intoto-be-compared information and transmitting the information to the upper computer; the upper computer is used for acquiring the to-be-compared information and comparing the to-be-compared informationwith a preset value; the driving module is used for driving an actuator of the electric civil air defense door to further control opening and closing of the electric civil air defense door; the uppercomputer sends a door opening instruction to the processor when judging that the to-be-compared information is lower than the preset value, and the processor controls the driving module to drive theactuator of the civil air defense door to act to open the civil air defense door. The environmental safety situation outside the door can be known accurately in real time, and the civil air defense door is opened automatically after environmental safety is confirmed, so that potential threat is reduced, and safety is improved.

Owner:成都天仁民防科技有限公司

Ratproof and termiteproof material

The invention discloses a ratproof and termiteproof material, which comprises the following components in percentage by weight: 80 to 85 percent of polypropylene, 8 to 20 percent of glass fiber, 0.6 to 2 percent of capsaicine, 0.8 to 2 percent of dihydrocapsaicine and 1 to 2.5 percent of cypermethrin. Because the capsaicine, the dihydrocapsaicine and the cypermethrin can generate strong odor irritating both olfactory sensation and taste sensation of mice and insects, the ratproof and termiteproof material can effectively prevent the bite and encroachment of mice and termites and is particularly suitable to manufacture civil engineering members used outdoors for a long period of time such as filling sacks and fixing buckles used in barrier building; a built barrier has less potential threat and high safety factor and passes experimental verification; and the mechanical property of the ratproof and termiteproof material is identical to that of ordinary polypropylene materials and does not influence the quality of products manufactured by the material.

Owner:CHONGQING DANHAI IND

Herbicide composition containing caprylic acid and MCPA-Na and application of herbicide composition

InactiveCN107980778AReduce dosageLow costBiocideAnimal repellantsEcological environmentActive component

The invention discloses herbicide composition containing caprylic acid and MCPA-Na and an application of the herbicide composition. The main active components of the herbicide composition comprise caprylic acid and MCPA-Na. The herbicide composition can be prepared into any pesticide allowable dosage form. The herbicide composition enlarges the herbicidal spectrum, has better effects on both broadleaved weeds and grassy weeds and shows a good synergistic effect in a certain ratio range, the herbicidal effect of the composition is improved to a certain extent as compared with a single agent, meanwhile, residues of the herbicide are reduced, and potential threat of the herbicide to the ecological environment is relieved.

Owner:HUNAN AGRI BIOTECH RES CENT

Authentication processing method for broadband network

ActiveCN100550727CAuthentication normalAvoid misjudgmentUser identity/authority verificationNetwork terminationNetwork addressing

The invention provides a method for authentication processing in a broadband network, the core of which is: record the address information of the network terminal in the online state; when receiving the authentication request message of the network terminal, obtain the address of the network terminal sending the authentication request message information; match the acquired address information with the recorded address information, and determine the network terminal matching the recorded address information; according to the authentication request message of the network terminal matching the recorded address information, the network The terminal is authenticated. The present invention utilizes the authentication request message of the network terminal and the address information of the network terminal to ensure the real-time performance of the detection of the network terminal being hanged, to ensure that the normal network terminal can surf the Internet casually and normally, and to avoid forcing the normal network terminal to go offline The phenomenon of dispersing the processing load of network equipment; thereby achieving the purpose of improving the reliability of authentication processing, reducing the potential threat of network equipment, and reducing the potential cost of network equipment authentication processing.

Owner:HUAWEI TECH CO LTD

A composition containing sodium 2-methyl-4-chloride and cyclohexenone herbicides and its application

The invention discloses a composition containing 2-methyl-4-chloride sodium and cyclohexenone herbicides. The active ingredients of the herbicide composition are: 2-methyl-4-chloride sodium and cyclohexenone herbicides. The mass ratio of sodium 2-methyl-4-chloride to the cyclohexenone herbicide is 1:10-10:1. Preferably, the mass ratio of the 2-methyl-4-chloride sodium to the cyclohexenone herbicide is 1:6 to 6:1; most preferably, the 2-methyl-4-chloride sodium and the cyclohexenone The mass ratio of herbicides is 1:1~6:1. The dosage form of the herbicide composition of the present invention can be any dosage form permitted on pesticides. The herbicide composition of the present invention exhibits a good synergistic effect within a certain proportion range, and the herbicide effect of the composition is significantly improved compared with a single agent, while reducing the amount and cost of herbicide, reducing residues, and reducing pesticide residues. potential threat to the environment.

Owner:HUNAN AGRI BIOTECH RES CENT +1

An application-based behavior processing method and device

InactiveCN104484599BAvoid Monitoring VulnerabilitiesRealize fine-grained permission controlDigital data authenticationPlatform integrity maintainanceApplication procedureWhitelist

An embodiment of the present invention provides an application-based behavior processing method and device. The method includes: when an application startup operation is detected, acquiring behavior authority information corresponding to the application; monitoring the application behavior information; and processing the behavior information according to the behavior authority information. The embodiment of the present invention configures the behavior authority information for the behavior, and uses a single behavior as the authority unit to monitor the application program, avoiding the monitoring loopholes caused by the unified authority configuration of the application program by the black and white lists, realizing fine-grained authority control, and enhancing The strength of protection, reducing potential threats, can also reduce the false alarm rate.

Owner:BEIJING QIHOO TECH CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com