Method for preparing calcium silicate from desulfurized gypsum

A technology for desulfurizing gypsum and calcium silicate, applied in the direction of silicate, alkaline earth metal silicate, etc., can solve the problems of large storage volume and low utilization rate of sulfur-containing gypsum, reduce decomposition temperature and processing energy consumption, and reduce Requirements, the effect of mitigating potential threats

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

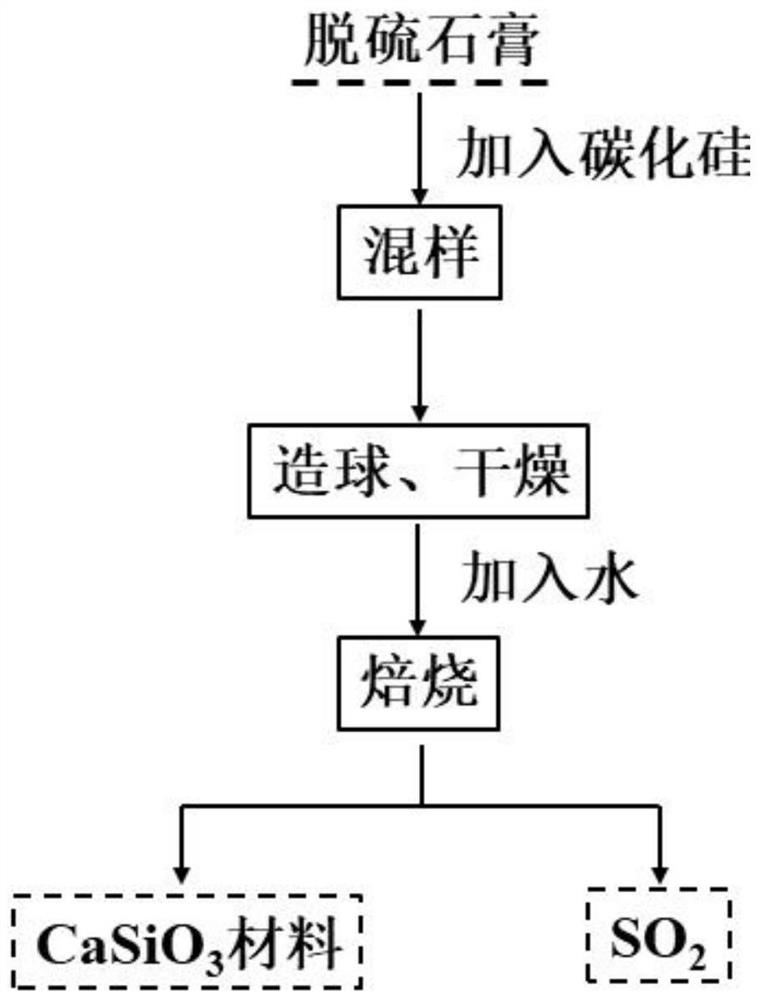

[0049] A kind of method for preparing calcium silicate with desulfurized gypsum

[0050] (1) Dry desulfurization gypsum and silicon carbide in a drying oven at 85°C for 18 hours in advance, mix the dried desulfurization gypsum and silicon carbide in a ratio of 3:1 by mass, put them in a ball mill and mix thoroughly for 3 hours, The speed of the ball mill is 100r / min; 5-8:2-5

[0051] (2) Add 10% water to the mixed sample to make pellets, the diameter of the pellets is 5mm-7mm, and then put the pellets into a drying oven for drying at 60°C for 20h;

[0052] (3) Put the prepared pellets into a muffle furnace for calcination in an air atmosphere, set the heating rate to 5°C / min, select a calcination temperature of 950°C, and keep the temperature at the highest temperature for 1 hour.

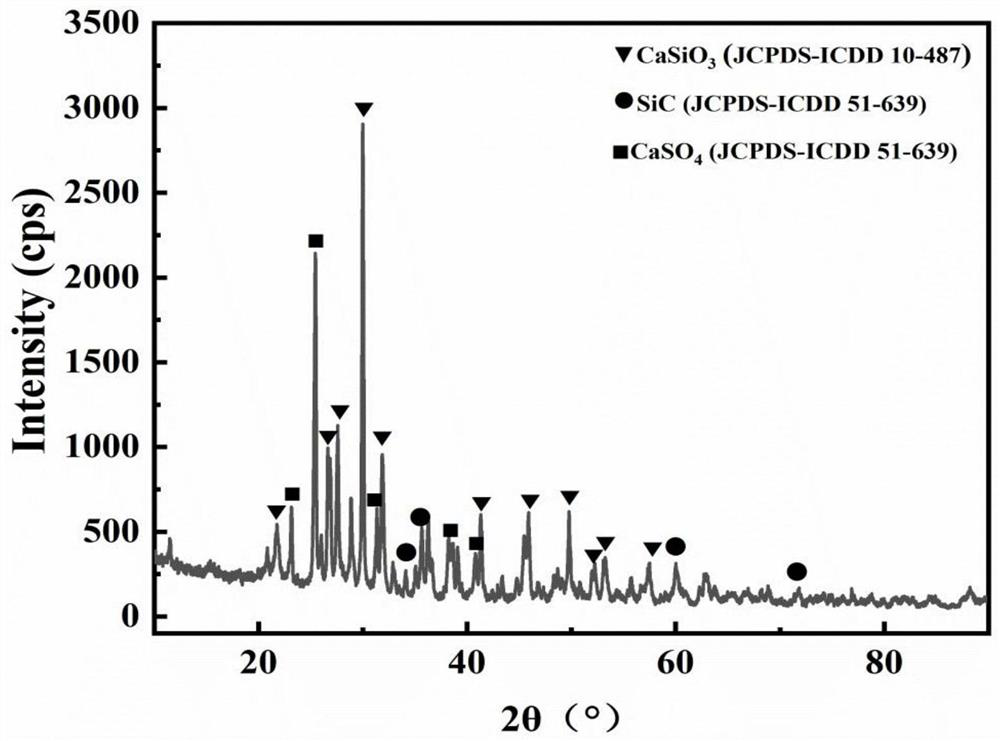

[0053] After testing, the desulfurization rate of the product after roasting is 67%, and the yield of calcium silicate is 69% of the theoretical value. XRD analysis of the product, the results ar...

Embodiment 2

[0055] Same as Example 1, the difference is: the desulfurized gypsum and silicon carbide are mixed in a mass ratio of 2:1.

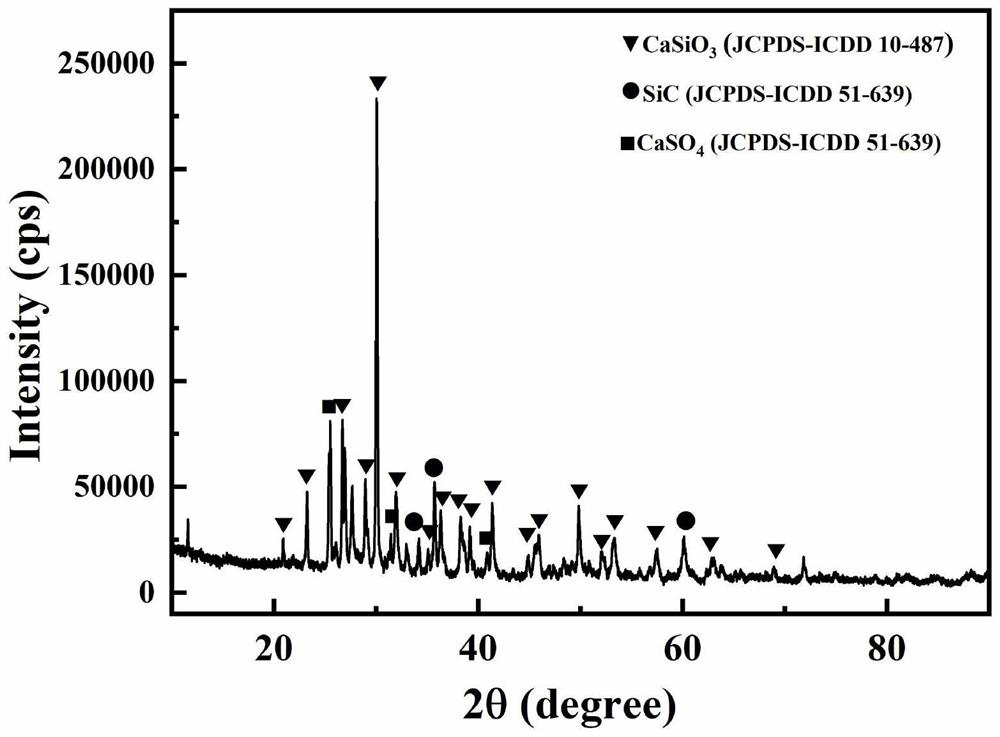

[0056] After testing, the desulfurization rate of the calcined product is 84%, and the yield of calcium silicate is 87% of the theoretical value. XRD analysis of the product, the results are as follows image 3 shown. according to image 3 It can be seen that a large amount of CaSiO was generated in the sample 3 Phase, CaSO 4 The amount of SiC and SiC is very small, indicating that the desulfurization effect is obvious and thorough under this condition, and the addition amount of SiC is also more appropriate.

Embodiment 3

[0058] Same as Example 1, the difference is: the desulfurized gypsum and silicon carbide are mixed in a mass ratio of 1:1.

[0059] After testing, the desulfurization rate of the product after roasting is 95%, and the yield of calcium silicate is 98% of the theoretical value. XRD analysis of the product, the results are as follows Figure 4 shown. according to Figure 4 It can be seen that a large amount of CaSiO was generated in the sample 3 Phase, CaSO 4 The amount of SiC is already very small, indicating that the desulfurization effect is obvious and complete under this condition, but the addition of SiC is excessive.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com