Sulfonated phenolic resin and preparation and application as catalyst thereof

A technology of sulfonated phenolic resin and phenolic resin, applied in the catalytic synthesis of trioctyl citrate and tributyl citrate, the field of sulfonated phenolic resin solid acid catalyst, resin type solid acid catalyst, can solve the problem of thermal stability Poor performance, affecting the catalytic effect and other problems, to achieve the effect of low raw material cost, good catalytic effect and simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

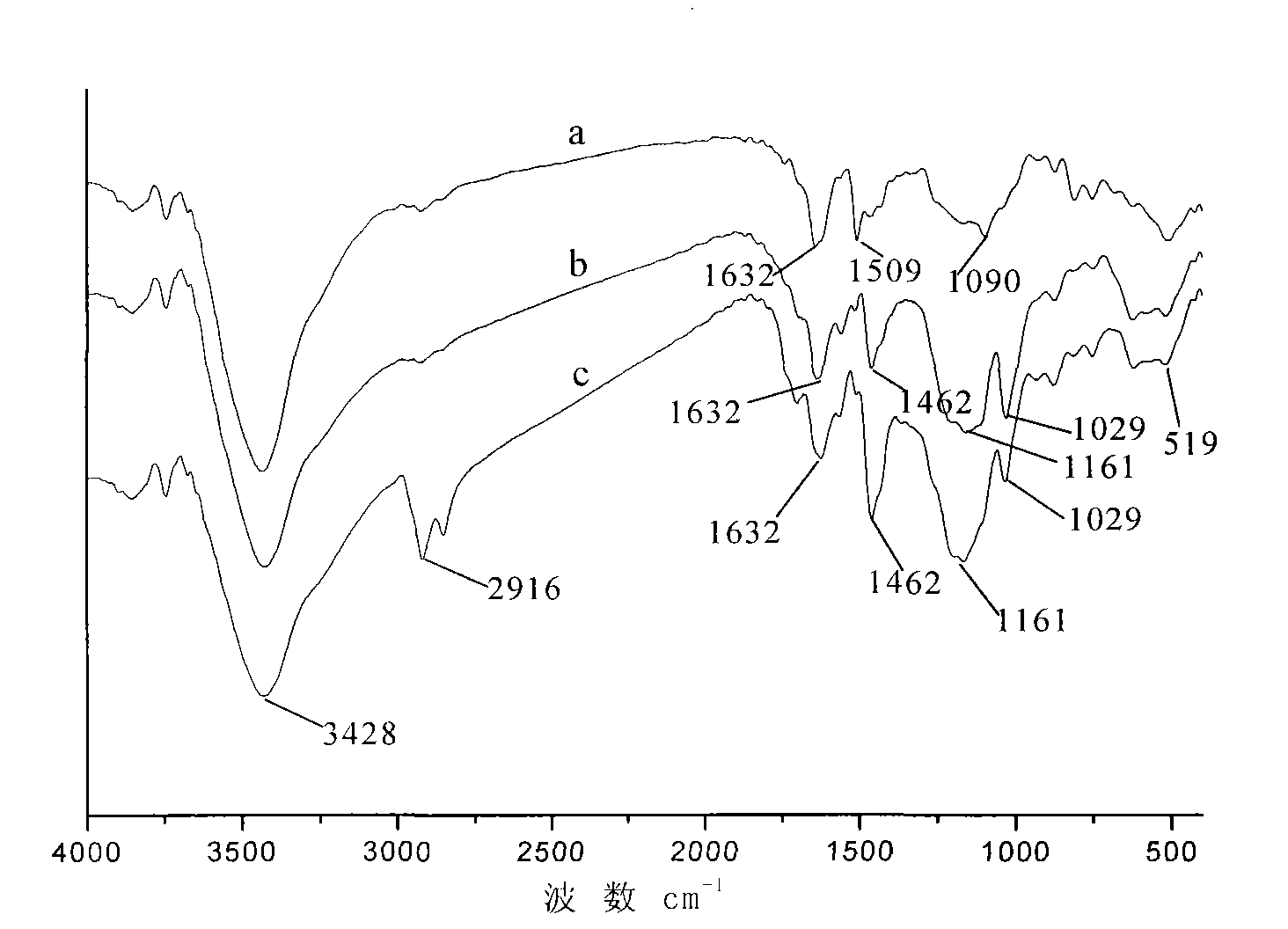

Image

Examples

Embodiment 1

[0067] Embodiment 1, the preparation of sulfonated phenolic resin catalyst

[0068] (1) Preparation of phenolic resin: join phenol in the formaldehyde solution of mass concentration 35~38%, make the molar ratio of phenol and formaldehyde be 1.5:1~2.5:1; 40-60% concentrated hydrochloric acid, heated to 90-110°C for 10-20 minutes; cooled after complete reaction, washed with distilled water, dried, and ground; extracted with ethanol for 20-30 hours to obtain phenolic resin;

[0069] (2) Sulfonation of phenolic resin: Add 2 to 3 times the volume of phenolic resin to dichloromethane into the self-made phenolic resin, and after swelling the phenolic resin for 2 to 3 hours, add concentrated sulfuric acid with the same volume as the resin, React at 80-100°C for 3-5 hours, raise the temperature to 100-120°C, and distill off the solvent dichloromethane completely; add oleum with a resin volume of 50-60% and a mass concentration of 30-60% to the remaining mixture , react at 100-120°C fo...

Embodiment 2

[0070] Embodiment 2, sulfonated phenolic resin catalyst catalytic synthesis trioctyl citrate

[0071] Add citric acid and n-octanol in a molar ratio of 1:5 to a two-necked flask with a water separator and a condenser, mix and heat to 80°C and reflux for about 15 minutes under stirring. When the citric acid is completely dissolved, measure the mixing The initial acid value of the solution; add a sulfonated phenolic resin catalyst with 4.5% citric acid mass to the mixed solution, control the temperature at 140°C, react for 5 hours, and separate the water produced by the reaction in time. After the reaction, take the reaction solution to measure the acidity. Value, calculate the esterification rate of trioctyl citrate: 96.0%.

Embodiment 3

[0072] Embodiment 3, sulfonated phenolic resin catalyst catalytic synthesis tributyl citrate

[0073] Add citric acid and n-butanol with a molar ratio of 1:5.5 into a two-necked flask with a water separator and a condenser, heat to 80°C after mixing, and reflux for about 15 minutes under stirring. When the citric acid is completely dissolved, Measure the initial acid value of the mixed solution; add a sulfonated phenolic resin catalyst with 3.8% citric acid mass to the mixed solution, control the temperature at 150°C, react for 6 hours, and separate the water produced by the reaction in time, and take the reaction solution after the reaction Measure the acid value and calculate the esterification rate of tributyl citrate: 99.0%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| esterification rate | aaaaa | aaaaa |

| esterification rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com