Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

86 results about "SORBITAN TRIOLEATE" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sorbitan Trioleate is a triester of oleic acid and hexitol anhydrides derived from sorbitol. It functions as a surfactant and emulsifying agent.

Pumpable multiple phase compositions for controlled release applications downhole

Pumpable multiple phase vesicle compositions carry agents and components downhole or through a conduit, and controllably releasing them at a different place and time by breaking the compositions. In one non-limiting embodiment the pumpable multiple phase vesicles have a third phase containing a first phase which bears the agent to be controllably released. The first and third phases of the vesicles are separated by a surface active material bilayer that forms the second phase. The pumpable multiple phase vesicles may have internal and external phases that are both oil miscible, both aqueous miscible, or both alcohol miscible. The surface active material bilayer may be composed of compounds such as phospholipids, alkyl polyglycosides, gemini surfactants, sorbitan monooleate, sorbitan trioleate, and many others. The agent may be released by one or more of a variety of mechanisms.

Owner:BAKER HUGHES INC

Additive for synthetic water-diesel oil fuel and its prepn and application

The additive for synthetic water-diesel oil fuel consists of fatty alcohol polyoxyethyleneether 6.8 wt%, alkylene phenol polyvinyl ether 5.2 wt%, amyl nitrate 7.4 wt%, high-alkali barium sulfonate 5.6 wt%, ethylene-acrylate copolymer 5.5 wt%, sorbitan monostearate polyoxyethyleneether 40 wt%, Span-60 10 wt%, sorbitan trioleate polyoxyethyleneether 10.3 wt% and ferrocene 9.2 wt%. It is produced through mixing while stirring at high speed to react and letting stand to eliminate bubble and become emulsion. The additive is used in producing mixed water-diesel oil fuel, which has the same performance as diesel oil and can save oil by 20-30 %.

Owner:石生玉

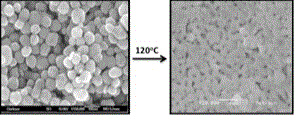

Preparation method of carbon-clad copper electronic paste

The invention discloses a preparation method of carbon-clad copper electronic paste. The preparation method includes: mixing formaldehyde and micron copper powder into mixed solvent A, heating and stirring nonstop the mixed solvent A with a magnetic sitter till supernate is black, pouring the supernate after standing, performing washing with deionized water, and performing drying to obtain pretreated copper powder; mixing glucose / saccharose and the pretreated copper powder to obtain mixed solvent B, and treating the mixed solvent B to obtain carbon-clad copper powder; mixing terpilenol, ethyl cellulose, ethyl acetate, polyether defoamer, silane coupling agent and sorbitan trioleate into mixed solution, and heating the mixed solution to obtain organic carrier; mixing glass powder, the carbon-clad copper powder and the organic carrier into the carbon-clad copper electronic paste. The preparation method has the advantages that production cost is effectively lowered since no special equipment for production is required, and the prepared carbon-clad copper electronic paste has excellent conductivity and has long shelf life.

Owner:XI'AN POLYTECHNIC UNIVERSITY

Flexible transparent electric conduction film coating material doping graphene and white graphene

InactiveCN106032407AStable electrical conductivity on the surface of the filmLow resistivityPolyurea/polyurethane coatingsElectrically-conductive paintsDoped grapheneAdhesive

A flexible transparent conductive film coating material of doped graphene and white graphene oriented to a liquid coating process, comprising a corona-treated PET or composite substrate layer, and a conductive paint coated on the surface of the PET or composite substrate layer layer, the conductive coating layer includes the following raw materials in weight percentage: 20-50% isopropanol, 20-50% n-butanol, 10-20% ethylene glycol monoethyl ether, 1-5% acetyl tributyl citrate, Adhesive 5-10%, Span 851-5%, ethyl cellulose 0.8-5%, 20-30 nanometer silver powder 4-10%, 100-400 nanometer silver powder 15-20%, graphene homogeneous solution 0.5-5 %, white graphene homogeneous solution 0.5-5%. The conductive film material has the characteristics of stable conductivity of the film-forming surface, low resistivity, high light transmittance, and strong adhesion. At the same time, the film material makes full use of the special properties of white graphene and graphene materials to achieve high performance after film formation. Transparent, conductive, heat dissipation, wear-resistant and other multiple effects.

Owner:CHANGZHOU XINMO ENERGY TECH CO LTD

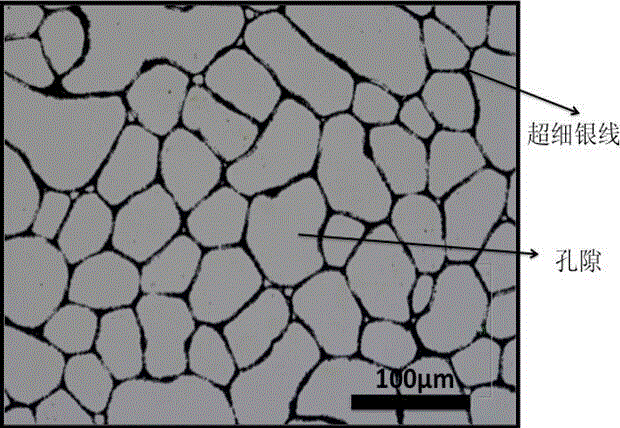

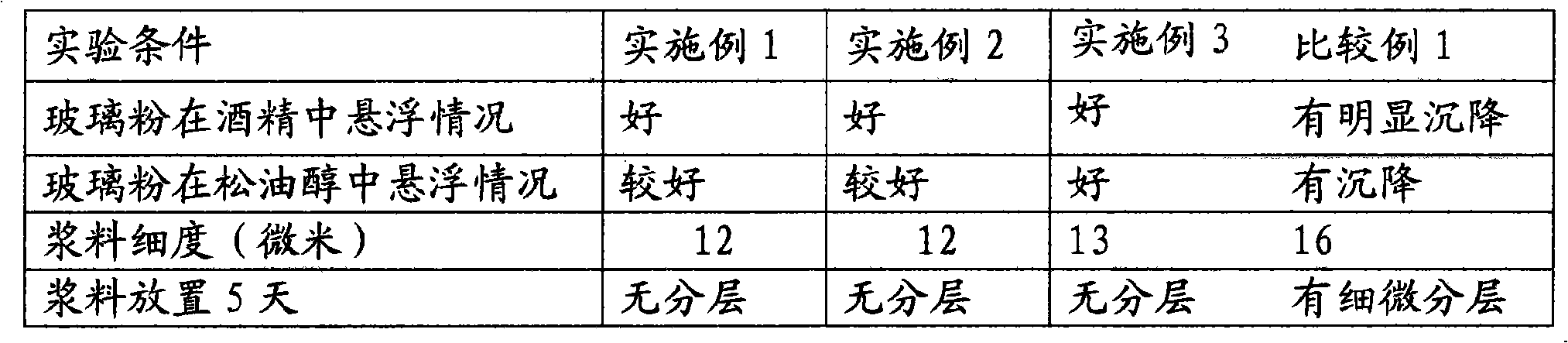

Surface treatment method of low temperature glass for solar cell conductive slurry

The invention discloses a surface activity treatment method of low temperature glass, and specifically relates to a surface treatment method applied to low temperature glass used by the frontal electrode slurry of a crystal silicon solar cell. The method performs special surface treatment for the surface of low-l-melting-point glass. The treatment method is capable of dissolving a surfactant in a solvent, and then adds the mixture in the process of grinding glass micro powders, or uses the surfactant to directly treat the well ground glass micro powders. The surfactant comprises one or more of sorbitan trioleate, lecithin, nonyl phenol epoxy adduct, propanetriol monooleate, high-grade fatty alcohol phosphate, triethanolamine and n-octyl ester. The glass micro powders treated by the method have better infiltration for the organic carriers in the slurry such that the glass micro powders have better dispersivity in the slurry and have repeatability and uniform stability in the production process of the slurry, such that the solar cell has better combination property.

Owner:SUZHOU ISILVER MATERIALS

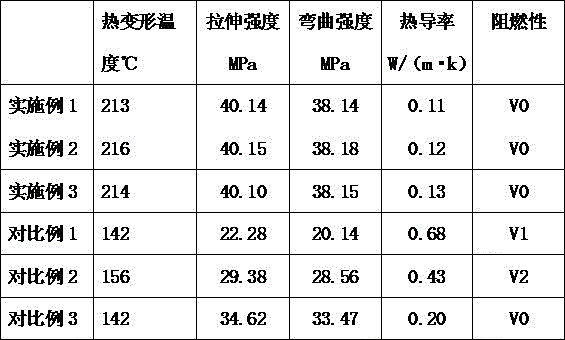

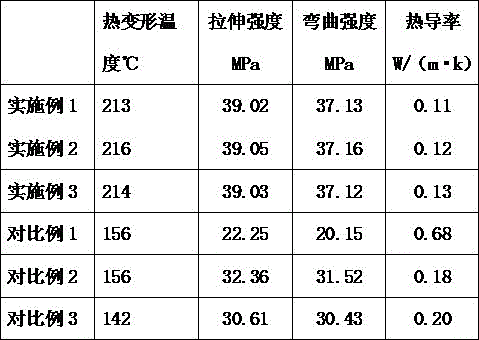

A high-performance capacitor plastic housing

ActiveCN106519600AImprove mechanical propertiesLow costPolytetramethylene terephthalateDibutyl sebacate

A high-performance capacitor plastic housing is disclosed. The plastic housing is prepared from polybutylene terephthalate, ABS plastic, a filler, a color concentrate, dibutyl sebacate, polyamide, a lubricant and an auxiliary agent. The auxiliary agent is prepared from, by weight, carboxyl cellulose, sorbitan trioleate, rosin, sodium hexametaphosphate, alkali lignin, acrylamide, diatomite, sodium tripolyphosphate, methyl salicylate, tea seed oil and mint oil. The plastic housing has characteristics of good mechanical properties, good processing performance, a low cost, a low melt viscosity, high impact strength, good thermal aging resistance and excellent thermal stability.

Owner:ANHUI FEIDA ELECTRICAL TECH CO LTD

Pumpable multiple phase compositions for controlled release applications downhole

Pumpable multiple phase vesicle compositions carry agents and components downhole or through a conduit, and controllably releasing them at a different place and time by breaking the compositions. In one non-limiting embodiment the pumpable multiple phase vesicles have a third phase containing a first phase which bears the agent to be controllably released. The first and third phases of the vesicles are separated by a surface active material bilayer that forms the second phase. The pumpable multiple phase vesicles may have internal and external phases that are both oil miscible, both aqueous miscible, or both alcohol miscible. The surface active material bilayer may be composed of compounds such as phospholipids, alkyl polyglycosides, gemini surfactants, sorbitan monooleate, sorbitan trioleate, and many others. The agent may be released by one or more of a variety of mechanisms.

Owner:BAKER HUGHES HLDG LLC

Modified plastic shell for capacitor

ActiveCN106519601AImprove mechanical propertiesLow costCapacitorsPolytetramethylene terephthalatePolyvinyl chloride

The invention discloses a modified plastic shell for a capacitor. The modified plastic shell is composed of polybutylene terephthalate, ABS plastic, a filling agent, color master batch, dimethyl trimethylsilylmethylphosphonate, polyvinyl chloride resin, a lubricating agent and a modifier. The modifier is composed of, by weight, carboxycellulose, sorbitan trioleate, rosin, sodium hexametaphosphate, alkali lignin, acrylamide, kieselguhr, sodium tripolyphosphate, methyl salicylate, camellia oil and peppermint oil. The prepared capacitor plastic shell is good in mechanical performance and processability, low in cost and melt viscosity and good in shock strength and thermal aging resistance and has excellent heat stability. A small amount of the prepared modifier can achieve the increase function obviously.

Owner:ANHUI FEIDA ELECTRICAL TECH CO LTD

High-temperature-resistant special ceramic for sparking nozzle of oil-fired machine and preparation method thereof

The invention discloses a high-temperature-resistant special ceramic for a sparking nozzle of an oil-fired machine and a preparation method thereof. The special ceramic is composed of the following raw materials in parts by weight: 30-40 parts of andalusite, 22-28 parts of volcanic rock, 10-15 parts of diatomite, 15-25 parts of aluminium oxide, 3-6 parts of tantalum carbide, 2-4 parts of cerous sulfide, 6-12 parts of titanium oxide, 5-10 parts of magnesium oxide, 4-8 parts of zirconium oxide, 3-5 parts of polyvinylpyrrolidone, 2.5-4.5 parts of sodium hydroxypropyl oxidized starch succinate, 4-6 parts of sorbitan trioleate, 3-5 parts of coconut oil monoethanolamide, 2-4 parts of dispersing agent NNO, and proper amount of deionized water. A bowl mill is employed for preparing an ultrafine powder, addition of proper amount of titanium oxide and magnesium oxide helps to reduce the sintering temperature of a blank and save energy, and addition of proper amount of tantalum carbide and cerous sulfide helps to reduce the possibility of the ceramic nozzle being oxidized in a high-temperature environment. experiment measuring results show that the ceramic nozzle is resistant to a high temperature up to 2500 DEG C and has the density larger than 4.0 g / cm<3>, and the nozzle has the service life larger than 10000 h.

Owner:铜陵市华冉科技服务有限公司

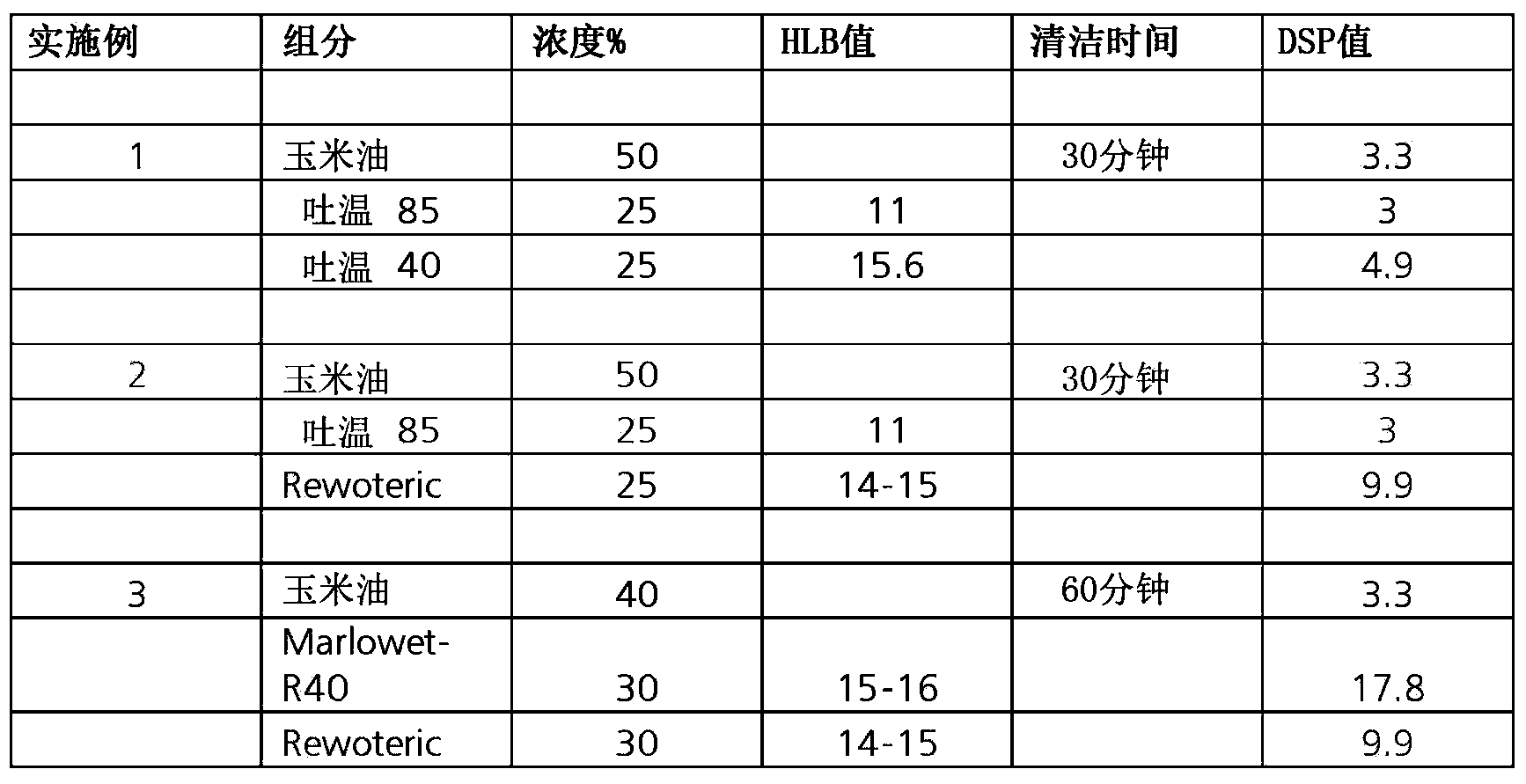

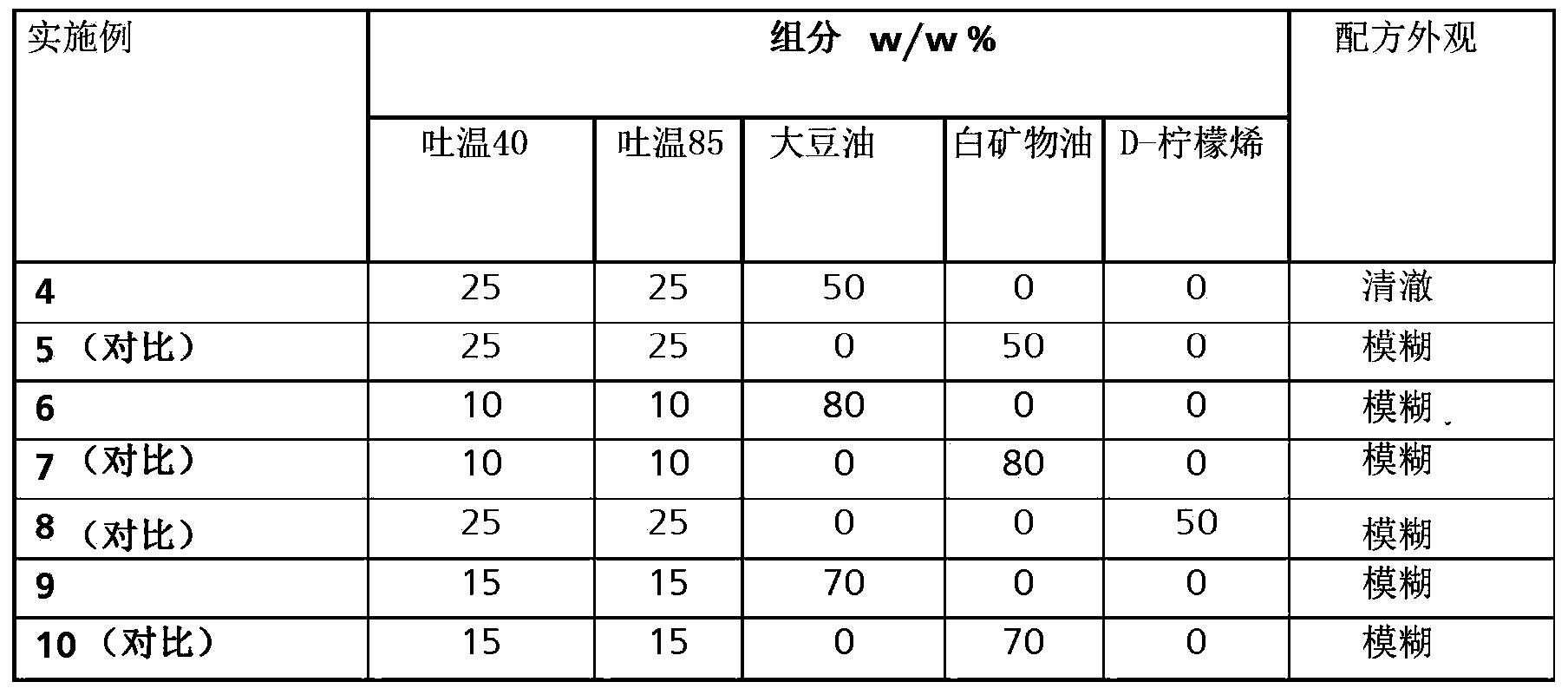

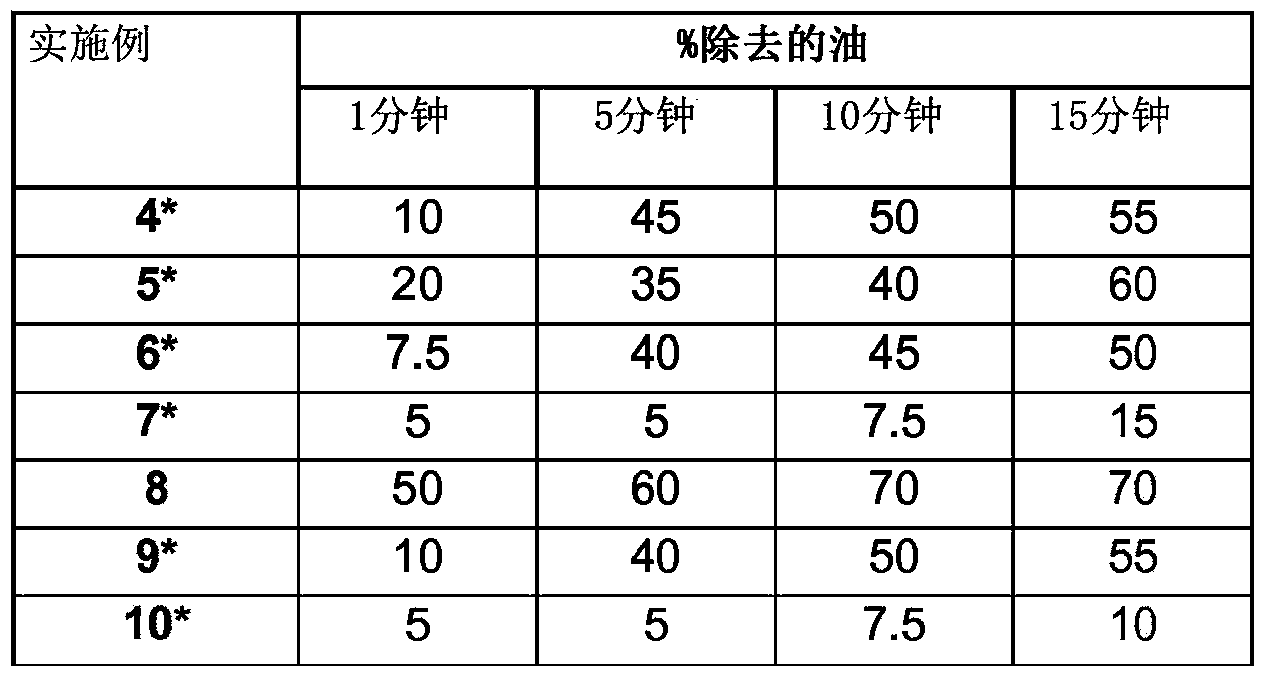

Oil recovery

An aqueous cleaning solution for treating hydrocarbon-contaminated soil and for cleaning hydrocarbon-contaminated surfaces is provided. Suitably it is prepared by progressively diluting a concentrate comprising: i) 10-60% by volume of a first emulsifier; (ii) 10-60% by volume of a second emulsifier and (iii) 20-70% by volume of vegetable oil In a preferred embodiment the concentrate comprises a polyethylene glycol sorbitan trioleate, a polyoxyethylene sorbitan monopalmitate and corn oil with the two sorbitan molecules having different HLB-values.

Owner:OTI GREENTECH GRP

Multifunctional modified asphalt paint capable of improving weathering resistance and enhancing brightness of oil paint and preparation method of multifunctional modified asphalt paint

InactiveCN104449379AGood weather resistanceImprove high temperature resistancePolyurea/polyurethane coatingsEpoxy resin coatingsMeth-Ethylic acid

The invention discloses a multifunctional modified asphalt paint capable of improving weathering resistance and enhancing brightness of an oil paint. The multifunctional modified asphalt paint is prepared from the following raw materials in parts by weight: 23-26 parts of modified asphalt, 8-12 parts of aniline-formaldehyde resin, 22-27 parts of epoxy resin, 4-6 parts of methylene dicyclohexane amine, 0.3-0.8 part of tetra-butyl hydroquinone, 2-4 parts of phytic acid, 2-3 parts of a silicone acrylic emulsion, 0.5-10 parts of dodecylamine, 2-4 parts of pearl powder, 0.3-0.6 part of sorbitan trioleate, 4-7 parts of polyurethane, 1-2 parts of polydimethylsiloxane, 1-3 parts of cellulose, 3-4 parts of fluorite, 5-8 parts of modified waste waterglass bonded sand, 12-14 parts of methyl ethyl ketone, 7-9 parts of methyl acrylate, 6-9 parts of pentaerythritol, 12-14 parts of dimethylbenzene, 0.01-0.03 part of dimethyl 2,2'-azobis(2-methylpropionate) and 8-12 parts of butyl acetate. The multifunctional modified asphalt paint disclosed by the invention can reduce environmental pollution and reduce the cost and can promote functions of heat resistance, fire resistance, corrosion resistance and the like of the oil paint.

Owner:TIANCHANG JULONG TRAVEL PAINT

Sewage adsorbent and preparation method thereof

InactiveCN106563420AHigh degree of recoveryLow costOther chemical processesWater/sewage treatment by sorptionSodium BentoniteSorbent

The present invention discloses a sewage adsorbent and a preparation method thereof, wherein the main raw materials of the sewage adsorbent comprise, by weight, 25-35 parts of sodium-based bentonite, 12-20 parts of polyacrylamide, 5-8 parts of polyvinylpyrrolidone, 2-8 parts of sorbitan trioleate, 17-24 parts of nanometer modified active carbon, 0.7-1.3 parts of a polyoxyethylene ether-based surfactant, 8-12 parts of polyaluminum chloride, and 0.8-2.0 parts of stearate, and the nanometer modified active carbon preparation method comprises: carrying out ultrasonic wave impregnation on active carbon by using nitric acid, magnesium acetate, polyurethane and sodium alginate, and drying to obtain the nanometer modified active carbon. According to the present invention, with the sewage adsorbent, the physical and chemical indexes of the seriously polluted sewage can achieve the GB18918-2002 standard; and the sewage adsorbent has advantages of simple treatment process, less consumption, good treatment effect, stable performance, high polluted-sewage recovery degree, effectively-reduced treatment agent cost, good economic benefits, and wide social benefits.

Owner:ZHENGZHOU YUANRAN BIOLOGY TECH CO LTD

Preparation method of polyvinyl alcohol microspheres

The invention discloses a preparation method of polyvinyl alcohol microspheres. The method comprises the following steps: dissolving polyvinyl alcohol into deionized water, standing for 30min, raising the temperature to 80 DEG C, and performing stirring for 30min; adding a product into plant oil containing sorbitan trioleate, and performing stirring for 30min at the temperature of 60-80 DEG C; adding glutaraldehyde, performing stirring for 10min, adding sorbitan oleate, performing continuous stirring for 1h, performing ultrasonic treatment and centrifugal separation precipitation, and cleaning for 3 times by using acetone and the deionized water respectively; finally, cleaning for 3 times by using the acetone, and performing vacuum drying on an obtained product to obtain white powder namely the polyvinyl alcohol microspheres. The preparation method of the polyvinyl alcohol microspheres is simple in operation, the prepared microspheres are uniform in particle size distribution, the average particle size is 15-45 microns, the shape is complete and smooth, and the dispersity is good.

Owner:SHAANXI YIPINDA PETROCHEM CO LTD

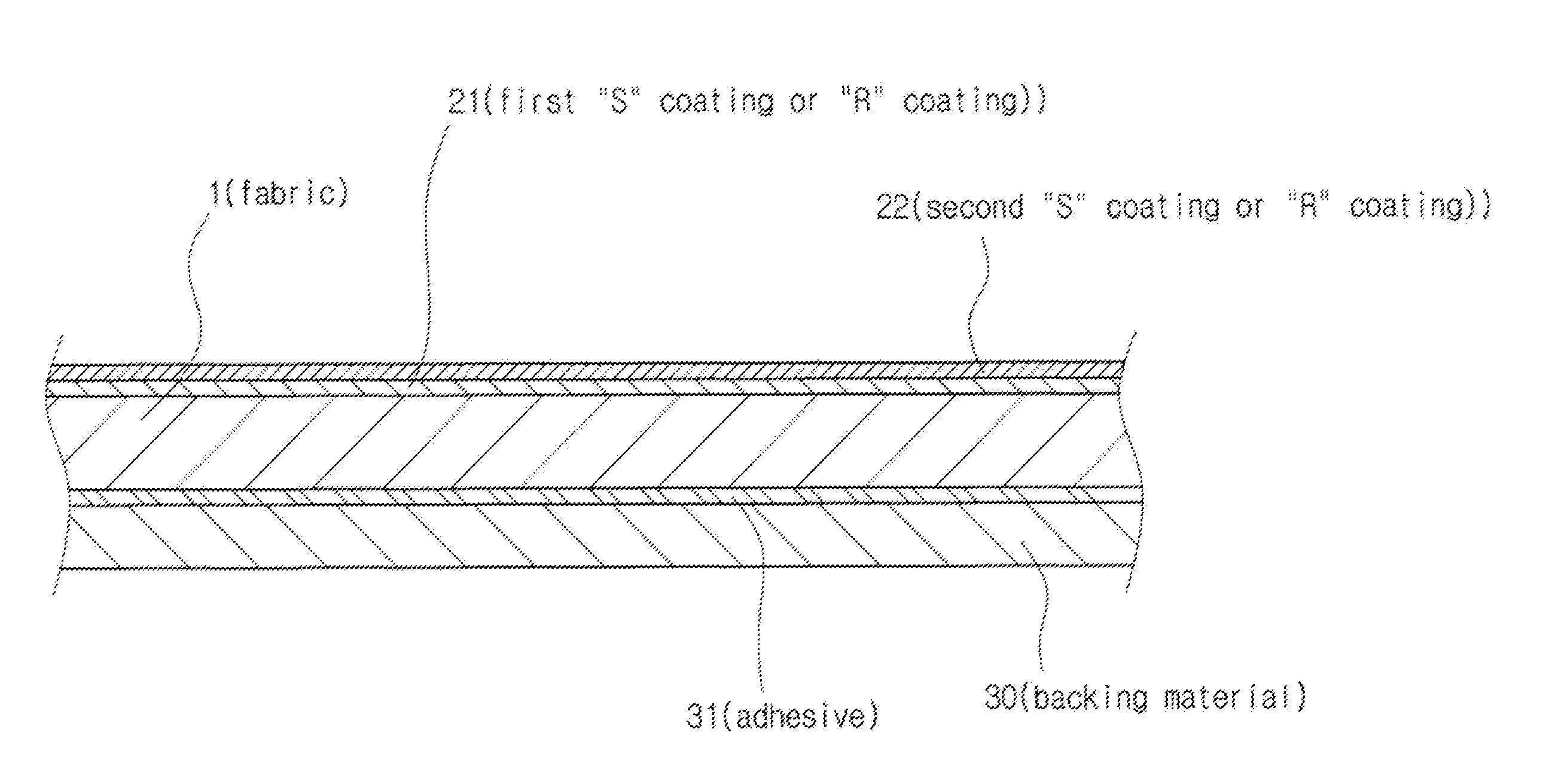

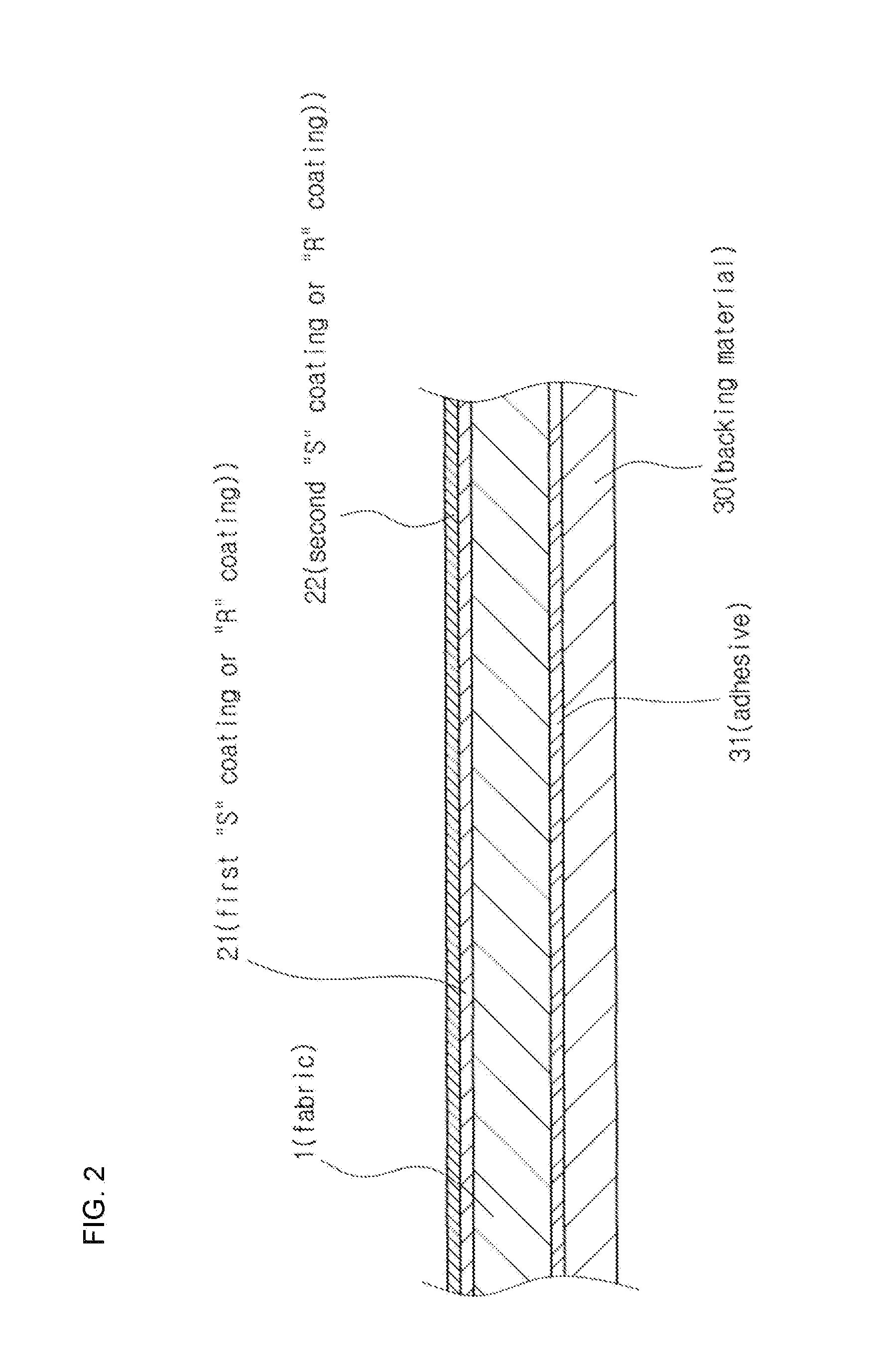

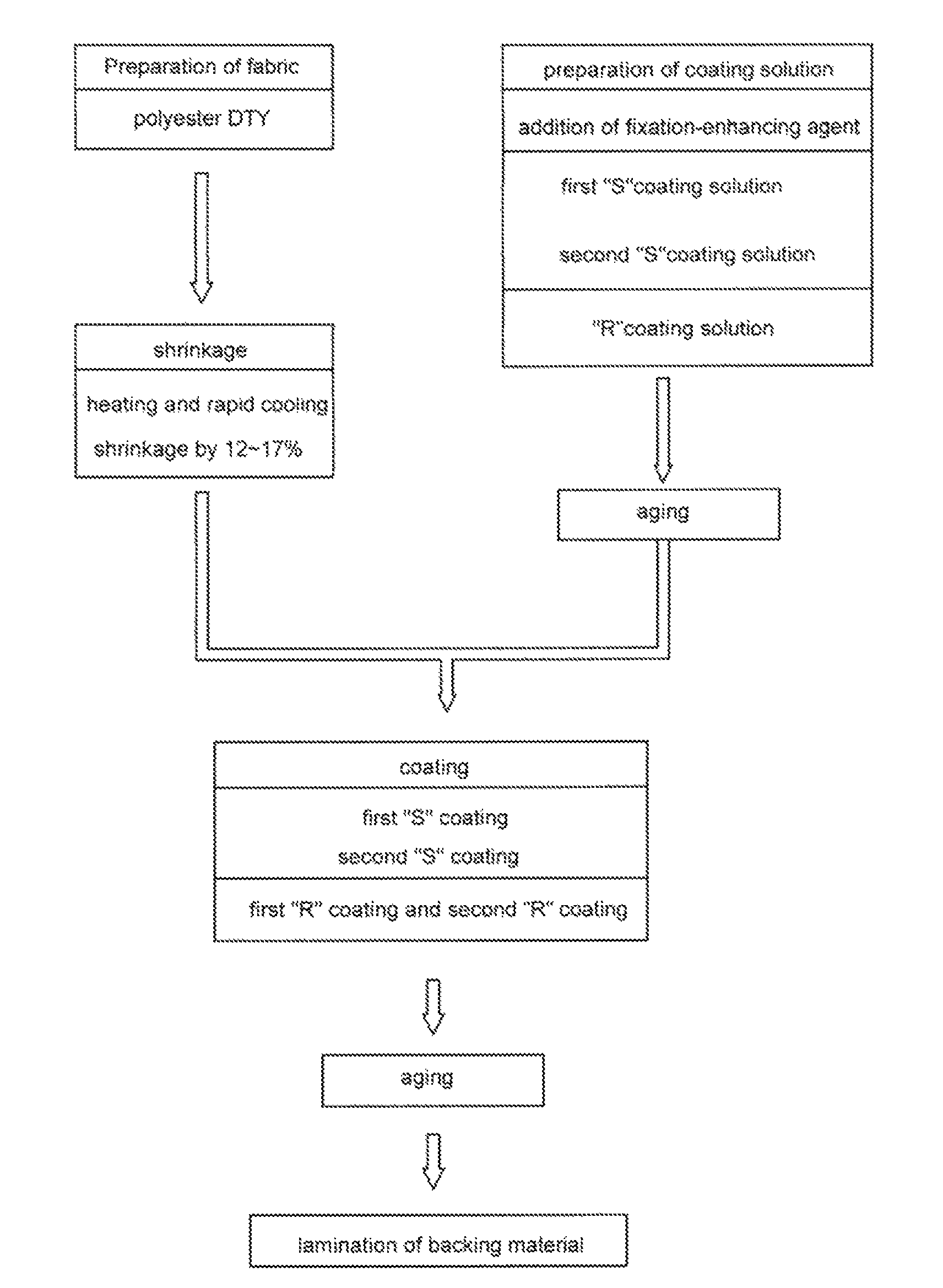

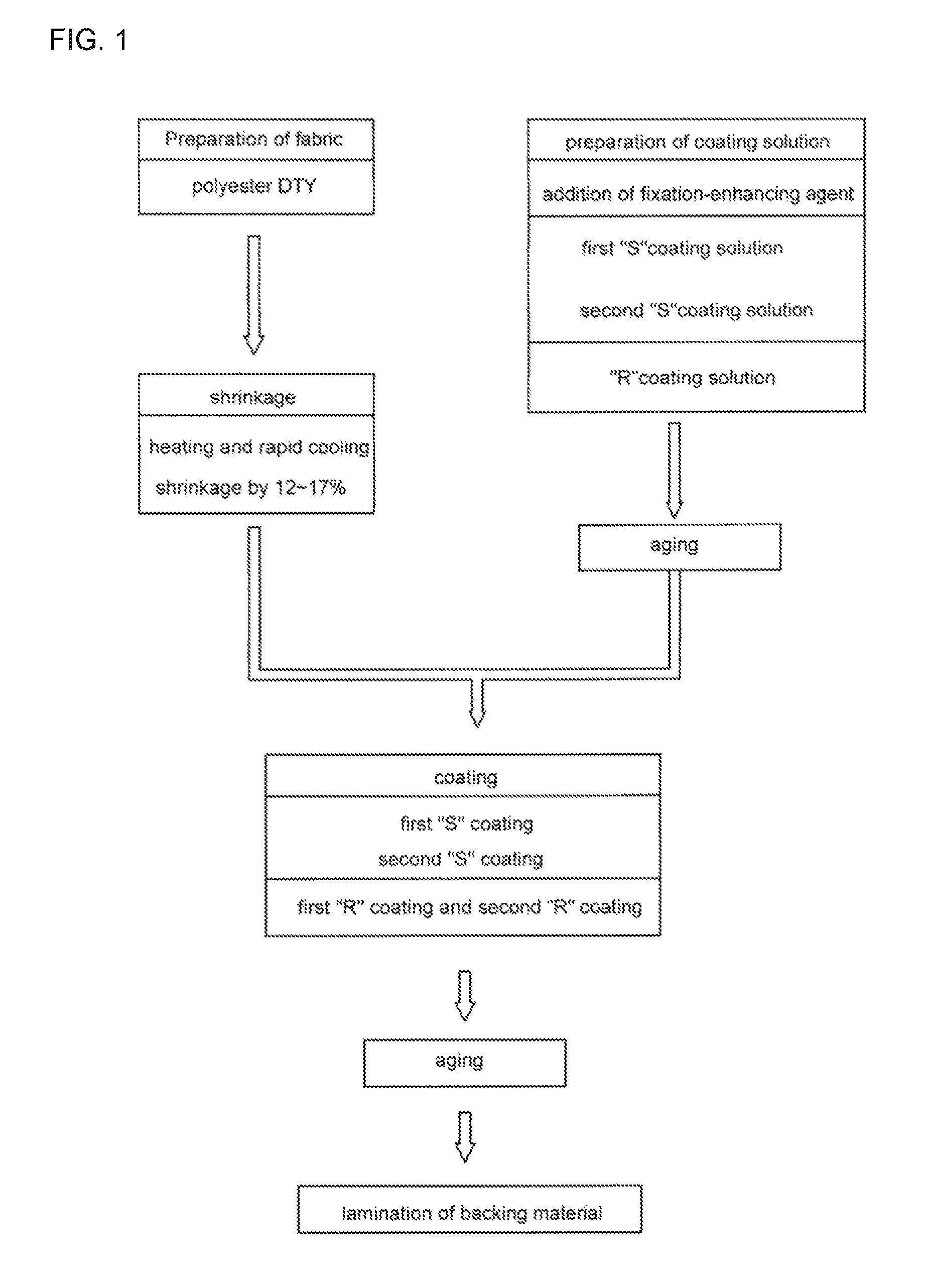

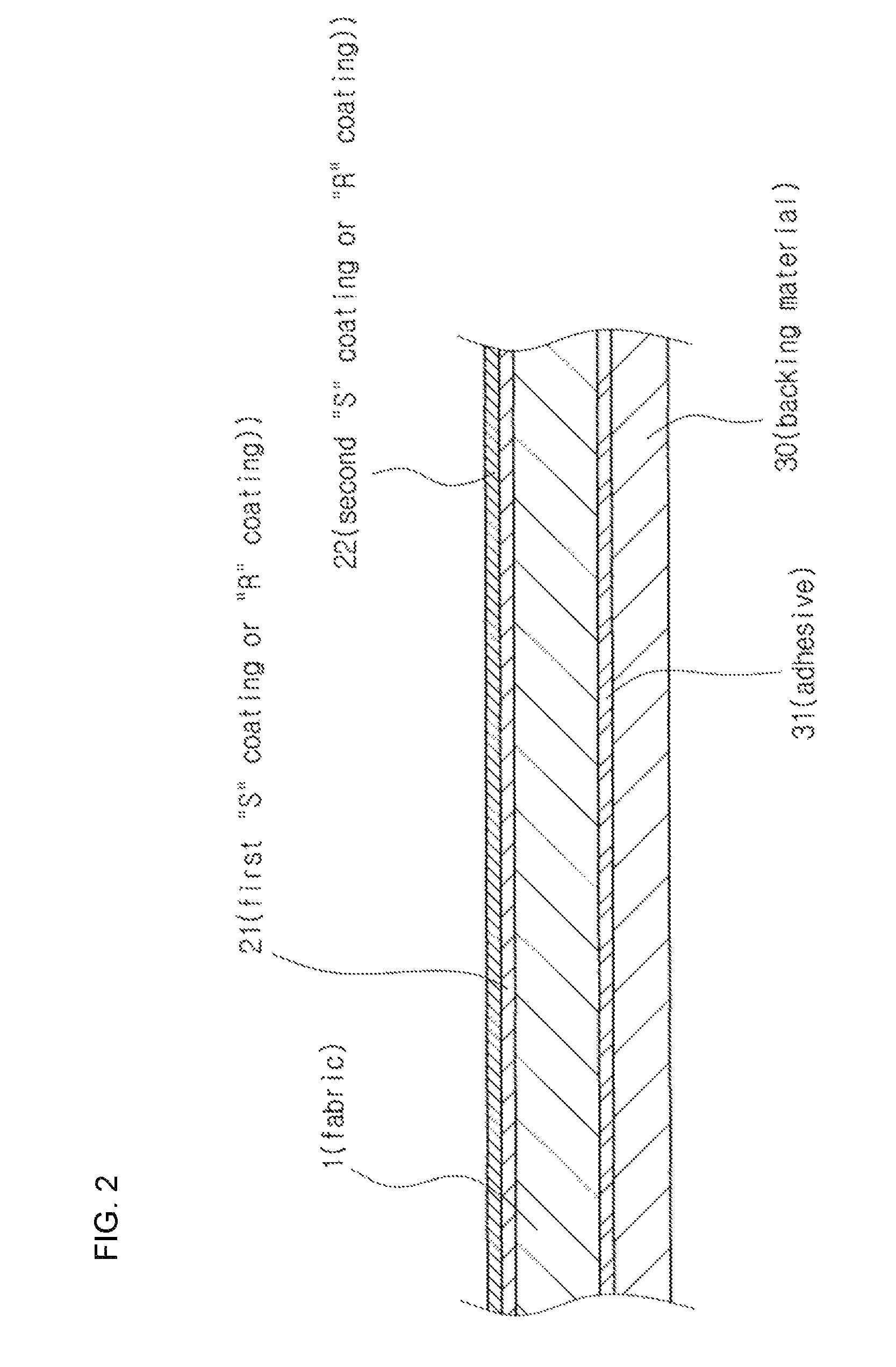

Readherable, repositionable and reusable adhesive fabric paper for printing and manufacturing method thereof

ActiveUS20150197113A1Simple processLow costDuplicating/marking methodsWoven fabricsPolyvinyl alcoholPulp and paper industry

Provided is an adhesive fabric paper that is used in color printers for personal computers, printing machines for indoor and outdoor advertisement, wide format printers, plotters, and so on to print colored images. In the invention, the rear side of the fabric is not subjected to gray coating and white coating, and the front side of the fabric is coated with a coating solution containing at least one fixation-strengthening agent selected from among titanium dioxide, silicon oil, silicon dioxide, polyoxyethylene sorbitan trioleate, and polyvinyl alcohol. The adhesive fabric paper shows the same functions as those of the rear side coating layer and can be manufactured by a simpler process at reduced costs.

Owner:LEE SANG YOUNG

Oiling agent for polyester and polyamide silk and preparing method and application thereof

The invention discloses an oil agent for polyester and cotton yarn, a preparation method and its application. It consists of the following components by weight percentage: 5-10% of white oil, 1-3.5% of C16-C18 alcohol, and an emulsifier 10-15%, sizing agent 1-5%, antistatic agent 1-5%, additive 1-5%, the balance is deionized water, and the emulsifier is selected from: sorbitan ester, propylene glycol fatty acid ester , ethylene glycol fatty acid ester, glyceryl monostearate, and one or more of sorbitan trioleate. The fiber after using the oil agent of the present invention has good smoothness and bundleability, and the quality of the finished fiber is good; the preparation process of the oil agent does not need to be cleaned, no waste is discharged, it is safe and environmentally friendly, and the preparation temperature is only 20-40°C, saving energy while saving energy. Reduced production costs.

Owner:苏州夏尔植物油脂科技有限公司

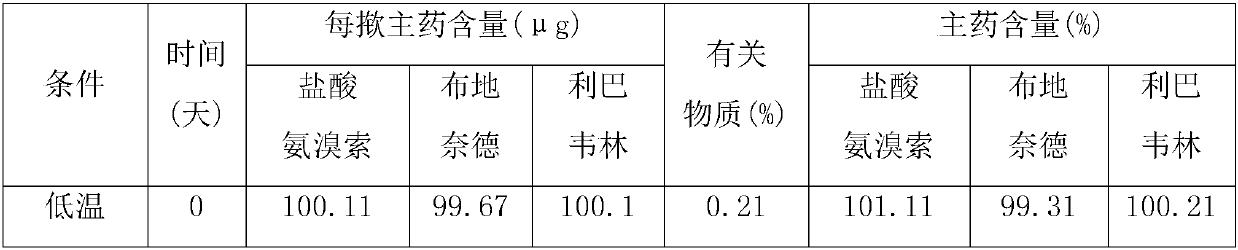

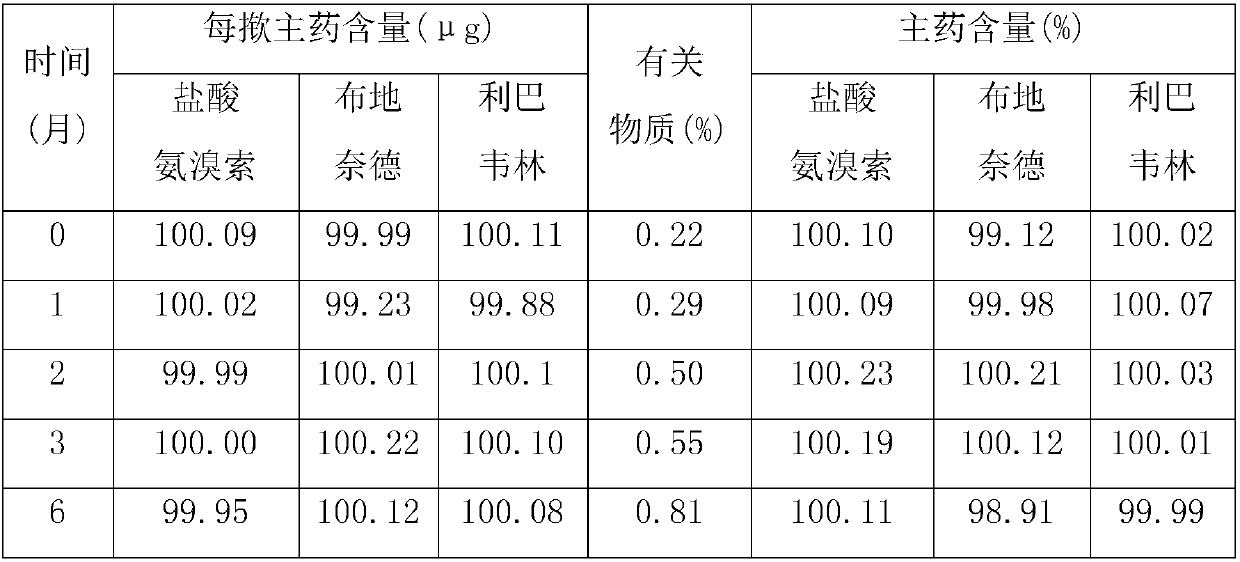

Aerosol for treating diseases of respiratory system and preparation method of aerosol

InactiveCN107669635AEffective treatmentQuality improvementOrganic active ingredientsDispersion deliveryDiseaseGlycerol

The invention relates to an aerosol for treating diseases of respiratory system and a preparation method of the aerosol, and belongs to the field of pharmaceutical preparations. The aerosol is prepared from the following components: 30-50g of ambroxol hydrochloride, 20-40g of budesonide, 20-30g of ribavirin, 100-200g of glycerol, 15-25g of sorbitan trioleate, 15-25g of PVP, 0.5-1g of sorbic acid,0.5-2g of peppermint essence, a proper amount of saccharin sodium, a proper amount of dichlorodifluoroethane and a proper amount of purified water. The aerosol provided by the invention is stable in quality, obvious in effect and is capable of effectively treating the diseases of respiratory system.

Owner:QINGDAO UNIV

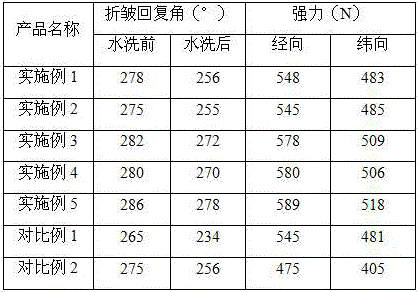

Softening and crease-shedding finishing agent for true silk and preparation method thereof

InactiveCN106223011AImprove wrinkle resistanceReduced wrinkle recovery angleWrinkle resistant fibresGrip property fibresBetainePolyethylene glycol

The invention provides a softening and crease-shedding finishing agent for true silk and a preparation method thereof. The preparation method comprises the following steps: (1) stirring tartaric acid, citric acid, caprylamidopropyl betaine, sorbitan trioleate, sodium hypophosphite, polyethyleneglycol and water at normal temperature for 30-60 minutes; (2) adding sodium hydroxide into the above solution, regulating the pH value, and stirring for 10-20 minutes; and (3) adding cocoylamidopropyldimethyl tertiary amine, triethanolamine N-cocoyl-L-glutamate, amino-modified organic silicon softener and fatty alcohol-polyoxyethylene ether into the above solution, and performing ultrasonic oscillation at 20-60 DEG C for 20-40 minutes to obtain the finishing agent. The softening and crease-shedding agent provided by the invention is non-toxic and has high binding fastness for a fabric; and after being finished, the fabric has good strength, fastness and hand feeling.

Owner:代长华

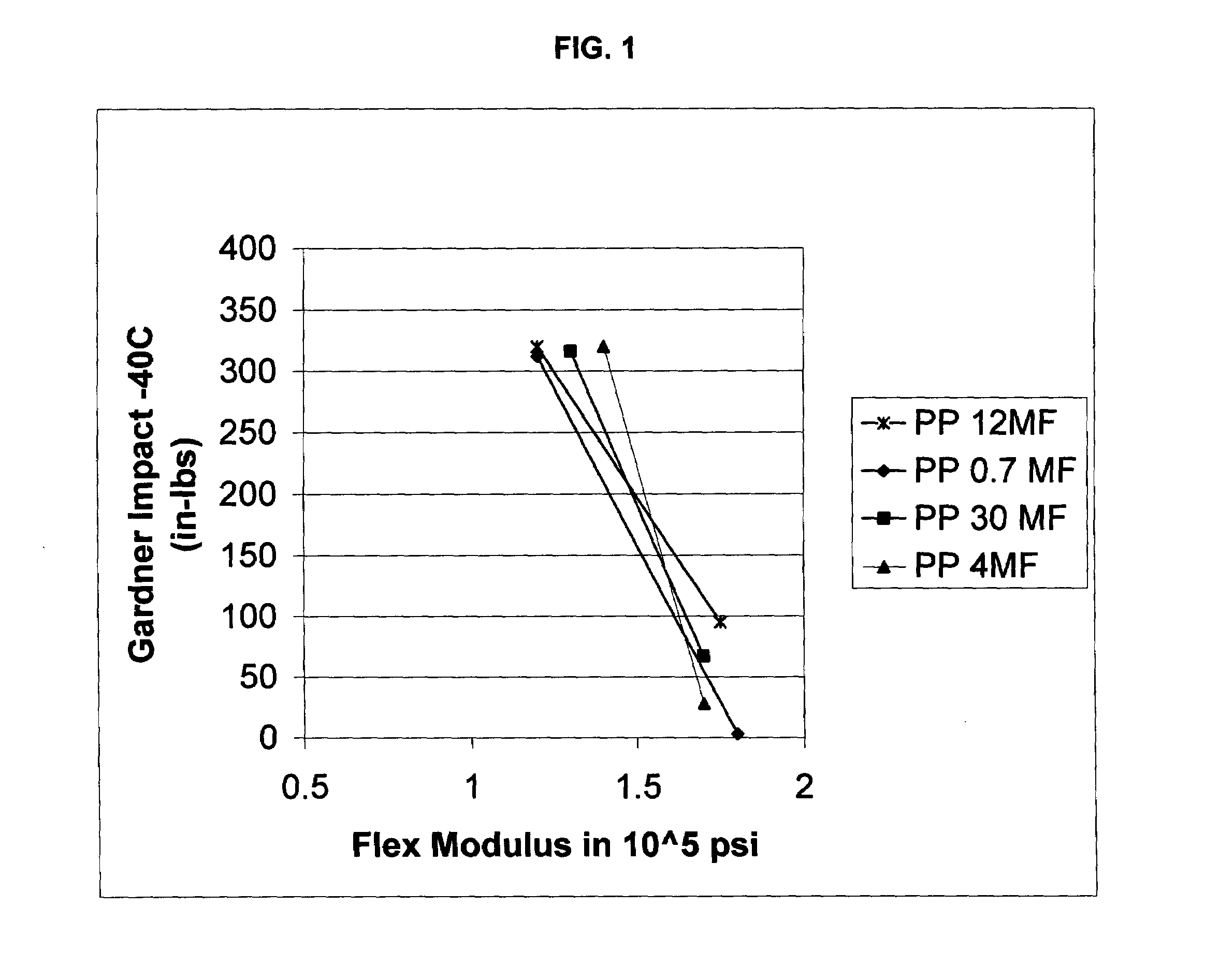

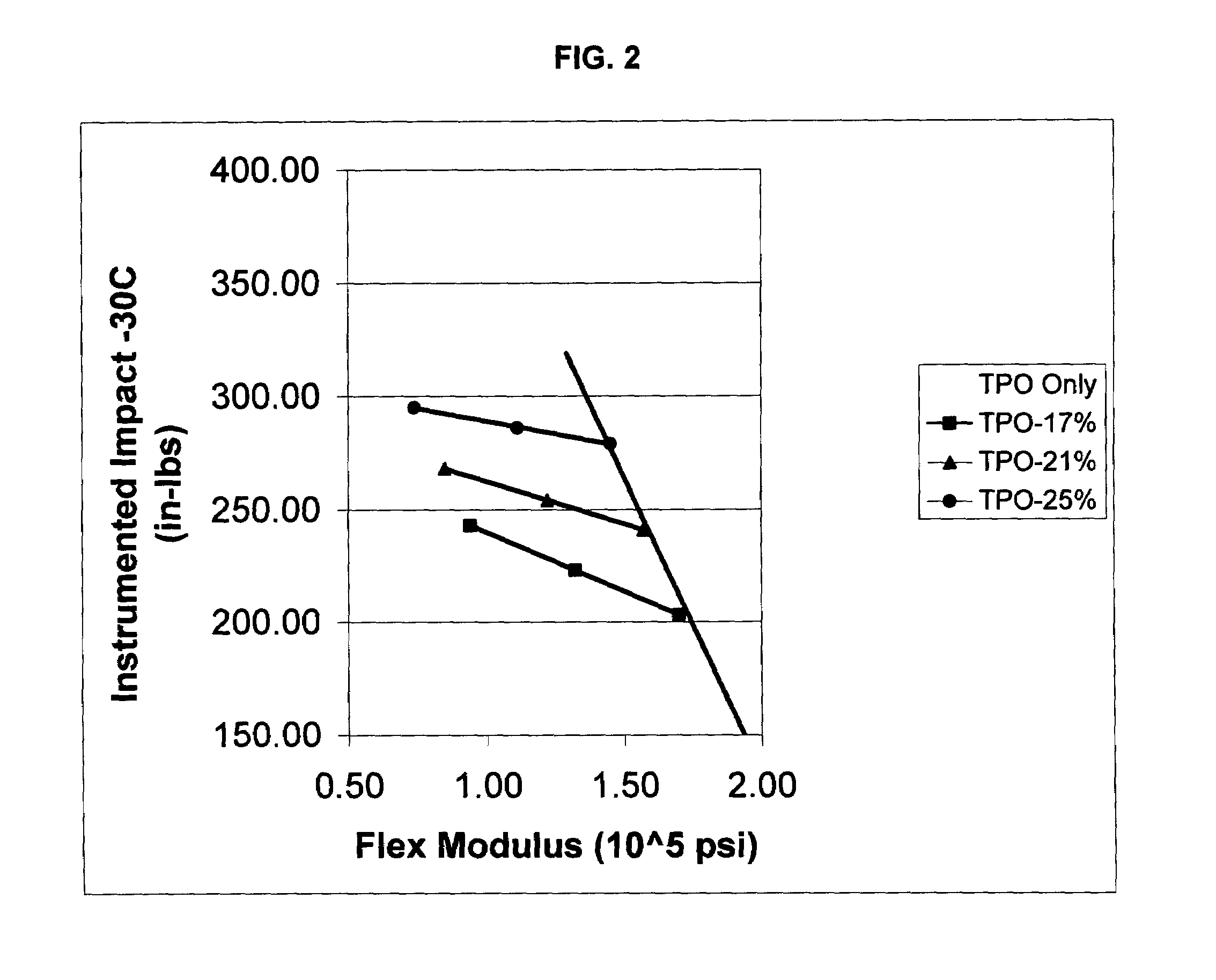

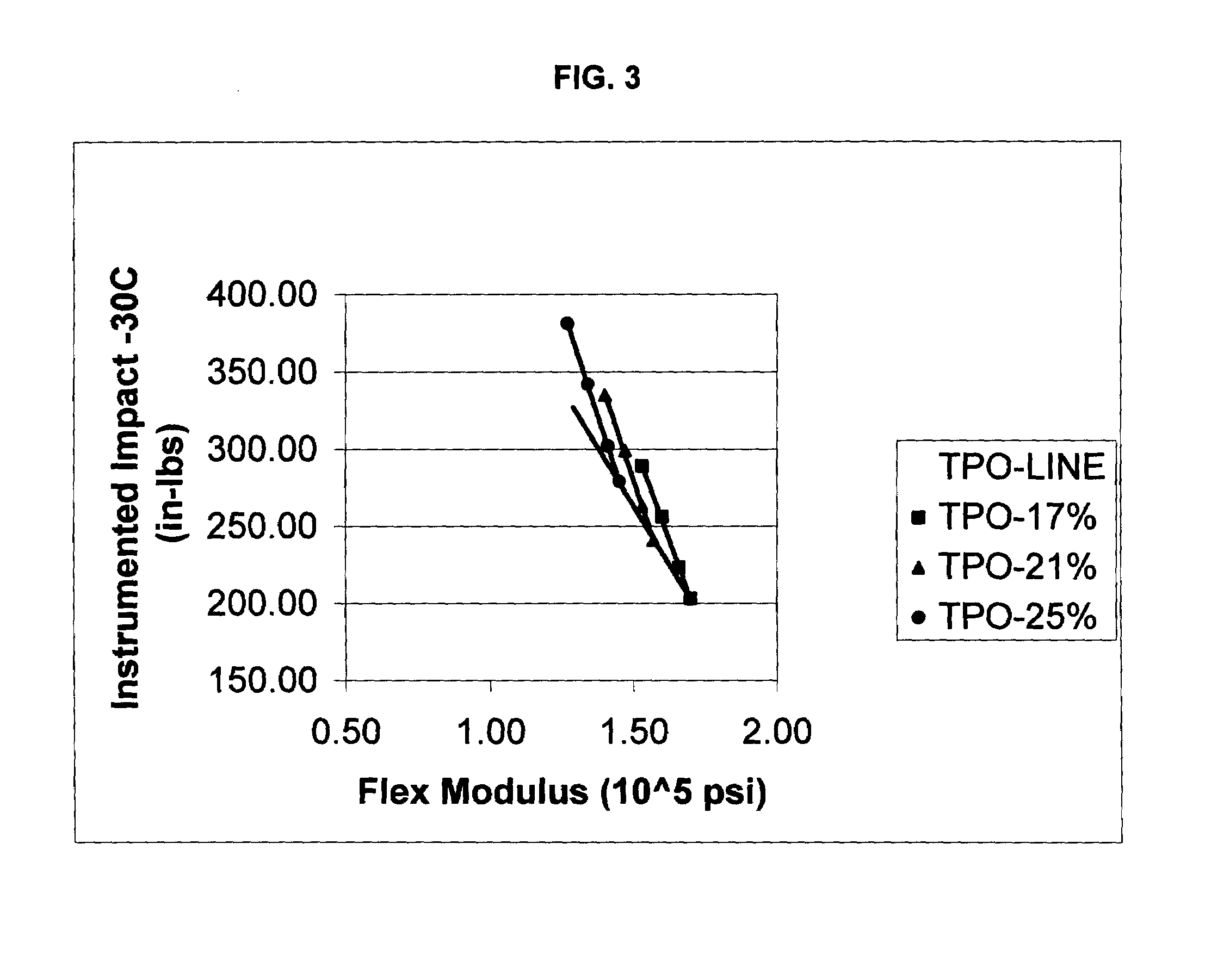

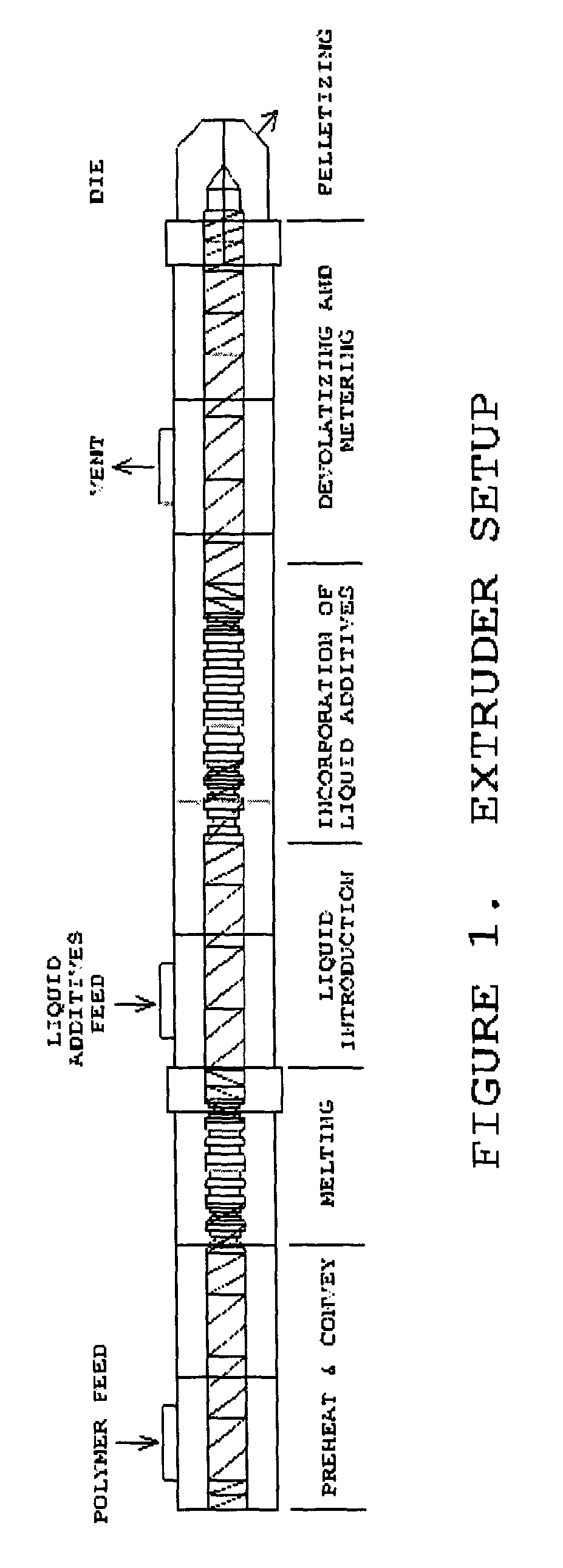

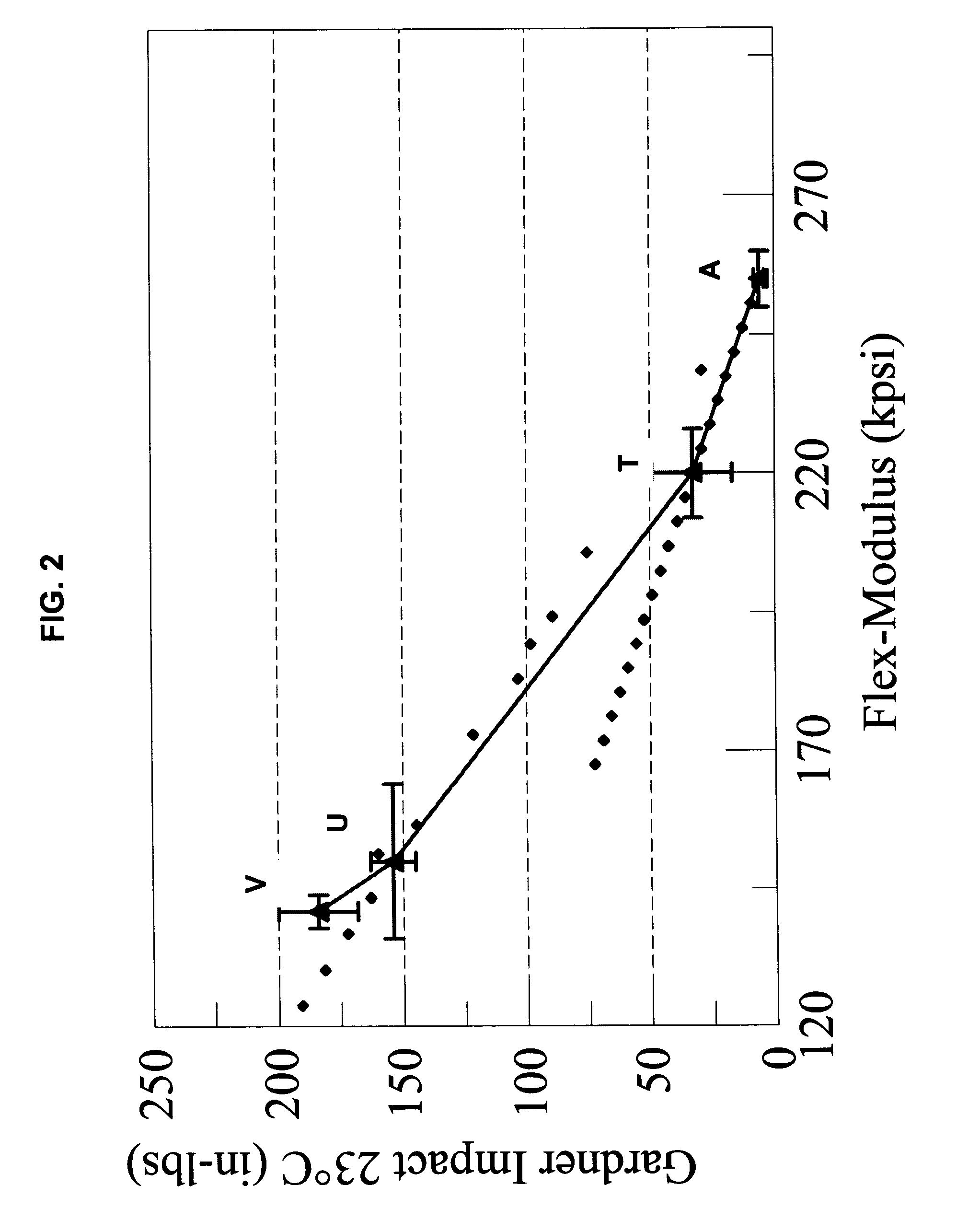

Impact modified thermoplastic olefin compositions

ActiveUS7041742B2Reduce flexural modulusReduce temperature riseNon-fibrous pulp additionFilm/foil adhesivesEthylene HomopolymersAlpha-olefin

The present invention provides impact modified thermoplastic olefin (“TPO”) compositions that exhibit both stiffness and toughness. TPO compositions according to the invention include a polyolefin homopolymer resin such as polypropylene, from about 17% by weight to about 30% by weight of a rubbery copolymer comprising at least one alpha olefin, and from about 1.0% to about 8.0% by weight of a nonionic surfactant, which acts as an impact modifying fluid. The preferred nonionic surfactant for use in the invention is an ethoxylated sorbitan fatty acid ester such as ethoxylated sorbitan trioleate (“ESTO”).

Owner:LYONDELLBASELL ADVANCED POLYMERS INC

Spreading oil coalescing agent

InactiveCN106070189ADiffusion fastEasy to useBiocidePlant growth regulatorsBULK ACTIVE INGREDIENTStearate

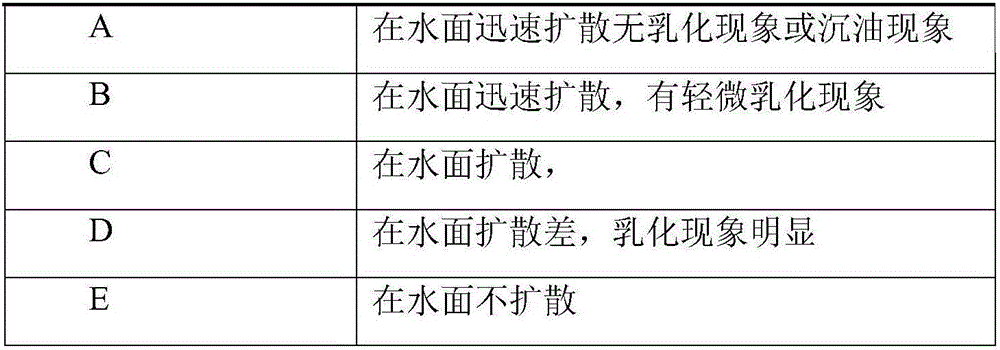

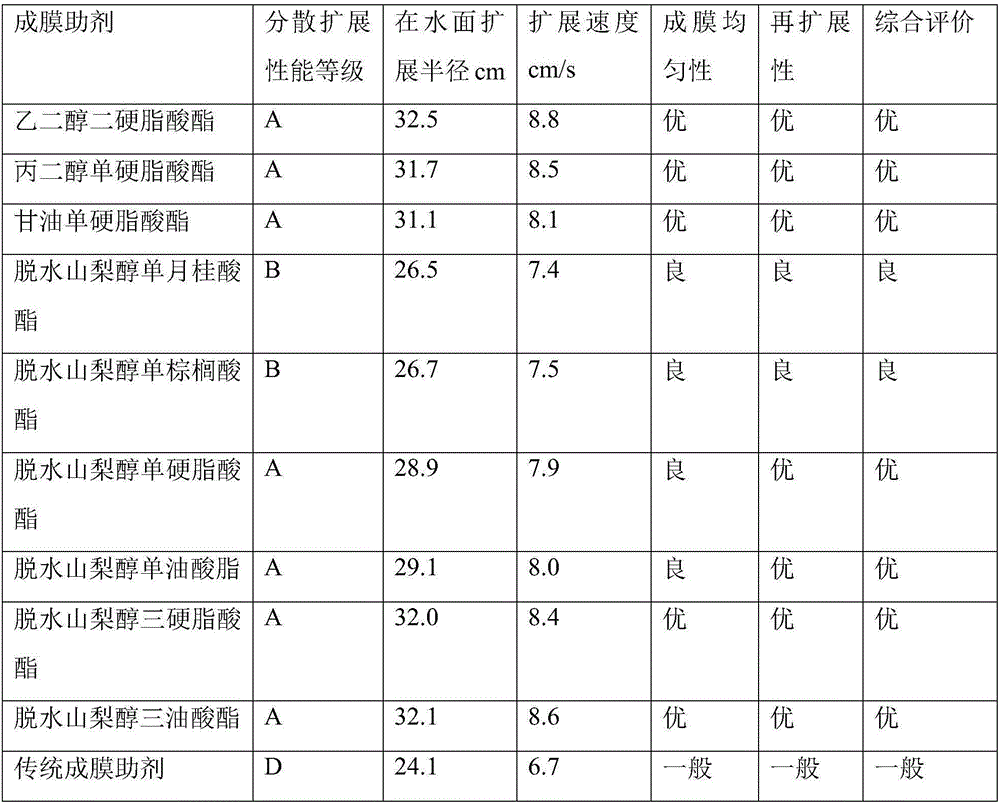

The invention relates to a novel spreading oil coalescing agent and an application of the oil coalescing agent in spreading oil, and belongs to the field of pesticide applications. One or more of ethylene glycol distearate, propylene glycol monostearate, glycerine monostearate, sorbitan monolaurate, sorbitan monopalmitate, sorbitan monostearate, sorbitan monooleate, sorbitan tristearate and sorbitan trioleate is or are active ingredients of the coalescing agent. The novel spreading oil coalescing agent can be used for preparing the coalescing agent for products such as a pesticide, a bactericide, a herbicide and a plant growth regulator in a paddy field.

Owner:JINGBO AGROCHEM TECH CO LTD

Impact modified polyolefin compositions

Owner:LYONDELLBASELL ADVANCED POLYMERS INC

Readherable, repositionable and reusable adhesive fabric paper for printing and manufacturing method thereof

ActiveUS9028631B1Simple processLow costLamination ancillary operationsSynthetic resin layered productsPolyvinyl alcoholPersonal computer

Provided is an adhesive fabric paper that is used in color printers for personal computers, printing machines for indoor and outdoor advertisement, wide format printers, plotters, and so on to print colored images. In the invention, the rear side of the fabric is not subjected to gray coating and white coating, and the front side of the fabric is coated with a coating solution containing at least one fixation-strengthening agent selected from among titanium dioxide, silicon oil, silicon dioxide, polyoxyethylene sorbitan trioleate, and polyvinyl alcohol. The adhesive fabric paper shows the same functions as those of the rear side coating layer and can be manufactured by a simpler process at reduced costs.

Owner:LEE IN OK

Preparation method of environmental-friendly breathable composite film

The invention provides a preparation method of an environmental-friendly breathable composite film. The preparation method comprises the following steps: pre-soaking and defibering kraft hardwood pulpdry pulp board into fiber slurry suspension, adding bamboo pulp, 2,2,6,6-tetramethyl-piperidin-1-oxyl, sodium bromide and sodium hypochlorite solution, dropping a NaOH solution, and maintaining the pH value of the reaction system; adding ethanol to terminate the reaction; washing the pulp; grinding to obtain pulp A; taking an aqueous solution of ethanol, regulating the pH, adding 3-aminopropyltriethoxysilane for stirring; adding the pulp A and wula sedge xylogen, stirring to obtain pulp B, and performing suction filtration on the pulp B with absolute ethyl alcohol so as to obtain pulp C; mixing, stirring and dissolving polylactic acid and dichloromethane, adding the pulp C, waxy modified corn starch and pea starch solution and sorbitan trioleate, and stirring to obtain a mixed solution; casting the mixed solution, and drying into a film, thereby obtaining the product. The film prepared by the method has excellent mechanical property and excellent breathability, the raw materials are green, non-toxic and reproducible, and sustainable development is well realized.

Owner:FOSHAN XIHUA TECH CO LTD

Gasoline-saving additive

InactiveCN104560237AEmission reductionLow running costLiquid carbonaceous fuelsN-Propyl alcoholHexamethylenetetramine

The invention discloses a gasoline-saving additive, which is prepared from the following raw materials in percentage by weight: 10 to 30 percent of methanol, 1 to 10 percent of copper sulfate, 2 to 10 percent of acetone, 3 to 15 percent of hexamethylenetetramine, 0.2 to 5 percent of sorbitan trioleate, 5 to 20 percent of n-propyl alcohol and 10 to 30 percent of isopropyl alcohol. The gasoline-saving additive can be added into gasoline of any grade, the quality of the gasoline is effectively improved, the octane value and combustion value of the gasoline are improved, power is improved, carbon deposit is eliminated, a fuel system is cleaned, an obvious gasoline saving effect is achieved, automobile exhaust pollutant emissions can be reduced, the lubricity of an engine can be enhanced, the service life of the engine can be prolonged, and the running cost of an automobile can be reduced.

Owner:山西华顿实业有限公司

Preparation method of additive

ActiveCN112481504AEasy to useReduce dosageProcess efficiency improvementZincum oxydatumPolyethylene glycol

The invention relates to a preparation method of an additive. According to the method, the additive is prepared from citric acid, tartaric acid, Tween-80, alkylphenol ethoxylates, fatty alcohol-polyoxyethylene ether, polyethylene glycol, polyacrylamide, iso-tridecanol polyoxyethylene ether, sorbitan trioleate, sulfuric acid, ethylene glycol, triethylamine, gelatin and other substances under a series of conditions. The substances are added to germanium-containing zinc oxide smoke leachate and uniformly mixed, an effective protective layer is formed on the surface of tannin germanium slag precipitate generated in the tannin germanium precipitation process, the capacity of adsorbing impurity ions such as Zn, Fe, Mn and As in the zinc oxide smoke leachate during precipitation is weakened, thegermanium grade in tannin germanium slag is improved, and the quality of a germanium concentrate prepared in the subsequent procedure is improved. The prepared additive is small in dosage and high inefficiency, excessive additives which do not participate in the reaction can be removed in the subsequent excessive tannin removal process, subsequent procedures are not affected, and great economic value is achieved.

Owner:KUNMING UNIV OF SCI & TECH

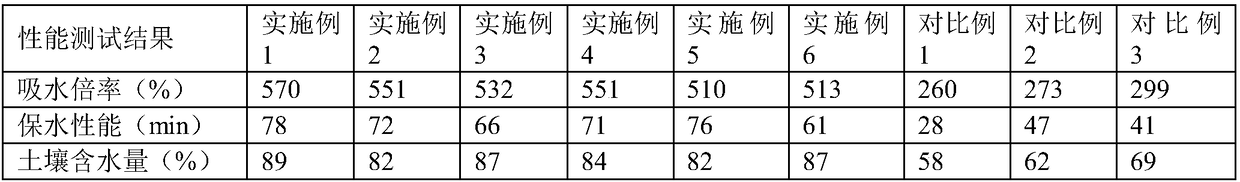

Water retaining agent and preparation method thereof

PendingCN108192630ABoth water retentionAlso has the effect of preserving fatAgriculture tools and machinesOrganic fertilisersSurface layerSolid particle

The invention relates to a water retaining agent and a preparation method thereof. The water retaining agent comprises the raw materials of: in parts by weight, 100-120 parts of acrylic acid, 70-90 parts of 1,3-diamino urea, 5-9 parts of initiator, 100-140 parts of water, 20-24 parts of polyoxyethylene sorbitan trioleate, 22-26 parts of polyoxyethylene sorbitan laurate, 40-50 parts of potassium chloride, 25-29 parts of potassium dihydrogen sulfate and 10-14 parts of polyacrylamide. The water retaining agent is solid particles of 1-2 mm, water absorption and swelling are conducted after the water retaining agent is applied to soil, and a water retaining layer is formed on the surface layer of the soil, so that anti-seepage and fertilizer-maintaining effects are achieved.

Owner:北京乾建绿化工程有限公司

Water-in-oil type ink cleaning agent and preparation method thereof

InactiveCN106752292ASolve flammableSolving Explosive ProblemsChemical paints/ink removersTurpentineCleansing Agents

The invention belongs to the technical field of cleaning agents and particularly relates to a water-in-oil type ink cleaning agent and a preparation method thereof. The water-in-oil type ink cleaning agent is characterized by mainly containing the following components in parts by weight: 15-25 parts of turpentine, 13-25 parts of tetrachloroethylene, 1-5 parts of oleic acid, 5-10 parts of isopropanol, 3-7 parts of dibutyl phthalate, 5-7 parts of fatty acid methyl ester ethoxylate, 2-7 parts of apricot glue, 0.5-1.5 parts of tetrasodium iminodisuccinate, 1-3 parts of sodium dodecyl benzene sulfonate, 0.3-1.3 parts of sorbitan trioleate, 1-5 parts of benzotriazole, 3-5 parts of sodium hydroxide, 30-70 parts of water, 7-16 parts of aids and 0.5-1.5 parts of an oxidant, wherein the aids are triethanolamine and n-butyl alcohol. According to the water-in-oil type ink cleaning agent, the problems that a solvent-type ink cleaning agent is inflammable and explosive can be solved, the pollution caused to a production environment and atmosphere is relieved, and the cleaning time is shortened.

Owner:温州乐发教育科技有限公司

High-melting-point heat-conducting electronic material and preparation method thereof

The invention discloses a high-melting-point heat-conducting electronic material which comprises the following components in parts by weight: 30-40 parts of ACS (acrylonitrile-chlorinated polyethylene-styrene) resin, 15-25 parts of fumaric acid resin, 1-3 parts of titanium dioxide, 2-5 parts of zinc carbonate, 0.5-3 parts of sulfinpyrazone, 10-13 parts of ethyl 9-fluorenylidene acetate, 1-3 parts of copper-beryllium alloy bar, 1-4 parts of magnesium thiocyanide, 0.5-2.5 parts of 1-butanethiol zinc, 8-14 parts of dinona phthalate, 9-15 parts of sorbitan trioleate, 3-7 parts of silthiopham and 15-20 parts of leaf acetal. The electronic material has the advantages of higher melting point and favorable heat-conducting property, and can better adapt to the existing electronic components.

Owner:SUZHOU KEMAO ELECTRONICS MATERIALS TECH

Modified cerium dioxide acid and alkali-resistant type strippable high molecular anti-rust film

InactiveCN106634276AGood dispersionImprove adhesionFireproof paintsAntifouling/underwater paintsPolymer sciencePolyethylene glycol

The invention discloses a modified cerium dioxide acid and alkali-resistant type strippable high molecular anti-rust film, which is prepared from the following raw materials including aluminum isopropoxide, a silane coupling agent KH792, tetraethoxysilane, sorbitan trioleate, polyglycol, methylvinyldiethoxysilane, polyvinyl alcohol, borax, cerium dioxide, oleic acid, a silane coupling agent KH560, polyetheramine, acrylamide, trolamine, benzotriazol, para-phenylene diamine, sodium benzoate, sodium dodecyl sulfate, a proper amount of polyoxyethylene fatty acid, a proper amount of nitric acid, a proper amount of hydrochloric acid, a proper amount of absolute ethyl alcohol and a proper amount of de-ionized water. A prepared anti-rust agent can form a layer of thin anti-rust film on a workpiece with anti-rust requirements; the film can be manually torn away; the strippable performance is good; the operation is simple; in addition, the prepared anti-rust film has high heat resistance, high acid and alkali corrosion resistance, oil resistance, water resistance and long anti-rust time, and is worthy of being popularized.

Owner:江海涛

Aqueous ethanol gasoline micro-emulsifier

InactiveCN106398785AImprove hydrophilicityGood emulsifying effectLiquid carbonaceous fuelsFuel additivesIsobutanolGasoline

The invention discloses an aqueous ethanol gasoline micro-emulsifier which is prepared by mixing an oleophilic emulsifier and a hydrophilic emulsifier, wherein the oleophilic emulsifier is prepared by mixing sorbitan monooleate, sorbitan trioleate and polyethylene glycol monostearate according to the volume ratio of (5 to 6.5) to (0.5 to 1.5) to (0.5 to 1.8); the hydrophilic emulsifier is prepared by mixing octaphenyl polyoxyethyiene with the polymerization degree of 10, octaphenyl polyoxyethyiene with the polymerization degree of 4, isobutanol and isopropanol according to the volume ratio of (0.5 to 1.5) to (0.5 to 1.5) to (4.5 to 6) to (2 to 4). By the adoption of the micro-emulsifier for regulating aqueous ethanol gasoline, the low-temperature stability of the micro-emulsified aqueous ethanol gasoline can be obviously improved.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

Low-toxicity lubricating oil emulsifier

InactiveCN109021954AHigh activityReduce surface tensionDrilling compositionOleic Acid TriglycerideAlkylbenzenes

The invention relates to the technical field of surfactants, and especially relates to a low-toxicity lubricating oil emulsifier. The emulsifier comprises, by weight, 2-5 parts of sorbitan trioleate,0.3-0.5 part of nonylphenol polyoxyethylene ether, 0.3-0.8 part of triethanolamine, 1-3 parts of oleic acid and 3-6 parts of calcium heavy alkylbenzene sulfonate, and further comprises, by weight, 3 parts of sorbitan trioleate, 0.35 part of nonylphenol polyoxyethylene ether, 0.5 part of triethanolamine, 2 parts of oleic acid and 5 parts of calcium heavy alkylbenzene sulfonate. A viscosity reducerprepared according to the above ratio has the advantages of strong activity and low surface tension, has good washing and viscosity-reducing effects on paraffin, colloids and asphalt, and can achievethe purposes of reducing the oil layer viscosity and improving the recovery rate of oil reservoirs.

Owner:常州艾乐森动力技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com