Water-in-oil type ink cleaning agent and preparation method thereof

A water-in-oil, cleaning agent technology, applied in the field of cleaning agents, can solve problems such as hidden fire safety hazards in printing workshops, production environment and air pollution, and unsatisfactory cleaning effects, so as to increase fire safety, shorten cleaning time, Improved fire safety effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

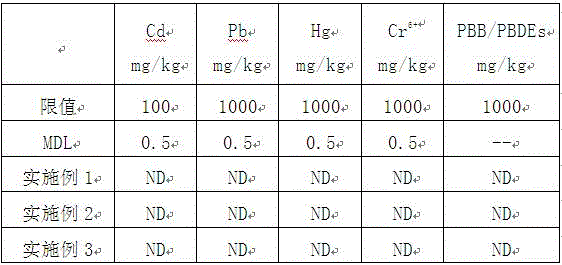

Examples

Embodiment 1

[0024] Embodiment 1 of the present invention provides a water-in-oil ink cleaning agent, which is mainly composed of the following components in parts by weight: 15 parts of turpentine, 13 parts of tetrachloroethylene, 1 part of oleic acid, and 5 parts of isopropanol , 3 parts of dibutyl phthalate, 5 parts of fatty acid methyl ester ethoxylate, 2 parts of apricot gum, 0.5 part of tetrasodium iminodisuccinate, 1 part of sodium dodecylbenzene sulfonate, dehydrated sorrel 0.3 parts of alcohol trioleate, 1 part of benzotriazole, 3 parts of sodium hydroxide, 30 parts of water, 2 parts of triethanolamine, 5 parts of n-butanol and 0.5 parts of 2,6-di-tert-butyl-p-cresol .

[0025] In addition, the present embodiment provides a preparation method of a water-in-oil type ink cleaning agent, comprising the following steps:

[0026] (1) First add 3 parts of sodium hydroxide and 30 parts of water into the reaction vessel, and stir at 30 r / min to completely dissolve it to obtain an aqueous...

Embodiment 2

[0032] Embodiment 2 of the present invention provides a water-in-oil ink cleaning agent, which is mainly composed of the following components in parts by weight: 25 parts of turpentine, 25 parts of tetrachloroethylene, 5 parts of oleic acid, and 10 parts of isopropanol , 7 parts of dibutyl phthalate, 7 parts of fatty acid methyl ester ethoxylate, 7 parts of apricot gum, 1.5 parts of tetrasodium iminodisuccinate, 3 parts of sodium dodecylbenzene sulfonate, sorbic acid 1.3 parts of alcohol trioleate, 5 parts of benzotriazole, 5 parts of sodium hydroxide, 70 parts of water, 7 parts of triethanolamine, 9 parts of n-butanol and 1.5 parts of 2,6-di-tert-butyl-p-cresol .

[0033] In addition, the present embodiment provides a preparation method of a water-in-oil type ink cleaning agent, comprising the following steps:

[0034] (1) First add 5 parts of sodium hydroxide and 70 parts of water into the reaction vessel, and stir at 40r / min to completely dissolve it to obtain an aqueous s...

Embodiment 3

[0040] Embodiment 3 of the present invention provides a water-in-oil ink cleaning agent, which is mainly composed of the following components in parts by weight: 20 parts of turpentine, 19 parts of tetrachloroethylene, 3 parts of oleic acid, and 7.5 parts of isopropanol , 5 parts of dibutyl phthalate, 6 parts of fatty acid methyl ester ethoxylate, 4.5 parts of apricot gum, 1 part of tetrasodium iminodisuccinate, 2 parts of sodium dodecylbenzene sulfonate, sorbic acid 0.8 parts of alcohol trioleate, 3 parts of benzotriazole, 4 parts of sodium hydroxide, 50 parts of water, 4.5 parts of triethanolamine, 7 parts of n-butanol and 1 part of 2,6-di-tert-butyl-p-cresol .

[0041] In addition, the present embodiment provides a preparation method of a water-in-oil type ink cleaning agent, comprising the following steps:

[0042] (1) First add 4 parts of sodium hydroxide and 50 parts of water into the reaction vessel, and stir at 35 r / min to completely dissolve it to obtain an aqueous s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com