Softening and crease-shedding finishing agent for true silk and preparation method thereof

An anti-wrinkle finishing agent and a softening technology, applied in the field of silk soft and wrinkle-resistant finishing agent and its preparation, can solve the problems of poor wrinkle resistance durability, decreased mechanical properties, and silk cracks of silk fabrics, and achieve good hand feel, high strength, and wrinkle recovery angle. reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

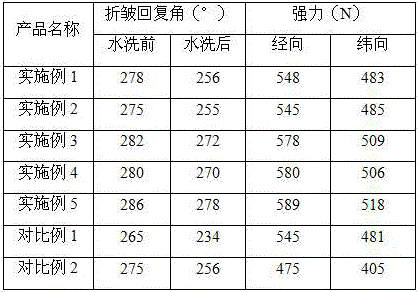

Examples

Embodiment 1

[0015] A soft and anti-wrinkle finishing agent for silk, prepared from the following ingredients in parts by weight: 10 parts of tartaric acid, 5 parts of citric acid, 15 parts of caprylic acid amidopropyl betaine, 8 parts of sorbitan trioleate, 15 parts of sodium phosphite, 10 parts of polyethylene glycol, 15 parts of cocamidopropyl dimethyl tertiary amine, 3 parts of N-cocoyl-L-glutamic acid triethanolamine, amino-modified silicone softener 10 parts, 5 parts of fatty alcohol polyoxyethylene ether, 10 parts of water, 0.1 part of sodium hydroxide.

[0016] The preparation method of the above-mentioned silk soft and anti-wrinkle finishing agent is as follows: (1) tartaric acid, citric acid, caprylic acid amidopropyl betaine, sorbitan trioleate sodium hypophosphite protective agent, polyethylene glycol, water , stirred at room temperature for 30 minutes; (2) adding sodium hydroxide to the above solution to adjust the pH, and the stirring time was 10 minutes; (3) adding cocoamido...

Embodiment 2

[0018] A soft and anti-wrinkle finishing agent for silk, which is prepared from the following ingredients in parts by weight: 20 parts of tartaric acid, 15 parts of citric acid, 7 parts of caprylic acid amidopropyl betaine, 3 parts of sorbitan trioleate, 10 parts of sodium phosphite, 5 parts of polyethylene glycol, 30 parts of cocamidopropyl dimethyl tertiary amine, 8 parts of N-cocoyl-L-glutamic acid triethanolamine, amino-modified silicone softener 20 parts, 3 parts of fatty alcohol polyoxyethylene ether, 20 parts of water, 0.05 part of sodium hydroxide.

[0019] The preparation method of the above silk soft and anti-wrinkle finishing agent is as follows: (1) tartaric acid, citric acid, caprylic acid amidopropyl betaine, sorbitan trioleate, sodium hypophosphite protective agent, polyethylene glycol, water, stirred at room temperature for 60 minutes; (2) Add sodium hydroxide to the above solution to adjust the pH, and the stirring time is 20 minutes; (3) Add cocoamidopropyl d...

Embodiment 3

[0021] A soft and anti-wrinkle finishing agent for silk, prepared from the following ingredients in parts by weight: 12 parts of tartaric acid, 12 parts of citric acid, 9 parts of caprylic acid amidopropyl betaine, 5 parts of sorbitan trioleate, 11 parts of sodium phosphite, 6 parts of polyethylene glycol, 18 parts of cocamidopropyl dimethyl tertiary amine, 7 parts of N-cocoyl-L-glutamic acid triethanolamine, amino-modified silicone softener 18 parts, 4 parts of fatty alcohol polyoxyethylene ether, 16 parts of water, 0.08 part of sodium hydroxide.

[0022] The preparation method of the above silk soft and anti-wrinkle finishing agent is as follows: (1) tartaric acid, citric acid, caprylic acid amidopropyl betaine, sorbitan trioleate, sodium hypophosphite protective agent, polyethylene glycol, water, stirred at room temperature for 40 minutes; (2) Add sodium hydroxide to the above solution to adjust the pH, and the stirring time is 15 minutes; (3) Add cocoamidopropyl dimethyl t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com