Surface treatment method of low temperature glass for solar cell conductive slurry

A technology of solar cells and low-temperature glass, which is applied in the field of surface treatment of low-temperature glass, and can solve problems such as poor glass phase dispersion, glass powder agglomeration, and poor dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

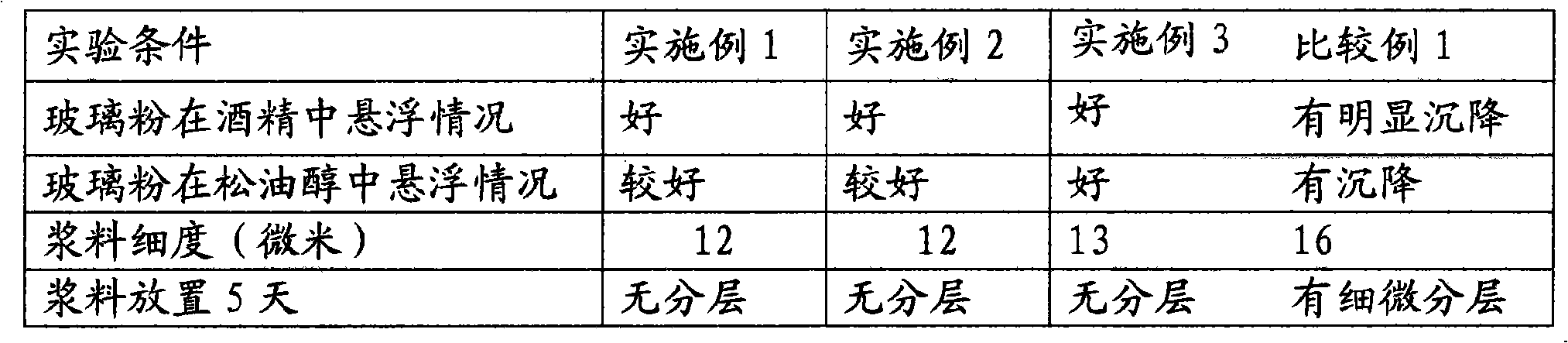

Examples

Embodiment 1

[0015] Take surfactant triethanolamine, n-octyl ester and solvent ethanol (ratio is 20:20:60) to make surfactant solution, take appropriate amount of surfactant solution and add through 1300 degree melting through water-quenched glass powder to mix, Put it in a planetary ball mill and grind it for 10 hours to obtain glass powder with a particle size D50 of less than 1 micron, and then dry it in an oven at a temperature of 90 degrees for 2 hours to obtain surface-treated low-melting glass powder.

Embodiment 2

[0017] Change the mixed solvent of triethanolamine, n-octyl ester and ethanol into the mixture of lecithin and ethanol as the surface treatment active agent in embodiment 1, and other processes are the same as embodiment 1.

Embodiment 3

[0019] First, put the glass powder melted at 1300 degrees and water-quenched in a ball mill to grind, then triethanolamine, n-octyl ester and solvent ethanol (ratio 20:20:60) are mixed evenly with the ground glass powder and heated in an oven. Dry at a temperature of 90 degrees for 2 hours to obtain surface-treated low-melting glass powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com