Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

192 results about "Diethylaniline" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Diethylaniline is the organic compound with the molecular formula (C₂H₅)₂NC₆H₅. It is a colorless liquid but commercial samples are often yellow. It is a precursor to several dyes and other commercial products.

Pdx@Pt/C core-shell structure cathode catalyst for fuel cell and preparation method of Pdx@Pt/C core-shell structure cathode catalyst

ActiveCN105633425AEasy to prepareSolve resource problemsMaterial nanotechnologyCell electrodesPrimary cellAniline

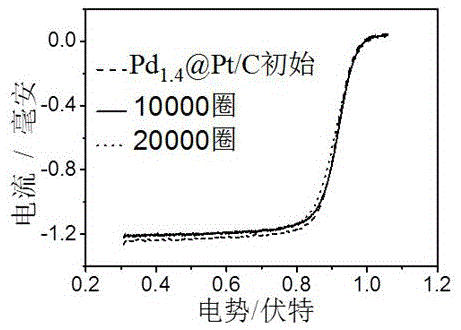

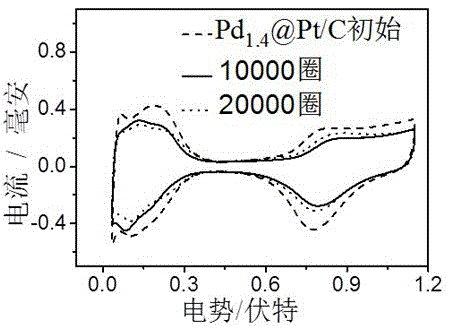

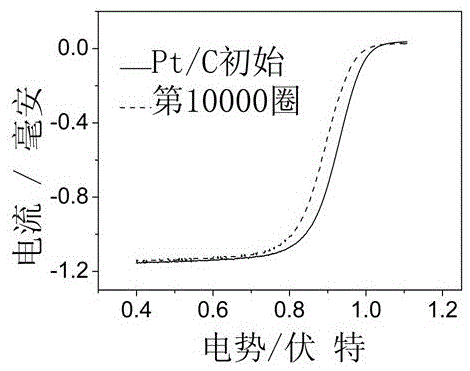

The invention discloses a Pdx@Pt / C core-shell structure cathode catalyst for a fuel cell and a preparation method of the Pdx@Pt / C core-shell structure cathode catalyst. The method comprises the following steps: (1) adding a palladium precursor and a conductive carrier to N,N-dimethyl formamide or ethanol, carrying out ultrasonic mixing, and then adding borane.N,N-diethyl aniline or sodium borohydride, reacting at a room temperature for 0.5-1.5h, carrying out centrifugal washing and vacuum drying and then obtaining a carbon-supported Pd catalyst, namely Pd / C; and (2) ultrasonically dispersing the Pd / C prepared in the step (1) into a formic acid solution with the concentration of 1-5ml formic acid / 20ml water, adding a water solution of a platinum compound at the atomic ratio of Pt to Pd being 1 to 1 or 1 to 2 or 1 to 3, reacting at the room temperature for 2-6h, and carrying out centrifugal washing and vacuum drying to obtain the product. The catalyst with high catalytic activity and stability is prepared by a primary cell reaction principle; the catalyst is lower than a pure Pt catalyst in cost; the preparation method is simple, convenient, mild in condition and easy to operate; and the problem that a high temperature and a surfactant are required for preparation of the core-shell structure catalyst by a conventional chemical reduction method is solved.

Owner:WUHAN UNIV

Thermoplastic powder coating

InactiveCN103740181AReduce surface temperatureEasy to usePolyurea/polyurethane coatingsPowdery paintsAluminateCooling effect

The invention discloses a thermoplastic powder coating. The thermoplastic powder coating is composed of following raw materials in parts by weight: 90-94 parts of polyethylene E309, 6-10 parts of thermoplastic polyurethane elastomer, 1-2 parts of perfluor-butyl potassium sulphonate, 0.2-0.4 part of tetramethyl thiuram disulfide, 0.4-1 part of N,N-diethyl aniline, 1-2 parts of ricinoleic acid, 1-2 parts of 1-ethoxyl-2-oleic imidazoline, 0.5-1 part of distearoyl isopropoxy aluminate, 2-4 parts of guar gum, 10-14 parts of epoxy soybean oil and 15-20 parts of modified fillers. The powder coating provided by the invention is particularly suitable for heat radiation coating of an LED (Light Emitting Diode) lamp and is convenient to use; the surface temperatures of a heat radiation cup, an aluminum substrate, a lamp cover and the like of the LED lamp so that the cooling effect is realized.

Owner:WUHU BAOYI AMUSEMENT EQUIP

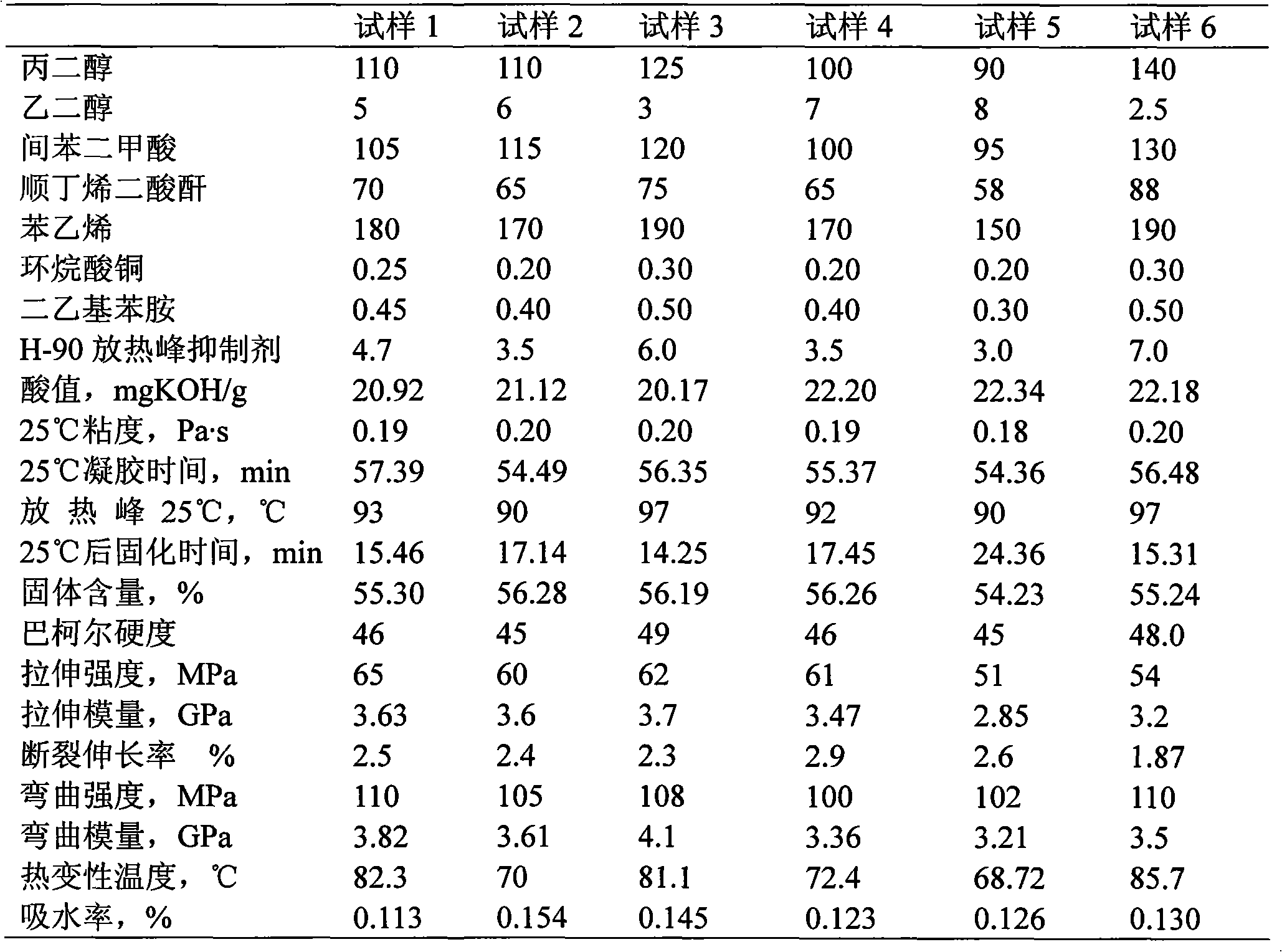

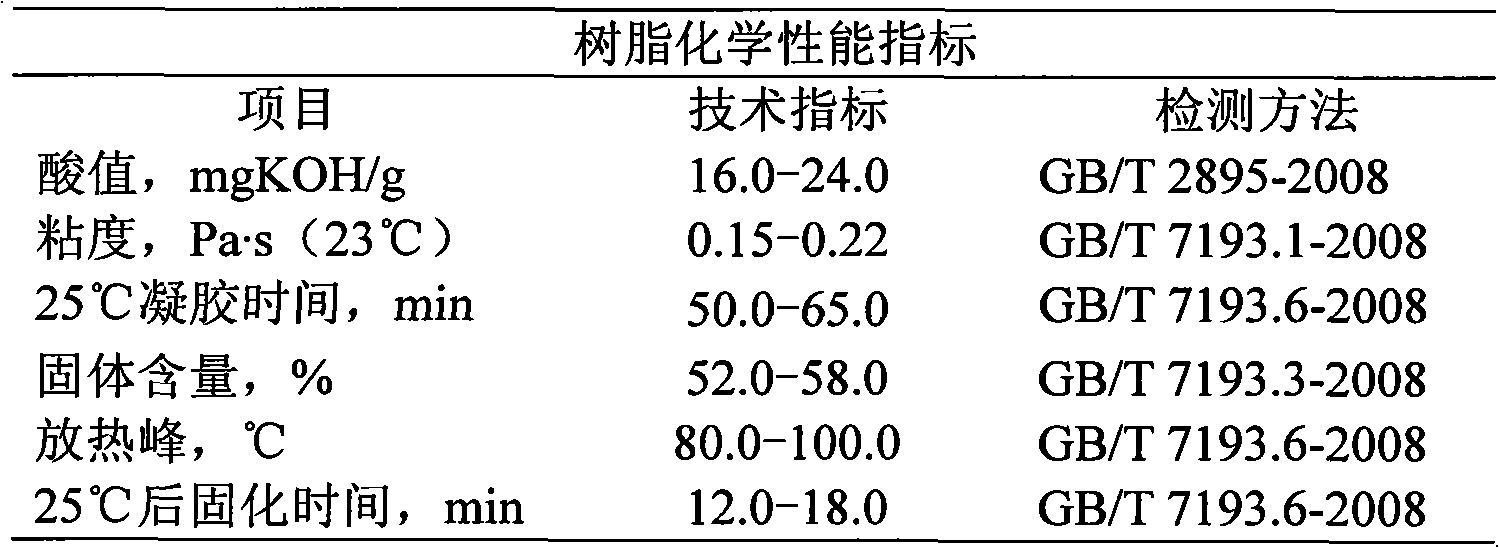

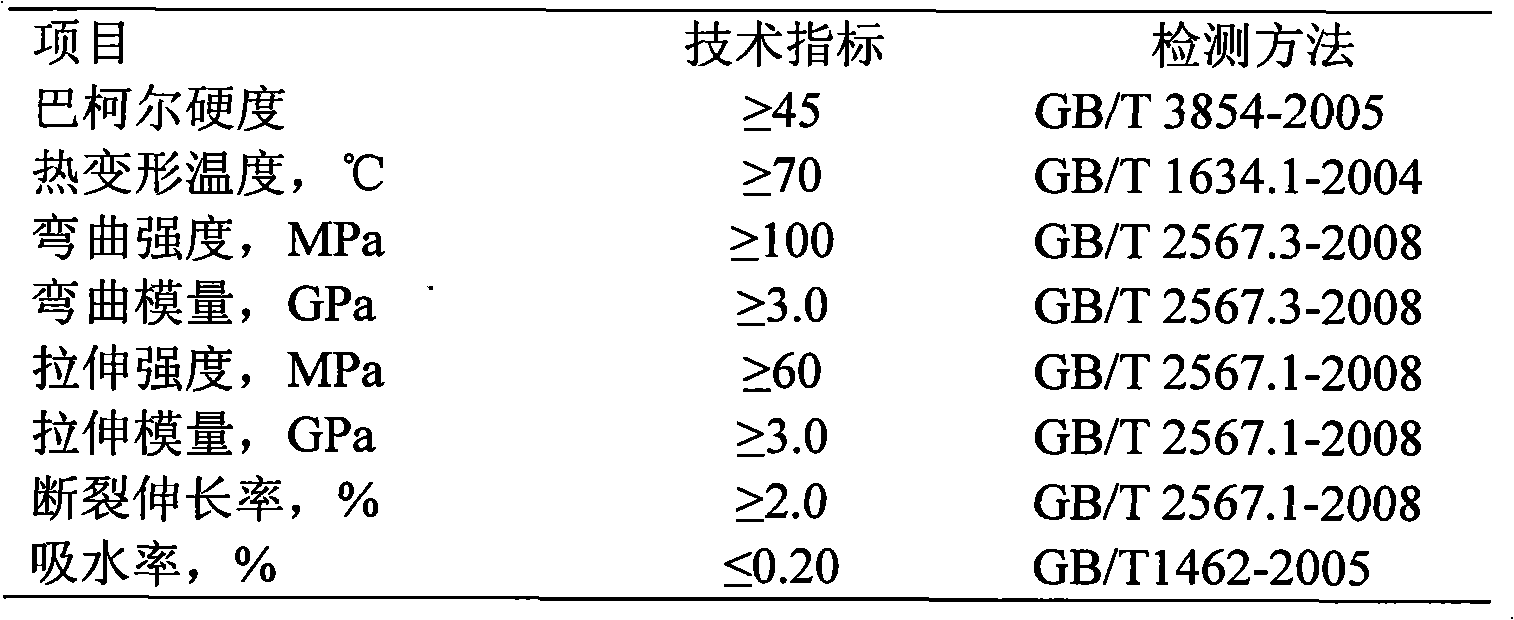

Unsaturated polyester resin for vacuum infusion process and resin composition thereof

The invention discloses an unsaturated polyester resin for a vacuum infusion process. Monomers such as propylene glycol, ethylene glycol, m-phthalic acid, maleic anhydride and the like are prepared into unsaturated polyester through condensation polymerization reaction, then the unsaturated polyester is added into styrene to prepare the unsaturated polyester resin and the unsaturated polyester resin is matched with auxiliary agents such as an H-90 exothermic peak inhibitor, diethylbenzene, copper uversol and the like to form a composition. In the invention, the m-phthalic acid is used as a saturated acid to be introduced into the resin, so that the heat resistance and the corrosion resistance of the resin are improved; the auxiliary agents such as the H-90 exothermic peak inhibitor, the copper uversol and the like are adopted, so that the poor phenomena such as product crack, local burning and the like caused by over-high heat release during resin solidification are effectively avoided; and the diethylbenzene is adopted, so that the demolding strength of a product can be achieved in 3-5 hours. The technical scheme provided by the invention is suitable for large-sized glass fiber reinforced plastic produced by the vacuum infusion process, in particular to large-sized thick workpieces, the glass fiber reinforced plastic products, such as fan housings, glass fiber reinforced plastic boats and the like, and the strength, the weather resistance and the water resistance of the product are improved.

Owner:CHANGZHOU HUARUN COMPOSITE MATERIALS

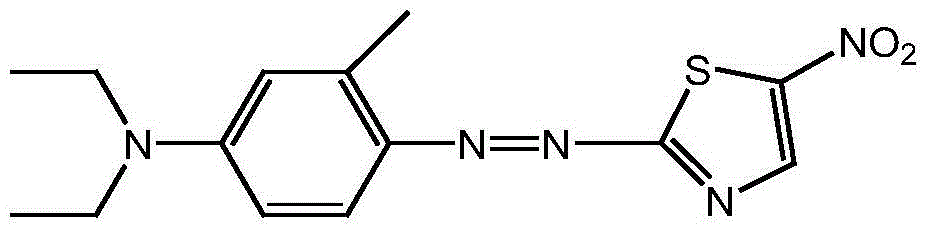

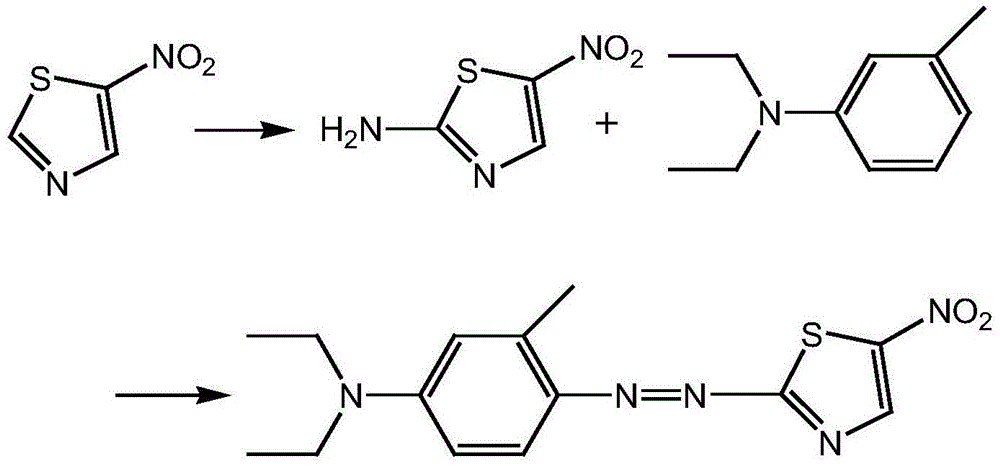

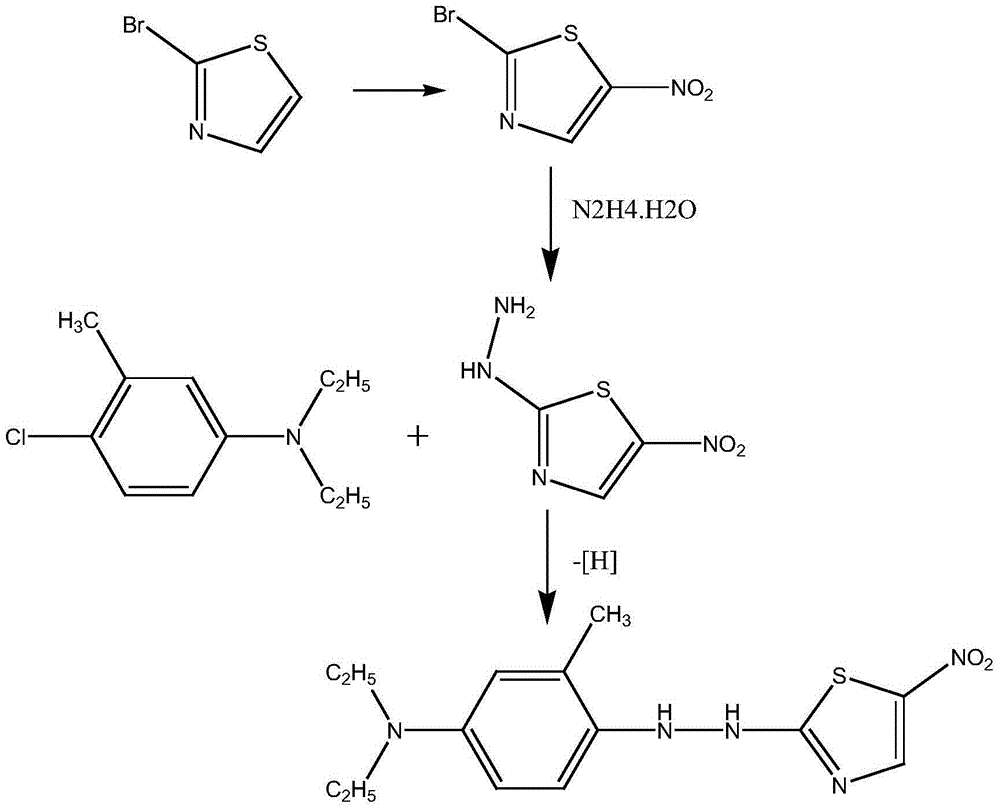

Method used for preparing disperse blue 360

The present invention discloses a method for preparing disperse blue 360. 2-Bromothiazole is used as a raw material and is subjected to four unit reaction processes of nitration, hydrazination, amination and oxidation to obtain the target product. Its specific route is as follows: 2-bromothiazole is used as a raw material and subjected to a nitration reaction under the action of a mixture of concentrated nitric acid and concentrated sulphuric acid using to produce 2-bromo-5-nitrothiazole, the resulting 2-bromo-5-nitrothiazole is reacted using 2-methyltetrahydrofuran as a solvent under the action of hydrazine hydrate to produce 2-hydrazino-5-nitrothiazole, the resulting 2-hydrazino-5-nitrothiazole is reacted with 3-methyl-4-chloro-N,N-diethylaniline under the action of triethylamine, cuprous bromide and butanol to produce 2-[[4-(diethylamino)-2-methylphenyl]diamine]-5-nitrothiazole, the prepared 2-[[4-(diethylamino)-2-methylphenyl]diamine]-5-nitrothiazole is reacted under the action of an oxidant to produce the target product. In the present invention, sodium perborate and a composite catalyst are used for the hydrazine oxidation, which solves the problem of a low conversion rate of hydrazine oxidation using hydrogen peroxide as an oxidant, and provides a new preparation method for synthesizing the azo dye.

Owner:JIANGSU DAOBO CHEM

Preparation method of photoinitiator TPO

InactiveCN103880882AReduce usageNo emissionsGroup 5/15 element organic compoundsBenzoyl chlorideAniline

The invention provides a preparation method of a photoinitiator TPO, comprises the following formula: 22.5% of diethyl aniline, 7.5% of absolute methanol, 34% of chlorodiphenylphosphine, and 36% of 2,4,6-trimethyl benzoyl chloride. The method comprises the following steps: 1, stirring and uniformly mixing diethyl aniline and absolute methanol; 2, warming to 20 DEG.C, slowly dropping chlorodiphenylphosphine, preserving heat for 2 hours; 3, pumping out the material, and filtering for later use; 4, uniformly mixing the 2,4,6-trimethyl benzoyl chloride; 5, warming to 80 DEG.C, slowly dropping the material for later use in the step 3, and then preserving for 1 hour; 6, carrying out suction filtering by using a suction filtering groove to obtain the photoinitiator TPO. The process is simple, the flammable and combustible solvent such as methylbenzene is unnecessary to use in the reaction process, the preparation method is safe, reliable and in favor of energy-saving and environment-protecting.

Owner:XIANGYANG KEMIN CHEM TECH CO LTD

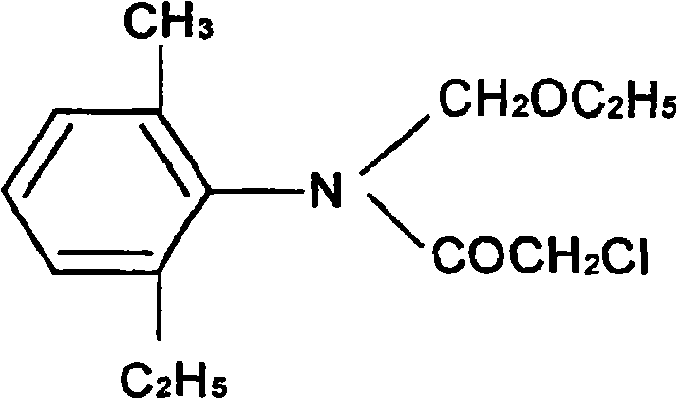

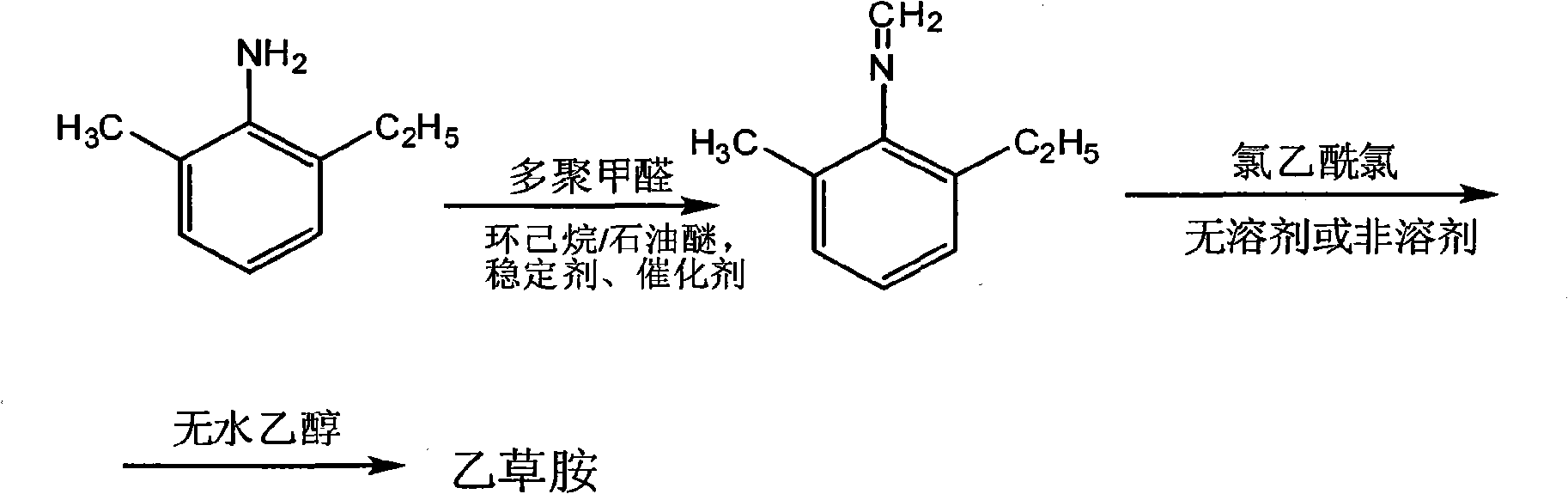

Methylene technique for producing acetochlor

InactiveCN101270062AOrganic compound preparationCarboxylic acid amides preparationAnilineAromatic solvents

The present invention relates to a preparation process of acetochlor in a methylene method, and is characterized in that the production process comprises the following steps: (1) under the influence of a catalyst and a stabilizer, 2-methyl-6-diethylaniline and paraformaldehyde have dehydration reaction in non-aromatic solvent cyclohexane, petroleum ether or the mixture of the cyclohexane and the petroleum ether, to prepare 2-methyl-6-ethyl-N-methylene aniline that requires no purification for the reaction in the next step; (2) under the condition with non-aromatic solvents or without solvents, the prepared 2-methyl-6-ethyl-N-methylene aniline and chloroacetic chloride have acylation reaction; then the products prepared in the acylation reaction and anhydrous alcohol react to prepare the crude product; and the acetochlor with more than 93 percent of the acetochlor content can be separated and prepared.

Owner:INNER MONGOLIA HONGYU TECH

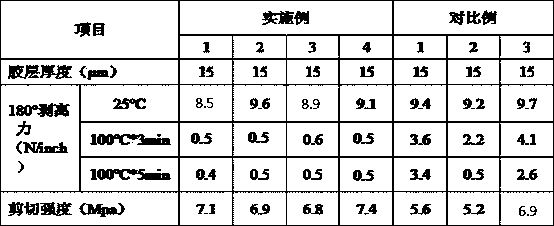

Reworkable thermal deadhesion adhesive tape for manufacture procedure and preparation method of adhesive tape

InactiveCN109913141AImprove peel forceEasy to peelNon-macromolecular adhesive additivesFilm/foil adhesivesDiaminodiphenyl ether(Hydroxyethyl)methacrylate

The invention discloses a reworkable thermal deadhesion adhesive tape for manufacture procedure. The adhesive tape comprises a substrate layer and a thermal deadhesion adhesive layer coating the surface of the substrate layer, wherein the thermal deadhesion adhesive layer comprises components as follows: butyl acrylate, 2-ethylhexyl acrylate, methyl methacrylate, hydroxyethyl methylacrylate, a styrene-isoprene-styrene block copolymer, thermoplastic phenolic resin, methylbenzotriazole, N,N-diethylaniline, azodiisobutyronitrile, 4,4'-diaminodiphenyl ether, polyethylene wax, gamma-methacryloxy propyl trimethoxyl silane, an antioxidant and a solvent. The reworkable thermal deadhesion adhesive tape for the manufacture procedure has notably reduced adhesion after being heated, can be easily stripped from an attached object and is convenient to rework, the adhesion of the adhesive layer can recover after the adhesive tape recovers the normal temperature, therefore, the adhesive tape can be recyclable, and the economic cost is saved.

Owner:苏州义铠轩电子科技有限公司

Scrubbing-resistant environment-friendly interior-wall latex paint

InactiveCN104804560AHigh bonding strengthGood scrub resistanceAntifouling/underwater paintsPaints with biocidesEmulsionAmmonium metatungstate

The invention discloses scrubbing-resistant environment-friendly interior-wall latex paint. The scrubbing-resistant environment-friendly interior-wall latex paint comprises the following components in parts by weight: 20-30 parts of deionized water, 30-45 parts of a styrene-acrylic emulsion, 1-5 parts of ammonium metatungstate, 2-6 parts of N,N-diethylaniline, 1-10 parts of titanium dioxide, 3-8 parts of a surfactant, 2-7 parts of a film forming agent, 5-8 parts of a foam killer, 5-15 parts of a nano-filler, 6-10 parts of a stain-resistant agent and 3-6 parts of a thickening agent. The scrubbing-resistant environment-friendly interior-wall latex paint can quickly cure to form a film, the coating is excellent in bonding strength, good in scrub resistance, environment-friendly and nontoxic and solid in paint film, the surface is smooth and easy to clean, and the scrubbing-resistant environment-friendly interior-wall latex paint is suitable for the interior and exterior wall decoration fields of houses, guest houses, schools, hospitals and the like.

Owner:田福东

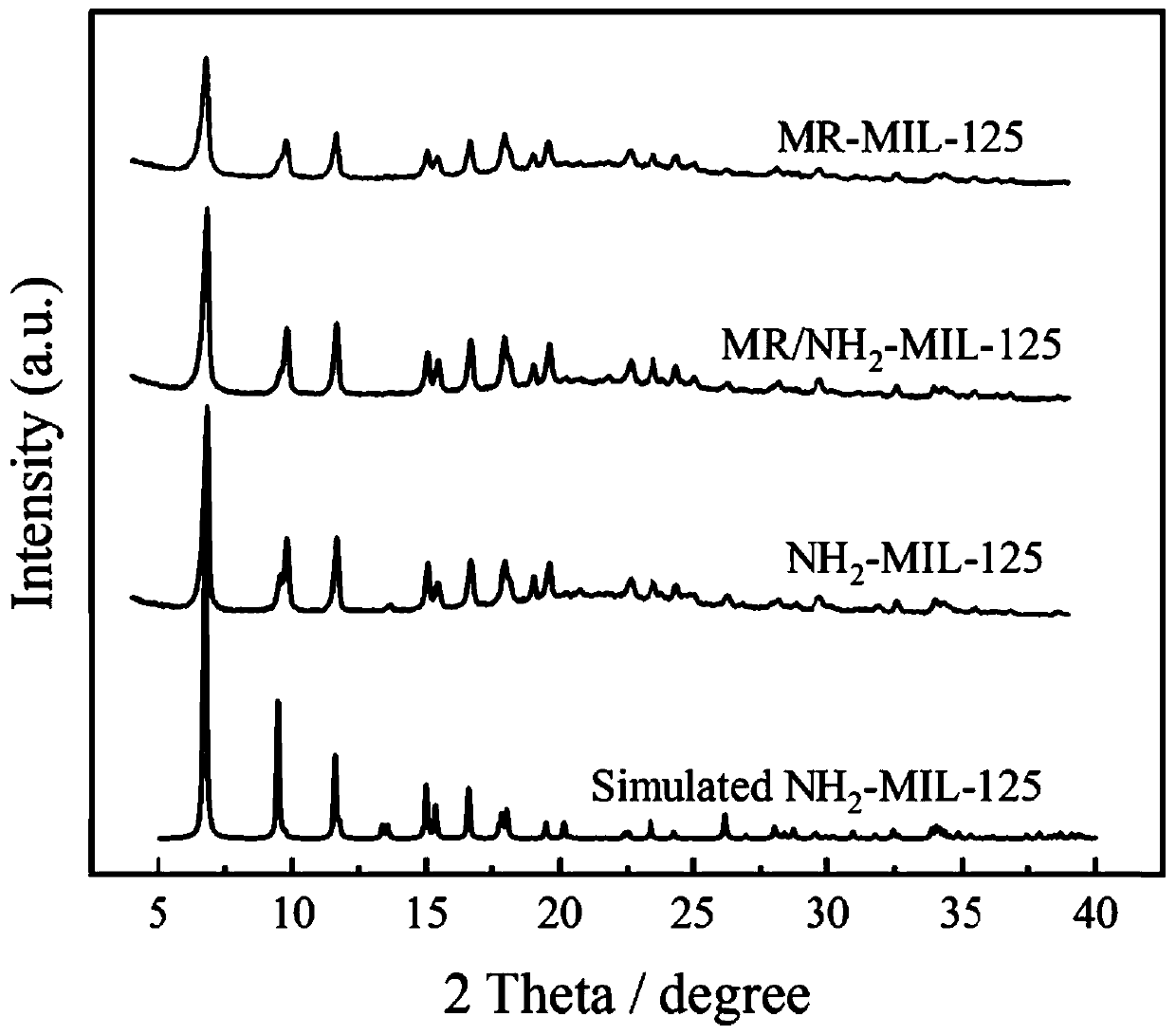

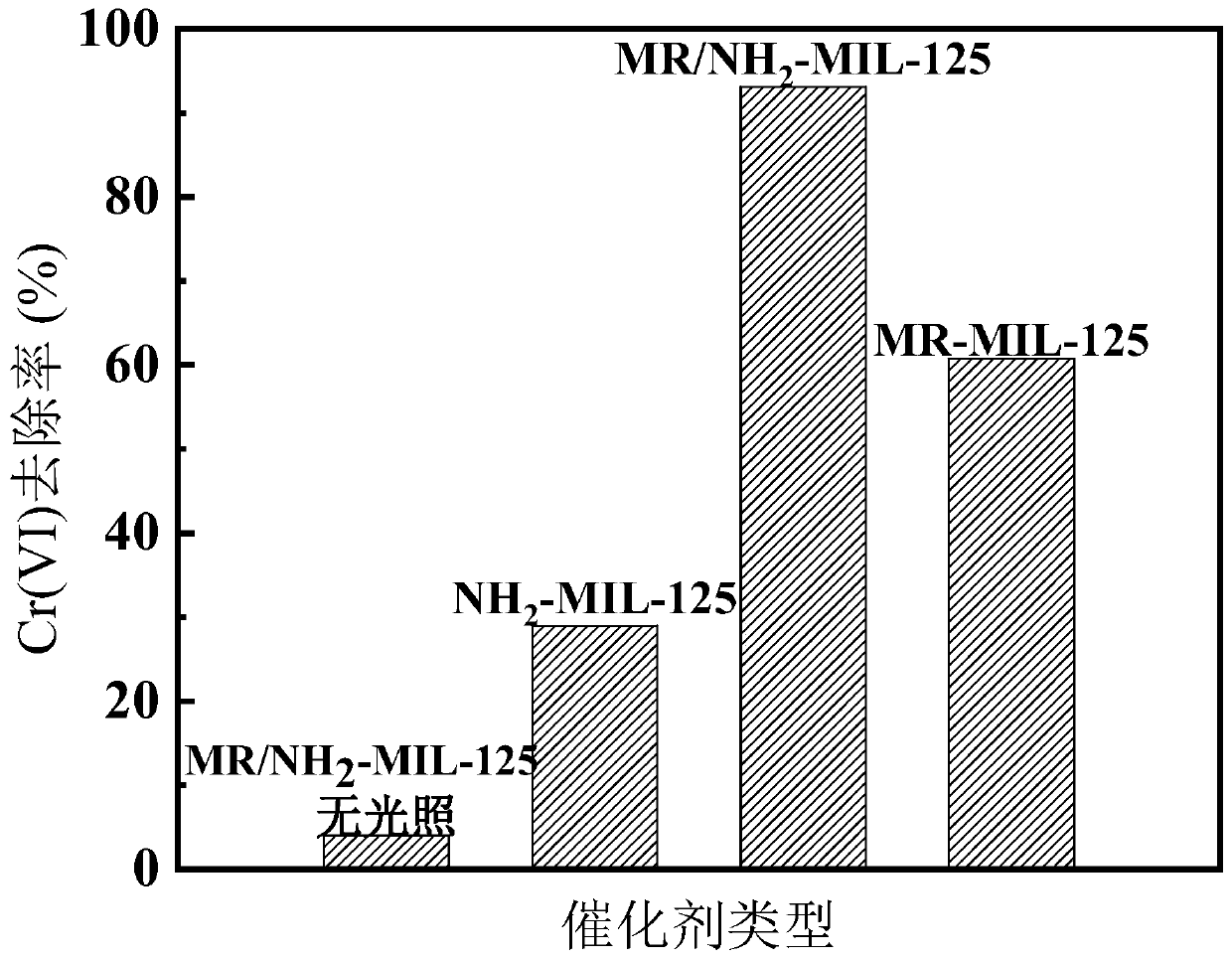

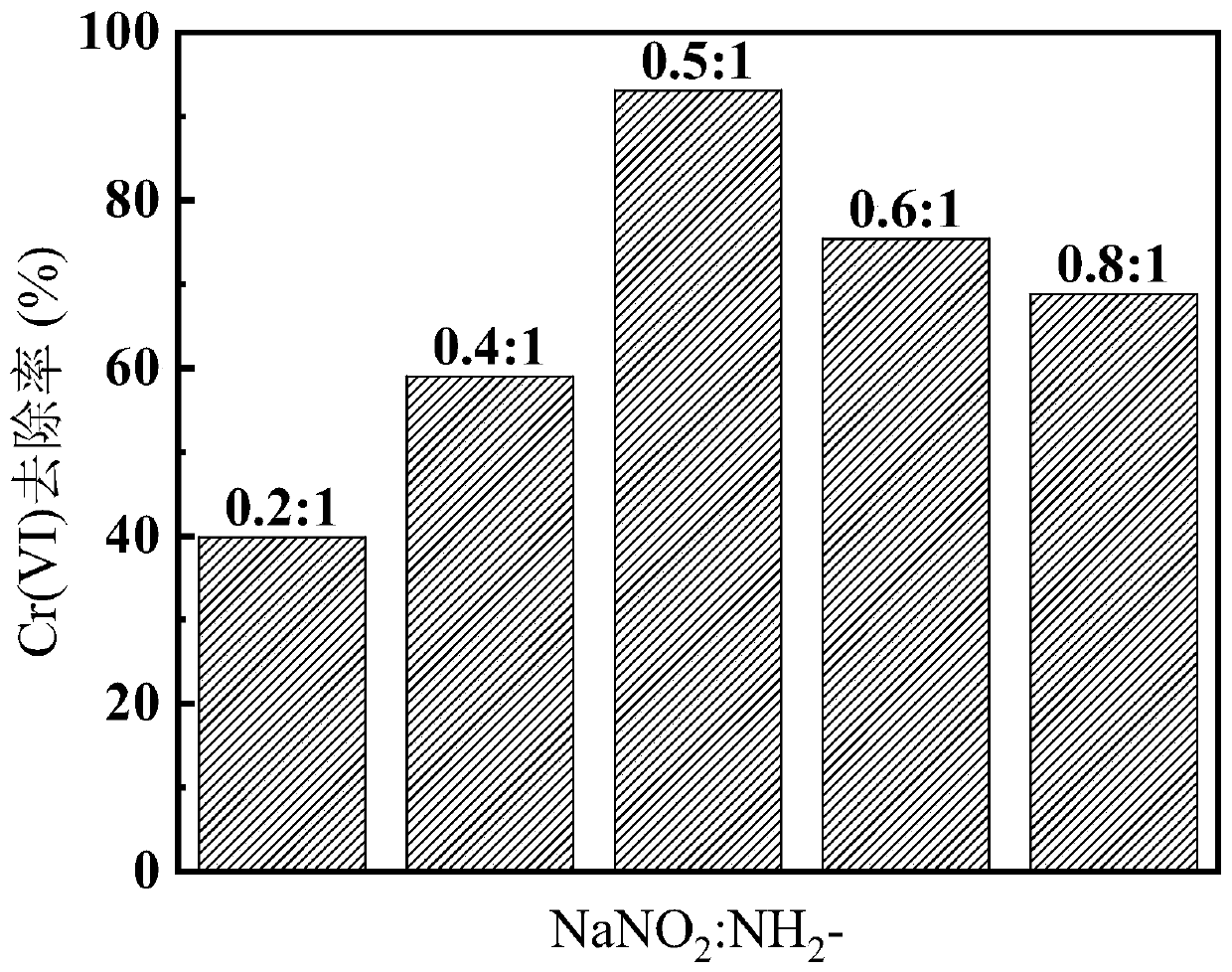

Ti-based MOF composite material, and preparation method and application thereof

ActiveCN111359664AReduce dosageImprove performanceWater/sewage treatment by irradiationWater treatment compoundsAnilineAcetic acid solution

The invention discloses an MR / NH2-MIL-125 composite material, a preparation method thereof, and an application of the MR / NH2-MIL-125 composite material in the field of photocatalysis. The preparationmethod comprises the following steps: (1) adding 2-aminoterephthalic acid and butyl titanate into a DMF / methanol solution, preparing NH2-MIL-125 by using a heating reflux method, and carrying out centrifugation, washing, drying and grinding treatment to obtain NH2-MIL-125(Ti) powder; (2) dispersing the NH2-MIL-125(Ti) powder into deionized water, stirring and mixing uniformly, adding NaNO2, dissolving, performing ice-water bath treatment to obtain a turbid liquid, dropwise adding hydrochloric acid, and continuously stirring; and (3) dropwise adding an acetic acid solution of diethylaniline into the mixed solution obtained in step (2), and carrying out a complete stirring reaction so as to obtain the MR / NH2-MIL-125 composite material.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

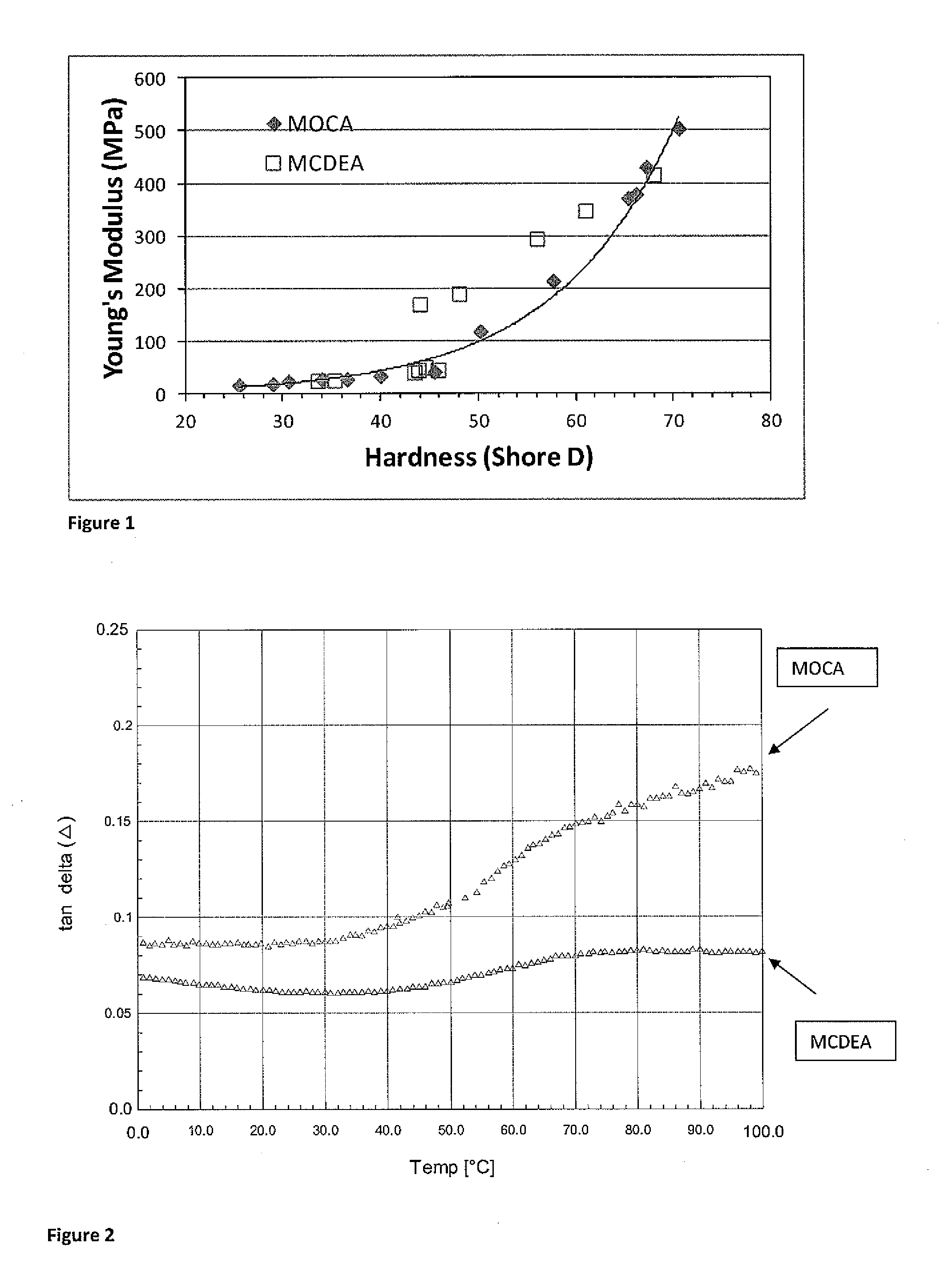

Polyurethane polishing pad

InactiveUS20150059254A1Other chemical processesLapping toolsPolypropylene glycolToluene diisocyanate

The invention provides a polishing pad suitable for planarizing semiconductor, optical and magnetic substrates. The polishing pad includes a cast polyurethane polymeric material formed from a prepolymer reaction of a polypropylene glycol and a toluene diisocyanate to form an isocyanate-terminated reaction product. The toluene diisocyanate has less than 5 weight percent aliphatic isocyanate; and the isocyanate-terminated reaction product having 5.55 to 5.85 weight percent unreacted NCO. The isocyanate-terminated reaction product being cured with a 4,4′-methylene-bis(3-chloro-2,6-diethylaniline) curative agent. The non-porous cured product having a tan delta of 0.04 to 0.10, a Young's modulus of 140 to 240 MPa and a Shore D hardness of 44 to 56.

Owner:DOW GLOBAL TECH LLC +1

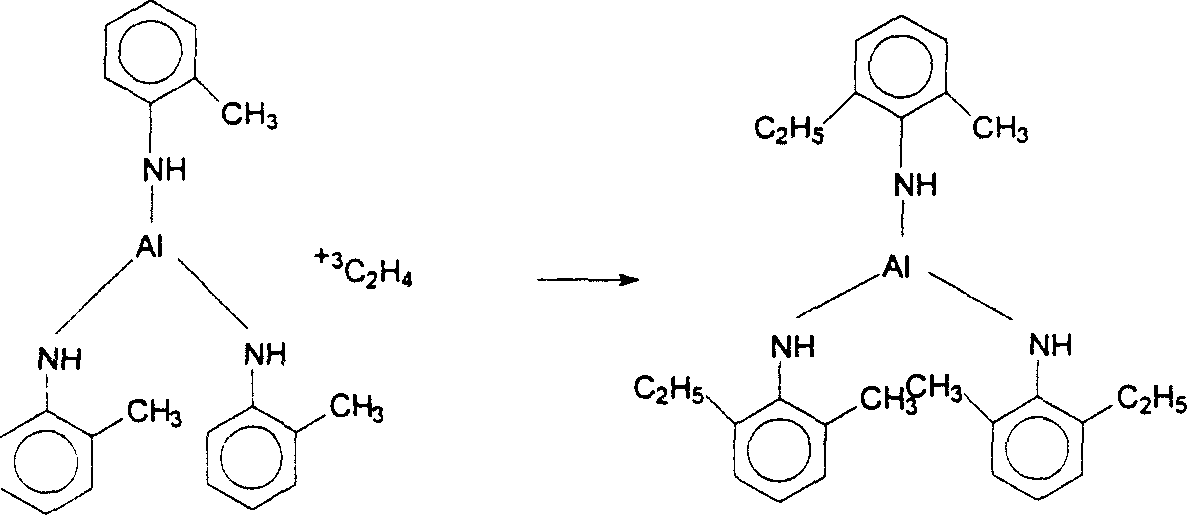

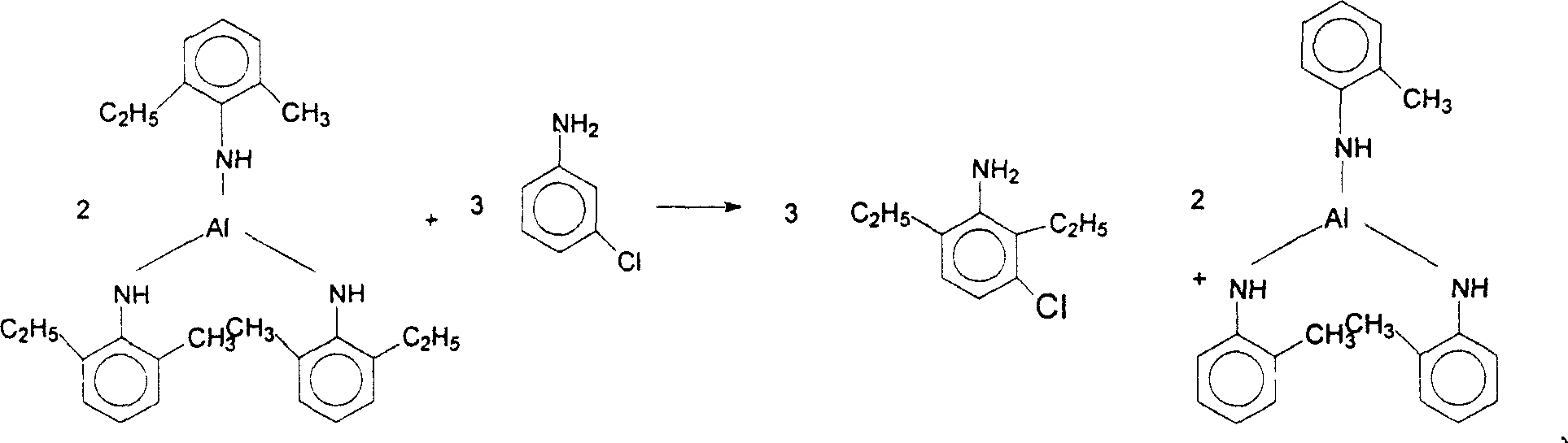

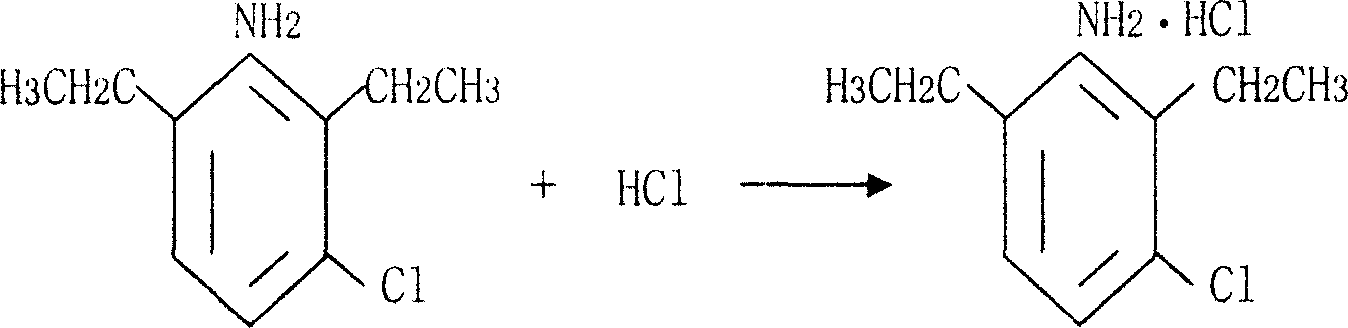

Preparation method of 3-chloro-2,6-diethyl aniline

InactiveCN1903832ASmooth responseSuit one's needsOrganic chemistryChemical recyclingM-chloroanilineAniline

The present invention discloses a preparation method of 3-chloro-2,6-diethylaniline. Said method includes the following steps: heating metal or its salt in aniline or alkylaniline and making them produce reaction to obtain aniline or alkylaniline metal complex catalyst, adding m-chloroaniline into the obtained complex catalyst, under the condition of 150deg.C-400deg.C and 10MPa-25MPa introducing ethylene, under the action of aniline or alkylaniline metal complex catalyst producing ethylated complex, then making m-chloroailine and ehylated complex produce metathetical reaction so as to obtain 3-chloro-2,6-diethylaniline, and make the complex catalyst obtain regeneration.

Owner:黄秋耉

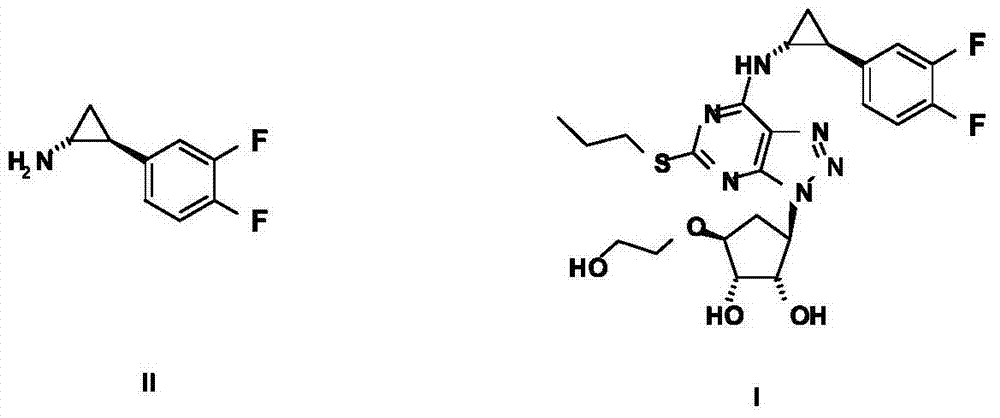

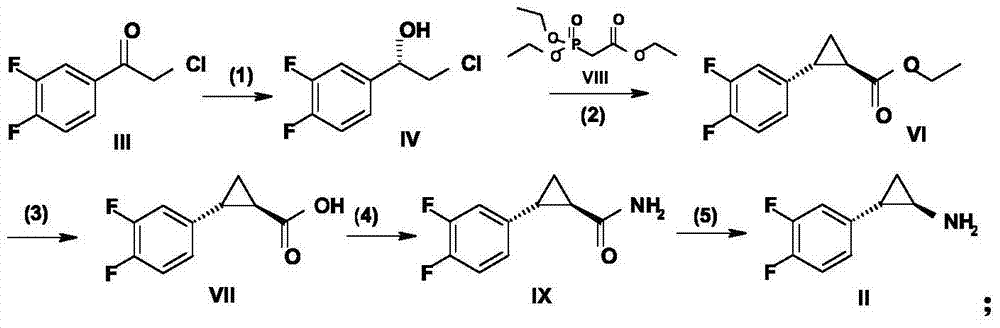

Preparation method of ticagrelor intermediate

ActiveCN104744266AReduce pollutionReduced Possibility of ContaminationOxygen-containing compound preparationOrganic compound preparationPotassium borohydrideTicagrelor

The inventiondiscloses a preparation method of ticagrelor. The method comprises the following steps: (1) reducing a compound shown in a formula III in the presence of a proton source provided by sodium borohydride or potassium borohydride and diethyl aniline hydrochloride to obtain a compound shown in a formula IV; (2) reacting the compound IV in the presence of alkali to generate a compound VI; (3) hydrolyzing the compound VI without purification to generate a compound VII; (4) reacting the compound VII to generate acyl chloride, reacting the acyl chloride to generate formamide, thus obtaining a compound shown in a formula IX; and (5) carrying out Hofmann rearrangement on the compound IX to obtain a compound shown in a formula II. Regents used in the method are nontoxic, harmless, environmentally friendly and low in price; the used key reagents can be recycled. Therefore, the method is applicable to industrial production.

Owner:SHANGYU JINGXIN PHARMA +1

Method for synthesizing herbicide pretilachlor by one-pot method

InactiveCN102173998AIncrease profitGood choiceBiocideOrganic compound preparationPropoxurPropyl ether

The invention discloses a method for synthesizing herbicide pretilachlor by a one-pot method, which comprises the following steps of: reacting 2,6-diethylaminobenzene with strong base in a nonprotonic solvent to generate amino sodium salt; then reacting the amino sodium salt with chloroethyl propyl ether to generate pretilachlor intermediate 2,6-diethyl-N-(2-propoxyethyl) phenylamine; and leadingthe intermediate 2,6-diethyl-N-(2-propoxyethyl)phenylamine not subjected to separation and chloroacetic chloride to carry out acylation reaction in the same reactor to obtain pretilachlor. The invention has the advantages of high reaction selectivity, high yield, short process flow, high utilization ratio of raw materials, reduced production cost and higher productive and practical value.

Owner:NANTONG UNIVERSITY

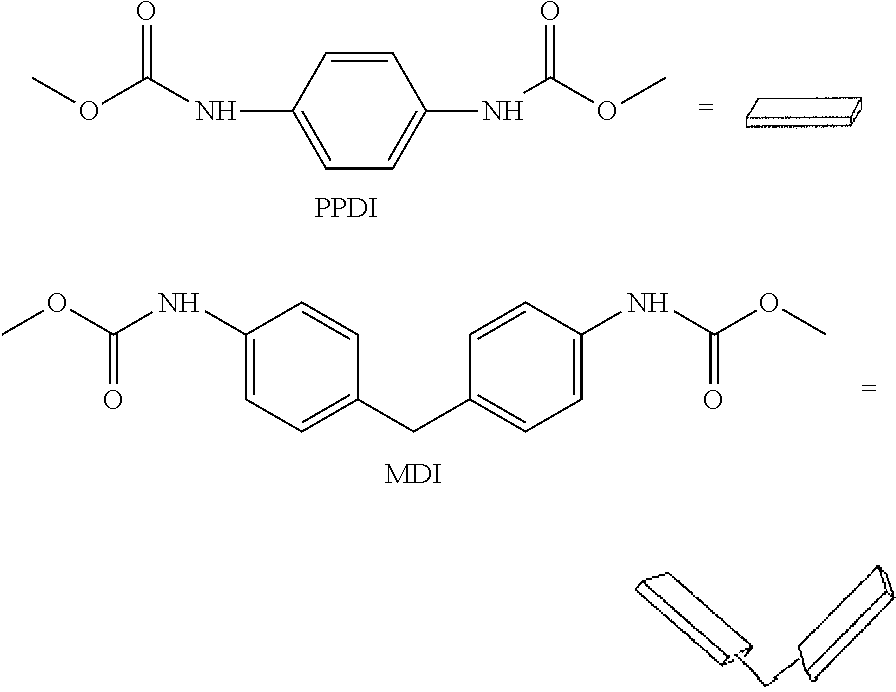

Shoe press belt

ActiveUS8568567B2Improve heat resistanceExcellent characteristicsMechanical paper treatmentPress sectionPolymer scienceCarbamate

The invention relates to a shoe press belt comprising polyurethane polymer prepared of a urethane prepolymer containing isocyanate groups and a chain extender, the urethane prepolymer being prepared using 1,4-phenylene-diisocyanate (PPDI) and the chain extender comprising methyl-bis(3-chloro-2,6-diethylaniline) (MCDEA).

Owner:METSO FABRICS INC

Method of preparing N-ethyl-N-cyanoethyl aniline

ActiveCN101307011AHigh selectivityReduce manufacturing costPhysical/chemical process catalystsCarboxylic acid nitrile preparationDistillationAcrylonitrile

The invention relates to a method for preparing N-ethide-N-cyanoethyl aniline, mainly comprising the following: (1) a step of condensation reaction, during which, aniline reacts with ethanol in the action of catalyst to generate N-ethyl aniline and N, N- diethylaniline which are separated through distillation to produce pure N-ethyl aniline; (2) a step of addition reaction, during which, the pure N-ethyl aniline obtained in the step (1) reacts with acrylonitrile in the action of the catalyst to produce the N-ethide-N-cyanoethyl aniline; particularly, the condensation reaction is performed in the action of a binary catalyst formed by any two of phosphorus oxychloride, phosphorus trichloride, phosphorus pentachloride, phosphorus trichloride and inorganic acid, and the content of one composition of the binary catalyst is between 5 and 95 percent. In the preparing process, on the basis of the prior process, the binary catalyst is used in the condensation reaction; and the reaction selectivity is improved and the production cost is lowered without changing the reaction condition and so on.

Owner:内蒙古美力坚科技化工有限公司

Modified cationic polyacrylamide papermaking retention agent

InactiveCN105297536ASimple preparation processImprove retention effectPaper/cardboardRetention agents additionFiberAniline

The invention discloses a modified cationic polyacrylamide papermaking retention agent, and belongs to the field of papermaking additives. The modified cationic polyacrylamide papermaking retention agent is produced by firstly, conducting preliminary modification on kaolin particles, hydrochloric acid and hydrogen peroxide; secondly, embedding the mixture in the surfaces of bamboo poles for further modification; thirdly, mixing modified kaolin particles with bamboo fiber, 2-methacryloyloxyethyl-trimethyl ammonium chloride and acrylamide monomers, placing the mixture in a reaction kettle, and making the mixture react with gamma-aminopropyltriethoxysilane, N,N-diethyl aniline and other substances. Embodiments prove that the prepared modified cationic polyacrylamide papermaking retention agent is simple in preparation process, good in retention effect, free of damage to the environment, remarkable in economic benefit and social benefit, capable of reducing input of paper pulp raw materials and capable of reducing the production cost by 70% or above.

Owner:仇颖超

Impact-resistant and high-strength plastic plate and preparation method thereof

The invention discloses an impact-resistant and high-strength plastic plate. The impact-resistant and high-strength plastic plate comprises raw materials in parts by weight as follows: 0.2-0.4 parts of hexabromocyclododecane, 4-6 parts of polyisoprene, 100-140 parts of polyvinyl chloride, 0.6-1 part of lauroyl diethanolamide, 0.7-1 part of p-toluenesulfonic acid, 10-14 parts of polyethylene fibers, 0.7-1 part of potassium dichromate, 50-60 parts of 96%-98% sulfuric acid, 0.4-1 part of caprylic capric triglyceride, 5-7 parts of tributyl citrate, 2-3 parts of zinc dihydrogen phosphate, 10-14 parts of clay, 0.6-1 part of dialkyl p-diphenol, 2-3 parts of calcium fluoride, 0.2-0.3 parts of N,N-diethyl aniline, 1-2 parts of aluminum tripolyphosphate, 3-5 parts of polyvinyl alcohol and 2-3 parts of fine silica aerogel. Polyisoprene, fine silica aerogel and the like are added, so that the impact-resistance strength of a finished plate is effectively improved.

Owner:宁波远欣石化有限公司

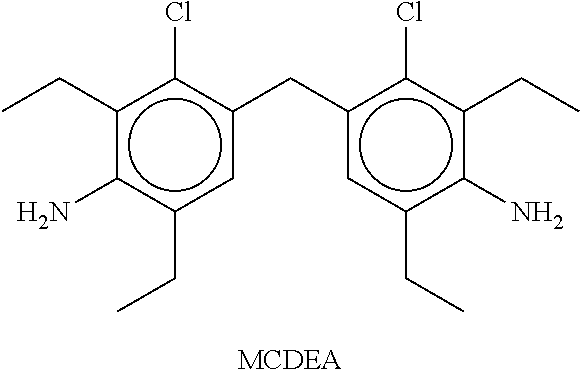

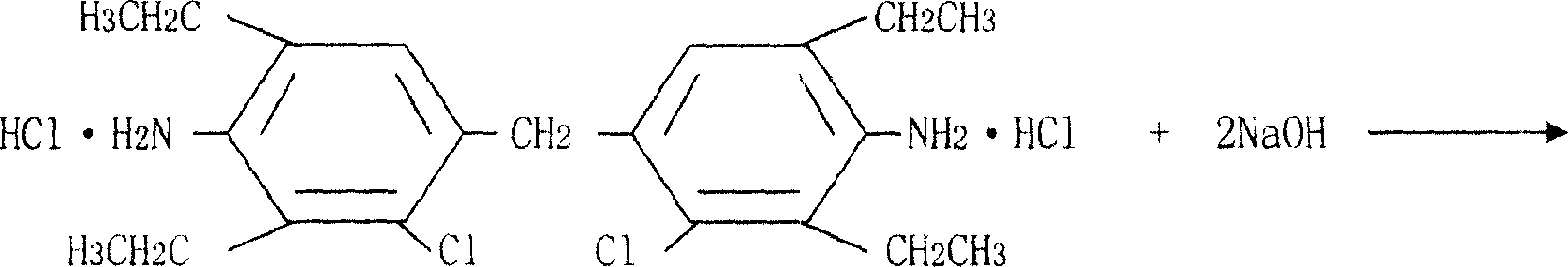

Prepn process of 4,4'-methylene-bis(3-chloro-2,6-diethyl aniline) (MCDEA)

The preparation process of 4, 4'-methylene-bis-(3-chloro-2, 6-diehtyl aniline) (MCDEA) belongs to the field of polymer synthesis technology. Under the protection of inert gas, material 3-chloro-2, 6-diehtyl aniline is reacted with hydrochloric acid in water solution to produce 3-chloro-2, 6-diehtyl aniline hydrochloride. Then, water solution of formaldehyde is dropped while heating to produce condensation; and through maintaining the temperature for finishing the reaction and neutralization with alkali, coarse MCDEA product is separated. Through further decolorizing, dewatering, crystallizing and pelletizing, MCDEA product is obtained. The preparation process is simple and has mild reaction condition, low production cost and high yield, and MCDEA has micro toxicity and may be used to replace MOCA as chain expander for PU material.

Owner:陆锦贤

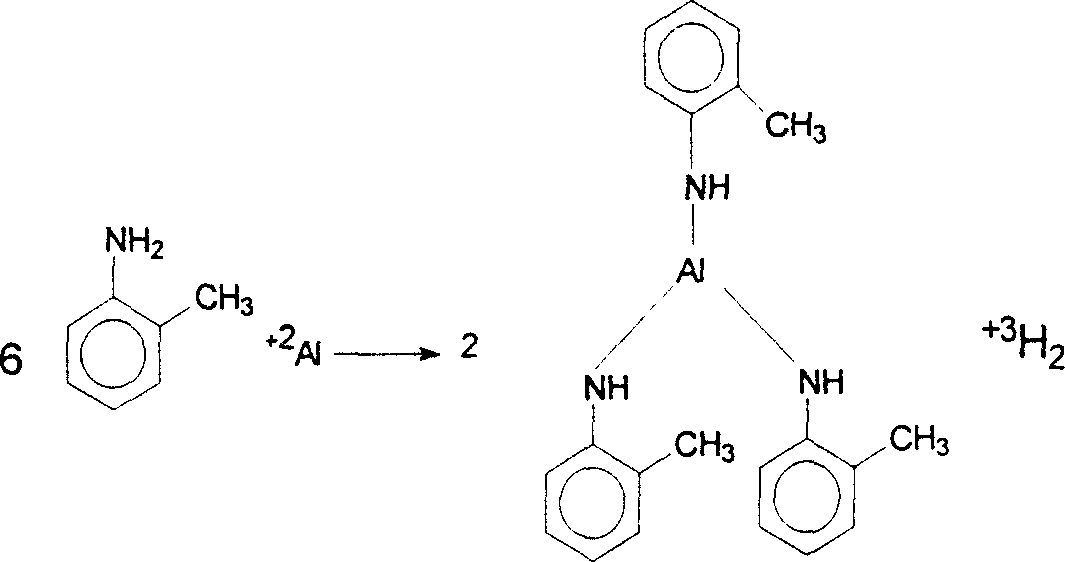

Preparation method of 2, 6-diethylaniline

InactiveCN107793319AReduce energy consumptionLow costAmino preparation from aminesAlkyl transferWastewater

The invention discloses a preparation method of 2, 6-diethylaniline. The preparation method comprises preparation of a catalyst complex, alkylation reaction, recovery and separation. The preparation method utilizes an alkyl aluminum complex as a catalyst. Alkyl aluminum can react with raw materials at the normal temperature so that energy consumption is low. Alkyl aluminum can be recycled. The preparation method is free of a washing process, does not produce waste water and reduces the solid waste amount by about 90% per ton than the waste amount based on aluminum powder and aluminum chlorideas catalysts. Alkyl aluminum has no corrosivity. The preparation device is prepared from carbon steel with a low cost.

Owner:HUAIAN SHUANGYANG CHEM

Light flame-retardant optical cable material and preparation method thereof

The invention discloses a light flame-retardant optical cable material, which is composed of the following raw materials in parts by weight: 1 to 2 parts of polyvinylpyrrolidone, 3 to 5 parts of triethyl citrate, 0.1 to 0.2 part of N,N-diethyl aniline, 6 to 7 parts of guanidine sulfamate, 20 to 23 parts of carbon nanotube, 0.3 to 0.4 part of N,N'-dicyclohexyl carbimide, 4 to 5 parts of phosphonitrilic chloride trimer, 0.2 to 0.4 part of sodium hydroxide, 1 to 2 parts of thiourea, 17 to 20 parts of nylon, 120 to 130 parts of polyvinyl chloride, 1 to 2 parts of disodium hydrogen phosphate, 2 to 3 parts of glycerol triacetate, 3 to 4 parts of rosin alcohol, 4 to 5 parts of light calcium carbonate, 0.8 to 1 part of beta-hydroxyalkyl amide, and 0.7 to 1 part of polyvinyl butyral. The provided optical cable material is light and thus is convenient for installation and transportation.

Owner:安徽电信器材贸易工业有限责任公司

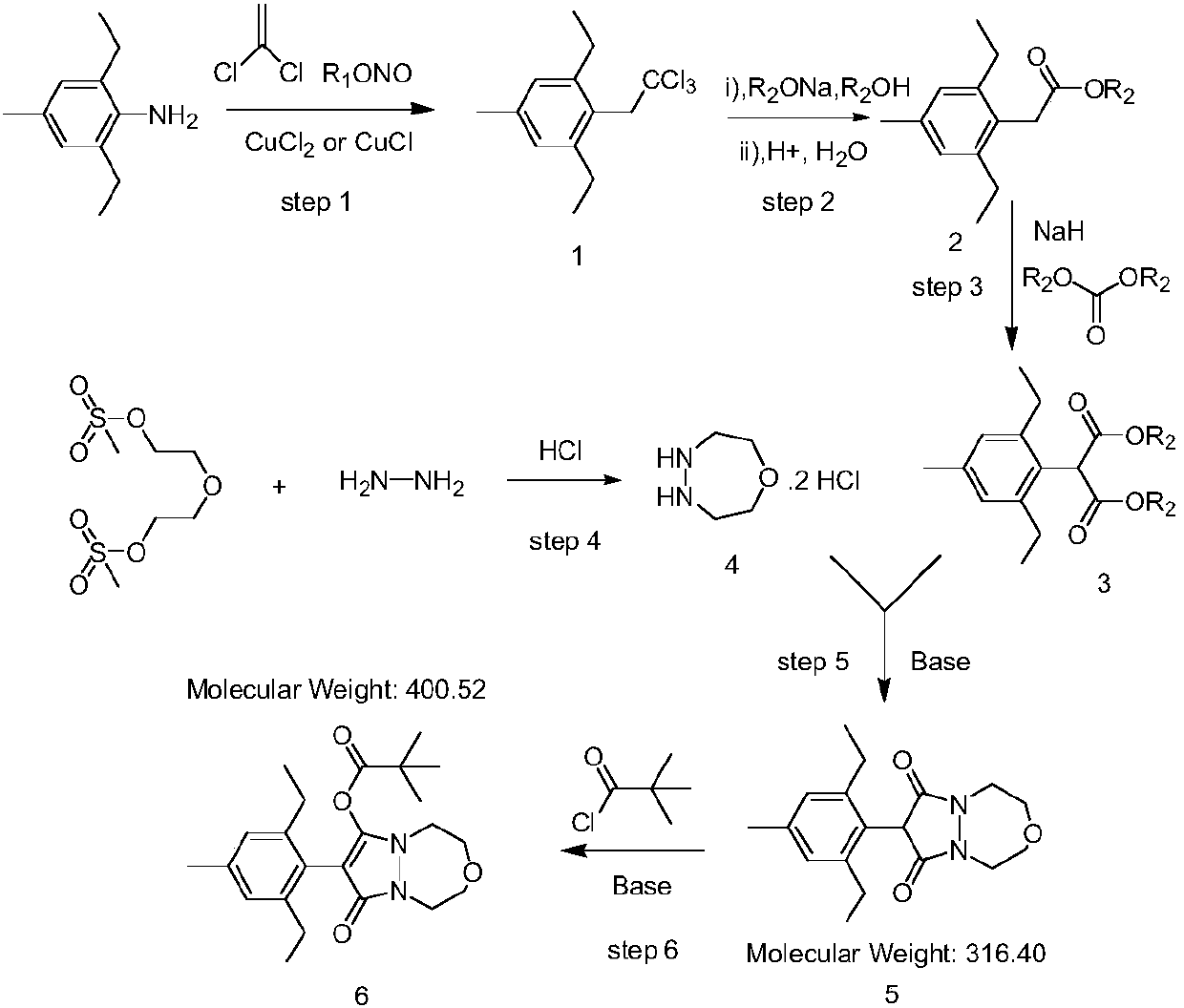

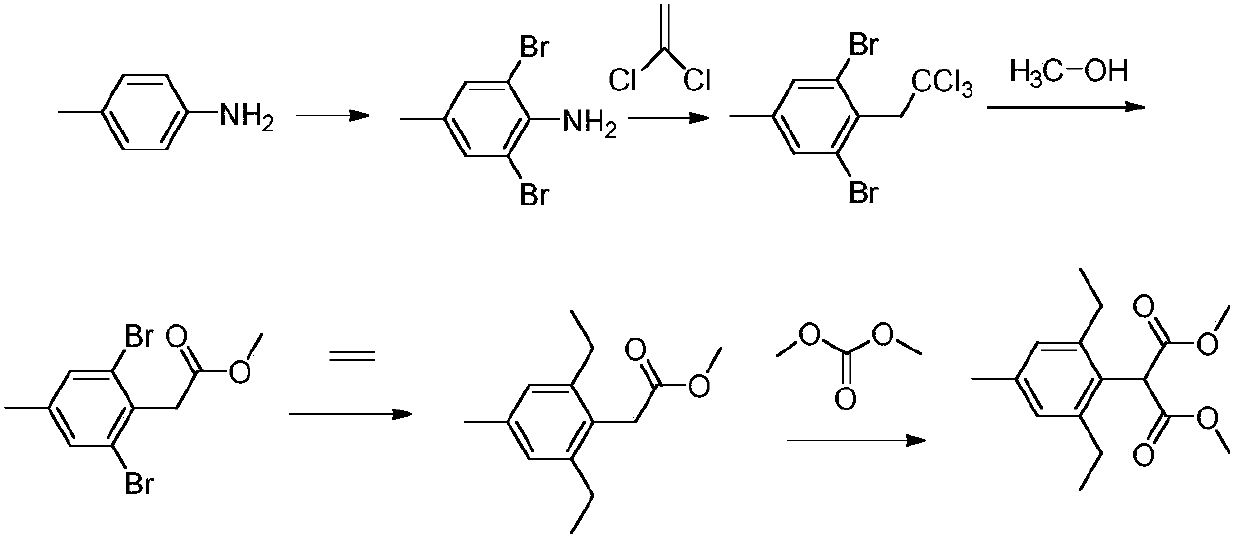

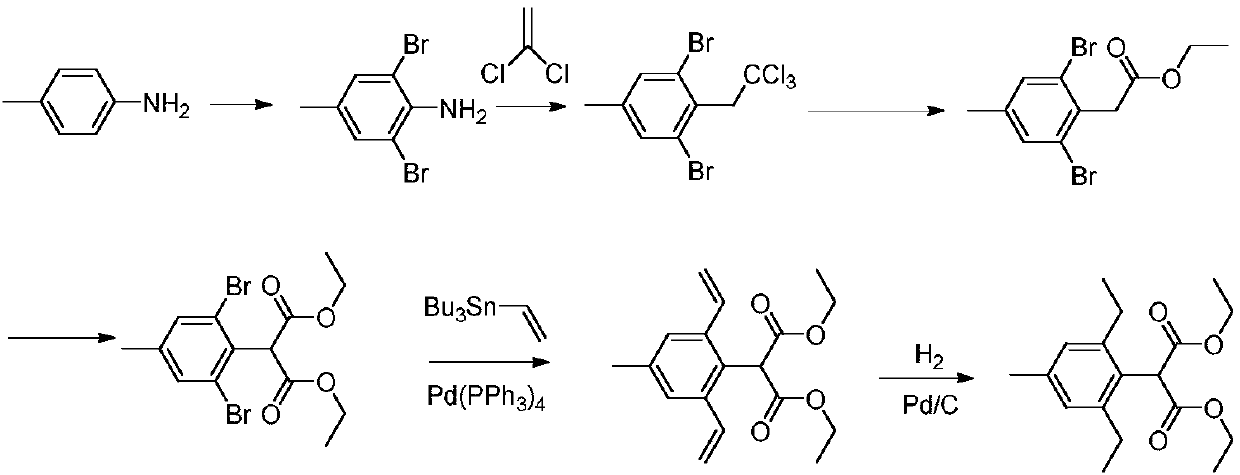

Preparation method of pinoxaden

The invention relates to the field of organic synthesis, in particular to a synthesis method of pinoxaden. The synthesis method comprises the following steps that under catalysis of copper chloride orcuprous chloride, 4-methyl-2,6-diethyl aniline reacts with 1,1-dichloroethylene and nitrous acid ester to generate a compound 1; the compound 1 reacts with sodium alcoholate, and a reaction product is subjected to acidic hydrolysis to obtain a compound 2; the compound 2 reacts with diester carbonate and strong base to obtain an intermediate 3; after diethylene glycol dimethanesulfonate reacts with hydrazine hydrate, salifying with hydrochloric acid is conducted to obtain an intermediate 4; the intermediate 3 and the intermediate 4 are subjected to ring forming under the effect of base to obtain a compound 5; and the compound 5 and pivaloyl chloride react under the effect of the base or base / DMAP to obtain the pinoxaden. The synthesis method of the pinoxaden does not use expensive or toxiccatalysts, does not need to adopt a protection / deprotection strategy, and has the characteristics of low cost and high atomic economy.

Owner:JIANGSU FLAG CHEM IND

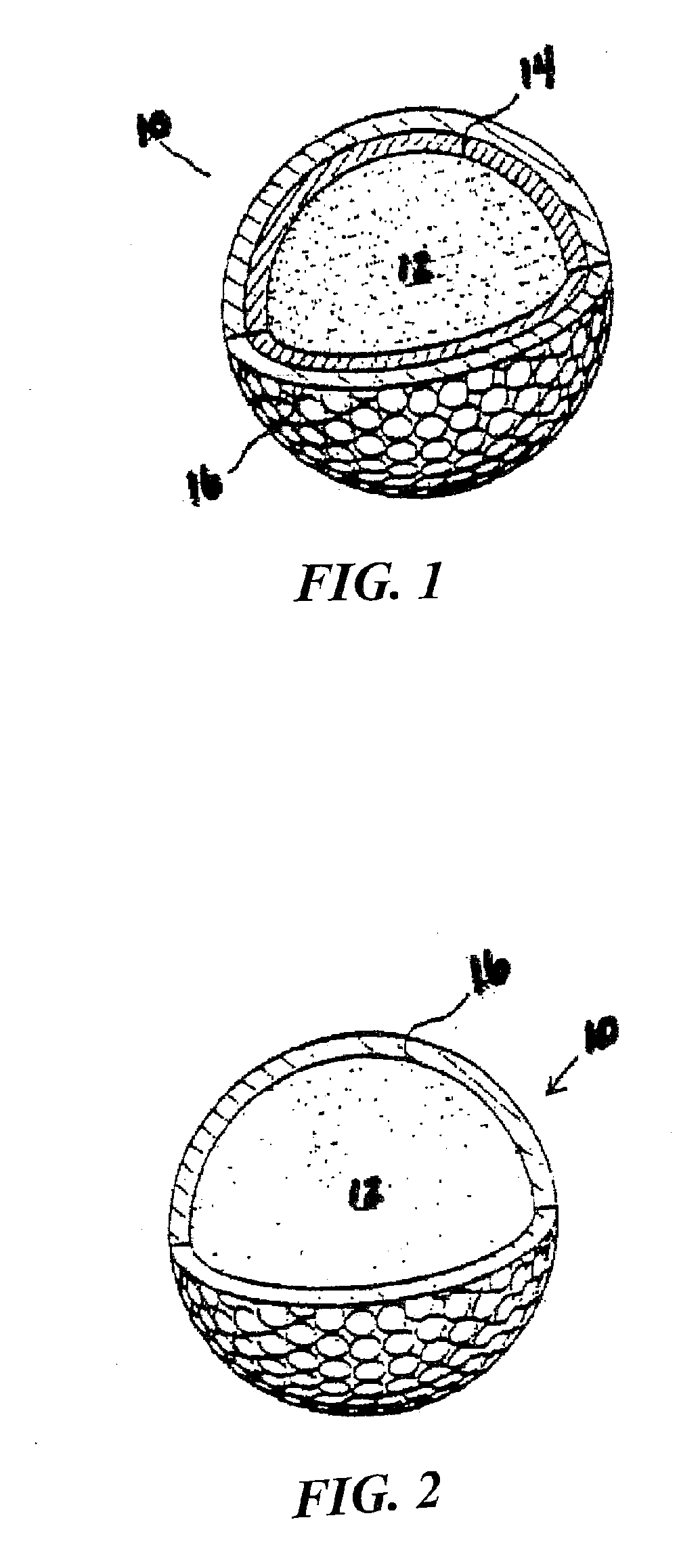

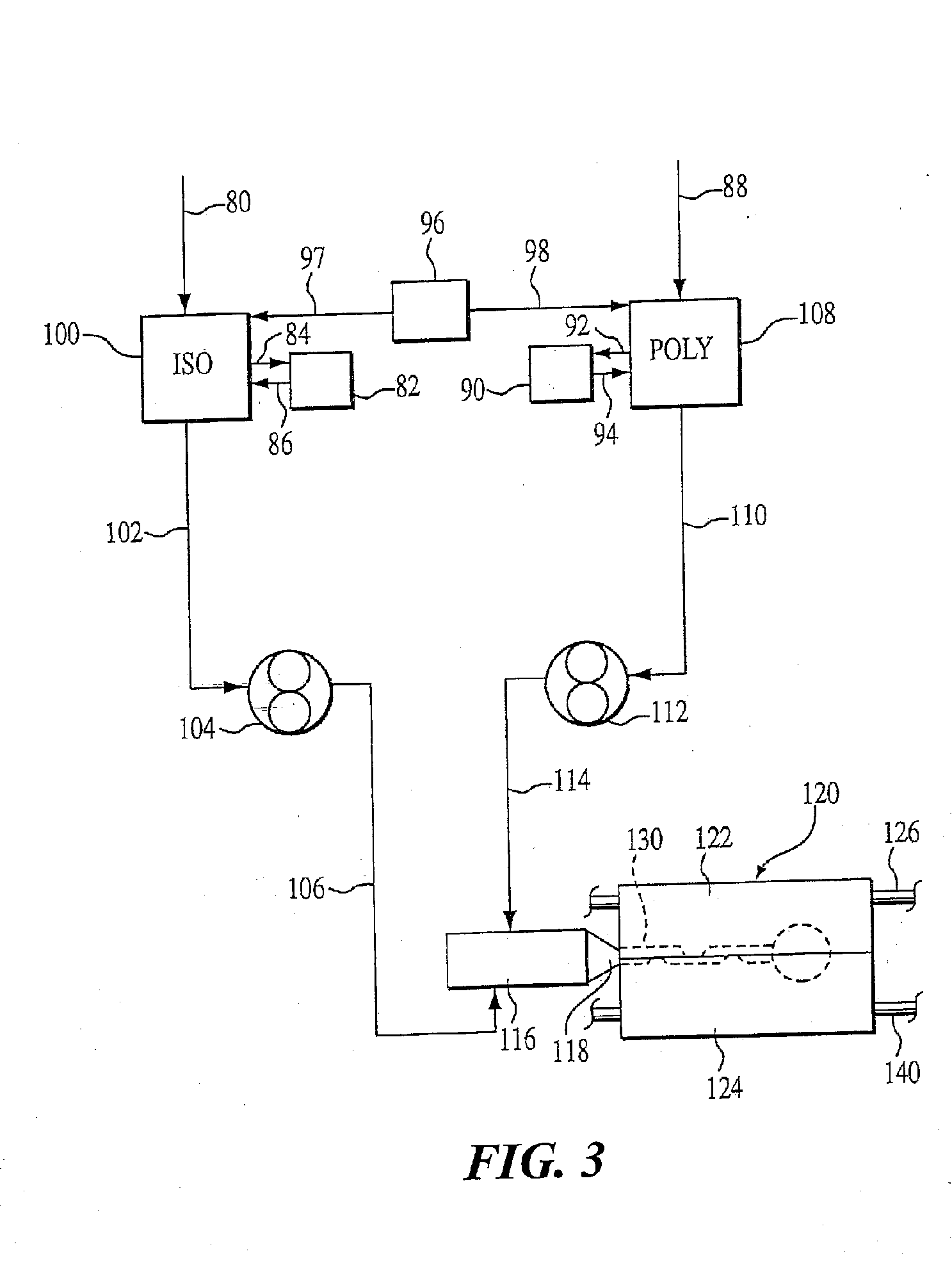

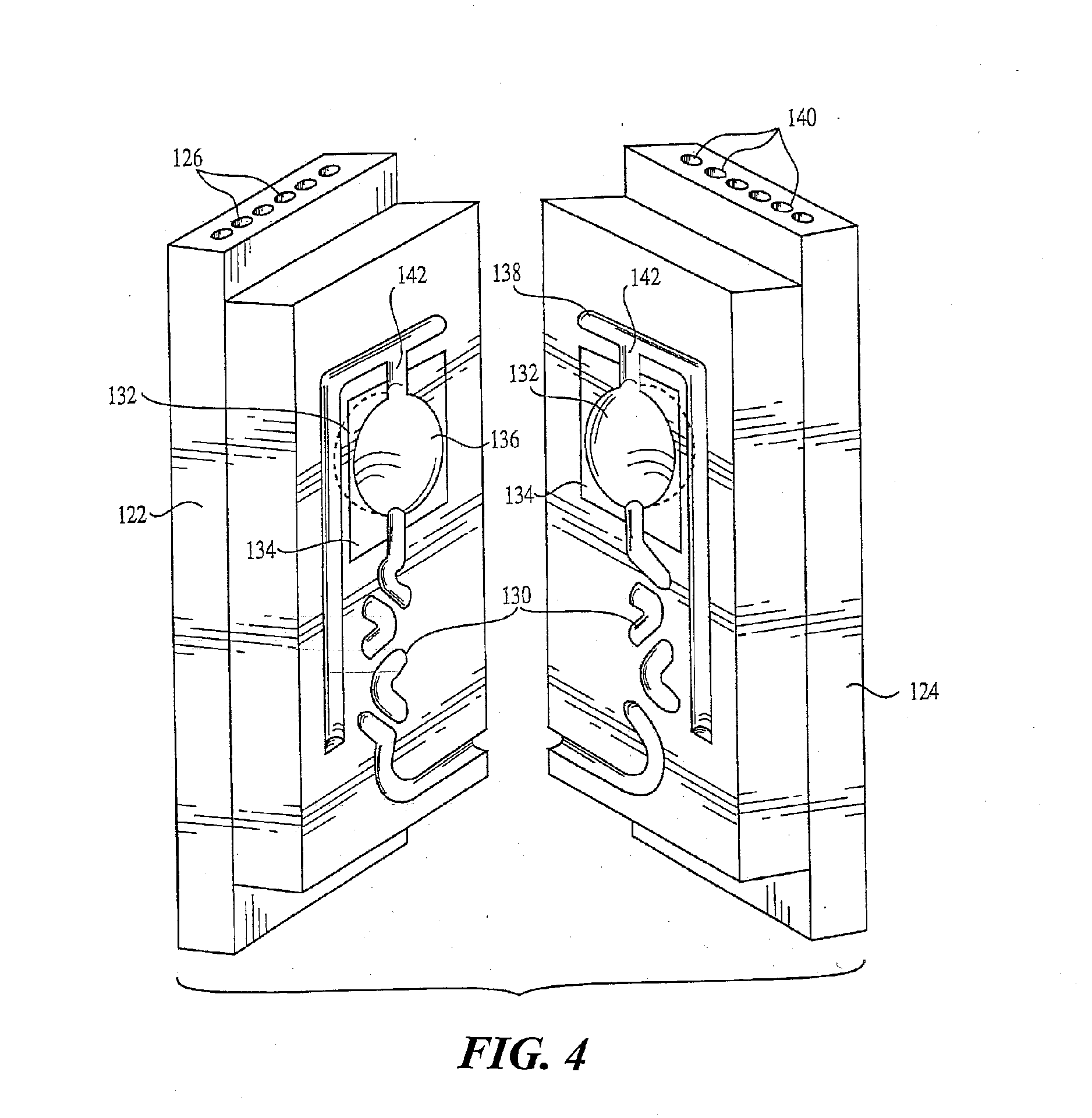

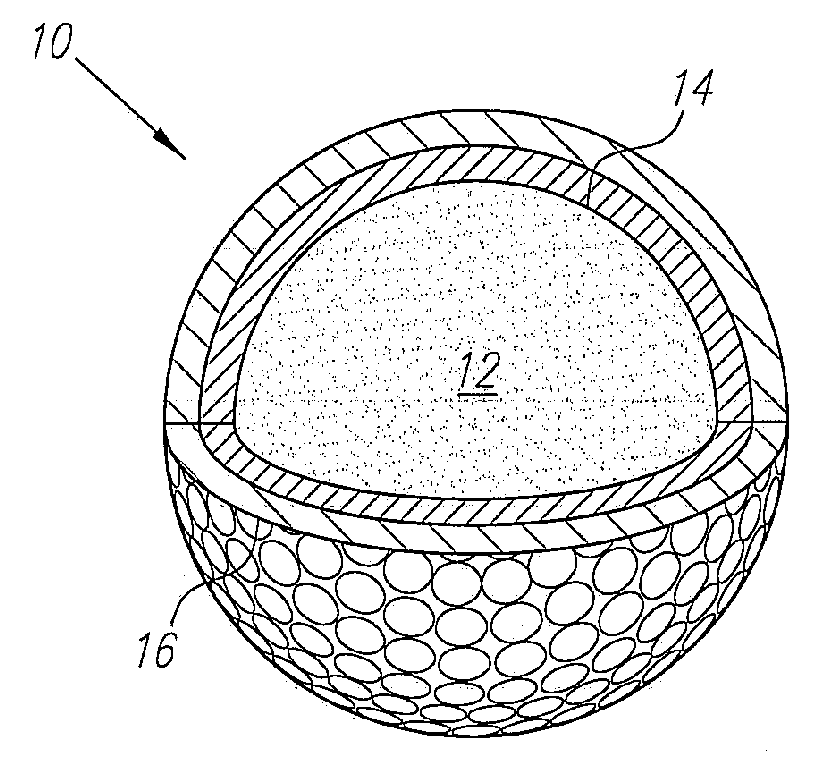

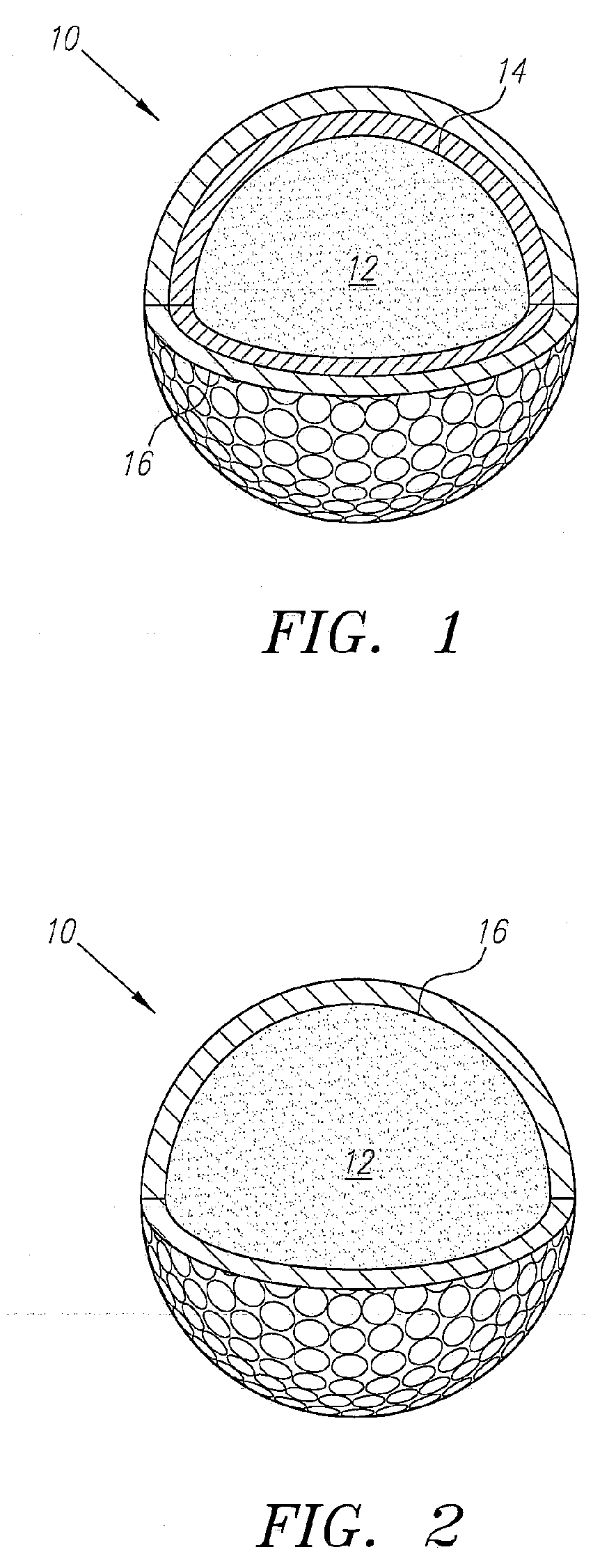

Reaction injection molded polyurea material for a golf ball cover

A reaction injection molded polyurea material that allows for a polyurea material with greater durability is disclosed herein. The reaction injection molded polyurea material includes 1,6, hexamethylene-diisocyanate and a polyol blend composed of polytetramethylene ether glycol, 4,4′-methylenebis-(2,6-diethyl)-aniline and a third agent selected from the group consisting of N,N′-bis-alkyl-p-phenylenediamine, N,N′-dialkylamino-diphenylmethane with tetrapropoxylated ethylenediamine and an aliphatic diamine. The polyurea is preferably utilized as a cover for a golf ball. The cover is preferably formed over a core and boundary layer.

Owner:TOPGOLF CALLAWAY BRANDS CORP

Polyurethane material for a golf ball cover

A curative blend for a thermosetting polyurethane material that allows for a polyurethane material with greater durability is disclosed herein. The curative blend is composed of 4,4′-methylenebis-(2,6-diethyl)-aniline and a second curing agent. A preferred polyurethane prepolymer is a polytetramethylene ether glycol terminated 4,4′-diphenylmethane diisocyanate polyurethane prepolymer. The thermosetting polyurethane is preferably utilized as a cover for a golf ball. The cover is preferably formed over a core and boundary layer.

Owner:CALLAWAY GOLF CO

Composition and method for reducing copper oxide to metallic copper

InactiveCN1248958AReduce manufacturing costInsulating substrate metal adhesion improvementPretreated surfacesMorpholineCopper oxide

A composition for reducing a copper oxide layer to metallic copper so as to facilitate bonding a resin to the metallic copper is disclosed. The composition is an aqueous reducing solution containing a cyclic borane compound. Example of such cyclic borane compounds include those having nitrogen or sulfur as a ring-forming member, such as morpholine borane, piperidine borane, pyridine borane, piperazine borane, 2,6-lutidine borane, 4-methylmorpholine borane, and 1,4-oxathiane borane, and also N, N-diethylaniline borane.

Owner:MORTON INT INC

Waterproof paint for exterior wall

ActiveCN104119757AStrong anti-penetrationImprove waterproof performanceCoatingsPotassiumAmmonium metavanadate

The invention discloses a waterproof paint for an exterior wall. The waterproof paint is prepared from the following raw materials in parts by weight: 53-60.2 parts of a silicone acrylic emulsion, 0.1-0.2 part of tantalum carbide, 0.3-0.7 part of copper 8-hydroxyquinoline, 0.1-0.3 part of fatty alcohol polyoxyethylene ether ammonium sulfate, 1-2 parts of potassium tetraborate, 0.4-0.6 part of ammonium metavanadate, 1-2 parts of polyurethane, 2-3 parts of polypropylene oxide glycol, 1.3-2 parts of sodium carboxymethylcellulose, 0.7-1 part of N, N-diethyl aniline, 0.1-0.2 part of trimethyl hexamethylene diamine, 4-6 parts of titanium dioxide, 8-10 parts of light calcium carbonate, 5-6 parts of coalescing agents and 10-15 parts of deionized water. The waterproof paint for the exterior wall is strong in seepage force resistance, remarkable in waterproof performance, good in weather resistance and strong in resistance to acid and base, has good high temperature resistance, is free from chemical odors which are harmful to human body and simple to operate, and is an ideal waterproof paint for the exterior wall.

Owner:ANHUI KUAILAI WATERPROOFING & ANTI CORROSION

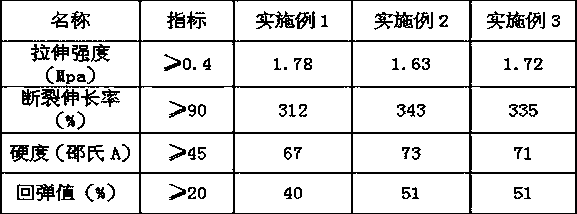

Environment-friendly polyurethane track material formula

The invention discloses an environment-friendly polyurethane track material formula, which is mainly characterized in that low-toxicity harmless chain expanding agents of 4,4'-methylene-bis(3-chloro-2,6-diethylaniline) (M-CDEA) and 4,4'-di-sec-butyl aminodiphenylmethane are used; the environment-friendly performance of the track material is improved. The formula uses a semi-prepolymer method for synthesizing a solvent-free polyurethane track material, wherein an ingredient A is prepared by the steps of taking a certain amount of polyether glycol; adding the polyether glycol into a reaction kettle; performing stirring for temperature rise to 110 to 120 DEG C; performing dewatering for 2 h; lowering the temperature to 40 to 60 DEG C; adding a certain amount of isocyanate; performing stirringand temperature rise to 80 to 90 DEG C; performing constant temperature reaction for 2 h; lowering the temperature; performing discharging. An ingredient B is prepared by the steps of performing stirring and temperature rise on polyether glycol, chain expanding agents and plasticizers to 110 to 120 DEG C; performing dewatering for 2 h; then, lowering the temperature to the room temperature; adding filling materials; performing uniform mixing; performing discharging. The ingredient A and the ingredient B are mixed according to a certain mass ratio; the catalyst is added; the material is uniformly stirred. The double-ingredient polyurethane track material has the advantages of non-toxicity, environment-friendly effect and good mechanical performance.

Owner:SHANDONG UNIV OF TECH

Production method for heat-insulating flame-resistant material

The invention relates to a production method for a heat-insulating flame-resistant material. The production method has the advantages that specific monomers and ratios are adopted, and nano titanium dioxides are coated with polymers by a high-temperature polymerization process, so that agglomeration of nano components in the flame-resistant material is avoided effectively, and dispersity and stability of the nano titanium dioxides in the flame-resistant material are improved; in addition, a synergistic effect is achieved through compounding of modified nano titanium dioxide powder, composite resin, docusate sodium, cyclododecanone, four parts of propylene glycol n-butyl ether and N,N-diethyl aniline, and accordingly, flame resistance and heat insulation of the material are improved greatly; the flame-resistant material acquired according to the specific ratios has various excellent performance such as heat insulation, wear resistance, rigidity, strength and adhesiveness; the production method for the heat-insulating flame-resistant material is simple and easy to operate and the material is easy to produce industrially.

Owner:上海禾舟智能科技有限公司

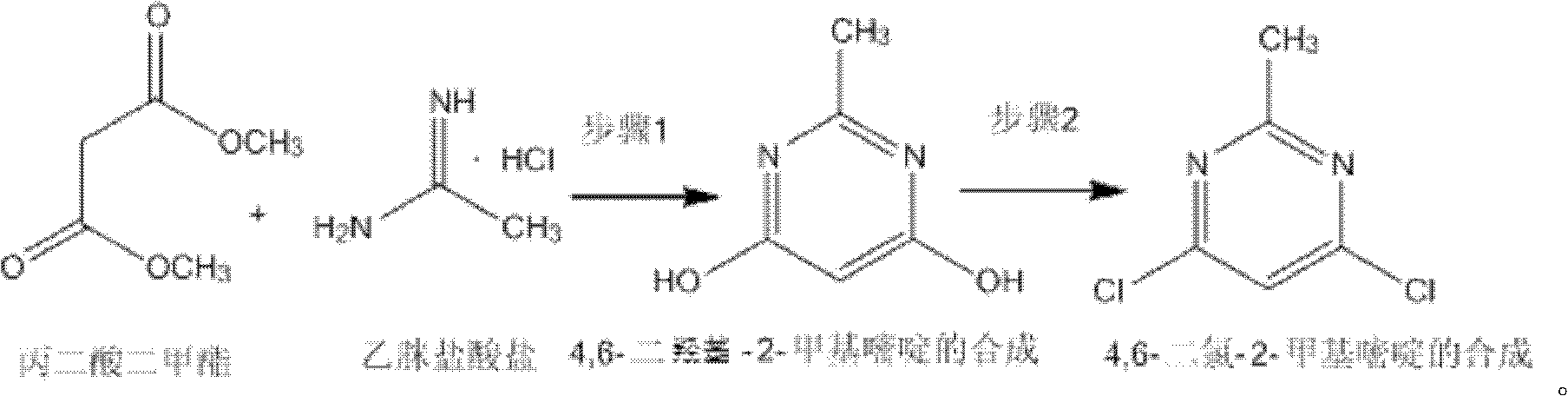

Method for synthetizing 4,6-dichloro-2-methyl pyridine

InactiveCN102432547AEasy to operateThe synthesis process is simpleOrganic chemistrySodium methoxideDistillation

The invention discloses a method for synthetizing 4,6-dichloro-2-methyl pyridine, which comprises the following steps of: under the ice-bath condition, adding sodium methoxide, dimethyl malonate and acetamidine hydrochloride into methanol; removing the ice bath, heating to a temperature of 18 to 25 DEG C and performing a reaction for 3 to 5 hours; carrying out reduced pressure distillation to remove the methanol; adding water for dissolving; regulating a pH value of the obtained solution to the range of 1 to 2; under the condition of a temperature of 0 DEG C, carrying out stirring and crystallization for 3 to 5 hours; carrying out extraction filtering, washing and drying to obtain white solid 4,6-dyhydroxyl-2-methyl pyridine; adding N,N-diethyl aniline and dichloroethane into the obtained 4,6-dyhydroxyl-2-methyl pyridine; heating to the reflux condition; then slowly adding a solution of triphosgene dichloroethane; performing a reflux reaction for 6 to 8 hours; washing reaction liquid; drying, filtering and concentrating an organic layer; and carrying out recrystallization and decolorization treatment on the obtain solid 4,6-dichloro-2-methyl pyridine. In the method, triphosgene is adopted to replace reagents with serious pollution to the environment and large toxicity, such as POC13, phosgene and the like. The method is safe, is easy to operate, has a simple synthetic process and is suitable for the industrial production.

Owner:太仓市运通化工厂

Graphene oxide modified ammonia ester waterproof coating and preparation method thereof

InactiveCN109161327AGood dispersionHigh mechanical strengthPolyurea/polyurethane coatingsAnilineTalc

The invention discloses graphene oxide modified ammonia ester waterproof coating and a preparation method thereof. The coating comprises a first component and a second component; the first component comprises 0 to 40 parts by weight of toluene diisocynate, 0 to 50 parts by weight of isophorone diisocyanate, 100 to 112 parts of polyether glycol and 1 to 2 parts of graphene oxide; and the second component comprises 70 to 80 parts by weight of polyether ternary alcohol, 30 to 40 parts by weight of 3-chlorine-2,6-diethyl aniline, 10 to 15 parts by weight of talcum powder, 10 to 15 parts by weightof castor oil, 1 to 2 parts of dibutyltin dilaurate or stannous octoate, 10 to 15 parts of dioctyl phthalate and 1 to 2 parts of a defoaming agent. The surface of the graphene oxide is provided with afunctional group such as hydroxy and can react with a polyurethane prepolymer and isocyanate to generate chain extension or crosslinking, the functional group such as hydroxyl exists among the graphene oxide sheet layers, the polyurethane prepolymer and the isocyanate are embedded among the sheet layers, a chemical bonding 'polyurethane prepolymer-graphene oxide-polyurethane prepolymer-graphene oxide' network structure is formed, and the mechanical strength of the polyurethane coating is improved.

Owner:WUXI HUICHENG GRAPHITE ALKENE TECH APPL CO LTD

Acrylate adhesive and preparation method thereof

InactiveCN107312466AHigh bonding strengthLow costNon-macromolecular adhesive additivesOrganic non-macromolecular adhesivePolymethyl methacrylateMetallic materials

The invention discloses an acrylate adhesive, which is composed of the following components in parts by mass: 90-100 parts of methyl methacrylate, 5-8 parts of methacrylic acid, Polymethyl methacrylate molding powder 25~30 parts, diethylaniline 0.1~0.2 parts, methyl ethyl ketone peroxide 0.1~0.2 parts, cobalt naphthenate 0.05~0.1 parts, acrylic acid 5~10 parts, phthalic acid 2~3 parts of dibutyl ester. The preparation method is as follows: Weigh each component of the above formula in sequence, stir evenly in the reaction kettle, and cure for 24 hours under the pressure of 0.1~0.2MPa and room temperature to obtain the finished product. The acrylate adhesive prepared by the invention can be used for bonding metal materials such as iron, copper, aluminum alloy, etc., and the bonding strength is greatly improved.

Owner:安徽友捷包装材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com