Reworkable thermal deadhesion adhesive tape for manufacture procedure and preparation method of adhesive tape

A heavy-duty thermal and adhesive tape technology, applied in the direction of adhesives, adhesive types, grafted polymer adhesives, etc., can solve difficult-to-bond objects with rough surfaces, affect process stability, and increase adhesion etc. to improve the cohesive performance, improve the bonding stability, and reduce the adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

[0036] Embodiments 1 to 4: A reworkable thermal adhesive tape for manufacturing process, comprising a substrate layer and a thermal adhesive layer coated on the surface of the substrate layer, the substrate layer is made of a 12 μm PET film,

[0037] The heat-losing adhesive layer comprises the following components in parts by weight:

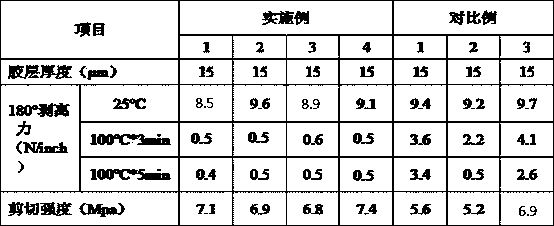

[0038] Table 1

[0039]

[0040] The above-mentioned styrene-isoprene-styrene block copolymer is a linear SIS without diblock SI, the softening point of the thermoplastic phenolic resin is 82°C, and the solvent is a mixture of toluene and ethyl acetate.

[0041] The antioxidant of above-mentioned embodiment 1 is antioxidant 1076, the antioxidant of embodiment 2 is antioxidant 168, the antioxidant of embodiment 3 is antioxidant 1010, the antioxidant of embodiment 4 is antioxidant Agent 164.

[0042] The preparation method of the reworkable heat loss adhesive tape for the above process comprises the following steps:

[0043] S1. Add styrene...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com