Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

493 results about "2-ethylhexyl acrylate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

2-Ethylhexyl acrylate is together with butyl acrylate one of the major base monomers for the preparation of acrylate adhesives. 2-Ethylhexyl acrylate can be react by free-radical polymerization to macromolecules having a molecular weight of up to 200,000 g/mol.

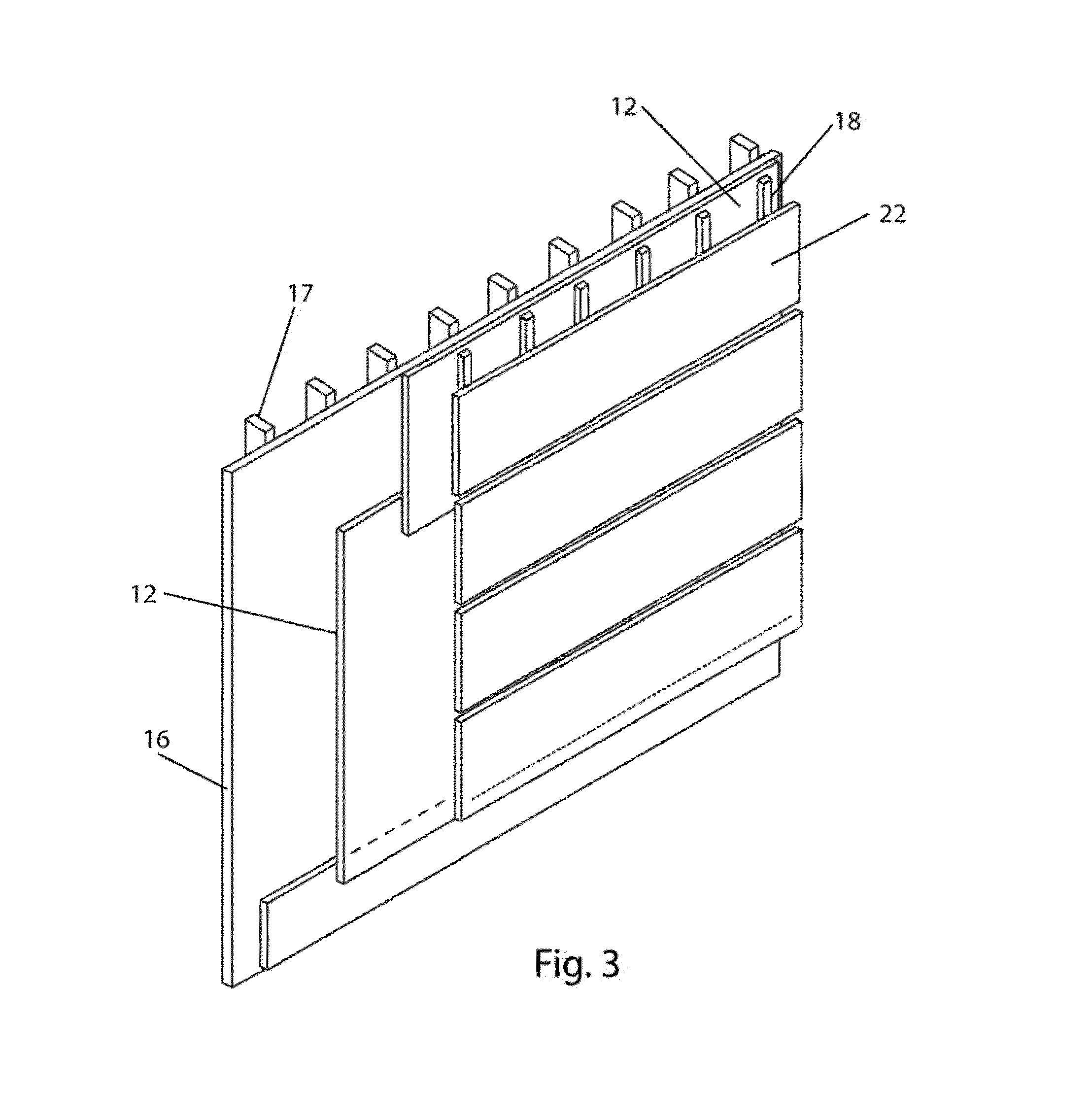

Display medium and manufacturing method thereof and electrophoretic display therewith

InactiveUS20140104674A1Improve reliabilityImprove display qualityConductive materialOrganic conductorsPolymer scienceDisplay device

A display medium adapted for an electrophoretic display is provided. The display medium includes at least one particle and a random copolymer bonded with the particle, wherein the random copolymer has a structural unit originated from a first monomer and a second monomer. The first monomer is selected from at least one or a combination of a group of specific compounds consisting of 2-ethylhexyl acrylate, lauryl methacrylate and octadecyl acrylate etc. and the second monomer is selected from at least one kind of a group of specific compounds composed of 2,2,2 trifluoroethyl acrylate, 2,2,3,3 tetrafluoropropyl methacrylate and 1,1,1,3,3,3-hexafluoroisopropyl acrylate. A method of manufacturing the display medium and an electrophoretic display with the display medium are also provided.

Owner:SIPIX TECH INC

Adhesive patch

InactiveUS20050260255A1Improve the level ofGood skin permeabilityNervous disorderOrganic non-active ingredientsPolymer scienceStyrene-isoprene-styrene block copolymer

A patch comprising a backing layer and an adhesive layer disposed on the backing layer and compounded with a drug and an adhesive base agent, wherein the adhesive base agent comprises styrene-isoprene-styrene block copolymer, 2-ethylhexyl acrylate—vinyl acetate copolymer and a basic nitrogen-including polymer including a basic nitrogen and having no adhesion property at normal temperature.

Owner:HISAMITSU PHARM CO INC

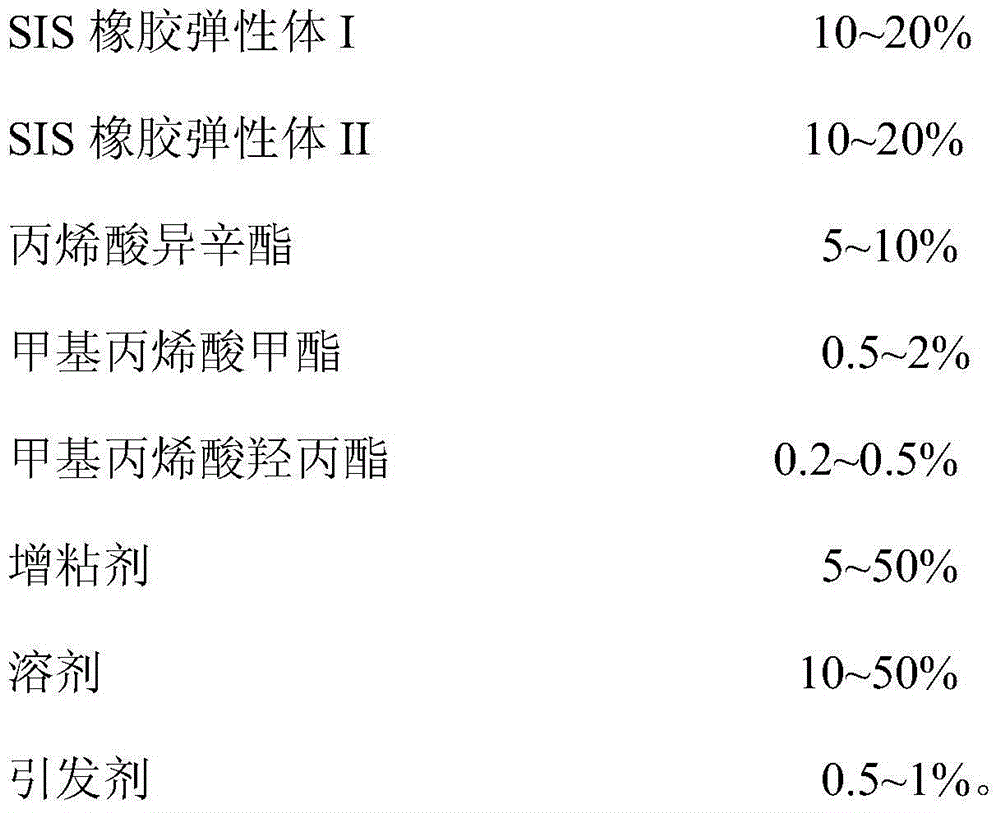

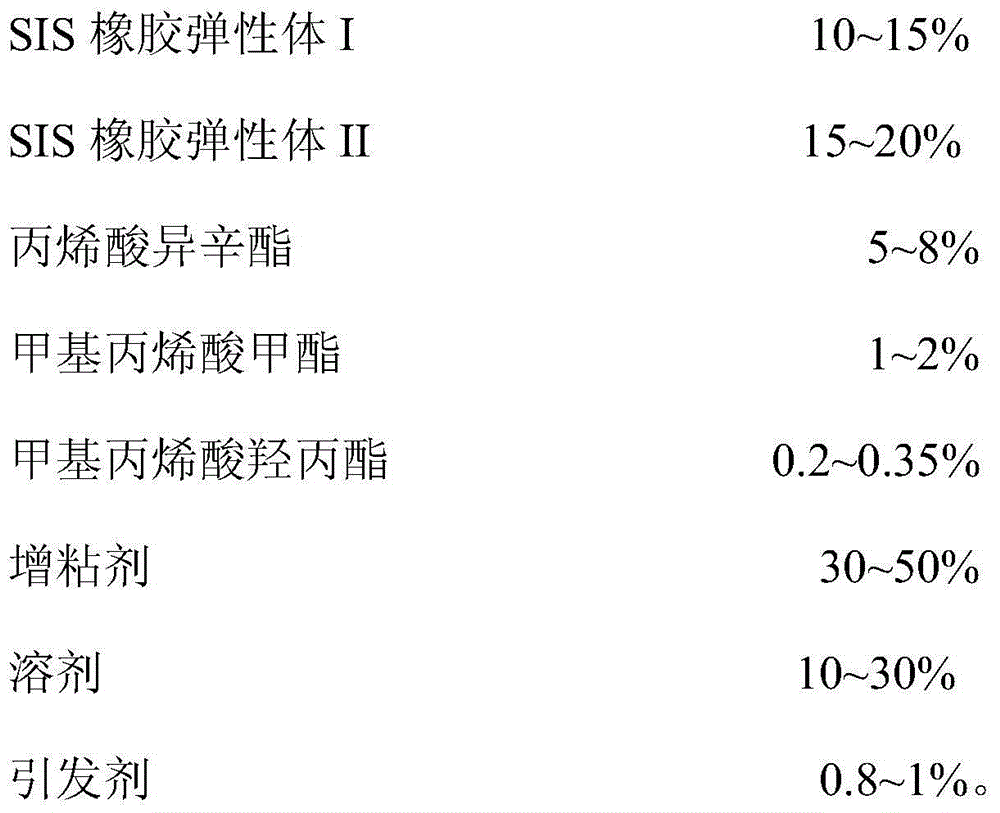

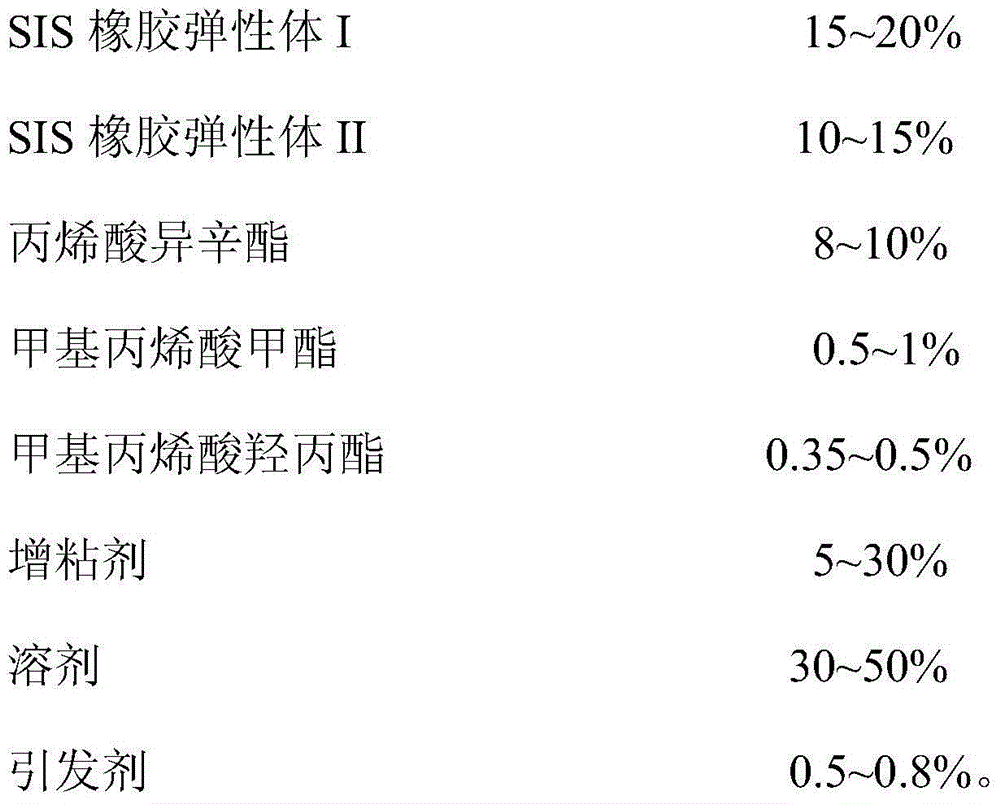

Acrylic acid modified hot-melt pressure-sensitive adhesive for bearing adhesive tape and preparation method of acrylic acid modified hot-melt pressure-sensitive adhesive

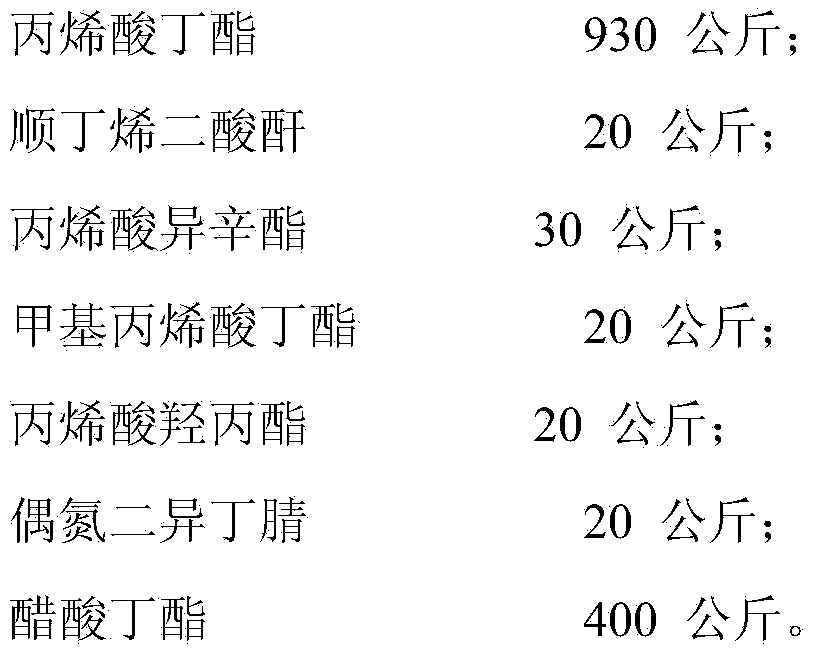

The invention relates to an acrylic acid modified hot-melt pressure-sensitive adhesive for a bearing adhesive tape. The acrylic acid modified hot-melt pressure-sensitive adhesive comprises the following raw materials in percentage by weight: 10-20 percent of an SIS rubber elastomer I, 10-20 percent of an SIS rubber elastomer II, 5-10 percent of 2-ethylhexyl acrylate, 0.5-2 percent of methyl methacrylate, 0.2-0.5 percent of hydroxypropyl methacrylate, 5-50 percent of a tackifier, 10-50 percent of a solvent, and 0.5-1 percent of an initiator. The acrylic acid modified hot-melt pressure-sensitive adhesive is high in cohesion, high in adhesion stress, high in ageing resistance, strong in adhesive force on a substrate, and wide in application range. A preparation method of the acrylic acid modified hot-melt pressure-sensitive adhesive comprises the following steps: the materials are weighed: the SIS rubber elastomer I, the SIS rubber elastomer II and a solvent account for the total amount of the solvent are added in a first reaction kettle, and 2-ethylhexyl acrylate, methyl methacrylate, hydroxypropyl methacrylate, the initiator and the rest of the solvent are added in a second reaction kettle to form a mixed solution; the mixed solution is slowly added in the first reaction kettle; the tackifier is added in the first reaction kettle, and the solvent is distilled out; the materials are discharged in heating, and the finished product is obtained. The preparation method is simple in process, and high in the production efficiency and yield.

Owner:DONGGUAN AOZON ELECTRONICS MATERIAL

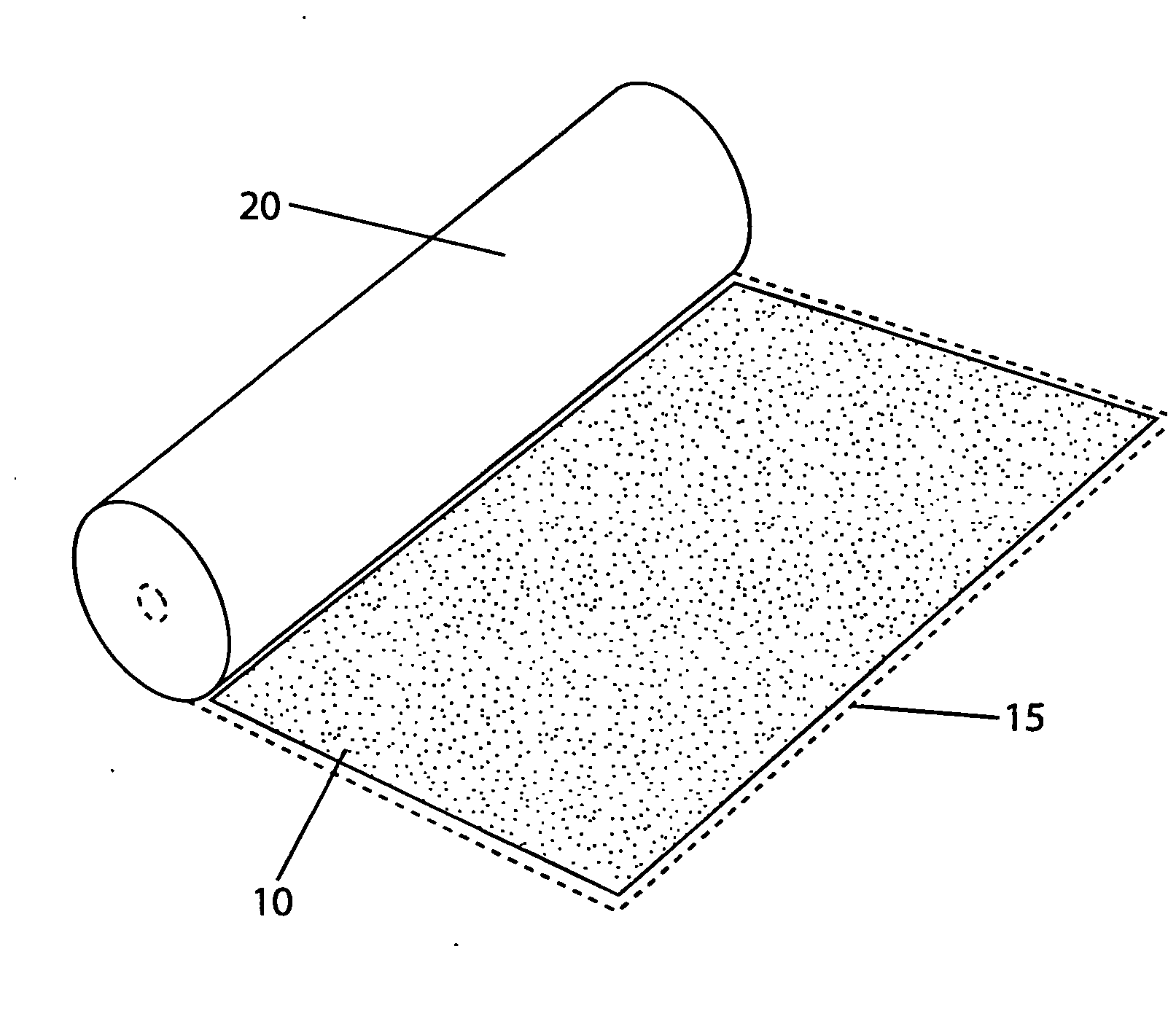

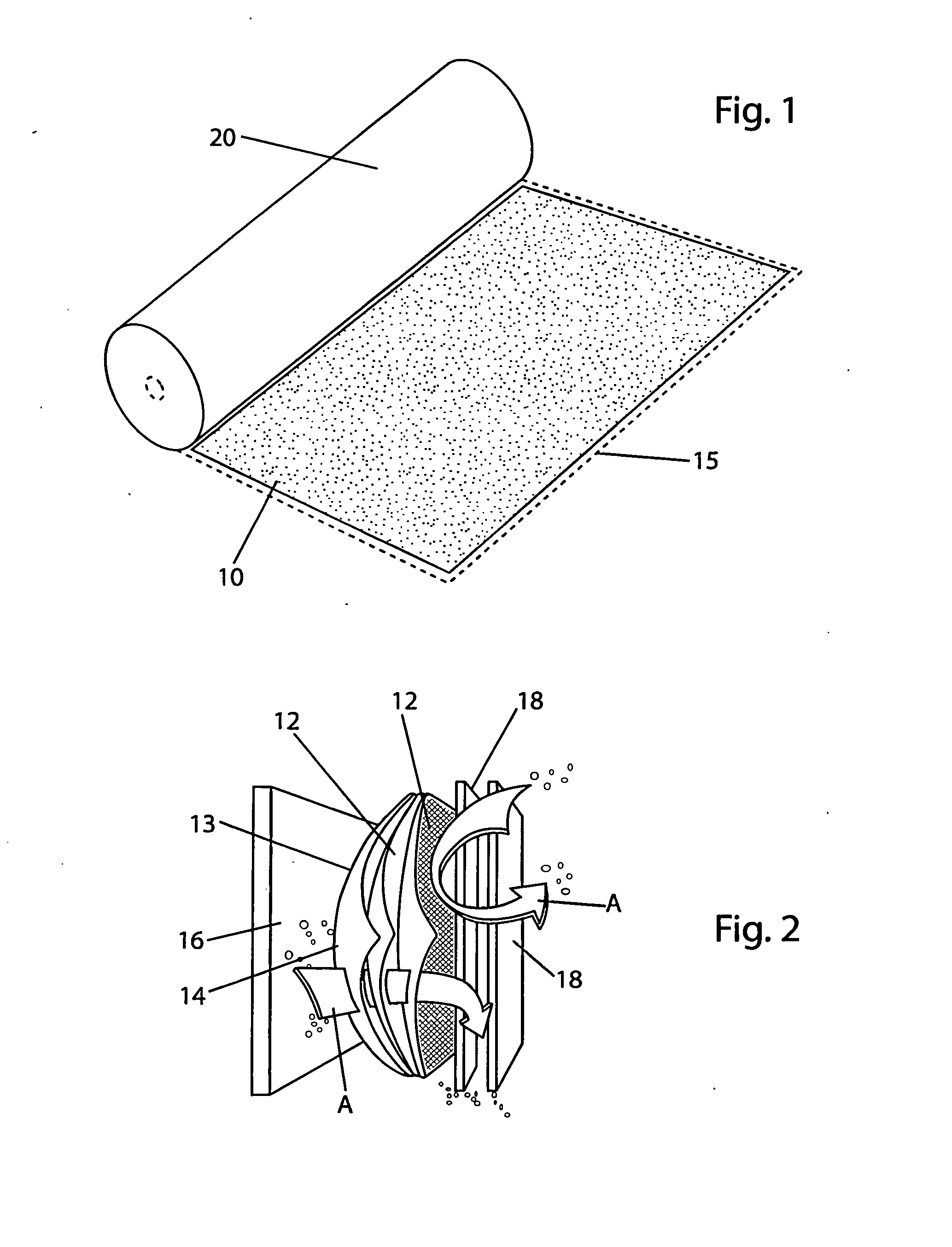

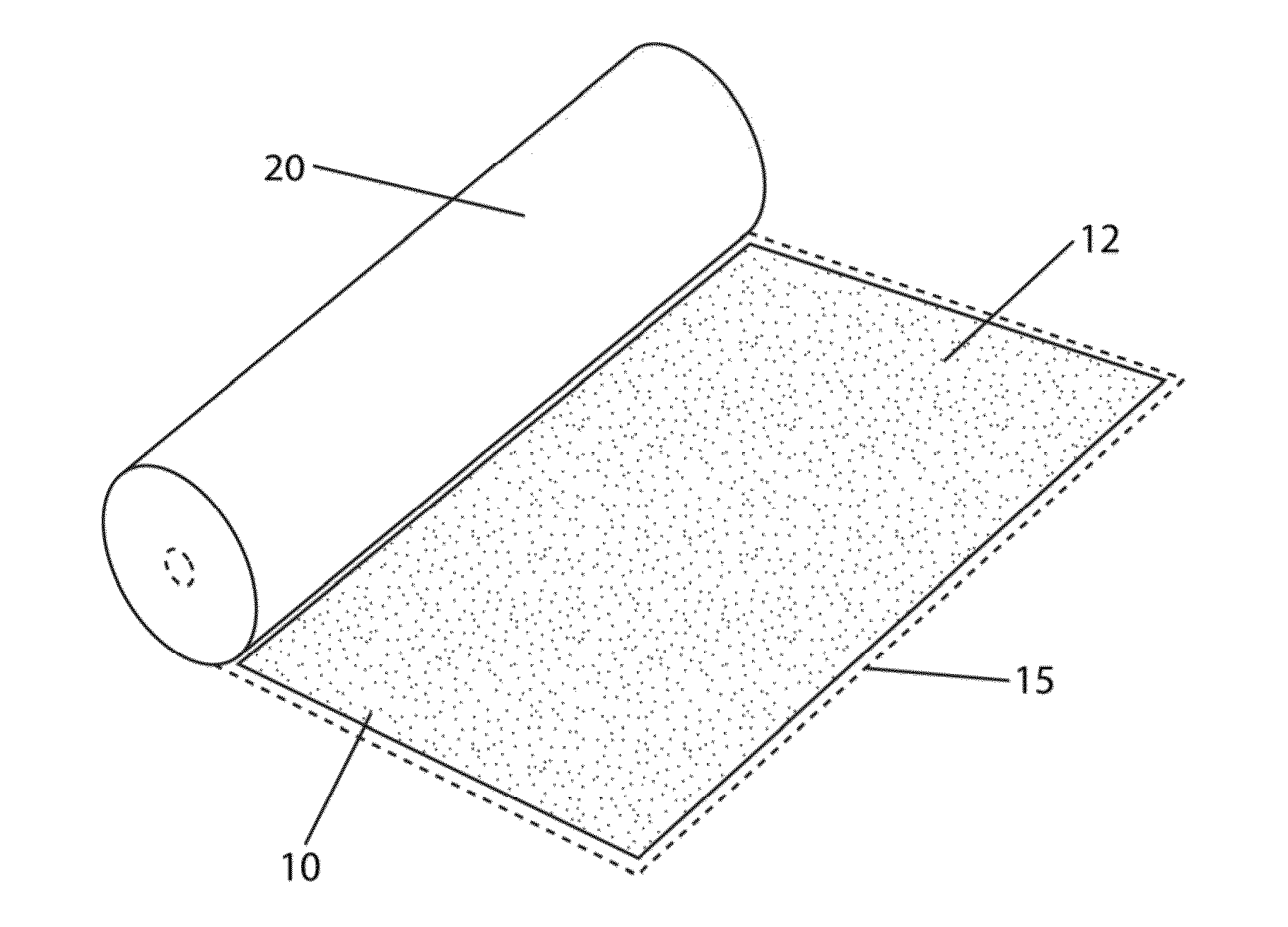

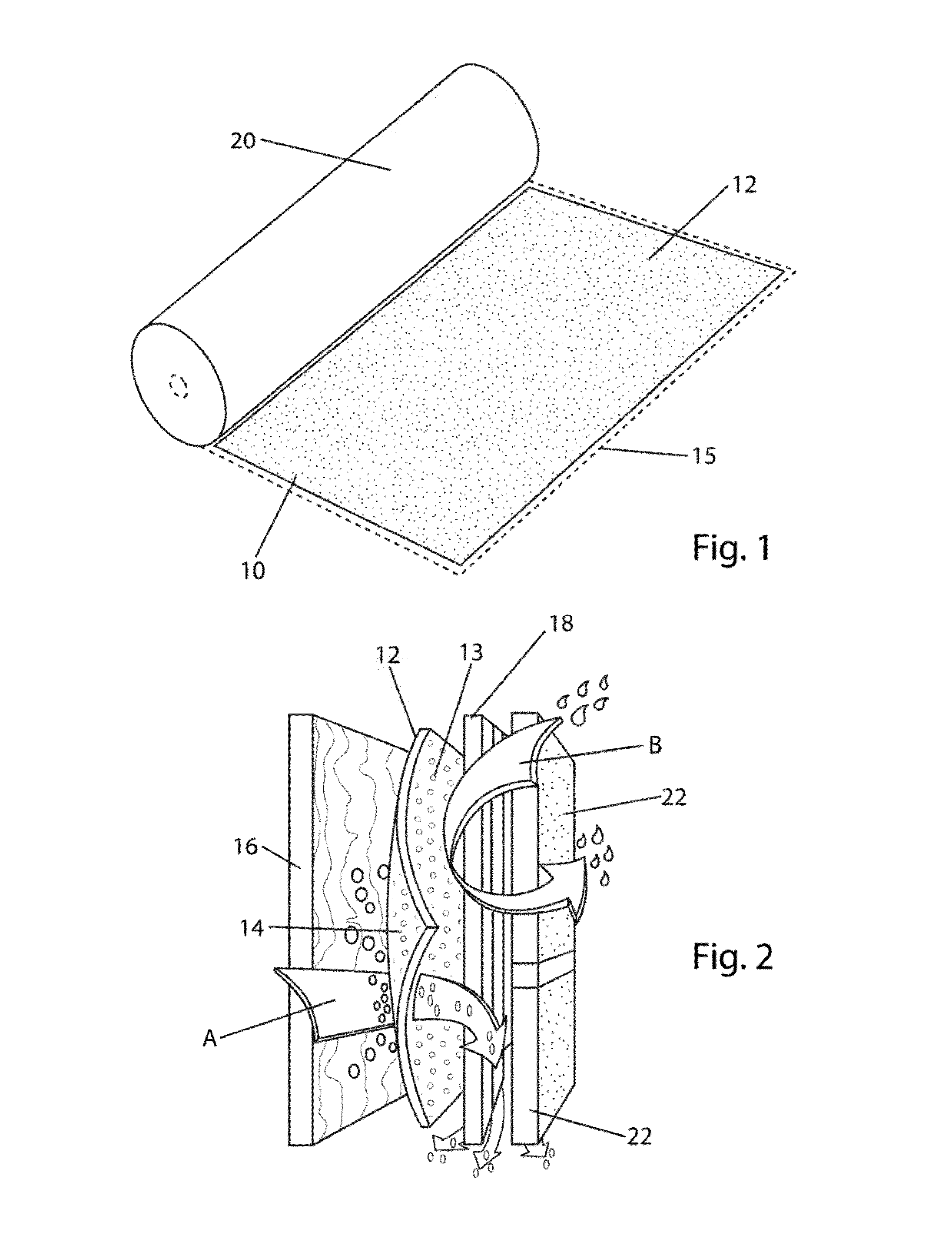

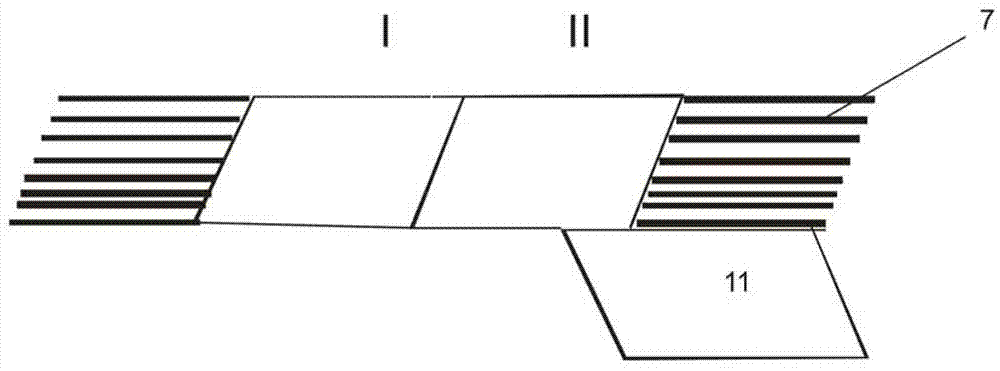

Building membrane with porous pressure sensitive adhesive

A breathable multilayer spun bonded polypropylene membrane having a coated pressure sensitive adhesive capable of allowing air and moisture vapor to pass through it. The adhesive is formed of a copolymer comprising a backbone of n-butyl acrylate, 2-ethylhexyl acrylate, and vinyl acetate which is mixed with a surfactant and emulsified to produce bubbles which form pores when the copolymer is set with about 80% to about 90% of the pore sizes ranging from about 200 microns to about 300 microns and a pore density in the cured pressure sensitive adhesive ranging from about 4200 per inch2 to about 4600 per inch 2, said pores being uniformly distributed to form a flow path through the adhesive.

Owner:VAPROSHIELD

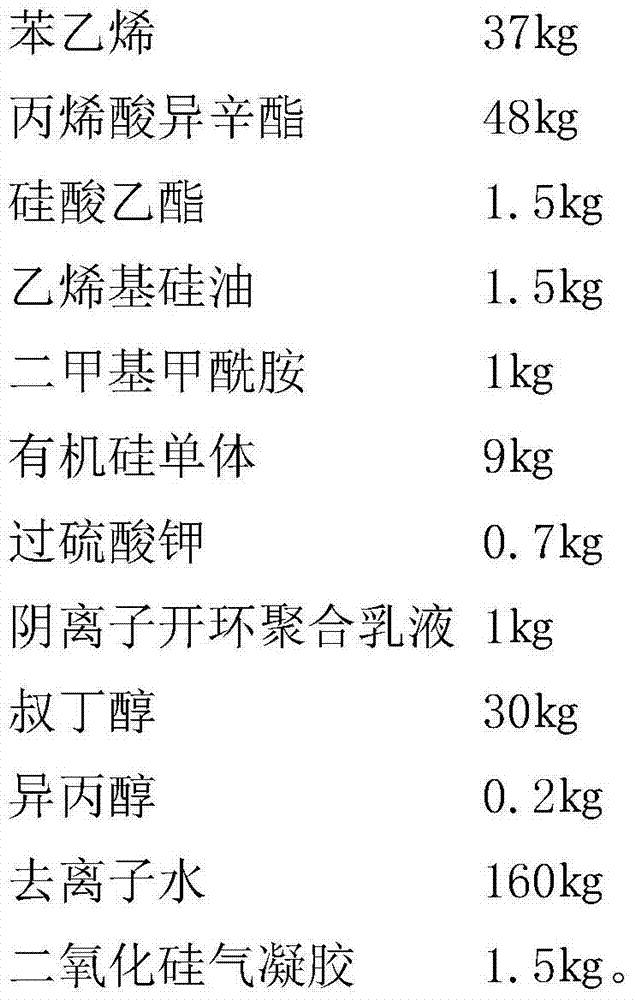

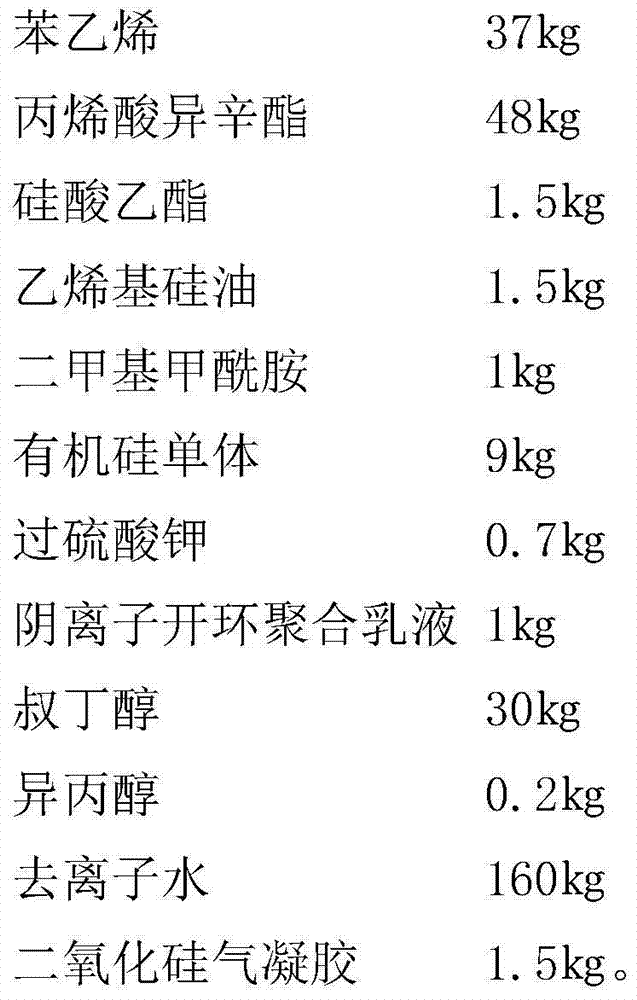

Method for modifying styrene-acrylic emulsion through organic silicon

ActiveCN103923271AHigh degree of polymerizationImprove water resistanceIsooctyl acrylatePotassium peroxodisulfate

The invention provides a method for modifying styrene-acrylic emulsion through organic silicon, relating to the field of chemical engineering technologies. The method comprises steps of (1) firstly putting deionized water, tertiary butanol and isopropanol into a reaction kettle and mixing uniformly through stirring, and heating up to 60-70DEG C, so as to prepare a solution a; (2) dissolving styrene, 2-ethylhexyl acrylate, ethyl silicate, organosilicone monomer and anion ring opening polymerization emulsion into the solution a, fully mixing through stirring till the temperature rises up to 80-90DEG C, and preserving heat for 2 hours, so as to prepare a solution b; (3) putting vinyl silicone oil, silicon dioxide aerogel and dimethyl formamide into the solution b, stirring for 30 minutes to be mixed uniformly to prepare a solution c; (4) controlling the temperature of the solution c at 60-65 DEG C, then dripping potassium peroxodisulfate for 0.5 hour, and cooling to room temperature, so as to prepare a solution d; (5) regulating the pH value of the solution d to be neutral with ammonia water, filtering the discharged material so as to prepare the styrene-acrylic emulsion. Due to the addition of organic silicon monomer, ethyl silicate and the like, the degree of crosslinking of a latex film is improved, and the weather fastness of the styrene-acrylic emulsion is greatly improved.

Owner:DONGZHI OASIS ENVIRONMENTAL PROTECTION CHEM

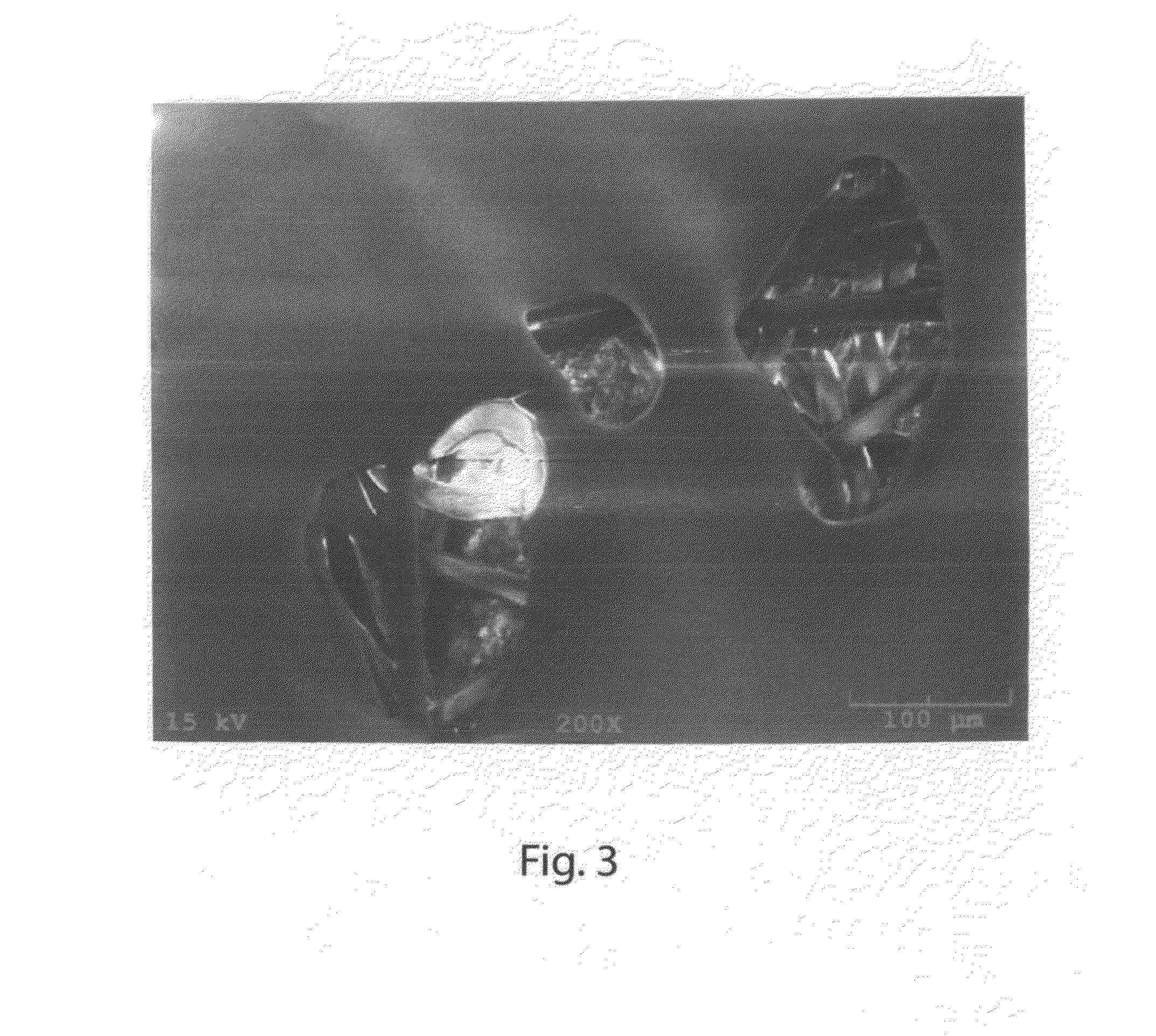

Core-shell type paint dyeing and printing adhesive agent emulsion and preparation method thereof

InactiveCN101368342AImprove bonding fastnessImprove stabilityDyeing processPotassium persulfatePolymer science

The invention discloses a method for preparing core-shell emulsion type adhesive which is modified by hydroxyl-terminated acrylic ester and is used in fabric printing and dyeing processes. The adhesive is prepared through the following steps: soft monomers copolymerize with crosslinking monomers and portions of hard monomers to produce core-shell particles; then a small portion of soft monomers and a large portion of crosslinking monomers copolymerize with hard monomers to coat the surface of the core layer, thus obtaining a shell layer and forming stable core-shell type emulsion. One or the mixture of two or more from 2-hydroxyethyl acrylate, hydroxypropyl acrylate, hydrobutyl acrylate and hydrohexyl acrylate is taken as a portion of soft monomers and crosslinking monomers; one or the mixture of two or more from hydroxylmethyl methacrylic acid, 2-hydroxyethyl acrylate methacrylic acid and hydroxypropyl methacrylic acid is taken as a portion of hard monomers and crosslinking monomers; one from butyl acrylate, ethyl acrylate and 2 ethylhexyl acrylate is taken as main soft monomers; one or the mixture of two or more from methyl methacrylate, crylic acid, cinnamene, acrylonitrile and methacrylic acid is taken as the hard monomers; surfactant sodium dodecyl sulfate, sodium dodecyl benzene sulfonate and octyl phenol polyethylene glycol are taken as emulsifying agent; potassium persulfate or ammonium persulfate is taken as initiator; and the copolymer emulsion is produced through emulsion copolymerization. Observed by transmission electron microscopy, the particles of the emulsion have visible core-shell structure and are even in distribution; the emulsion is stable, absolutely has no formaldehyde release both during the machining and using processes; the emulsion can be used both for pigment printing and for pigment dyeing.

Owner:JIANGNAN UNIV

Elastic raindrop impression resisting styrene-acrylic emulsion and preparation method thereof

The invention discloses an elastic raindrop impression resisting styrene-acrylic emulsion. The elastic raindrop impression resisting styrene-acrylic emulsion is prepared from, by mass, 80-130 parts of water, 38-60 parts of styrene, 22-45 parts of methyl methacrylate, 12-18 parts of 2-ethylhexyl acrylate, 22-73 parts of butyl acrylate, 0.5-5 parts of acrylic acid, 0.5-5 parts of methacrylic acid, 1-5 parts of acrylamide, 7-18 parts of an anionic emulsifier, 0.5-2 parts of a reactive emulsifier, 1-5 parts of a crosslinking monomer, 0.2-0.9 part of an initiator, 0.1-0.5 part of an oxidant and 0.1-0.5 part of a reducing agent. The elastic raindrop impression resisting styrene-acrylic emulsion has excellent mechanical strength and higher weather resistance.

Owner:CHANGSHU BATF TECH CO LTD

Preparation method of single-component solvent-type high-stripping acrylic acid pressure-sensitive adhesive

InactiveCN104817986AHigh peel strengthGood first stickMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesIsooctyl acrylateEthyl acetate

The invention discloses a preparation method of a single-component solvent-type high-stripping acrylic acid pressure-sensitive adhesive, wherein the preparation method comprises: 1) preparing raw materials of the high-stripping acrylic acid pressure-sensitive adhesive, comprising, by weight: (A) an internal-polymerization monomer (hard monomer): 10 parts of methyl methacrylate, 12 parts of styrene and 10 parts of vinyl acetate, (B) a viscous monomer (soft monomer): 45 parts of butyl acrylate and 40 parts of 2-ethylhexyl acrylate, (C) a modified monomer: 6 parts of methyl acrylic acid and 2 parts of hydroxyethyl acrylate, (D) a solvent: 40 parts of ethyl acetate and 15 parts of ethanol, (E) a curing (crosslinking) agent: 0.5 parts of triacetylacetone; (F) a residual monomer eliminating agent and a crosslinking agent: 0.2 parts of triethanolamine; (G) 1 part of an initiator (of which the use amount accounts for 0.8% of the total mass of the monomers); and (H) 0.02 parts of a chain transfer agent. The preparation method can be used for preparing the acrylic acid pressure-sensitive adhesive being good in original adhesion, high in stripping strength, good in adhesion permanence and excellent in coating processing performance, thereby greatly developing the available range of the acrylic acid pressure-sensitive adhesive.

Owner:江苏耐斯数码科技股份有限公司

Double-sided pressure sensitive adhesive tape for computer embroidery and preparation method thereof

ActiveCN101602919AHigh peel strengthGood peeling effectFilm/foil adhesivesEster polymer adhesivesIsooctyl acrylateBenzoyl peroxide

The invention relates a double sided pressure-sensitive adhesive tape for computer embroidery and a preparation method thereof. The double-sided pressure sensitive adhesive tape comprises base material, a pressure-sensitive adhesive layer coated on the two sides of the base material and a release paper layer; wherein, the pressure sensitive adhesive layer is prepared by being coated with pressure sensitive adhesive which is prepared by the following components according to the parts by weight: 80.0-100.0 parts of 2-ethylhexyl acrylate, 8.0-15.0 parts of butyl acrylate, 3.0-7.5 parts of acrylic acid, 8.0-15.0 parts of vinyl acetate, 1.0-7.5 parts of hydroxy-ethyl acrylate, 0.20-1.0 part of benzoyl peroxide, 120.0-200.0 parts of main solvent, 5.0-30.0 parts of auxiliary solvent and 2.0-6.0 parts of crosslinking and curing agent solution. In the formula design of the invention, the molecular weight design dispersion coefficient is designed to be a little smaller, the molecular weight is not too large and the soft monomer is increased so as to improve the peeling strength, thus reaching the aim that the adhesive tape has high peeling performance and can be pasted repeatedly.

Owner:永大(中山)有限公司

Acrylic pressure-sensitive adhesive tape or sheet and process for producing the same

InactiveUS20100112346A1Improve adhesionBroaden applicationFilm/foil adhesivesAcid polymer adhesivesPolymer scienceMeth-

Provided is an acrylic pressure-sensitive adhesive tape or sheet highly adhesive to hard-to-adhere adherends such as coatings having the surface control agent bleeding thereon.The acrylic pressure-sensitive adhesive tape or sheet, according to the present invention, having a viscoelastic layer (X) containing microspheres and an acrylic polymer containing an alkyl (meth)acrylate as the principal monomer component as the base polymer and a pressure-sensitive adhesive layer (Y) formed at least on one side of the viscoelastic layer (X) by irradiation of an acrylic monomer mixture or a prepolymer of the acrylic monomer mixture with active energy ray, wherein the amount of acrylic acid in the acrylic monomer mixture for the pressure-sensitive adhesive layer (Y) or a prepolymer of the acrylic monomer mixture is 6 to 12 wt % with respect to all monomer components and the amount of n-butyl acrylate is 35 to 65 wt % with respect to the total amount of 2-ethylhexyl acrylate and n-butyl acrylate.

Owner:NITTO DENKO CORP

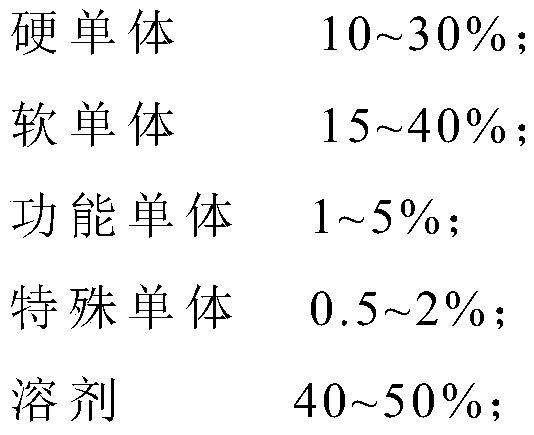

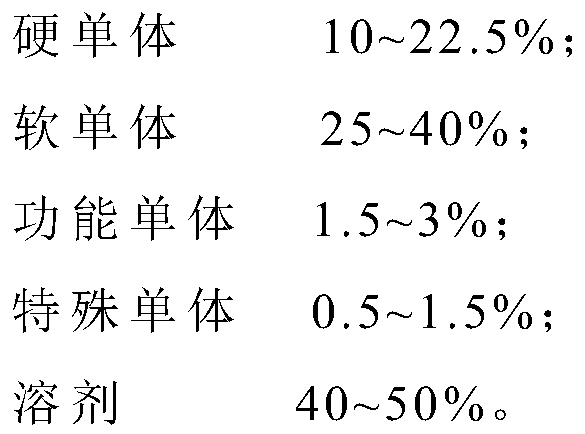

Polyacrylate, pressure-sensitive adhesive and preparation method

ActiveCN109762097AThe polymerization process is simpleHigh temperature resistance and good adhesionEster polymer adhesivesPressure sensitive film/foil adhesivesIsooctyl acrylateGlycidyl methacrylate

The invention relates to polyacrylate. Polyacrylate is synthesized from raw materials in percentage by mass as follows: 10%-30% of a hard monomer, 15%-40% of a soft monomer, 1%-5% of a functional monomer, 0.5%-2% of a special monomer and 40%-50% of a solvent, wherein the hard monomer comprises one or more of methyl acrylate, methyl methacrylate, vinyl acetate, acrylonitrile and isobornyl methacrylate; the soft monomer comprises one or more of ethyl acrylate, n-butyl acrylate, 2-ethylhexyl acrylate and n-propyl acrylate; the functional monomer comprises one or more of hydroxyethyl acrylate, acrylic acid, methacrylic acid, hydroxypropyl acrylate and 2-hydroxyethyl methacrylate; the special monomer comprises one or more of methacrylamido ethyl ethylene urea, hydroxyethyl methacrylate phosphate and glycidyl methacrylate. A pressure-sensitive adhesive has good high-temperature-resistant adhesive property, does no squeeze out, has no residue, has low cost and can be applied to masking tapesused in capacitor taping in the electronics industry as well as certain high-temperature-resistant adhesive tapes.

Owner:CYBRID TECHNOLOGIES INC

High-salt-mist high-weather-proof water paint and preparing method thereof

ActiveCN104140732AFlat and bright appearanceImprove the level ofAnti-corrosive paintsMethacrylateIsooctyl acrylate

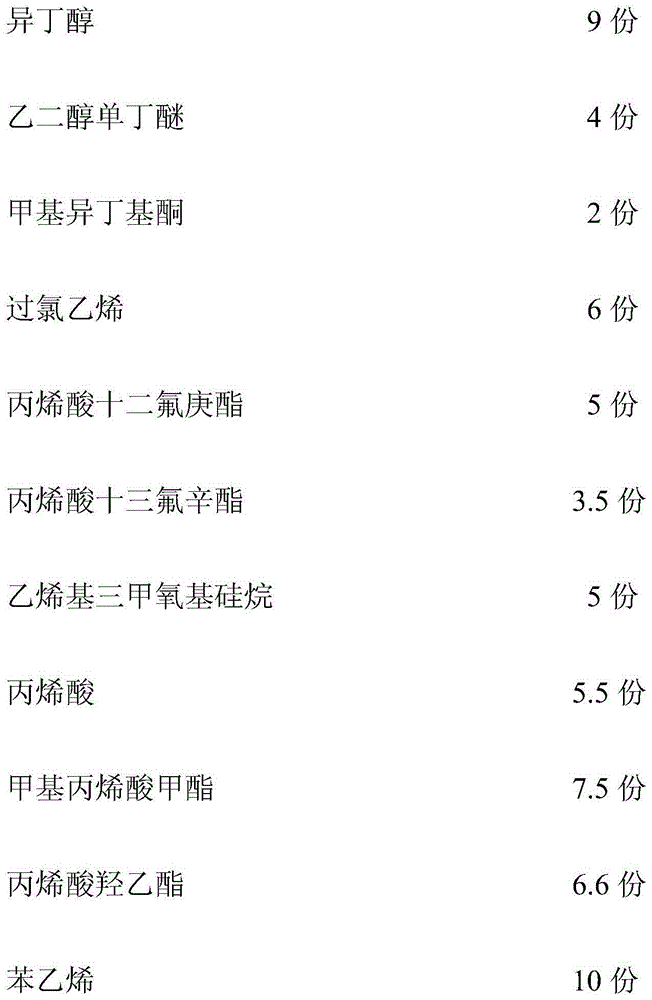

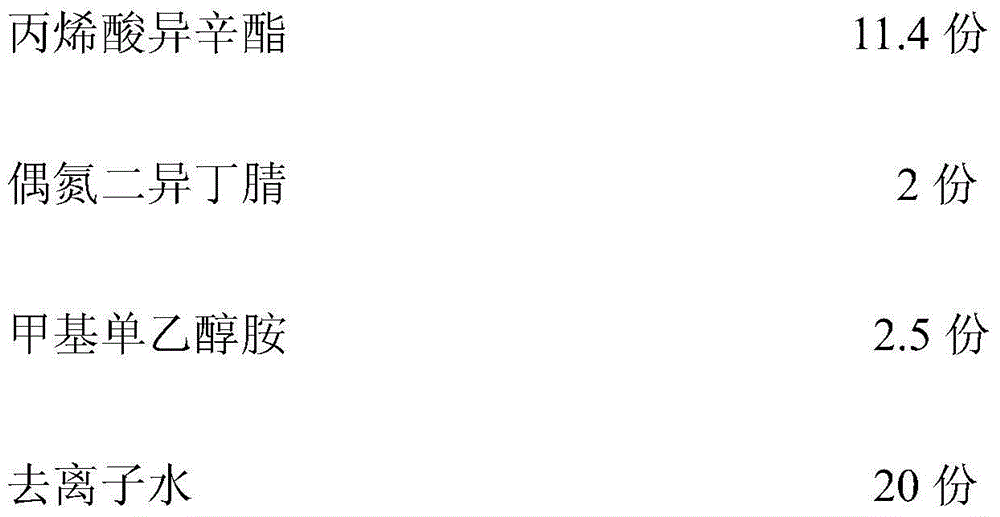

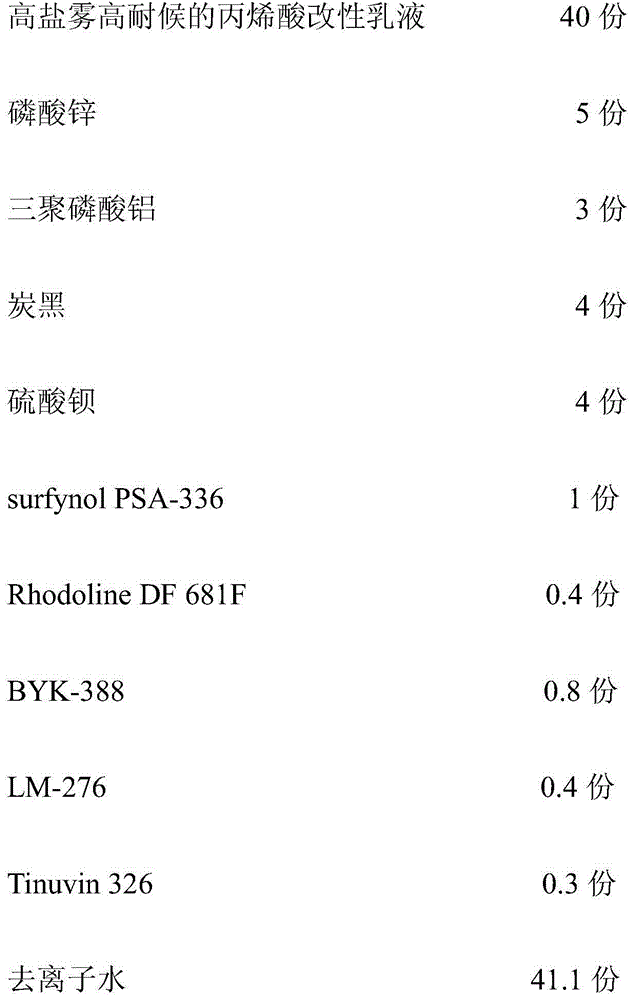

The invention relates to high-salt-mist high-weather-proof water paint and a preparing method of the high-salt-mist high-weather-proof water paint. The high-salt-mist high-weather-proof water paint mainly comprises acrylic acid modified emulsion. The acrylic acid modified emulsion is composed of isobutyl alcohol, ethylene glycol monobutyl ether, methyl isobutyl ketone, vinylidene chloride, dodecafluoroheptyl methacrylate, perluorooctyl acrylate, vinyl trimethoxy silane, acrylic acid, methyl methacrylate, hydroxyethyl acrylate, phenylethylene, 2-ethylhexyl acrylate, azodiisobutyronitrile, N-methyl monoethanolamine and deionized water. The paint is quite excellent primer-topcoat coating and suitable for metal workpieces, the paint is dried at normal temperature after being sprayed, the appearance of a coating is smooth and bright, the leveling property is good, the mechanical property is good, the weather-proof property is excellent, after 2500 hours of QUV aging tests, the dulling rate is smaller than or equal to 15%, and delta E is smaller than or equal to 1.5, meanwhile, corrosion resistance is good, salt mist resistance reaches 1000 hours, and the one-way corrosion width is smaller than or equal to 2 mm.

Owner:HAOLISEN COATING SHANGHAI +1

Pressure sensitive adhesive, preparation method thereof and protective films using same

ActiveCN101962525AImprove overlay performanceReduce polarityLiquid surface applicatorsFilm/foil adhesivesTectorial membraneAcrylic resin

Owner:KUNSHAN BYE MACROMOLECULE MATERIAL CO LTD

Multipolymer type waterproof sealant for construction

InactiveCN102994016ANon-toxic and environmentally friendlyExtended service lifeMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesIsooctyl acrylatePolyester

The invention discloses a multipolymer type waterproof sealant for construction, wherein raw materials in a prescription based on ratio of part by weight are as follows: vinyl acetate, organic silicone monomer containing unsaturated double bonds, vinyl versatate, butyl acrylate, 2-ethylhexyl acrylate, acrylic acid and de-ionized water. The multipolymer type waterproof sealant has the advantages that the sealant can be used for coating surfaces of substances such as cement components, ceramics, glass, plywoods, shaving boards, palm fiber boards, bamboo slag boards, paper slag boards, composite boards, aluminum-plastic panels, polyvinyl chloride (PVC) boards, fireproof plates, metal, plastics, leather, rubber and the like and has the bonding strength that other waterproof materials cannot reach; the sealant has good stability and the shelf life at 5-35 DEG C. is more than 12 months; and the multipolymer type waterproof sealant for the construction has the advantages of no toxicity, no odor, no pollution, no corrosion, no combustion, no wiredrawing during coating and the like; and the problems of easy combustion, short shelf life, wiredrawing during coating, serious air pollution and the like during applications of solvent type materials, polyester type materials and the like are solved.

Owner:GUANGDONG BADESE CHEM

Heat-resistant strippable micro-viscous pressure-sensitive adhesive film and preparation thereof

InactiveCN101275059AEasy to operateSatisfy processabilityFilm/foil adhesivesEster polymer adhesivesToluene diisocyanateViscous pressure

The present invention provides a heat resistance peeling mild adhesive pressure sensitive adhesive film for electronic manufacturing industry or package industry, and its manufacturing method, 2-ethylhexyl acrylate, methacrylic acid 2-ethylhexyl acrylate, butyl acrylate, methyl methacrylate and 2-hydroxyethyl acrylate copolymer liquid cement are prepared by solution polymerization process, then a coating composition is prepared by adding a toluene diisocyanate crosslinking agent, the mild adhesive pressure sensitive adhesive film is obtained by coating and drying, the peeling strength of the mild adhesive pressure sensitive adhesive film, the polyimide film and the pet film is above 300g / 25mm, the peeling strength after ageing 1 hour also keeps above 37g / 25mm, the any residual does not retain after peeling, the mild adhesive pressure sensitive adhesive film has mild adhesive ability under the high temperature 180 DEG C, 90 DEG C and the acid-base environment, having a convenient operation, being directly peeled.

Owner:SHENZHEN DANBOND TECH

Low-toxicity and low-odor single-component acrylate pressure sensitive adhesive and preparation method thereof

InactiveCN105907340AGood dye compatibilityImprove stabilityEster polymer adhesivesPressure sensitive film/foil adhesivesFunctional monomerSolvent

The invention provides a preparation method of a low-toxicity and low-odor single-component acrylate pressure sensitive adhesive. An acrylate adhesive is prepared first, main raw materials of the adhesive include 10-15% of butyl acrylate, 5-10% of 2-ethylhexyl acrylate, 10-15% of methyl acrylate, 2-5% of methyl methacrylate, 1-3% of functional monomer, 0-3% of specialty monomer, 50-70% of solvent and 0.05-0.15% of initiator, and a certain amount of curing agent and a certain amount of inhibitor are added after reaction ends. The acrylate pressure sensitive adhesive has the advantages of being high in stripping strength, high in stability and good in pigment / dye compatibility and can be used for the field of car window membranes and the like.

Owner:西安航天三沃化学有限公司

Adhesive material for adhesive tapes and preparation method thereof

ActiveCN103725231AImprove heat resistanceImprove aging resistanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesMethacrylateIsooctyl acrylate

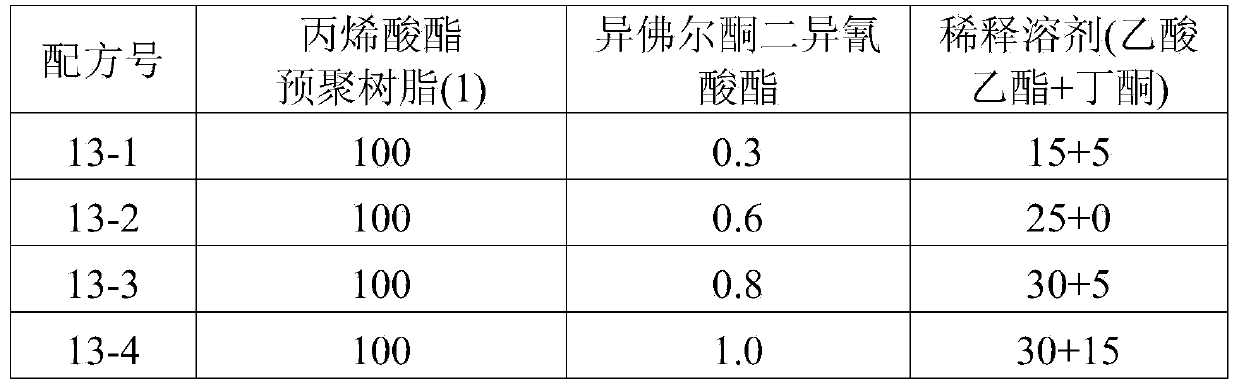

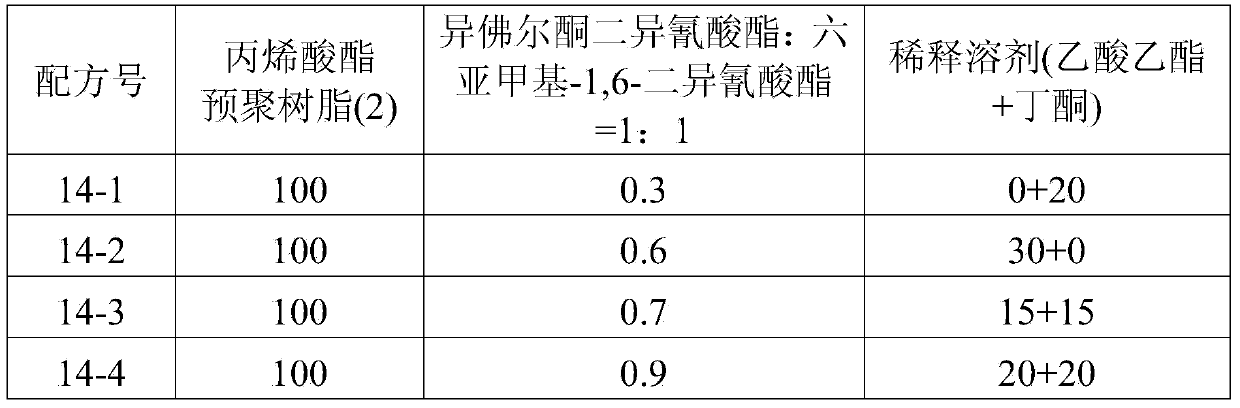

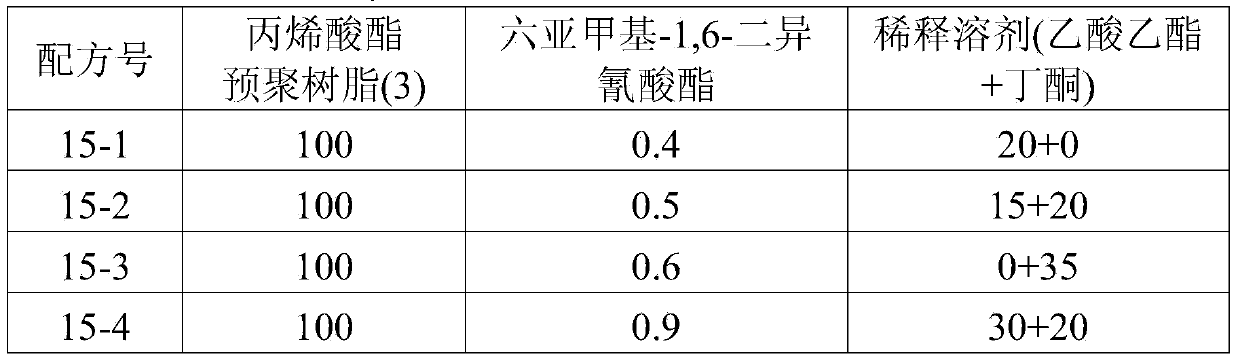

The invention discloses an adhesive material for adhesive tapes. The invention is characterized in that the adhesive material is prepared by mixing 1000 parts by mass of acrylate prepolymer resin with the solid content of 40%, 3-10 parts by mass of curing agent and 200-500 parts by mass of diluting solvent. The preparation method of the acrylate prepolymer resin comprises the following steps: adding 350 parts of butyl acrylate, 150-200 parts of 2-ethylhexyl acrylate, 250-350 parts of ethyl methacrylate, 200-300 parts of functional monomer, 100-150 parts of glycidyl methacrylate, 1200 parts of solvent and 8-20 parts of initiator into a reaction kettle, and stirring and mixing; and in a nitrogen protective atmosphere, heating to 70-75 DEG C to react for 4-6 hours, and adding a solvent until the solid content reaches 40%. The adhesive material for adhesive tapes has the advantages of high heat resistance, high aging resistance, high working properties and favorable product performance, is convenient to use, and can be used for manufacturing various single-sided and double-sided pressure-sensitive adhesive tapes and optical clear adhesive tapes.

Owner:SICHUAN DONGFANG INSULATING MATERIAL

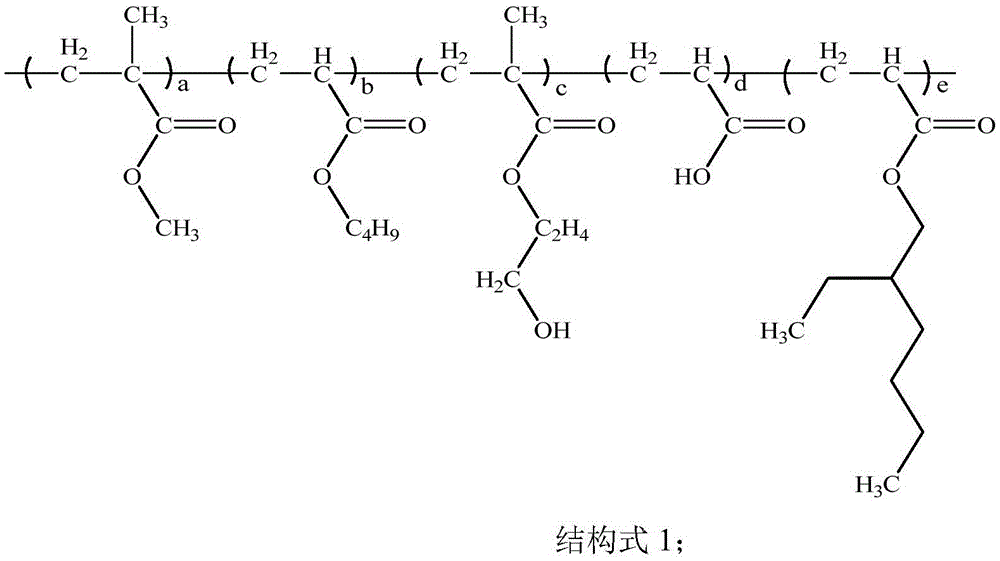

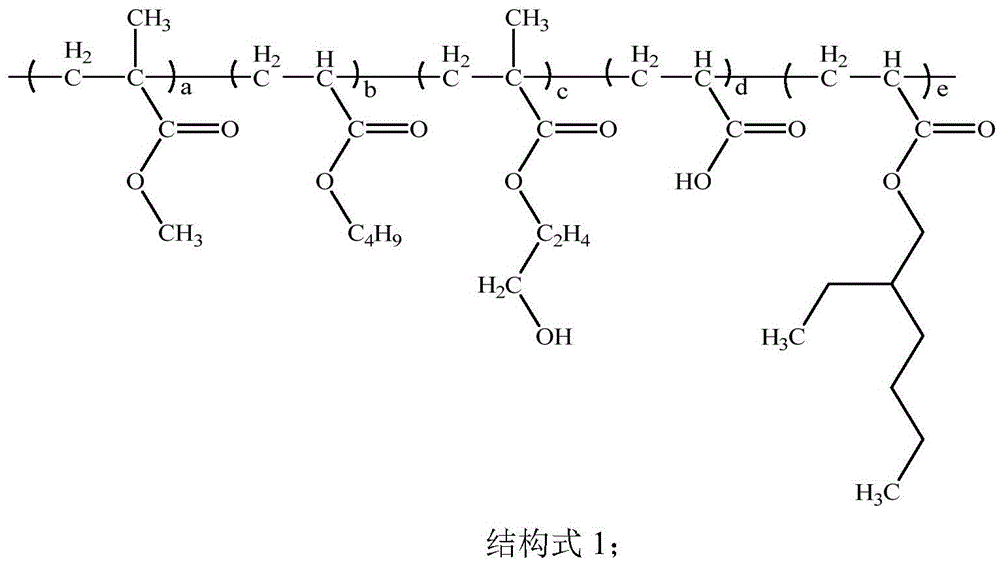

Ultraviolet light curing transfer printing glue and preparation method and application thereof

ActiveCN105602515AHigh glass transition temperatureHigh tensile shear strengthDuplicating/marking methodsPolyureas/polyurethane adhesivesIsooctyl acrylateUltraviolet lights

The invention discloses an ultraviolet light curing transfer printing glue composition for a transfer printing film. The ultraviolet light curing transfer printing glue composition comprises the following components in parts by weight: 20-40 parts of modified acrylate, 20-40 parts of epoxy resin, 10-30 parts of reactive diluent, 3-8 parts of photoinitiator, 5-15 parts of adhesion promoter, 2-5 parts of silane coupling agent and 0-1 part of auxiliary, and the modified acrylate is prepared by modifying pentapolymer prepared from methyl methacrylate (MMA), n-butyl acrylate ((i)n( / i)-BA), hydroxypropyl methacrylate (HMPA), acrylic acid (AA) and 2-ethylhexyl acrylate (EHA) through free radical copolymerization by using polyurethane containing isocyanato. The prepared ultraviolet light curing transfer printing glue has good adhesion to a glass base material, and is good in water resistance, high in tensile strength and excellent in transfer printing effect.

Owner:GUANGDONG UNIV OF TECH

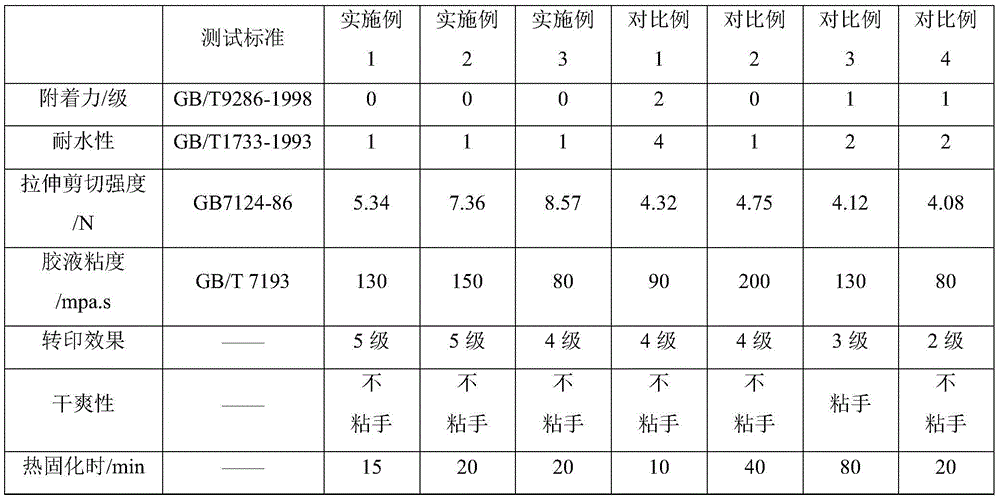

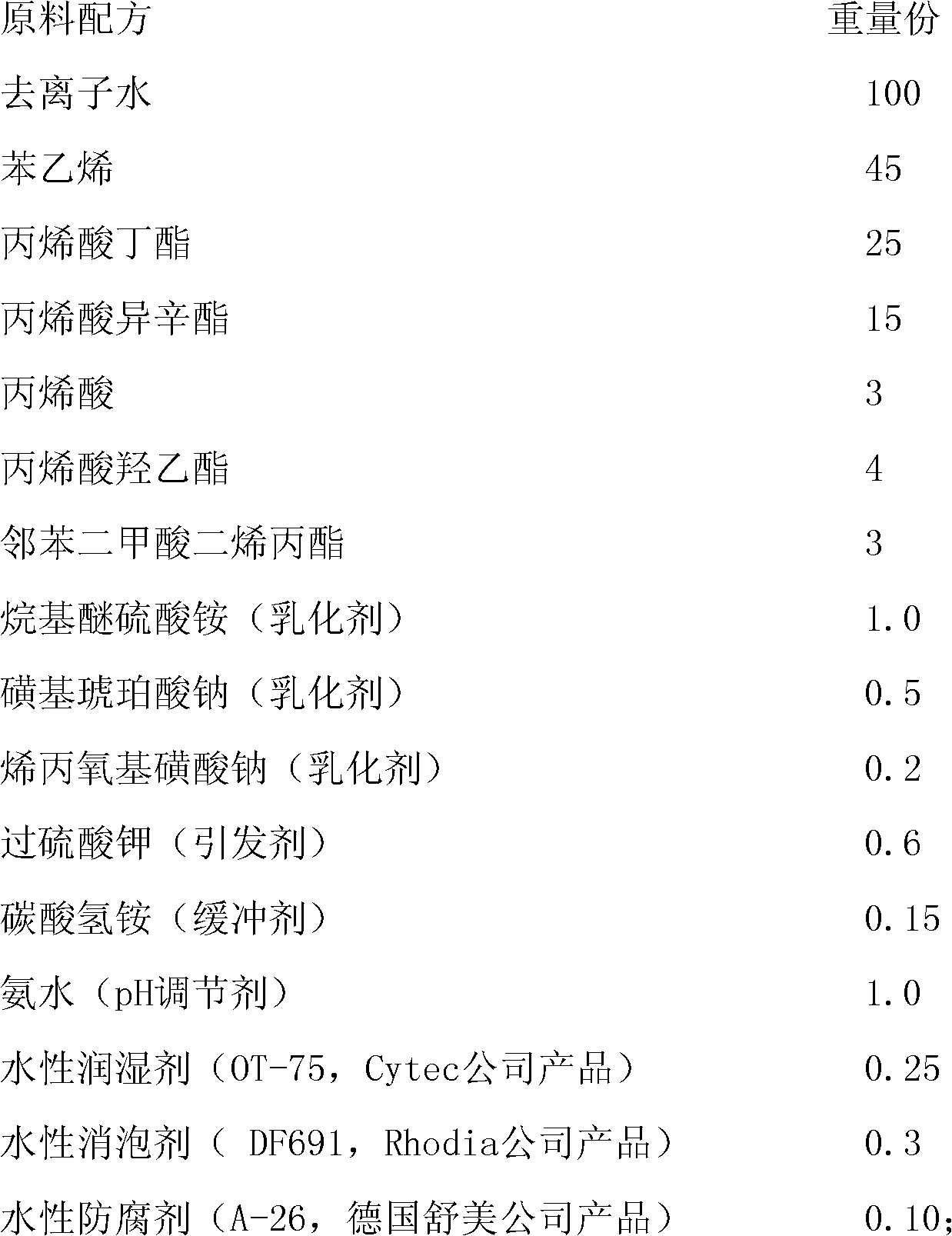

Water-based dry-type complex film adhesive and preparation method thereof

ActiveCN102134463AReduce the amount addedReduce contentHydrocarbon polymer adhesivesIsooctyl acrylateWater based

The invention discloses a water-based dry-type complex film adhesive and a preparation method thereof, belonging to the field of preparation of adhesive. The preparation method of the complex film adhesive comprises the following steps: by using monomers, an emulsifier, an initiator, a buffering agent, deionized water, a pH regulator and water-based assistants as raw materials, emulsifying, carrying out seed reaction and polymerization reaction, and compounding to obtain the complex film adhesive of which the solid content is 45-55%, wherein the monomers comprise a hard monomer, soft monomers and functional monomers; the hard monomer is styrene; the soft monomers comprise butyl acrylate and 2-ethylhexyl acrylate; the functional monomers comprise acrylic acid or methacrylic acid, 2-hydroxyethyl acrylate or 2-hydroxypropyl acrylate, and diallyl phthalate; and the emulsifier comprises ammonium alkyl ether sulfate, sodium sulfosuccinate and sodium allyloxysulfonate in a weight ratio of 2:1:(0.4-0.8). The complex film adhesive has the advantages of high bonding strength, favorable affinity and covering performance for ink, and environment protection since the content of VOCs (volatile organic compounds) is lowered.

Owner:NANTONG GAOMENG NEW MATERIAL

Preparation method of acrylate microemulsion with high solid content

InactiveCN102993355AImprove adhesionPromote environmental protectionEster polymer adhesivesCross-linkEthyl acrylate

The invention discloses a preparation method of acrylate microemulsion with high solid content. The preparation method comprises the steps: adding an initiator ammonium persulfate (APS) into a mixed solution including distilled water, an emulsifier and a PH regulator, adding mixed monomers including butyl acrylate (BA), ethylene-ethyl acrylate (EEA) and 2-ethylhexyl acrylate (2-EHA) for reaction, and adding a cross-linking modifier, namely, N-Methylol acrylamide (NMA), to prepare the acrylate microemulsion with high solid content. For the microemulsion, the amount of the used emulsifier is low, and the prepared acrylate microemulsion is high in solid content.

Owner:QINGDAO PENGHAI SOFT CO LTD

Preparation method and application of high temperature solvent resistant acrylate pressure sensitive adhesive

ActiveCN104449486AImprove mechanical propertiesImprove high temperature resistanceNon-macromolecular adhesive additivesFilm/foil adhesivesIsooctyl acrylateCarvacryl acetate

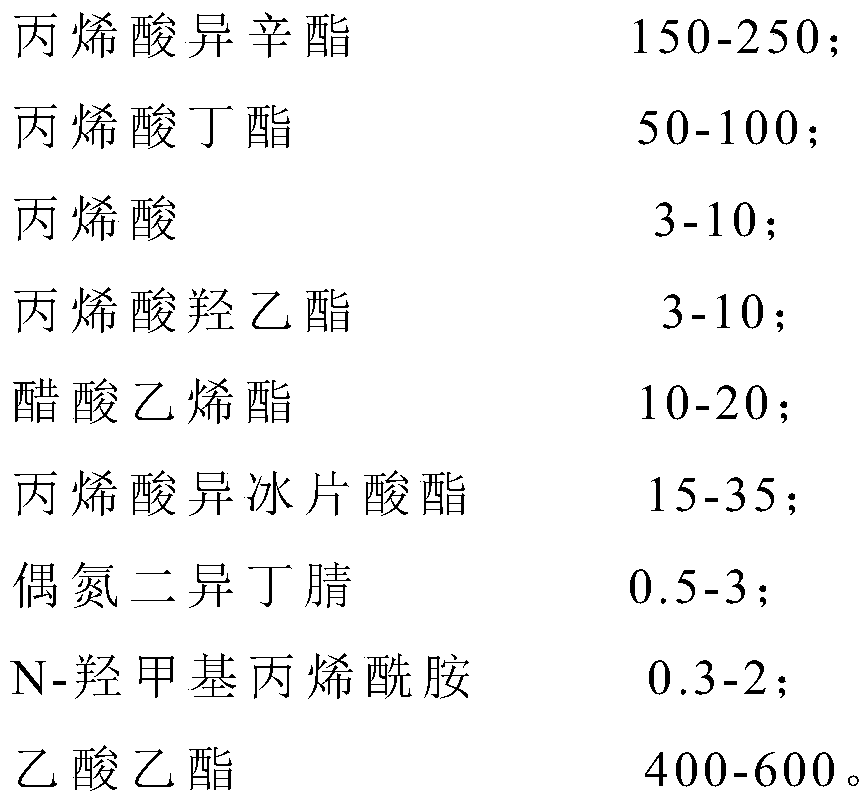

The invention relates to a high temperature solvent resistant acrylate pressure sensitive adhesive which comprises the following components in parts by weight: 150-250 parts of 2-ethylhexyl acrylate, 50-100 parts of butyl acrylate, 3-10 parts of acrylic acid, 3-10 parts of hydroxyethyl acrylate, 10-20 parts of vinyl acetate, 15-35 parts of bornyl isoacrylate, 0.5-3 parts of azobisisobutyronitrile, 0.3-2 parts of N-hydroxymethyl acrylamide and 400-600 parts of ethyl acetate. The mechanical property, high temperature resistance and weather resistance of the emulsion type acrylate pressure sensitive adhesive are improved, so that the application range of the emulsion type acrylate pressure sensitive adhesive is widened, and the pressure sensitive adhesive has the characteristics of high viscidity, high temperature resistance, damp-heat aging resistance and low cost.

Owner:新丰杰力电工材料有限公司

Colored continuous-phase silicone-acrylic emulsion reactable with protective glue and preparation method thereof

Owner:中山市巴德富化工科技有限公司

Aqueous transfer glue and preparation method thereof

InactiveCN102190992AImprove folding resistanceIncrease brightnessNon-macromolecular adhesive additivesEster polymer adhesivesFunctional monomerPaperboard

The invention relates to an aqueous transfer glue which is prepared through an emulsion polymerization with methyl methacrylate, butyl acrylate monomer, acrylic acid 2- Octyl Nitrite, a functional monomer, an initiator, an emulsifier buffering agent, a functional auxiliary agent, a PH adjusting agent and deionized water. The invention also provides the preparation method of the aqueous transfer glue. The invention is characterized by simple technology, low cost, environment friendliness and the ultimate product meets the 16 limitation requirements on harmful substances in the tobacco industry. Meanwhile, the golden paperboard and silver paperboard prepared from the aqueous transfer glue provided in the invention have better flexibility resistance and brightness than those of the products currently for sale. In particular, regarding to help with the limitation of harmful substances, the aqueous transfer glue is far better than the carboxylated styrene-butadiene rubber latex used in the current tobacco package industry.

Owner:上海奇想青晨新材料科技股份有限公司

Special reactive typehigh-activityleveling agent for epoxy powder coatings as well as preparation method and application of leveling agent

InactiveCN103965676AGood compatibilityImprove wettabilityPowdery paintsEpoxy resin coatingsEpoxyIsooctyl acrylate

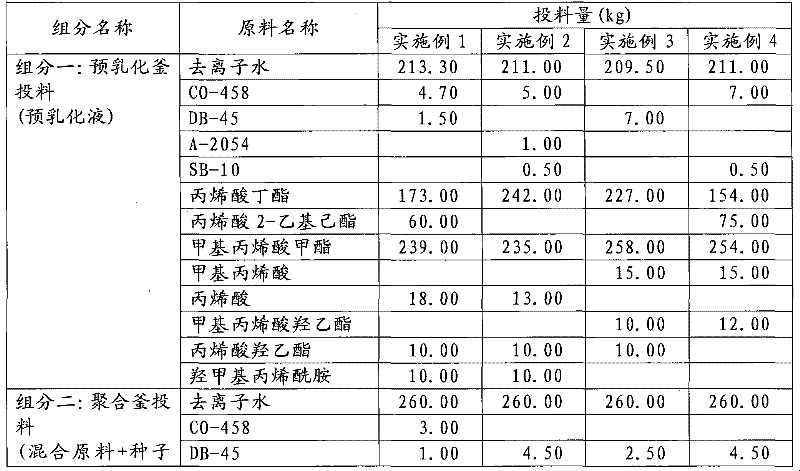

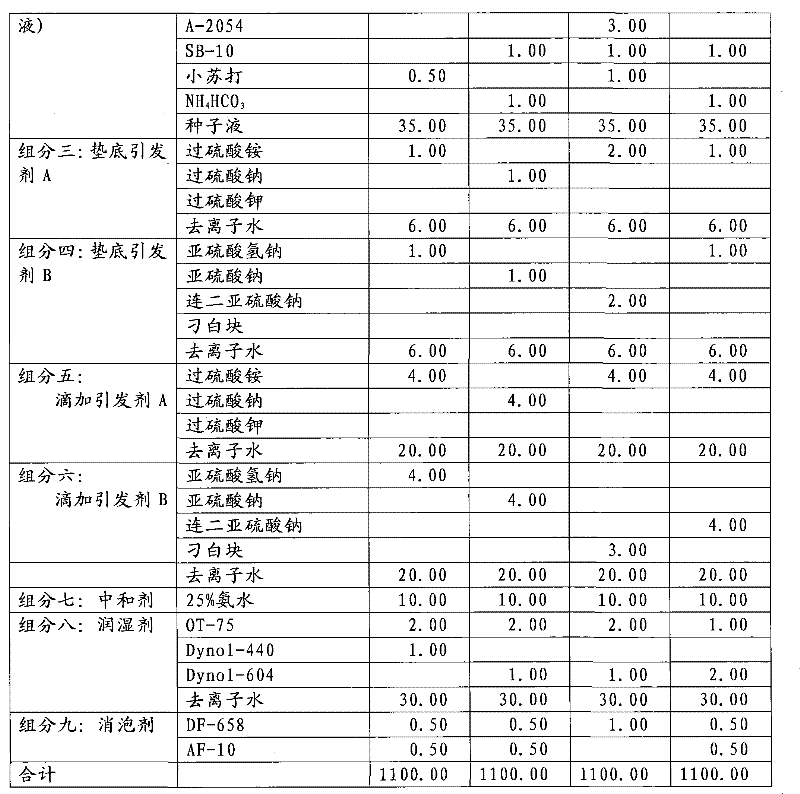

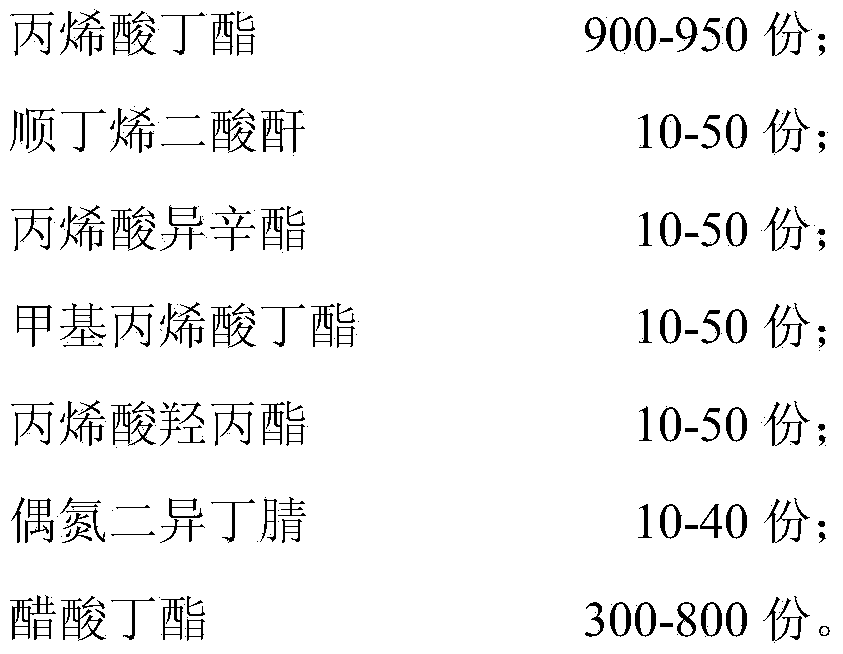

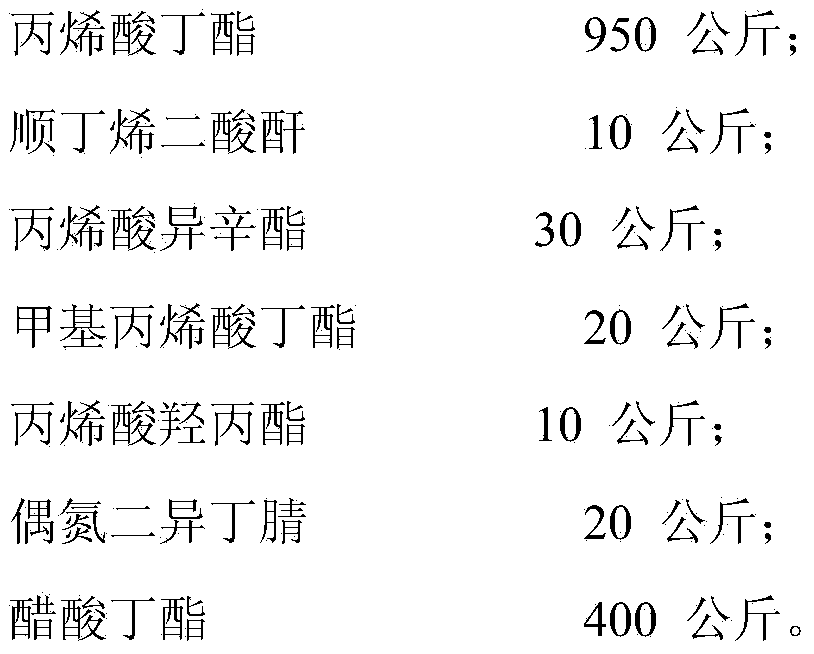

The invention relates to a special reactive typehigh-activityleveling agent for epoxy powder coatings as well as a preparation method and an application of the leveling agent. Theleveling agent comprises the raw materials in parts by weight as follows: 900-950 parts of butyl acrylate, 300-800 parts of butyl acetate, 10-50 parts of maleic anhydride, 10-50 parts of hydroxypropyl acrylate, 10-50 parts of 2-ethylhexyl acrylate, 10-50 parts of butyl methacrylate and 10-40 parts of azobisisobutyronitrile. The leveling agent is mainly prepared into a solid leveling agent in the later period to be applied to the powder coatings, and polar groups such as hydroxyl groups, anhydride and the like are introduced, so that thecompatibility with epoxy resin in the powder coatings and the wettability of the coatings and substrates are promoted, and the coatings have excellent leveling and brightening effects; in addition, active groups, namely, carboxyl groups, participate in a curing reaction, so that the compactness of the coatings is improved, thesolvent resistance of films is improved, and theleveling agent is suitable for the various epoxy powder coatings.

Owner:TIANJIN XIANGSHENG NEW MATERIALS CO LTD

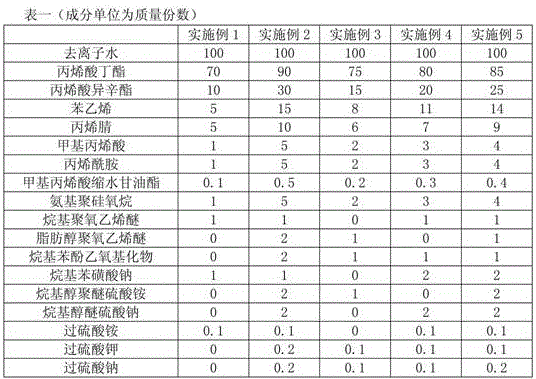

Acrylate elastic emulsion with excellent low-temperature breaking elongation and preparation method thereof

ActiveCN106632823AHigh elongation at breakImprove flexibilityCoatingsIsooctyl acrylateGlycidyl methacrylate

The invention discloses acrylate elastic emulsion with excellent low-temperature breaking elongation, comprising, by weight, 100 parts of deionized water, 70-90 parts of butyl acrylate, 10-30 parts of 2-ethylhexyl acrylate, 5-15 parts of styrene, 5-10 parts of acrylonitrile, 1-5 parts of methacrylic acid, 1-5 parts of acrylamide, 0.1-0.5 part of glycidyl methacrylate, 1-5 parts of aminopolysiloxane, 2-10 parts of an emulsifier, and 0.1-0.5 part of persulfate. The acrylate elastic emulsion has excellent low-temperature breaking elongation.

Owner:上海巴德富实业有限公司

Vapor permeable, water resistive, air barrier polyester membrane having a polyacrylic coating with porous pressure sensitive adhesive added to the rear surface of the membrane

An ultra violet stable polyester membrane with a polyacrylic coating on one side and a coated pressure sensitive adhesive coating on its other side capable of allowing water vapor to pass through it. The pressure sensitive adhesive is formed of a copolymer comprising a backbone of n-butyl acrylate, 2-ethylhexyl acrylate, and vinyl acetate which is mixed with at least one surfactant and emulsified to produce air bubbles which form pores when the copolymer is set with about 80% to about 90% of the pore sizes ranging from about 200 microns to about 300 microns and being uniformly distributed to form a flow path through the pressure sensitive adhesive.

Owner:VAPROSHIELD

Hydrophobic masking tape and preparation method thereof

ActiveCN103173157ANo pollution in the processCapable of outdoor useFilm/foil adhesivesOrganic non-macromolecular adhesiveSodium bicarbonateEmulsion

The invention provides a hydrophobic masking tape and a preparation method thereof. The hydrophobic masking tape comprises a masking tape layer and an adhesive layer which is coated on the surface of the masking tape layer, wherein the adhesive formula of the adhesive layer comprises the following components in parts by weight: 200-300 parts of butyl acrylate, 100-200 parts of 2-ethylhexyl acrylate, 2-10 parts of acrylic acid, 2-10 parts of 2-hydroxyethyl acrylate, 30-60 parts of styrene-acrylic emulsion, 5-10 parts of sodium benzene sulfonate, 300-500 parts of water, 2-7 parts of ammonium persulfate and 0.1-0.5 part of sodium bicarbonate. A hydrophobic adhesive is adopted in a preparation process to remove the conventional organic solvent, and the masking tape is subjected to ultraviolet pretreatment, so that the produced masking tape is pollution-free and environment-friendly and has an outdoor use function.

Owner:SHANGHAI SMITH ADHESIVE NEW MATERIAL

Adhesive tape for jacketing elongate material such as especially cable looms and jacketing method

An adhesive tape, especially for wrapping cables, consisting of a preferably textile carrier and of a pressure-sensitive adhesive which is applied on at least one side of the carrier and is in the form of a dried polymer dispersion, the polymer being synthesized from: a) 40% to 90% by weight of n-butyl acrylate and / or 2-ethylhexyl acrylate b) 0% to 10% by weight of an ethylenically unsaturated monomer having an acid or acid-anhydride function c) 60% to 10% by weight of one or more ethylenically unsaturated monofunctional monomers different from (a) and (b) d) 0% to 1% by weight of a difunctional or polyfunctional monomer and the pressure-sensitive adhesive comprising between 15 and 100 parts by weight of a tackifier (based on the mass of the dried polymer dispersion).

Owner:TESA SE

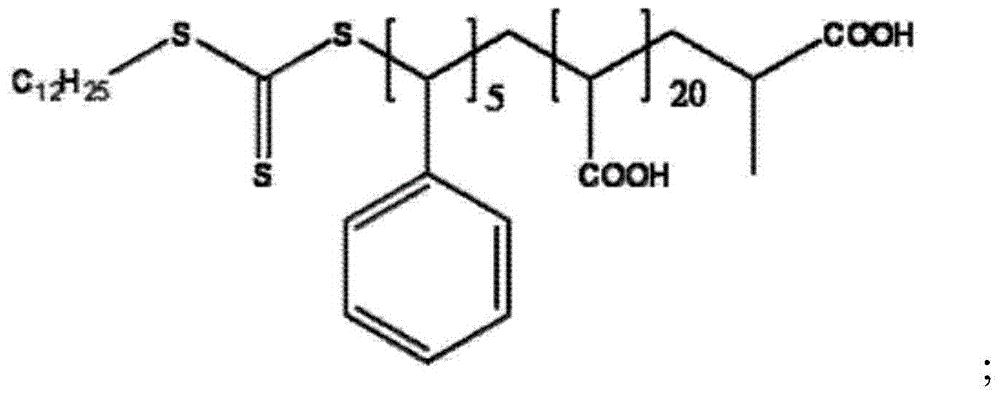

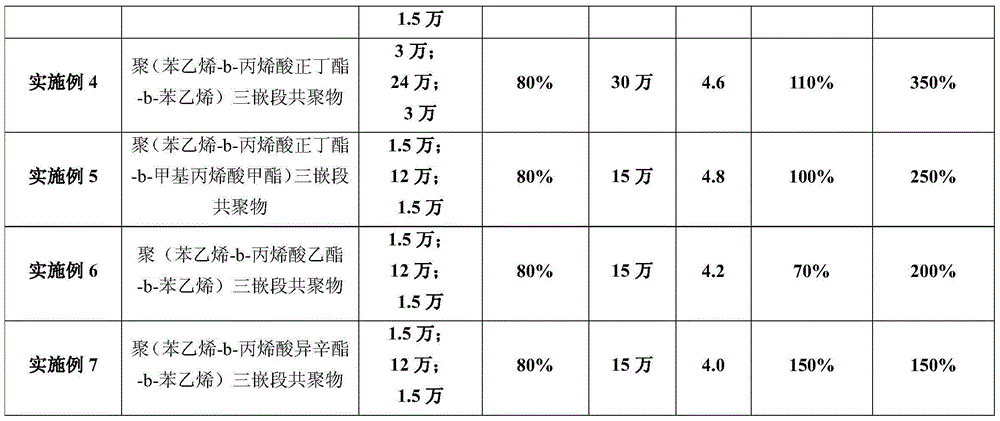

Application of block polymer as dielectric elastomer

ActiveCN105153624AExcellent electrostrictive performanceQuick responseIsooctyl acrylatePolymer science

The invention discloses an application of a block polymer as a dielectric elastomer. The structural general formula of the block polymer is B-C-D, wherein B and D are independently selected from a styrene homopolymer or a methyl methacrylate homopolymer; C is selected from a butyl acrylate homopolymer, a n-butyl acrylate homopolymer, a n-butyl methacrylate homopolymer, a isobutyl methacrylate homopolymer, a tert-butyl acrylate homopolymer, a 2-ethylhexyl acrylate homopolymer, an iso-octyl acrylate homopolymer, an ethyl acrylate homopolymer or a homopolymer of at least two kinds of butyl acrylate, n-butyl acrylate, n-butyl methacrylate, isobutyl methacrylate, tert-butyl acrylate, 2-ethylhexyl acrylate, iso-octyl acrylate and ethyl acrylate. The block polymer can have larger deformation under high-frequency driving without swelling by a solvent and can be used as the dielectric elastomer.

Owner:ZHEJIANG UNIV

Acrylic copolymers with improved low temperature performance

InactiveUS20060276587A1Reduce temperature riseImprove low temperature impact performanceCoatingsCore shell2-ethylhexyl acrylate

This invention relates to a core / shell impact modifier having as a core a copolymer or terpolymer having from 25 to 75 percent by weight of 2-ethylhexyl acrylate (2-EHA) monomer units with from 25 and 75 percent by weight of n-octyl acrylate (n-OA) monomer units. This core-shell impact modifier is used in performance polymers to improve low temperature impact performance.

Owner:ARKEMA INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com