Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

47results about How to "Improve overlay performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

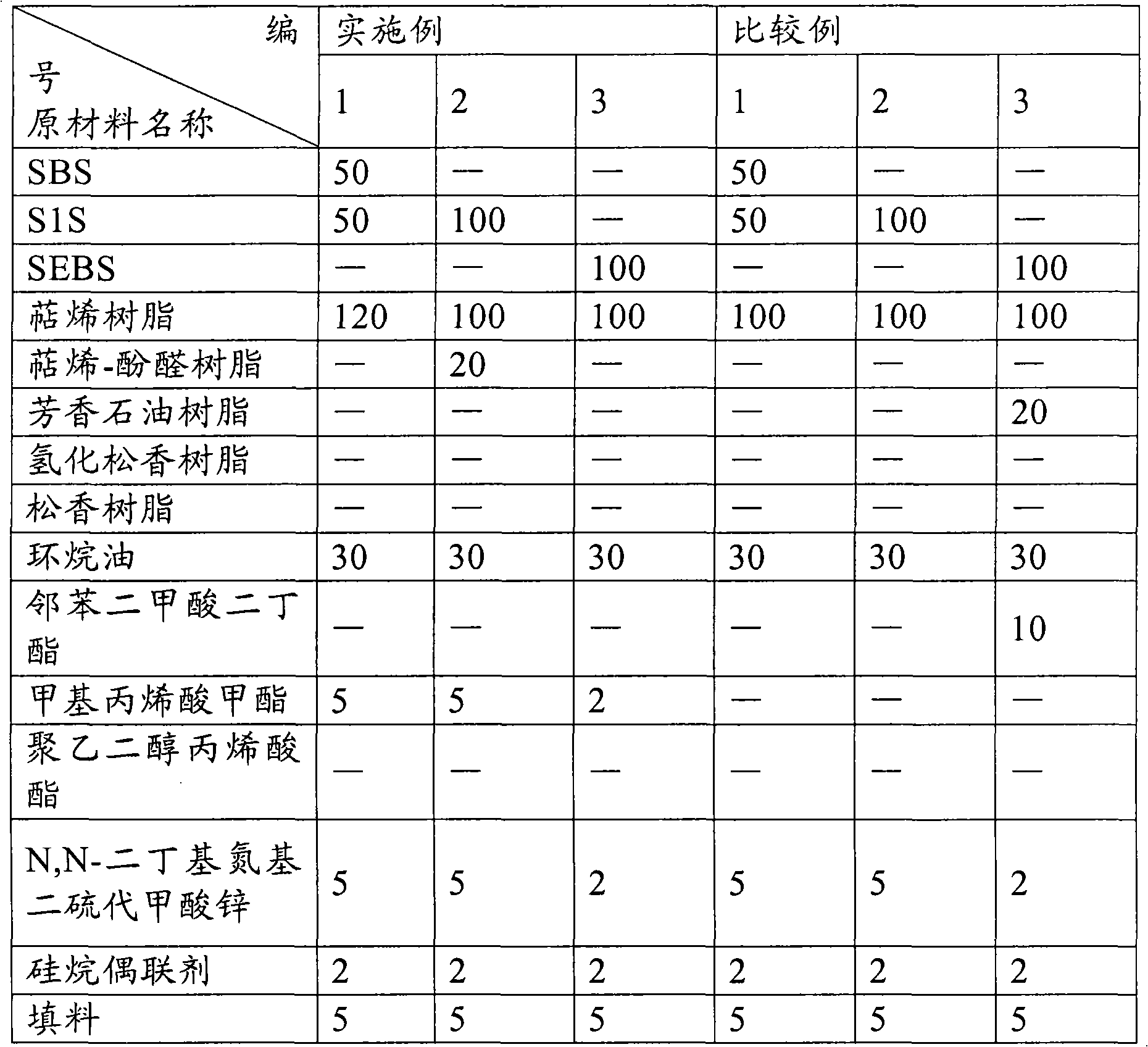

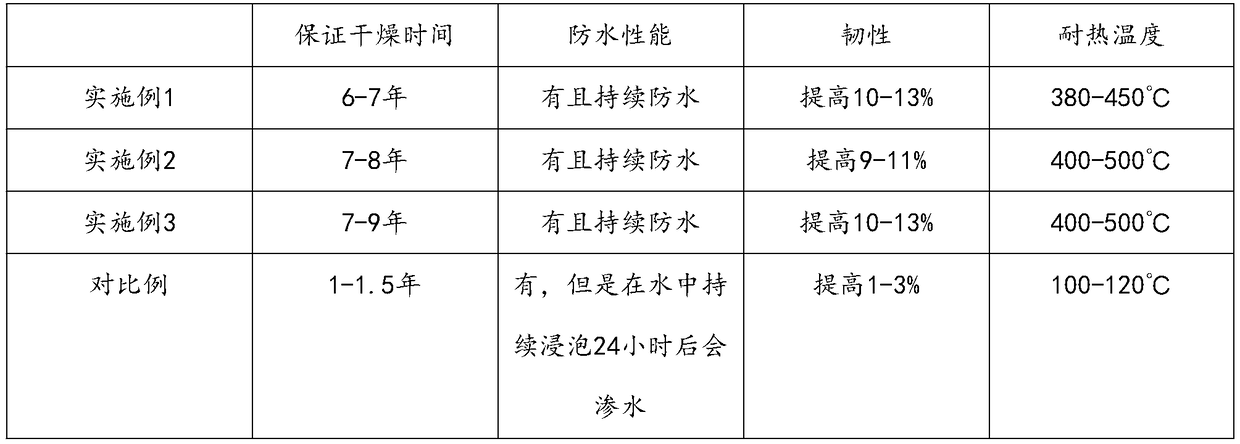

Preparation methods of hot melt pressure-sensitive adhesive and protective film as well as hot melt pressure-sensitive adhesive

ActiveCN102051149AImprove heat resistanceGood weather resistanceLiquid surface applicatorsNon-macromolecular adhesive additivesTectorial membranePolyolefin

The invention discloses preparation methods of a hot melt pressure-sensitive adhesive and a protective film as well as the hot melt pressure-sensitive adhesive. The preparation method of the hot melt pressure-sensitive adhesive comprises the following steps: adding thermoplastic elastomers, a tackifier, a plasticizer, an antiager, an antioxidant, a crosslinker, a filler and the like into a double-mixed column mixer, stirring, heating until the materials are melted down, and uniformly mixing to obtain the pressure-sensitive adhesive. The preparation method of the protective film comprises the following steps: directly pumping the melted and uniformly mixed pressure-sensitive adhesive into a coating roll of the a hot melt coating machine by a heat transfer pump, coating the pressure-sensitive adhesive onto one face of a polyolefin plastic film or thin plastic-coated paper, cooling, and rolling to obtain the protective film (paper). The hot melt pressure-sensitive adhesive disclosed by the invention can obtain good initial stickiness, cohesion and age stripping property by changing the different ratio of the thermoplastic elastomer as well as the variety and usage amount of the tackifier. The prepared polyethylene (PE) film substrate protective film has low interfacial tension, good initial stickiness, high cohesion and high temperature resistance, light resistance and weather resistance, and the comprehensive performance and product cost of the hot melt pressure-sensitive adhesive disclosed by the invention are better than those of the traditional solvent pressure-sensitive adhesive taking natural rubber as the main material.

Owner:KUNSHAN BYE MACROMOLECULE MATERIAL CO LTD

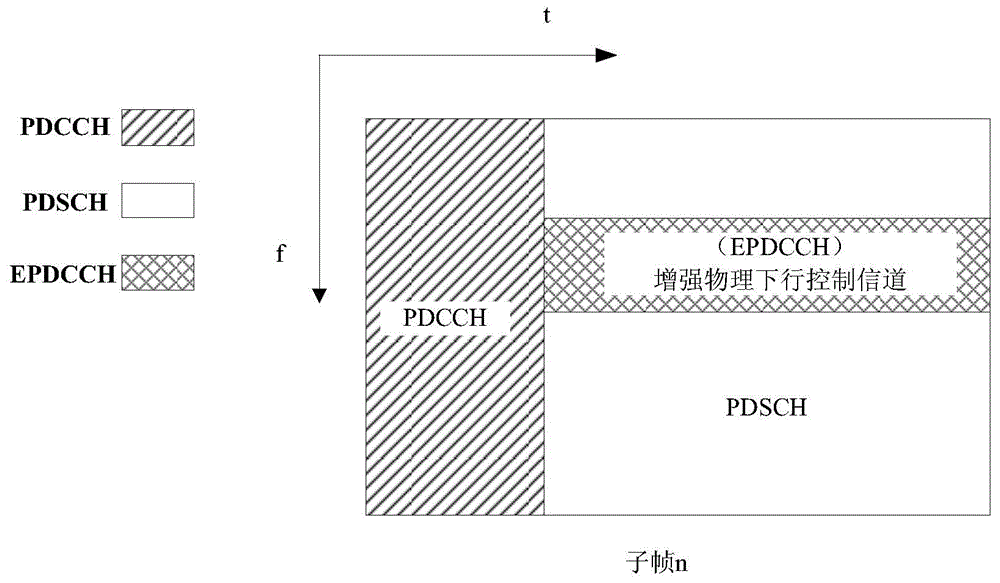

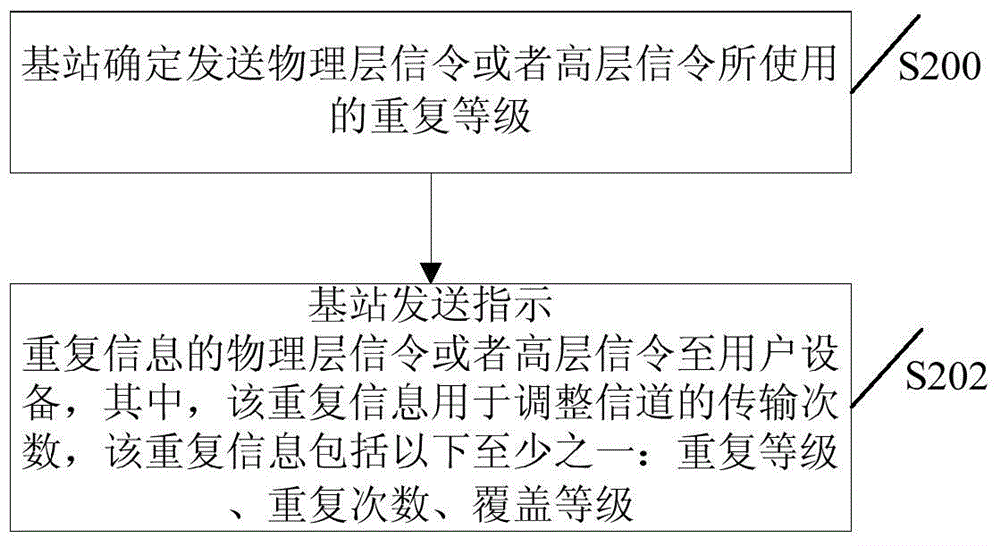

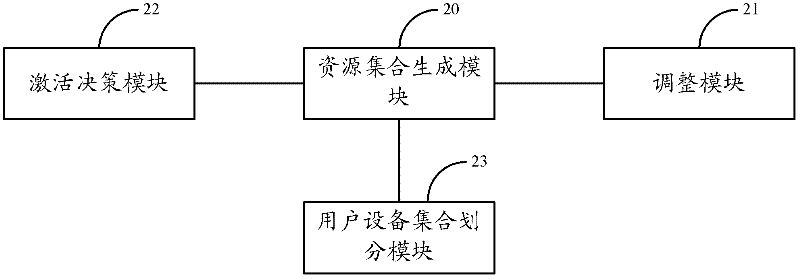

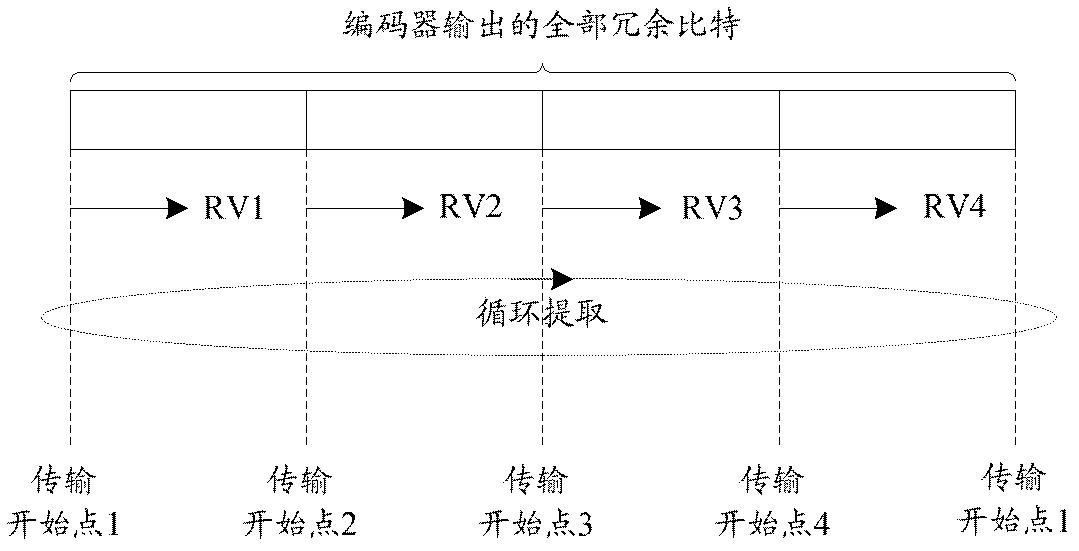

Repeated information sending and receiving method, base station, and user equipment

ActiveCN104811262AAvoid wasting resourcesImprove overlay performanceError prevention/detection by using return channelChannel coding adaptationChannel usePhysical layer

Disclosed are a method for sending / receiving repeated information, a base station and a user equipment. The method for sending repeated information comprises: sending to a user equipment, by a base station, a physical layer signalling or a high layer signalling which indicates repeated information, wherein the repeated information is used for adjusting the number of times of transmission of a channel, and the repeated information comprises at least one of the following: a repetition level, the number of times of repetition and a coverage level. By means of the present invention, the problem of wasting of resources or deficient number of times of repetition caused by transmitting a corresponding channel using the fixed number of times of repeat transmission is solved, thereby avoiding wasting of resources and improving the coverage performance of a user equipment.

Owner:ZTE CORP

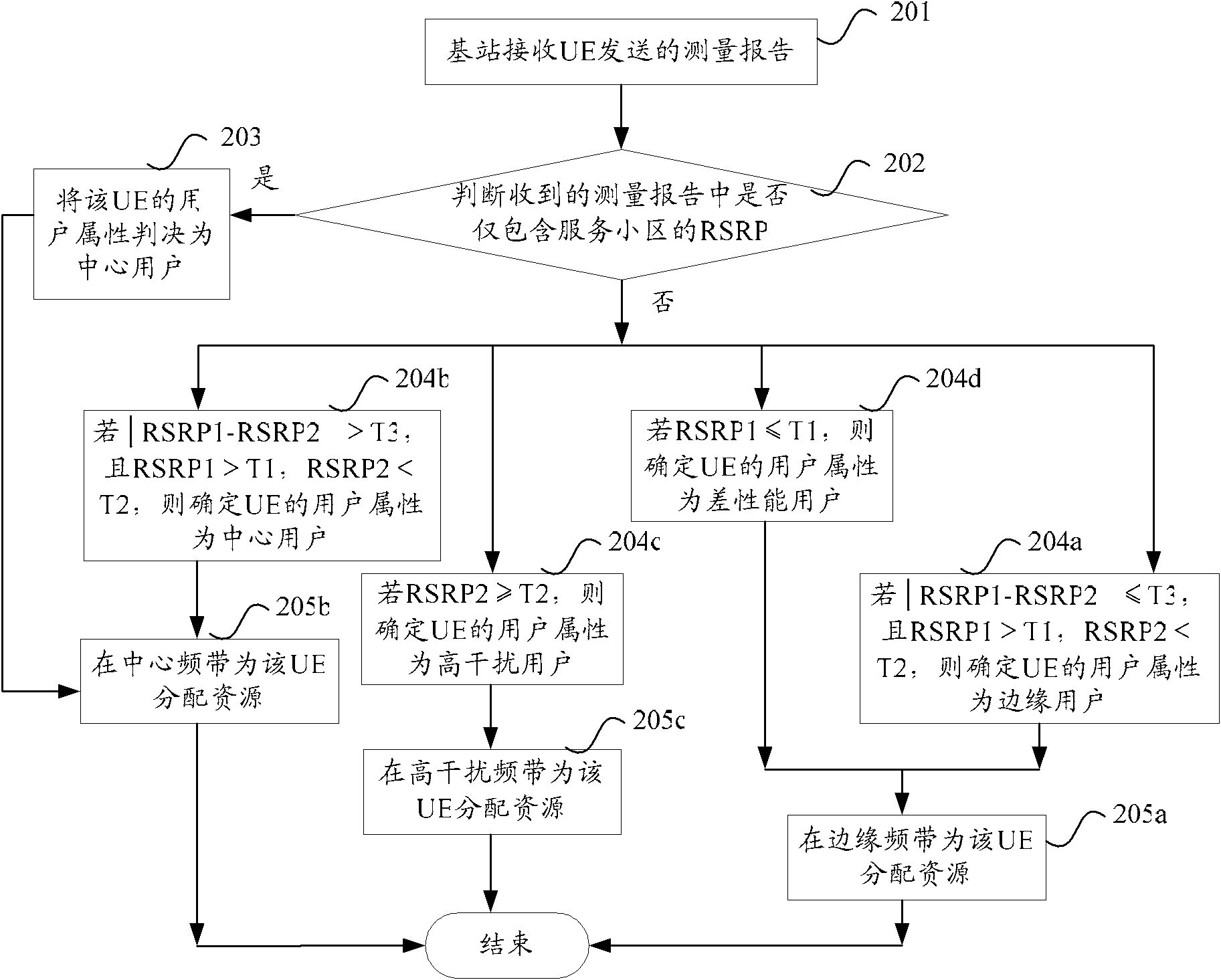

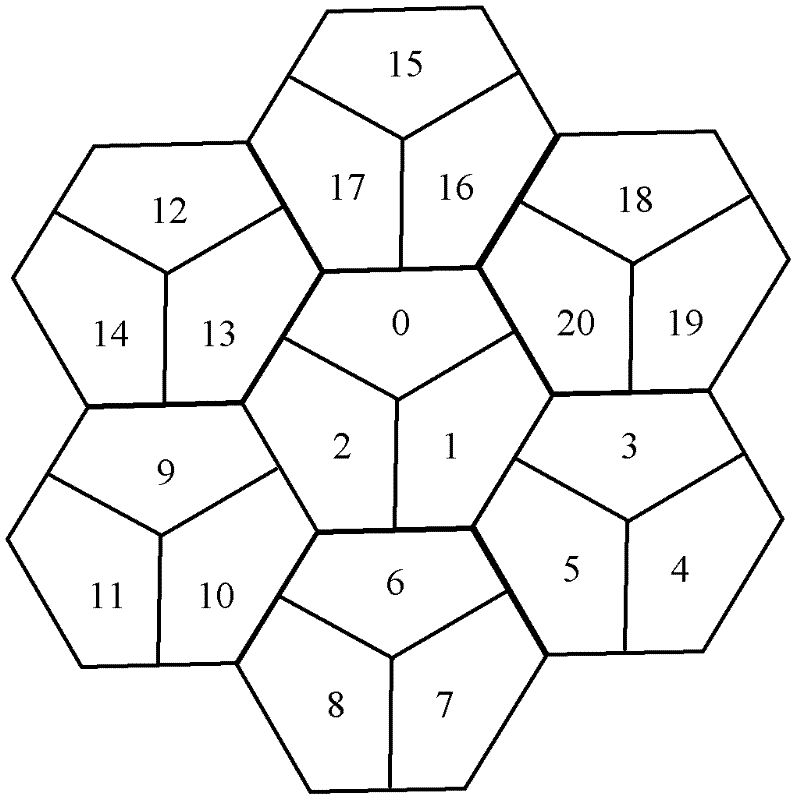

Resource allocation method, apparatus and base station

ActiveCN102204310AImprove overlay performanceIncrease coverageDistributed allocationNetwork planningFrequency bandBase station

The embodiments of the invention provides a resource allocation method, an apparatus and a base station. The method comprises: network side equipment receives a measuring report sent by UE; the network side equipment obtains RSRP1 and RSRP2 from the measuring report and the RSRP1 is RSRP from the UE to a serving cell and the RSRP2 is the RSRP from the UE to an adjacent cell; the network side equipment determines a frequency band which the UE is suitable for using according to an absolute value of the RSRP1, an absolute value of the RSRP2 and difference between the RSRP1 and the RSRP2, wherein the frequency band comprises a central frequency band and an edge frequncy band; and the network side equipment allocates resource for the UE on the frequncey band fit for a determining result according to the determining result. In the embodiments of the invention, the network side equipment determines the frequency band fit for the UE according to the difference between the RSRP1 and the RSRP2, the absolute value of the RSRP1 and the absolute value of the RSRP2 and allocates resource for the UE on the suitable frequnency band, thereby increasing covering performance of the cell.

Owner:HUAWEI TECH CO LTD

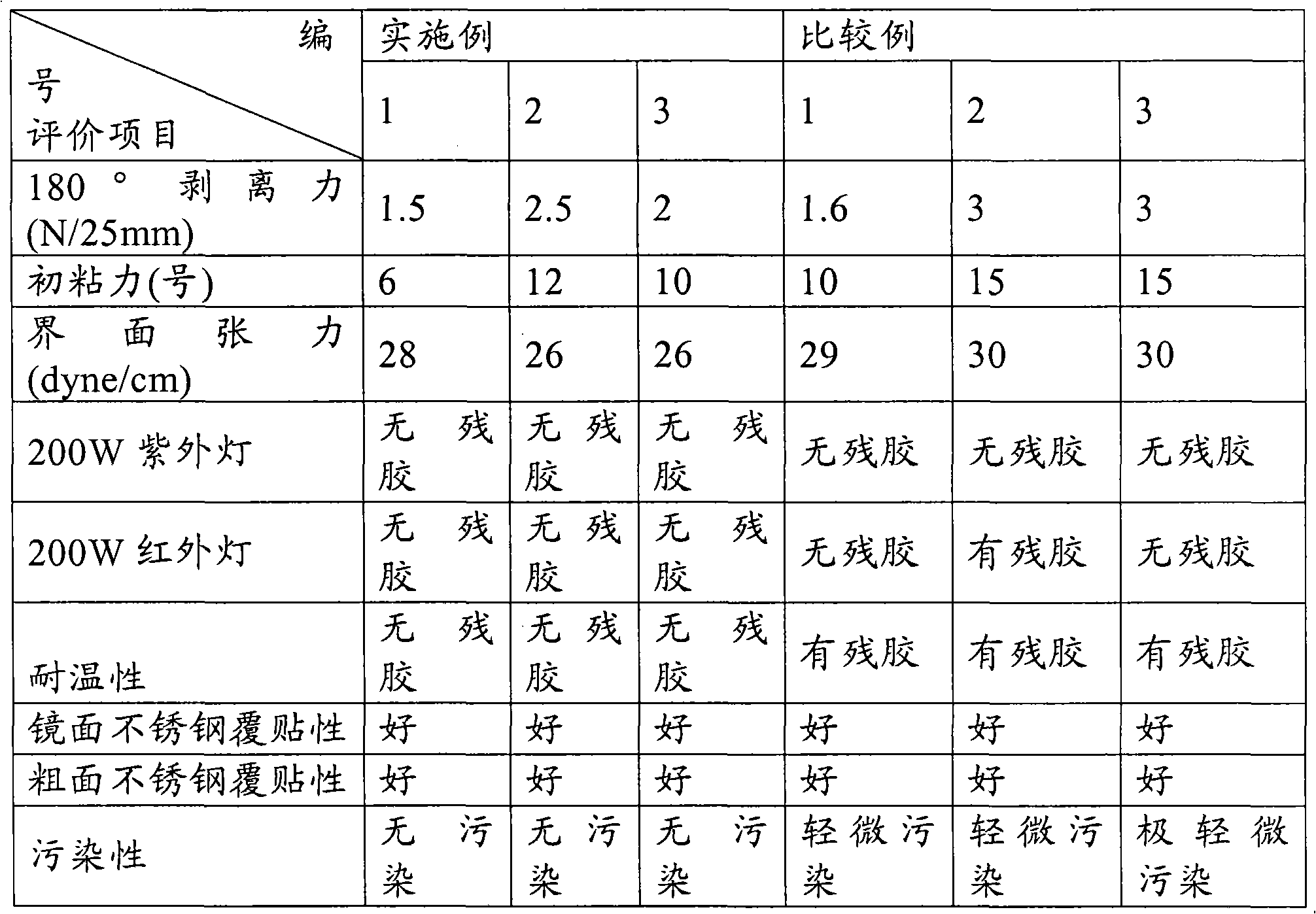

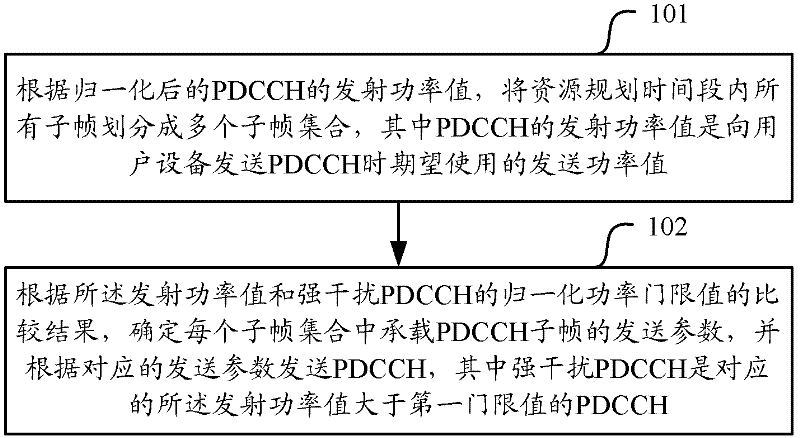

Method for sending PDCCHs (Physical Downlink Control Channels) and equipment for sending PDCCHs

ActiveCN102404853AImprove overlay performanceReduce distractionsPower managementNetwork traffic/resource managementTelecommunicationsResource planning

The embodiment of the invention relates to the technical field of wireless communications and particularly relates to a method for sending PDCCHs (Physical Downlink Control Channels) and equipment for sending the PDCCHs which are used for solving the problem that the inter-cell interference (ICI) of a downlink control area is strong in the prior art. The method comprises the following steps of: dividing all subframes in a resource planning time period into a plurality of subframe sets according to normalized transmitting power values of the PDCCHs; and determining transmitting parameters which bear subframes of the PDCCHs in each subframe set according to a compared result of the transmitting power values and normalized power threshold values of the PDCCHs with strong interference, and further, sending the PDCCHs according to corresponding transmitting parameters, wherein the PDCCHs with the strong interference are the PDCCHs of which the transmitting power values are larger than first threshold values correspondingly. When the transmitting parameters which bear the subframes of the PDCCHs are determined, the ICI is considered; therefore, the ICI of the downlink control area is lowered.

Owner:DATANG MOBILE COMM EQUIP CO LTD

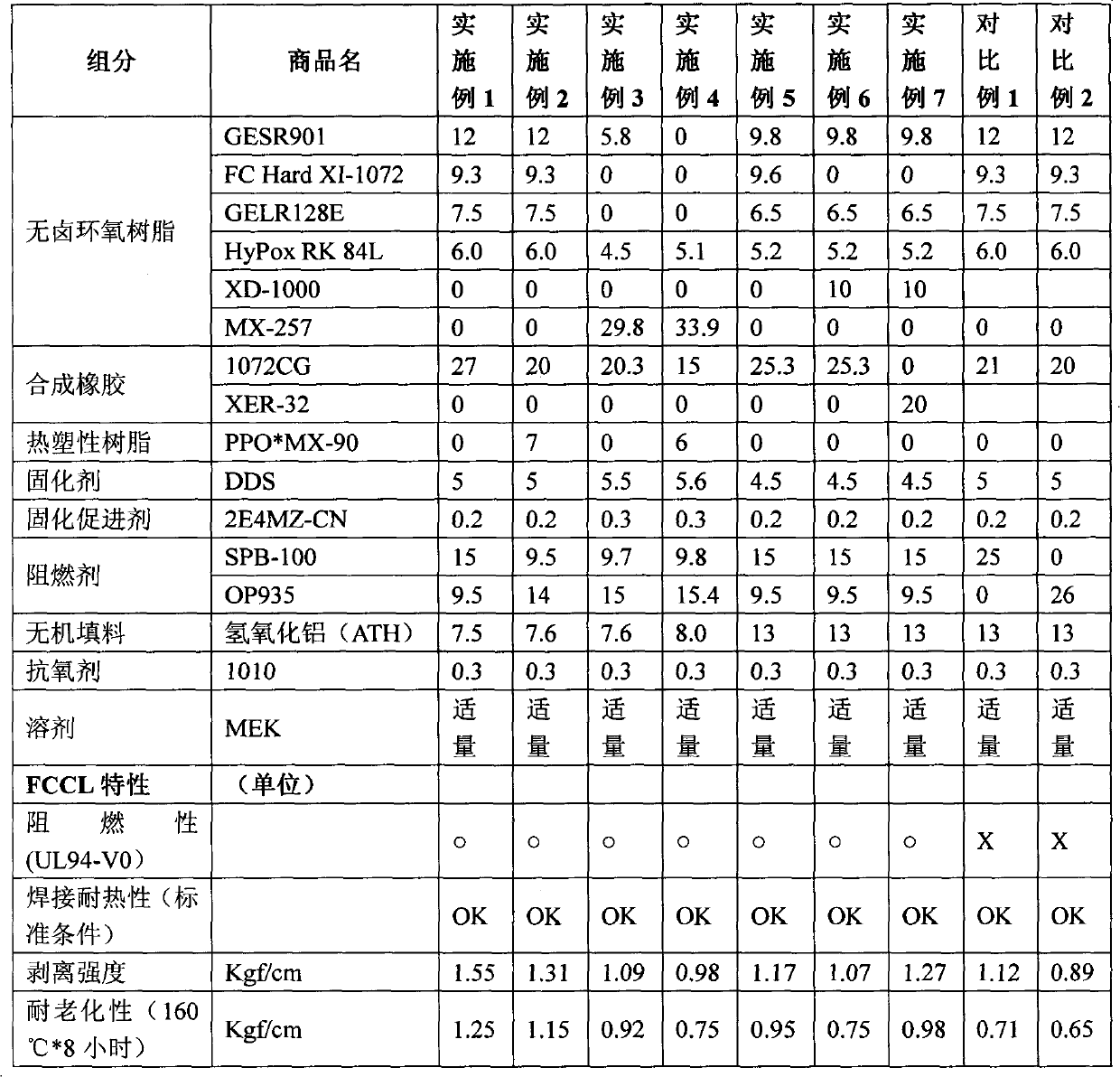

Halogen-free flame-retardant adhesive composition and flexible copper-clad plate using same

ActiveCN101921557AImprove heat resistanceHigh peel strengthNon-macromolecular adhesive additivesCarboxyl rubber adhesivesEpoxyDip soldering

The invention discloses a halogen-free flame-retardant adhesive composition. The composition comprises the following components in part by weight: 15 to 45 parts of halogen-free epoxy resin, 15 to 60 parts of thermoplastic resin and / or synthetic rubber, 0.1 to 8 parts of curing agent and 5 to 60 parts of phosphorus-containing composite flame retardant. The invention also discloses a flexible copper-clad plate using the adhesive composition. The cured product of the adhesive composition provided by the invention shows high flame retardance, peeling strength, electric performance and welding heat resistance, does not comprise harmful substances or elements such as halogen, antimonide and the like and does not pollute environment; the flame retardant rating of the flexible copper-clad plate prepared from the composition of the invention reaches UL-94V0, and the flexible copper-clad plate also has the advantages of high heat resistance, high peeling strength, soldering resistance, no demixing after being subjected to dip soldering at the temperature of 300 DEG C for 1 minute and no bubbles; and because the halogen-free composition of the invention has high sticking performance, the speed of a production line can be increased and the production efficiency is improved.

Owner:ALLSTAE TECH ZHONGSHAN

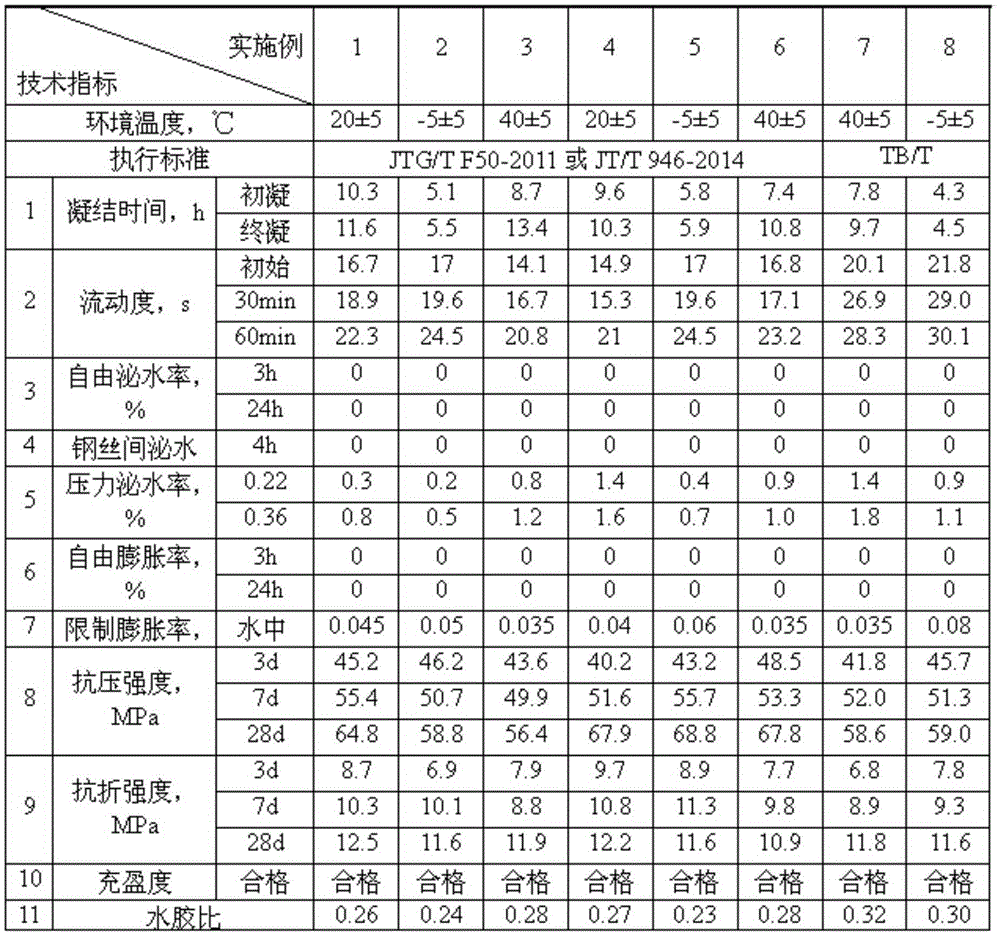

Pre-stressed duct grouting agent, and preparation and application methods thereof

The invention provides a pre-stressed duct grouting agent which has the characteristics of high fluidity, bleeding prevention and the like. The pre-stressed duct grouting agent comprises the following components: 2 to 10 percent of a water reducing agent, 0.1 to 10 percent of a viscosity modifying agent, 0 to 1 percent of a defoaming agent, and 35 to 78 percent of a coagulation time regulating agent; the coagulation time regulating agent comprises the following components: 28 to 52 percent of clinker, 42 to 68 percent of plaster, 4 to 30 percent of fillers, and 0 to 3 percent of a coagulation accelerator. The invention further provides a preparation method and an application method of the pre-stressed duct grouting agent. The invention has the advantages that the pre-stressed duct grouting agent contains the cement coagulation time regulating agent, so that the coagulation time of a cement-based composite material can be regulated based on external temperature changes to guarantee the normal use and normal strength growth of the cement-based composite material; meanwhile, the cement-based composite material achieves micro-expansion at the later stage due to the addition of the cement coagulation time regulating agent.

Owner:WUHAN BILLION TECH DEV CO LTD

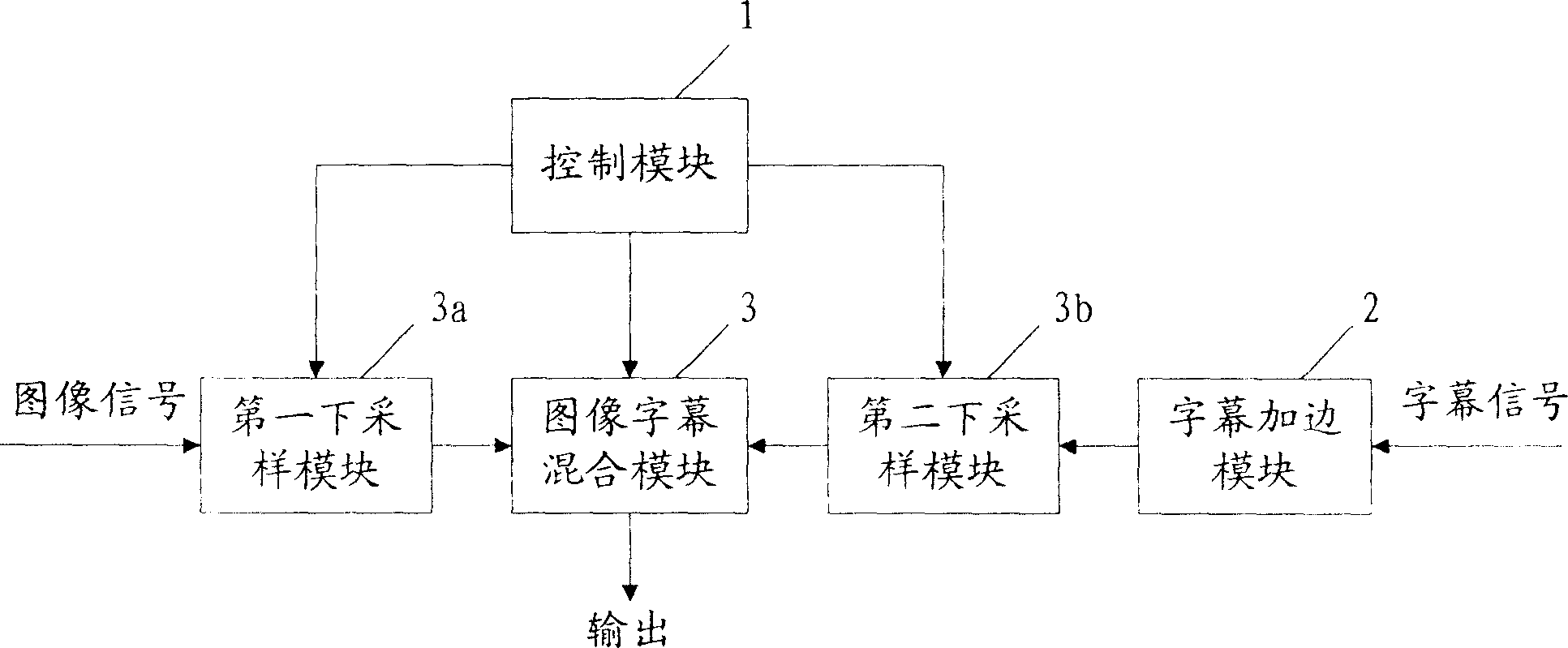

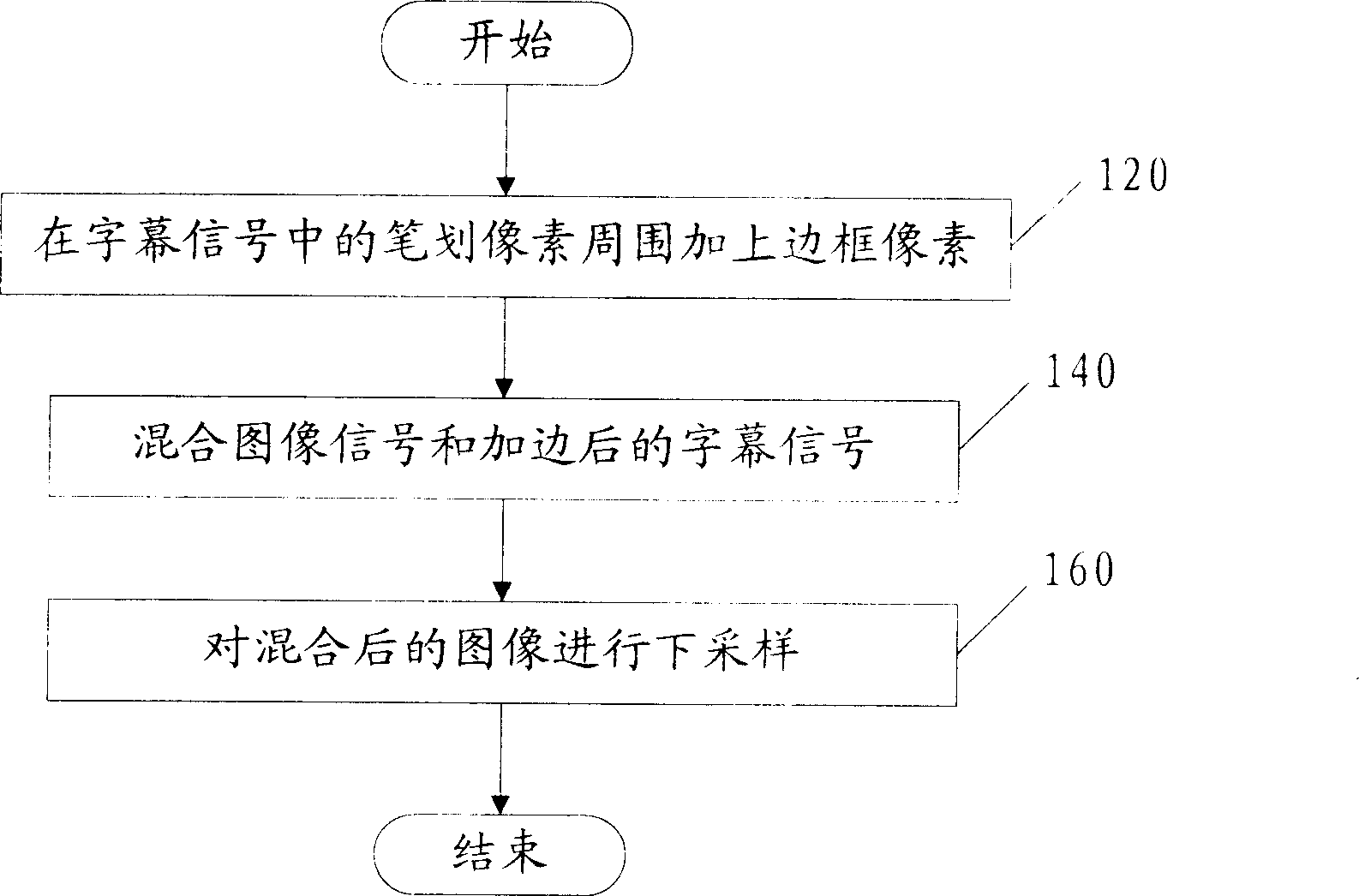

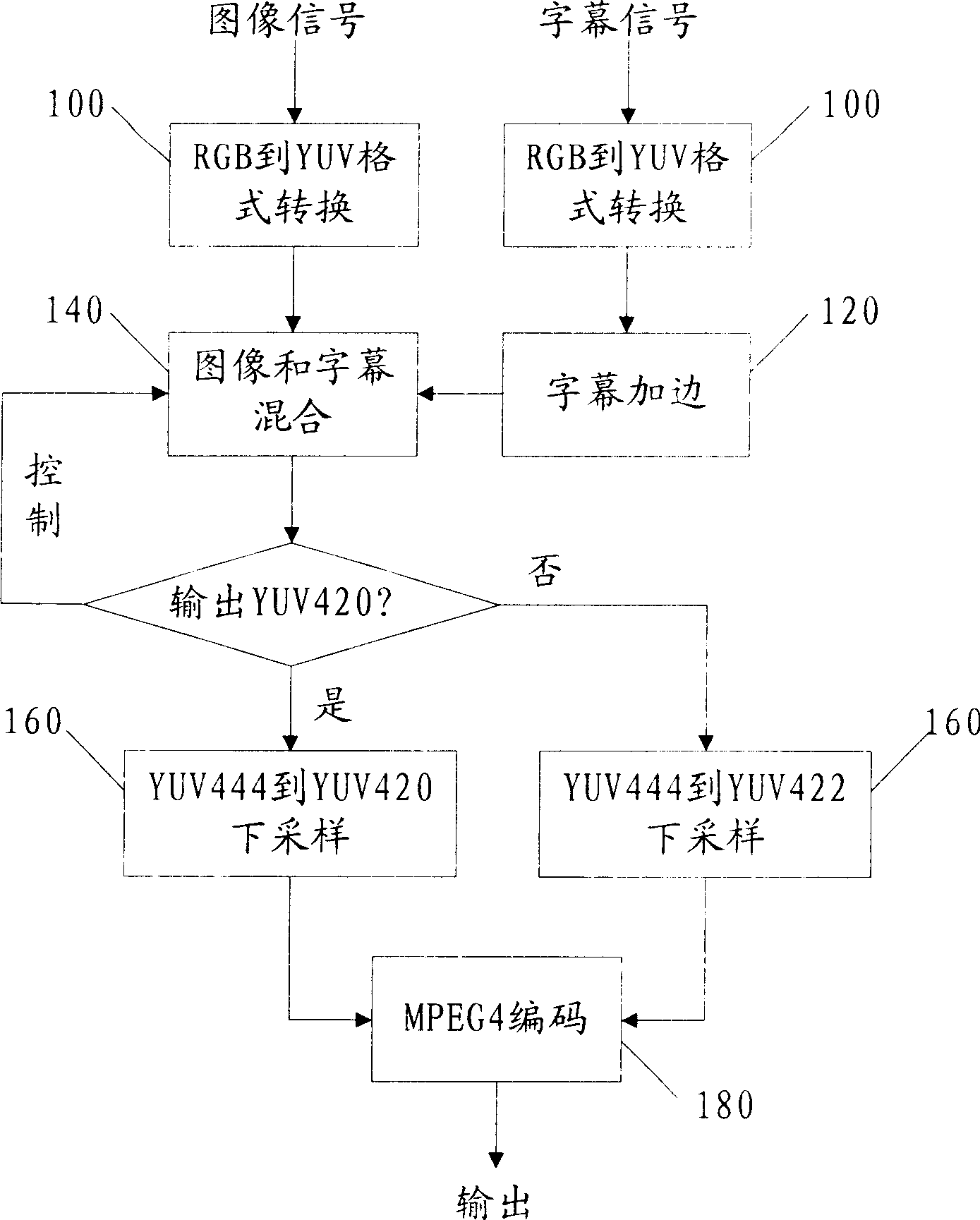

Captions adding system and method

InactiveCN1889636AImprove overlay performanceSolve the problem of color pollutionTelevision system detailsColor television detailsComputer scienceImage signal

A caption adding system is featured as connecting control module to the first and the second sampling modules as well as image-caption mixing module, connecting image-caption mixing module separately to the first sampling module and the second sampling module, inputting image signal to image-caption mixing module via the first sampling module, inputting caption signal to image-caption mixing module via caption edging module and the second sampling module, outputting mixed image and caption signal from image-caption mixing module.

Owner:CHIPNUTS TECH INC

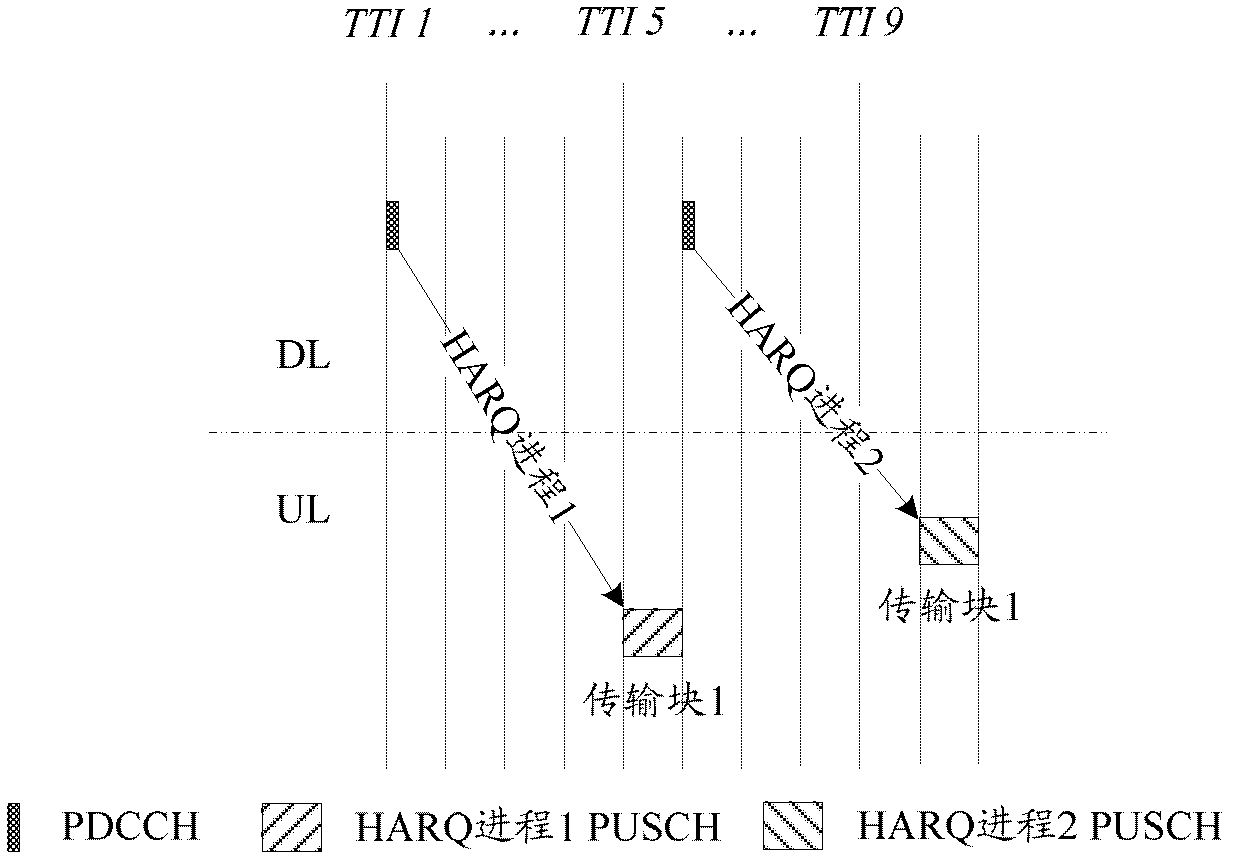

Method and device for enhancing uplink coverage, and base station

ActiveCN103313270AImprove overlay performanceAchieve flexibilityError prevention/detection by using return channelNetwork planningReal-time computingTransmission time

The invention discloses a method and a device for enhancing uplink coverage, and a base station. The method comprises the step that a network side controls UE (user equipment) to use more than two HARQ (hybrid automatic repeat request) processes to transmit the same UL (uplink) transmission block. According to the method disclosed by the invention, the base station controls the UE to use more than two HARQ processes to transmit the same UL transmission block and controls the enhancement of the uplink coverage by controlling the cluster length of the TTI (transmission time interval) and the maximum trial transmission times of the HARQ processes, so that not only can the coverage performance of the UL be improved, but also the flexibility of the resource allocation can be realized.

Owner:ZTE CORP

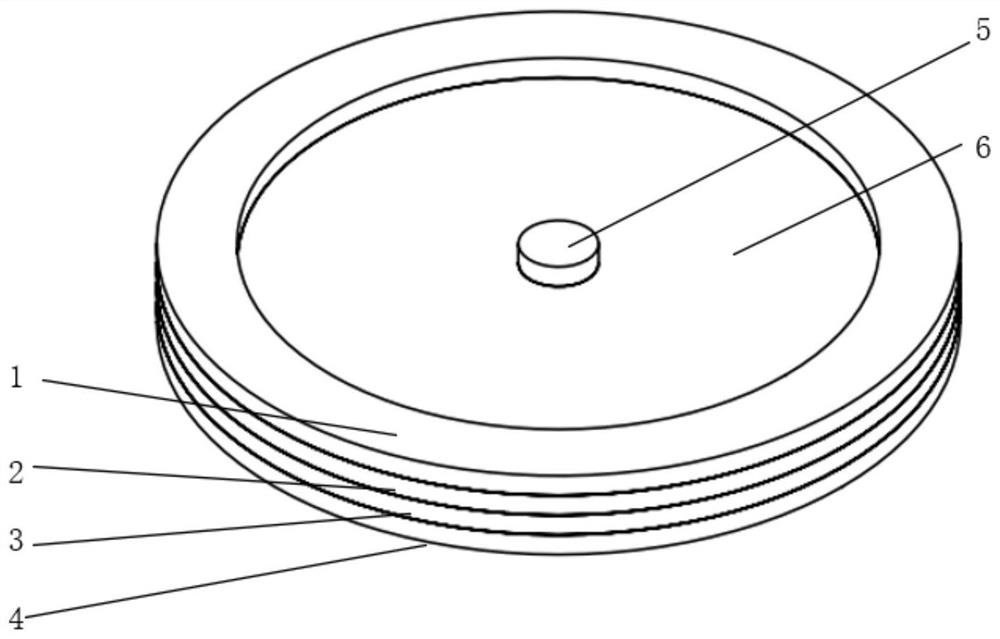

Multi-layer film type acoustic meta-material structure and design method thereof

PendingCN113409753AIncrease amplitudeBroaden the frequency band of sound insulationSound producing devicesLow noiseNoise

The invention discloses a multi-layer film type acoustic meta-material structure and a design method thereof. The meta-material structure comprises a plurality of stacked film type acoustic meta-material units with different structural parameters, and each meta-material unit is divided by a hard frame to form the wide-frequency-band low-frequency sound insulation structure with a plurality of sound insulation peaks. The method comprises the following steps: calculating the sound insulation peak frequency of a meta-material unit; and according to the sound insulation peak frequency, constructing the acoustic meta-material structure in one form of equal spacing, peak value and valley value complementing and noise source customization. The structure can be applied to various vehicles and building decoration, and a brand new noise reduction method is provided for creating a low-noise environment.

Owner:SOUTH CHINA UNIV OF TECH

System and method of image captions adding

InactiveCN1905643AImprove overlay performanceSolve the problem of color pollutionTelevision system detailsColor television detailsColor imageMethod of images

The invention relates to a system and method for superimposing subtitles on dynamic or static images. The existing method has the defects on pollution of each other's color images and subtitles through the way of superimposing subtitles on the video content directly. The system includes a control module, a hybrid module and an image sampling module, which are connected with each other. The image-signals are input at one end of the hybrid module. The subtitle-signals are input at the other end of the hybrid module by the subtitles bordering module involved in the described system. Then the mixed signals of images and subtitles are output through the image sampling module.

Owner:CHIPNUTS TECH INC

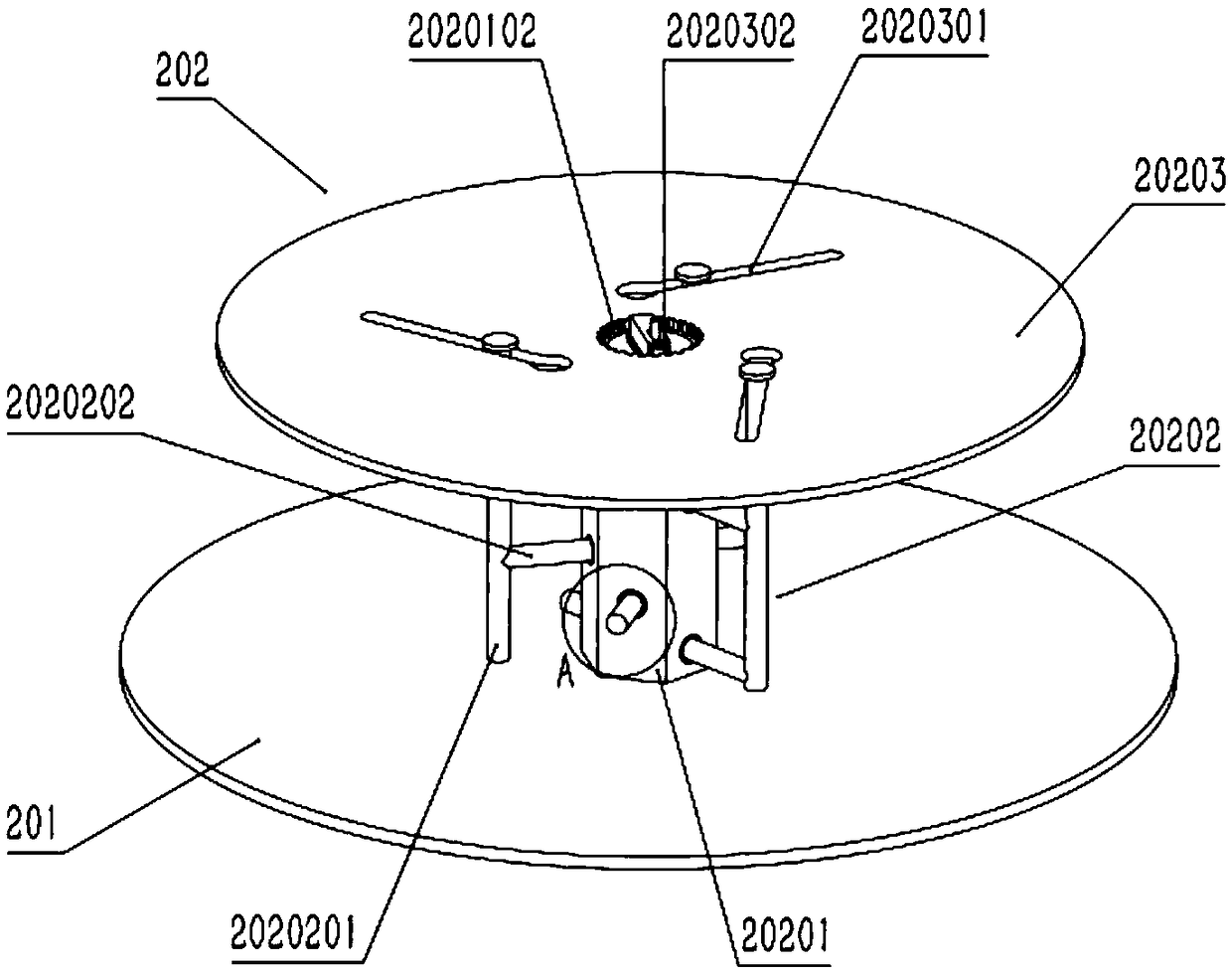

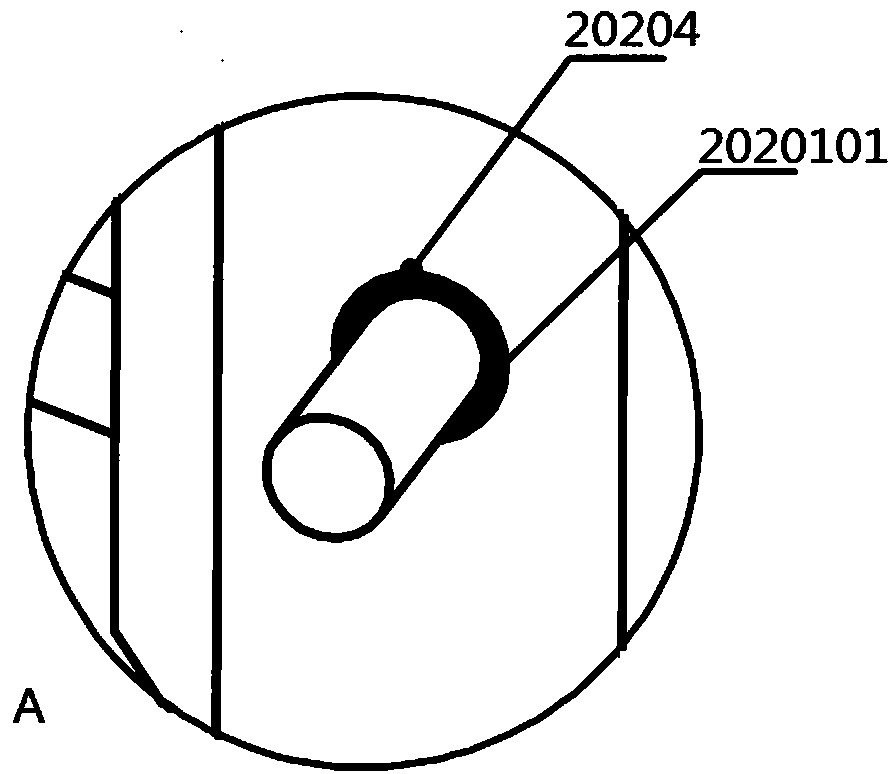

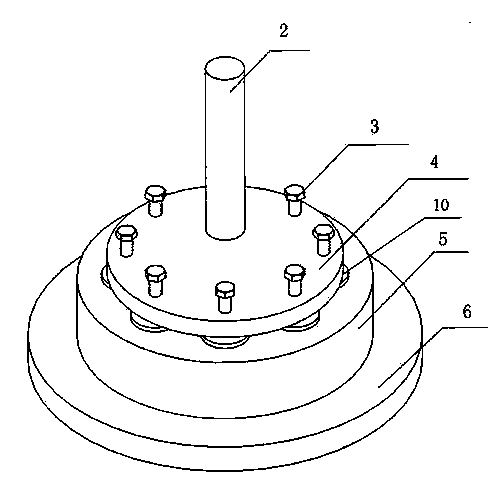

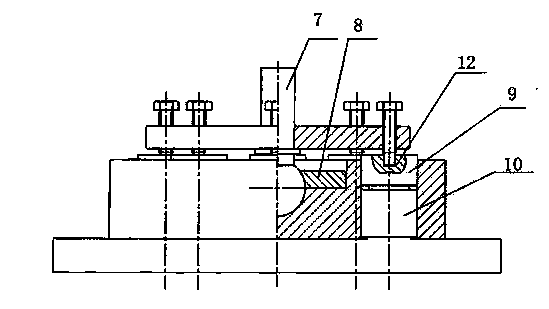

Small multilayer pay-off device

PendingCN109335835AAchieving Aperture RequirementsRealize one-way self-lockingFilament handlingEngineeringStructural framework

The invention relates to a small multilayer pay-off device, and belongs to the field of production application. The small multilayer pay-off device is composed of a structural framework and wire supporting discs. The small multilayer pay-off device is characterized in that a central rotating shaft and universal wheels are arranged on the structural framework, moreover, wire leading ports are formed in the structural framework, the wire supporting discs are supported through the universal wheels, the central rotating shaft penetrates through the wire supporting discs so that the wire supportingdiscs can rotate around the central rotating shaft, when wire coils are replaced, the wire supporting discs are supported upwards supports so as to be away from the central rotating shaft, and the wire supporting discs are taken out from one side of the structural framework, and the wire supporting discs are installed in the structural framework again after new wire coils are loaded into the wiresupporting discs. According to the small multilayer pay-off device, the structure is firm, the use is convenient, and the taking and use efficiency of electric wires, packaging pipes and other soft materials which are packaged by turns is greatly improved.

Owner:济南图马机电设备有限公司

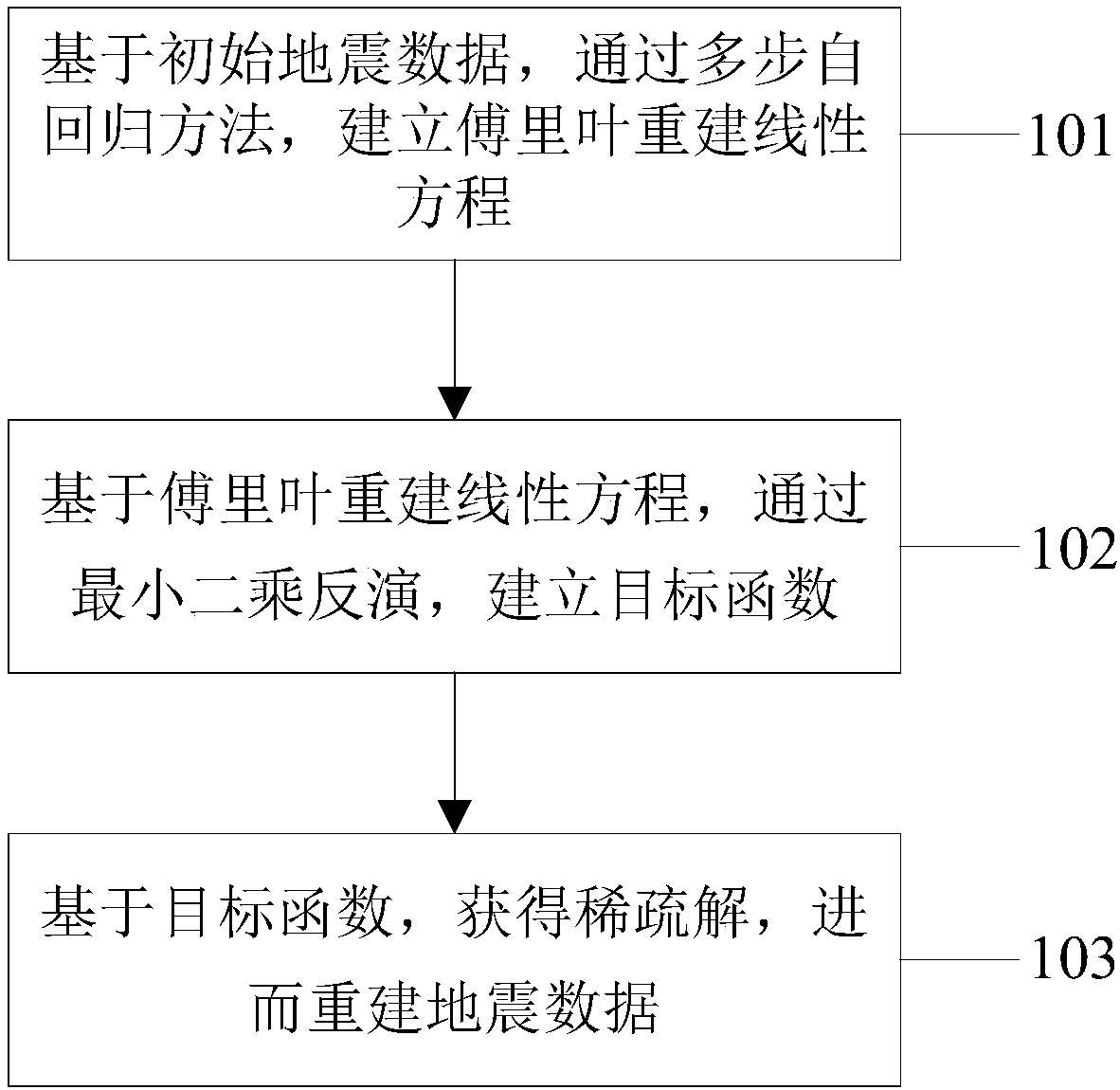

Method and system for reconstructing seismic data based on Fourier transform

InactiveCN109557581AAccurate reconstructionGood application effectSeismic signal processingFast Fourier transformReconstruction method

A method and system for reconstructing seismic data based on Fourier transform are disclosed. The method may comprise the following steps: establishing a Fourier reconstruction linear equation by a multi-step autoregressive method based on initial seismic data; establishing a target function by least squares inversion based on Fourier reconstruction linear equation; obtaining a sparse solution based on the objective function, and further reconstructing seismic data. The method combines the least squares Fourier reconstruction method and the multi-step autoregressive method to obtain a good application effect for accurately reconstructing complex seismic data, which plays a very important role for improving the precision of subsequent velocity analysis, improving the superposition effect, enhancing the quality of pre-stack migration, etc.

Owner:CHINA PETROLEUM & CHEM CORP +1

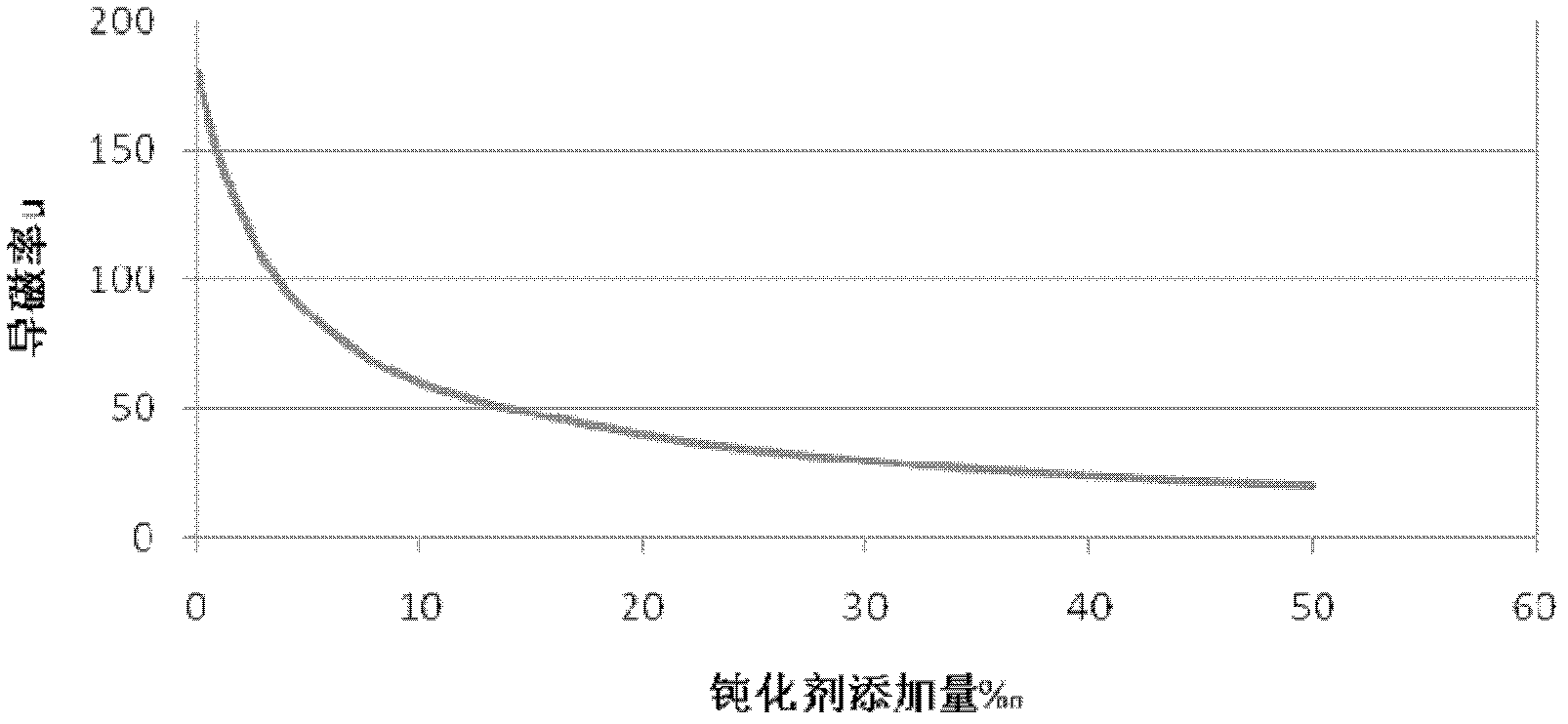

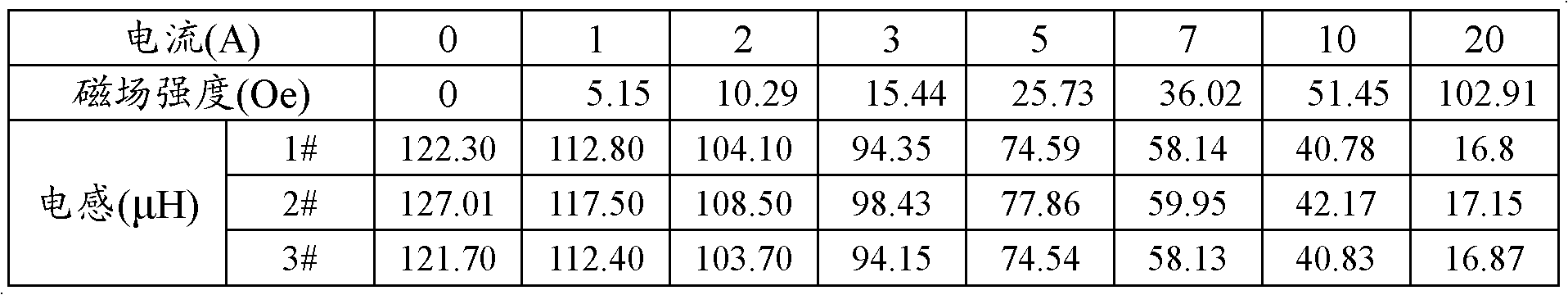

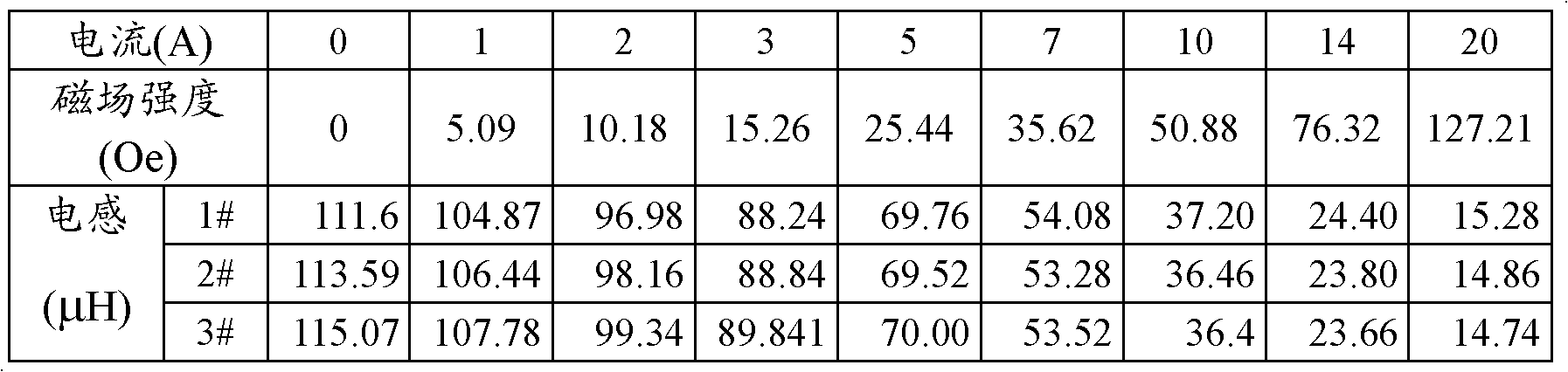

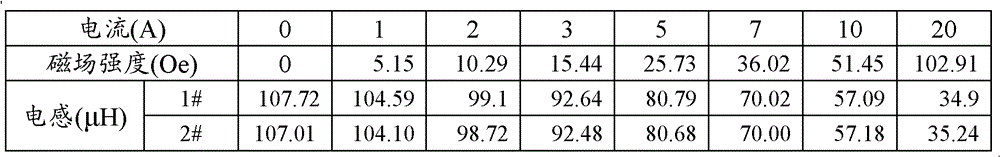

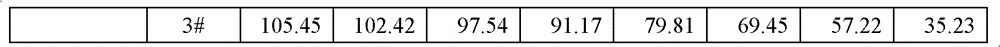

Manufacturing method for ferrum-silicon-aluminum magnetic cores

ActiveCN102982990AEasy to dry pressHigh densityInorganic material magnetismInductances/transformers/magnets manufactureSiliconHeat treated

The invention relates to a manufacturing method for ferrum-silicon-aluminum magnetic cores. The manufacturing method for the ferrum-silicon-aluminum magnetic cores includes that ferrum-silicon-aluminum magnetic powder is processed through acid and then dry-pressed, so that the power is easy to mold, product density is improved, and meanwhile, the power can achieve high magnetic conductivity after heat treatment. Compared with the prior art, the manufacturing method for the ferrum-silicon-aluminum magnetic cores has the advantages that by means of control of the appending proportion, intensity of pressure of molding, sintering temperature and the like in power allocation, the ferrum-silicon-aluminum magnetic cores with 147 (+ / - 8%) of magnetic conductivity are manufactured, and the ferrum-silicon-aluminum magnetic cores are low in iron loss and good in composition performance; process sequences are simple; and raw and auxiliary materials are low in cost.

Owner:湖南普盛新材料有限公司

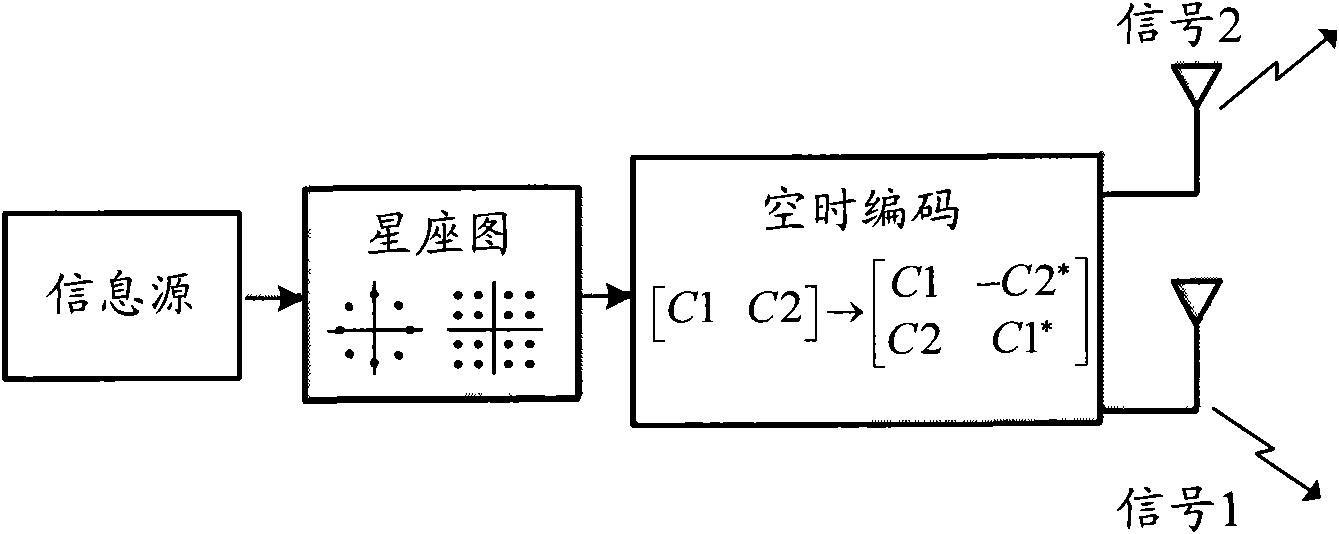

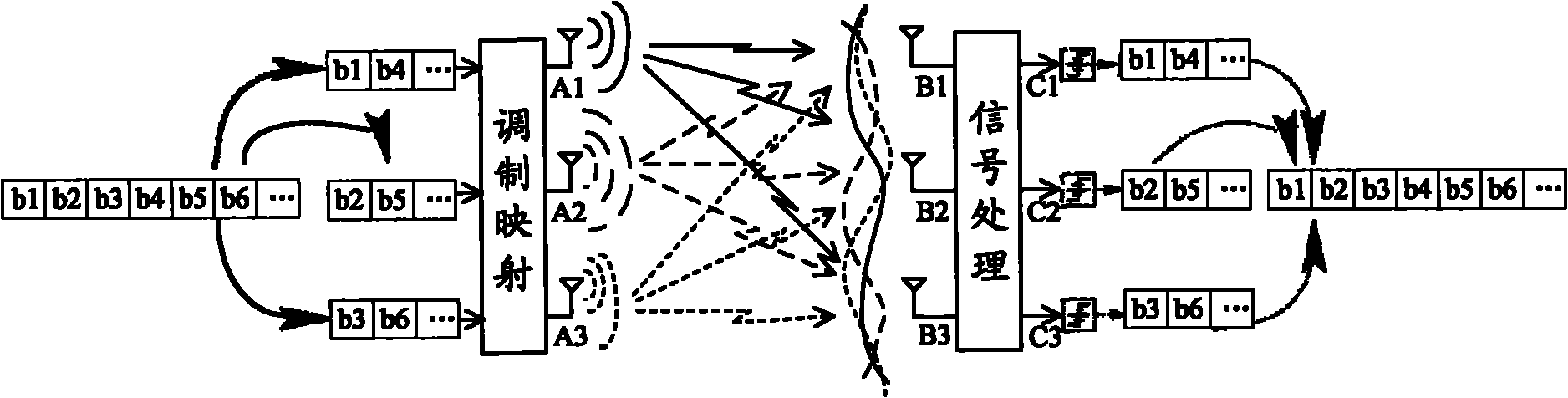

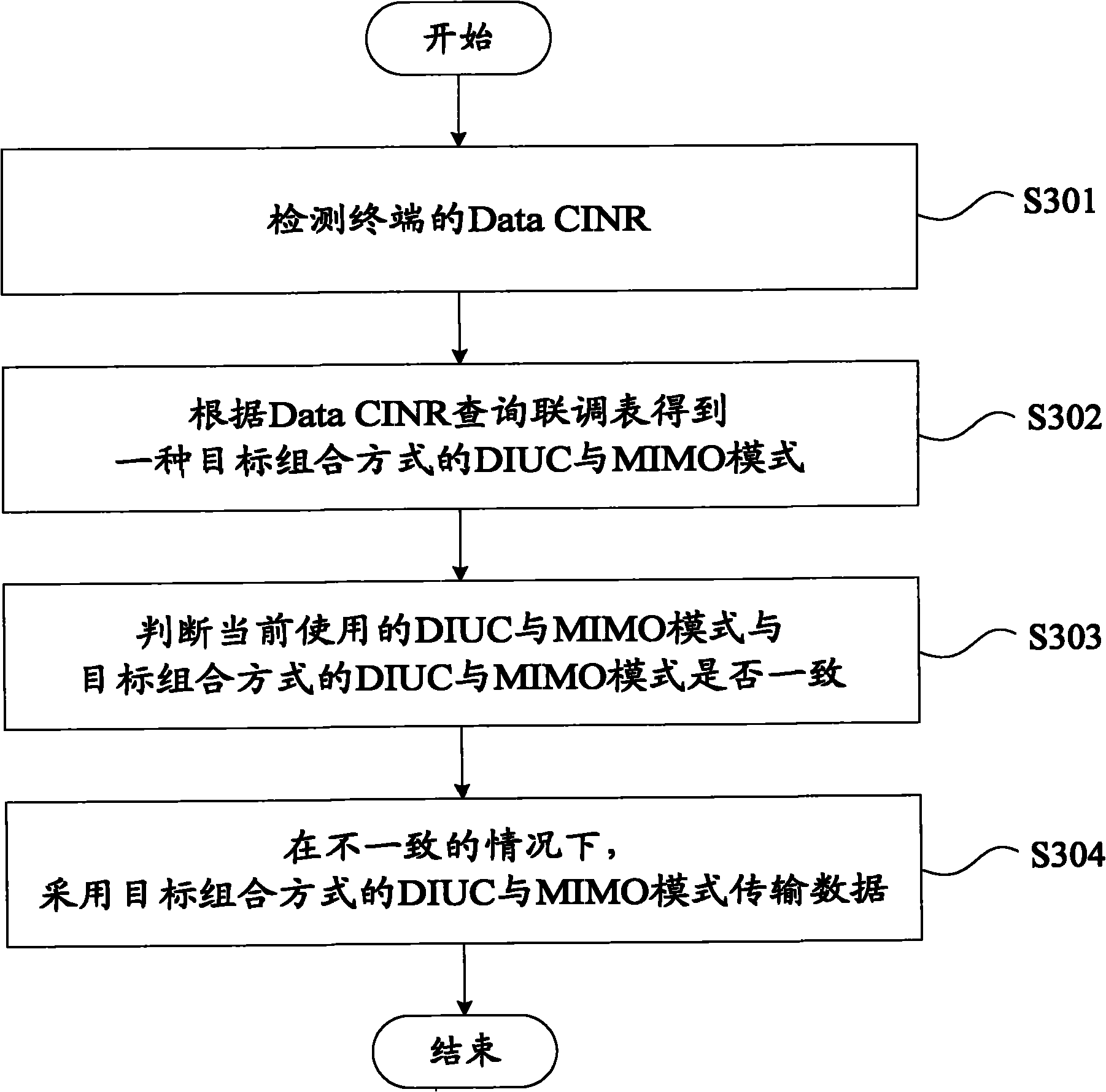

Data transmission method and device for multiple-input multiple-output system

ActiveCN101998538ARealize adaptive adjustmentImprove overlay performanceNetwork traffic/resource managementDiversity/multi-antenna systemsFrequency spectrumDependability

The invention provides data transmission method and device for a multiple-input multiple-output system. The data transmission method comprises the following steps of: checking a data area-carry interference-to-noise ratio of a terminal; obtaining a modulation coding mode and a multiple-input multiple-output mode of an object combination mode according to a data area-carry interference-to-noise ratio inquiry joint debugging table, wherein the joint debugging table is used for recording the mapping relation of various combination modes of the modulation code mode and the multiple-input multiple-output mode corresponding to the data area-carry interference-to-noise ratio; and transmitting data by adopting the modulation coding mode and the multiple-input multiple-output mode of the object combination mode. The invention realizes the self-adapting regulation of DIUC (Downlink Interval Usage Code) and MIMO (Multiple-Input Multiple-Output) modes in a data transmission process, increases frequency spectrum availability, thereby increasing system throughput and link reliability and overcoming the problems of lower system throughput and lower link reliability caused by mutually and independently determining and switching the DIUC and MIMO modes of the data transmission method in the correlation technology.

Owner:ZTE CORP

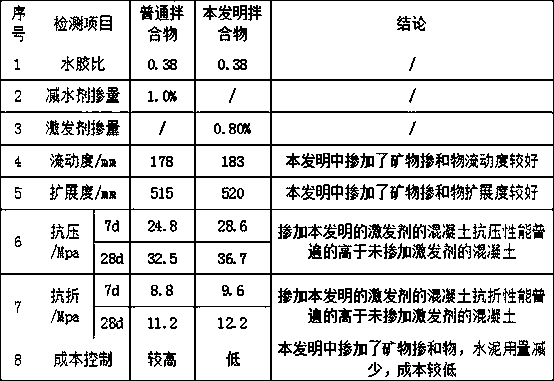

Compound type exciting agent and preparation method thereof

The invention relates to an additive for concrete and in particular relates to the additive which is mainly applied to a concrete mixture system added with a mineral admixture in the field of the concrete and has an exciting effect on the mineral admixture. The invention designs a compound type exciting agent; auxiliary agents including a water reducing agent, a defoaming agent, a viscosity reducer and the like are added on the basis of the exciting agent to participate in preparation; the exciting agent prepared by the invention has a good exciting effect on the mineral admixture and cement;the dosage of the mineral admixture can be increased in a utilization process, so that the production cost is reduced and the property of the concrete also can be enhanced. The compound type excitingagent is applied to a concrete system; two substances including fly ash and mineral powder are mainly used as the admixture and various exciting type chemical substances are added to prepare the compound type exciting agent; the substances with the exciting effect are mutually stacked to use so that the corresponding effects are mutually complemented to reach the maximum exciting effect.

Owner:云南森博混凝土外加剂有限公司

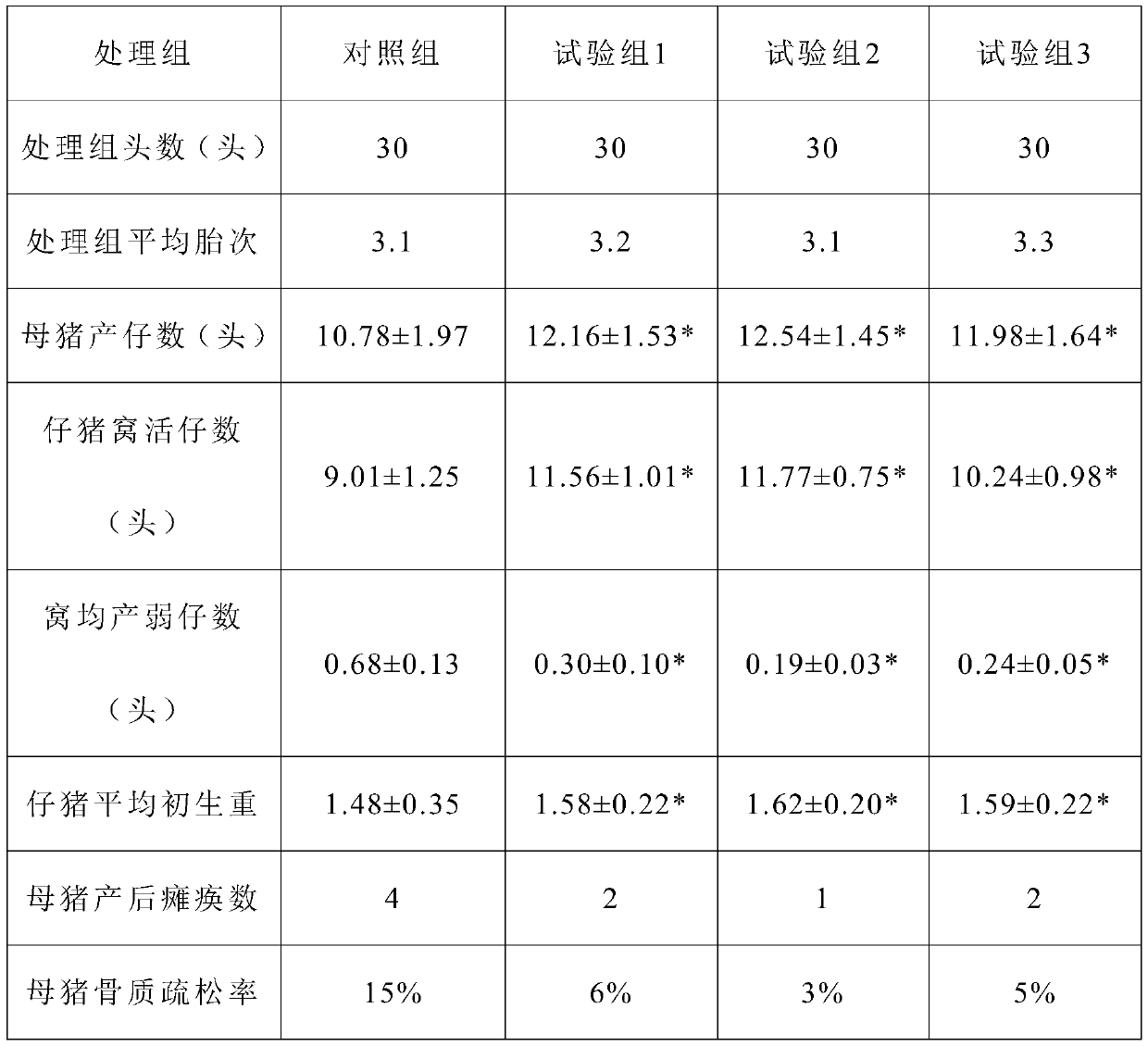

Feed additive for improving bone strength of sows and improving reproductive performance of sows

The invention provides a feed additive for improving bone strength of sows and improving reproductive performance of the sows and a preparing method of the feed additive, and belongs to the technicalfield of feed additives of sows. The feed additive is prepared from compound Chinese herbal medicines, compound organic microelements, multivitamins, microecologics, other nutrients and a carrier, wherein the compound Chinese herbal medicines involve herba epimedii, radix scutellariae, radix puerariae, fructus psoraleae, soy isoflavone, rhizoma drynariae, catechinic acid, radix morindae officinalis, cowherb seeds and camellia saponin; the compound organic microelements comprise methionine chelate zinc, ferrous fumarate, selenium saccharomyces cerevisiae, copper mothionine and manganese bisglycinate; the multivitamins comprise 25-hydroxyvitamin D3, beta-carotene, vitamin A, vitamin E, vitamin B2, vitamin B12, vitamin K2, folic acid, nicotinic acid and biotin; the microecologics involve bacillus natto and candida utilis; the other nutrients involve lactobionic acid, linoleic acid and beta-glucosan fibers. By means of the feed additive, the bone strength of the sows can be improved, the production performance is improved, the mortality of the sows due to trophism limb and hoof diseases is reduced, and the benefits of the pig industry are increased.

Owner:播恩集团股份有限公司

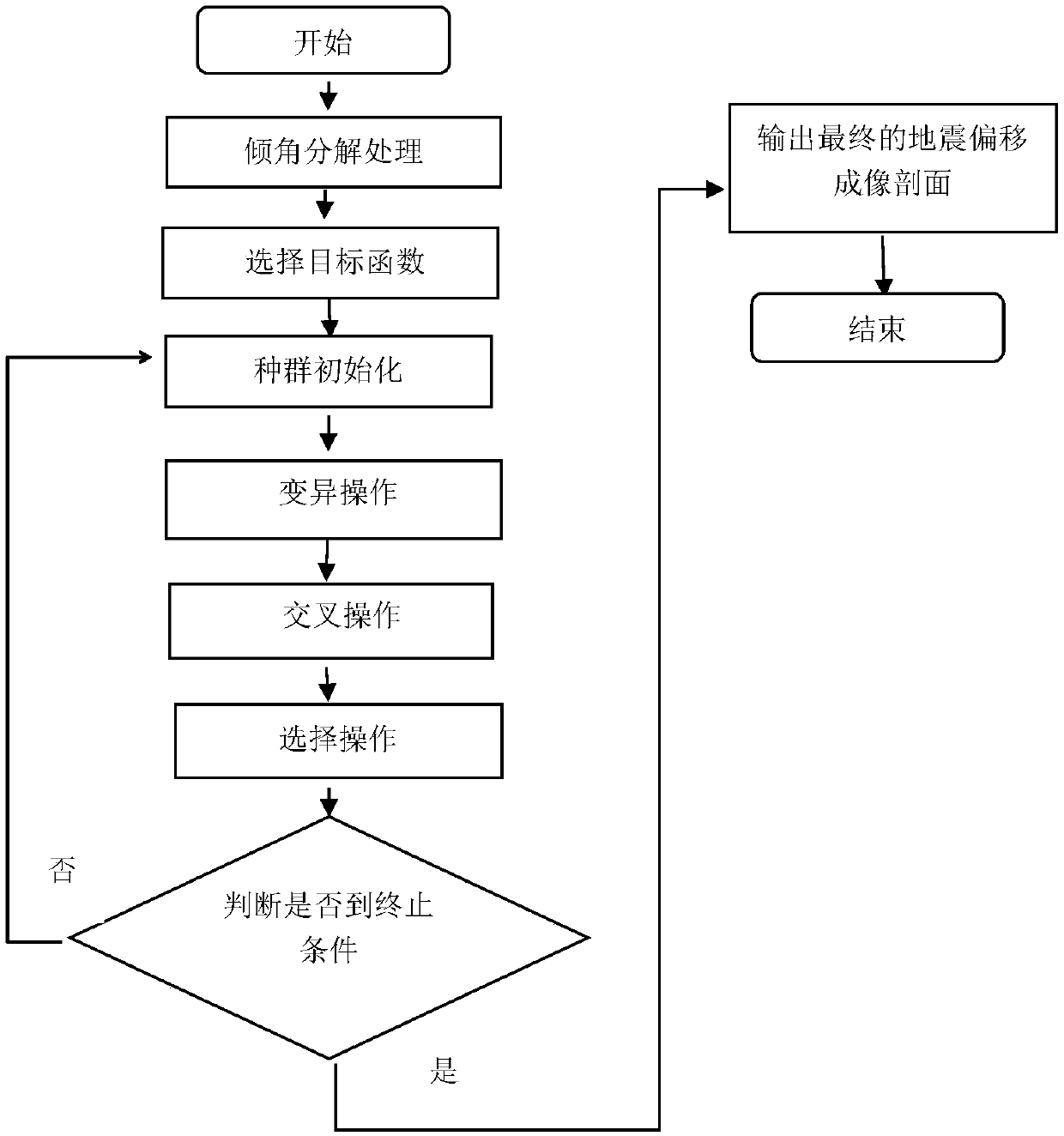

Differential evolution algorithm-based CRS dip decomposition method

ActiveCN109557585AImprovement effectImprove overlay performanceSeismic signal processingDifferential evolutionData processing

The invention belongs to the field of oil-gas exploration seismic data processing, and specifically relates to a differential evolution algorithm-based CRS dip decomposition method. According to the method, a dip is divided into a plurality of parts through dispersing an emergence angle alpha, a parameter with a highest similarity is obtained for each part on the basis of a differential evolutionalgorithm, and finally the parts are superposed. According to the differential evolution algorithm-based CRS dip decomposition method, in order to solve coherent values of three independent variablesalpha, RNIP and RN, a correlation coefficient for balancing the sizes of the coherent values is used as a target function to search three parameters. An angle parameter range of the whole search spaceis divided into relatively small parts, so that event information which interferes mutually to cause shielding can be recognized. Through combining dip division with a global optimization scheme, complicated subsurface structure conditions are effectively restored and the effect of common reflection surface superposition is improved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Preparation method of manganese-zinc soft magnetic ferrite material

The invention discloses a preparation method of a manganese-zinc soft magnetic ferrite material, and belongs to the technical field of soft magnetic ferrite. The preparation method comprises the steps that ferric oxide, manganese carbonate, hydrochloric acid and the like are put into a ball mill for ball milling; a ball milling mixture is collected, dried in a drying oven and then crushed in a crusher to obtain sieving particles; uniform stirring with triethanolamine, tetrabutyl titanate and the like is performed; the mixture is calcined; a calcined product, strontium carbonate, columbic anhydride, calcium oxide and zirconium boride are subjected to ball milling treatment, and then fused and milled in an electric furnace; a milling mixture is uniformly mixed with a polyvinyl alcohol solution; spray drying is performed; a dried product is put into a mold, pressed by a pressing machine, and calcined in a calcining furnace; and a calcined product is collected to obtain the manganese-zinc soft magnetic ferrite material. The manganese-zinc soft magnetic ferrite material prepared by the method has higher purity and stable performance.

Owner:TRUSYN CHEM TECH

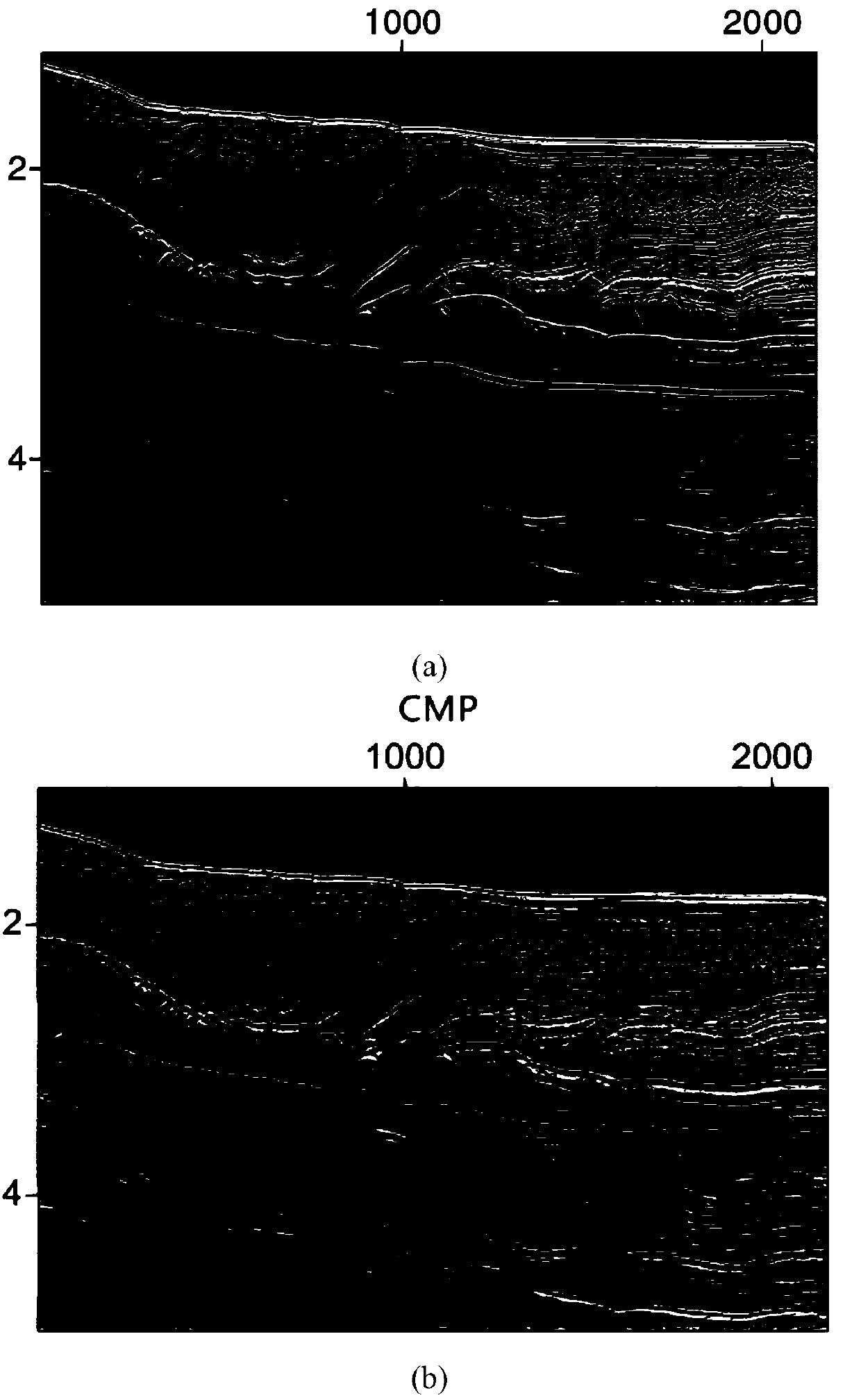

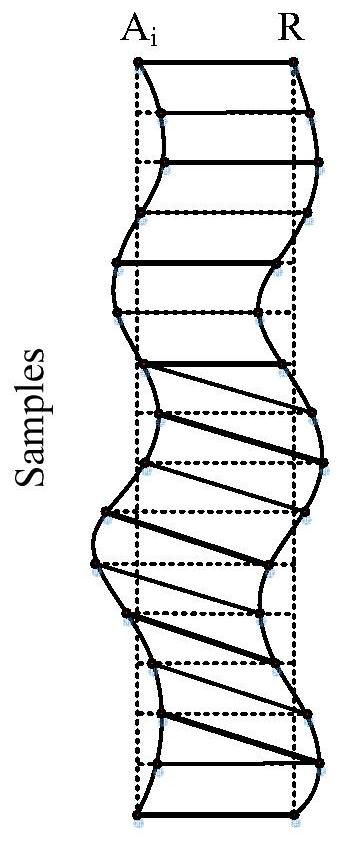

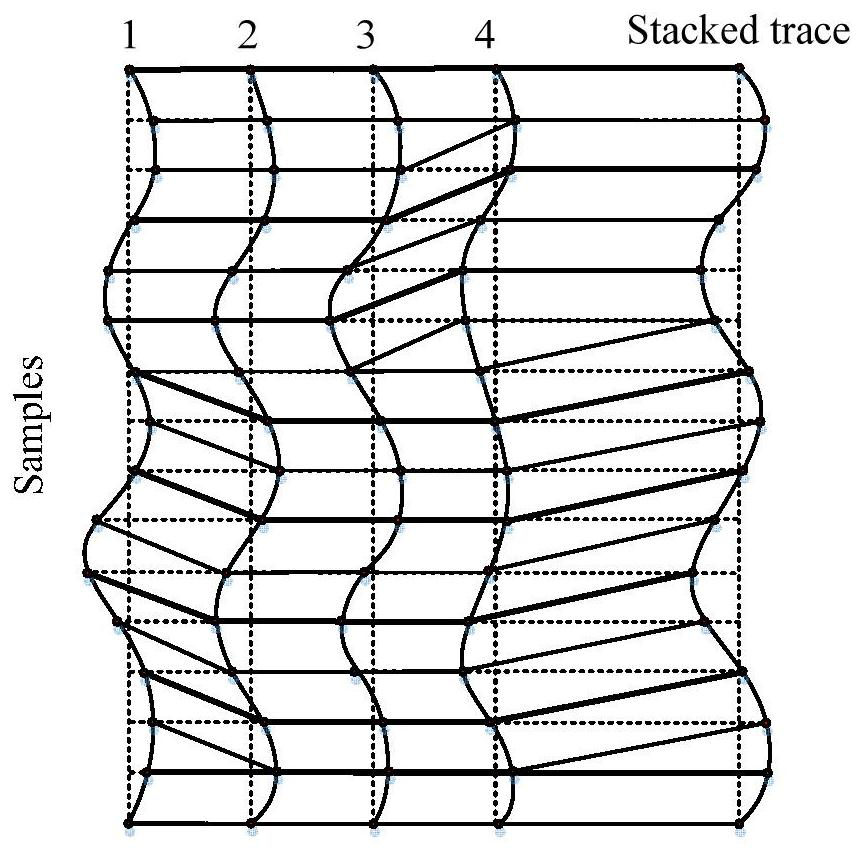

Seismic data weighted stacking method based on dynamic time warping

ActiveCN111610566ATake advantage ofImprove overlay performanceSeismic signal processingSynthetic dataSeismic trace

The invention provides a seismic data weighted stacking method based on dynamic time warping. The method comprises the steps of S1 selecting a reference seismic trace, and setting the reference seismic trace as an arithmetic mean value of a pre-stack seismic data matrix in a spatial direction; S2 calculating DTW matching points between each pre-stack seismic trace and the reference seismic trace through the following formula, and searching sampling points associated with each sampling point of the reference seismic trace in the CMP trace set; S3 setting the weight of each sampling point according to the noise of each related sampling point; S4 updating each sampling point of the reference seismic trace as a weighted average value of the sampling points related to the sampling point; and S5repeating the steps S2 to S4 until convergence, and outputting the reference seismic trace as a final superimposed seismic trace. According to the method, the advantages of a DTW method and a weighted stacking method are combined, the influence of seismic trace time migration errors and seismic data noise on data stacking is overcome, and a good application effect is obtained through testing on synthetic data and real seismic data.

Owner:CHONGQING UNIV OF TECH

Wind generating set based on direct piezoelectric effect

InactiveCN103758701ASimple structureEasy to manufacture and installFinal product manufactureWind motor combinationsElectricityEngineering

The invention discloses a wind generating set based on direct piezoelectric effect, comprising a windward member, a piezoelectric generating component and a subsequent processing circuit module. The wind generating set generates power from wind by combining wind energy utilization and piezoelectric power generation and has the advantages of simple structure, convenience in mounting, manufacturing and maintenance, low cost, high wind energy utilization rate, low start wind speed and the like.

Owner:JILIN UNIV

A prestressed channel grouting agent and its preparation and use method

The invention provides a prestressed channel grouting agent with the characteristics of high fluidity and no bleeding, which comprises the following components: 2-10% of water reducing agent, 0.1-10% of viscosity modifier, and 0.0% of defoaming agent ~1%, setting time regulator 35~78%; the setting time regulator includes the following components: clinker 28~52%; gypsum 42~68%; filler 4~30%; %; The present invention also provides a preparation method and a use method of the above-mentioned prestressed channel grouting agent. Because the present invention contains the cement setting time regulator, it can adjust the setting time of the cement-based composite material according to the change of external air temperature, so as to ensure the normal use and normal growth of the strength of the cement-based composite material. At the same time, the addition of the cement setting time regulator makes the Cement-based composites produce micro-expansion in the later stage.

Owner:WUHAN BILLION TECH DEV CO LTD

High-superposition magnetic core material

InactiveCN105070453ALow coercivityReduced characteristicsInorganic material magnetismInductances/transformers/magnets manufactureLithium chlorideIron powder

The invention discloses a high-superposition magnetic core material. The high-superposition magnetic core material is prepared from, by weight, 60-65 parts of hydroxyl iron powder, 10-15 parts of iron sesquioxide, 25-27 parts of manganese oxide, 21-23 parts of zinc oxide, 4-5 parts of silane coupling agent kh570, 5-7 parts of organic silicon resin, 1-2 parts of polyving akohol, 7-9 parts of sodium silicate, 0.4-0.5 part of neodymium oxide, 1-1.3 parts of glass powder, 0.4-0.7 part of lithium chloride and a proper amount of water. The prepared magnetic core material has the functions of very good superposition performance, high stability, the low loss and other aspects, the preparing technology is simple, material sources are wide, cost is low, and good applicability is achieved.

Owner:TIANCHANG CITY ZHAOTIAN MAGNETOELECTRICITY TECH

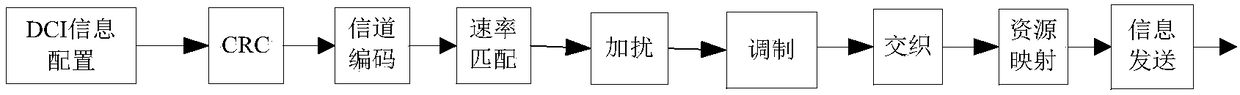

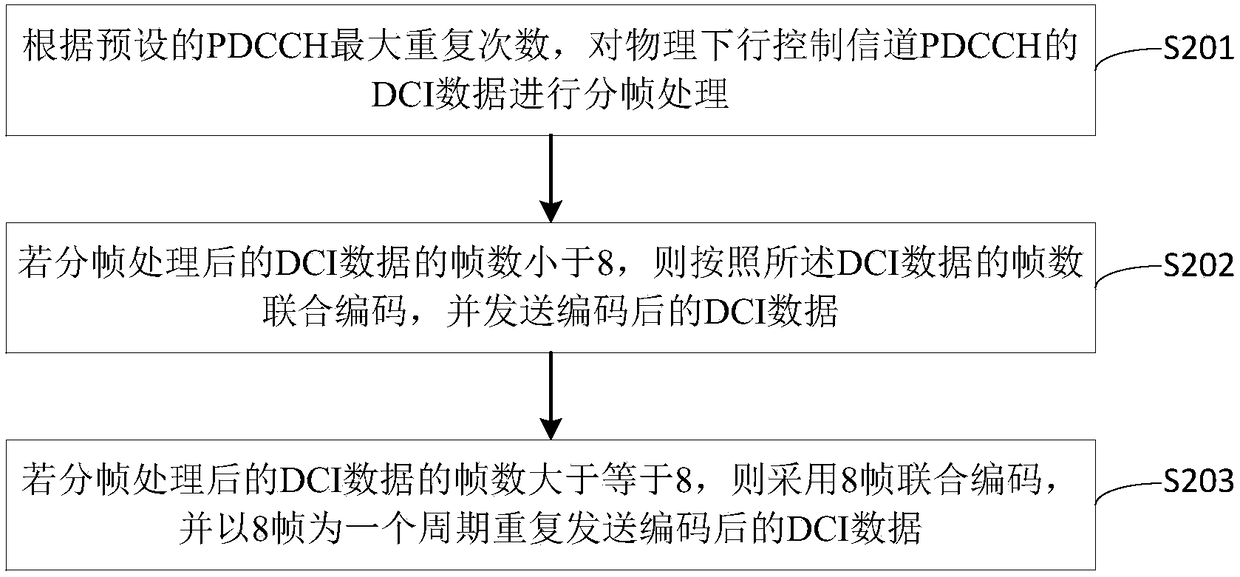

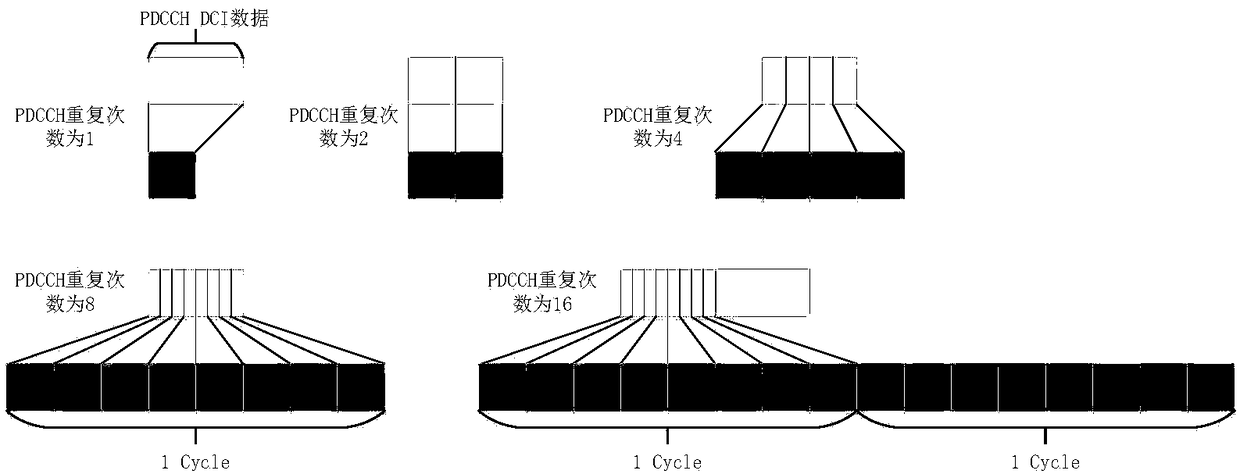

Transmission processing method and device of downlink control channel

ActiveCN108737018AImprove demodulation performanceImprove overlay performanceTransmission path divisionSignal allocationControl channelComputer hardware

The invention provides a transmission processing method and device of a downlink control channel. The transmission processing method comprises steps of performing framing processing on DCI data of a physical downlink control channel PDCCH based on a preset maximum number of PDCCH repetition times; if the frame number of the DCI data after the framing processing is smaller than 8, performing jointencoding according to the frame number of the DCI data and sending the encoded DCI data; and if the frame number of the DCI data after the framing processing is greater than or equal to 8, adopting 8-frame joint encoding and transmitting the encoded DCI data repeatedly by regarding eight frames as a period. By giving consideration to a coverage enhancement problem, the transmission method of the PDCCH is designed again to perform PDCCH transmission periodically; and users with poor coverage can further improve the demodulation performance of the system, improve the coverage performance and further enhance transmission reliability by increasing the number of repetition times.

Owner:POTEVIO INFORMATION TECH

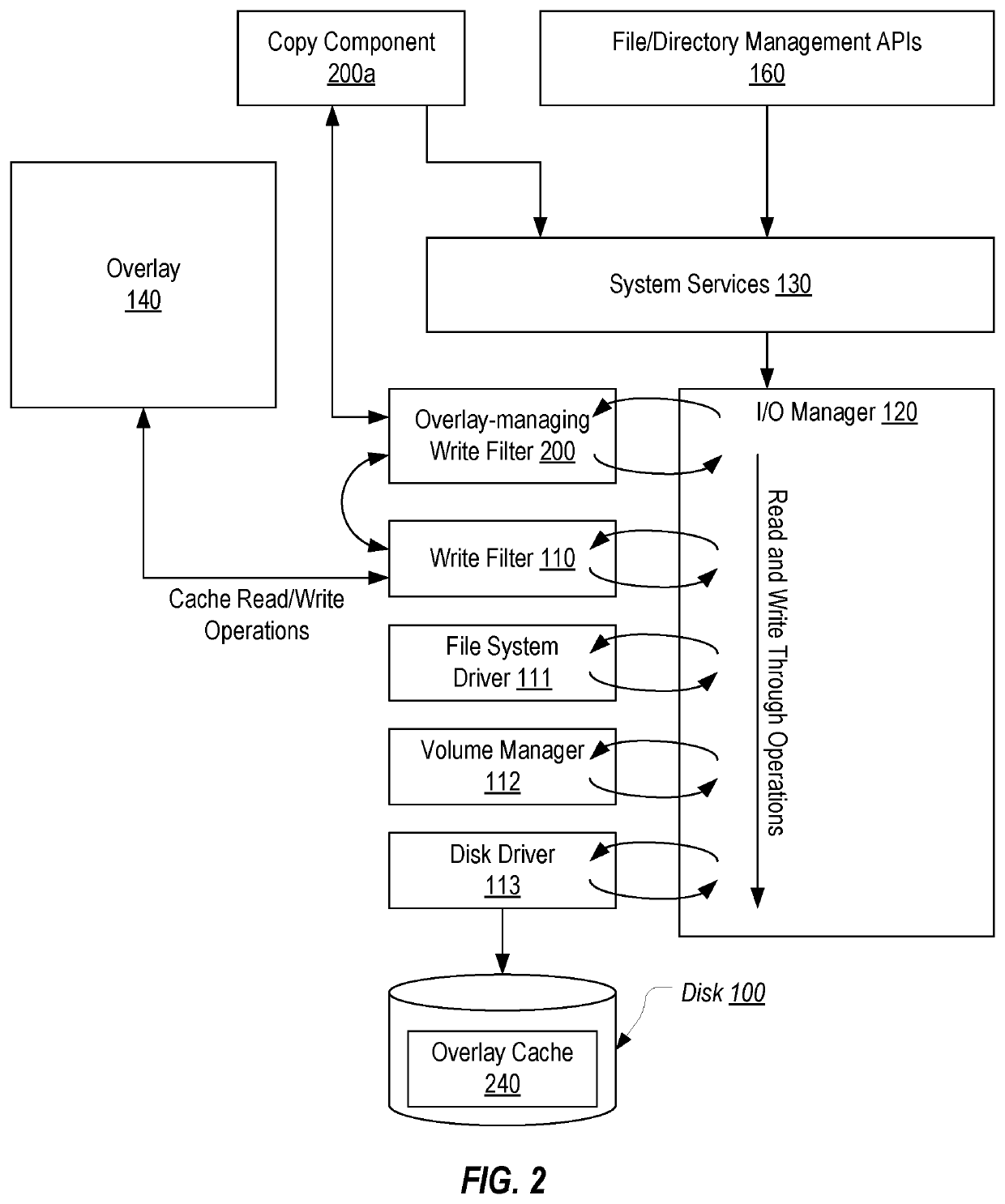

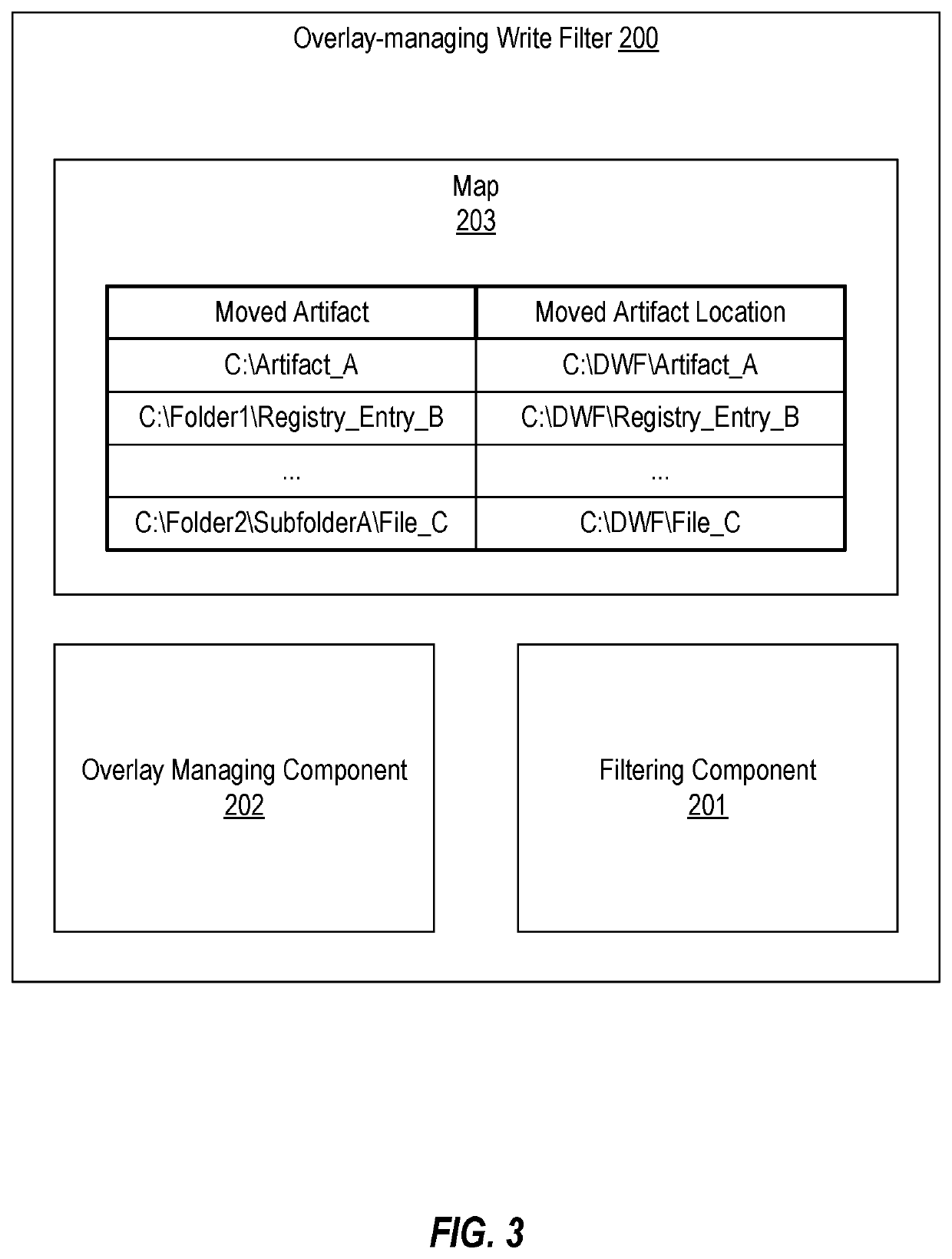

Handling file commit and commit-delete operations in an overlay optimizer

ActiveUS20200050685A1Improve write performanceImprove overlay performanceFile/folder operationsSpecial data processing applicationsSoftware engineeringCommit

File commit and commit-delete operations can be successfully completed in environments that employ an overlay optimizer to enhance the performance of a write filter. The overlay optimizer can be structured into upper and lower instances relative to the write filter. The upper instance can cause files to be moved from the write filter's overlay into an overlay cache to thereby optimize the performance of the overlay. To prevent the failure of commit and commit-delete operations that target files that have been moved to the overlay cache, the lower instance can be configured to detect when the write filter is attempting to perform a commit or commit-delete operation and can modify the processing of such operations to cause them to be completed successfully even though the files targeted by the operations do not exist in the write filter's overlay.

Owner:DELL PROD LP

Silicon textured paper production technology

InactiveCN106968123AHigh paper elongationGood flexibilityDefoamers additionSpecial paperPaper sheetPaper production

The invention relates to the papermaking technology, in particular to a silicon textured paper production technology. The silicon textured paper production technology includes the steps of pulp making, papermaking drifting, dehydrating and forming, drying, paper rewinding and slitting, and impregnation and processing. In the pulp making step, soft long fibers are selected, devillicating and beating are used, the beating degree is controlled to be 25-31 oC, the wet weight is 14-16 g, it is ensured that paper feels soft, 45-55 kg of wet strength agent is added into each ton of paper during pulp preparing to provide high wet strength for the paper so that the paper cannot be broken in the impregnation process, and then 10-20 kg of softening agent is added into each ton of paper so as to improve the softness of the paper. The technology has the advantages that the silicon textured paper produced from pure wood pulp fibers is economical and environmentally friendly, the paper is high in elongation and good in softness, and after the paper is manufactured into adhesive tape, the adhesive tape is not likely to tear when adhered to corners or wound; the paper is high in smoothness, so that when the paper is manufactured into the adhesive tape, the covering property of the adhesive tape is good and the adhesive tape is not likely to fall off.

Owner:浙江晶鑫特种纸业有限公司

Halogen-free flame-retardant adhesive

InactiveCN111621250AImprove flame retardant performanceHigh peel strengthOther rubber adhesivesEpoxy resin adhesivesPolymer scienceAdhesive

The invention relates to a halogen-free flame-retardant adhesive, which comprises the following components in parts by weight: 15-45 parts of halogen-free epoxy resin; 15-60 parts of thermoplastic resin and / or synthetic rubber; 0.1-8 parts of a curing agent; and 5-60 parts of a phosphorus-containing composite flame retardant. The halogen-free flame-retardant adhesive has good flame retardancy, peel strength, electrical properties and welding heat resistance, does not contain harmful substance elements such as halogen and antimonide, and does not pollute the environment. The flame retardant grade of the flexible copper-clad plate prepared from the composition reaches UL-94V0 grade, and the flexible copper-clad plate also has good heat resistance, high peel strength and soldering tin resistance, and is not layered and bubbled after being subjected to tin immersion at 310 DEG C for 1 minute. The halogen-free flame-retardant adhesive has good laminating performance, so that the productionline speed can be increased, and the production efficiency can be improved.

Owner:广东欣兴旺软板技术有限公司

Halogen-free flame-retardant adhesive composition and flexible copper-clad plate using same

ActiveCN101921557BImprove flame retardant performanceHigh peel strengthNon-macromolecular adhesive additivesCarboxyl rubber adhesivesPolymer scienceFirming agent

The invention discloses a halogen-free flame-retardant adhesive composition. The composition comprises the following components in part by weight: 15 to 45 parts of halogen-free epoxy resin, 15 to 60 parts of thermoplastic resin and / or synthetic rubber, 0.1 to 8 parts of curing agent and 5 to 60 parts of phosphorus-containing composite flame retardant. The invention also discloses a flexible copper-clad plate using the adhesive composition. The cured product of the adhesive composition provided by the invention shows high flame retardance, peeling strength, electric performance and welding heat resistance, does not comprise harmful substances or elements such as halogen, antimonide and the like and does not pollute environment; the flame retardant rating of the flexible copper-clad plate prepared from the composition of the invention reaches UL-94V0, and the flexible copper-clad plate also has the advantages of high heat resistance, high peeling strength, soldering resistance, no demixing after being subjected to dip soldering at the temperature of 300 DEG C for 1 minute and no bubbles; and because the halogen-free composition of the invention has high sticking performance, the speed of a production line can be increased and the production efficiency is improved.

Owner:ALLSTAE TECH ZHONGSHAN

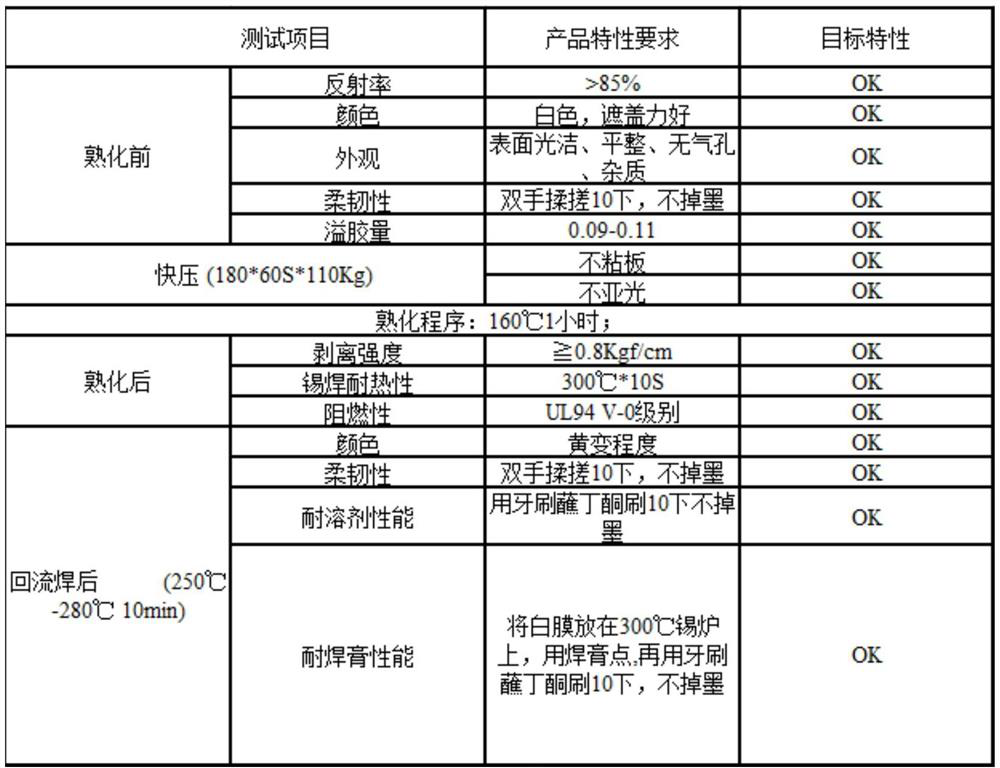

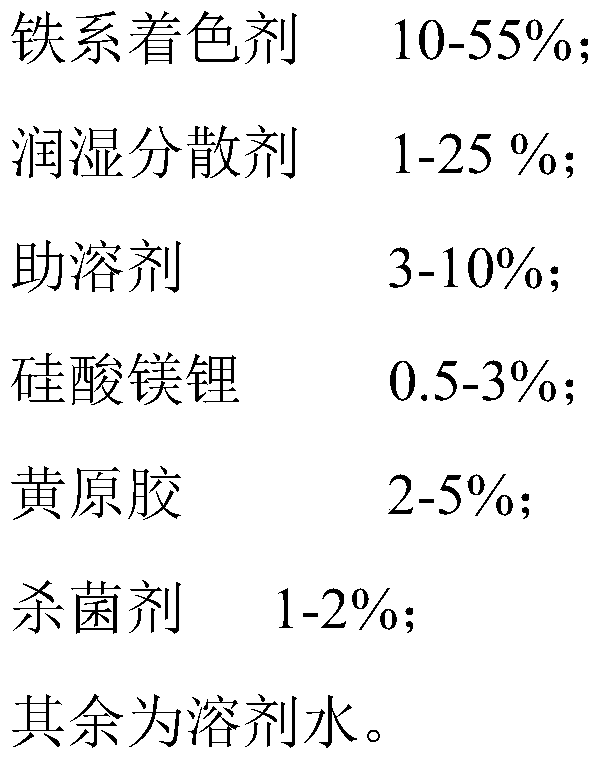

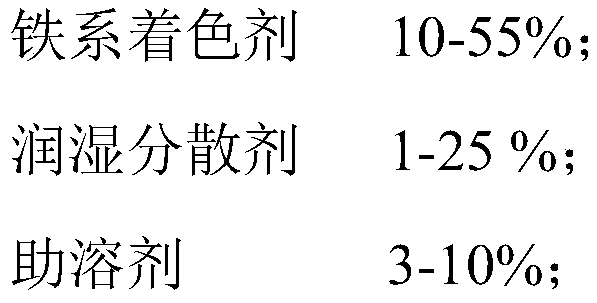

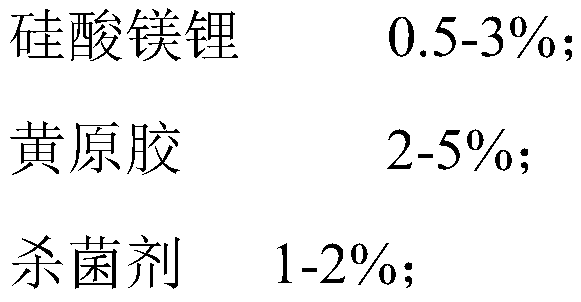

Ferrite water-based pigment paste for cosmetics, preparation method thereof and preparation method of make-up products

ActiveCN111449988AGood storage stabilityHigh viscosityCosmetic preparationsMake-upSolventXanthan gum

The invention relates to ferrite water-based pigment paste for cosmetics, a preparation method thereof and a preparation method of make-up products. The pigment paste is prepared from the following components in percentage: 10-55 percent of ferrite colorant, 1-25 percent of a wetting dispersant, 3-10 percent of cosolvent, 0.5-3 percent of magnesium lithium silicate, 2-5 percent of xanthan gum, 1-2percent of bactericide and the balance being solvent water. An excellent effect can be achieved by using an antisettling technology of combining 0.5-3 percent of magnesium lithium silicate and 2-5 percent of xanthan gum, and the paste is excellent in storing stability, can be placed at normal temperature for 3 years or placed at high temperature of 55 DEG C for 6 months, and has the disperse system viscosity variation being less than 5 percent. The invention provides a set of paste meeting the requirement of related regulations of cosmetics (including eyes and mucous contact cosmetics) from different countries in the world and can be used for making different colors by mixing different colors of pastes. The stability and compatibility of paste are highly required to meet the demand of combination.

Owner:宁波爱诗化妆品有限公司

Wear-resistant coating material for a wooden tea table surface plates

The invention relates to a wear-resistant coating material for a wooden tea table surface plates, and relates to the technical field of tea table processing and production, wherein the wear-resistantcoating material is prepared from the following materials by weight: 10-15 parts of a resin, 4-9 parts of a silane coupling agent KH-550, 4-8 parts of modified perlite, 5-9 parts of an adhesion aid, 1-5 parts of N,N-methylenebisacrylamide, 4-9 parts of n-dodecyltrichlorosilane, 1-5 parts of polydicyclopentadiene, 1-6 parts of 2-(heptadecenyl)-4,5-dihydro-1H-imidazole-1-ethanol, 1-3 parts of dioctyl epoxy tetrahydrophthalate, 2-7 parts of nanometer titanium dioxide, 4-8 parts of an anti-aging agent A, 4-9 parts of a filler, and 16-22 parts of deionized water. According to the present invention,the method is reasonable, the operation is convenient, and the wear-resistant coating material has characteristics of wear resistance and high temperature resistance.

Owner:聚宝实木家私

Preparation method for silicone iron cores with magnetic conductivity of 125

ActiveCN102982991BLow costReduce iron lossInorganic material magnetismInductances/transformers/magnets manufactureIron powderThermal treatment

The invention relates to a preparation method for silicone iron cores. The preparation method includes that silicone iron powder core and silicone iron powder material are dry-press molded after acid treatment, the powder material is more prone to being molded, product density is improved, and meanwhile high magnetic conductivity of the product can be achieved after thermal treatment. Compared with the prior art, the preparation method for the silicone iron cores with the magnetic conductivity of 125 has the significant advantages that the magnetic conductivity of the manufactured silicone iron cores is 125 while iron loss is low and overlay performance is good, the process steps are simple, and raw and auxiliary material cost is low.

Owner:湖南普盛新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com