Compound type exciting agent and preparation method thereof

An activator and composite technology, applied in the field of external additives, can solve the problems of single performance of concrete soil materials, high cost of rare earth elements, difficulty in functioning, etc., and achieve the effects of improving various properties, reducing bleeding, and reducing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

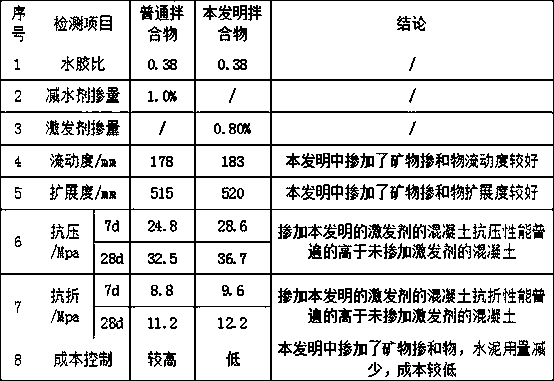

Examples

Embodiment 1

[0037] The compound activator described in the present invention is mainly composed of mineral admixture, sodium sulfate, gypsum dihydrate, calcium hydroxide, naphthalene-based water reducer, triisopropanolamine, polyoxyethylene polyoxypropylene pentaerythritol ether, micro Pearl and sodium nitrite, the weight ratio of each component is 200 parts of mineral admixture, 10 parts of dihydrate gypsum, 3 parts of sodium sulfate, 3 parts of calcium hydroxide, 0.5 parts of naphthalene-based water reducer, three parts 0.1 part of isopropanolamine, 0.001 part of polyoxyethylene polyoxypropylene pentaerythritol ether, 0.01 part of microbeads, and 0.1 part of sodium nitrite.

[0038] The mineral admixture is obtained by mixing fly ash and mineral powder, and the weight ratio of fly ash to mineral powder is 4:6.

Embodiment 2

[0040] The compound activator described in the present invention is mainly composed of mineral admixture, sodium sulfate, gypsum dihydrate, calcium hydroxide, naphthalene-based water reducer, triisopropanolamine, polyoxyethylene polyoxypropylene pentaerythritol ether, micro beads and sodium nitrite, the weight ratio of each component is: 180 parts of mineral admixture, 5 parts of dihydrate gypsum, 2 parts of sodium sulfate, 2 parts of calcium hydroxide, 0.3 parts of naphthalene-based water reducer, 0.1 part of triisopropanolamine, 0.001 part of polyoxyethylene polyoxypropylene pentaerythritol ether, 0.01 part of microbeads, and 0.1 part of sodium nitrite.

[0041] The mineral admixture is obtained by mixing fly ash and mineral powder, and the weight ratio of fly ash to mineral powder is 4:6.

Embodiment 3

[0043] The compound activator described in the present invention is mainly composed of mineral admixture, sodium sulfate, gypsum dihydrate, calcium hydroxide, naphthalene-based water reducer, triisopropanolamine, polyoxyethylene polyoxypropylene pentaerythritol ether, micro Beads and sodium nitrite, the weight ratio of each component is: 240 parts of mineral admixture, 15 parts of dihydrate gypsum, 4 parts of sodium sulfate, 4 parts of calcium hydroxide, 0.7 parts of naphthalene-based water reducer, 0.2 parts of triisopropanolamine, 0.002 parts of polyoxyethylene polyoxypropylene pentaerythritol ether, 0.02 parts of microbeads, and 0.2 parts of sodium nitrite.

[0044] The mineral admixture is obtained by mixing fly ash and mineral powder, and the weight ratio of fly ash to mineral powder is 5:5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com