Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

68results about How to "Reduced porosity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

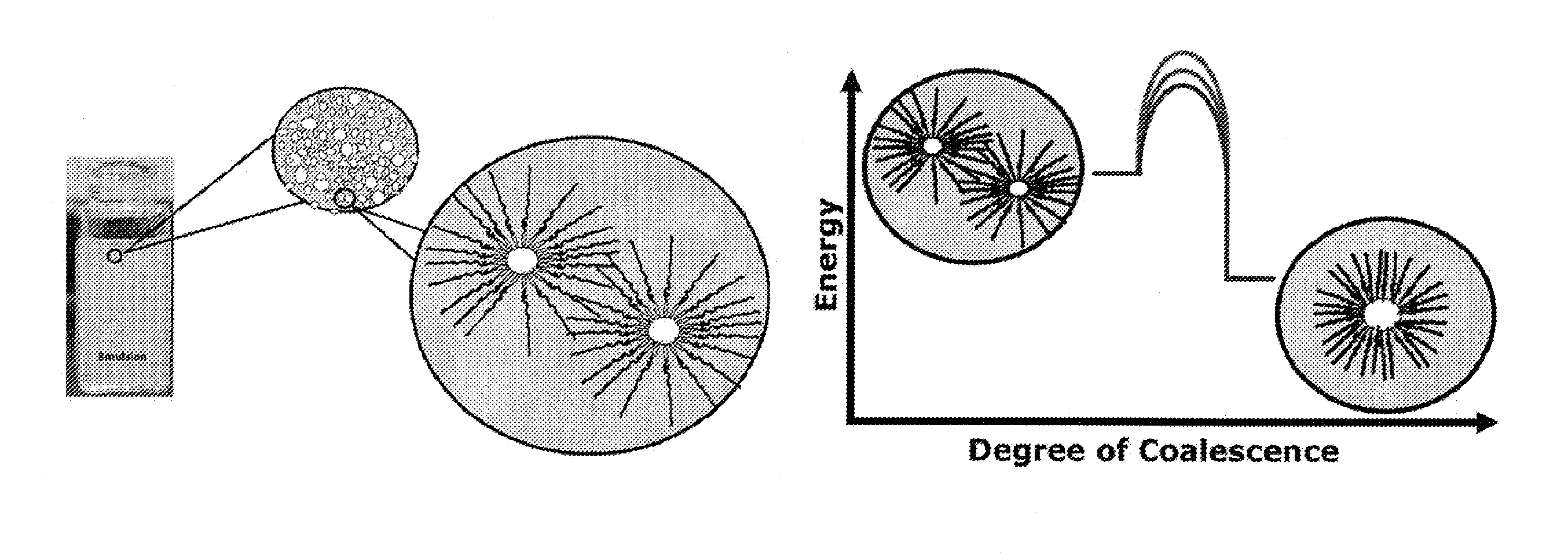

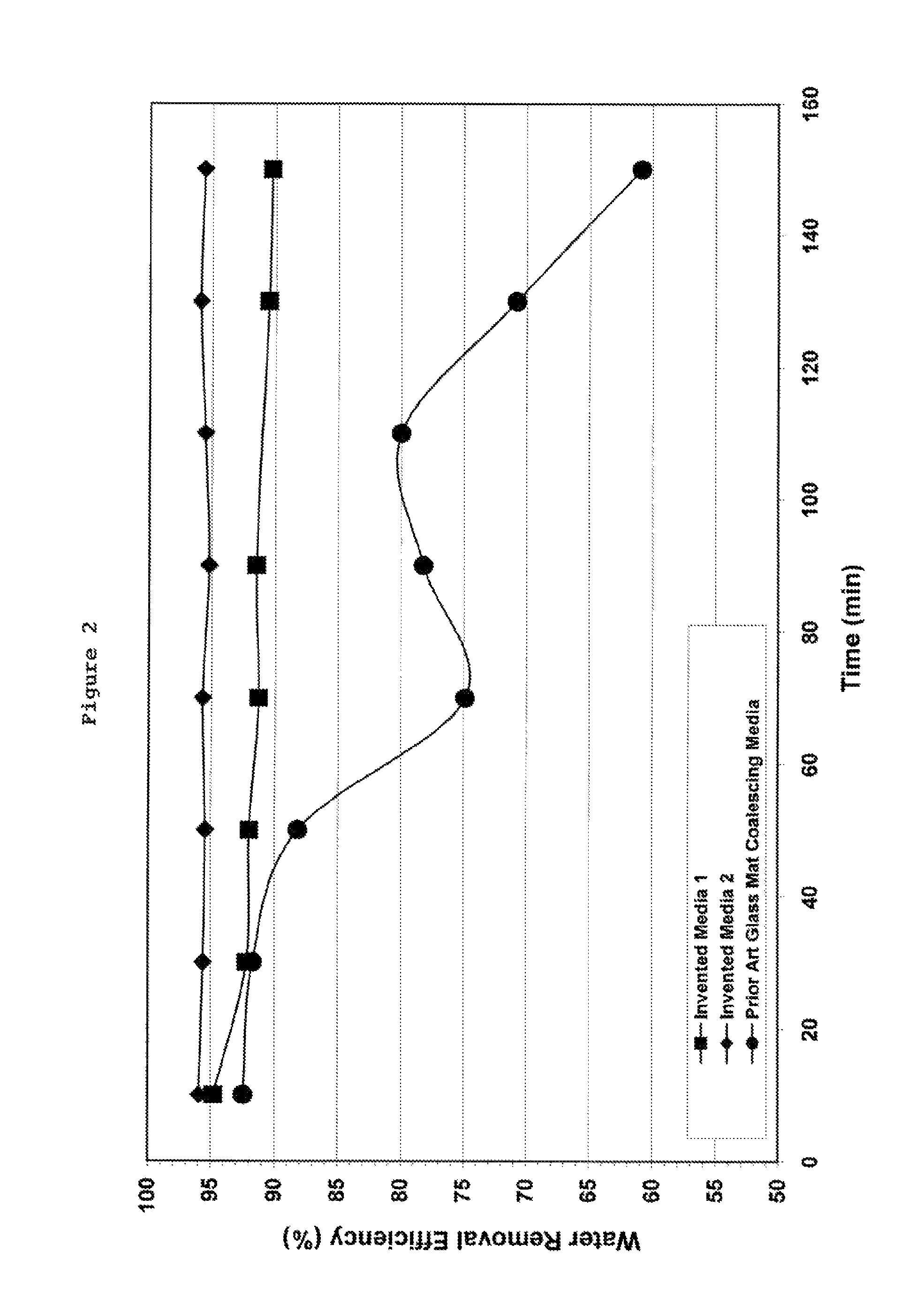

Coalescence media for separation of water-hydrocarbon emulsions

ActiveUS20110147299A1Low energyHigh surface areaLoose filtering material filtersGravity filtersNatural fiberMicrofiber

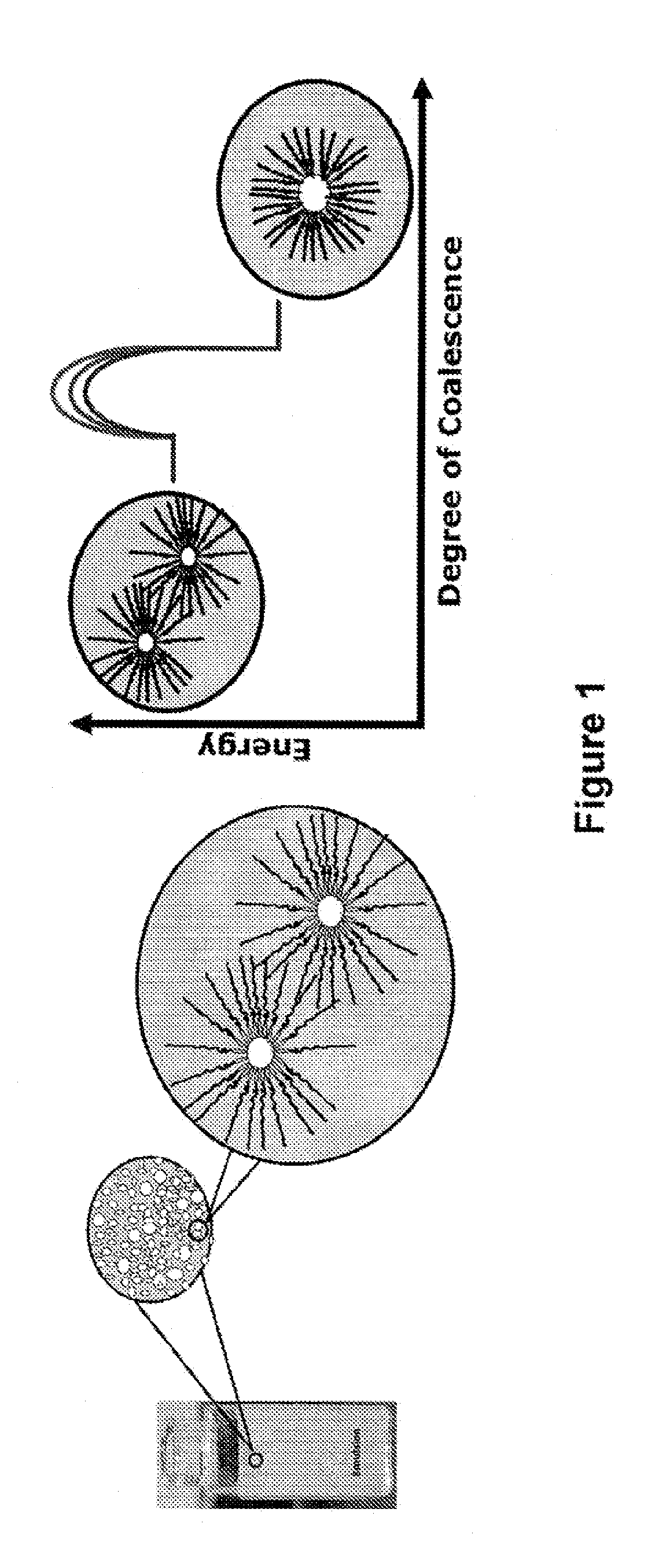

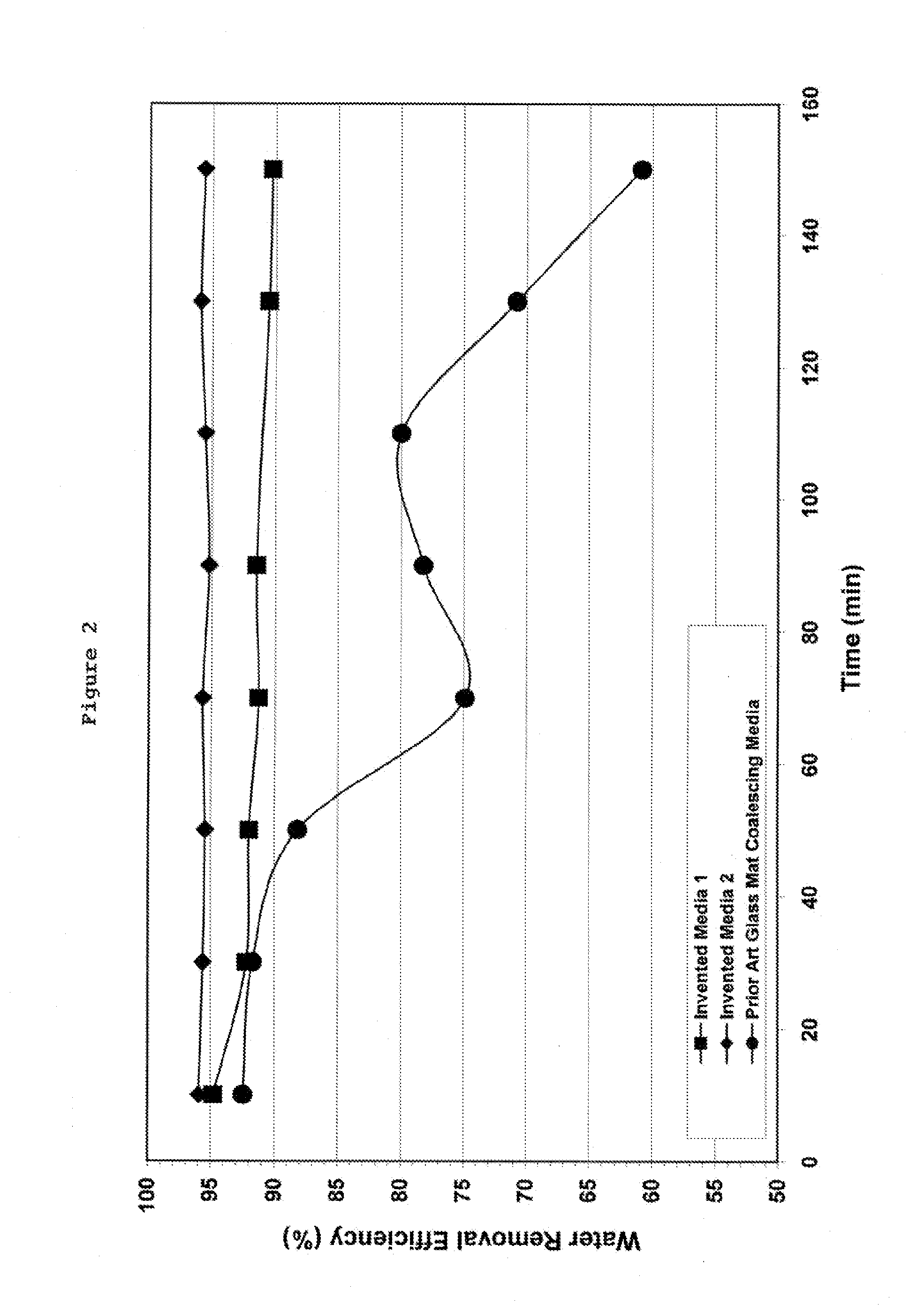

A coalescence media for separation of water-hydrocarbon emulsions comprises an emulsion-contacting sheet formed of: (a) at least one component of the group consisting of natural fibers, cellulose fibers, natural-based fibers, and cellulose-based fibers, at least one component of the group consisting of high-surface-area fibrillated fibers, surface-area-enhancing synthetic material, glass microfibers, and nanoceramic functionalized fibers; and (c) at least one component of the group consisting of a dry strength additive, and a wet strength additive, wherein the fibrous components of the media constitute at least about 70% of the media. In preferred embodiments, the coalescence media comprises kraft fibers, fibrillated lyocell fibers, glass microfibers or nanoceramic functionalized fibers, a wet strength additive, and a dry strength additive. Preferably, the coalescence media is formed as a single, self- supporting layer from a wet-laid process using a homogenously distributed, wet-laid furnish. It may also be formed as a multi-layer structure.

Owner:A AHLSTROM CORP

Composite microsphere prepn of lactic acid-hydroxyacetic acid copolymer and its prepn process

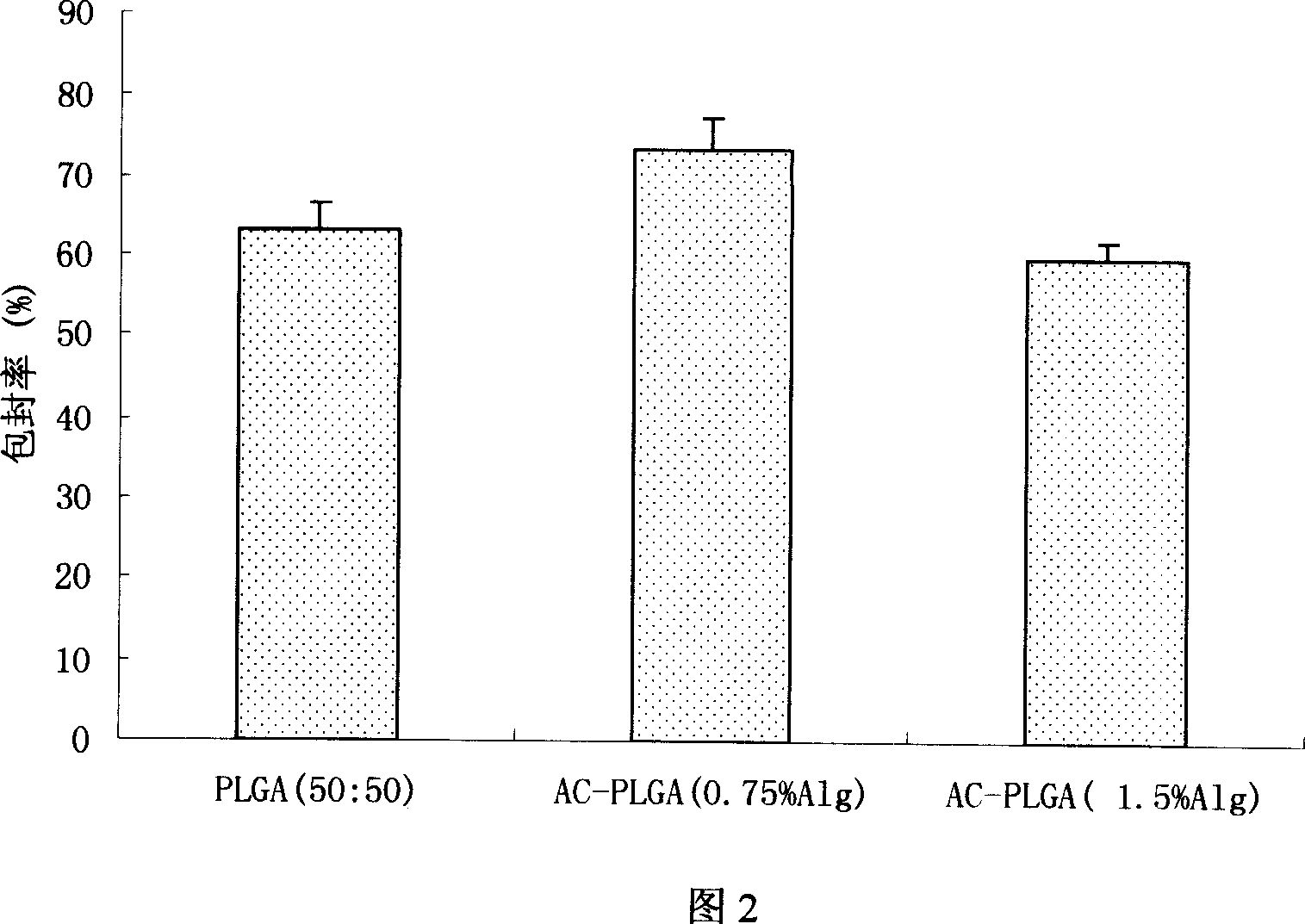

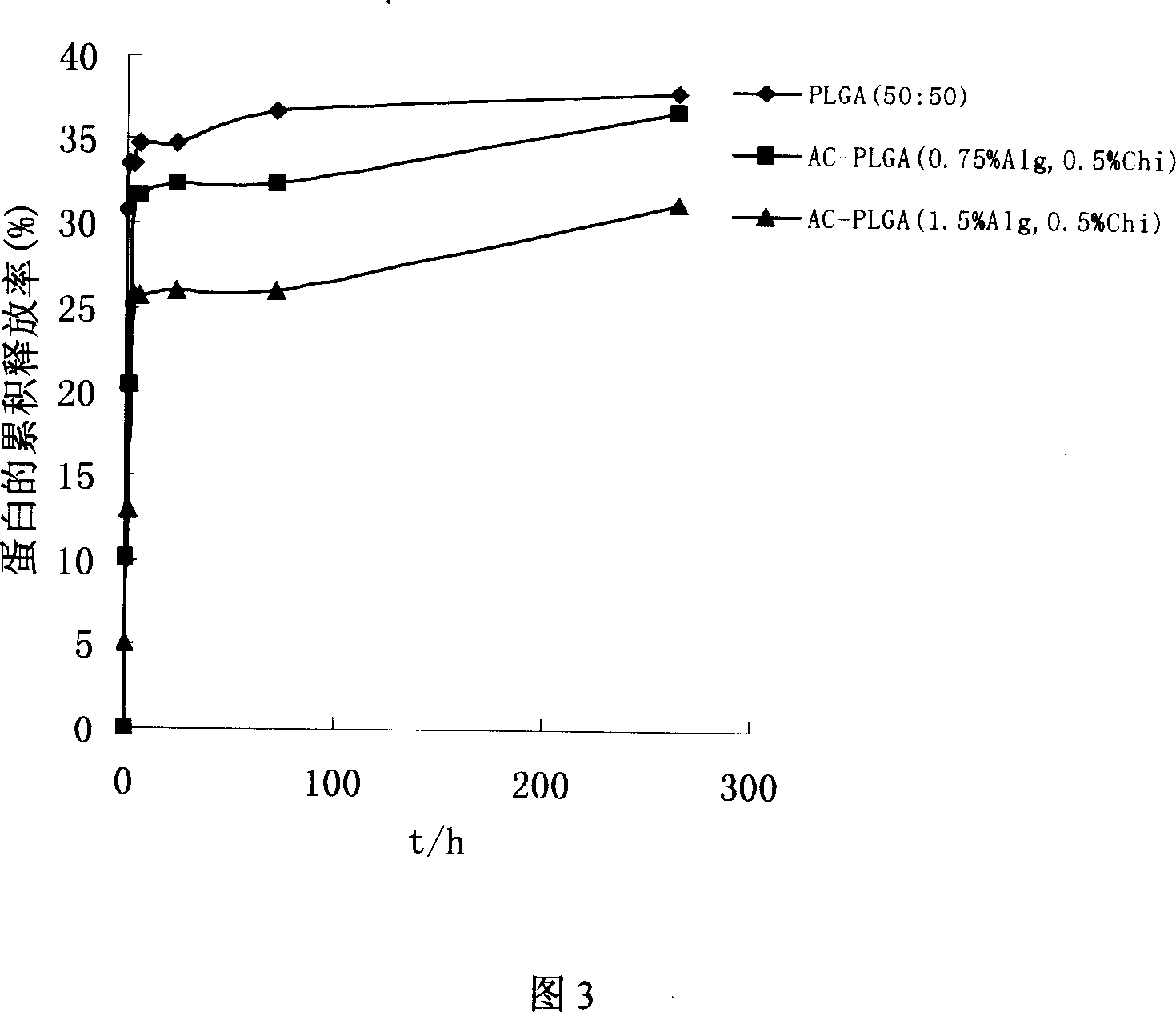

ActiveCN1973901ADelayed releaseReduced burstPharmaceutical delivery mechanismPharmaceutical non-active ingredientsEmulsionChitosan binding

The composite microsphere preparation of lactic acid-hydroxyacetic acid copolymer consists of medicine, calcium alginate, chitosan, glycolide-lactide copolymer, emulsifier and medicine supplementary material. It is prepared through adding low concentration sodium alginate solution to inner water phase containing medicine, forming initial emulsion with PLGA-containing organic phase, injecting PVA solution with chitosan and calcium chloride to form complex emulsion, decompression rotary evaporation to cure, water washing and freeze drying. The process is simple and feasible, and has no influence on the size of microsphere and no change in protein encapsulating rate, capacity of forming one hydrophilic micro environment to protect protein medicine, and capacity of reducing the release of medicine.

Owner:ZHEJIANG UNIV

High-heat conductivity and wear-resistant composite material

A high-heat conductivity and wear-resistant composite material comprises a main material and an auxiliary material, wherein the main material comprises zirconium corundum fine powder, nanometer aluminum nitride, pure calcium aluminate cement, carbon fiber, magnesium zirconium sand, silica micropowder, aluminum oxide micropowder, sodium tripolyphosphate, silicon carbide, graphene and the like; and the auxiliary material comprises phosphoric acid, ink-grade aluminum hydroxide, aluminum oxide, graphene, a sintering agent and the like. The high-heat conductivity and wear-resistant composite material provided by the invention has high compressive strength, high compactness, very high wear resistance, corrosion resistance and scouring resistance, heat shock stability and high heat conductivity. The high-heat conductivity and wear-resistant composite material is applied to wear-resistant and flame-isolating parts of a circulating fluidized bed boiler and chemical and industrial kilns, and can prolong the service life of wear-resistant layers of the wear-resistant and flame-isolating parts, so that the complex repair times, the maintenance cycle and the maintenance cost are reduced, and thus a requirement on long-cycle safe operation of the high-temperature wear-resistant layer of the circulating fluidized bed boiler is met.

Owner:YIXING GUOQIANG FURNACE IND

Coalescence media for separation of water-hydrocarbon emulsions

ActiveUS8833567B2Weaken energyLarge specific surface areaSemi-permeable membranesWater/sewage treatmentEmulsionSynthetic materials

A coalescence media for separation of water-hydrocarbon emulsions comprises an emulsion-contacting sheet formed of: (a) at least one component of the group consisting of natural fibers, cellulose fibers, natural-based fibers, and cellulose-based fibers, at least one component of the group consisting of high-surface-area fibrillated fibers, surface-area-enhancing synthetic material, glass microfibers, and nanoceramic functionalized fibers; and (c) at least one component of the group consisting of a dry strength additive, and a wet strength additive, wherein the fibrous components of the media constitute at least about 70% of the media. In preferred embodiments, the coalescence media comprises kraft fibers, fibrillated lyocell fibers, glass microfibers or nanoceramic functionalized fibers, a wet strength additive, and a dry strength additive. Preferably, the coalescence media is formed as a single, self-supporting layer from a wet-laid process using a homogenously distributed, wet-laid furnish. It may also be formed as a multi-layer structure.

Owner:A AHLSTROM CORP

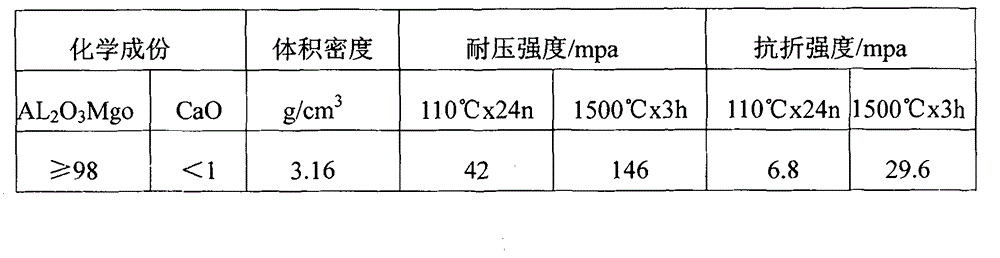

Compact electro-fused corundum-spinel ladle casting material

The invention relates to a compact electro-fused corundum-spinel ladle casting material, and belongs to the field of unshaped refractory material. According to the invention, compact electro-fused corundum, electro-fused spinel, and sintered spinel are adopted as main raw materials; alumina micro-powder, magnesium grain fine powder, silicon micro-powder, sodium tripolyphosphate, and polypropylene fiber are adopted as auxiliary materials; calcium aluminum magnesium cement is adopted as a binding agent; and a ladle working lining is obtained by uniform mixing and casting forming. The material specifically comprises the raw materials of, by weight: 50-80% of 25-0.074mm compact electro-fused corundum, 5-20% of electro-fused spinel, 1-15% of sintered spinel with a specification no higher than 0.074mm, 5-20% of the auxiliary raw materials with a specification no higher than 0.088mm, and 1-15% of the binding agent calcium aluminum magnesium cement. According to the ladle casting material provided by the invention, erosion and corrosion resistances are substantially improved, and service live of ladle lining is prolonged.

Owner:PINGXIANG JINGXIANG IND

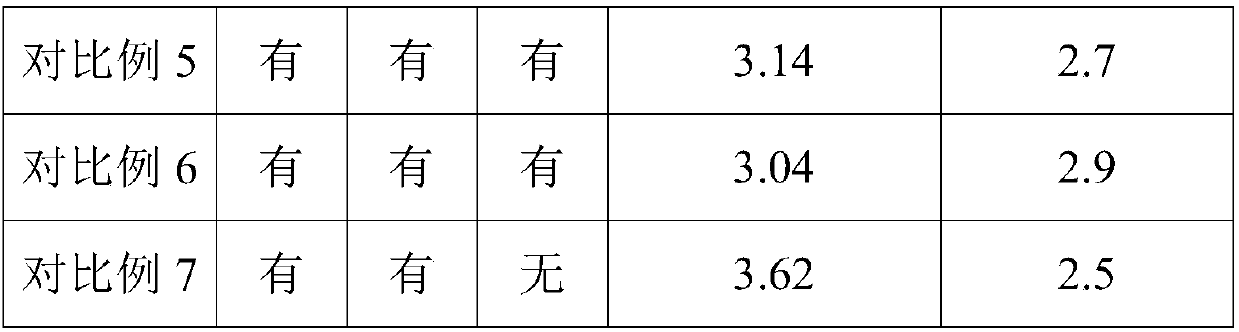

Dual-modified waterborne epoxy resin anticorrosive paint and preparation method thereof

InactiveCN113308174AReduced porosityImprove adhesionAnti-corrosive paintsEpoxy resin coatingsHexagonal boron nitrideSilicic acid

The invention discloses a dual-modified water-borne epoxy resin anticorrosive coating and a preparation method thereof, and relates to a coating. According to the method, tetraethyl orthosilicate serves as a silicon source, monodisperse nano SiO2 with the surface containing a large number of hydroxyl groups is obtained, and the monodisperse nano SiO2 reacts with a silane coupling agent KH550 to obtain aminated nano SiO2; dopamine is subjected to self-polymerization on the surface of hexagonal boron nitride, and polydopamine modified hexagonal boron nitride is obtained; then, the aminated nano SiO2 and polydopamine are used for modifying hexagonal boron nitride, and a modified SiO2 loaded hexagonal boron nitride composite material is obtained; and finally, the nano SiO2 / hexagonal boron nitride double-modified waterborne epoxy resin coating is prepared by stirring the epoxy resin, the modified SiO2-loaded hexagonal boron nitride, a waterborne curing agent, a waterborne dispersing agent, a waterborne leveling agent, a waterborne defoaming agent and other auxiliaries at a high speed. According to the epoxy coating prepared by the invention, the adhesive force and the mechanical property of a coating on a metal surface are enhanced, so that the coating has excellent corrosion resistance.

Owner:ANHUI UNIVERSITY

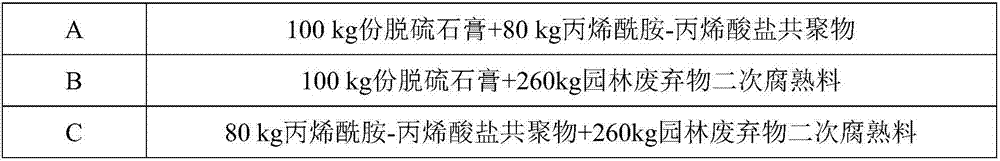

Seashore saline land improver, preparation method of seashore saline land improver and seashore saline land improvement method

InactiveCN107011911AIncrease Phosphorus ContentLight weightAgriculture tools and machinesOther chemical processesMonosodium glutamateLand improvement

The invention discloses a seashore saline land improver, a preparation method of the seashore saline land improver and a seashore saline land improvement method. The seashore saline land improver comprises the following components in parts by mass: 5-20 parts of industrial waste gypsum, 0.2-1 part of monosodium glutamate waste residue, 30-60 parts of plant waste ground and decomposed material, 0.01-1 part of anionic polyacrylamide and 5-15 parts of bacillus flora. The seashore saline land improver is applicable to seashore saline areas in both north and south China and can rapidly improve the saline land within 50-70 days, and the salinity of the saline land is reduced to a concentration suitable for plant growth. Moreover, the improver has excellent fertilizer maintenance and salinity reduction effects and can achieve the effects of improving the pore structure of soil and reducing the volume weight of soil.

Owner:SHENZHEN TECHAND ECOLOGY & ENVIRONMENT CO LTD

Pressure casting method for auto spare parts

The invention discloses a pressure casting method for auto spare parts, and relates to the technical field of metal pressure casting which uses an aluminum alloy. The pressure casting method for the auto spare parts includes the following steps that 1 modification treatment: raw materials are melt, the modification treatment is conducted at a temperature which is increased to 750 DEG C to 800 DEG C, and the standing of the raw materials is stayed for 2-4 hours; 2 smelting: the modified raw materials are conducted to be liquid raw materials at a temperature which is increased to 650 DEG C to 800 DEG C; 3 die compounding: die assembly is conducted until a gap ranging from 20 mm to 30 mm occurs in a die joint face; 4 oxygen gas is injected into the gap; 5 the die assembly is conducted continuously until the dies are closed completely; 6 the liquid raw materials are injected into a charging barrel; 7 after the liquid raw materials is injected, the oxygen gas is injected into the charging barrel; 8 pressure casting is conducted; 9 cooling is conducted; 10 the dies are opened, and the pressure casting of a product is finished. Compared with the prior art, the pressure casting method can solve the problems that the pressure casting mechanical property of existing aluminum alloy pieces is poor and air holes are prone to generate in die casting pieces.

Owner:中山普瑞科精密压铸有限公司

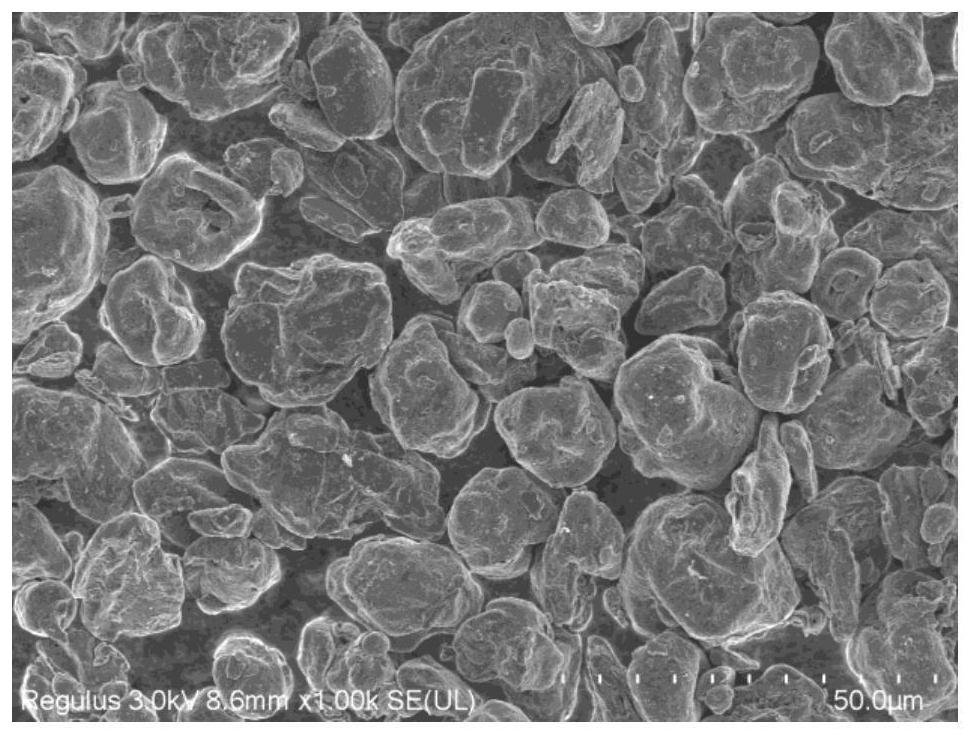

Silicon-carbon composite material, preparation method thereof, lithium battery negative electrode material and lithium battery

The invention provides a silicon-carbon composite material, a preparation method thereof, a lithium battery negative electrode material and a lithium battery. The preparation method comprises the following steps: S1, mixing nano silicon, a carbon source, an etching agent, a binder and a solvent to obtain a mixture; S2, performing primary carbonization treatment on the mixture to obtain a graphene-like carbon film coated silicon material; S3, mixing the graphene-like carbon film coated silicon material, a carbon series conductive agent and a polymer conductive agent, and carrying out compactionmolding to obtain a molded material blank; and S4, carrying out secondary carbonization treatment on the molded material blank to obtain the silicon-carbon composite material; wherein the etching agent is an alkali metal salt. Through the synergistic effect of the primary carbonization treatment and the secondary carbonization treatment, the silicon-carbon composite material with longer cycle life and better rate capability is obtained.

Owner:YINLONG ENERGY CO LTD

Method for preparing three-dimensional graphene/ foamed nickel composite material by taking loofah sponge as raw material

ActiveCN109473288ACarbonation deoxidation effect is goodSimple methodHybrid capacitor electrodesHybrid/EDL manufacturePorous grapheneCarbonization

The invention belongs to the field of graphene material synthesis, and particularly relates to a method for preparing a three-dimensional graphene / foamed nickel composite material by taking loofah sponge as a raw material. The method comprises the following specific steps that: after the loofah sponge is cleaned, carrying out carbonization, carrying out natural cooling to the room temperature, and smashing to obtain loofah sponge powder; carrying out purification processing on the foamed nickel; weighing the loofah sponge powder and sodium carbonate powder, after grinding is carried out, dripping polyethylene glycol 400, stirring the mixture into a slurry form, and coating the foamed nickel subjected to purification processing with the slurry to obtain an intermediate product; and puttingthe intermediate product in a high-temperature tube furnace, introducing pure nitrogen, carrying out calcination, after the intermediate product is cooled to the room temperature, carrying out repeated dipping by distilled water until the pH (Potential of Hydrogen) of the solution is neutral, and drying to obtain the three-dimensional graphene / foamed nickel composite material. The invention provides a preparation method for novel biomass three-dimensional porous graphene. The method has the advantages of wide loofah sponge raw material source, low price, simple preparation process technology, environment protection, wide industrial prospect and huge social and economic benefit.

Owner:江苏江科石墨烯研究院有限公司

Battery electrode, preparation method thereof and battery

ActiveCN102054979ALower internal resistanceImprove rate charge and discharge performanceElectrode carriers/collectorsLi-accumulatorsMicro nanoPower flow

The invention provides a battery electrode, a preparation method thereof, and a battery. The battery electrode comprises a current collector and an active substance layer coated on the current collector; a micro-nano particle layer is adhered to the surface of the active substance layer; the active substance layer comprises electrode active substance and electrode binder; the micro-nano particle layer comprises micro-nano dry powder particles; and the micro-nano dry powder particles comprise dry powder particles of the micro-nano electrode active substance. Interface impedance between the electrode and electrolyte is reduced and rate discharge performance of the battery is improved; a micro-nano active material reduces serious volume effect of the material; and specifically, the micro-nano particle layer may not comprise the binder preferably, so that the large-current discharge characteristic of the battery is improved further. The method is simple and is easy to implement; and the combinability between the micro-nano particle layer and the active substance layer is high, and the surface of the active substance layer is not polluted by the substances of an upper layer.

Owner:SHANGHAI BYD

Production method of graphene organically-modified bentonite particles for treating humic acid in water

InactiveCN109248658AOvercoming reunion behaviorRich layersOther chemical processesWater contaminantsCvd grapheneHumic acid

The invention discloses a production method of graphene organically-modified bentonite particles for treating humic acid in water. Sodium bentonite is modified with an organic matter, the obtained organically modified bentonite is modified with graphene under the action of microwaves, and the graphene with a single-layer structure enters the interlayer of the organically modified bentonite to makethe surface and the internal of the organic bentonite stripped to a certain degree, so the agglomeration behavior of graphene is effectively overcome, the original tight and thick structure of the organic bentonite is changed, and original pores and gaps are increased; and an appropriate amount of starch is added as a pore-forming agent, and further acts in a high-temperature roasting environmentin order to make a sheet have a higher peeling degree from the surface than powder, and achieve a folding, curling and multilayer surface, a loose structure, a thin sheet, a perfect and fine pore structure and a larger specific surface, so the graphene modified organic bentonite particles have a micro-porous structure.

Owner:WUHU PENGLEI NEW MATERIAL

Analysis device

InactiveUS20050164188A1Reduced porosityReduce thicknessBioreactor/fermenter combinationsPeptide librariesUsage analysisAnalytical chemistry

Owner:KANE JEFFREY

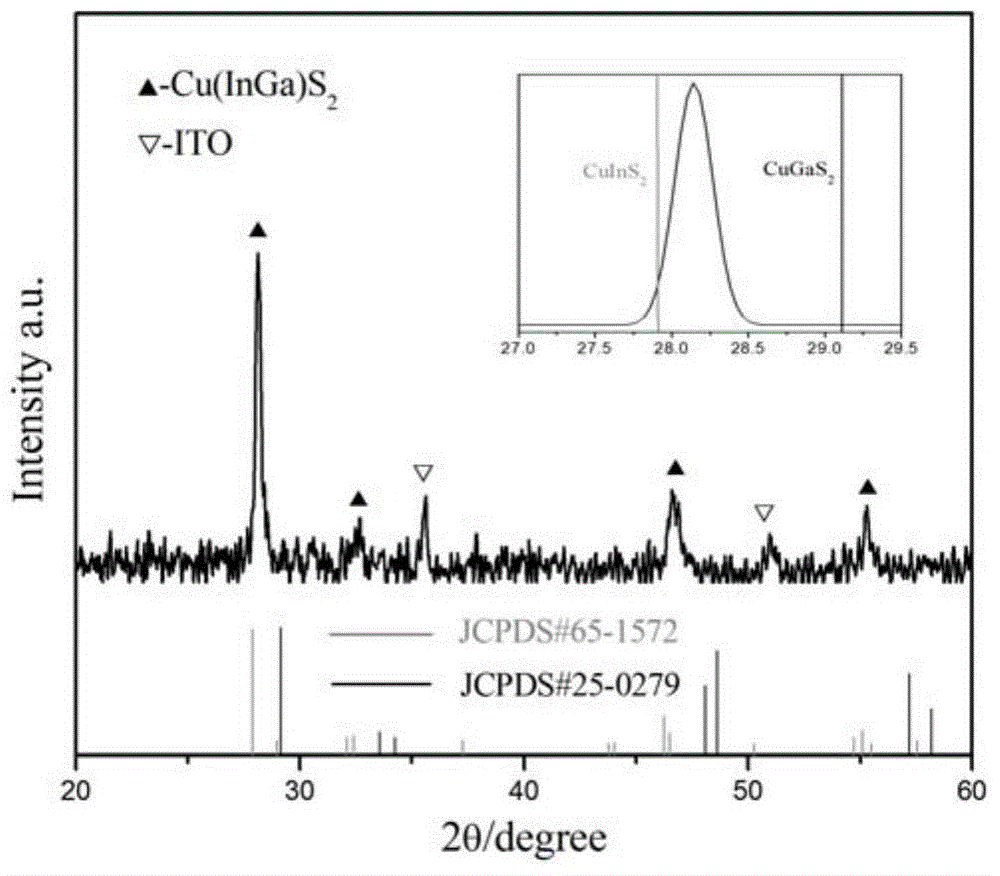

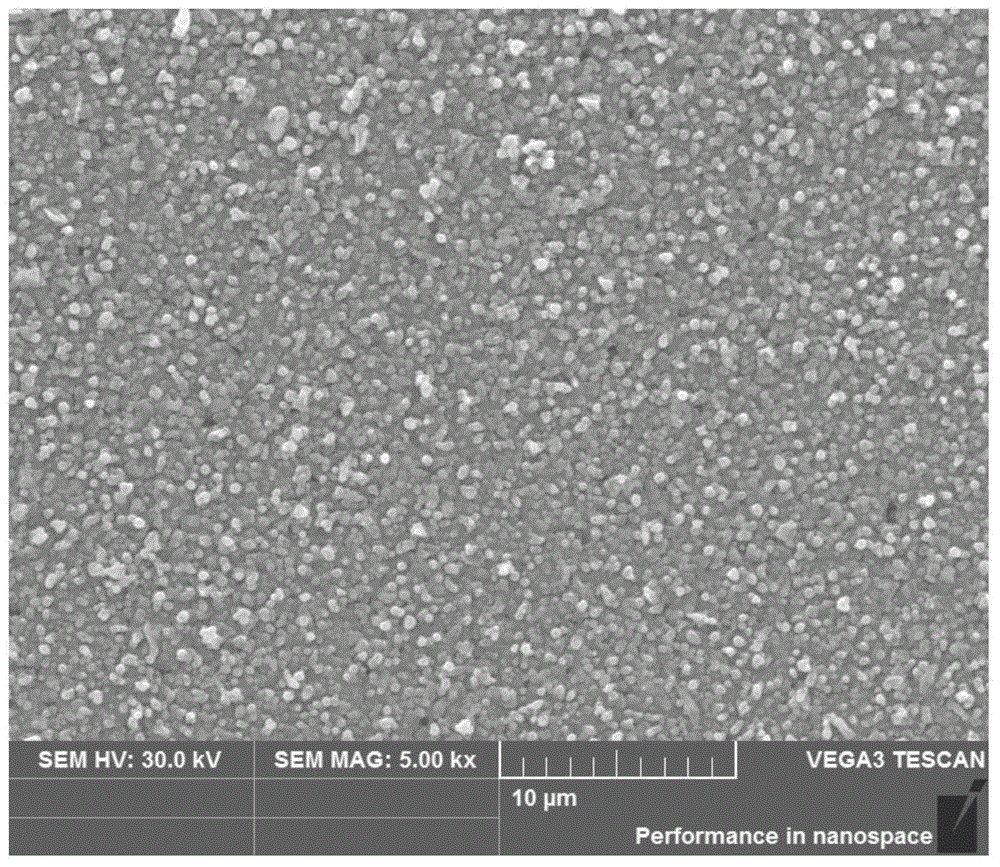

Sulfide annealing copper indium gallium sulfur solar cell thin film material preparation method after double-potential step method electrodeposition

ActiveCN105226117AReduced porosityIncrease plating ratePhotovoltaic energy generationSemiconductor devicesCopper indium gallium selenide solar cellsIon

The invention discloses a sulfide annealing copper indium gallium sulfur solar cell thin film material preparation method after double-potential step method electrodeposition. The method comprises the steps that copper and gallium metal salt is used as a main raw material; the main raw material is dissolved in an ionic liquid at a certain concentration; a copper gallium precursor thin film is prepared on ITO conductive glass through double-potential cycle step method electrodeposition; sulfide annealing is carried out on the precursor thin film; in the annealing process, indium in the ITO conductive layer diffuses into the thin film; and finally a copper indium gallium sulfur thin film is generated. Compared with a traditional constant potential deposition technology, the method provided by the invention has the advantages that by controlling double potential pulse potential, controllable preparation of the crystalline phase, the composition, the morphology and the like of the thin film can be realized; pore structures are reduced; the thin film morphology is improved; the plating rate is improved; and hydrogen evolution reaction does not produce any adverse effect on the thin film in the deposition process. Compared with a high-vacuum vapor phase method, the method provided by the invention has the advantages of good film quality, low cost, high controllability and the like.

Owner:XIANGTAN UNIV

Glazed paper webs

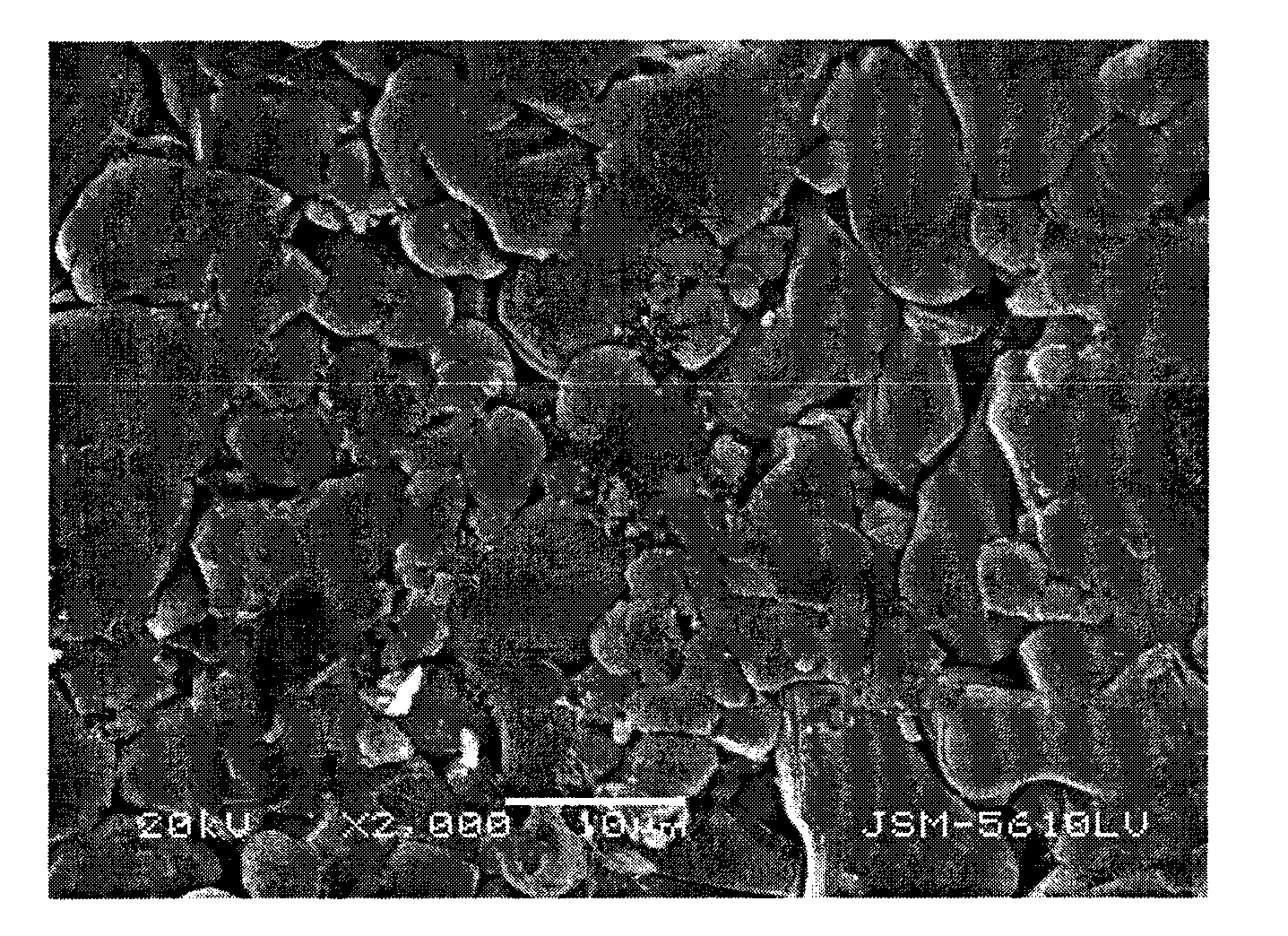

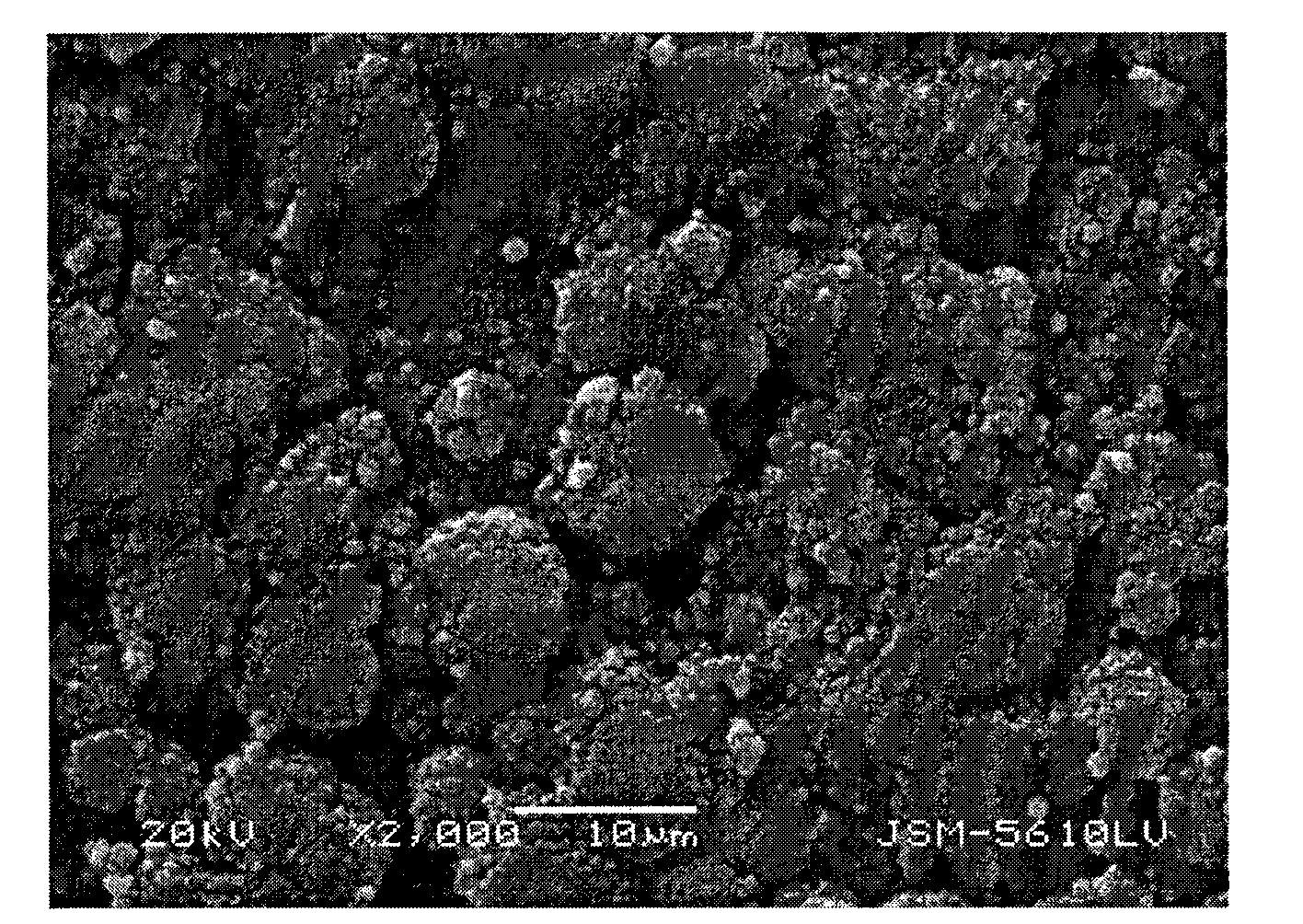

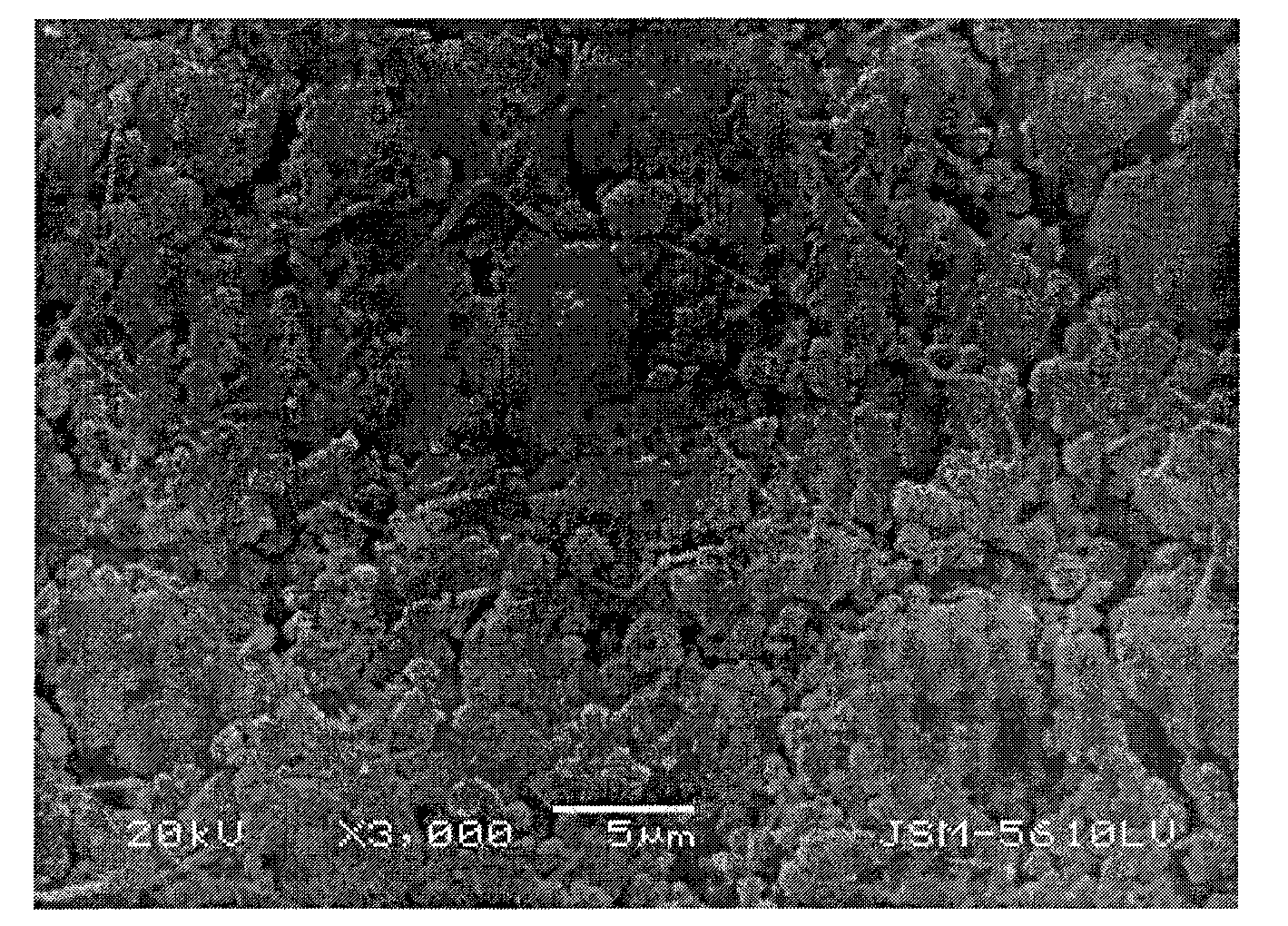

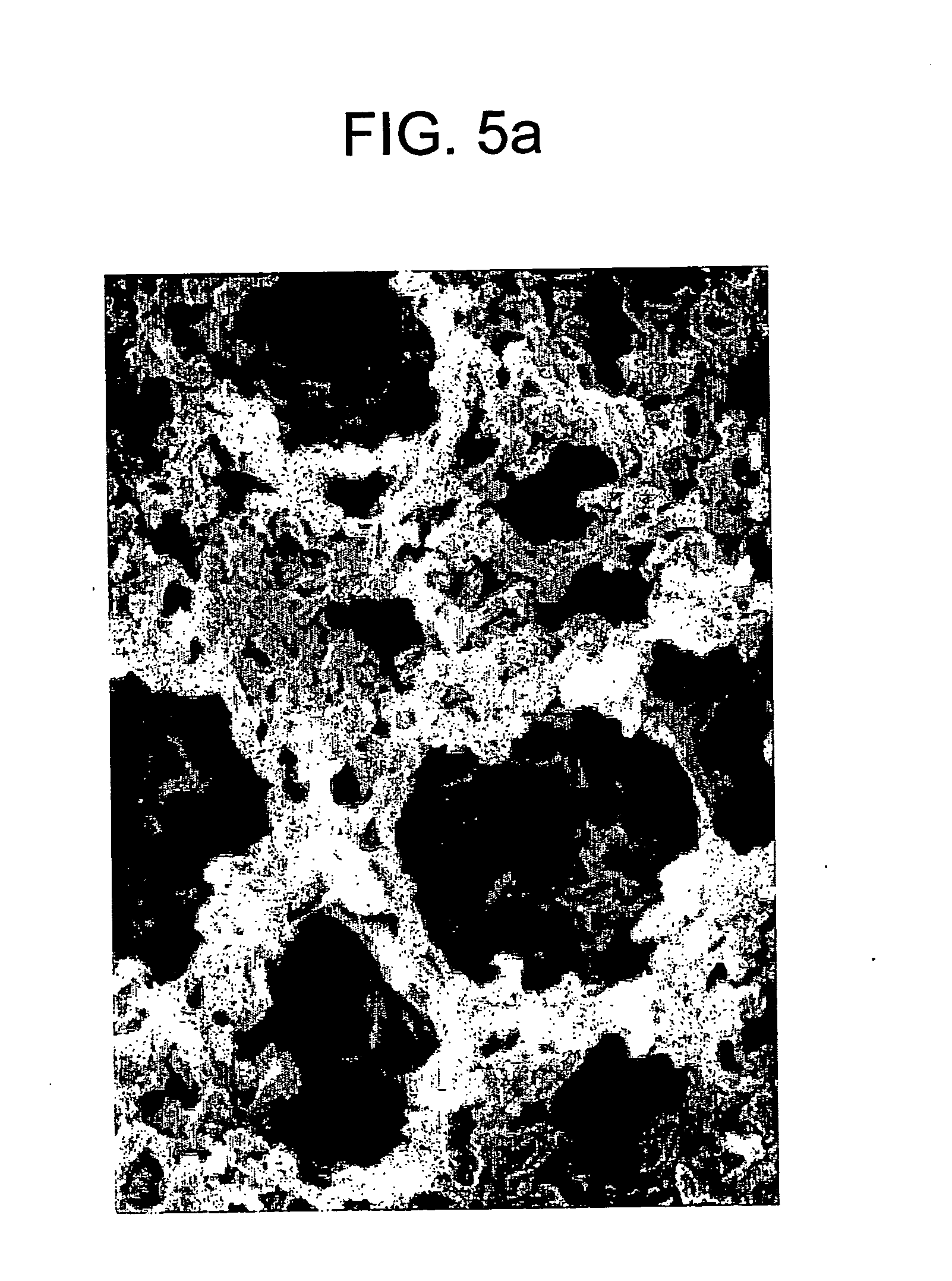

ActiveUS6998019B2Improve bindingEquilibrium moisture content decreasedNon-fibrous pulp additionNatural cellulose pulp/paperAramidesPulp and paper industry

Provided is a process for preparing a smooth and glossy surfaced paper web. The process comprises subjecting the paper web to shear by using calender rolls driven at different speeds or calender rolls with different diameters. The resulting paper has a totally different structure than the original paper, as it has a much smaller void structure and a much higher degree of bonding between the elements of the sheet. The process is particularly applicable to improving the electrical insulation properties of an aramid paper web.

Owner:NEENAH NORTHEAST LLC

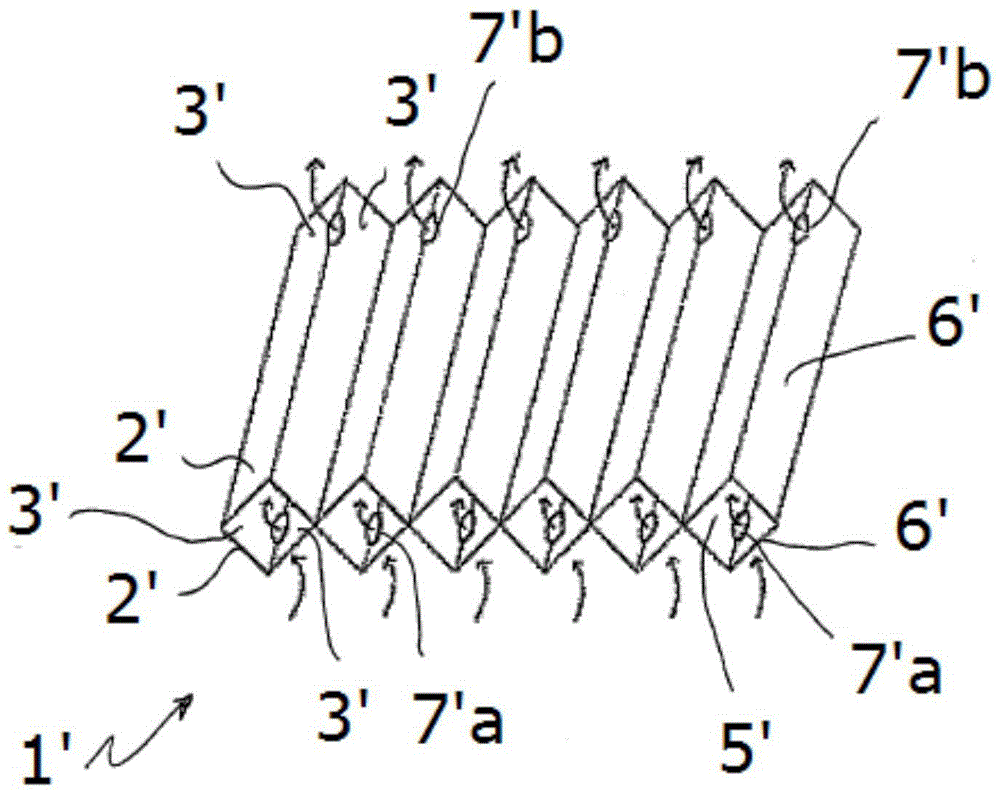

Filter Element

InactiveCN104801131ASolution to short lifeImprove breathabilityCombination devicesDispersed particle filtrationEngineeringNonwoven fabric

In respect of the object of specifying a filter element which can be used as an inertial separator and, while being of compact construction, can be used in small installation spaces, said filter element displaying a low level of flow resistance, the highest possible dust-holding capacity and the best possible separating-off action, a filter element which is configured in the form of an inertial separator, that is to say has means which separate off particles by deflection of a flow medium, is characterized in that the means comprise, or have, nonwoven fabric.

Owner:CARL FREUDENBERG KG

Method for preparing porous nanoparticle/polydimethylsiloxane membrane through water surface spreading

The invention discloses a method for preparing a porous nanoparticle / polydimethylsiloxane membrane through water surface spreading, belonging to the technical field of membrane separation. Porous nanoparticles are added into a polydimethylsiloxane membrane casting solution for dispersion, and a mixed matrix membrane casting solution is immiscible with water and can be spread on a water surface to form a thin film, so the mixed matrix membrane casting solution is crosslinked on a liquid-liquid interface and assembled into the porous nanoparticle / polydimethylsiloxane composite membrane. A water surface spreading method avoids the phenomenon of pore permeation, improves the loading capacity of the porous nanoparticles, reduces the surface defects of the membrane, reduces the thickness of an active layer at the top of the composite membrane, and increases the flux and selectivity of the pervaporation membrane. The invention provides the two-step preparation method consisting of forming the thin film on a liquid-liquid interface in advance by a porous nanoparticle / polydimethylsiloxane mixed matrix material and then compounding the thin film with a porous support body; and the method is simple and easy to operate, mild in preparation conditions and low in cost.

Owner:BEIJING UNIV OF TECH

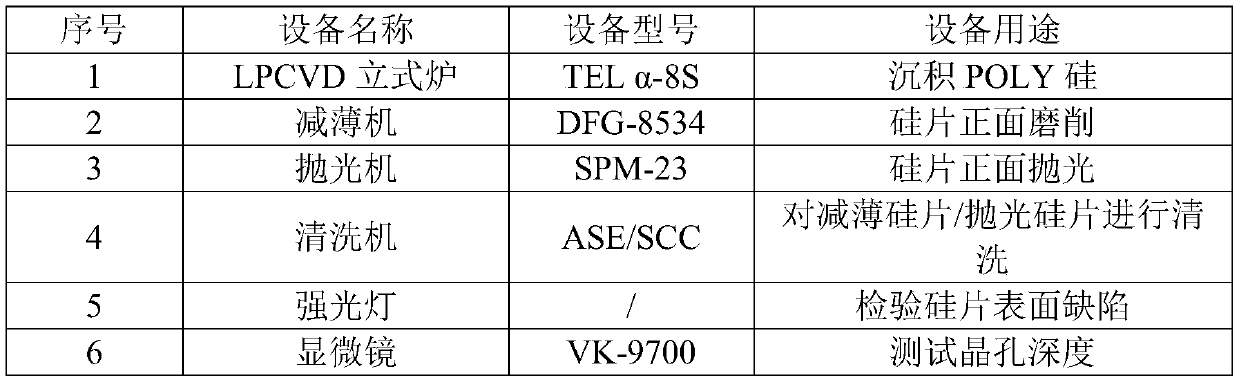

Processing technology for reducing edge crystal holes of zone-melting POLY back-sealed single-side-polished wafer

ActiveCN110718457AImprove pass rateReduced porosityFinal product manufactureSemiconductor/solid-state device manufacturingMetallurgyAcid corrosion

The invention provides a processing technology for reducing edge crystal holes of a zone-melting POLY back-sealed single-side-polished wafer. POLY back-sealing, thinning and polishing are carried outon an acid corrosion wafer in sequence, and optimal matching is carried out on a cleaning procedure after thinning. Because the thinning procedure is performed after the POLY back sealing procedure, the phenomenon of crystal holes generated in the POLY back sealing process can be greatly reduced. Compared with the prior art, the processing cost is not increased under the same processing steps, thepercent of pass of finished products is greatly increased, and the processing technology has very high practical application value.

Owner:TIANJIN ZHONGHUAN ADVANCED MATERIAL TECH

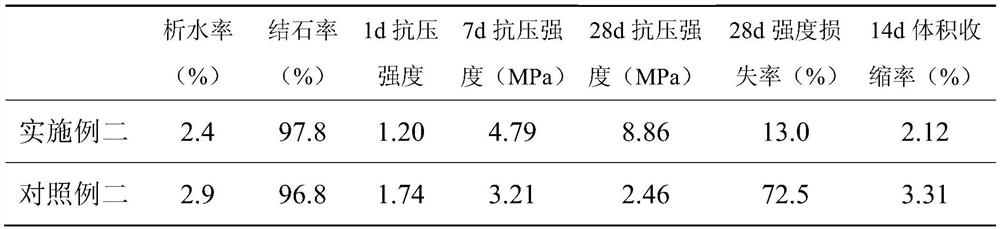

Product-stable cement-water glass double-liquid grouting material for shield synchronous grouting

PendingCN112028594AParticle dispersion increasedImprove stabilitySolid waste managementUnderground chambersPortland cementShrinkage rate

The invention discloses a product-stable cement-water glass double-liquid grouting material for shield synchronous grouting, which is composed of a liquid A and a liquid B. The product-stable cement-water glass double-liquid grouting material is characterized in that the liquid A comprises the following components: cement, fly ash, a retarder and water, wherein the cement is 42.5-grade ordinary Portland cement, the fly ash is II-grade fly ash, and the retarder is ammonium dihydrogen phosphate with the purity of more than or equal to 99.0%, the pH value of 4.0-4.5 and the clarity of less than or equal to 3; and the liquid B is water glass with the baume degree of 30-40 degrees and the modulus of 3.1-3.3. The grouting material is used for shield synchronous grouting, the gelling time is short, and the anti-floating performance of pipe pieces is good; and a reaction product is good in stability, not prone to disintegration and cracking under the natural condition of actual engineering, small in volume shrinkage rate and free of degradation of compressive strength, and a formed segmental lining structure is high in strength and good in waterproof performance.

Owner:SOUTHWEST JIAOTONG UNIV +1

Three-dimensional porous composite scaffold and preparation method thereof

The invention discloses a three-dimensional porous composite scaffold and a preparation method thereof. The composite scaffold is prepared by taking 2-10 wt% of silk fibroin solution, hyaluronic acid and sodium alginate as raw materials, wherein the ratio of the hyaluronic acid to the silk fibroin solution is 0.1 g : 5-30 ml, the ratio of mixed solution composed of the silk fibroin solution and the hyaluronic acid to sodium alginate is 15-25 ml : 0.1 g; the solution of the hyaluronic acid and sodium alginate is physically mixed with silk fibroin, and the three-dimensional porous composite scaffold can be obtained after freeze-drying. The obtained scaffold is not favorable for adhesion and proliferation of fibroblasts, but also has good hydrophily and the like, some problems of an existing scaffold material are solved, multiple materials are composited, the advantages of original materials are maintained, and property shortcomings of original materials are overcome. The three-dimensional porous composite scaffold is simple in preparation process, the required cost in the needed raw material ratio is low, and the three-dimensional porous composite scaffold is suitable for mass production.

Owner:BEOGENE BIOTECH GUANGZHOU +1

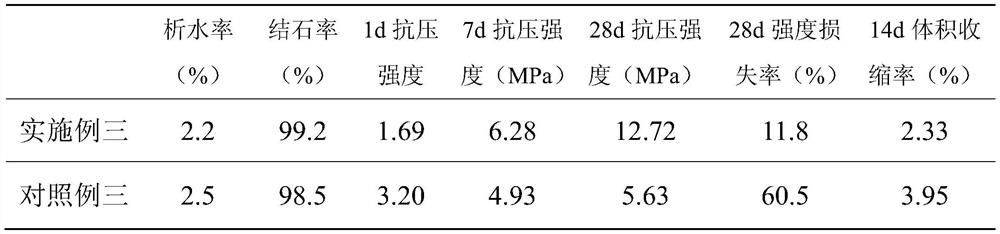

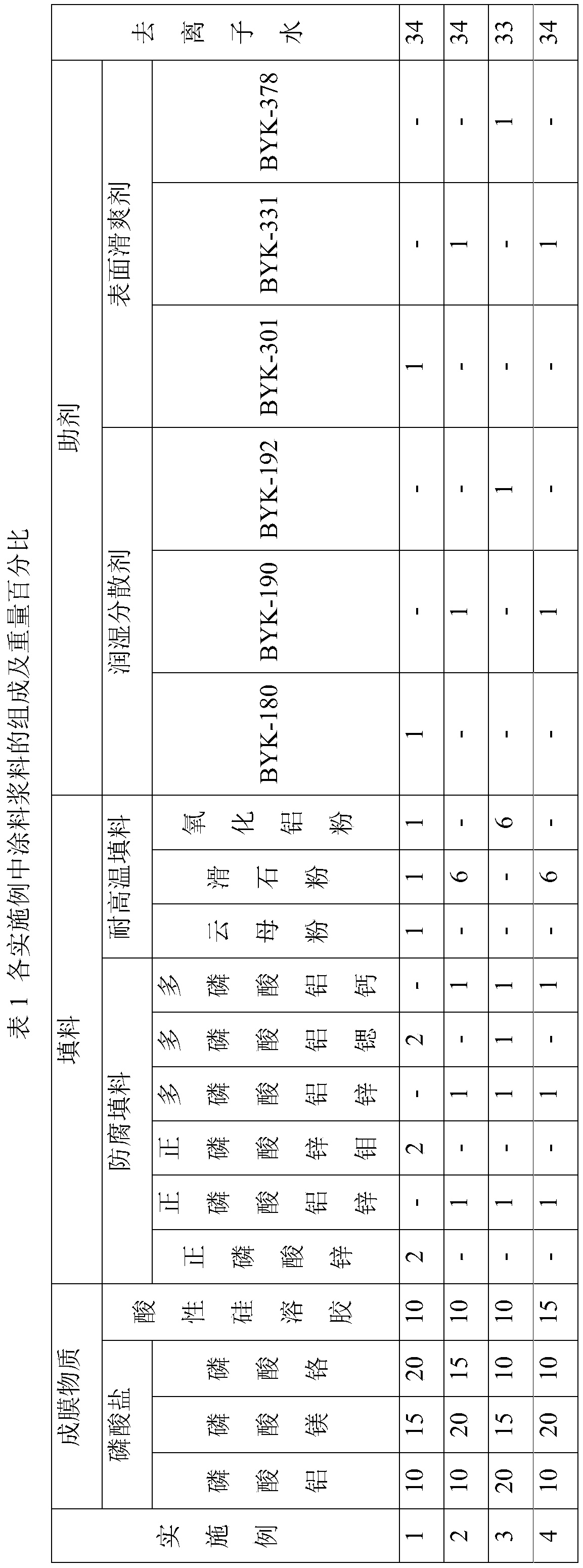

High-temperature-resistant anticorrosive smooth coating layer used in stainless steel blade surfaces and preparation method of coating layer

InactiveCN110016244AHigh temperature resistantCorrosion resistanceFireproof paintsAnti-corrosive paintsSurface finishEngine efficiency

The invention relates to a high-temperature-resistant anticorrosive smooth coating layer used in stainless steel blade surfaces and a preparation method of the coating layer. The coating layer is prepared by using the following steps: a phosphate and silica sol are adopted as film forming substances, modified orthophosphate or polyphosphate powder is adopted as an anticorrosive filler, mica powder, talc powder and aluminum oxide powder are selected as a high-temperature-resistant filler, particle size distribution of the filler is strictly controlled, surface auxiliary agents such as a wettingdispersing agent and a surface slip agent are added to prepare a coating material, the coating material is sprayed onto the stainless steel blade surfaces, and heating curing is performed to preparethe smooth coating layer. According to the method provided by the invention, the coating layer prepared by the method is resistant to high-temperature corrosion and has an excellent surface finish, and can significantly improve aerodynamic performance of engines when applied to the stainless steel blade surfaces of the aero-engines, thereby improving efficiency of the engines.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Cold-rolled dual-phase steel with tensile strength being 780MPa and high hole reaming performance and preparation method thereof

The invention discloses cold-rolled dual-phase steel with the tensile strength being 780MPa and high hole reaming performance and a preparation method thereof and belongs to the technical field of steel plate production. A steel plate comprises the following chemical components in percentage by weight: 0.08-0.10% of C, 0.50-0.60% of Si, 2.00-2.20% of Mn, 0.040-0.060% of V, 0.03-0.05% of Al, equalto or less than 0.010% of P, equal to or less than 0.002% of S, equal to or less than 0.003% of N and the balance of Fe and unavoidable impurities. Through controlling C content and reasonable alloy matching, the hardness difference of ferrite-martensite is reduced as much as possible to improve the hole reaming performance on the premise of ensuring the strength.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

High wear-resistant fishing net suitable for complex seabed fishing environment

InactiveCN107082932AImprove toughnessReduced porosityConjugated synthetic polymer artificial filamentsArtifical filament manufactureLow-density polyethyleneWear resistant

The invention belongs to the technical field of fishing net processing, and particularly relates to a high wear-resistant fishing net suitable for a complicated seabed fishing environment. The fishing net is prepared by modifying high density polyethylene by modified nanosilicon dioxide with a surface hydroxy number not higher than 0.4 / nm<2>; the use amount of the high density polyethylene is 74 to 78 percent of the total amount of raw materials of the finishing net. Compared with the prior art, the high wear-resistant fishing net has the following advantages: the high density polyethylene is modified by using the modified nanosilicon dioxide, an interval multipore structure is reduced, processability and mechanical properties are obviously improved, the prepared finishing net is high in strength, good in toughness and strong in impact resistance, and has stronger creep resistance and weather fastness in the complicated seabed environment and environment with strong wind and big waves, and the service life is greatly prolonged in the complicated seabed environment, and is more remarkably prolonged in a simple environment.

Owner:CHAOHU LOTUS FISHING NET

Composite coating used for titanium alloy investment precision casting, surface coating and preparation method and application thereof

ActiveCN110125326ASmall specific surface areaReduce hydrationFoundry mouldsFoundry coresOxide ceramicAdhesive

The invention discloses a composite coating used for the titanium alloy investment precision casting, a surface coating and a preparation method and application thereof. Preparation materials of the composite coating used for titanium alloy investment precision casting comprise a refractory material, an adhesive, an anti-hydration agent and a regulator, wherein the refractory material comprises yttrium oxide, and the anti-hydration agent is a derivative of a saturated fatty acid. The structural formula of the derivative of the saturated fatty acid is shown in the following formula (1) that R represents an alkyl group, X and Y independently represent a substituent group, wherein the substituent group contains one or more of an alkyl group, a hydroxyl group, a phenyl group or a carboxyl group. The surface coating comprises the composite coating, and further comprises a wetting agent and a defoaming agent. The composite coating used for the titanium alloy investment precision casting andthe surface coating have the advantages of being simple in component, stable in performance, not easy to gel, not easy to dissolve in water, long in service life and low in production cost, and the reaction degree of yttrium oxide ceramic type shell and the titanium alloy prepared by using the coating is small, and the formed alpha adhesion layer is small in thickness.

Owner:湖南洛兰新材料有限公司

Ceramic water permeable brick and production method thereof

ActiveCN107759197AReduce manufacturing costHigh strengthCeramic materials productionCeramicwareBrickMetallic materials

The invention belongs to the field of inorganic non-metal materials, and discloses a ceramic water permeable brick and a production method thereof. The ceramic water permeable brick is prepared from an aggregate, a binding agent and a combustible raw material; heat generated during a combustion process of the combustible raw material can be used for heating a green brick from inside to outside, and meanwhile, a kiln is used for heating the green brick from outside to inside, so that the uniformity of inner and outer structures of the green brick is increased under the combined action of insideand outside heating, and the performance of the green brick can be more uniform; in addition, the heat efficiency is increased to a large extent. Residue generated after fuel combustion can be used as the aggregate of the ceramic water permeable brick in situ and can be fully utilized, zero emission of fuel residue is realized, and the production cost of the ceramic water permeable brick is saved; in addition, the volume of the combustible raw material is lessened after combustion, larger pore diameter is formed between residue particles, and meanwhile, certain gaps are formed in the residueper se, so that the properties of high strength and good water permeability are given to the ceramic water permeable brick through the special structure. During roasting of the ceramic water permeablebrick, a gradient temperature rising mode is adopted, the combustible raw material can be fully combusted, meanwhile, the green brick can be prevented from being over-combusted, and the quality of the ceramic water permeable brick is ensured.

Owner:JINGDEZHEN CERAMIC INSTITUTE

Glazed paper webs

InactiveUS20060096728A1High modulusSmall void structureNon-fibrous pulp additionNatural cellulose pulp/paperAramidesPulp and paper industry

Owner:FIBERMARK NORTH AMERICA

Multielement high-strength wear-resistant composite paint and preparation method thereof

InactiveCN104628403AImprove high temperature resistanceImprove stabilityWear resistantBound property

The invention relates to a refractory material and a preparation method thereof, particularly a multielement high-strength wear-resistant composite paint and a preparation method thereof. The multielement high-strength wear-resistant composite paint is composed of a main material and an auxiliary material, wherein the main material is composed of fused alumina zirconia fine powder, kyanite, pure calcium aluminate cement, aluminium titanate, magnesium zircon sand, silicon micropowder, aluminum oxide micropowder, sodium tripolyphosphate, calcium chromate and gahnite; and the auxiliary material is composed of phosphoric acid, aluminum hydroxide for inks, aluminum chloride, boron-iron-molybdenum alloy, borax and agglutinant. The multielement high-strength wear-resistant composite paint provided by the invention has the advantages of high compressive strength, higher hardness, high Mohs hardness, high density, favorable wear resistance, favorable erosion resistance, favorable scour resistance, high thermal shock stability and high binding property. When being used for a circulating fluid bed boiler, the multielement high-strength wear-resistant composite paint prolongs the service life of the paint coat, reduces the repair frequency and lowers the maintenance cost.

Owner:YIXING GUOQIANG FURNACE IND

Oil corrosion-resistant agent for concrete and preparation method thereof

The invention provides an oil corrosion-resistant agent for concrete, belonging to the field of building material preparation. The oil corrosion-resistant agent comprises organic silicon, water glass, an air entraining agent, polyol and water, wherein the addition amounts of the above components by weight percent are respectively 10-30%, 10-20%, 0-0.05%, 5-15% and 35-75%. According to the invention, when the oil corrosion-resistant agent for concrete is used in the concrete, the oil corrosion resistance and the durability of the concrete can be improved significantly. Tests show that when the oil corrosion-resistant agent accounting for 2-3% of the total weight of the concrete is added to the concrete, the oil-resistant penetration height ratio of the concrete can be increased by more than 35%, the oil absorption rate can be increased by more than 40%, and the compressive strength of the concrete at various ages can be increased by more than 16%.

Owner:北京东方建宇混凝土科学技术研究院有限公司

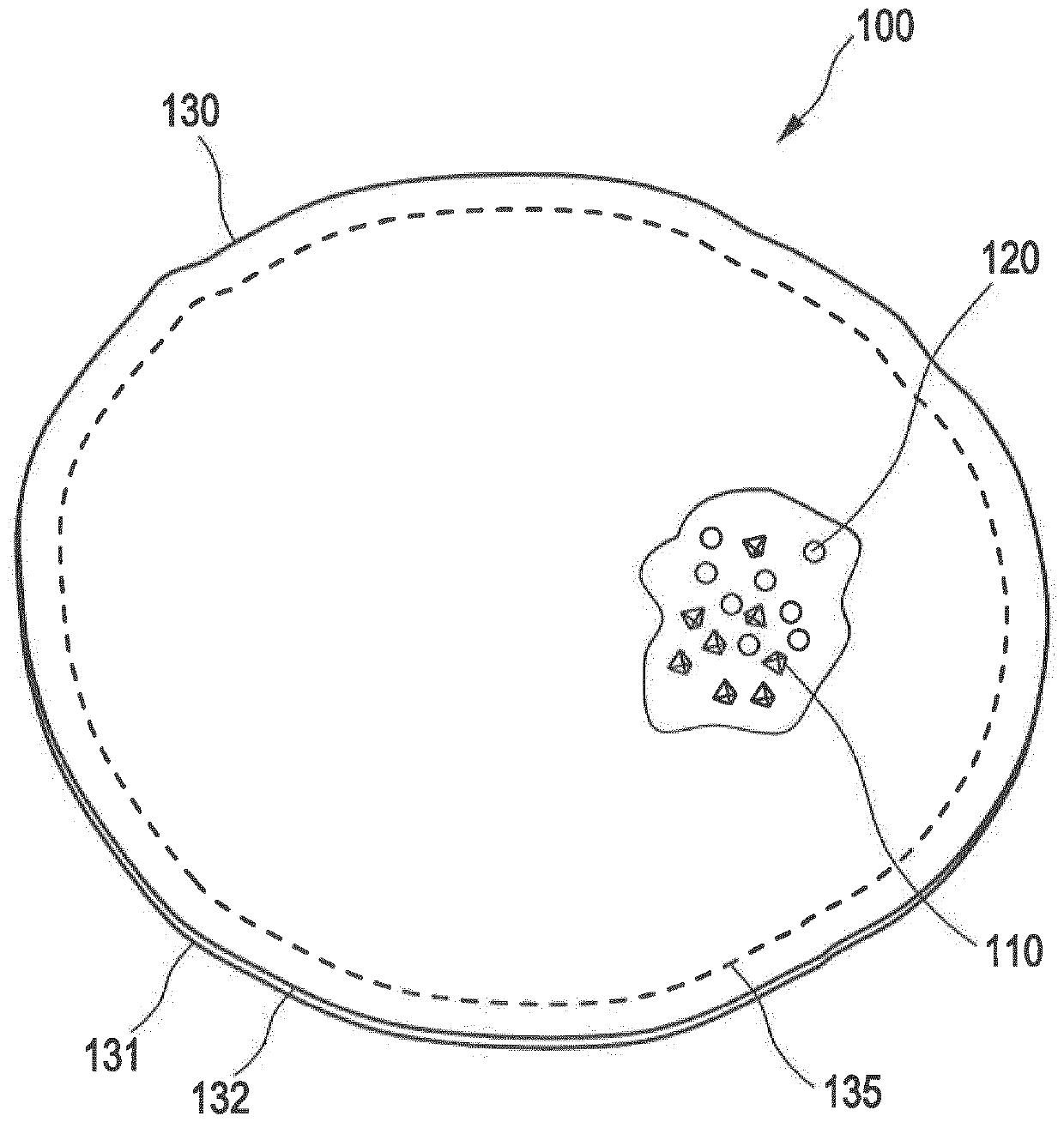

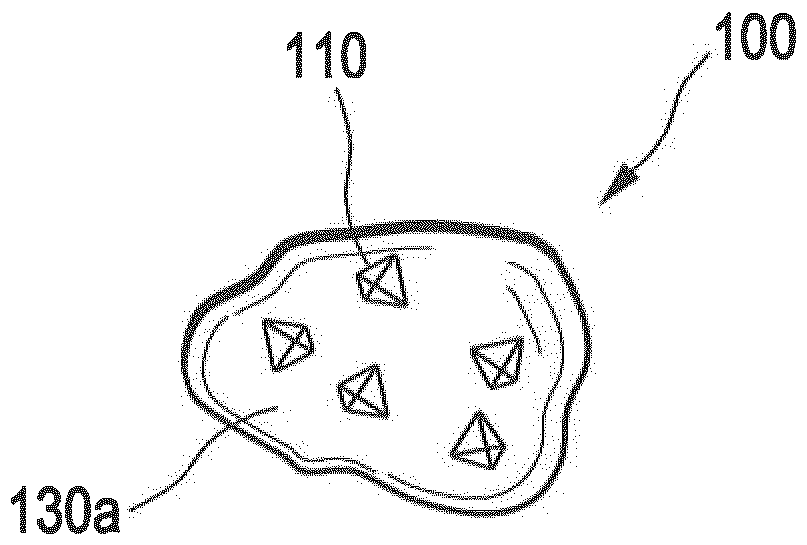

Implant and kit for treating bone defect

ActiveCN110167606AEnsure biological reconstructionAllowed to growBone implantSurgeryBone defectBiomedical engineering

The invention relates to an implant, especially for treating a bone defect. The implant has osteoconductive support bodies and an insertion aid. The insertion aid is designed for insertion of the osteoconductive support bodies into a bone defect and for holding together the osteoconductive support bodies. The invention also relates to a kit.

Owner:AESCULAP AG

Sound insulation wall for studio

ActiveCN109024997AImprove sound insulation and noise reductionImprove waterproof performanceNon-macromolecular adhesive additivesWallsEngineeringUltimate tensile strength

The invention provides a sound insulation wall for a studio, and belongs to the technical field of sound pollution control. The sound insulation wall for a studio comprises a first wall body and a second wall body, wherein the first wall body and the second wall body are provided with a soundproof module therebetween, the soundproof module includes a first sound absorbing cotton layer, a second sound absorbing cotton layer, and a damping plate disposed between the first sound absorbing cotton layer and the second sound absorbing cotton layer, each of the first sound absorbing cotton layer andthe second sound absorbing cotton layer is provided with a binder on both sides, and each of the first wall and the second wall is sprayed with paint on a side away from the soundproof module. The sound insulation wall has good sound insulation effect, and solves the problem that the sealed sound insulation device is detachably connected, the fixation is not firm, the contact between adjacent components is not tight, and the sound leakage is caused. Meanwhile, the binder for adhesion between the components of the sound insulation wall is additionally provided. The joint strength is excellent and the sound insulation effect is good.

Owner:NANYANG INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com