High-temperature-resistant anticorrosive smooth coating layer used in stainless steel blade surfaces and preparation method of coating layer

A stainless steel, high temperature resistant technology, used in anti-corrosion coatings, coatings, fire-resistant coatings, etc., can solve problems such as corrosion or erosion damage, reduced air flow of compressors, and reduced efficiency, and achieves improved finish, improved efficiency, and reduced porosity. effect of structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

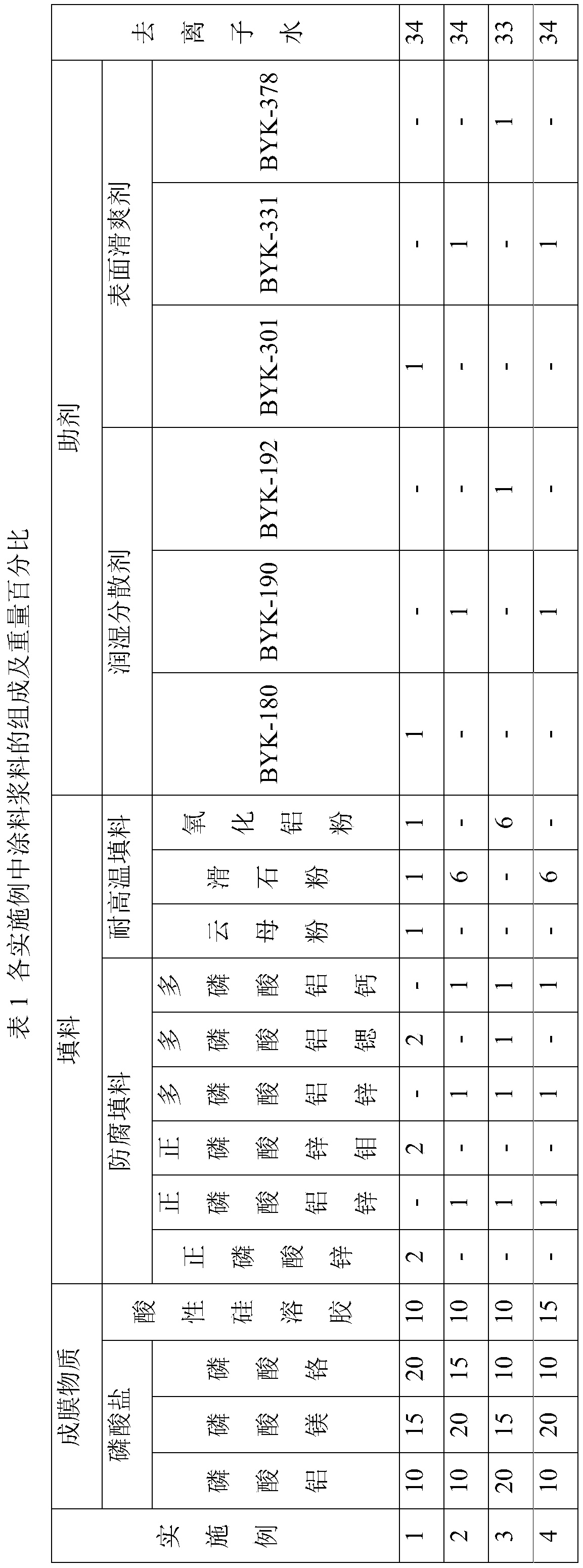

[0021] According to the dosage in Table 1, aluminum phosphate, magnesium phosphate, chromium phosphate and acidic silica sol are used as film-forming substances, zinc orthophosphate, zinc molybdenum orthophosphate and aluminum strontium polyphosphate powder are added as anti-corrosion fillers, and mica powder and talcum powder are selected. , Alumina powder is used as a high temperature resistant filler, the average particle size of all fillers is 2-3.5μm, the wetting and dispersing agent is BYK-180, and the surface slip agent is BYK-301. After preparing the coating, it is sprayed on the surface of the stainless steel blade. The layer was dried at room temperature for 20 minutes, then kept at 80°C for 15 minutes, and finally heated at 340°C for 30 minutes to prepare a smooth coating.

Embodiment 2

[0023] According to the dosage in Table 1, aluminum phosphate, magnesium phosphate, chromium phosphate and acidic silica sol are used as film-forming substances, aluminum zinc orthophosphate, aluminum zinc polyphosphate and aluminum calcium polyphosphate powder are added as anti-corrosion fillers, and talcum powder is selected as anti-corrosion filler. High-temperature fillers, the average particle size of all fillers is 2-3.5 μm, add the wetting and dispersing agent BYK-190, and the surface slippery agent is BYK-331. After the coating is prepared, it is sprayed on the surface of the stainless steel blade, and the coating is dried at room temperature for 20 minutes. Then keep at 80°C for 15min, and finally heat at 340°C for 30min to prepare a smooth coating.

Embodiment 3

[0025] According to the dosage in Table 1, aluminum phosphate, magnesium phosphate, chromium phosphate and acidic silica sol are used as film-forming substances, and aluminum zinc orthophosphate, aluminum zinc polyphosphate, aluminum strontium polyphosphate and aluminum calcium polyphosphate powder are added as anti-corrosion fillers, Select alumina powder as the high temperature resistant filler, the average particle size of all fillers is 2-3.5μm, add the wetting and dispersing agent BYK-192, the surface slippery agent is BYK-378, spray on the surface of the stainless steel blade after preparing the coating, The layer was dried at room temperature for 20 minutes, then kept at 80°C for 15 minutes, and finally heated at 340°C for 30 minutes to prepare a smooth coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com