Product-stable cement-water glass double-liquid grouting material for shield synchronous grouting

A synchronous grouting and double-liquid grouting technology, applied in the field of grouting materials, can solve the problem of endangering the safety and waterproof performance of the segment lining structure, reducing the compressive strength and impermeability pressure of the segment, and limiting the cement-sodium silicate double liquid problems such as slurry application, to avoid appearance cracking, reduce the risk of leaching, and increase the degree of dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A kind of embodiment of the present invention is, a kind of cement-sodium silicate two-liquid grouting material for synchronous grouting of shield machine with stable product, is made up of A liquid and B liquid, is characterized in that:

[0021] The components of the A liquid are cement, fly ash, retarder and water; wherein, the cement is 42.5 grade ordinary portland cement, the fly ash is grade II fly ash, and the retarder Ammonium dihydrogen phosphate with purity = 99.0%, pH value = 4.0, clarity = 3;

[0022] Described B liquid is the water glass that Baume degree is 30 °, and modulus is 3.1.

[0023] The weight ratio of each component of this example is: 252 parts of cement, 29 parts of fly ash, 1.9 parts of retarder, 675 parts of water; 319 parts of water glass.

[0024] In order to verify the product stability of the cement-sodium silicate double-liquid grout for shield synchronous grouting of the present invention, a corresponding comparative example without ad...

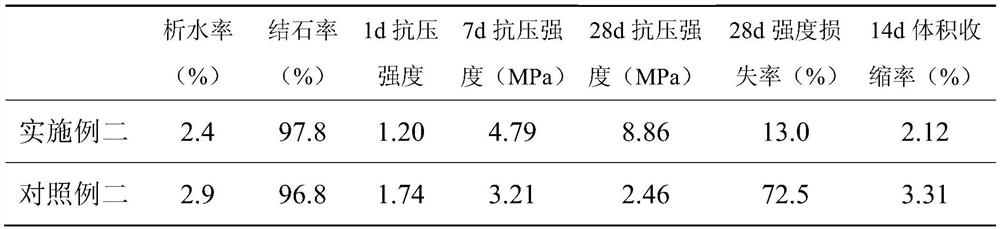

Embodiment 2

[0034] The component of this example is basically the same as that of Example 1, the difference is only:

[0035] The retarder is ammonium dihydrogen phosphate with purity = 99.5%, pH value = 4.5, clarity = 2.5;

[0036] Water glass with a Baume degree of 40° and a modulus of 3.3;

[0037] The weight ratio of each component is: 263 parts of cement, 66 parts of fly ash, 2.6 parts of retarder, 659 parts of water and 319 parts of water glass.

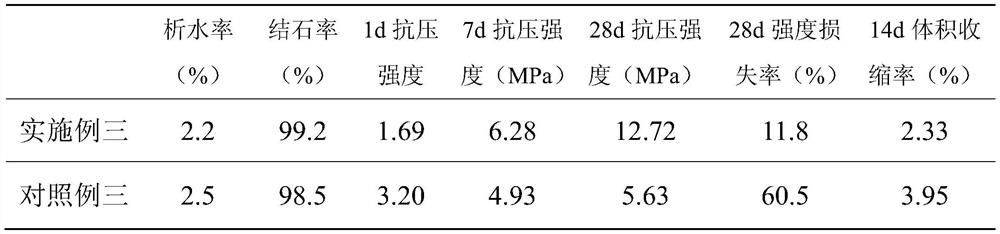

Embodiment 3

[0047]The components of this example are basically the same as Example one, the difference is only:

[0048] The retarder is ammonium dihydrogen phosphate with purity = 99.8%, pH value = 4.2, clarity = 2.0;

[0049] Water glass with a Baume degree of 35° and a modulus of 3.2;

[0050] The weight ratio of each component is: 278 parts of cement, 120 parts of fly ash, 2.8 parts of retarder, 636 parts of water and 319 parts of water glass.

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com