Processing technology for reducing edge crystal holes of zone-melting POLY back-sealed single-side-polished wafer

A processing technology and back-sealing technology, which is applied in the field of processing technology to reduce crystal holes on the edge of single-throw wafers of zone-melted POLY back-sealing, can solve the problem of poor mechanical properties of zone-melt silicon wafers and the inability to solve the problem of 8-inch POLY back-seal single-throw wafer edges Crystal hole phenomenon, easy crystal drop and other problems, to achieve the effect of optimizing the cleaning process, reducing the crystal hole phenomenon, and solving the effect of corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0025] 1. Experimental equipment and raw materials

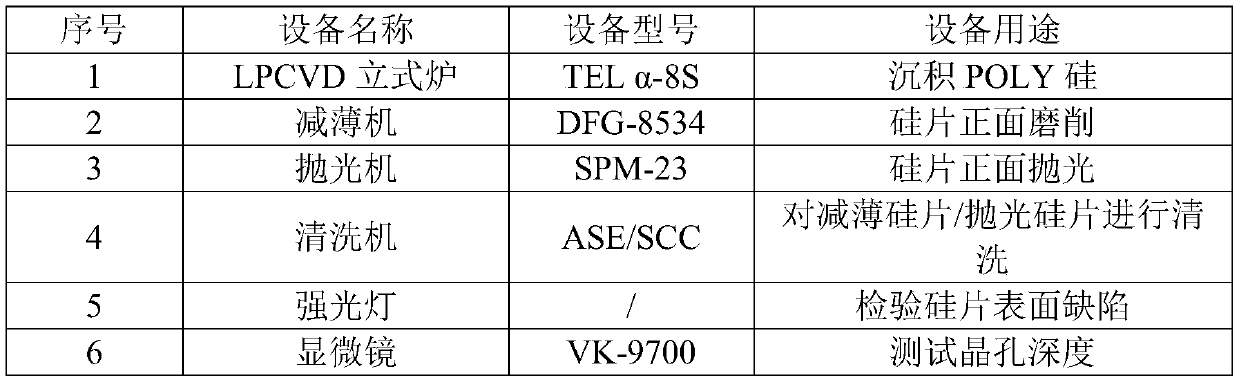

[0026] 1.1 Experimental equipment

[0027]

[0028] 1.2 Experimental raw materials

[0029]

[0030]

[0031] 2. Experimental plan

[0032]

[0033] 3. Experiment implementation

[0034] 3.1 Experimental process

[0035] serial number Processing technology Processing Equipment Process parameters 1 Corrosion sheet / / 2 POLY back seal LPCVD vertical furnace See 3.2.1 3 Thinning Thinning machine and washing machine See 3.2.2 and 3.2.3 4 polishing Polishing machine and cleaning machine See 3.2.4 and 3.2.5

[0036] 3.2 Process parameters

[0037] 3.2.1 Process parameters of POLY back seal

[0038] LPCVD (Low Pressure Chemical Vapor Deposition) process is adopted, and the specific process parameters are as follows.

[0039]

[0040] 3.2.2 Thinning process parameters

[0041] thickness feed rate C.T RPM Air Cut 15μm — — or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com